Real-Time Implementation of an Adaptive PID Controller for the Quadrotor MAV Embedded Flight Control System

Abstract

1. Introduction

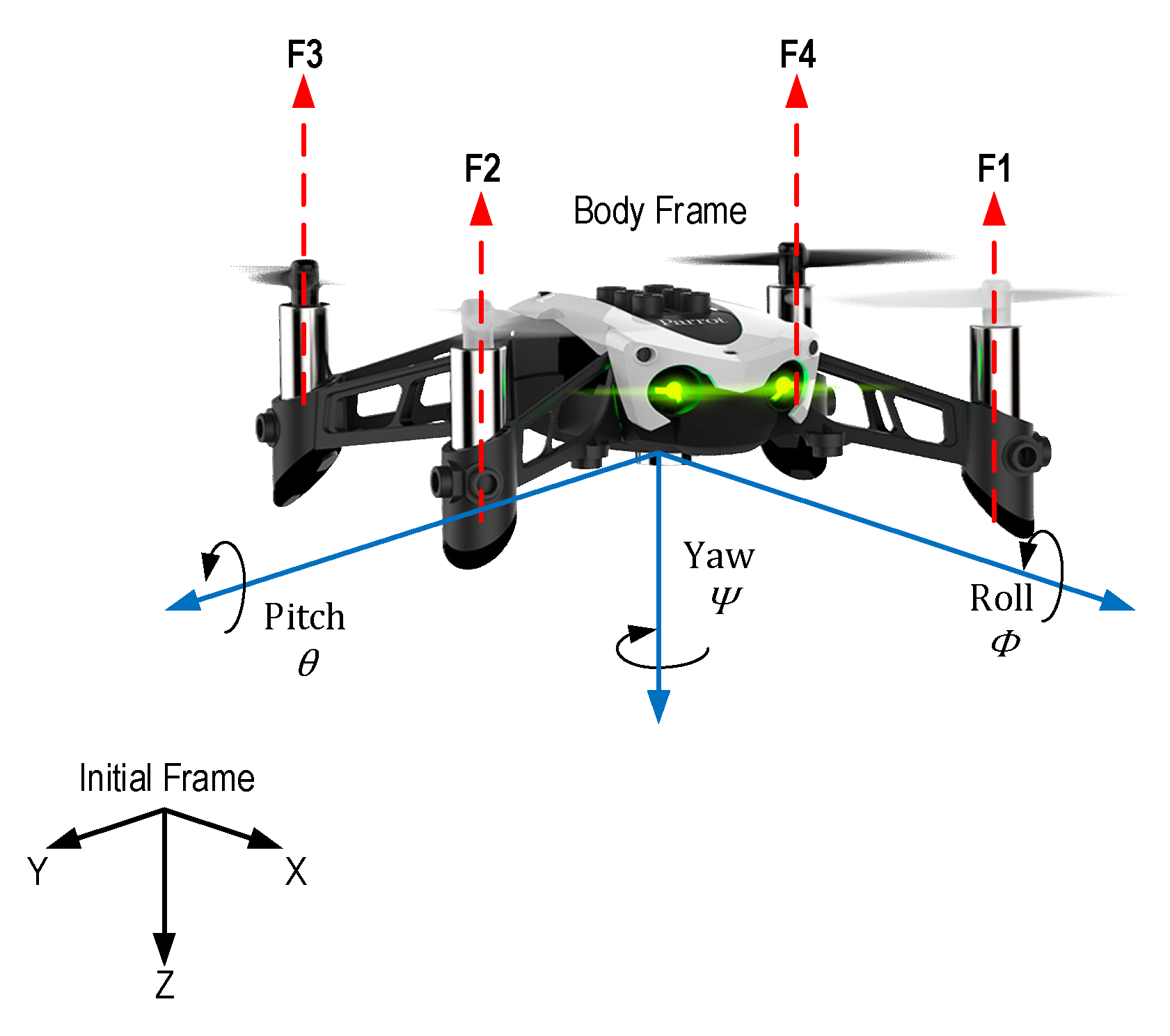

2. MAV Quadrotor Modeling

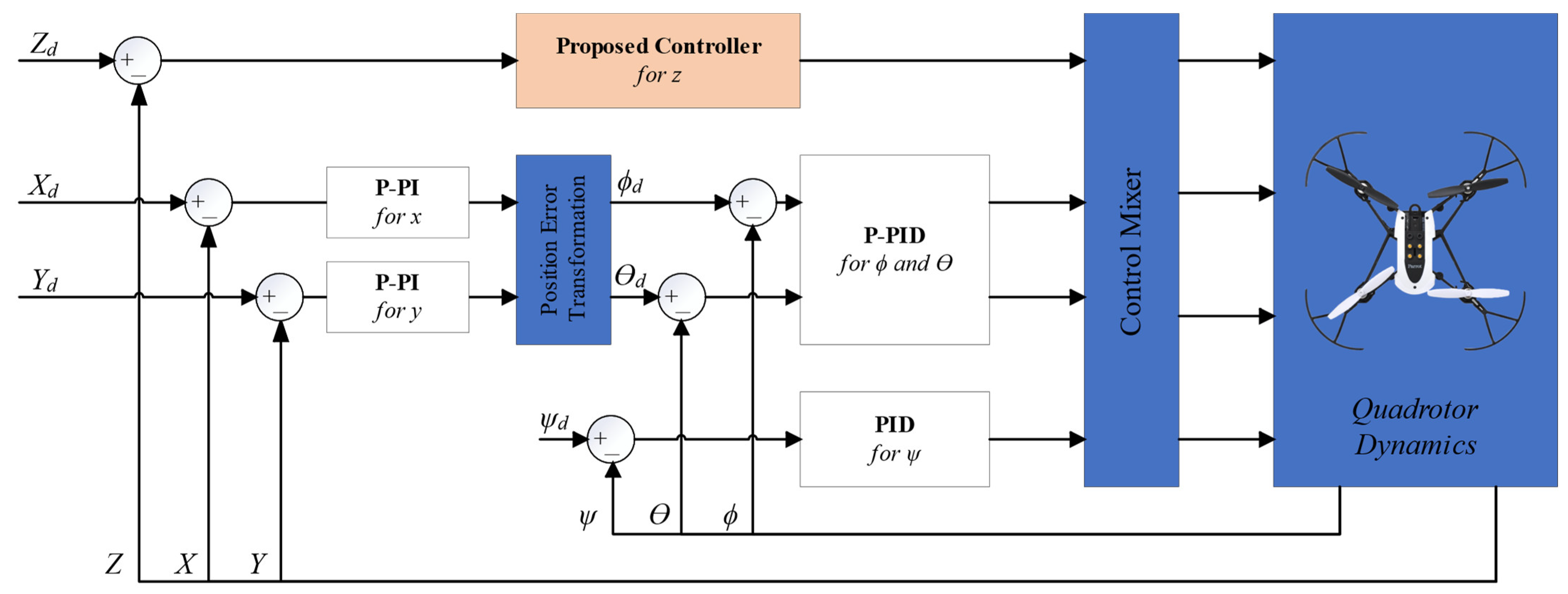

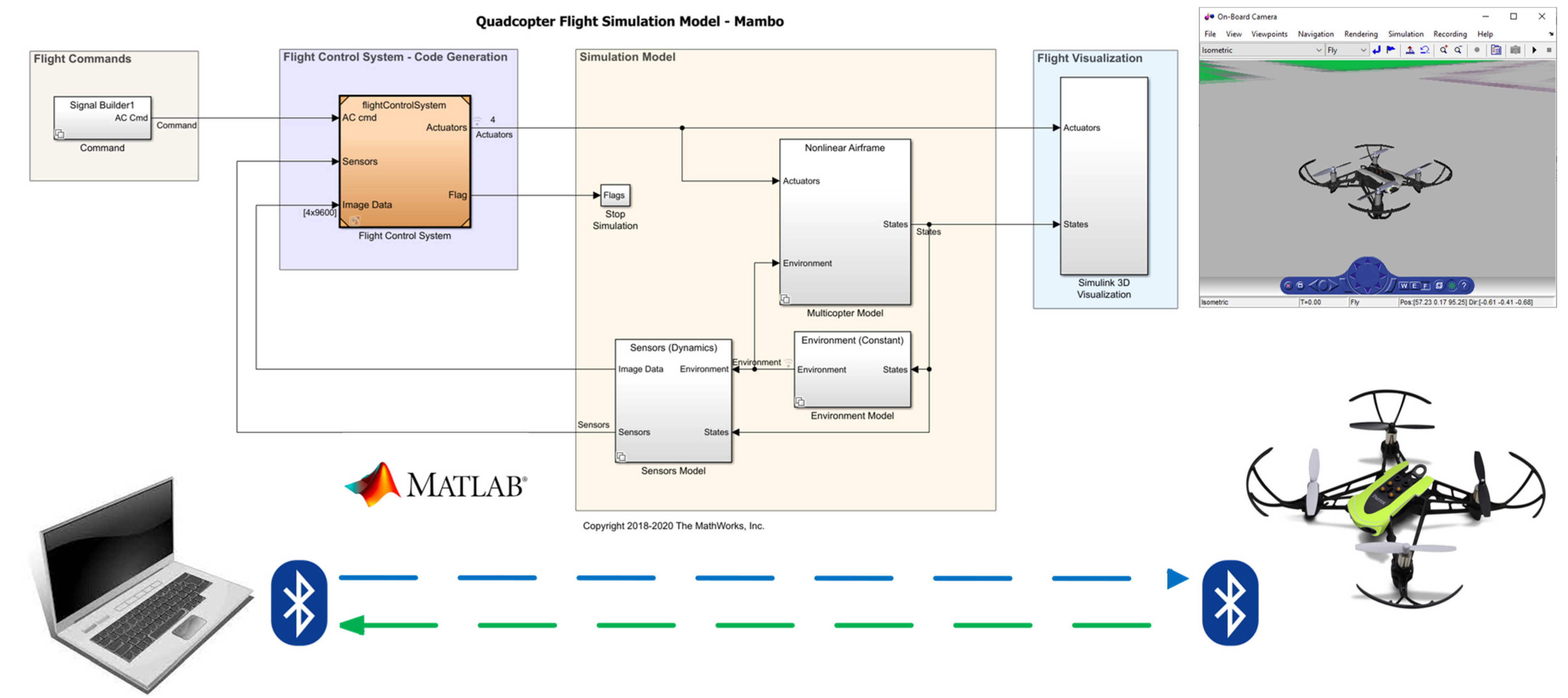

3. Flight Controller Design

3.1. Attitude and Yaw Controller

3.2. Position Controller

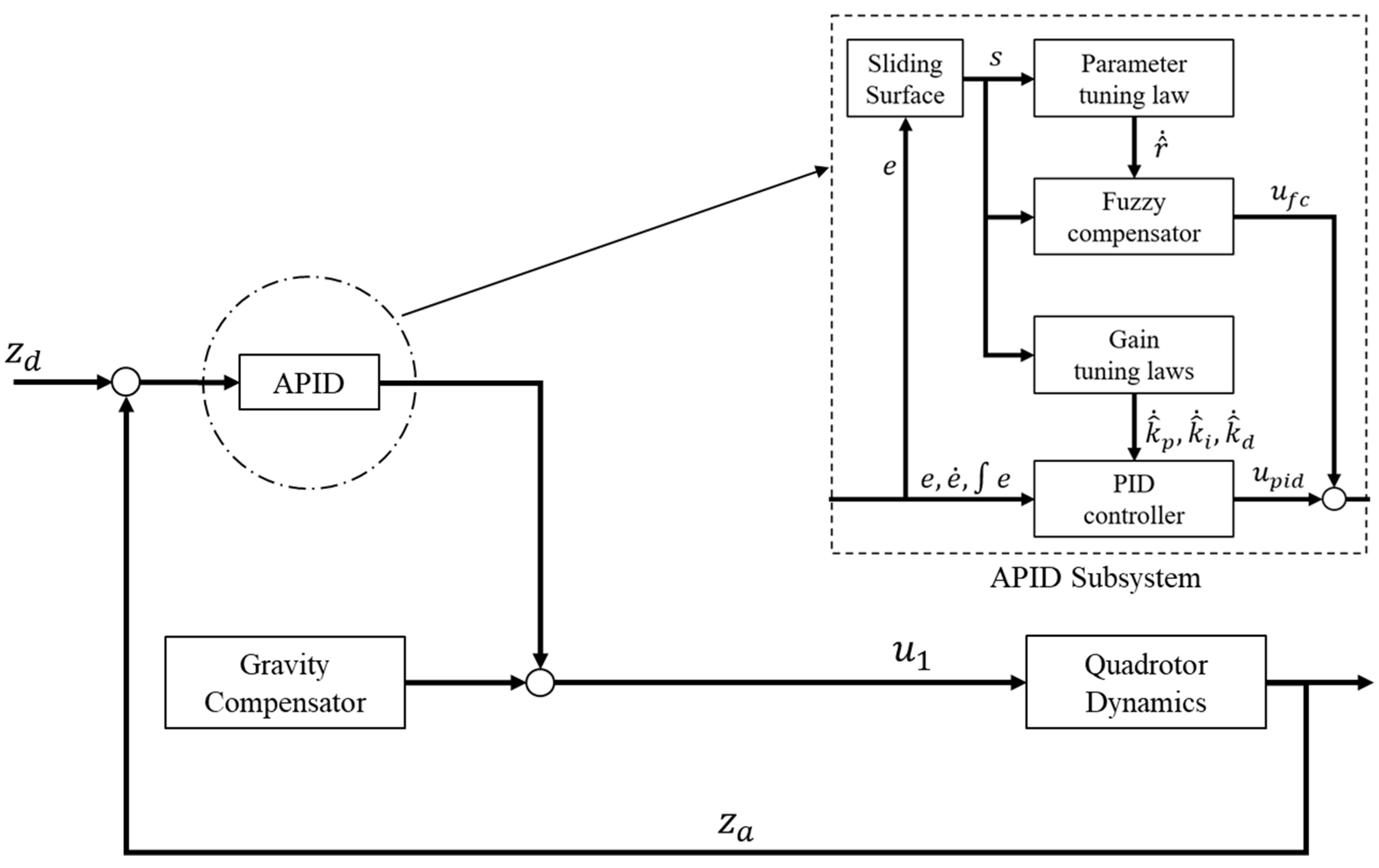

3.3. Altitude Control Design

3.3.1. PID Controller Design

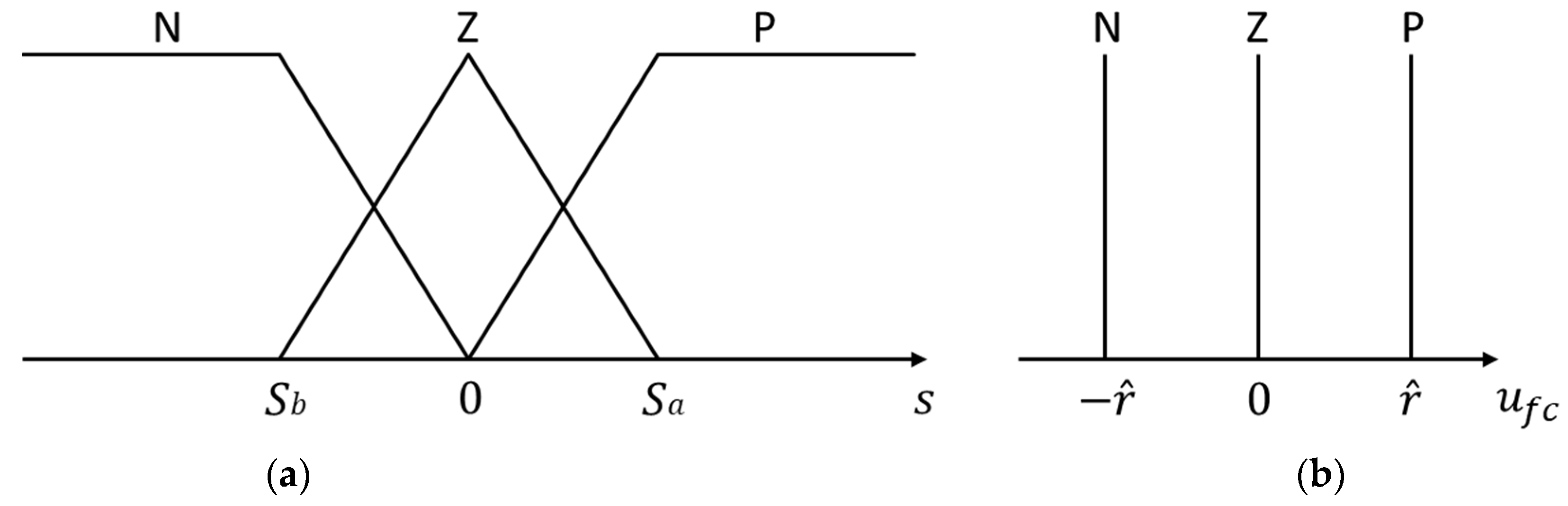

3.3.2. Design of Fuzzy Compensator

3.4. Stability Analysis

- APIDC system parameter initialization.

- Utilization of tracking error, , and the sliding surface, , as denoted in (18)

- Implementation of the PID controller, , as shown in (27), using the gains parameter , as revised by (30).

- Usage of the fuzzy compensator, as described in (37), with the parameter is as projected by (50).

- Application of the control law, as specified in (12).

- Return to Step 2

4. Simulation Results

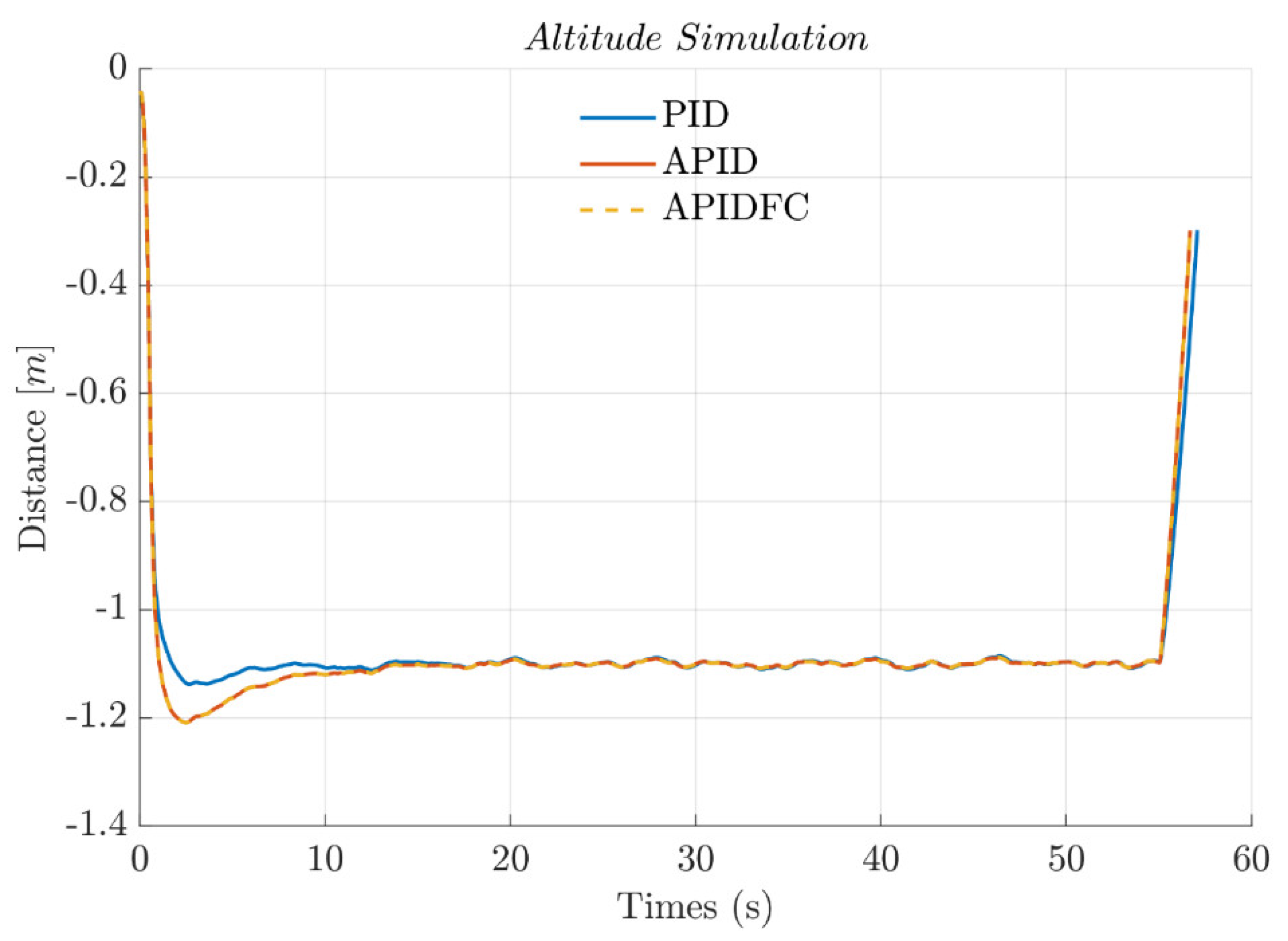

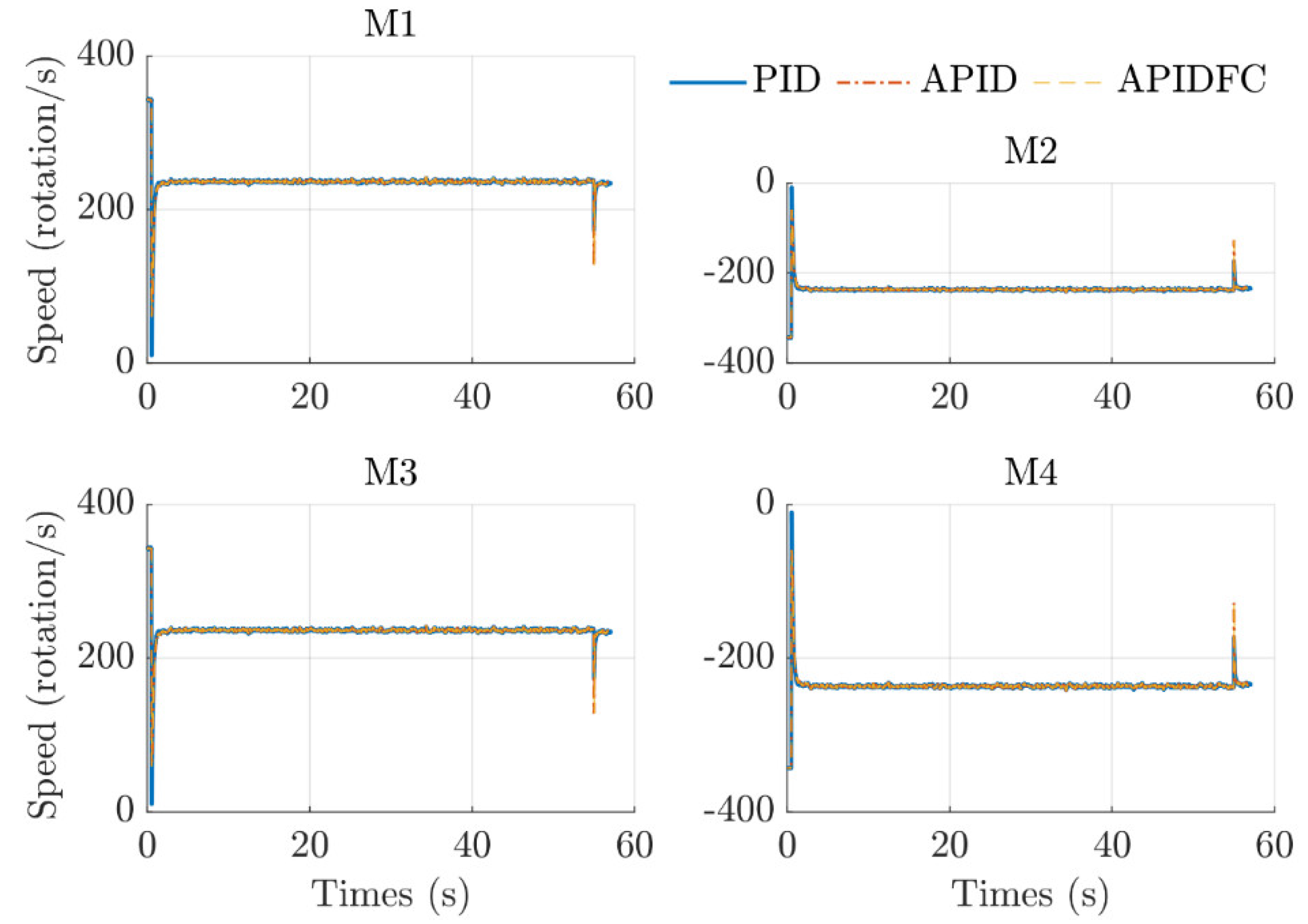

4.1. Hovering Test

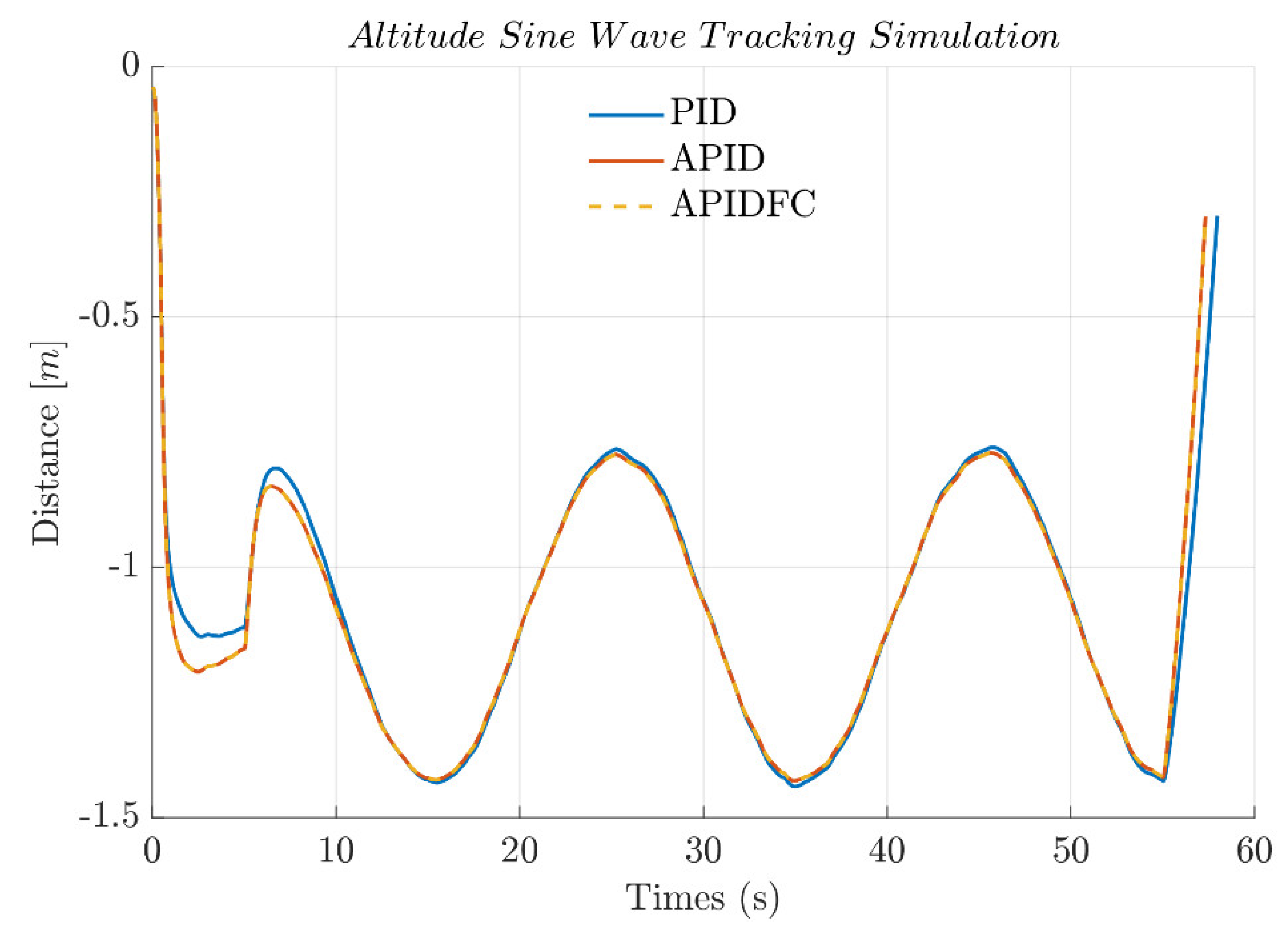

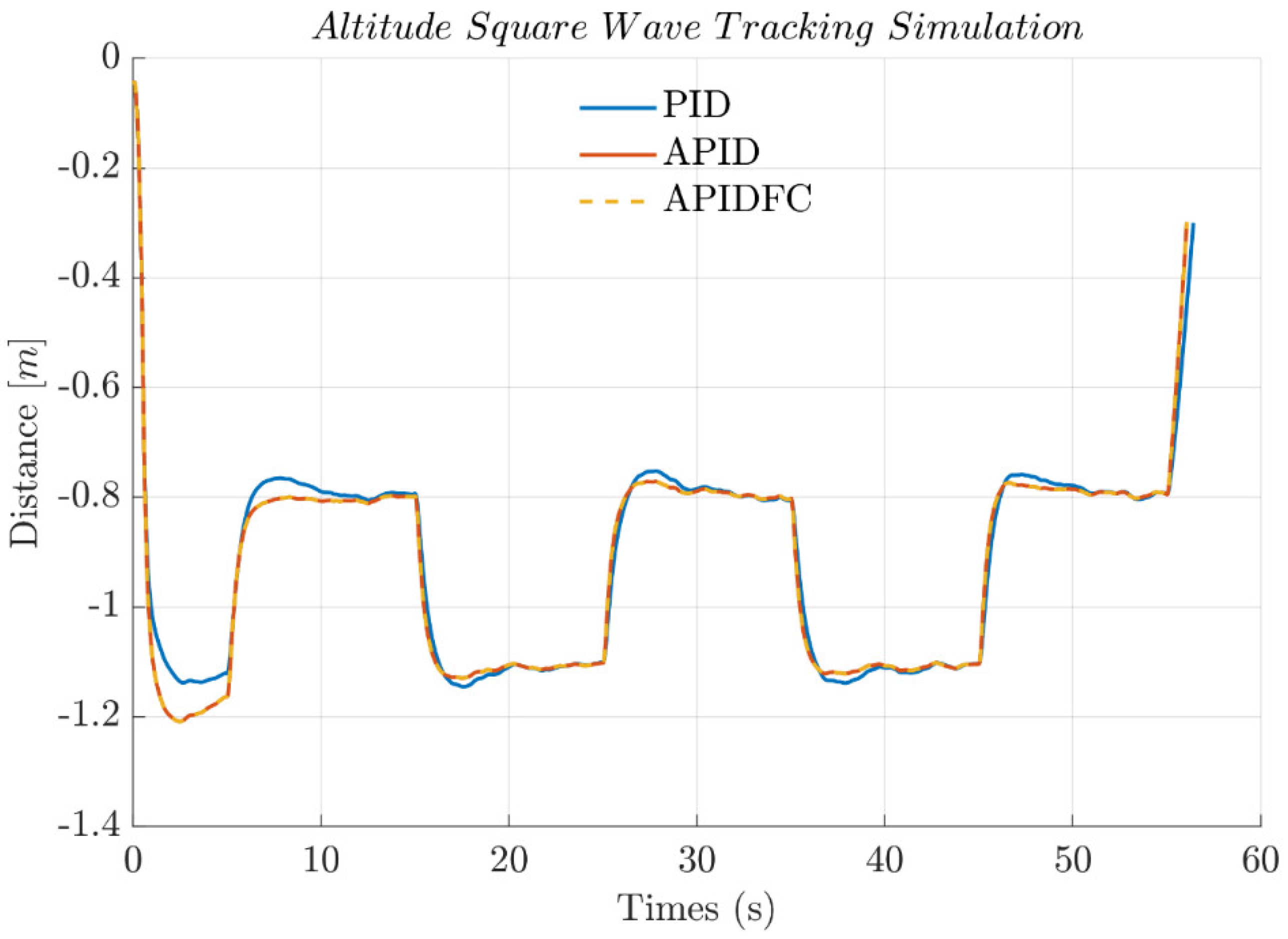

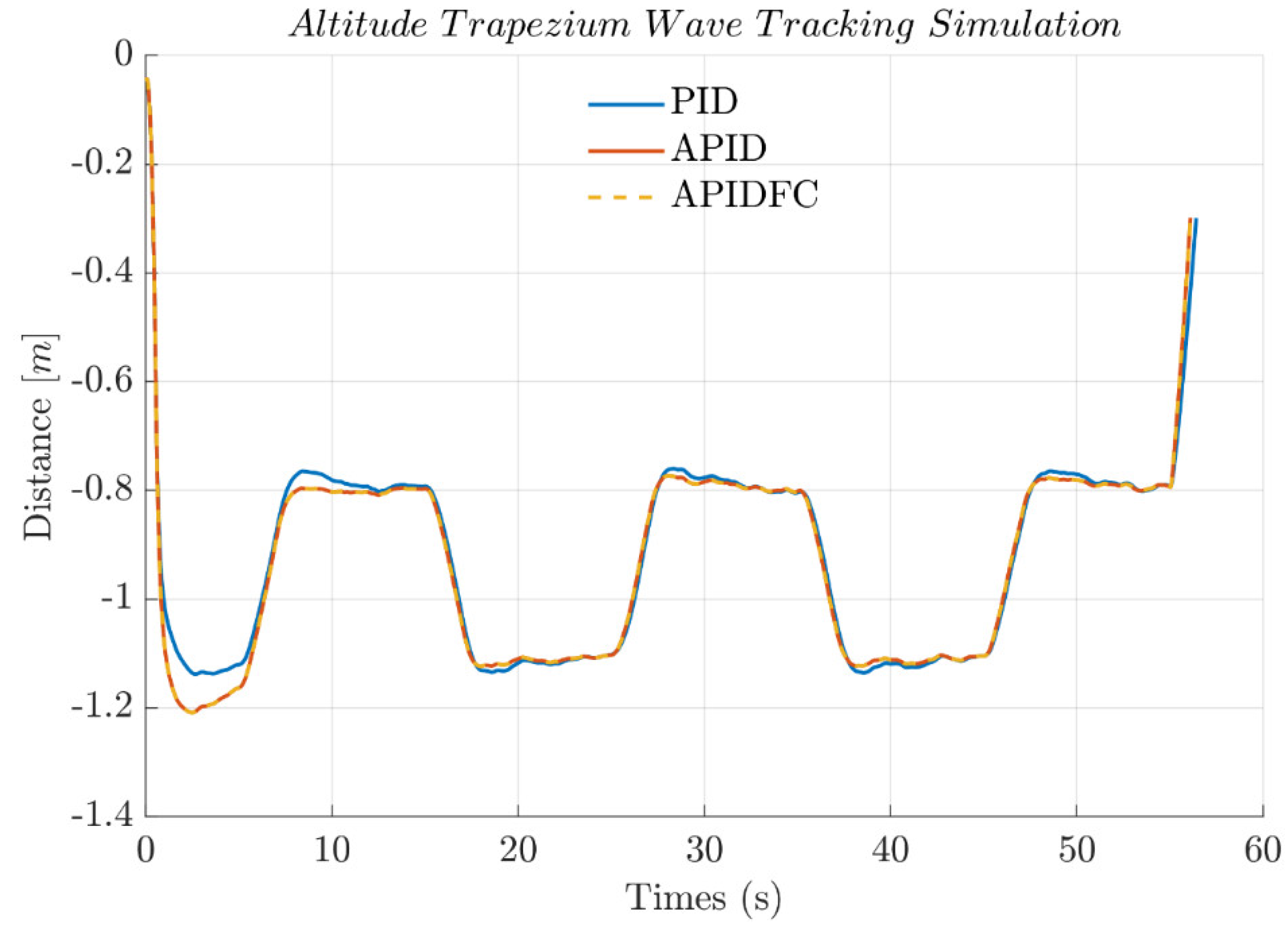

4.2. Altitude Tracking Test

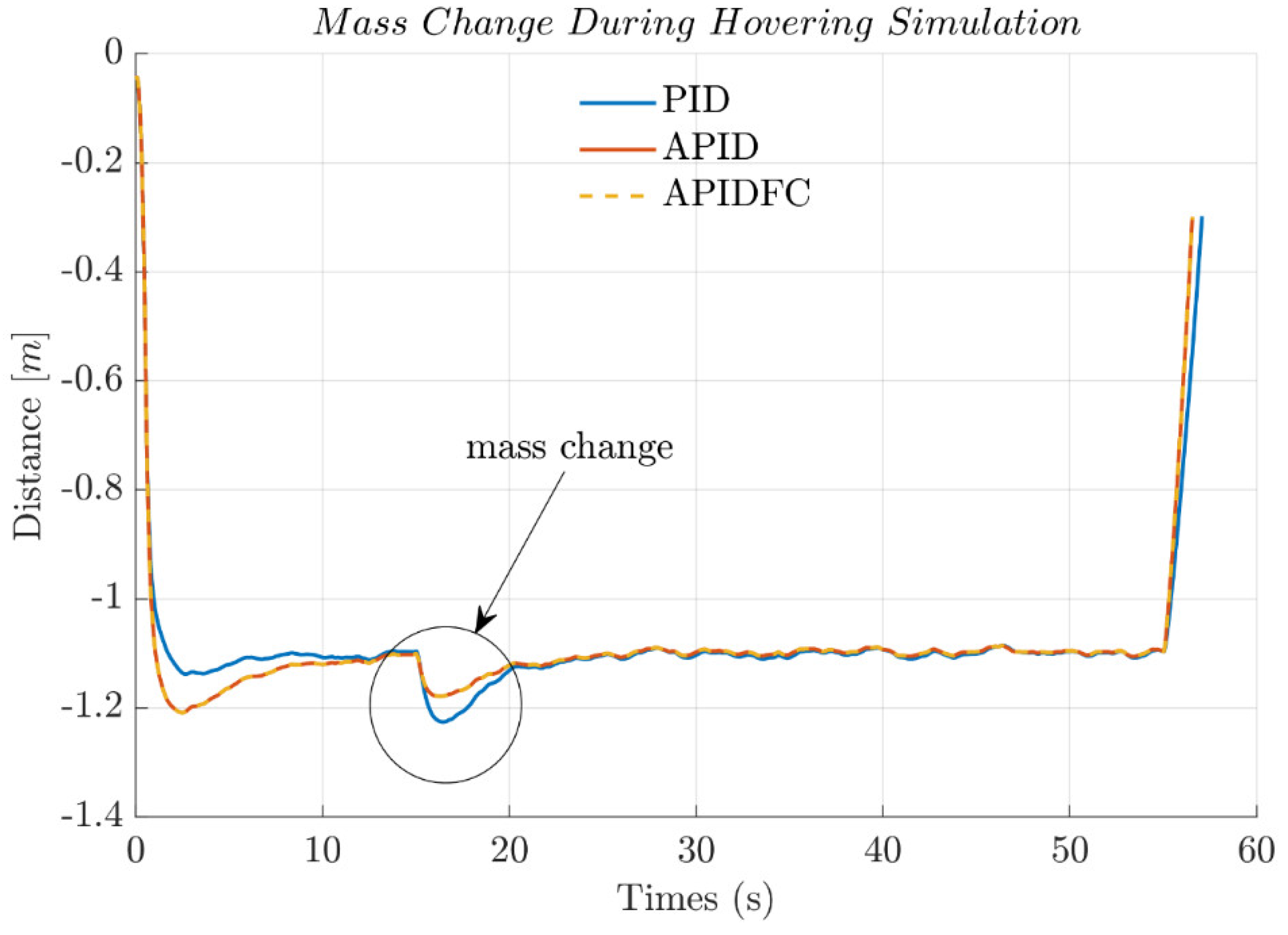

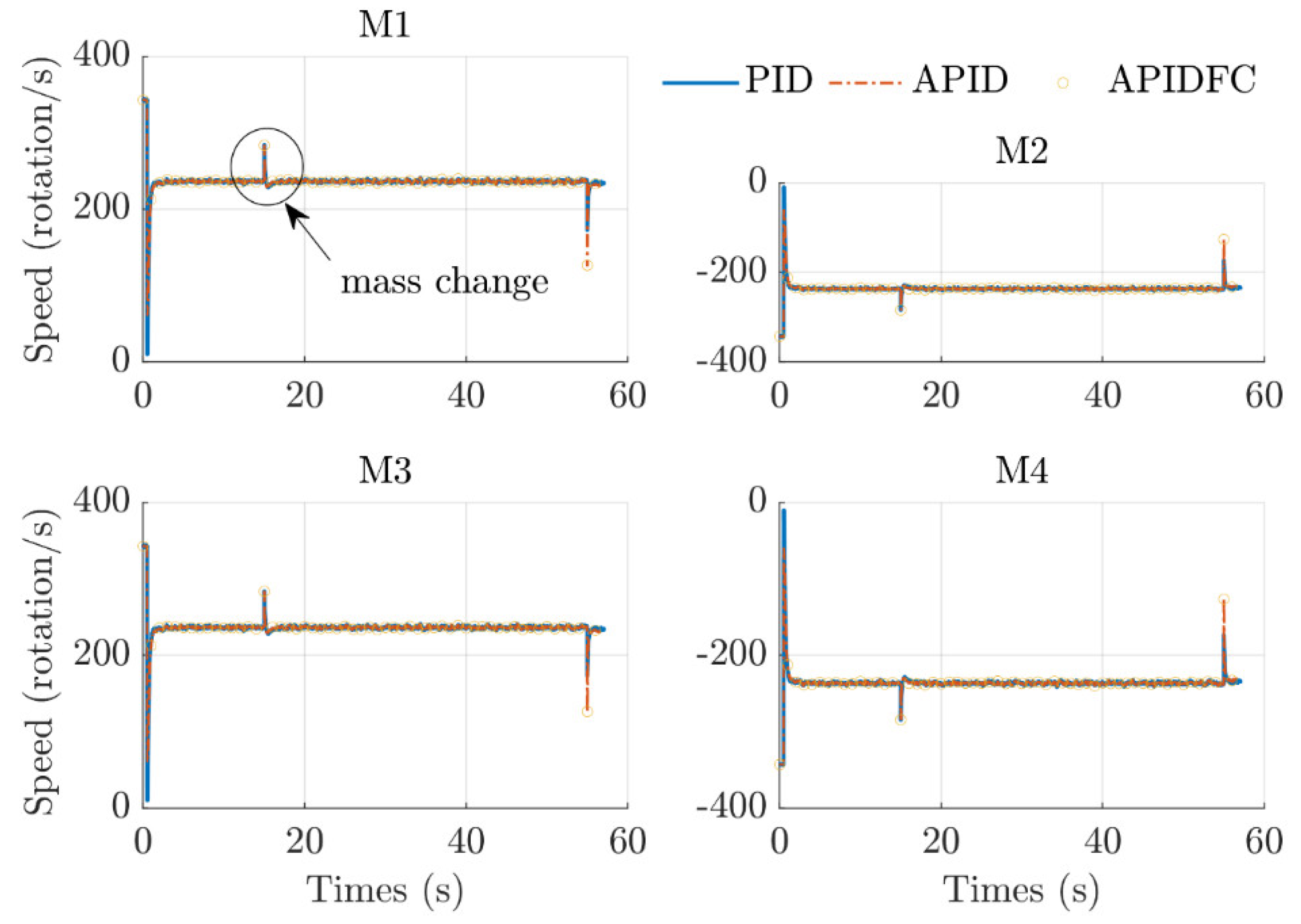

4.3. Changing the Mass during the Hovering Test

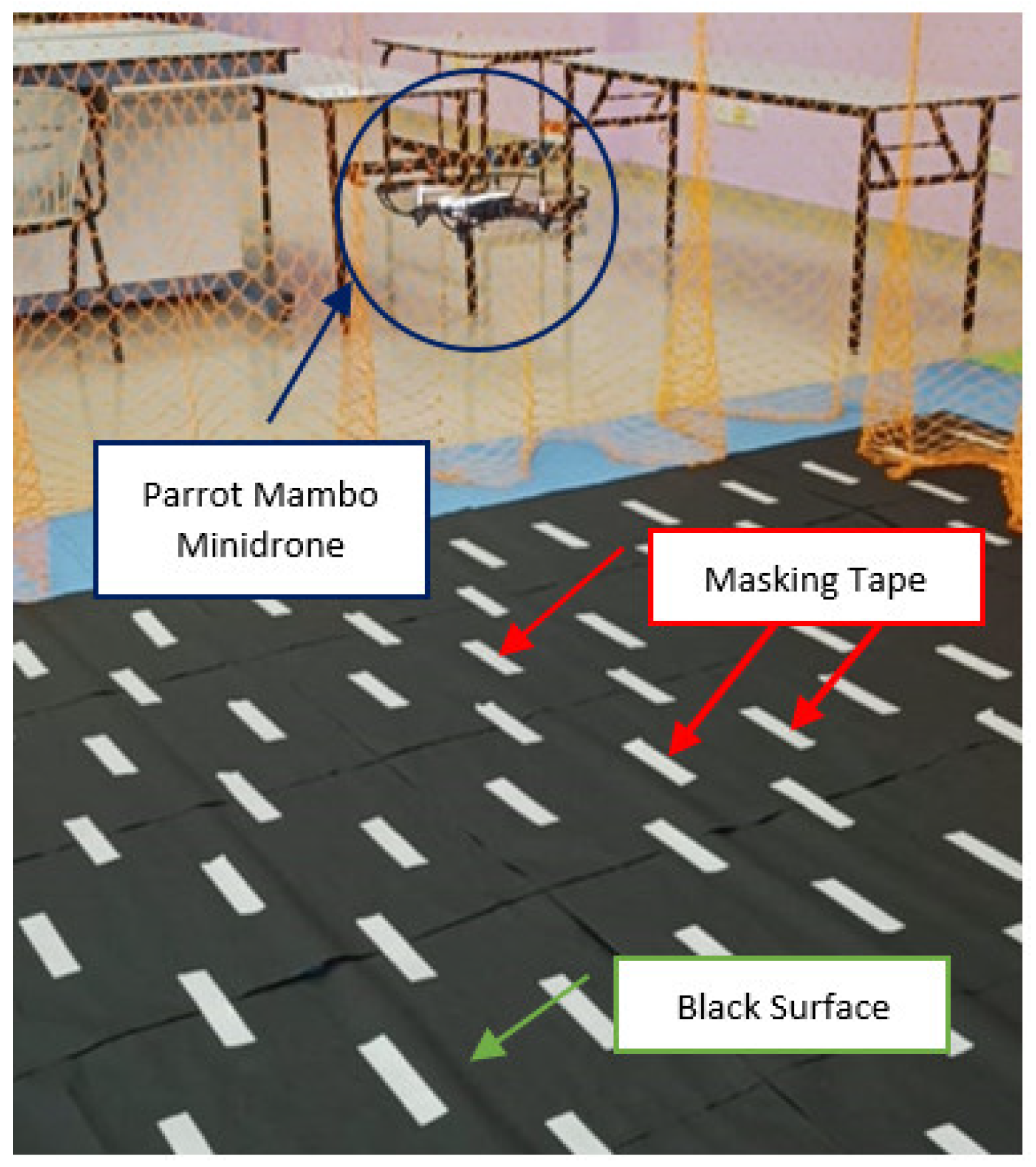

5. Experimental Results

- The experiment is conducted in an air conditioning hall.

- The Parrot Mambo Minidrone structure is assumed to be in a good condition.

- The propellors are assumed to be in good condition, with no dents.

- All the motors are assumed to be in good condition.

- The execution starting point is always the same.

- The lighting condition is considered fair to good.

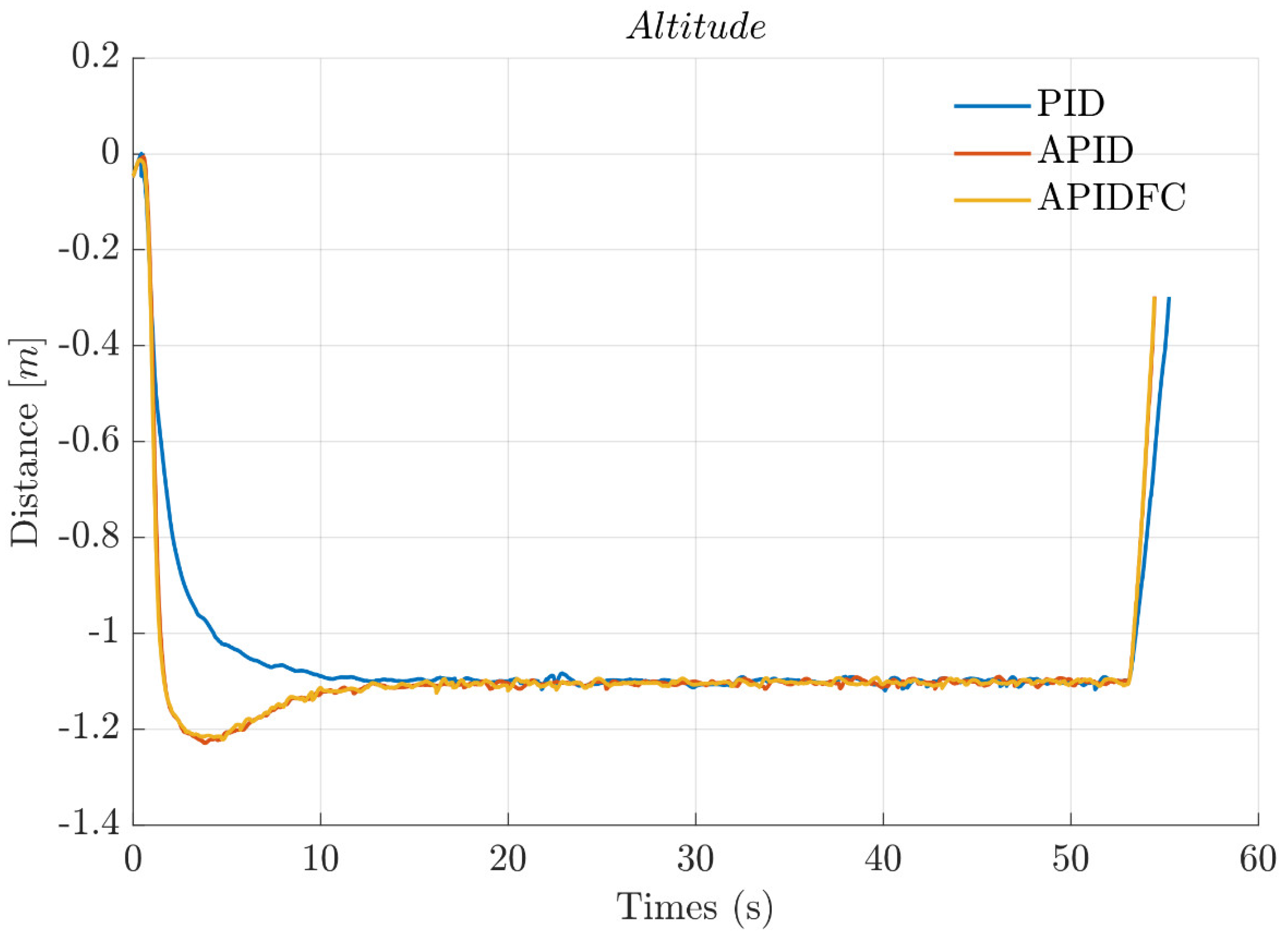

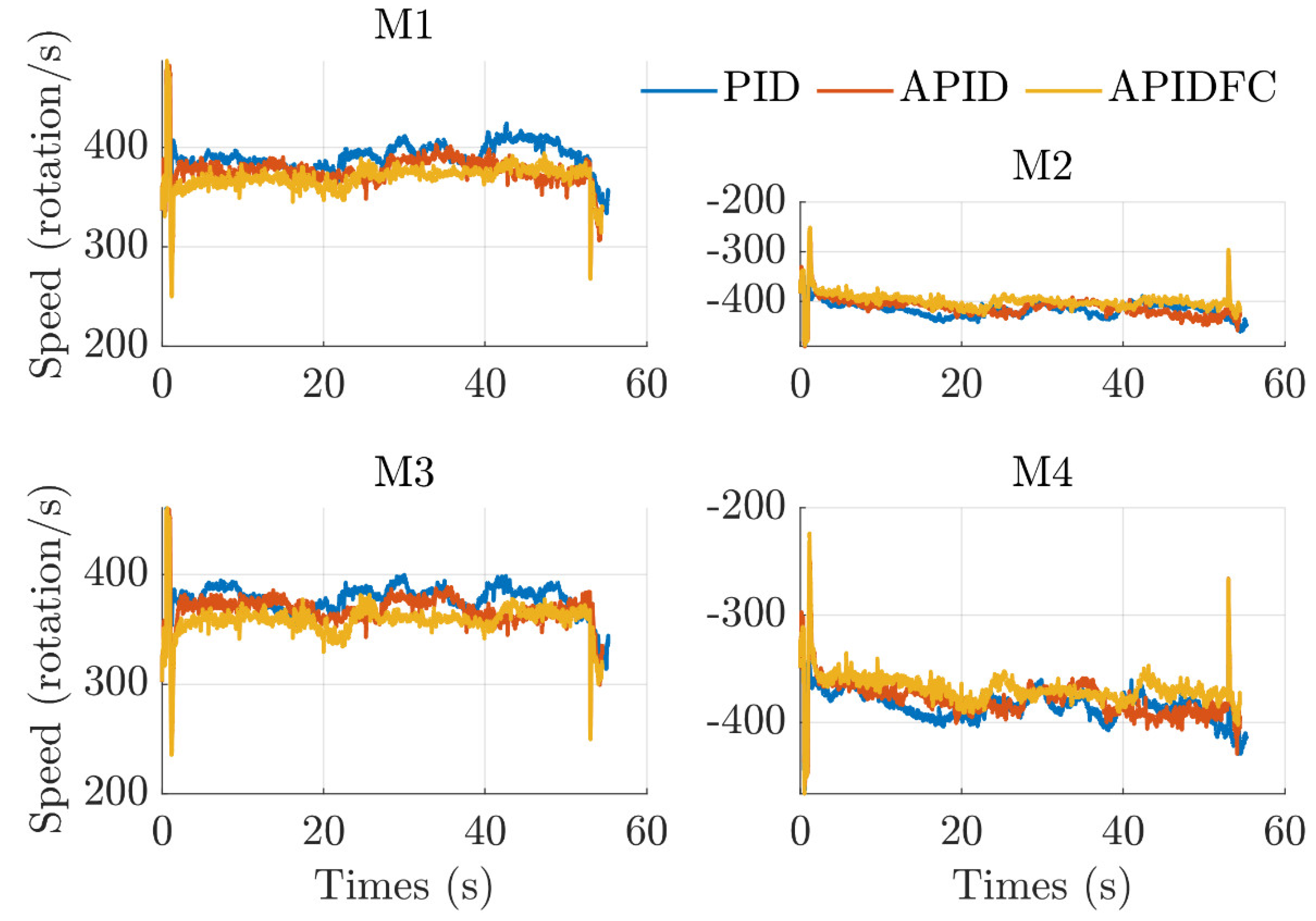

5.1. Hovering Test

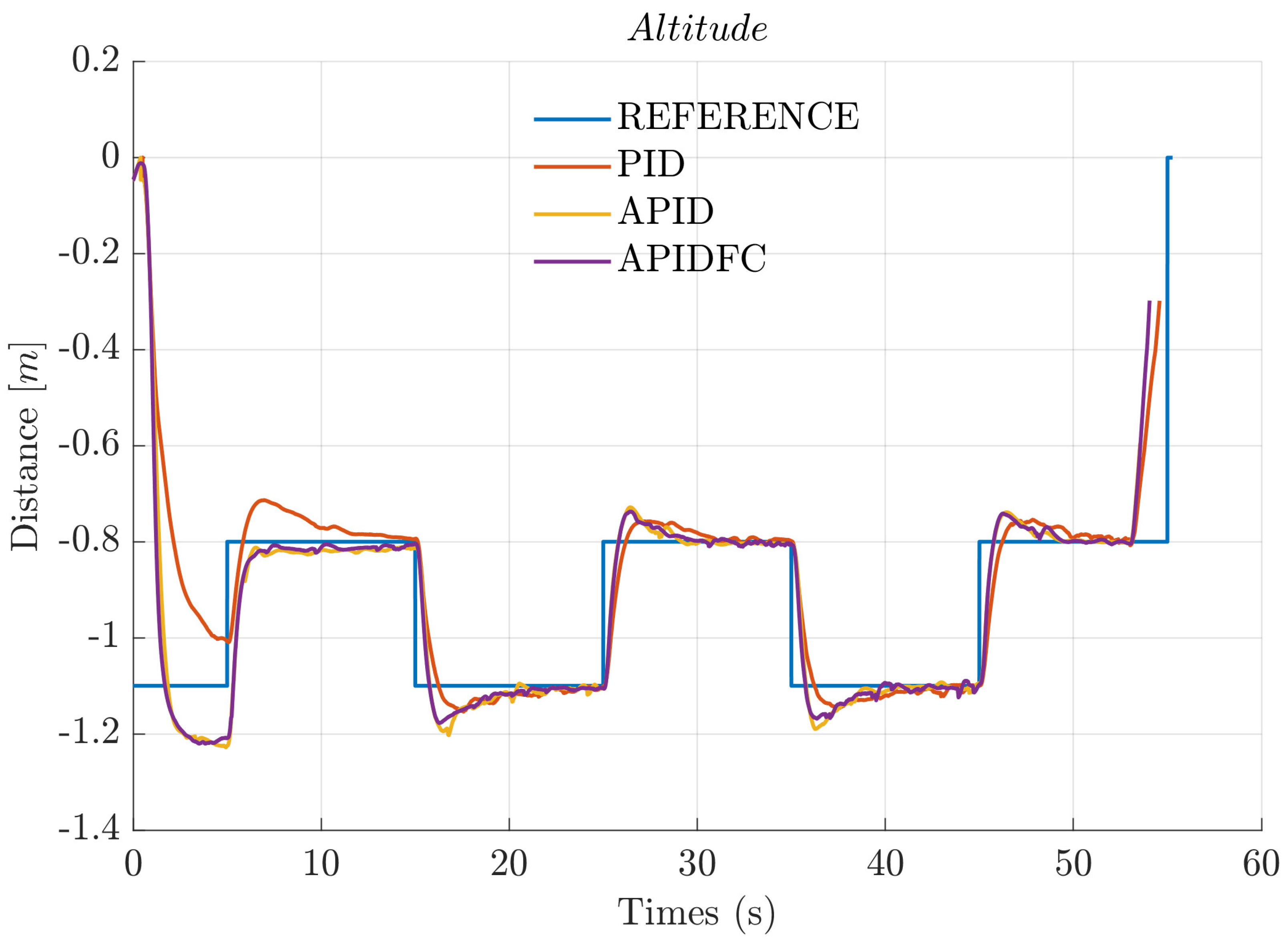

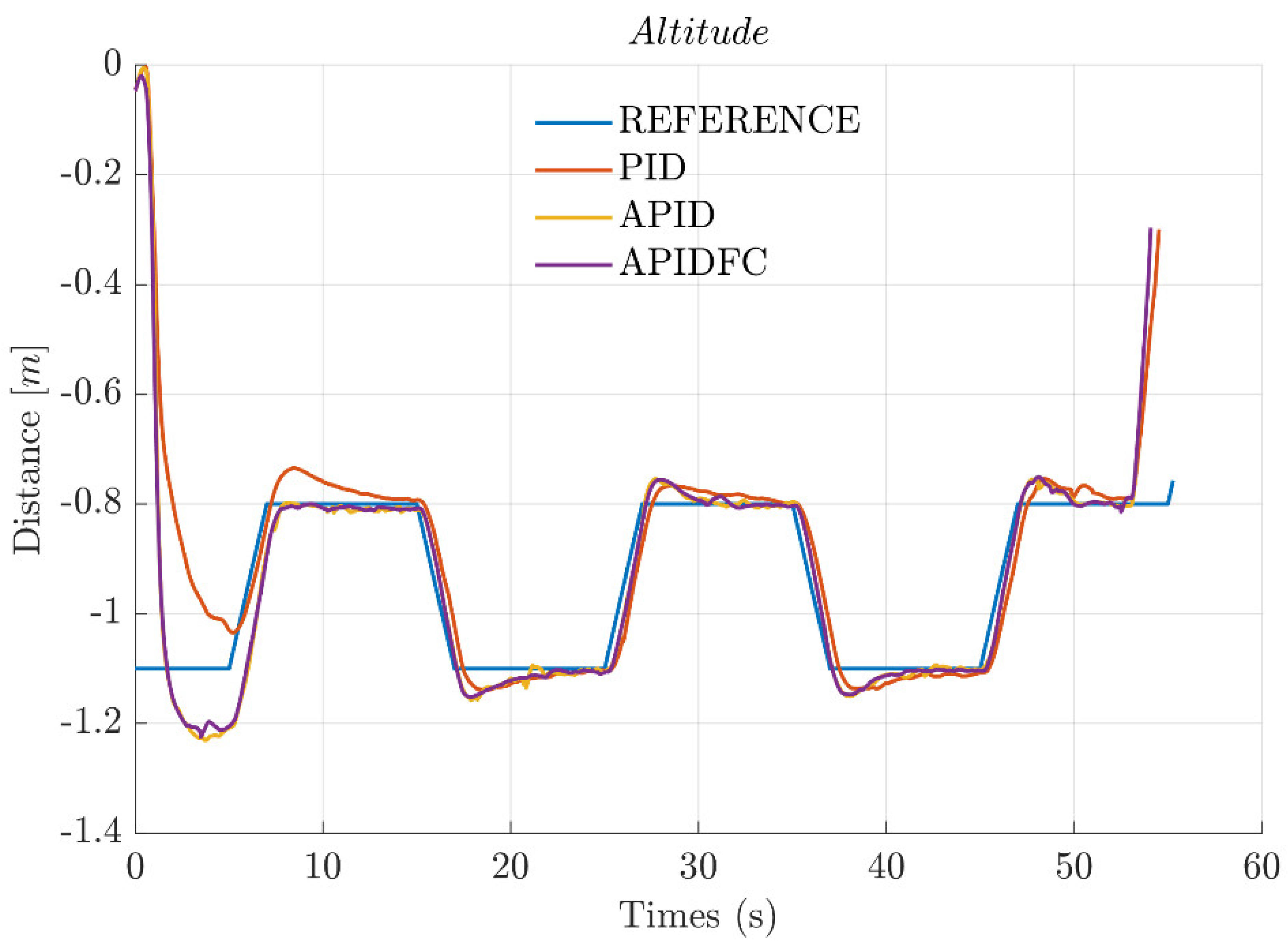

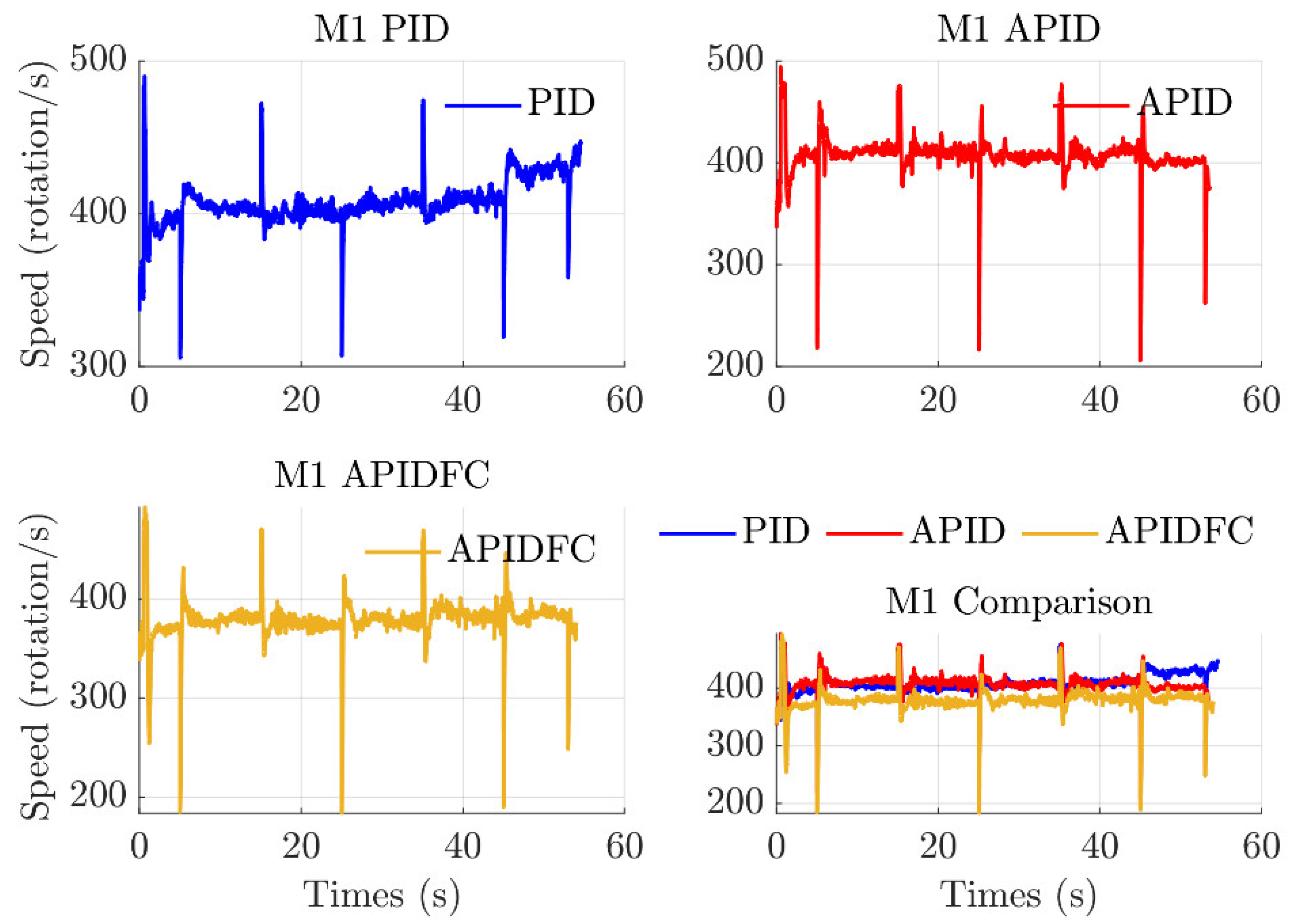

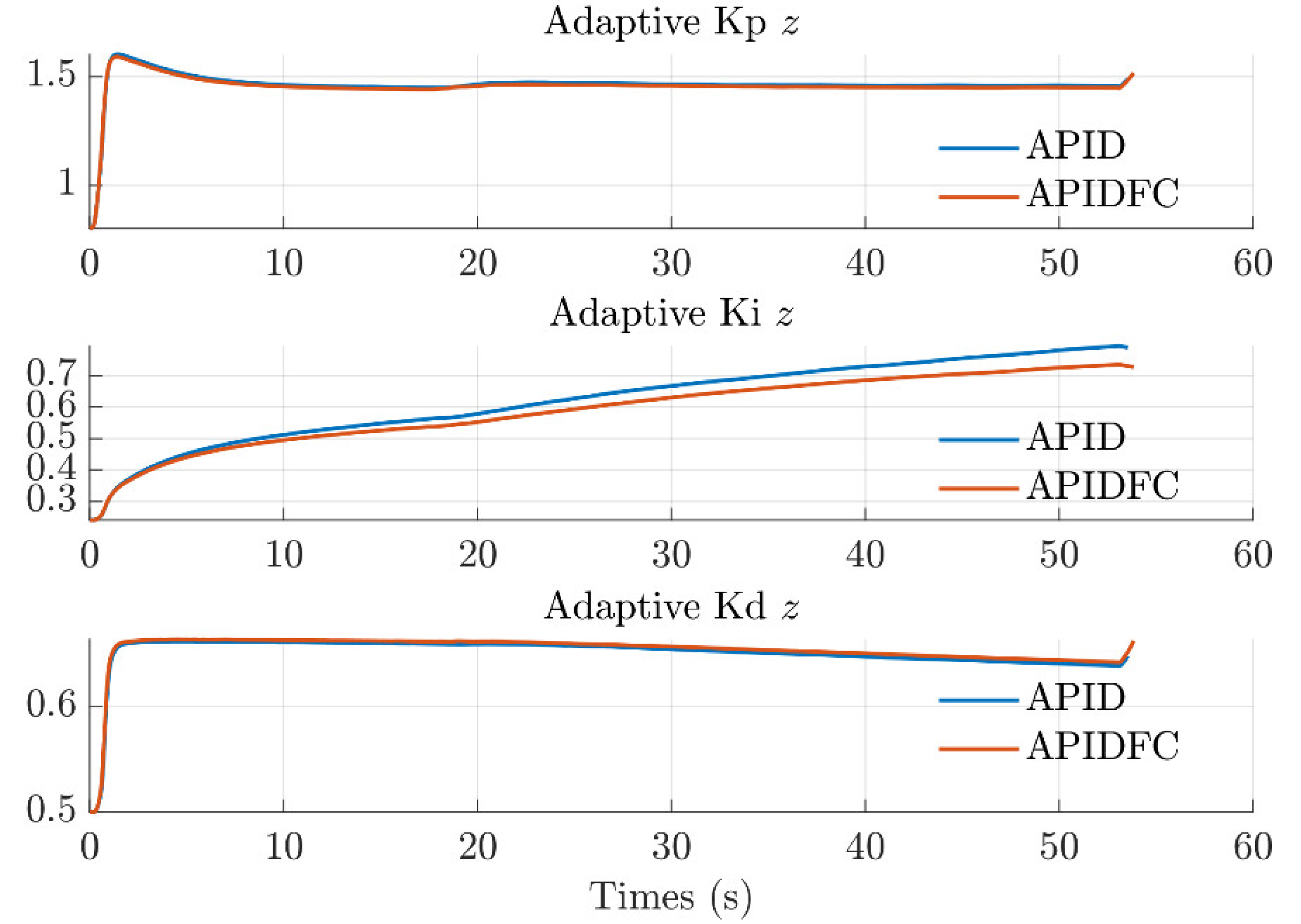

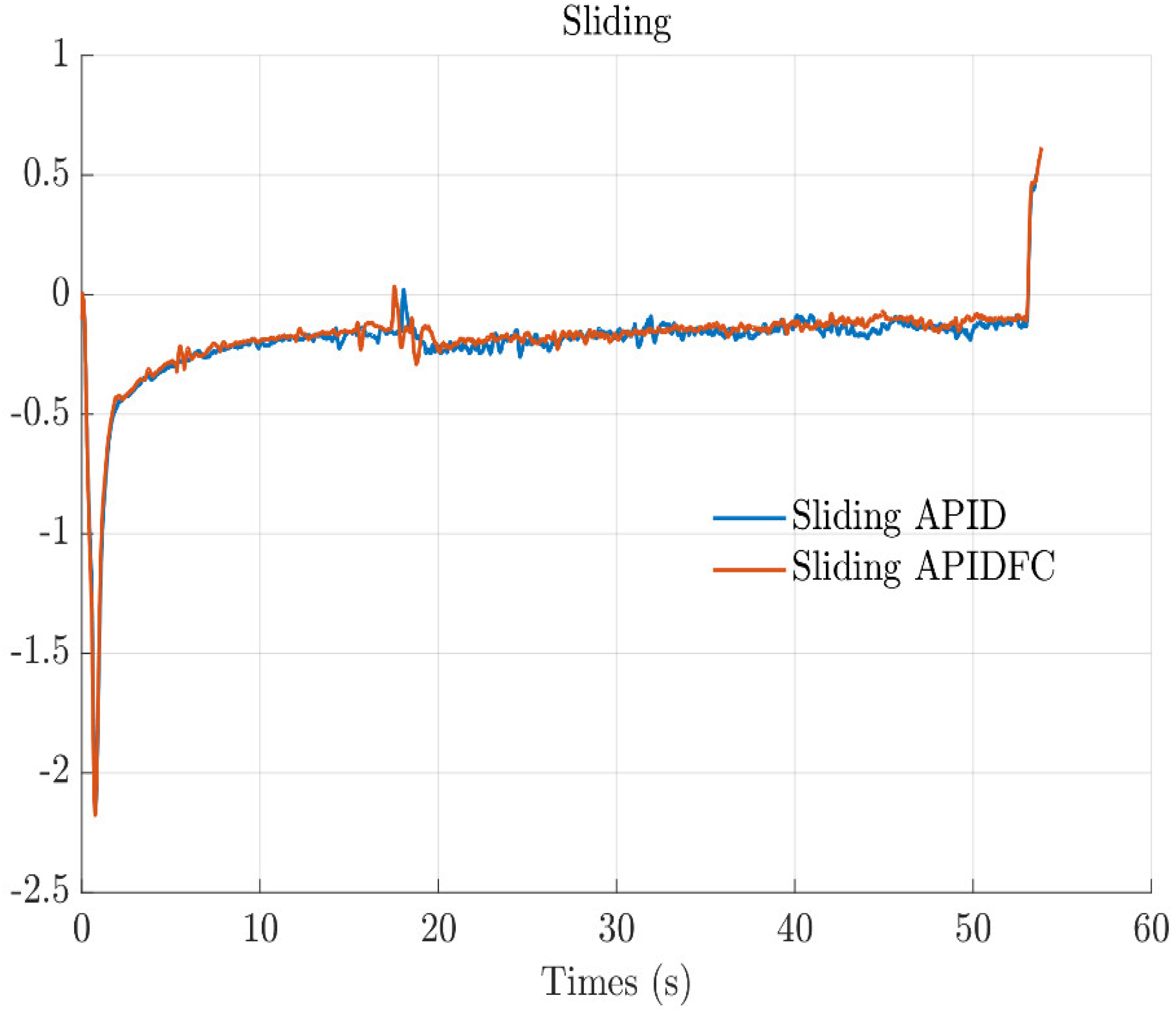

5.2. Altitude Tracking Test

5.3. Changing Mass during Hovering Test

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, H.; Hoffmann, G.M.; Waslander, S.L.; Tomlin, C.J. Aerodynamics and control of autonomous quadrotor helicopters in aggressive maneuvering. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; IEEE Press: New York, NY, USA, 2009; pp. 3277–3282. [Google Scholar] [CrossRef]

- Lori, A.A.R.; Danesh, M.; Amiri, P.; Ashkoofaraz, S.Y.; Azargoon, M.A. Transportation of an Unknown Cable-Suspended Payload by a Quadrotor in Windy Environment under Aerodynamics Effects. In Proceedings of the 2021 7th International Conference on Control, Instrumentation and Automation (ICCIA), Tabriz, Iran, 23–24 February 2021; IEEE Press: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Candan, F.; Beke, A.; Kumbasar, T. Design and Deployment of Fuzzy PID Controllers to the nano quadcopter Crazyflie 2.0. In Proceedings of the 2018 Innovations in Intelligent Systems and Applications (INISTA), Thessaloniki, Greece, 3–5 July 2018; IEEE Press: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Preiss, J.A.; Wolfgang, H.; Sukhatme, G.S. Ayanian. Crazyswarm: A Large Nano-Quadcopter Swarm. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; IEEE Press: New York, NY, USA, 2017; pp. 3299–3304. [Google Scholar]

- Yoo, J.; Jang, D.; Kim, H.J.; Johansson, K.H. Hybrid Reinforcement Learning Control for a Micro Quadrotor Flight. IEEE Control Syst. Lett. 2021, 5, 505–510. [Google Scholar] [CrossRef]

- Hönig, W.; Ayanian, N. Flying multiple UAVs using ROS. In Robot Operating System (ROS); Springer: Cham, Switzerland, 2017; Volume 707, pp. 83–118. [Google Scholar]

- KSubash, V.V.; Srinu, M.V.; Siddhartha, M.R.V.; Harsha, N.C.S.; Akkala, P. Object Detection using Ryze Tello Drone with Help of Mask-RCNN. In Proceedings of the 2020 2nd International Conference on Innovative Mechanisms for Industry Applications (ICIMIA), Bangalore, India, 5–7 March 2020; IEEE Press: New York, NY, USA, 2020; pp. 484–490. [Google Scholar] [CrossRef]

- Pohudina, O.; Kovalevskyi, M.; Pyvovar, M. Group Flight Automation Using Tello EDU Unmanned Aerial Vehicle. In Proceedings of the 2021 IEEE 16th International Conference on Computer Sciences and Information Technologies (CSIT), LVIV, Ukraine, 22–25 September 2021; IEEE Press: New York, NY, USA, 2021; Volume 2, pp. 151–154. [Google Scholar] [CrossRef]

- Giernacki, W.; Rao, J.; Sladic, S.; Bondyra, A.; Retinger, M.; Espinoza-Fraire, T. DJI Tello Quadrotor as a Platform for Research and Education in Mobile Robotics and Control Engineering. In Proceedings of the 2022 International Conference on Unmanned Aircraft Systems (ICUAS), Dubrovnik, Croatia, 21–24 June 2022; IEEE Press: New York, NY, USA, 2022; pp. 735–744. [Google Scholar] [CrossRef]

- Saito, T.; Mase, K. Dronepilot.NET development: AR.drone SDK supporting native and managed code. In Proceedings of the 2013 International Conference on Advanced Computer Science Applications and Technologies, Kuching, Malaysia, 23–24 December 2013; IEEE Press: New York, NY, USA, 2013; pp. 60–64. [Google Scholar] [CrossRef]

- Indrawati, V.; Prayitno, A.; Utomo, G. Comparison of two fuzzy logic controller schemes for position control of AR.Drone. In Proceedings of the 2015 7th International Conference on Information Technology and Electrical Engineering (ICITEE), Chiang Mai, Thailand, 29–30 October 2015; IEEE Press: New York, NY, USA, 2015; pp. 360–363. [Google Scholar] [CrossRef]

- Zhao, T.; Jiang, H. Landing system for AR.Drone 2.0 using onboard camera and ROS. In Proceedings of the 2016 IEEE Chinese Guidance, Navigation and Control Conference (CGNCC), Nanjing, China, 12–14 August 2016; IEEE Press: New York, NY, USA, 2016; pp. 1098–1102. [Google Scholar]

- Babu, V.M.; Das, K.; Kumar, S. Designing of self tuning PID controller for AR drone quadrotor. In Proceedings of the 2017 18th International Conference on Advanced Robotics (ICAR), Hong Kong, China, 10–12 July 2017; IEEE Press: New York, NY, USA, 2017; pp. 167–172. [Google Scholar] [CrossRef]

- Kaplan, M.R.; Eraslan, A.; Beke, A.; Kumbasar, T. Altitude and Position Control of Parrot Mambo Minidrone with PID and Fuzzy PID Controllers. In Proceedings of the 2019 11th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Turkey, 28–30 November 2019; IEEE Press: New York, NY, USA, 2020; pp. 785–789. [Google Scholar] [CrossRef]

- Castañeda, H.; Gordillo, J.L. Embedded flight control based on adaptive sliding mode strategy for a quadrotor micro air vehicle. Electronics 2019, 8, 793. [Google Scholar] [CrossRef]

- Alqaisi, W.; Kali, Y.; Ghommam, J.; Saad, M.; Nerguizian, V. Position and attitude tracking of uncertain quadrotor unmanned aerial vehicles based on non-singular terminal super-twisting algorithm. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2020, 234, 396–408. [Google Scholar] [CrossRef]

- Noordin, A.; Basri, M.A.M.; Mohamed, Z. Simulation and experimental study on pid control of a quadrotor MAV with perturbation. Bull. Electr. Eng. Inform. 2020, 9, 1811–1818. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Chen, J.; Fang, C. Altitude control for variable load quadrotor via learning rate based robust sliding mode controller. IEEE Access 2019, 7, 9736–9744. [Google Scholar] [CrossRef]

- Najm, A.A.; Ibraheem, I.K. Nonlinear PID controller design for a 6-DOF UAV quadrotor system. Eng. Sci. Technol. Int. J. 2019, 22, 1087–1097. [Google Scholar] [CrossRef]

- Pounds, P.E.I.; Bersak, D.R.; Dollar, A.M. Stability of small-scale UAV helicopters and quadrotors with added payload mass under PID control. Auton. Robot. 2012, 33, 129–142. [Google Scholar] [CrossRef]

- Mellinger, D.; Lindsey, Q.; Shomin, M.; Kumar, V. Design, modeling, estimation and control for aerial grasping and manipulation. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; IEEE Press: New York, NY, USA, 2011; pp. 2668–2673. [Google Scholar] [CrossRef]

- Min, B.C.; Hong, J.H.; Matson, E.T. Adaptive Robust Control (ARC) for an altitude control of a quadrotor type UAV carrying an unknown payloads. In Proceedings of the 2011 11th International Conference on Control, Automation and Systems, Gyeonggi-do, Korea, 26–29 October 2011; IEEE Press: New York, NY, USA, 2011; pp. 1147–1151. [Google Scholar]

- Ashis, C.K.; Sharma, K.R. Dynamic Modeling and Altitude Control of Parrot Rolling Spider using LQR. In Proceedings of the 2019 2nd International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT), Kannur, India, 5–6 July 2019; IEEE Press: New York, NY, USA, 2019; pp. 1377–1381. [Google Scholar] [CrossRef]

- Roy, R.; Islam, M.; Sadman, N.; Mahmud, M.A.P.; Gupta, K.D.; Ahsan, M.M. Review on Comparative Remarks, Performance Evaluation and Improvement Strategies of Quadrotor Controllers. Technologies 2021, 9, 37. [Google Scholar] [CrossRef]

- Okasha, M.; Kralev, J.; Islam, M. Design and Experimental Comparison of PID, LQR and MPC Stabilizing Controllers for Parrot Mambo Mini-Drone. Aerospace 2022, 9, 298. [Google Scholar] [CrossRef]

- Noordin, A.; Basri, M.A.M.; Mohamed, Z.; Lazim, I.M. Position and Attitude Control of Quadrotor MAV Using Sliding Mode Control with Tanh Function. Lect. Notes Electr. Eng. 2022, 900, 193–204. [Google Scholar] [CrossRef]

- Xu, L.; Shao, X.; Zhang, W. USDE-Based Continuous Sliding Mode Control for Quadrotor Attitude Regulation: Method and Application. IEEE Access 2021, 9, 64153–64164. [Google Scholar] [CrossRef]

- Abro, G.E.M.; Zulkifli, S.A.B.M.; Asirvadam, V.S.; Ali, Z.A. Model-free-based single-dimension fuzzy smc design for underactuated quadrotor uav. Actuators 2021, 10, 191. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Bao, C. Design of a Fixed-Wing UAV Controller Combined Fuzzy Adaptive Method and Sliding Mode Control. Math. Probl. Eng. 2022, 2022, 2812671. [Google Scholar] [CrossRef]

- Nettari, Y.; Labbadi, M.; Kurt, S. ScienceDirect Adaptive robust finite-time tracking control for quadrotor subject to disturbances. Adv. Space Res. 2022, in press. [Google Scholar] [CrossRef]

- Hassani, H.; Mansouri, A.; Ahaitouf, A. Backstepping-based supertwisting sliding mode attitude control for a quadrotor aircraft subjected to wind disturbances: Experimental validation. Int. J. Dyn. Control 2022. [Google Scholar] [CrossRef]

- Noordin, A.; Basri, M.A.M.; Mohamed, Z.; Lazim, I.M. Adaptive PID Controller Using Sliding Mode Control Approaches for Quadrotor UAV Attitude and Position Stabilization. Arab. J. Sci. Eng. 2020, 46, 963–981. [Google Scholar] [CrossRef]

- Hsu, C.; Chiu, C.; Tsai, J. Auto-tuning PID controller design using a sliding-mode approach for DC servomotors. Int. J. Intell. Comput. Cybern. 2011, 4, 93–110. [Google Scholar] [CrossRef]

| Specification | Parameter | Unit | Value |

|---|---|---|---|

| Quadrotor mass | |||

| Lateral moment arm | |||

| Thrust coefficient | |||

| Drag coefficient | |||

| Rolling moment of inertia | |||

| Pitching moment of inertia | |||

| Yawing moment of inertia | |||

| Rotor moment of inertia |

| Position/Angle Control | Velocity Control | ||||

|---|---|---|---|---|---|

| Gains | Kp | Kp | Ki | Kd | |

| State | |||||

| : PID | 0.80000 | 0.24000 | 0.5000000 | ||

| : P-PI | 0.7 | 0.20000 | 0.10000 | ||

| : P-PI | 0.7 | 0.20000 | 0.10000 | ||

| : PID | 0.00400 | 0.00400 | 0.0012000 | ||

| : P-PID | 4 | 0.00300 | 0.00600 | 0.0001200 | |

| : P-PID | 4 | 0.00243 | 0.00486 | 0.0000972 | |

| Sliding | Learning Rate APID | Learning Rate Fuzzy Compensator | ||||

|---|---|---|---|---|---|---|

| State | ||||||

| 0.1 | 0.5 | 1 | 0.1 | 0.1 | −0.001 | |

| PID | APID | APIDFC | |

|---|---|---|---|

| Hover | 1.4586 | 1.3801 | 1.2877 |

| Sine | 1.6831 | 1.3675 | 1.3048 |

| Square | 1.6761 | 1.4327 | 1.3952 |

| Trapezium | 1.5323 | 1.2611 | 1.1983 |

| Mass Change | 1.4700 | 0.8003 | 0.7937 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noordin, A.; Mohd Basri, M.A.; Mohamed, Z. Real-Time Implementation of an Adaptive PID Controller for the Quadrotor MAV Embedded Flight Control System. Aerospace 2023, 10, 59. https://doi.org/10.3390/aerospace10010059

Noordin A, Mohd Basri MA, Mohamed Z. Real-Time Implementation of an Adaptive PID Controller for the Quadrotor MAV Embedded Flight Control System. Aerospace. 2023; 10(1):59. https://doi.org/10.3390/aerospace10010059

Chicago/Turabian StyleNoordin, Aminurrashid, Mohd Ariffanan Mohd Basri, and Zaharuddin Mohamed. 2023. "Real-Time Implementation of an Adaptive PID Controller for the Quadrotor MAV Embedded Flight Control System" Aerospace 10, no. 1: 59. https://doi.org/10.3390/aerospace10010059

APA StyleNoordin, A., Mohd Basri, M. A., & Mohamed, Z. (2023). Real-Time Implementation of an Adaptive PID Controller for the Quadrotor MAV Embedded Flight Control System. Aerospace, 10(1), 59. https://doi.org/10.3390/aerospace10010059