Emission and Reduction of Air Pollutants from Charcoal-Making Process in the Vietnamese Mekong Delta

Abstract

1. Introduction

2. Materials and Methods

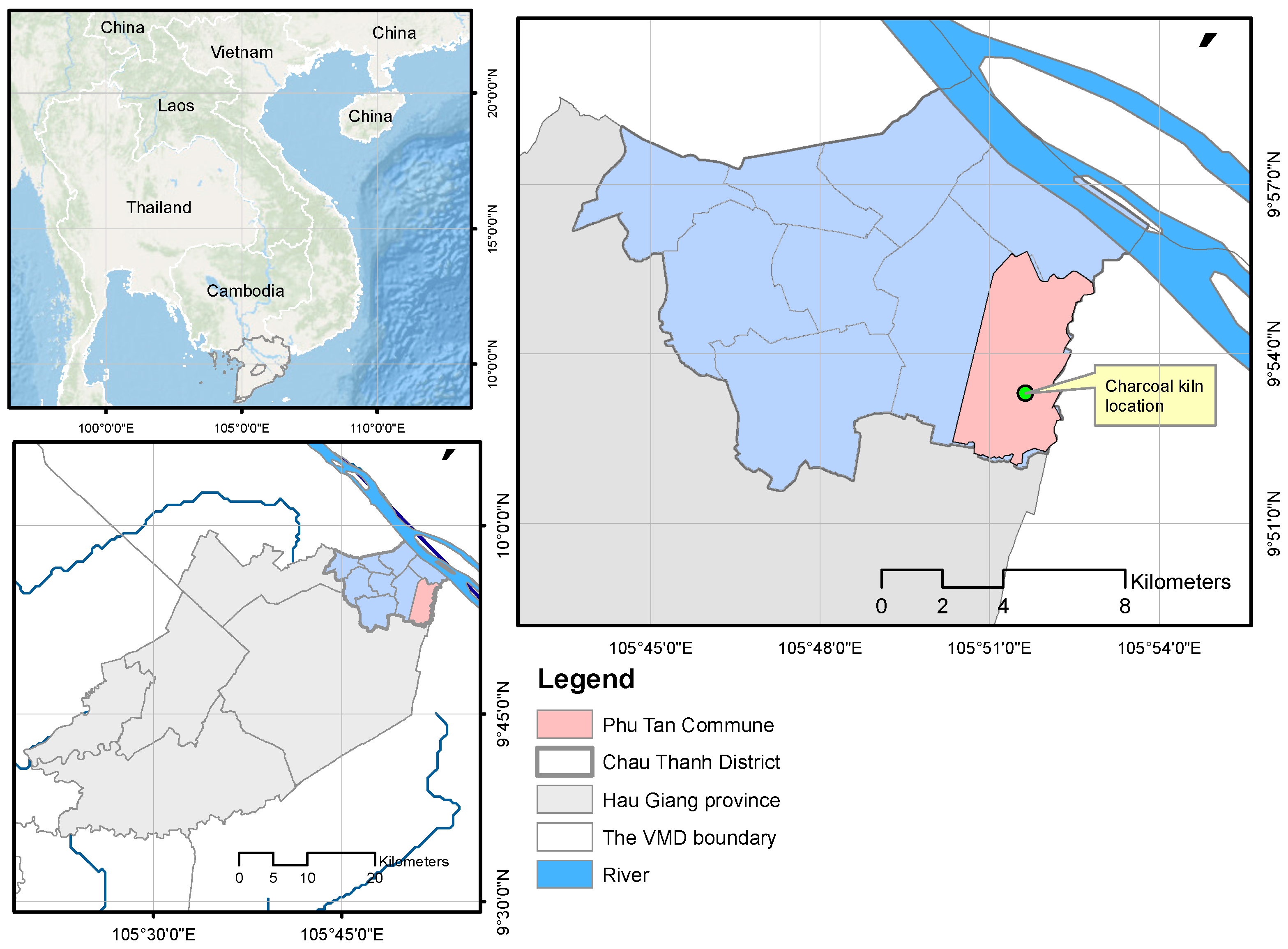

2.1. Study Site

2.2. Household Interviews

- n: the sample size of households selected for the interviews;

- N: the total given households making charcoal in the study site (N = 227 households);

- e: margin of error (e = 10%). Given the calculation result from Formula (1), which shows the sample size of 70 target households making charcoal.

2.3. Determining the Concentration of Pollutants Emitted from the Carbonization Process

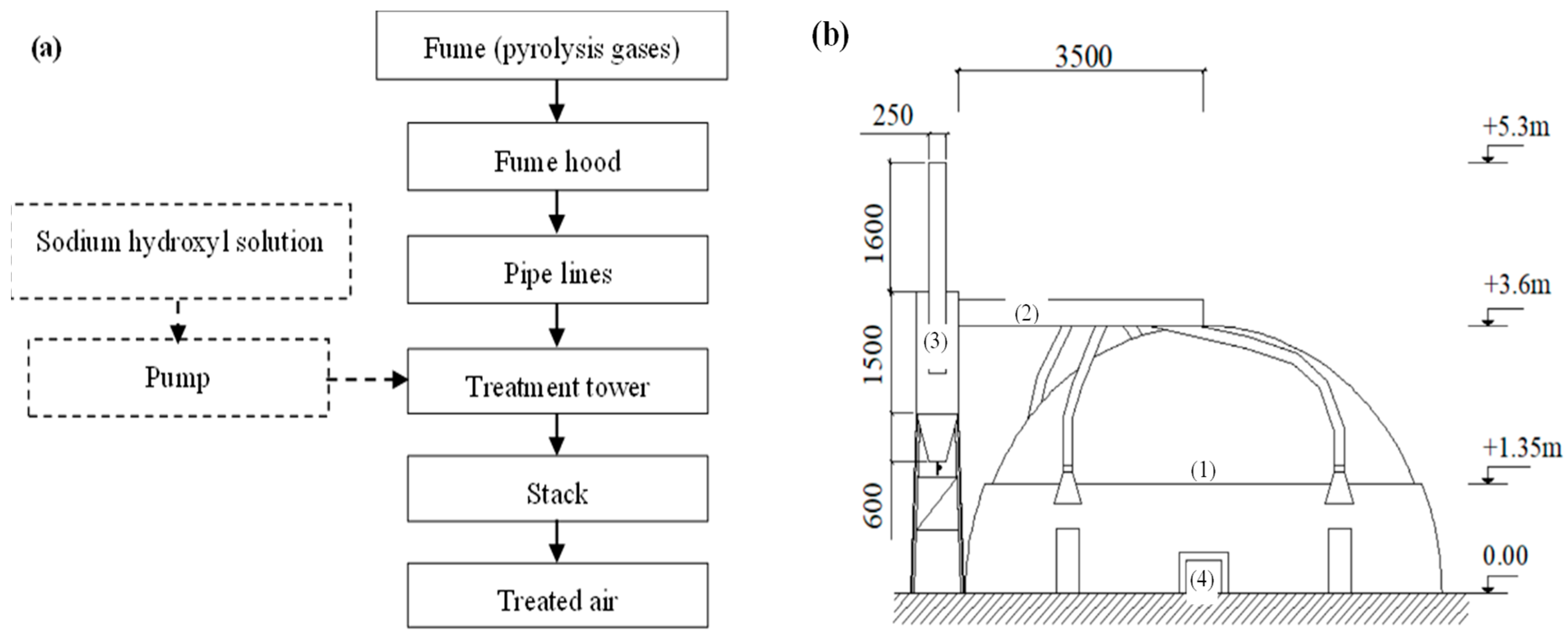

2.4. Reduction Method of Air Pollutants

2.5. Data Analysis

3. Results and Discussion

3.1. Effects of the Traditional Charcoal Production

3.2. Structure of the Charcoal Kiln and the Carbonization Process

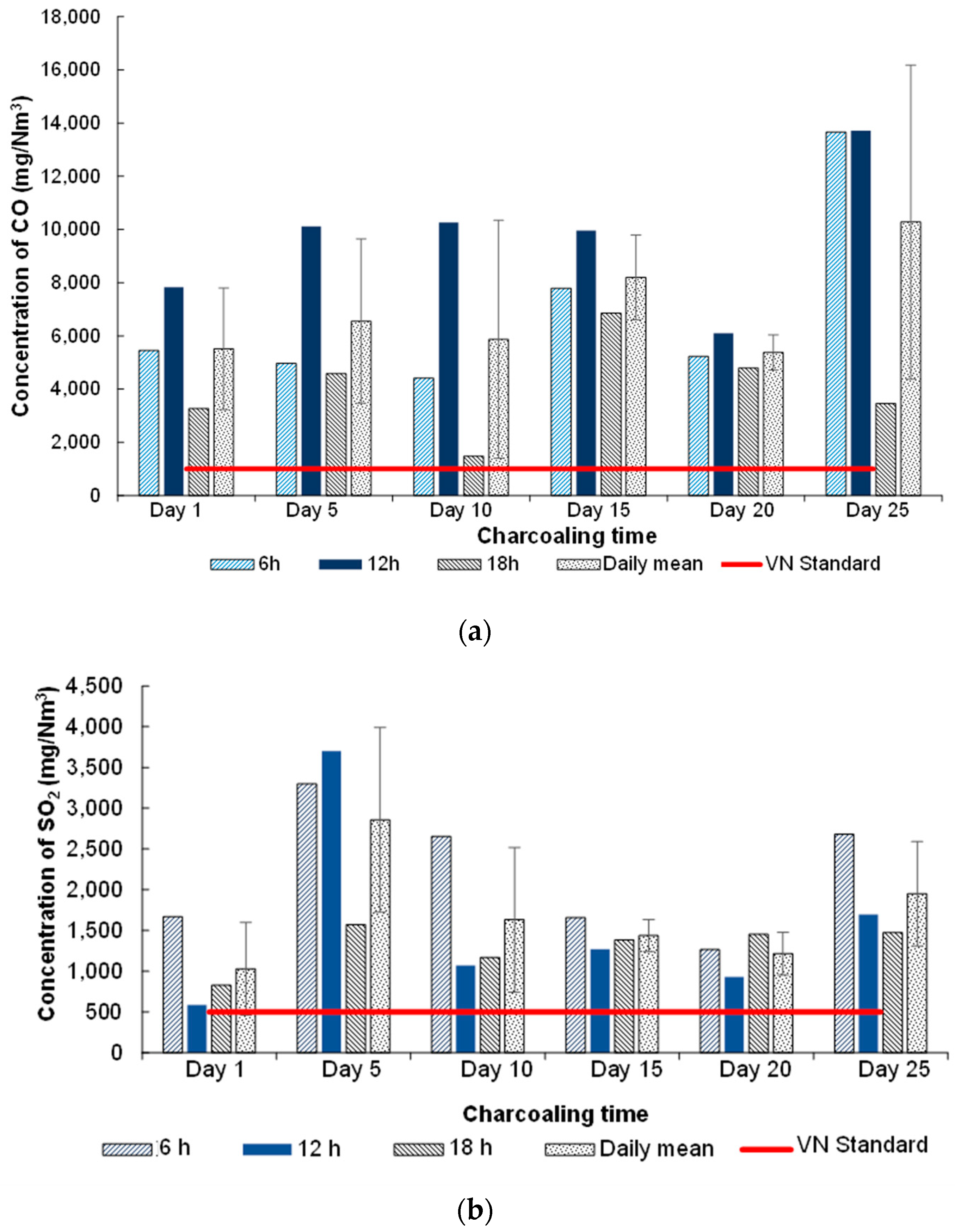

3.3. Determination of Air Pollutants Emitted from the Charcoal Kiln

3.4. Estimation of CO2 Emission

3.5. Air Pollutant Reduction Efficiency of the Air Pollution Treatment System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| QUESTIONAIRE ON SURVEYING THE ENVIRONMENTAL SITUATION, HEALTH, AND LIVELIHOOD AT HOUSEHOLD LEVEL |

I. For households with making charcoal

|

I. For households without making charcoal

|

References

- Kilahama, F. Impact of increased charcoal consumption to forests and woodlands in Tanzania. For. Ecol. Manag. 2008, 308, 45–55. [Google Scholar]

- Eniola, P.; Odebode, S.; Ayandele, B. Contributions of charcoal production to socio-economic activities of rural dwellers in the rain forest agro-ecological zone of Nigeria. Recent Adv. Petrochem. Sci. 2018, 6, 555683. [Google Scholar]

- Nabukalu, C.; Gieré, R. Charcoal as an energy resource: Global trade, production and socioeconomic practices observed in Uganda. Resources 2019, 8, 183. [Google Scholar] [CrossRef]

- Leman, A.; Feriyanto, D.; Nazri, A.A.; Sunar, N.; Salleh, M.N.M. Burner Characteristics for Activated Carbon Production. MATEC Web Conf. EDP Sci. 2017, 87, 02018. [Google Scholar]

- Ortiz, O.; Martinez, N.; Mengual, C.; Noriega, S. Steady state simulation of a rotary kiln for charcoal activation. Lat. Am. Appl. Res. 2003, 33, 51–57. [Google Scholar]

- de Oliveira Vilela, A.; Lora, E.S.; Quintero, Q.R.; Vicintin, R.A.; da Silva e Souza, T.P. A new technology for the combined production of charcoal and electricity through cogeneration. Biomass Bioenergy 2014, 69, 222–240. [Google Scholar] [CrossRef]

- Pennise, D.M.; Smith, K.R.; Kithinji, J.P.; Rezende, M.E.; Raad, T.J.; Zhang, J.; Fan, C. Emissions of greenhouse gases and other airborne pollutants from charcoal making in Kenya and Brazil. J. Geophys. Res. Atmos. 2001, 106, 24143–24155. [Google Scholar] [CrossRef]

- da Silva Viana Jacobson, L.; de Souza Hacon, S.; de Castro, H.A.; Ignotti, E.; Artaxo, P.; Saldiva, P.H.; de Leon, A.C. Acute effects of particulate matter and black carbon from seasonal fires on peak expiratory flow of schoolchildren in the Brazilian Amazon. PLoS ONE 2014, 9, e104177. [Google Scholar]

- Msuya, N.; Masanya, E.; Temu, A.K. Environmental burden of charcoal production and use in Dar es Salaam, Tanzania. J. Environ. Prot. 2011, 2, 1364–1369. [Google Scholar] [CrossRef]

- El-Batrawy, O.A. Air Quality around Charcoal Making Kilns and the Potential Health Hazards. Int. J. Environ. 2019, 8, 180–188. [Google Scholar]

- Salam, M.T.; Millstein, J.; Li, Y.F.; Lurmann, F.W.; Margolis, H.G.; Gilliland, F.D. Birth outcomes and prenatal exposure to ozone, carbon monoxide, and particulate matter: Results from the children’s health study. Environ. Health Perspect. 2005, 113, 1638–1644. [Google Scholar] [CrossRef] [PubMed]

- Lui, K.H.; Bandowe, B.A.; Tian, L.; Chan, C.S.; Cao, J.J.; Ning, Z.; Lee, S.C.; Ho, K.F. Cancer risk from polycyclic aromatic compounds in fine particulate matter generated from household coal combustion in Xuanwei, China. Chemosphere 2017, 169, 660–668. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; You, S.; Zhang, H.; Zheng, W.; Zou, L. Investigating the environmental quality deterioration and human health hazard caused by heating emissions. Sci. Total Environ. 2018, 628, 1209–1222. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Zi, T.; Lang, J.; Huang, D.; Wei, P.; Chen, D.; Cheng, S. Impact of rural residential coal combustion on air pollution in Shandong, China. Chemosphere 2020, 260, 127517. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Kang, K.; Kim, T. Measurement of particulate matter (PM2.5) and health risk assessment of cooking-generated particles in the kitchen and living rooms of apartment houses. Sustainability 2018, 10, 843. [Google Scholar] [CrossRef]

- Okello, B.; O’connor, T.; Young, T. Growth, biomass estimates, and charcoal production of Acacia drepanolobium in Laikipia, Kenya. For. Ecol. Manag. 2001, 142–143, 143–153. [Google Scholar] [CrossRef]

- Lew, J.; Kammen, D. Review of Social and Environmental Impacts of Charcoal in Africa; Woodrow Wilson School of Public and International Affairs, Princeton University: Princeton, NJ, USA, 1997. [Google Scholar]

- Ankona, E.; Nisnevitch, M.; Knop, Y.; Billig, M.; Badwan, A.; Anker, Y. The Eastern Mediterranean charcoal industry: Air pollution prevention by the implementation of a new ecological retort system. Earth Space Sci. 2022, 9, e2021EA002044. [Google Scholar] [CrossRef]

- Sparrevik, M.; Adam, C.; Martinsen, V.; Cornelissen, G. Emissions of gases and particles from charcoal/biochar production in rural areas using medium-sized traditional and improved ‘retort’ kilns. Biomass Bioenergy 2015, 72, 65–73. [Google Scholar] [CrossRef]

| Types of Wood | Fresh Mass of Wood Specimens (g) | Produced Charcoal Mass (g) | Charcoal Mass (g)/1 kg of Wood | CPE (%) |

|---|---|---|---|---|

| 25-year Rhizophora (R25) | 4100 | 1240 | 302 | 30.2 |

| 10-year Rhizophora (R10) | 2200 | 550 | 250 | 25.0 |

| 10-year Eucalyptus (E10) | 3300 | 810 | 245 | 24.5 |

| 5-year Eucalyptus (E5) | 1300 | 276 | 212 | 21.2 |

| Types of Wood | Loss of Water Vapor (g) | Emitted CO2 (g) | Emitted CO (g) |

|---|---|---|---|

| 25-year Rhizophora (R25) | 849.15 | 691.90 | 880.60 |

| 10-year Rhizophora (R10) | 889.89 | 725.10 | 922.85 |

| 10-year Eucalyptus (E10) | 886.86 | 722.63 | 919.71 |

| 5-year Eucalyptus (E5) | 909.96 | 741.45 | 943.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toan, P.V.; Kim, L.; Thanh, N.T.; Toan, H.L.; Tuan, L.A.; Minh, H.V.T.; Kumar, P. Emission and Reduction of Air Pollutants from Charcoal-Making Process in the Vietnamese Mekong Delta. Climate 2023, 11, 149. https://doi.org/10.3390/cli11070149

Toan PV, Kim L, Thanh NT, Toan HL, Tuan LA, Minh HVT, Kumar P. Emission and Reduction of Air Pollutants from Charcoal-Making Process in the Vietnamese Mekong Delta. Climate. 2023; 11(7):149. https://doi.org/10.3390/cli11070149

Chicago/Turabian StyleToan, Pham Van, Lavane Kim, Nguyen Truong Thanh, Huynh Long Toan, Le Anh Tuan, Huynh Vuong Thu Minh, and Pankaj Kumar. 2023. "Emission and Reduction of Air Pollutants from Charcoal-Making Process in the Vietnamese Mekong Delta" Climate 11, no. 7: 149. https://doi.org/10.3390/cli11070149

APA StyleToan, P. V., Kim, L., Thanh, N. T., Toan, H. L., Tuan, L. A., Minh, H. V. T., & Kumar, P. (2023). Emission and Reduction of Air Pollutants from Charcoal-Making Process in the Vietnamese Mekong Delta. Climate, 11(7), 149. https://doi.org/10.3390/cli11070149