Experimental Study on Optimum Design of Aircraft Icing Detection Based on Large-Scale Icing Wind Tunnel

Abstract

:1. Introduction

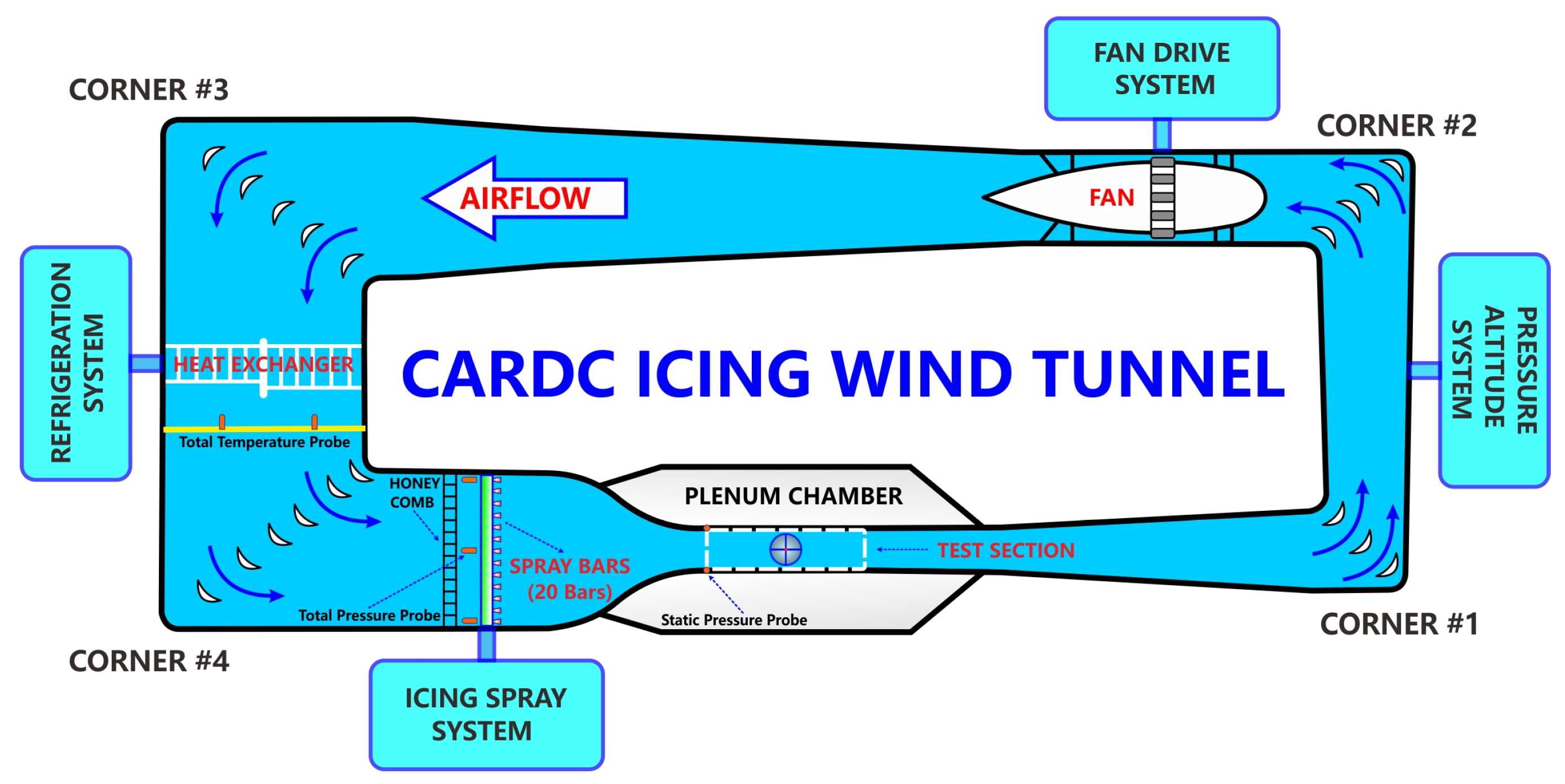

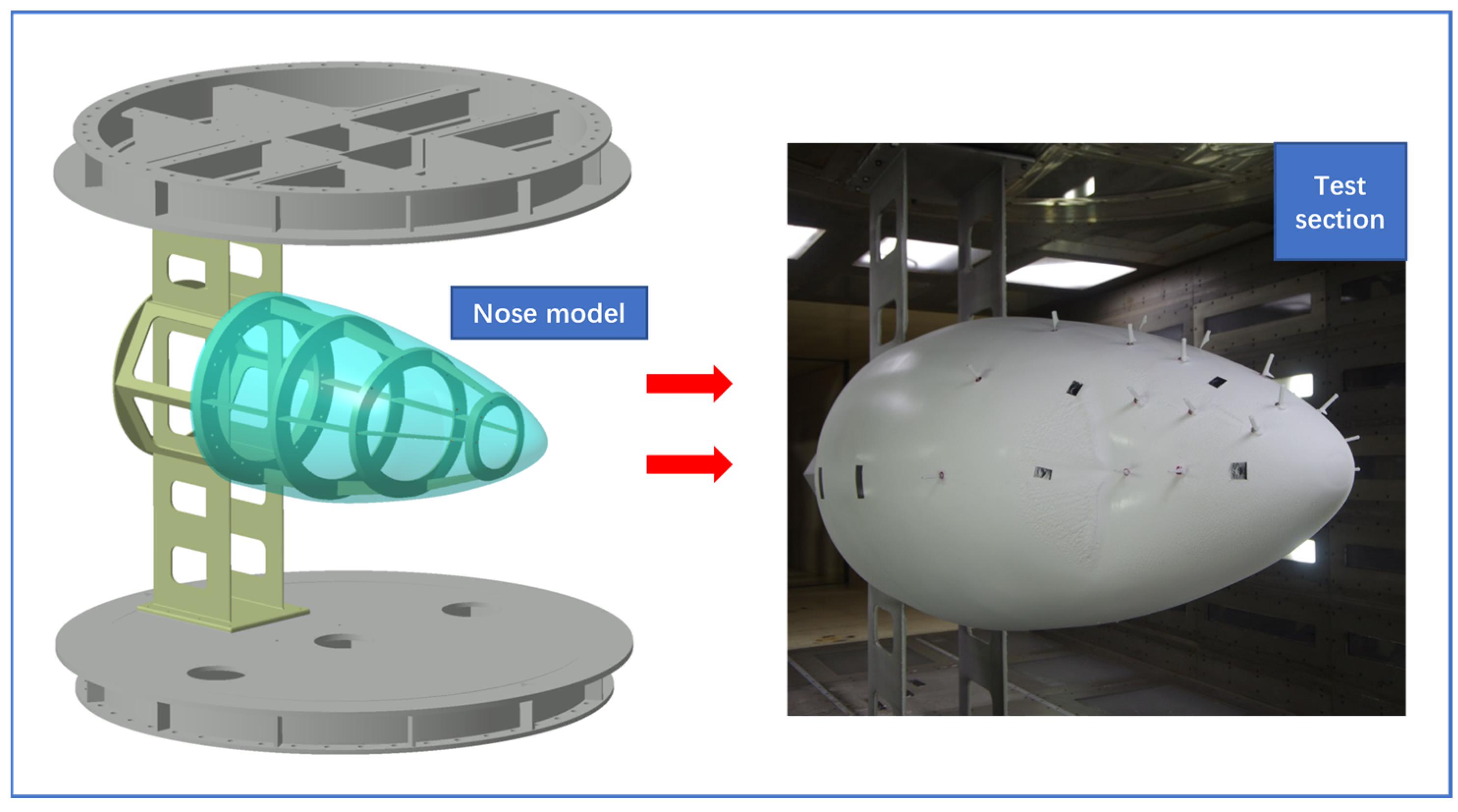

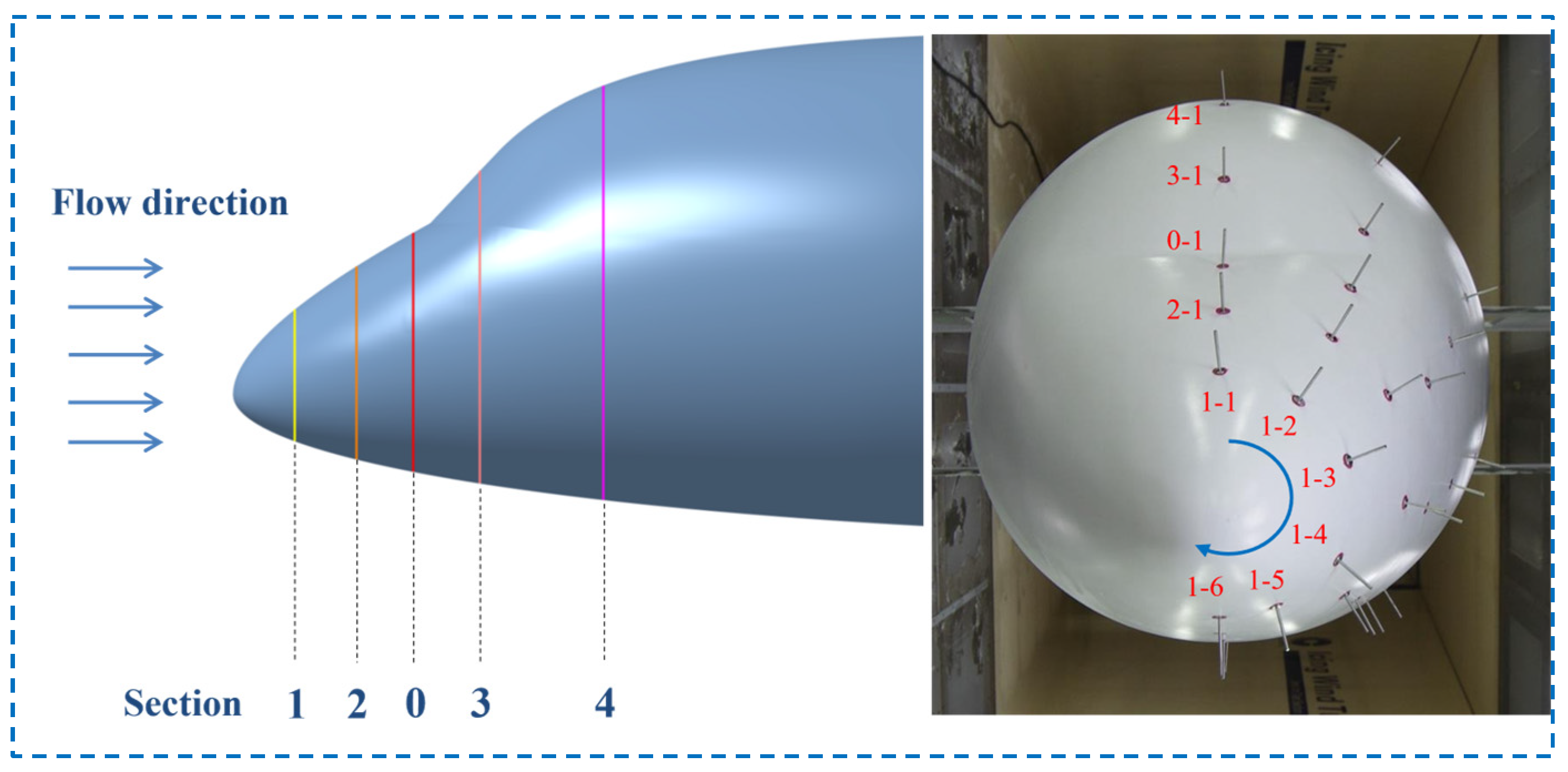

2. Experimental Setup

3. Test Methods

3.1. Selection of Operating Conditions

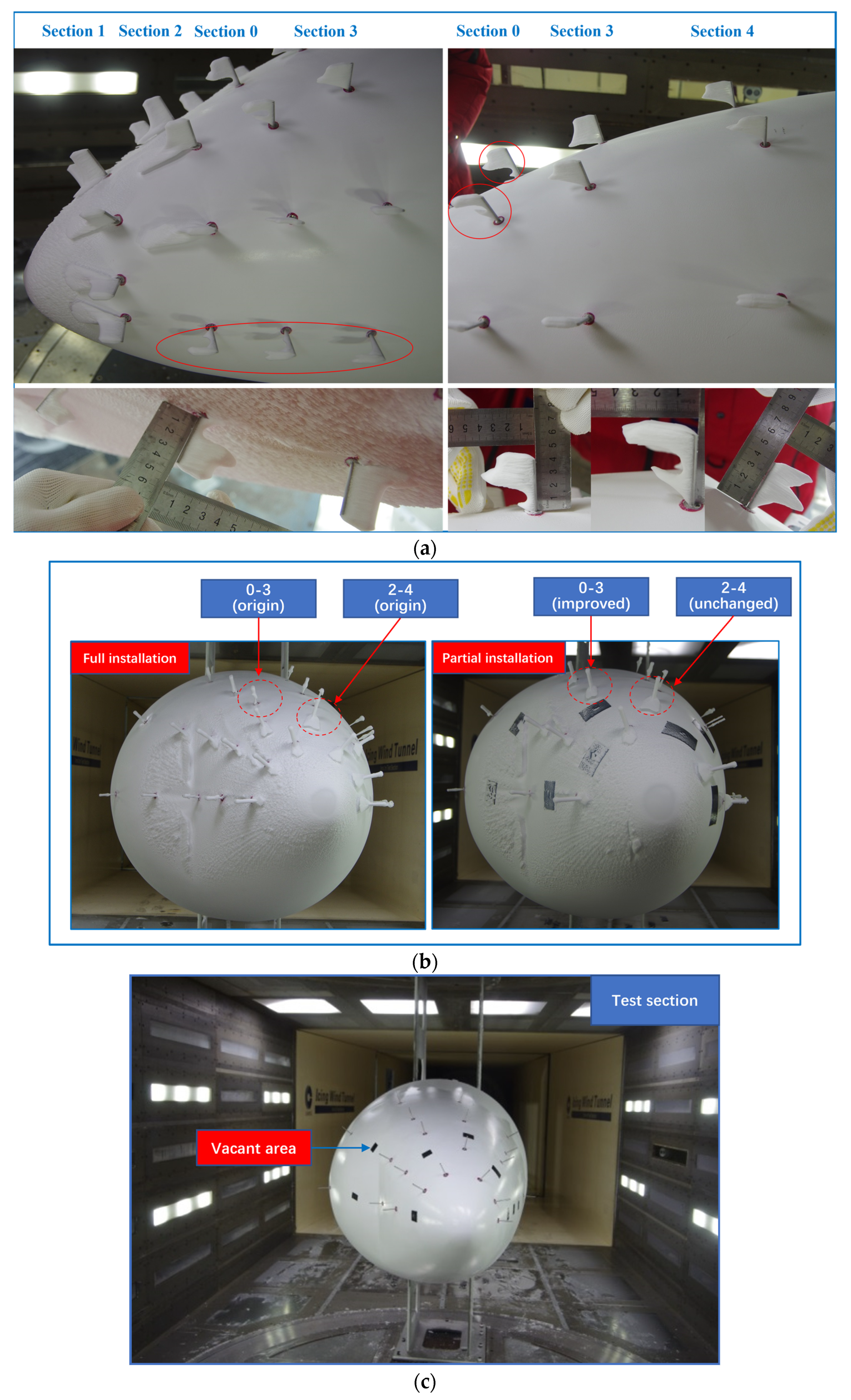

3.2. Interference Testing of Sensor Array

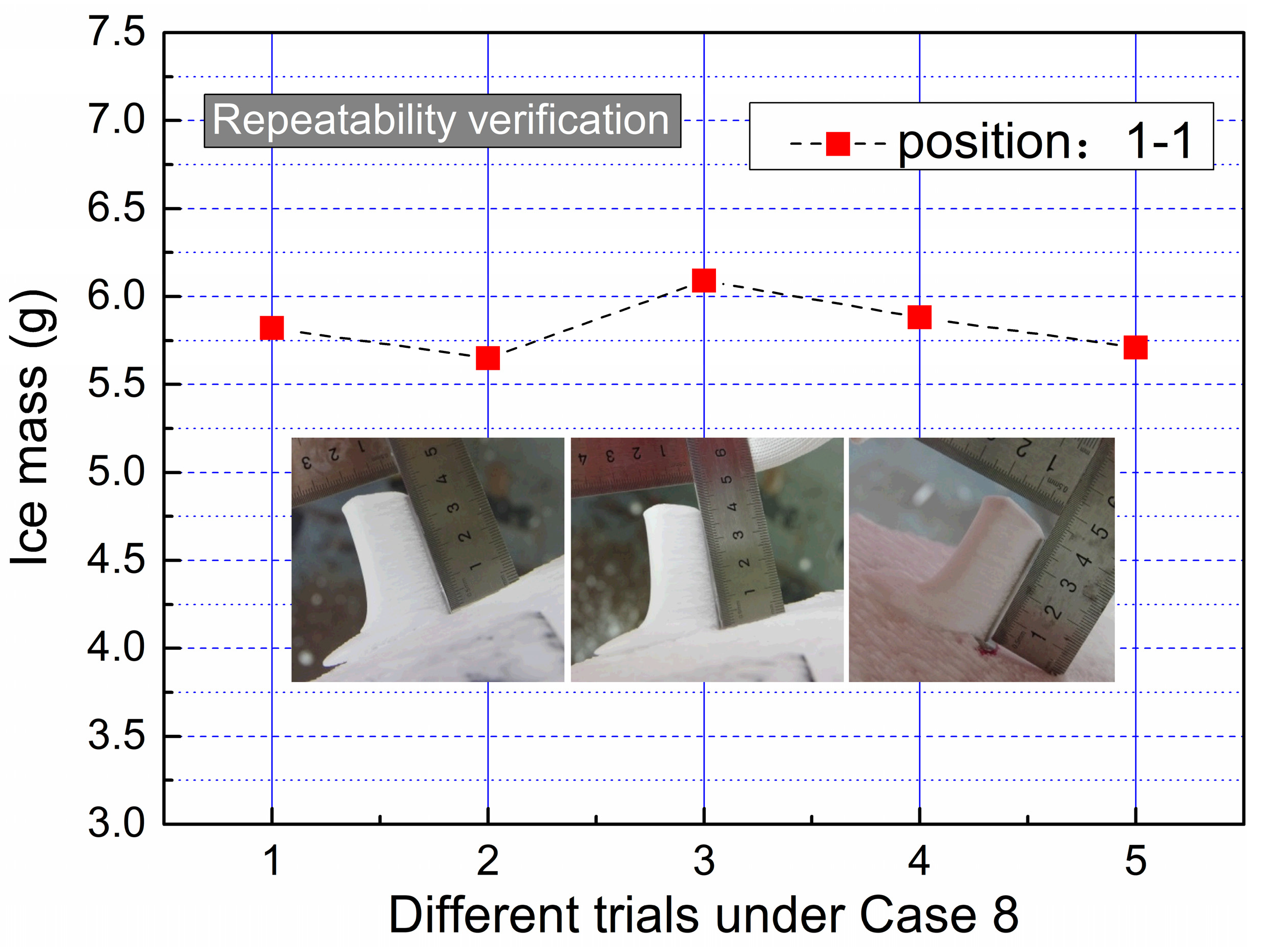

3.3. Repeatability Verification of Ice Shapes

3.4. Scheme of the Icing Test

4. Icing Properties of the Sensor Probes

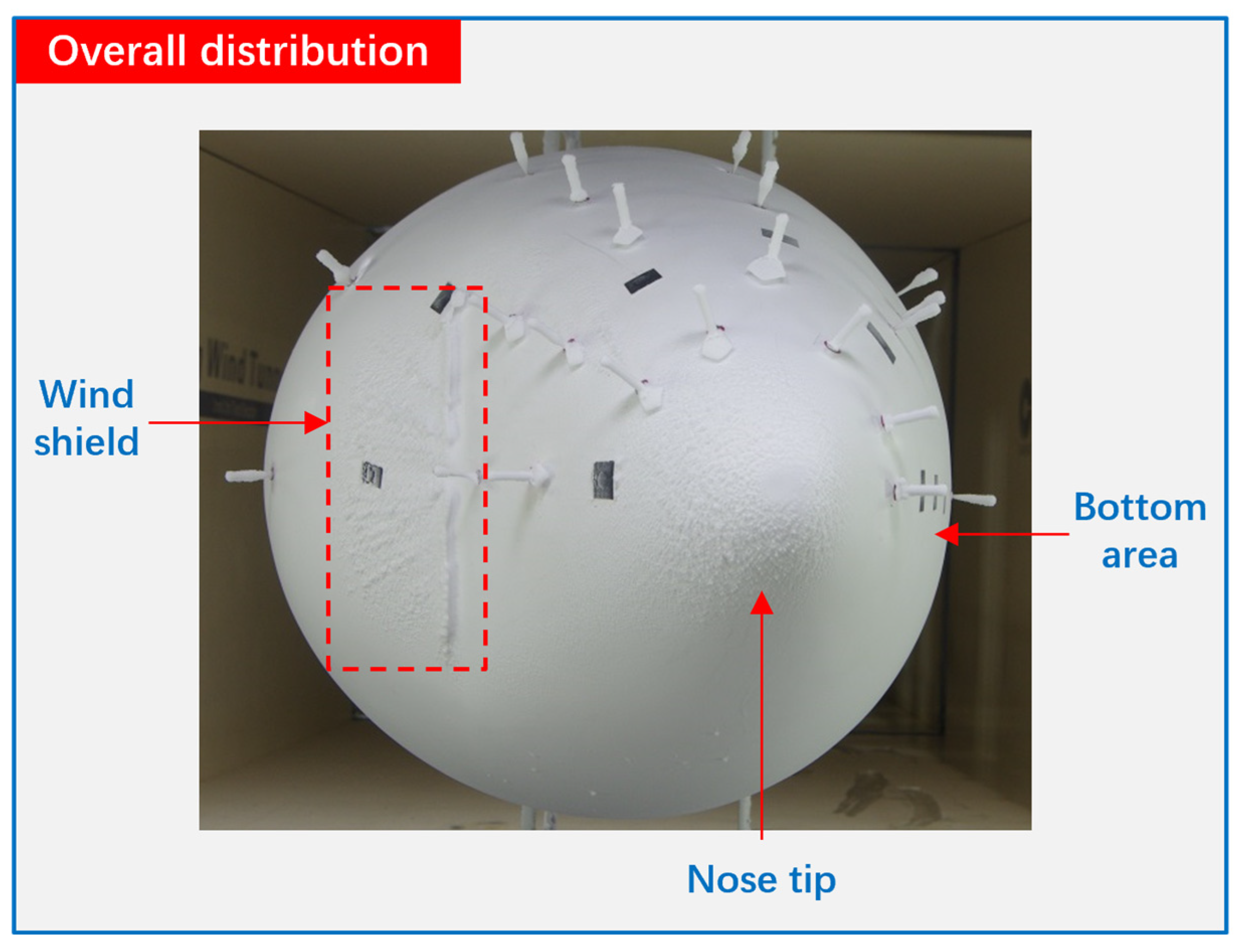

4.1. Overall Distribution of Ice Accretion

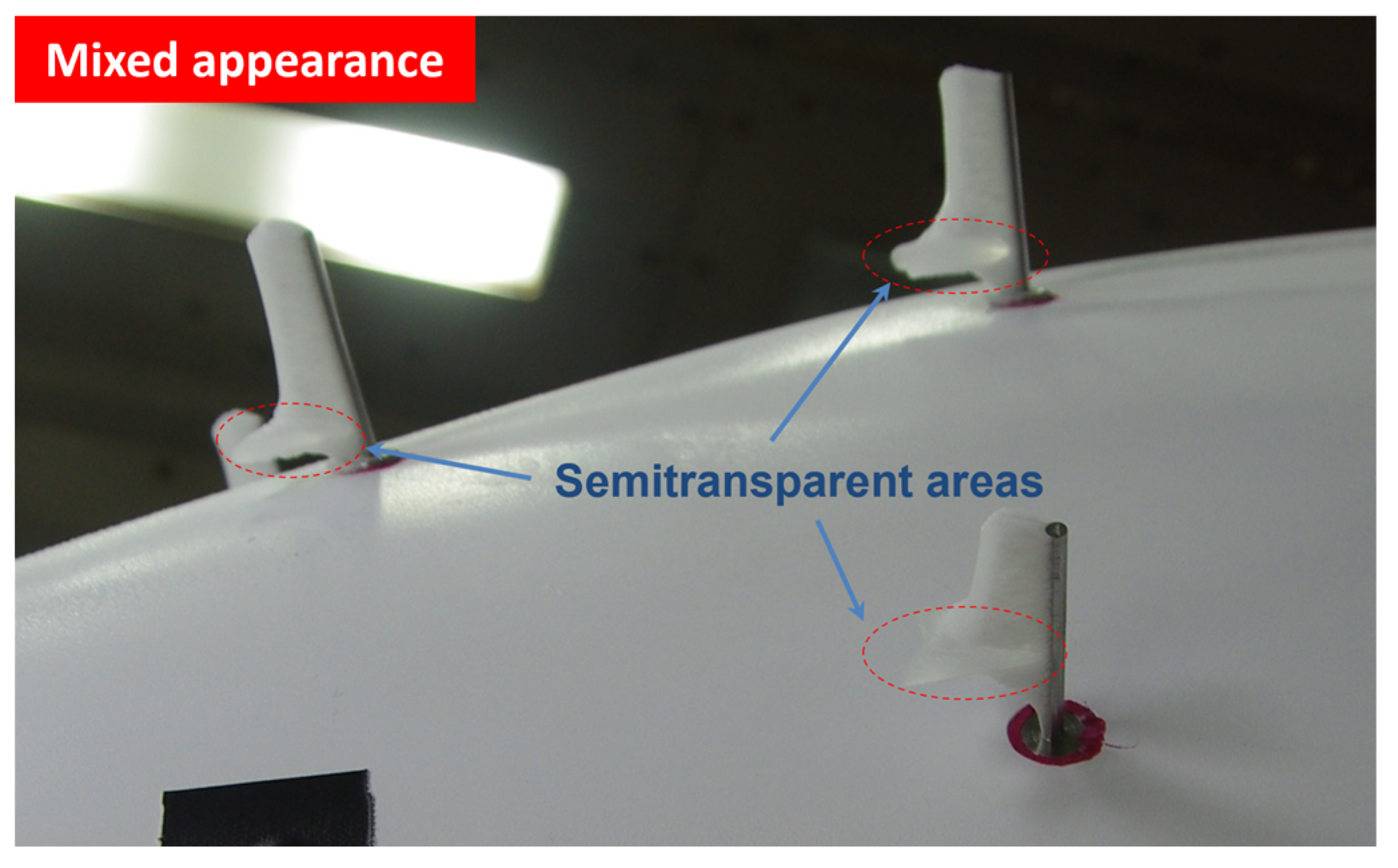

4.2. Local Icing Characteristics under Rime Ice Conditions

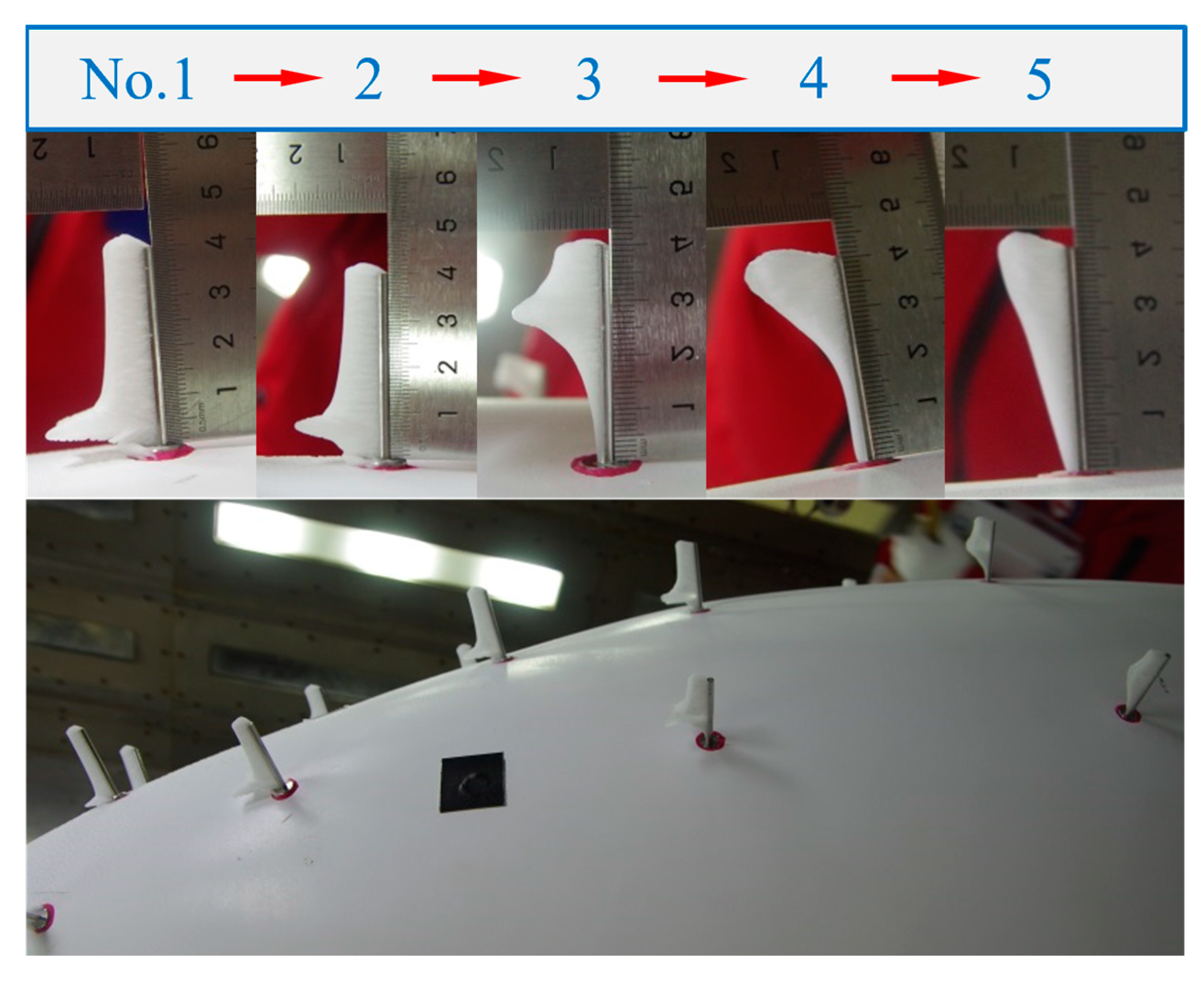

4.3. Analysis of Water Collection Characteristics on Probe Surface

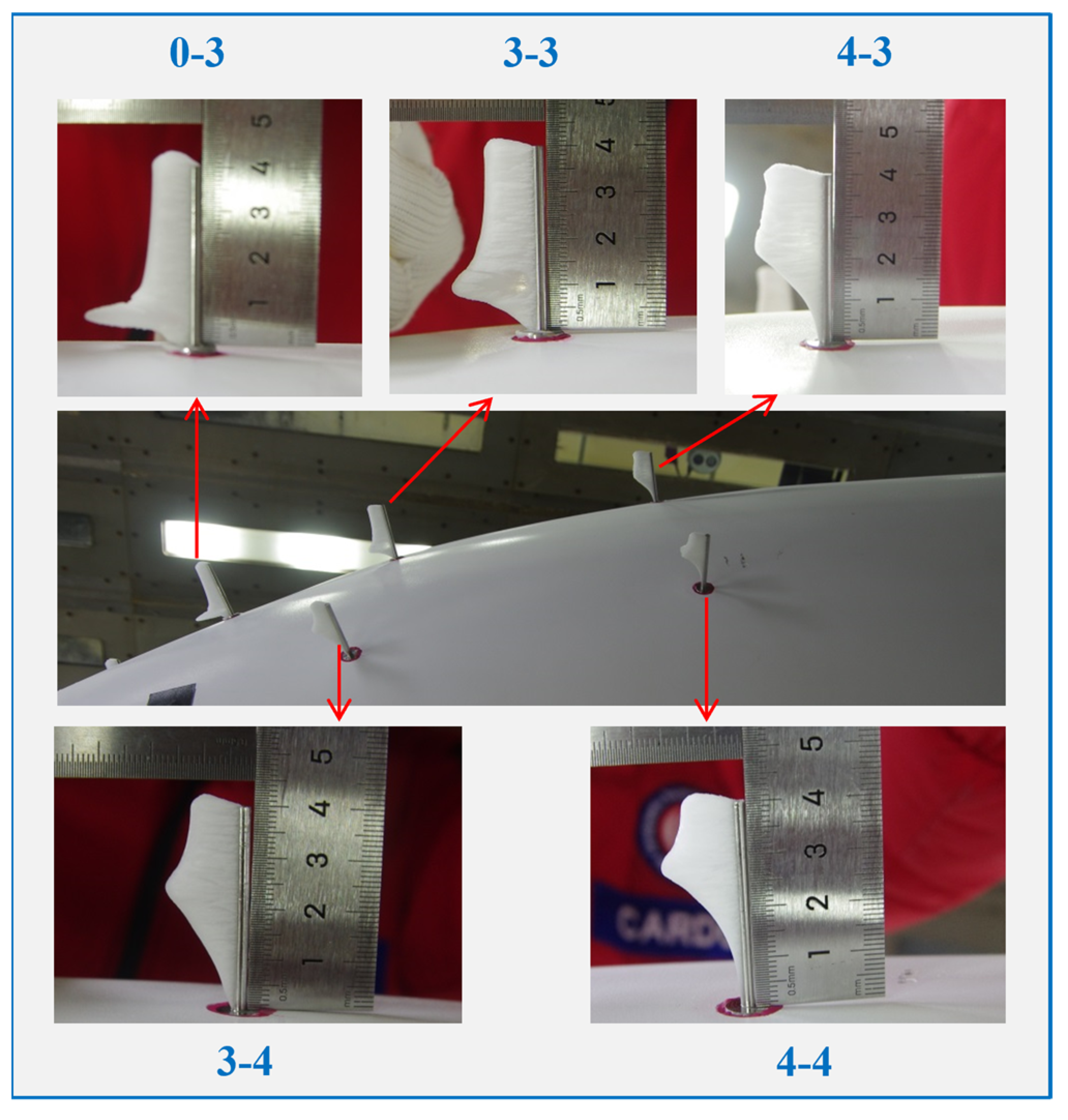

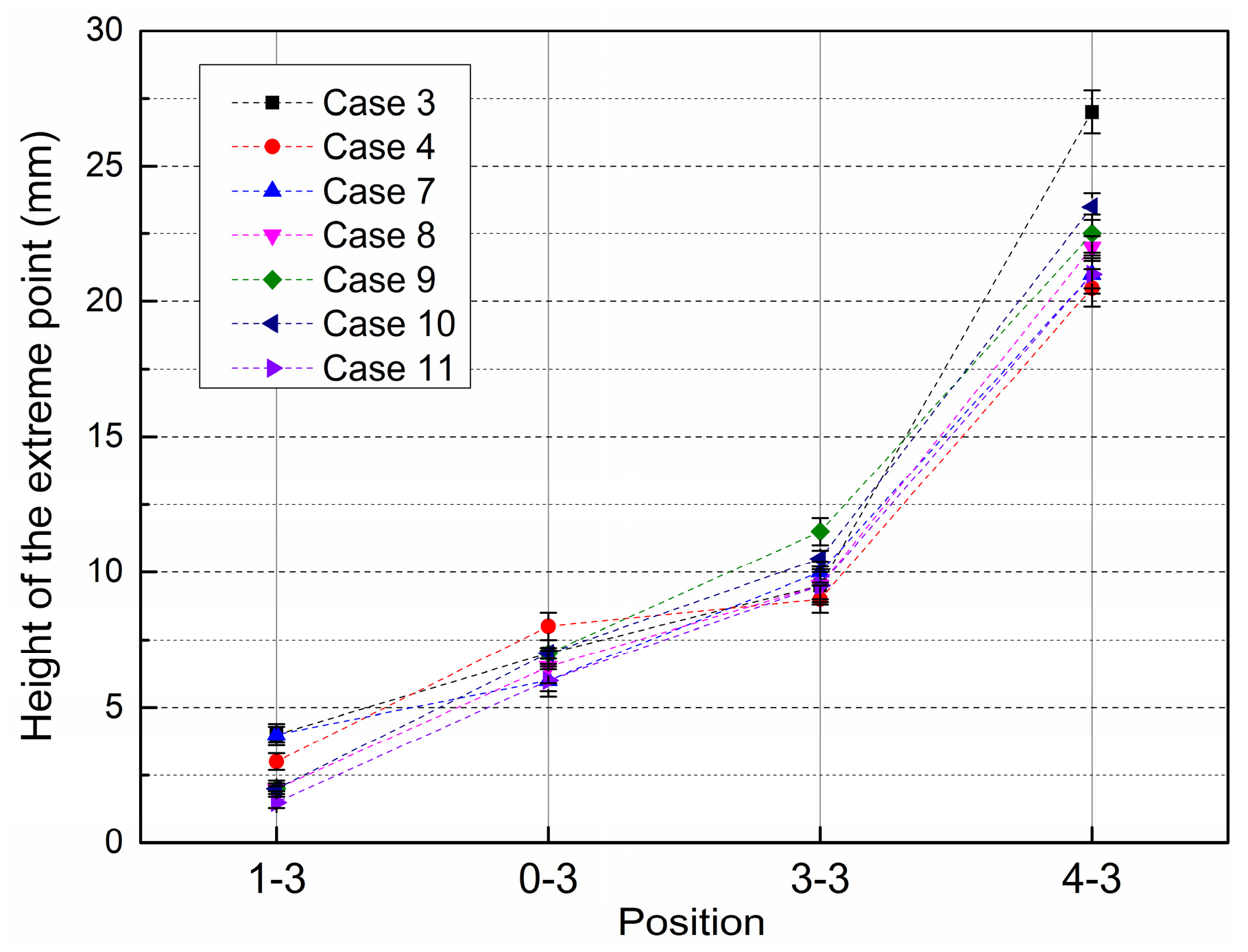

4.4. Variety Rule of the Water Collection Extreme Point with Surface Position

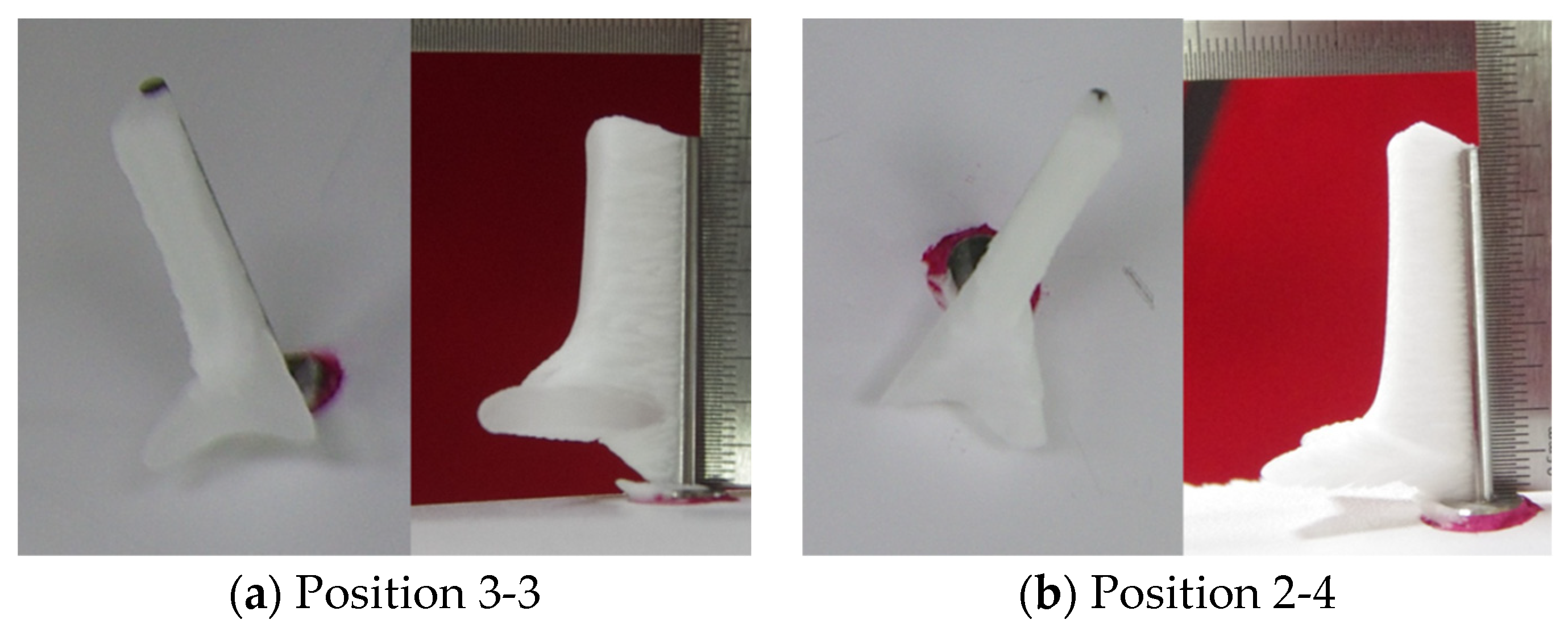

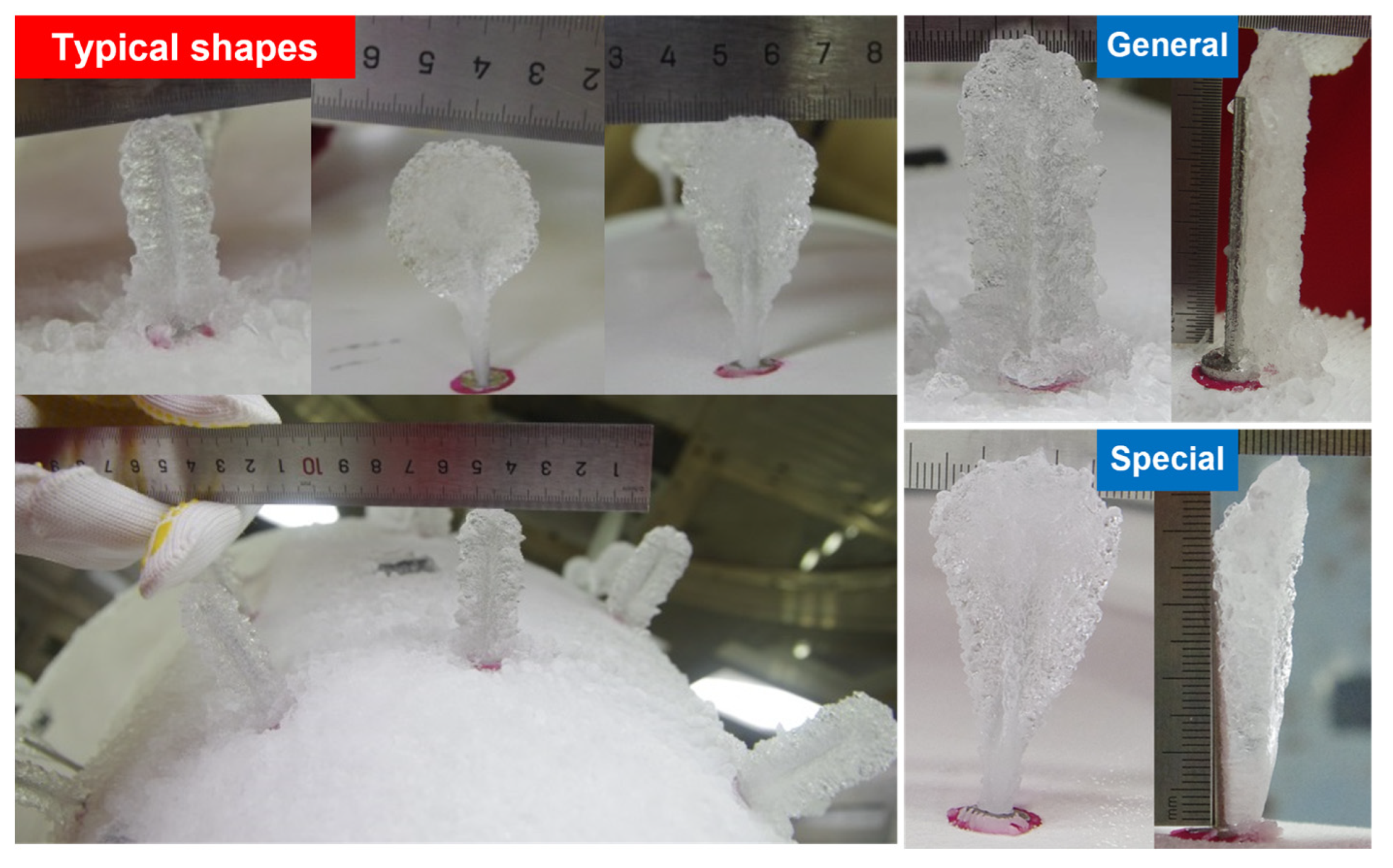

4.5. Local Icing Characteristics under Glaze Ice Conditions

5. Analysis of the Sensor Optimal Position and the Influence of Ambient Parameters

5.1. Analysis of Optimal Location Based on Icing Mass

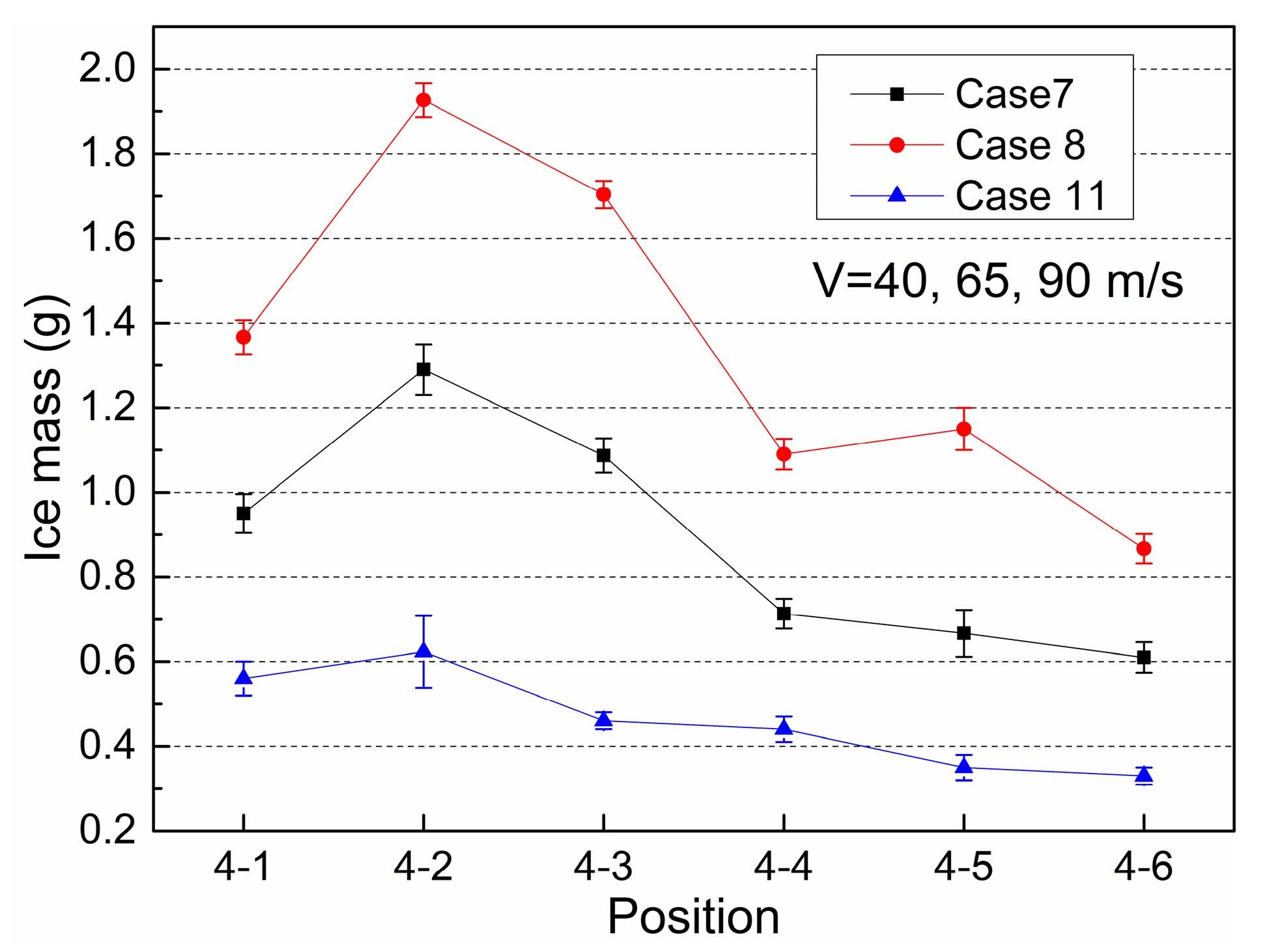

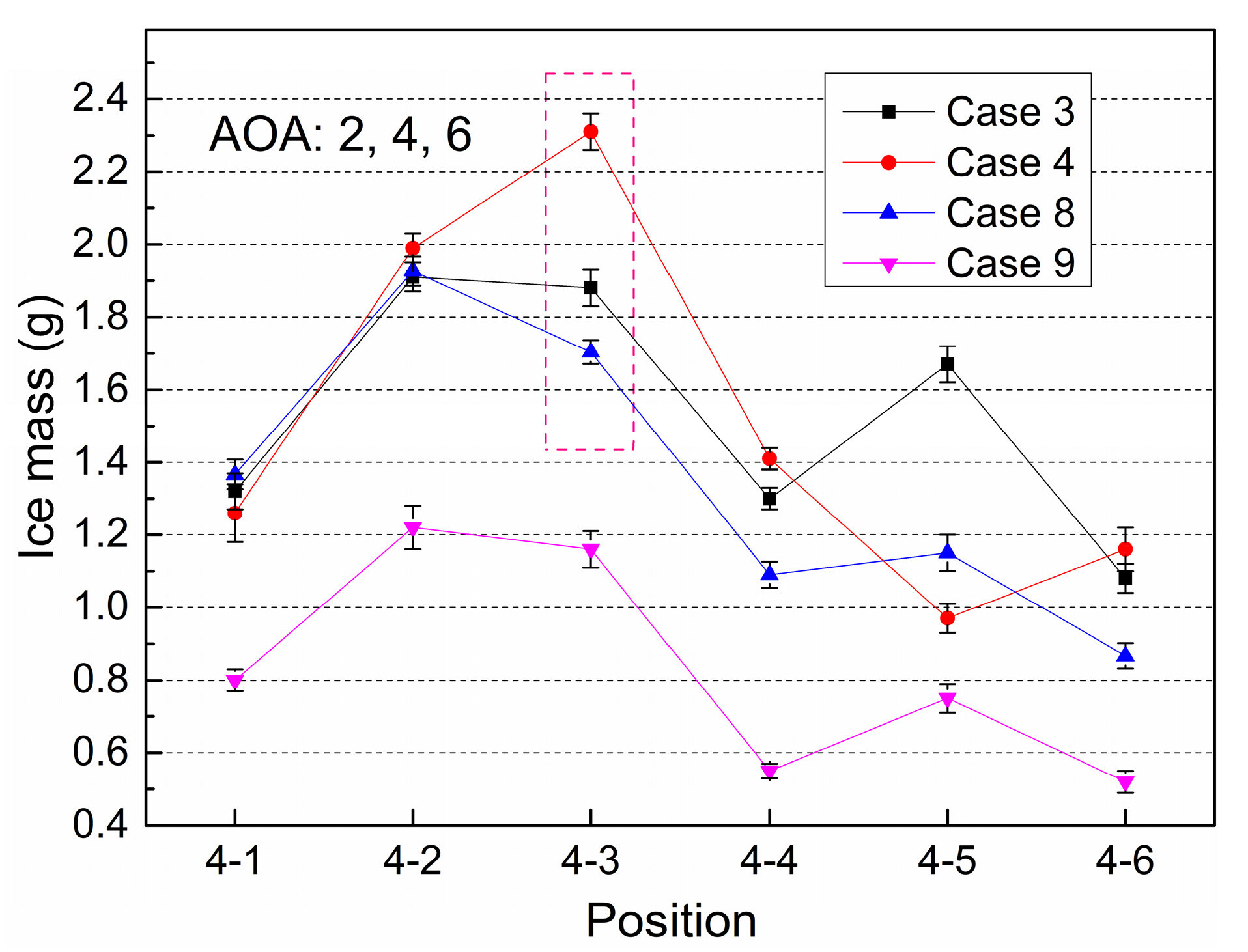

5.2. Influence Law of Incoming Flow Parameters

6. Conclusions

- (a)

- Under rime ice conditions, the water collection coefficient on the probe surface first increases and then decreases from the bottom, reaching the extreme value at a certain position. The height of the extreme points varies with different installation positions.

- (b)

- As the boundary layer on the wall develops gradually along the flow direction, the closer the sensor probe is installed downstream of the airflow, the higher the axial position of the water collection extreme point, which has a variation range of 2~30 mm. Improper design will cause the sensor probe to fail to capture the point with the maximum icing thickness, affecting the sensitivity of icing detection.

- (c)

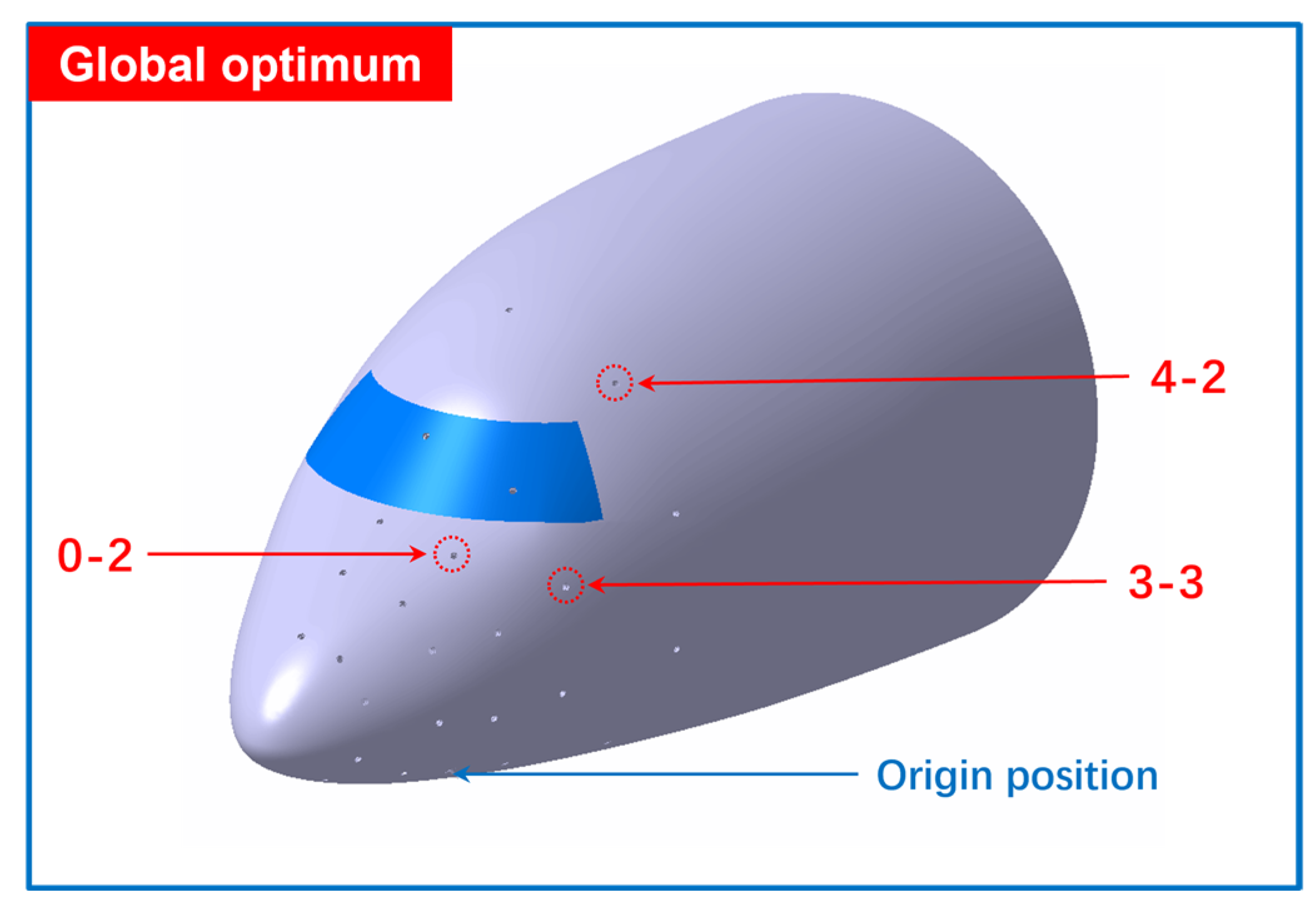

- The original location of the sensor has relatively low icing mass and is not the optimal installation point. The local optimal positions for Sections 1–4 are Points 1-4, 2-4, 0-2, 3-3 and 4-2 respectively, with Points 0-2, 3-3 and 4-2 being the global optimal positions.

- (d)

- The change in airflow velocity significantly affects the overall icing amount, while the change in angle of attack mainly affects the distribution of ice accretion on the nose surface. The sensitivity of each probe position to changes in flow parameters varies, and the points with larger icing mass and lower sensitivity to changes in attack angle will have better detection effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lynch, F.T.; Khodadoust, A. Effects of ice accretions on aircraft aerodynamics. Prog. Aerosp. Sci. 2001, 37, 669–767. [Google Scholar] [CrossRef]

- Thomas, S.K.; Cassoni, R.P.; MacArthur, C.D. Aircraft anti-icing and de-icing techniques and modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Elangovan, R.; Olsen, R. Analysis of layered composite skin electro-thermal anti-icing system. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008. AIAA 2008-0446. [Google Scholar]

- Fortin, G.; Perron, J. Ice adhesion models to predict shear stress at shedding. J. Adhes. Sci. Technol. 2012, 26, 523–553. [Google Scholar] [CrossRef]

- Yamazaki, M.; Jemcov, A.; Sakaue, H. A Review on the Current Status of Icing Physics and Mitigation in Aviation. Aerospace 2021, 8, 188. [Google Scholar] [CrossRef]

- Ikiades, A. Fiber Optic Ice Sensor for Measuring Ice Thickness, Type and the Freezing Fraction on Aircraft Wings. Aerospace 2023, 10, 31. [Google Scholar] [CrossRef]

- Melody, W.; Basar, T.; Perkins, W.R.; Voulgaris, P.G. Parameter identification for inflight detection and characterization of aircraft icing. Control Eng. Pract. 2000, 8, 985–1001. [Google Scholar] [CrossRef]

- Gui, Y.; Zhou, Z.; Li, Y.; Xu, Y. Multiple safety boundaries for aircraft icing. Acta Aeronaut. Astronaut. Sin. 2017, 38, 520723. (In Chinese) [Google Scholar]

- Zheng, D.; Li, Z.; Du, Z.; Ma, Y.; Zhang, L.; Du, C.; Li, Z.; Cui, L.; Zhang, L.; Xuan, X.; et al. Design of capacitance and impedance dual-parameters planar electrode sensor for thin ice detection of aircraft wings. IEEE Sens. J. 2022, 22, 11006–11015. [Google Scholar] [CrossRef]

- Dong, Y.; Ai, J. Research on inflight parameter identification and icing location detection of the aircraft. Aerosp. Sci. Technol. 2013, 29, 305–312. [Google Scholar] [CrossRef]

- Manatbayev, R.; Baizhuma, Z.; Bolegenova, S. Numerical simulations on static Vertical Axis Wind Turbine blade icing. Renew. Energy 2021, 170, 997–1007. [Google Scholar] [CrossRef]

- Pasandideh-Fard, M.; Chandra, S.; Mostaghimi, J. A three-dimensional model of droplet impact and solidification. Int. J. Heat Mass Transf. 2002, 45, 2229–2242. [Google Scholar] [CrossRef]

- Guo, X.; Wang, Z.; Zhao, R.; Wu, Y.; Wu, X.; Yi, X. Liquid water content measurement with SEA multi-element sensor in CARDC icing wind tunnel: Calibration and performance. Appl. Therm. Eng. 2023, 235, 121255. [Google Scholar] [CrossRef]

- Li, Y.; Tagawa, K.; Feng, F.; Li, Q.; He, Q. A wind tunnel experimental study of icing on wind turbine blade airfoil. Energy Convers. Manag. 2014, 85, 591–595. [Google Scholar] [CrossRef]

- CCAR25-R4; Airworthiness Standards for Transport Aircraft. Civil Aviation Administration of China: Beijing, China, 2011. (In Chinese)

- Liu, H.L.; Fan, T.Y.; Xing, Y.M.; Sheng, Q. Study for spray experiment and simulation of nozzle on icing wind tunnel. Adv. Mater. Res. 2012, 490–495, 2573–2577. [Google Scholar] [CrossRef]

| Case | Temperature (℃) | Velocity (m/s) | Attack (°) | MVD (μm) | Time (s) |

|---|---|---|---|---|---|

| 1 | −10 | 90 | 2 | 20 | 180 |

| 2 | −10 | 90 | 2 | 30 | 180 |

| 3 | −25 | 90 | 4 | 20 | 80 |

| 4 | −25 | 90 | 6 | 20 | 80 |

| 5 | −25 | 65 | 2 | 15 | 300 |

| 6 | −25 | 40 | 2 | 15 | 300 |

| 7 | −25 | 65 | 2 | 20 | 80 |

| 8 | −25 | 90 | 2 | 20 | 80 |

| 9 | −25 | 65 | 2 | 30 | 80 |

| 10 | −25 | 90 | 2 | 30 | 80 |

| 11 | −25 | 40 | 2 | 20 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, L.; Yi, X.; Hu, Z.; Guo, X. Experimental Study on Optimum Design of Aircraft Icing Detection Based on Large-Scale Icing Wind Tunnel. Aerospace 2023, 10, 926. https://doi.org/10.3390/aerospace10110926

Ding L, Yi X, Hu Z, Guo X. Experimental Study on Optimum Design of Aircraft Icing Detection Based on Large-Scale Icing Wind Tunnel. Aerospace. 2023; 10(11):926. https://doi.org/10.3390/aerospace10110926

Chicago/Turabian StyleDing, Liang, Xian Yi, Zhanwei Hu, and Xiangdong Guo. 2023. "Experimental Study on Optimum Design of Aircraft Icing Detection Based on Large-Scale Icing Wind Tunnel" Aerospace 10, no. 11: 926. https://doi.org/10.3390/aerospace10110926

APA StyleDing, L., Yi, X., Hu, Z., & Guo, X. (2023). Experimental Study on Optimum Design of Aircraft Icing Detection Based on Large-Scale Icing Wind Tunnel. Aerospace, 10(11), 926. https://doi.org/10.3390/aerospace10110926