Optimizing N Fertilization to Improve Yield, Technological and Nutritional Quality of Tomato Grown in High Fertility Soil Conditions

Abstract

1. Introduction

2. Results

2.1. Agronomic Parameters

2.2. Technological Characteristics and Mineral Compositions

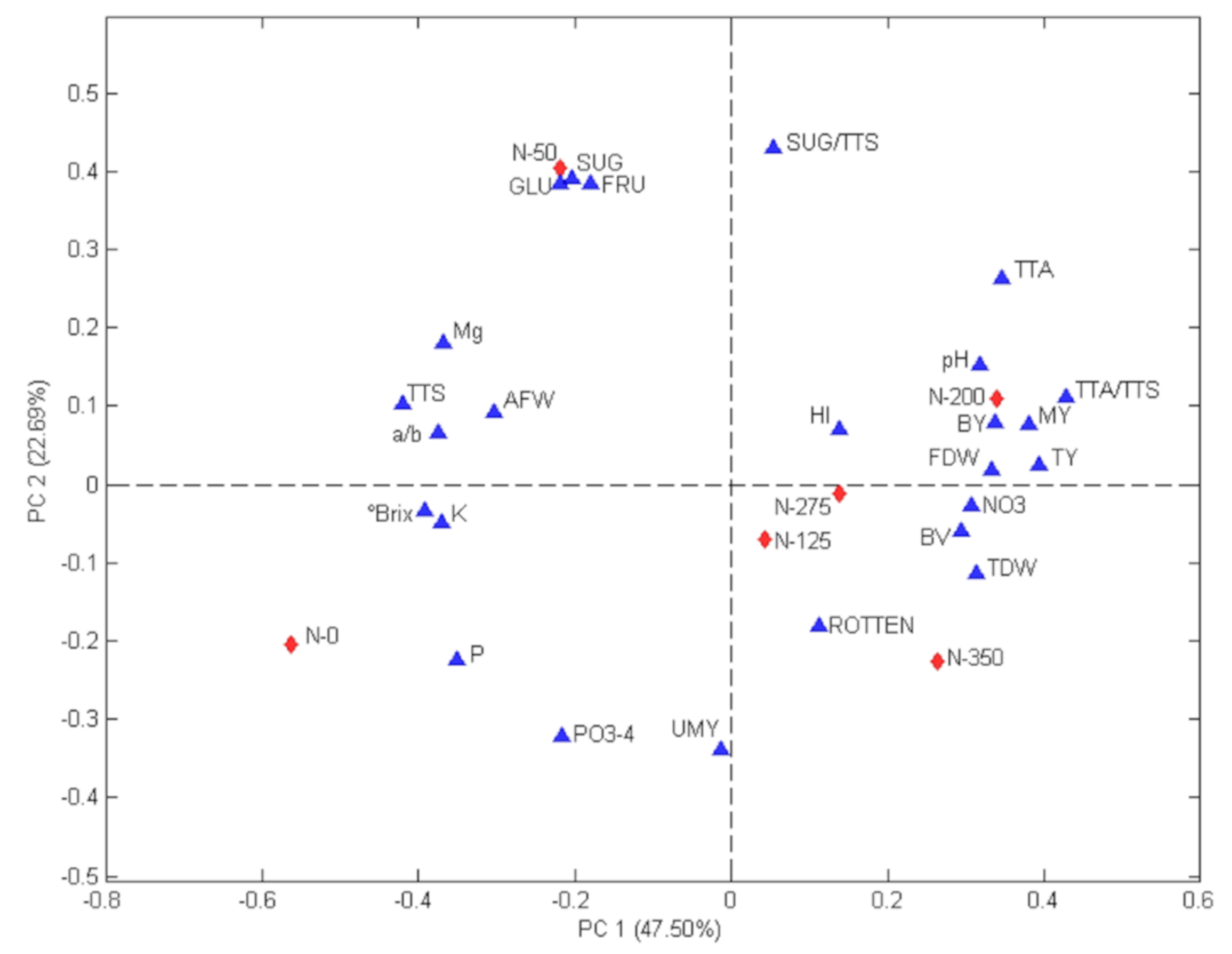

2.3. Relationships between Treatments and Evaluated Parameters

3. Discussion

4. Materials and Methods

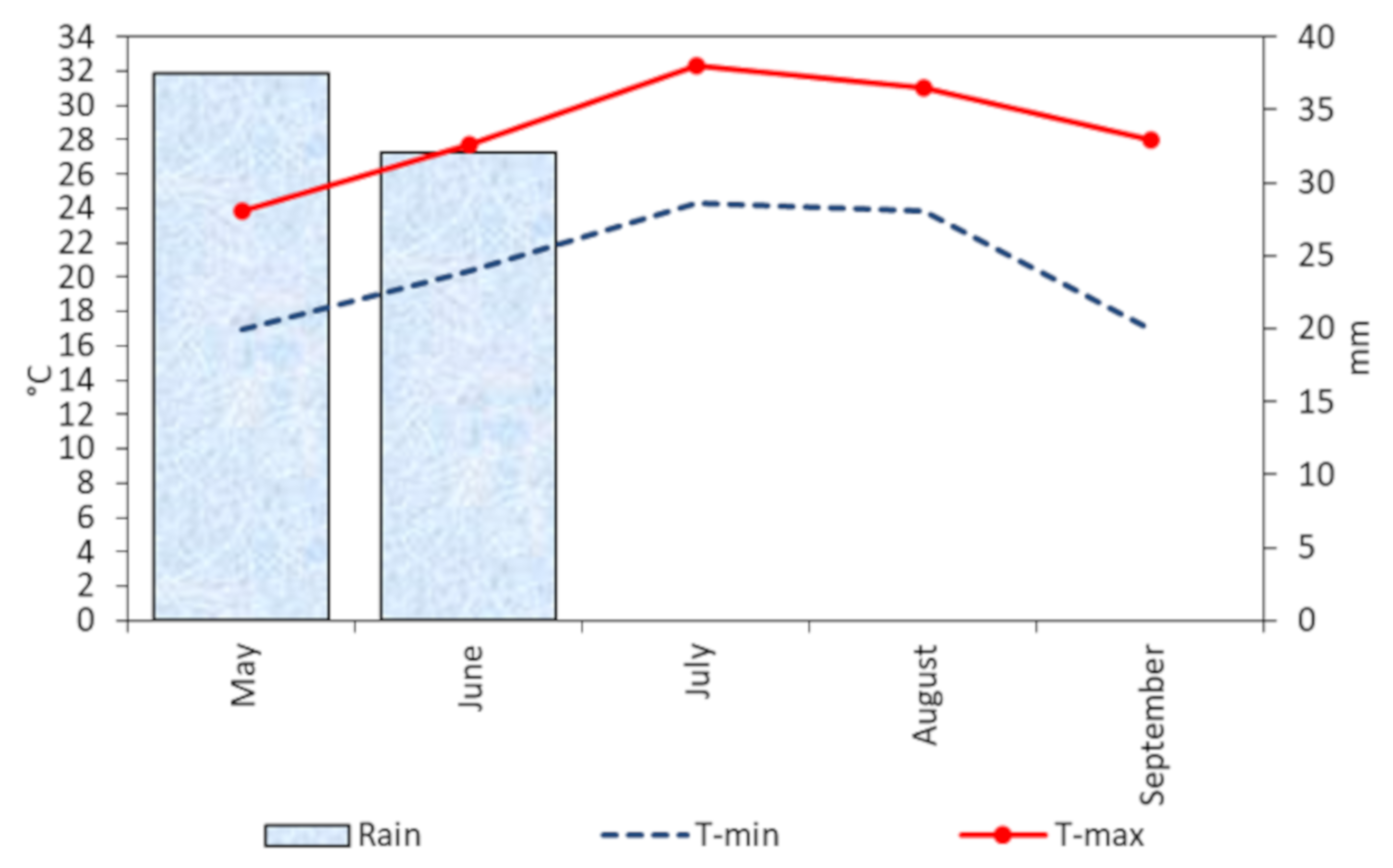

4.1. Experimental Conditions

4.2. Experimental Design, N Application and Crop Management

4.3. Yield Assessment

4.4. Fruit Quality Analyses

4.4.1. Technological Characteristics

4.4.2. Sugar Analysis

4.4.3. Mineral Composition

Sample Preparation

Analytical Determinations

4.5. Data Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ronga, D.; Rizza, F.; Badeck, F.W.; Milc, J.; Laviano, L.; Montevecchi, G.; Pecchioni, N.; Francia, E. Physiological responses to chilling in cultivars of processing tomato released and cultivated over the past decades in Southern Europe. Sci. Hortic. 2018, 231, 118–125. [Google Scholar] [CrossRef]

- WPTC. World Processing Tomato Council. Available online: www.wptc.to (accessed on 29 March 2020).

- Loiudice, R.; Impembo, M.; Laratta, B.; Villari, G.; Voi, A.L.; Siviero, P.; Castaldo, D. Composition of San Marzano tomato varieties. Food Chem. 1995, 53, 81–89. [Google Scholar] [CrossRef]

- Ercolano, M.R.; Sacco, A.; Ferriello, F.; D’Alessandro, R.; Tononi, P.; Traini, A.; Barone, A.; Zago, E.; Chiusano, M.L.; Buson, G.; et al. Patchwork sequencing of tomato San Marzano and Vesuviano varieties highlights genome-wide variations. BMC Genom. 2014, 15, 138. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Leonardi, C.; Ambrosino, P.; Esposito, F.; Fogliano, V. Antioxidant activity and carotenoid and tomatine contents in different typologies of fresh consumption tomatoes. J. Agric. Food Chem. 2000, 48, 4723–4727. [Google Scholar] [CrossRef] [PubMed]

- Toor, R.K.; Savage, G.P. Changes in major antioxidant components of tomatoes during post-harvest storage. Food Chem. 2005, 99, 724–727. [Google Scholar] [CrossRef]

- Frusciante, L.; Carli, P.; Ercolano, M.R.; Pernice, R.; Di Matteo, A.; Fogliano, V.; Pellegrini, N. Antioxidant nutritional quality of tomato. Mol. Nutr. Food Res. 2007, 51, 609–617. [Google Scholar] [CrossRef]

- Migliori, C.A.; Salvati, L.; Di Cesare, L.F.; Lo Scalzo, R.; Parisi, M. Effects of preharvest applications of natural antimicrobial products on tomato fruit decay and quality during long-term storage. Sci. Hortic. 2017, 222, 193–202. [Google Scholar] [CrossRef]

- Sellitto, V.M.; Golubkina, N.A.; Pietrantonio, L.; Cozzolino, E.; Cuciniello, A.; Cenvinzo, V.; Florin, I.; Caruso, G. Tomato yield, quality, mineral composition and antioxidants as affected by beneficial microorganisms under soil salinity induced by balanced nutrient solutions. Agriculture 2019, 9, 110. [Google Scholar] [CrossRef]

- Serio, F.; Ayala, O.; Bonasia, A.; Santamaria, P. Antioxidant Properties and Health Benefits of Tomato. In Recent Progress in Medicinal Plants—Search for Natural Drugs; Series: Recent Progress in Medicinal, Plants; Govil, J.N., Singh, V.K., Arunchalam, C., Eds.; Sci Tech Publishing: Houston, TX, USA, 2006; Volume 13, p. 551. [Google Scholar]

- De Sio, F.; Rapacciuolo, M.; De Giorgi, A.; Trifirò, A.; Giuliano, B.; Vitobello, L.; Cuciniello, A.; Caruso, G. Yield, quality and antioxidants of peeled tomato as affected by genotype and industrial processing in southern Italy. Adv. Hortic. Sci. 2018, 32, 379–387. [Google Scholar]

- Suárez, M.H.; Rodríguez, E.M.; Rodríguez, C.; Romero, D. Mineral and trace element concentrations in cultivars of tomatoes. Food Chem. 2007, 104, 489–499. [Google Scholar] [CrossRef]

- Ronga, D.; Parisi, M.; Pentangelo, A.; Mori, M.; Di Mola, I. Effects of nitrogen management on biomass production and dry matter distribution of processing tomato cropped in southern Italy. Agronomy 2019, 9, 855. [Google Scholar] [CrossRef]

- Chou, S.S.; Chung, J.; Hwang, D.A. High performance liquid chromatography method for determining nitrate and nitrite levels in vegetables. J. Food Drug Anal. 2003, 11, 233–238. [Google Scholar]

- Sadeghi, E.; Sharafi, K.; Almasi, A.; Dayhim, M.; Azizi, E.; Ghayebzadeh, M. Study on the nitrite and nitrate levels changes by drying and frying processing in vegetables. Iran. J. Health Environ. 2015, 7, 491–498. [Google Scholar]

- Salehzadeh, H.; Maleki, A.; Rezaee, R.; Shahmoradi, B.; Ponnet, K. The nitrate content of fresh and cooked vegetables and their health related risks. PLoS ONE 2020, 15, e0227551. [Google Scholar] [CrossRef] [PubMed]

- Hoff, J.E.; Wilcox, G.E. Accumulation of nitrate in tomato fruit and its effect on detinning. J. Am. Hort. Sci. 1970, 95, 92–94. [Google Scholar]

- Farrow, R.P.; Johnson, J.E.; Gould, W.A.; Charbonneau, J.E. Detinning in canned tomatoes caused by accumulations of nitrate in the fruit. J. Food Sci. 1971, 36, 341–345. [Google Scholar] [CrossRef]

- Tilman, D.; Balzer, C.; Hill, J.; Befort, B.L. Global food demand and the sustainable intensification of agriculture. Proc. Natl. Acad. Sci. USA 2011, 108, 20260–20264. [Google Scholar] [CrossRef]

- Ronga, D.; Lovelli, S.; Zaccardelli, M.; Perrone, D.; Ulrici, A.; Francia, E.; Milc, J.; Pecchioni, N. Physiological responses of processing tomato in organic and conventional Mediterranean cropping systems. Sci. Hortic. 2015, 190, 161–172. [Google Scholar] [CrossRef]

- Ronga, D.; Caradonia, F.; Setti, L.; Hagassou, D.; Giaretta Azevedo, C.V.; Milc, J.; Pedrazzi, S.; Allesina, G.; Arru, L.; Francia, E. Effects of innovative biofertilizers on yield of processing tomato cultivated in organic cropping systems in Northern Italy. Acta Hortic. 2019, 1233, 129–136. [Google Scholar] [CrossRef]

- Howarth, R.W. Coastal nitrogen pollution: A review of sources and trends globally and regionally. Harmful Algae 2008, 8, 14–20. [Google Scholar] [CrossRef]

- Ercolano, M.R.; Gomez, L.D.; Andolfi, A.; Simister, R.; Troise, C.; Angelino, G.; Borrelli, C.; McQueen-Mason, S.J.; Evidente, A.; Frusciante, L.; et al. Residual biomass saccharification in processing tomato is affected by cultivar and nitrogen fertilization. Biomass Bioenergy 2015, 72, 242–250. [Google Scholar] [CrossRef]

- Cammarano, D.; Holland, J.; Ronga, D. Spatial and temporal variability of spring barley yield and quality quantified by crop simulation model. Agronomy 2020, 10, 393. [Google Scholar] [CrossRef]

- Ronga, D.; Caradonia, F.; Parisi, M.; Bezzi, G.; Parisi, B.; Allesina, G.; Pedrazzi, S.; Francia, E. Using digestate and biochar as fertilizers to improve processing tomato production sustainability. Agronomy 2020, 10, 138. [Google Scholar] [CrossRef]

- Wight, J.R.; Lingle, J.C.; Flocker, W.J.; Leonard, S.J. The effect of irrigation and nitrogen fertilization treatments on yield, maturation and quality of canning tomatoes. Proc. Am. Soc. Hort. Sci. 1962, 81, 451–457. [Google Scholar]

- Dadomo, M.; Gainza, A.M.; Dumas, Y.; Bussières, P.; Macua, J.I.; Christou, M.; Branthôme, X. Influence of water and nitrogen availability on yield components of processing tomato in the European Union countries. Acta Hortic. 1994, 376, 271–274. [Google Scholar] [CrossRef]

- Colla, G.; Battistelli, A.; Moscatello, S. Effect of reduced irrigation and nitrogen fertirigation rate on yield, carbohydrate accumulation, and quality of processing tomatoes. Acta Hortic. 2001, 542, 187–196. [Google Scholar] [CrossRef]

- Parisi, M.; Giordano, L.; Pentangelo, A.; D’Onofrio, B.; Villari, G. Effects of different levels of nitrogen fertilization on yield and fruit quality in processing tomato. Acta Hortic. 2006, 700, 129–132. [Google Scholar] [CrossRef]

- Warner, T.; Zhang, T.Q.; Hao, X. Effects of nitrogen fertilization on fruit yield and quality of processing tomatoes. Can. J. Plant Sci. 2004, 84, 865–871. [Google Scholar] [CrossRef]

- Kaniszewski, T.; Kosson, R.; Grzegorzewska, M.; Kowalski, A.; Badelek, E.; Szwejda-Grzybowska, J.; Tuccio, L.; Agati, G. Yield and quality traits of field grown tomato affected by cultivar and nitrogen application rate. J. Agr. Sci. Tech. 2019, 21, 683–697. [Google Scholar]

- Hagassou, D.; Francia, E.; Ronga, D.; Buti, M. Blossom end-rot in tomato (Solanum lycopersicum L.): A multi-disciplinary overview of inducing factors and control strategies. Sci. Hortic. 2019, 249, 49–58. [Google Scholar] [CrossRef]

- Scholberg, J.; McNeal, B.L.; Jones, J.W.; Boote, K.J.; Stanley, C.D.; Obreza, T.A. Growth and canopy characteristics of field-grown tomato. Agron. J. 2000, 92, 152–159. [Google Scholar] [CrossRef]

- Caradonia, F.; Ronga, D.; Catellani, M.; Giaretta Azevedo, C.V.; Terrazas, R.A.; Robertson-Albertyn, S.; Francia, E.; Bulgarelli, D. Nitrogen fertilizers shape the composition and predicted functions of the microbiota of field-grown tomato plants. Phytobiomes J. 2019, 3, 315–325. [Google Scholar] [CrossRef]

- Ronga, D.; Francia, E.; Rizza, F.; Badeck, F.W.; Caradonia, F.; Montevecchi, G.; Pecchioni, N. Changes in yield components, morphological, physiological and fruit quality traits in processing tomato cultivated in Italy since the 1930’s. Sci. Hortic. 2019, 257, 108726. [Google Scholar] [CrossRef]

- Di Cesare, L.F.; Migliori, C.; Viscardi, D.; Parisi, M. Quality of tomato fertilized with nitrogen and phosphorous. Ital. J. Food Sci. 2010, 2, 186–190. [Google Scholar]

- Alam, M.M.; Billah, K.M.; Prince, M.H.; Hasan, K.M. Effect of nitrogen and phosphorous fertilizer application on the growth and yield of tomato: A mini-review. Int. J. Adv. Agric. Sci. 2017, 2, 855. [Google Scholar]

- Gautier, H.; Diakou-Verdin, V.; Bénard, C.; Reich, M.; Buret, M.; Bourgaud, F.; Poëssel, J.L.; Caris-Veyrat, C.; Génard, M. How does tomato quality (sugar, acid, and nutritional quality) vary with ripening stage, temperature, and irradiance? J. Agric. Food Chem. 2008, 56, 1241–1250. [Google Scholar] [CrossRef]

- Cammarano, D.; Ceccarelli, S.; Grando, S.; Romagosa, I.; Benbelkacem, A.; Akar, T.; Ronga, D. The impact of climate change on barley yield in the Mediterranean basin. Eur. J. Agron. 2019, 106, 1–11. [Google Scholar] [CrossRef]

- Cammarano, D.; Hawes, C.; Squire, G.; Holland, J.; Rivington, M.; Murgia, T.; Roggero, P.P.; Fontana, F.; Casa, R.; Ronga, D. Rainfall and temperature impacts on barley (Hordeum vulgare L.) yield and malting quality in Scotland. Field Crop. Res. 2019, 241, 107559. [Google Scholar] [CrossRef]

- Farneselli, M.; Benincasa, P.; Tosti, G.; Pace, R.; Tei, F.; Guiducci, M. Nine-year results on maize and processing tomato cultivation in an organic and in a conventional low input cropping system. Ital. J. Agron. 2013, 8. [Google Scholar] [CrossRef]

- Selman, I.W.; Grant, S.A. Some effects on nitrogen supply in the infection ot tomato plants with tomato spotted wilt virus. Ann. Appl. Biol. 1957, 45, 448–455. [Google Scholar] [CrossRef]

- De Giorgi, A.; Palmieri, A.; Giordano, I.; Zaccardelli, M.; Impembo, M.; Pentangelo, A.; Villari, G.; Grimaldi, M. Contenuto di nitrati e parametri qualitativi del pomodoro da industria: Influenza di alcune variabili agronomiche. In Proceedings of the Convegno Nazionale CISETA, Cernobbio, Italy, 12–14 September 2001; pp. 326–332. [Google Scholar]

- Pennazio, S.; Roggero, P. Mineral nutrition and sistemic virus infection in plants. Phytopathol. Medit. 1997, 36, 54–66. [Google Scholar]

- Ronga, D.; Zaccardelli, M.; Lovelli, S.; Perrone, D.; Francia, E.; Milc, J.; Ulrici, A.; Pecchioni, N. Biomass production and dry matter partitioning of processing tomato under organic vs. conventional cropping systems in a Mediterranean environment. Sci. Hortic. 2017, 224, 163–170. [Google Scholar] [CrossRef]

- Higashide, T.; Heuvelink, E. Physiological and morphological changes over the past 50 years in yield components in tomato. J. Am. Soc. Hortic. Sci. 2009, 134, 460–465. [Google Scholar] [CrossRef]

- Grandillo, S.; Zamir, D.; Tanksley, S.D. Genetic improvement of processing tomatoes: A 20 years perspective. Euphytica 1999, 110, 85–97. [Google Scholar] [CrossRef]

- Barrios-Masias, F.H.; Jackson, L.E. California processing tomatoes: Morphological, physiological and phenological traits associated with crop improvement during the last 80 years. Eur. J. Agron. 2014, 53, 45–55. [Google Scholar] [CrossRef]

- Branthôme, X.; Plè, Y.; Machado, J.R. Influence of drip-irrigation on the technological characterization of processing tomatoes. Acta Hortic. 1994, 376, 285–290. [Google Scholar] [CrossRef]

- Dumas, Y.; Leon, I.C.; Portas, C.A.M.; Bièche, B. Influence of water and nitrogen availability on yield and quality of processing tomato in the European Union Countries. Acta Hortic. 1994, 376, 185–192. [Google Scholar] [CrossRef]

- Rodriguez, A.; Leoni, S.; Bussieres, P.; Dadomo, M.; Christou, M.; Macua, I.J.; Cornillon, P. The influence of water and nitrogen levels on the quality of the processing tomato grown in European union countries. Acta Hortic. 1994, 376, 275–278. [Google Scholar] [CrossRef]

- Mitchell, J.P.; Shennan, C.; Grattan, S.R.; May, D.M. Tomato fruit yield and quality under water deficit and salinity. J. Am. Soc. Hortic. Sci. 1991, 116, 215–221. [Google Scholar] [CrossRef]

- Dorais, M.; Ehret, D.L.; Papadopoulos, A.P. Tomato (Solanum lycopersicum) health components: From the seed to the consumer. Phytochem. Rev. 2008, 7, 231–250. [Google Scholar] [CrossRef]

- Favati, F.; Lovelli, S.; Galgano, F.; Miccolis, V.; Tommaso, T.; Candido, V. Processing tomato quality as affected by irrigation scheduling. Sci. Hortic. 2009, 122, 562–571. [Google Scholar] [CrossRef]

- Arias, R.; Lee, T.C.; Logendra, L.; Janes, H. Correlation of lycopene measured by HPLC with the L*, a*, b * color readings of a hydroponic tomato and the relationship of maturity with color and lycopene content. J. Agric. Food Chem. 2000, 48, 1697–1702. [Google Scholar] [CrossRef] [PubMed]

- Christou, M.; Leoni, S.; Cornillon, P.; Gainza, A.; Dumas, Y.; Rodriguez, A.; Dimirkou, A. Influence of water and nitrogen availability on elemental composition of processing tomato fruit in Eu. countries. Acta Hortic. 1994, 376, 279–284. [Google Scholar] [CrossRef]

- Miyazaki, M. Studies on the accumulation of nitrate in tomato fruit for canning. Sci. Hortic. 1975, 3, 109–128. [Google Scholar] [CrossRef]

- Santamaria, P. Nitrate in vegetables: Toxicity, content, intake and EC regulation. J. Sci. Food Agric. 2006, 86, 10–17. [Google Scholar] [CrossRef]

- Joint FAO/WHO Expert Committee on Food Additives (JECFA). Available online: https://www.who.int/foodsafety/areas_work/chemical-risks/jecfa/en/ (accessed on 4 April 2020).

- European Food Safety Authority (EFSA). Nitrate in vegetables-Scientific Opinion of The Panel on Contaminants in The Food Chain. EFSA J. 2008, 689, 1–79. [Google Scholar]

- Horio, T.; Iwamoto, T.; Komura, S. Studies on the internal corrosion of can. IV. Possible mechanism of the action of nitrate in canned drinks. J. Food Hyg. Soc. Jpn. 1968, 9, 133–138. [Google Scholar] [CrossRef]

- Iwamoto, Y.; Ikegami, Y.; Maeda, Y.; Horio, T. Studies on internal corrosion of can. VI. Influence of oxygen in headspace and of nitrate upon headspace corrosion in canned orange juice. Rep. Toyo Junior Coll. Food Technol. Toyo Inst. Food Technol. 1972, 10, 1–9. [Google Scholar]

- Hobson, G.; Grierson, D. Tomato. In Biochemistry of Fruit Ripening; Chapman and Hall: London, UK, 1993; pp. 405–442. [Google Scholar]

- Association of Official Analytical Chemists. Official Methods of Analysis of the Association of Official Analytical Chemists (AOAC), 15th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 1990; pp. 1058–1059. [Google Scholar]

- Hernández, M.; Rull, J.; Rios, D.; Rodríguez, E.; Díaz, C. Chemical composition of cultivar of tomatoes resistant and non resistant against the tomato yellow leaf curl virus (TYLCV). Electron. J. Environ. Agric. Food. Chem. 2005, 4, 1049–1054. [Google Scholar]

- Bremner, J.M. Total Nitrogen. In Methods of Soil Analysis; Part 2: Chemical and Microbial Properties, Number 9 in Series Agronomy; Black, C.A., Ed.; American Society of Agronomy: Madison, WI, USA, 1965; pp. 1049–1178. [Google Scholar]

- Jackson, J.E. A Users Guide to Principal Components; Wiley Sons Ltd: New York, NY, USA, 1991. [Google Scholar]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemometr. Intell. Lab. 1987, 2, 37–52. [Google Scholar] [CrossRef]

| Treatments | MY (t ha−1) | TY (t ha−1) | UMY (t ha−1) | ROTTEN (Fruit no.) | BY (t ha−1) | TSWV (Fruit no.) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N-0 | 35.3 | c | 55.7 | b | 11.7 | a | 8.7 | b | 1.7 | b | 12.0 | b |

| N-50 | 43.0 | bc | 59.4 | b | 8.2 | b | 8.2 | bc | 2.1 | b | 15.0 | ab |

| N-125 | 52.4 | a | 66.2 | ab | 7.1 | b | 6.8 | c | 2.5 | a | 15.3 | ab |

| N-200 | 53.8 | a | 71.8 | a | 9.4 | ab | 8.5 | b | 2.5 | a | 14.0 | ab |

| N-275 | 45.9 | ab | 62.0 | ab | 8.0 | b | 8.1 | bc | 2.1 | ab | 17.7 | ab |

| N-350 | 46.2 | ab | 64.8 | ab | 6.8 | b | 11.9 | a | 2.1 | ab | 18.7 | a |

| Average | 46.1 | 63.3 | 8.5 | 8.7 | 2.2 | 15.5 | ||||||

| p-value | * | * | * | * | * | * | ||||||

| Treatments | FDW (t ha−1) | TDW (t ha−1) | HI | AFW (g) | N-Efficiency (kg kg−1) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| N-0 | 2.0 | c | 7.1 | b | 0.28 | b | 51.9 | ab | - | |

| N-50 | 2.2 | bc | 7.6 | b | 0.28 | b | 52.6 | a | 43.3 | a |

| N-125 | 2.8 | a | 7.6 | b | 0.38 | a | 51.3 | ab | 22.7 | b |

| N-200 | 2.8 | a | 7.8 | b | 0.36 | a | 50.1 | b | 14.2 | c |

| N-275 | 2.5 | ab | 8.7 | a | 0.29 | b | 51.6 | ab | 9.2 | d |

| N-350 | 2.4 | bc | 9.0 | a | 0.26 | b | 51.6 | ab | 6.6 | d |

| Average | 2.4 | 8.0 | 0.31 | 51.5 | 19.2 | |||||

| p-value | * | * | * | * | * | |||||

| Treatment | TSS % fw | SSC Brix | TTA % Citric Acid | TTA/TTS % | GLU % fw | FRU % fw | SUG % fw | SUG/TSS % | pH | COL a/b | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N-0 | 5.28 | a | 4.92 | a | 0.26 | a | 4.99 | b | 1.29 | b | 1.45 | a | 2.74 | ab | 52.0 | a | 4.40 | a | 2.23 | a |

| N-50 | 5.27 | a | 4.79 | a | 0.29 | a | 5.44 | ab | 1.40 | a | 1.54 | a | 2.94 | a | 55.8 | a | 4.47 | a | 2.18 | ab |

| N-125 | 5.13 | a | 4.84 | a | 0.28 | a | 5.46 | ab | 1.27 | b | 1.40 | a | 2.67 | ab | 52.5 | a | 4.52 | a | 2.15 | ab |

| N-200 | 5.01 | a | 4.65 | a | 0.29 | a | 5.73 | a | 1.28 | b | 1.45 | a | 2.73 | ab | 54.5 | a | 4.50 | a | 2.15 | ab |

| N-275 | 5.04 | a | 4.64 | a | 0.28 | a | 5.63 | ab | 1.29 | b | 1.43 | a | 2.72 | ab | 54.0 | a | 4.47 | a | 2.09 | b |

| N-350 | 5.05 | a | 4.64 | a | 0.28 | a | 5.64 | ab | 1.23 | b | 1.41 | a | 2.63 | b | 51.9 | a | 4.46 | a | 2.09 | b |

| Average | 5.13 | 4.75 | 0.28 | 5.48 | 1.29 | 1.45 | 2.74 | 53.5 | 4.47 | 2.15 | ||||||||||

| p-value | NS | NS | NS | * | * | NS | * | NS | NS | * | ||||||||||

| Treatment | Nitrate (ppm) | K (ppm) | Mg (ppm) | Phosphates (ppm) | P (ppm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| N-0 | 11.33 | c | 2685.0 | a | 122.2 | a | 385.7 | a | 137.8 | a |

| N-50 | 14.93 | b | 2605.0 | ab | 121.5 | a | 346.3 | a | 111.8 | b |

| N-125 | 13.07 | bc | 2631.0 | a | 118.5 | a | 382.9 | a | 142.5 | a |

| N-200 | 15.07 | b | 2389.0 | b | 115.9 | a | 345.2 | a | 96.5 | b |

| N-275 | 14.93 | b | 2590.0 | ab | 115.8 | a | 365.1 | a | 105.3 | b |

| N-350 | 19.70 | a | 2481.0 | ab | 110.1 | a | 362.2 | a | 114.8 | b |

| Average | 14.84 | 2563.5 | 117.3 | 364.6 | 118.1 | |||||

| p-value | * | * | NS | NS | * | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ronga, D.; Pentangelo, A.; Parisi, M. Optimizing N Fertilization to Improve Yield, Technological and Nutritional Quality of Tomato Grown in High Fertility Soil Conditions. Plants 2020, 9, 575. https://doi.org/10.3390/plants9050575

Ronga D, Pentangelo A, Parisi M. Optimizing N Fertilization to Improve Yield, Technological and Nutritional Quality of Tomato Grown in High Fertility Soil Conditions. Plants. 2020; 9(5):575. https://doi.org/10.3390/plants9050575

Chicago/Turabian StyleRonga, Domenico, Alfonso Pentangelo, and Mario Parisi. 2020. "Optimizing N Fertilization to Improve Yield, Technological and Nutritional Quality of Tomato Grown in High Fertility Soil Conditions" Plants 9, no. 5: 575. https://doi.org/10.3390/plants9050575

APA StyleRonga, D., Pentangelo, A., & Parisi, M. (2020). Optimizing N Fertilization to Improve Yield, Technological and Nutritional Quality of Tomato Grown in High Fertility Soil Conditions. Plants, 9(5), 575. https://doi.org/10.3390/plants9050575