Pathways in Agro-Industrial Waste Upcycling: A Review of Sustainable Textile Innovations and Economic Perspectives

Abstract

1. Introduction

2. Methodology

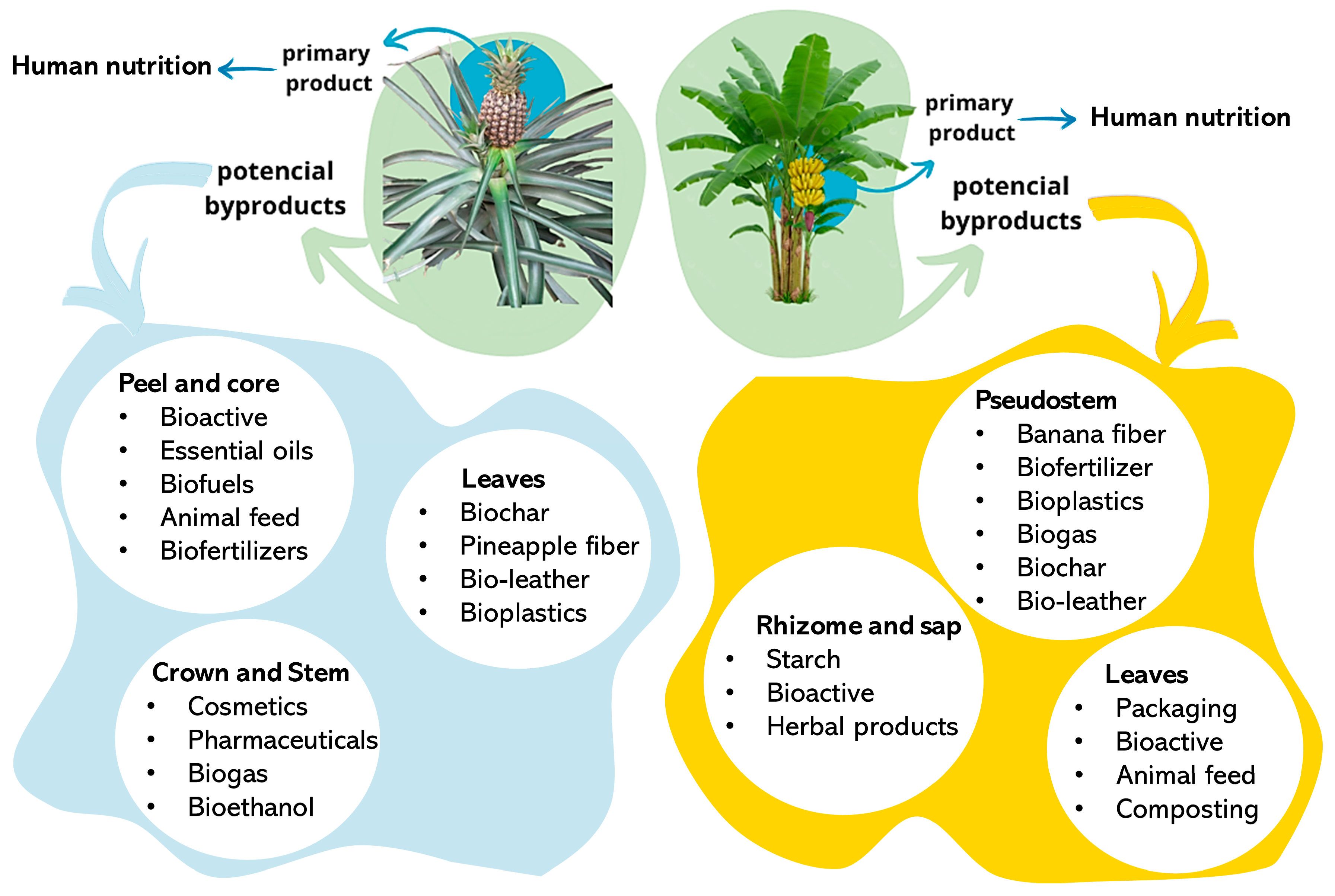

3. Agro-Industrial Waste

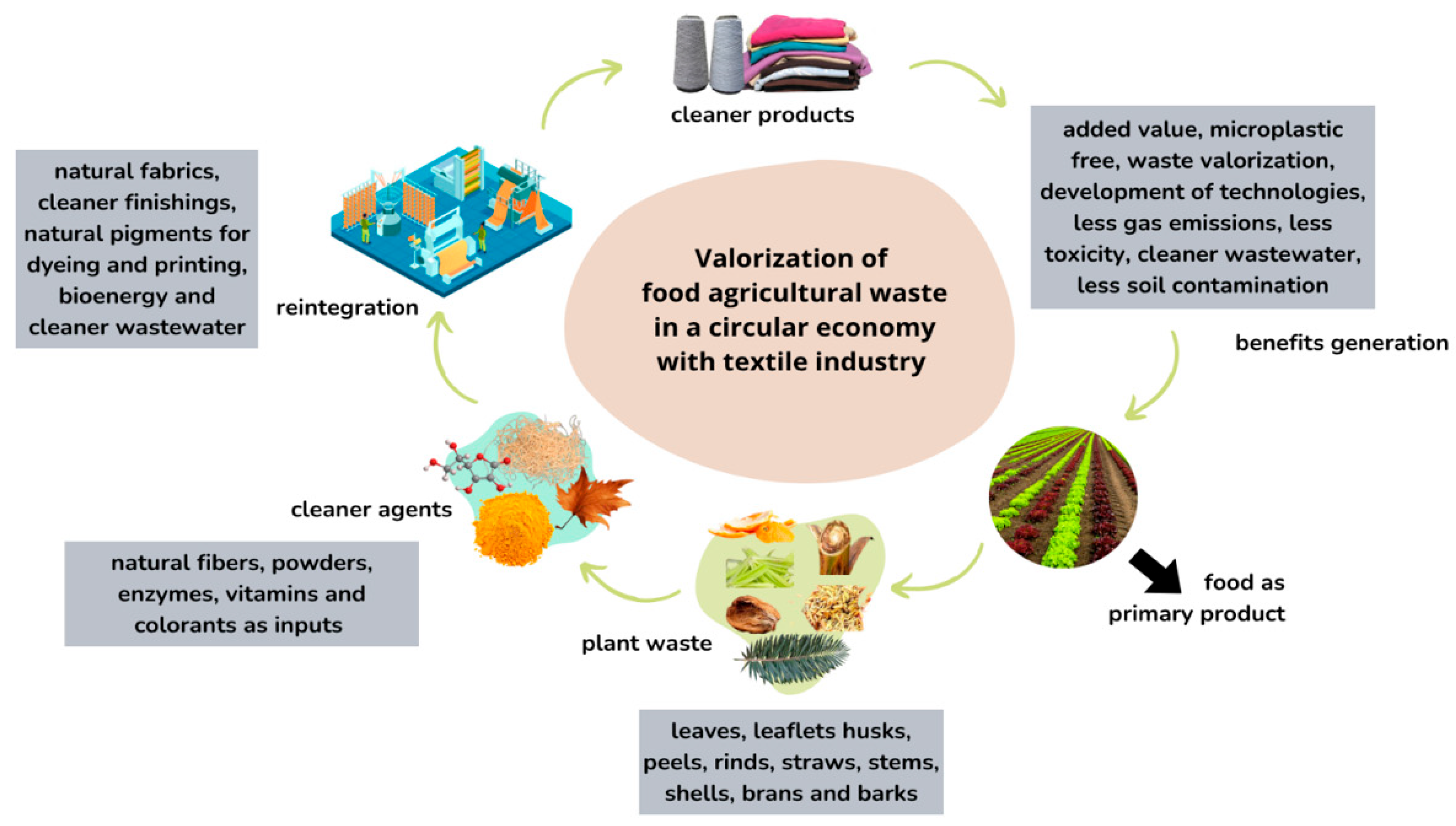

4. Upcycling of Agro-Industrial Waste into Textile Processing

4.1. Textile Fibers from Tucum Palm Tree: A Study Case

4.2. Fiber Extraction

4.3. Obtainment of Finishing Agents

4.4. Colorant Extraction

4.5. Agro-Industrial Residues and Plant-Based Resources for the Alternative Leathers Manufacturing

4.6. Other Upcycling Options for the Textile Industry

5. Economic Aspects and Sustainability in the Utilization of Agro-Industrial Waste

5.1. Economic and Technical Feasibility Analysis

5.2. Sustainability and Circular Economy of Agro-Industrial Waste in the Textile Industry

6. Conclusions and Future Perspectives

7. Future Research Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deshmukh, S.M.; Dhokpande, S.R.; Sankhe, A.; Khandekar, A. Effluent Wastewater Technologies for Textile Industry: A Review. Rev. Inorg. Chem. 2025, 45, 21–40. [Google Scholar] [CrossRef]

- Tripathi, M.; Sharma, M.; Bala, S.; Thakur, V.K.; Singh, A.; Dashora, K.; Hart, P.; Gupta, V.K. Recent Technologies for Transforming Textile Waste into Value-Added Products: A Review. Curr. Res. Biotechnol. 2024, 7, 100225. [Google Scholar] [CrossRef]

- Subramanian, K.; Sarkar, M.K.; Wang, H.; Qin, Z.-H.; Chopra, S.S.; Jin, M.; Kumar, V.; Chen, C.; Tsang, C.-W.; Lin, C.S.K. An Overview of Cotton and Polyester, and Their Blended Waste Textile Valorisation to Value-Added Products: A Circular Economy Approach–Research Trends, Opportunities and Challenges. Crit. Rev. Environ. Sci. Technol. 2022, 52, 3921–3942. [Google Scholar] [CrossRef]

- Clark, J.H. Using Green Chemistry to Progress a Circular Fashion Industry. Curr. Opin. Green Sustain. Chem. 2022, 38, 100685. [Google Scholar] [CrossRef]

- de Oliveira, C.R.S.; da Silva Júnior, A.H.; Mulinari, J.; Immich, A.P.S. Textile Re-Engineering: Eco-Responsible Solutions for a More Sustainable Industry. Sustain. Prod. Consum. 2021, 28, 1232–1248. [Google Scholar] [CrossRef]

- Centobelli, P.; Abbate, S.; Nadeem, S.P.; Garza-Reyes, J.A. Slowing the Fast Fashion Industry: An All-Round Perspective. Curr. Opin. Green Sustain. Chem. 2022, 38, 100684. [Google Scholar] [CrossRef]

- Ikram, M. Transition toward Green Economy: Technological Innovation’s Role in the Fashion Industry. Curr. Opin. Green Sustain. Chem. 2022, 37, 100657. [Google Scholar] [CrossRef]

- Salazar Sandoval, S.; Amenábar, A.; Toledo, I.; Silva, N.; Contreras, P. Advances in the Sustainable Development of Biobased Materials Using Plant and Animal Waste as Raw Materials: A Review. Sustainability 2024, 16, 1073. [Google Scholar] [CrossRef]

- Flohr, T.T.; Neiva, E.G.C.; Dantas, M.P.; Corrêa, R.C.G.; Yamaguchi, N.U.; Peralta, R.M.; da Silva Júnior, A.H.; da Cruz, J.A.; de Aguiar, C.R.L.; de Oliveira, C.R.S. Characterization of Atlantic Forest Tucum (Bactris setosa Mart.) Leaf Fibers: Aspects of Innovation, Waste Valorization and Sustainability. Plants 2024, 13, 2916. [Google Scholar] [CrossRef]

- Akatwijuka, O.; Gepreel, M.A.-H.; Abdel-Mawgood, A.; Yamamoto, M.; Saito, Y.; Hassanin, A.H. Overview of Banana Cellulosic Fibers: Agro-Biomass Potential, Fiber Extraction, Properties, and Sustainable Applications. Biomass Conv. Bioref. 2024, 14, 7449–7465. [Google Scholar] [CrossRef]

- Phan, K.; Raes, K.; Van Speybroeck, V.; Roosen, M.; De Clerck, K.; De Meester, S. Non-Food Applications of Natural Dyes Extracted from Agro-Food Residues: A Critical Review. J. Clean. Prod. 2021, 301, 126920. [Google Scholar] [CrossRef]

- Saba, B.; Christy, A.D.; Jabeen, M. Kinetic and Enzymatic Decolorization of Industrial Dyes Utilizing Plant-Based Biosorbents: A Review. Environ. Eng. Sci. 2016, 33, 601–614. [Google Scholar] [CrossRef]

- Dahiya, D.; Nigam, P.S. Waste Management by Biological Approach Employing Natural Substrates and Microbial Agents for the Remediation of Dyes’ Wastewater. Appl. Sci. 2020, 10, 2958. [Google Scholar] [CrossRef]

- Gaminian, H.; Ahvazi, B.; Vidmar, J.J.; Ekuere, U.; Regan, S. Revolutionizing Sustainable Nonwoven Fabrics: The Potential Use of Agricultural Waste and Natural Fibres for Nonwoven Fabric. Biomass 2024, 4, 363–401. [Google Scholar] [CrossRef]

- Plakantonaki, S.; Kiskira, K.; Zacharopoulos, N.; Belessi, V.; Sfyroera, E.; Priniotakis, G.; Athanasekou, C. Investigating the Routes to Produce Cellulose Fibers from Agro-Waste: An Upcycling Process. ChemEngineering 2024, 8, 112. [Google Scholar] [CrossRef]

- FAO. World Food and Agriculture–Statistical Yearbook 2024; FAO: Rome, Italy, 2024; ISBN 978-92-5-139255-3. [Google Scholar]

- FAO. Pesticides Use and Trade, 1990–2022; FAO: Rome, Italy, 2024; p. 13. [Google Scholar]

- FAO. Inorganic Fertilizers; FAO: Rome, Italy, 2024. [Google Scholar]

- FAO. Land Statistics 2001–2022; FAO: Rome, Italy, 2024. [Google Scholar]

- FAOSTAT. Employment Indicators 2000–2022; FAOSTAT: Rome, Italy, 2024. [Google Scholar]

- FAO. Food and Agriculture Organization of the United Nations. FAOSTAT Analytical Brief 96–Agricultural Production Statistics 2010–2023; FAO: Rome, Italy, 2024. [Google Scholar]

- Jayaprakash, K.; Osama, A.; Rajagopal, R.; Goyette, B.; Karthikeyan, O.P. Agriculture Waste Biomass Repurposed into Natural Fibers: A Circular Bioeconomy Perspective. Bioengineering 2022, 9, 296. [Google Scholar] [CrossRef]

- Bhatia, T.; Sindhu, S.S. Sustainable Management of Organic Agricultural Wastes: Contributions in Nutrients Availability, Pollution Mitigation and Crop Production. Discov. Agric. 2024, 2, 130. [Google Scholar] [CrossRef]

- OECD. FAO Background Notes on Sustainable, Productive and Resilient Agro-Food Systems: Value Chains, Human Capital, and the 2030 Agenda; OECD: Paris, France, 2019; ISBN 978-92-64-63750-4. [Google Scholar]

- United Nations Transforming Our World. The 2030 Agenda for Sustainable Development; United Nations Transforming Our World: New York, NY, USA, 2015; p. 41. [Google Scholar]

- Gupta, P.K.; Patra, S.; Samanta, K.K. Potential of Okra for Application in Textiles: A Review. J. Nat. Fibers 2021, 18, 1788–1800. [Google Scholar] [CrossRef]

- Mahmud, M.A.; Anannya, F.R. Sugarcane Bagasse–A Source of Cellulosic Fiber for Diverse Applications. Heliyon 2021, 7, e07771. [Google Scholar] [CrossRef]

- da Silva, J.J.; da Silva, B.F.; Stradiotto, N.R.; Petrović, M.; Gros, M.; Gago-Ferrero, P. Identification of Organic Contaminants in Vinasse and in Soil and Groundwater from Fertigated Sugarcane Crop Areas Using Target and Suspect Screening Strategies. Sci. Total Environ. 2021, 761, 143237. [Google Scholar] [CrossRef]

- FAOSTAT. Crops and Livestock Products. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 2 January 2025).

- Patil, H.; Athalye, A. Valorization of Corn Husk Waste for Textile Applications. J. Nat. Fibers 2023, 20, 2156017. [Google Scholar] [CrossRef]

- Borah, M.P.; Jose, S.; Kalita, B.B.; Shakyawar, D.; Pandit, P. Water Repellent Finishing on Eri Silk Fabric Using Nano Silica. J. Text. Inst. 2020, 111, 701–708. [Google Scholar] [CrossRef]

- Haque, M.A.; Mia, R.; Mahmud, S.T.; Bakar, M.A.; Ahmed, T.; Farsee, M.S.; Hossain, M.I. Sustainable Dyeing and Functionalization of Wool Fabrics with Black Rice Extract. Resour. Environ. Sustain. 2022, 7, 100045. [Google Scholar] [CrossRef]

- Hazarika, D.; Gogoi, N.; Jose, S.; Das, R.; Basu, G. Exploration of Future Prospects of Indian Pineapple Leaf, an Agro Waste for Textile Application. J. Clean. Prod. 2017, 141, 580–586. [Google Scholar] [CrossRef]

- Rosa, F.R.; Arruda, A.F.; Siqueira, E.M.A.; Arruda, S.F. Phytochemical Compounds and Antioxidant Capacity of Tucum-Do-Cerrado (Bactris Setosa Mart), Brazil’s Native Fruit. Nutrients 2016, 8, 110. [Google Scholar] [CrossRef]

- da Fonseca, R.P.; Rocha, J.C.; Cheriaf, M. Mechanical Properties of Mortars Reinforced with Amazon Rainforest Natural Fibers. Materials 2021, 14, 155. [Google Scholar] [CrossRef] [PubMed]

- Unuofin, J.O.; Moloantoa, K.M.; Khetsha, Z.P. The Biobleaching Potential of Laccase Produced from Mandarin Peelings: Impetus for a Circular Bio-Based Economy in Textile Biofinishing. Arab. J. Chem. 2022, 15, 104305. [Google Scholar] [CrossRef]

- Jain, A.; Rastogi, D.; Chanana, B. Utilization of Cornhusk for Textile Usages. J. Basic Appl. Eng. Res. 2018, 5, 405–408. [Google Scholar]

- Martins, A.P.; Sanches, R.A. Assessment of Coconut Fibers for Textile Applications. Matéria 2019, 24, e12428. [Google Scholar] [CrossRef]

- Lyu, P.; Xia, L.; Jiang, X.; Liu, X.; Xu, W.; Hurren, C.; Wang, X. Efficient Extraction of Technical Fibers from Hemp in an Ethanol-Water Mixture. Ind. Crops Prod. 2022, 178, 114620. [Google Scholar] [CrossRef]

- Sreenivas, H.T.; Krishnamurthy, N.; Arpitha, G.R. A Comprehensive Review on Light Weight Kenaf Fiber for Automobiles. Int. J. Lightweight Mater. Manuf. 2020, 3, 328–337. [Google Scholar] [CrossRef]

- Shahar, F.S.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A. A Short Review on the Extraction of Kenaf Fibers and the Mechanical Properties of Kenaf Powder Composites. IOP Conf. Ser. Mater. Sci. Eng. 2019, 670, 012028. [Google Scholar] [CrossRef]

- Sankar, K.; Constâncio Trindade, A.C.; Kriven, W.M. The Influence of Alkaline Treatment on the Mechanical Performance of Geopolymer Composites Reinforced with Brazilian Malva and Curaua Fibers. J. Am. Ceram. Soc. 2023, 106, 339–353. [Google Scholar] [CrossRef]

- Kovačević, Z.; Strgačić, S.; Bischof, S. Barley Straw Fiber Extraction in the Context of a Circular Economy. Fibers 2023, 11, 108. [Google Scholar] [CrossRef]

- Sunny, G.; Rajan, T.P. Review on Areca Nut Fiber and Its Implementation in Sustainable Products Development. J. Nat. Fibers 2022, 19, 4747–4760. [Google Scholar] [CrossRef]

- Jatuphatwarodom, S.; Jatuphatwarodom, N.; Susawat, K. Dyeing and Water Repellent Finishing of Thai Rice Straw Blended Fabric for Home Textile Products. In Proceedings of the RSU International Research Conference, Riga, Latvia, 1–3 April 2019. [Google Scholar]

- Shuvo, I.I.; Rahman, M.; Vahora, T.; Morrison, J.; DuCharme, S.; Choo-Smith, L.-P. Producing Light-Weight Bast Fibers from Canola Biomass for Technical Textiles. Text. Res. J. 2020, 90, 1311–1325. [Google Scholar] [CrossRef]

- da Silva Simão, R.; de Moraes, J.O.; de Souza, P.G.; Mattar Carciofi, B.A.; Laurindo, J.B. Production of Mango Leathers by Cast-Tape Drying: Product Characteristics and Sensory Evaluation. LWT 2019, 99, 445–452. [Google Scholar] [CrossRef]

- García, C.; Prieto, M.A. Bacterial Cellulose as a Potential Bioleather Substitute for the Footwear Industry. Microb. Biotechnol. 2019, 12, 582–585. [Google Scholar] [CrossRef] [PubMed]

- Provin, A.P.; de Dutra, A.R.A.; de Sousa e Silva Gouveia, I.C.A.; Cubas, E.A.L.V. Circular Economy for Fashion Industry: Use of Waste from the Food Industry for the Production of Biotextiles. Technol. Forecast. Soc. Change 2021, 169, 120858. [Google Scholar] [CrossRef]

- Zhang, A.-N.; Zhao, H.-B.; Cheng, J.-B.; Li, M.-E.; Li, S.-L.; Cao, M.; Wang, Y.-Z. Construction of Durable Eco-Friendly Biomass-Based Flame-Retardant Coating for Cotton Fabrics. Chem. Eng. J. 2021, 410, 128361. [Google Scholar] [CrossRef]

- Deng, M.; Zhang, G.; Zeng, Y.; Pei, X.; Huang, R.; Lin, J. Simple Process for Synthesis of Layered Sodium Silicates Using Rice Husk Ash as Silica Source. J. Alloys Compd. 2016, 683, 412–417. [Google Scholar] [CrossRef]

- Ren, Y.; Liu, Y.; Wang, Y.; Guo, X.; Liu, X. Preparation of Durable and Flame Retardant Lyocell Fabrics by Using a Biomass-Based Modifier Derived from Vitamin C. Cellulose 2020, 27, 6677–6689. [Google Scholar] [CrossRef]

- Ariram, N.; Madhan, B. Development of Bio-Acceptable Leather Using Bagasse. J. Clean. Prod. 2020, 250, 119441. [Google Scholar] [CrossRef]

- Baraldi, R.F.D.S.; Neiva, E.C.; Da Silva Júnior, A.H.; Costa, T.M.; Gonçalves, M.J.; De Aguiar, C.L.; Nihues, T.C.; Schlindwein, R.; Missner, M.E.P.; De Oliveira, C.R.S. Bio-Based Flame Retardant for Cotton Fabric Prepared from Eggshell Microparticles, Phytic Acid, and Chitosan: An Eco-Friendly Approach for Dry Use. Processes 2025, 13, 2690. [Google Scholar] [CrossRef]

- NFPA 701; Standard Methods of Fire Tests for Flame Propagation of Textiles and Films. National Fire Protection Association (NFPA): Quincy, MA, USA, 2019.

- Kanwal, R.; Hashim, M.; Naz, S.; Malik, S.A.; Mengal, N.; Ashraf, R.F. Sustainable Coloration of Polyester Fabric Using Onion Peel Extract with Ultrasonic Energy. In Proceedings of the International Conference on Sustainability: Developments and Innovations, Riyadh, Saudi Arabia, 18–22 February 2024; Mansour, Y., Subramaniam, U., Mustaffa, Z., Abdelhadi, A., Ezzat, M., Abowardah, E., Eds.; Springer Nature: Singapore, 2025; Volume 1, pp. 325–332. [Google Scholar]

- Jordeva, S.; Kertakova, M.; Zhezhova, S.; Golomeova, L.S.; Mojsov, K. Dyeing of Textiles with Natural Dyes. Tekst. Ind. 2020, 68, 12–21. [Google Scholar] [CrossRef]

- Çolak, S.; Arğun, F.N.; Kaygusuz, M. Fashionable Leather Products From Ecofriendly Desinged Vegetable Tanned Leathers. Motif Akad. Halkbilim Derg. 2021, 36, 1384–1398. [Google Scholar] [CrossRef]

- Manuja, A.; Ojha, I.; Singh, D.M. Eco-Printing: Domestic Technique of Textile Printing Using the Leaves of Rose Indica. IJETMS 2023, 7, 116–121. [Google Scholar] [CrossRef]

- Kurinjimalar, C.; Usharani, N.; Kanimozhi, B.; Jayakumar, G.C.; Kanth, S.V. Extraction and Optimization of Natural Colorant from Garcinia mangostana Linn Peels for Leather Dyeing. Clean. Eng. Technol. 2022, 7, 100423. [Google Scholar] [CrossRef]

- Islam, M.R.; Khan, A.N.N.; Mahmud, R.U.; Haque, S.M.N.; Khan, M.M.I. Sustainable Dyeing of Jute-Cotton Union Fabrics with Onion Skin (Allium CEPA) Dye Using Banana Peel (Musa) and Guava Leaves (Psidium guajava) Extract as Biomordants. Pigment Resin Technol. 2022, 53, 369–375. [Google Scholar] [CrossRef]

- Xia, W.; Li, Z.; Tang, Y.; Li, Q. Sustainable Recycling of Café Waste as Natural Bio Resource and Its Value Adding Applications in Green and Effective Dyeing/Bio Finishing of Textile. Sep. Purif. Technol. 2023, 309, 123091. [Google Scholar] [CrossRef]

- Sukemi; Pratumyot, K.; Srisuwannaket, C.; Niamnont, N.; Mingvanish, W. Dyeing of Cotton with the Natural Dye Extracted from Waste Leaves of Green Tea (Camellia sinensis var. assamica). Color. Technol. 2019, 135, 121–126. [Google Scholar] [CrossRef]

- Kashyap, R.; Sharma, N.; Sharma, L. Divya Dyeing of Cotton with Natural Dye Extract from Coconut Husk. Int. J. Sci. Technol. Eng. 2016, 3, 92–95. [Google Scholar]

- Rossi, T.; Silva, P.M.S.; De Moura, L.F.; Araújo, M.C.; Brito, J.O.; Freeman, H.S. Waste from Eucalyptus Wood Steaming as a Natural Dye Source for Textile Fibers. J. Clean. Prod. 2017, 143, 303–310. [Google Scholar] [CrossRef]

- dos Santos Silva, P.M.; Fiaschitello, T.R.; de Queiroz, R.S.; Freeman, H.S.; da Costa, S.A.; Leo, P.; Montemor, A.F.; da Costa, S.M. Natural Dye from Croton urucurana Baill. Bark: Extraction, Physicochemical Characterization, Textile Dyeing and Color Fastness Properties. Dye. Pigment. 2020, 173, 107953. [Google Scholar] [CrossRef]

- Punyachareonnon, P.; Deerattrakul, V.; Luepong, K. The Influence of pH, Temperature and Time on Dyeing of Silk Fabric by Black Bean Anthocyanin-Rich Extract as Colorant. Prog. Color Color. Coat. 2021, 14, 179–186. [Google Scholar] [CrossRef]

- Popescu, V.; Blaga, A.C.; Pruneanu, M.; Cristian, I.N.; Pîslaru, M.; Popescu, A.; Rotaru, V.; Crețescu, I.; Cașcaval, D. Green Chemistry in the Extraction of Natural Dyes from Colored Food Waste, for Dyeing Protein Textile Materials. Polymers 2021, 13, 3867. [Google Scholar] [CrossRef]

- Lee Park, C.; Fracarolli Nunes, M. Vegan Luxury for Non-Vegan Consumers: Impacts on Brand Trust and Attitude towards the Firm. J. Retail. Consum. Serv. 2024, 77, 103669. [Google Scholar] [CrossRef]

- Muthu, S.S.; Ramchandani, M. Natural/Agro-Derived Versus Artificial Vegan Leather: How Leather Alternatives Influence the Sustainable Luxury and Fashion Industry. In Vegan Alternatives for Leather; Muthu, S.S., Ramchandani, M., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 63–74. ISBN 978-3-031-65365-0. [Google Scholar]

- Wijayarathna, E.R.K.B.; Svensson, S.E.; Sar, T.; Zamani, A. Multilayer Biocomposite Vegan Leather Materials Derived from Vegetable-Tanned Fungal Biomass Cultivated on Food Waste. Sci. Rep. 2025, 15, 15366. [Google Scholar] [CrossRef]

- Patil, H.; Patil, Y.; Maiti, S.; Athalye, A.; Adivarekar, R.V. Valorization of Fruit Vegetable Waste for Semi-Synthetic Leather. Iran Polym. J. 2024, 33, 597–605. [Google Scholar] [CrossRef]

- Patil, K.K.R.; Shashidara, K.C.; Sowmya, H.S.; Suresh, S.R. Vegan Areca Palm Leather–Waste to Wealth Generation through Agri-Start-Up. Curr. Sci. 2024, 126, 94. [Google Scholar] [CrossRef]

- Mecca, S.; Digiovanni, S.; Milanesi, R.; Frigerio, C.; Mangiagalli, M.; Tarricone, G.; Boventi, M.; Bordignon, S.; Clerici, M.; Lotti, M.; et al. Development of Leather-like Materials from Enzymatically Treated Green Kiwi Peel and Valorization of By-Products for Microbial Bioprocesses. ACS Sustain. Chem. Eng. 2025, 13, 15924–15934. [Google Scholar] [CrossRef]

- Rimantho, D.; Chaerani, L.; Sundari, A.S. Initial Mechanical Properties of Orange Peel Waste as Raw Material for Vegan Leather Production. Case Stud. Chem. Environ. Eng. 2024, 10, 100786. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X.; Wang, X.; Yue, O.; Jiang, H. Engineered, Environmentally Friendly Leather-like Bio-Based Materials. Trends Biotechnol. 2025, 43, 1104–1115. [Google Scholar] [CrossRef]

- Fuad, S.M.; Farmer, M.C.; Adisa, A. Economic Opportunities of Bioelectricity from Cotton Gin Waste. J. Agric. Appl. Econ. 2025, 57, 14–41. [Google Scholar] [CrossRef]

- Shah, M.A.; Hayder, G.; Kumar, R.; Kumar, V.; Ahamad, T.; Kalam, M.A.; Soudagar, M.E.M.; Mohamed Shamshuddin, S.Z.; Mubarak, N.M. Development of Sustainable Biomass Residues for Biofuels Applications. Sci. Rep. 2023, 13, 14248. [Google Scholar] [CrossRef] [PubMed]

- Zheng, N.-Y.; Lee, M.; Lin, Y.-L. Co-Processing Textile Sludge and Lignocellulose Biowaste for Biofuel Production through Microwave-Assisted Wet Torrefaction. J. Clean. Prod. 2020, 268, 122200. [Google Scholar] [CrossRef]

- Xu, Y.; Su, Q.; Shen, H.; Xu, G. Physicochemical and Sorption Characteristics of Poplar Seed Fiber as a Natural Oil Sorbent. Text. Res. J. 2019, 89, 4186–4194. [Google Scholar] [CrossRef]

- Wu, J.; Yang, J.; Huang, G.; Xu, C.; Lin, B. Hydrothermal Carbonization Synthesis of Cassava Slag Biochar with Excellent Adsorption Performance for Rhodamine B. J. Clean. Prod. 2020, 251, 119717. [Google Scholar] [CrossRef]

- Rahman, M.M.; Maniruzzaman, M.; Mahmud, P.; Khatun, S.; Hossain, M.K.; Hossain, M.I.; Hossain, M.I.; Hasanuzzaman, M.; Alam, M.A.; Al-amin, M.; et al. Adsorptive Removal of Toxic Heavy Metal and Dyes from Wastewater by Rice Husk (Lignocellulosic biomass) Derived Activated Biochar: A Fixed-Bed Column Adsorption Study. Carbohydr. Polym. Technol. Appl. 2025, 9, 100698. [Google Scholar] [CrossRef]

- Vasconcelos, W.M.; Mulinari, J.; Leal, T.W.; de Oliveira, C.R.S.; da Silva Júnior, A.H.; Lourenço, L.A.; Lenzi, C. Exploring Pristine Tucumã (Astrocaryum Aculeatum) Waste as a Sustainable Adsorbent for Textile Dye Removal. Environ. Qual. Manag. 2025, 34, e70014. [Google Scholar] [CrossRef]

- Prado-Acebo, I.; Cubero-Cardoso, J.; Lu-Chau, T.A.; Eibes, G. Integral Multi-Valorization of Agro-Industrial Wastes: A Review. Waste Manag. 2024, 183, 42–52. [Google Scholar] [CrossRef]

- Kamboj, A.; Sadh, P.K.; Yadav, B.; Kumari, A.; Kumar, R.; Surekha; Saharan, B.S.; Brar, B.; Kumar, D.; Goyal, C.; et al. Unravelling the Potential of Sugarcane Bagasse: An Eco-Friendly and Inexpensive Agro-Industrial Waste for the Production of Valuable Products Using Pretreatment Processes for Sustainable Bio-Economy. J. Environ. Chem. Eng. 2024, 12, 114461. [Google Scholar] [CrossRef]

- Chatterjee, B.; Mazumder, D. A Critical Review of the Advances in Valorizing Agro-Industrial Wastes through Mixed Culture Fermentation. J. Environ. Chem. Eng. 2024, 12, 111838. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Lin, Y.; Qin, Y.; He, R.; Wang, M.; Sun, Q.; Peng, Y. Nanocellulose from Agro-Industrial Wastes: A Review on Sources, Production, Applications, and Current Challenges. Food Res. Int. 2024, 192, 114741. [Google Scholar] [CrossRef]

- Phiri, R.; Mavinkere Rangappa, S.; Siengchin, S. Agro-Waste for Renewable and Sustainable Green Production: A Review. J. Clean. Prod. 2024, 434, 139989. [Google Scholar] [CrossRef]

- Wagh, M.S.; Sowjanya, S.; Nath, P.C.; Chakraborty, A.; Amrit, R.; Mishra, B.; Mishra, A.K.; Mohanta, Y.K. Valorisation of Agro-Industrial Wastes: Circular Bioeconomy and Biorefinery Process–A Sustainable Symphony. Process Saf. Environ. Prot. 2024, 183, 708–725. [Google Scholar] [CrossRef]

- Rame, R.; Purwanto, P.; Sudarno, S. Biotechnological Approaches in Utilizing Agro-Waste for Biofuel Production: An Extensive Review on Techniques and Challenges. Bioresour. Technol. Rep. 2023, 24, 101662. [Google Scholar] [CrossRef]

- Verma, P.; Kaushik, R.; Sirohi, R. A Review on the Preparation, Characterization, and Applications of Agro-Waste-Derived Oligosaccharides. Food Biosci. 2024, 62, 105221. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Amin, M.; Hadzima-Nyarko, M.; Saad Agwa, I.; Zeyad, A.M.; Tayeh, B.A.; Adesina, A. Possibilities for the Application of Agro-Industrial Wastes in Cementitious Materials: A Brief Review of the Brazilian Perspective. Clean. Mater. 2022, 3, 100040. [Google Scholar] [CrossRef]

- Lima, C.A.; Bento, H.B.S.; Picheli, F.P.; Paz-Cedeno, F.R.; Mussagy, C.U.; Masarin, F.; Torres Acosta, M.A.; Santos-Ebinuma, V.C. Process Development and Techno-Economic Analysis of Co-Production of Colorants and Enzymes Valuing Agro-Industrial Citrus Waste. Sustain. Chem. Pharm. 2023, 35, 101204. [Google Scholar] [CrossRef]

- Mulinari, J.; Junior, F.W.R.; de Oliveira, C.R.S.; da Silva Júnior, A.H.; Scariot, M.A.; Radünz, L.L.; Mossi, A.J. Biochar as a Tool for the Remediation of Agricultural Soils. In Biochar and Its Application in Bioremediation; Thapar Kapoor, R., Treichel, H., Shah, M.P., Eds.; Springer Nature: Singapore, 2021; pp. 281–303. ISBN 978-981-16-4059-9. [Google Scholar]

- Ramaiah, G.; Simeno, Z.; Negawo, T.A.; Baraki, S.Y.; Legese, R.; Asfaw, D. Extraction of Ensete Fibers and Its Woven Fabric Green Composite Development for Ceiling Board Applications. Ind. Crops Prod. 2025, 223, 120189. [Google Scholar] [CrossRef]

- Wang, B.; Li, Z.; Wang, Y.; Zhang, B.; Lv, C.; Bi, X.; Zhao, T. Eco-Friendly Dyeing of Cotton Fabrics with Microbial Pigments: Anionic Modification for Superior Color, Antibacterial, Hydrophobic and UV Protection Properties. Ind. Crops Prod. 2025, 223, 120276. [Google Scholar] [CrossRef]

- Umesh, M.; Suresh, S.; Santosh, A.S.; Prasad, S.; Chinnathambi, A.; Al Obaid, S.; Jhanani, G.K.; Shanmugam, S. Valorization of Pineapple Peel Waste for Fungal Pigment Production Using Talaromyces Albobiverticillius: Insights into Antibacterial, Antioxidant and Textile Dyeing Properties. Environ. Res. 2023, 229, 115973. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, M.A.S.; Rabbi, M.S.; Ahmed, R.U.; Billah, M.M. Biodegradable Natural Polymers and Fibers for 3D Printing: A Holistic Perspective on Processing, Characterization, and Advanced Applications. Clean. Mater. 2024, 14, 100275. [Google Scholar] [CrossRef]

- Gupta, N.; Paul, J.S.; Jadhav, S.K. Biovalorizing Agro-Waste ‘de-Oiled Rice Bran’ for Thermostable, Alkalophilic and Detergent Stable α-Amylase Production with Its Application as Laundry Detergent Additive and Textile Desizer. Int. J. Biol. Macromol. 2024, 256, 128470. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, H.; Li, X. Environmental Policy Effects of the Carbon Tax, Subsidy, and Policy Combinations of China’s Textile Industry: Evidence from the DSGE Model. J. Clean. Prod. 2024, 439, 140791. [Google Scholar] [CrossRef]

- Nesterov, D.; Barrera-Martínez, I.; Martínez-Sánchez, C.; Sandoval-González, A.; Bustos, E. Approaching the Circular Economy: Biological, Physicochemical, and Electrochemical Methods to Valorize Agro-Industrial Residues, Wastewater, and Industrial Wastes. J. Environ. Chem. Eng. 2024, 12, 113335. [Google Scholar] [CrossRef]

- Karanikas, N.; Hasan, S.M.T. Occupational Health & Safety and Other Worker Wellbeing Areas: Results from Labour Inspections in the Bangladesh Textile Industry. Saf. Sci. 2022, 146, 105533. [Google Scholar] [CrossRef]

- Ghasemy Yaghin, R. Enhancing Supply Chain Production-Marketing Planning with Geometric Multivariate Demand Function (a Case Study of Textile Industry). Comput. Ind. Eng. 2020, 140, 106220. [Google Scholar] [CrossRef]

- Chhandama, M.V.L.; Chetia, A.C.; Satyan, K.B.; Supongsenla, A.; Ruatpuia, J.V.; Rokhum, S.L. Valorisation of Food Waste to Sustainable Energy and Other Value-Added Products: A Review. Bioresour. Technol. Rep. 2022, 17, 100945. [Google Scholar] [CrossRef]

- Withanage, S.V.; Dias, G.M.; Habib, K. Review of Household Food Waste Quantification Methods: Focus on Composition Analysis. J. Clean. Prod. 2021, 279, 123722. [Google Scholar] [CrossRef]

- Mohanta, Y.K.; Mishra, A.K.; Lakshmayya, N.S.V.; Panda, J.; Thatoi, H.; Sarma, H.; Rustagi, S.; Baek, K.-H.; Mishra, B. Agro-Waste-Derived Bioplastics: Sustainable Innovations for a Circular Economy. Waste Biomass Valor. 2025, 16, 3331–3355. [Google Scholar] [CrossRef]

- Butturi, M.A.; Neri, A.; Mercalli, F.; Gamberini, R. Sustainability-Oriented Innovation in the Textile Manufacturing Industry: Pre-Consumer Waste Recovery and Circular Patterns. Environments 2025, 12, 82. [Google Scholar] [CrossRef]

- Farhana, K.; Kadirgama, K.; Mahamude, A.S.F.; Mica, M.T. Energy Consumption, Environmental Impact, and Implementation of Renewable Energy Resources in Global Textile Industries: An Overview towards Circularity and Sustainability. Mater. Circ. Econ. 2022, 4, 15. [Google Scholar] [CrossRef]

- Panhwar, A.; Sattar Jatoi, A.; Ali Mazari, S.; Kandhro, A.; Rashid, U.; Qaisar, S. Water Resources Contamination and Health Hazards by Textile Industry Effluent and Glance at Treatment Techniques: A Review. Waste Manag. Bull. 2024, 1, 158–163. [Google Scholar] [CrossRef]

- Andrade Siqueira, T.C.; Zanette da Silva, I.; Rubio, A.J.; Bergamasco, R.; Gasparotto, F.; Aparecida de Souza Paccola, E.; Ueda Yamaguchi, N. Sugarcane Bagasse as an Efficient Biosorbent for Methylene Blue Removal: Kinetics, Isotherms and Thermodynamics. Int. J. Environ. Res. Public Health 2020, 17, 526. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, C.; Liu, K.; Zhu, L.; Song, Z.; Li, D. Atmospheric Microplastic over the South China Sea and East Indian Ocean: Abundance, Distribution and Source. J. Hazard. Mater. 2020, 389, 121846. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, B.; Gu, C.; Shen, C.; Yin, S.; Aamir, M.; Li, F. Are We Underestimating the Sources of Microplastic Pollution in Terrestrial Environment? J. Hazard. Mater. 2020, 400, 123228. [Google Scholar] [CrossRef]

- UNEP. Food Waste Index Report 2024. In Think Eat Save: Tracking Progress to Halve Global Food Waste; UNEP: Geneva, Switzerland, 2024; ISBN 978-92-807-4139-1. [Google Scholar]

- Sagar, N.A.; Pathak, M.; Sati, H.; Agarwal, S.; Pareek, S. Advances in Pretreatment Methods for the Upcycling of Food Waste: A Sustainable Approach. Trends Food Sci. Technol. 2024, 147, 104413. [Google Scholar] [CrossRef]

- United Nations World Population Prospects. Available online: https://population.un.org/wpp/graphs?loc=900&type=Demographic%20Profiles&category=Line%20Charts (accessed on 3 June 2025).

- Clark, J.H.; Farmer, T.J.; Herrero-Davila, L.; Sherwood, J. Circular Economy Design Considerations for Research and Process Development in the Chemical Sciences. Green Chem. 2016, 18, 3914–3934. [Google Scholar] [CrossRef]

- Nájera-Martínez, E.F.; Melchor-Martínez, E.M.; Sosa-Hernández, J.E.; Levin, L.N.; Parra-Saldívar, R.; Iqbal, H.M.N. Lignocellulosic Residues as Supports for Enzyme Immobilization, and Biocatalysts with Potential Applications. Int. J. Biol. Macromol. 2022, 208, 748–759. [Google Scholar] [CrossRef]

- Sakao, T.; Bocken, N.; Nasr, N.; Umeda, Y. Implementing Circular Economy Activities in Manufacturing for Environmental Sustainability. CIRP Ann. 2024, 73, 457–481. [Google Scholar] [CrossRef]

- Mak, T.M.W.; Xiong, X.; Tsang, D.C.W.; Yu, I.K.M.; Poon, C.S. Sustainable Food Waste Management towards Circular Bioeconomy: Policy Review, Limitations and Opportunities. Bioresour. Technol. 2020, 297, 122497. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Azelee, N.I.W.; Ramli, A.N.M.; Rashid, S.A.; Manas, N.H.A.; Dailin, D.J.; Illias, R.M.; Rajagopal, R.; Chang, S.W.; Zhang, Z.; et al. Microbial Biotechnology Approaches for Conversion of Pineapple Waste in to Emerging Source of Healthy Food for Sustainable Environment. Int. J. Food Microbiol. 2022, 373, 109714. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Yan, N.; Lapkin, A.A. Towards Circular Economy: Integration of Bio-Waste into Chemical Supply Chain. Curr. Opin. Chem. Eng. 2019, 26, 148–156. [Google Scholar] [CrossRef]

- Alan, H.; Köker, A.R. Analyzing and Mapping Agricultural Waste Recycling Research: An Integrative Review for Conceptual Framework and Future Directions. Resour. Policy 2023, 85, 103987. [Google Scholar] [CrossRef]

- MacArthur, E. Foundation A New Textiles Economy; Redesigning Fashion’s Future: London, UK, 2017. [Google Scholar]

- Rana, P.; Sethi, S. Utilising Agro-Waste in Textile Industry: Advancing Sustainability with a Year-Round Waste Cycle. Mater. Circ. Econ. 2025, 7, 30. [Google Scholar] [CrossRef]

| Fiber Source | Extraction Approach | Main Contributions | Ref. |

|---|---|---|---|

| Banana (Musa spp.) stem | Chemical retting, mechanical or manual extraction | In this revision, authors verified that mechanical extraction was the chosen method to recover fibers from the banana stem. Fibers isolated from the inner stem were soft and silk-like, whereas fibers from the outer stem were harsher and less pliable than the first. | [22] |

| Pineapple [Ananas comosus (L.) Merril] leaves | Water retting and degumming | Optimal fiber retting, conducted over 7 days at ambient temperature, achieved a yield of 2.8%. Scanning Electron Microscopy (SEM) analysis confirmed the removal of pectin and leaf matter. The fiber’s physical properties (tensile strength, friction, water absorbency, and surface texture) suggest its potential for high-quality yarn production. | [33] |

| Corn (Zea mays L.) husk | Enzyme retting | A two-step scouring process improved absorbency and whiteness of fibers for better bleaching and dyeing results. Blended yarns of corn husk fibers and coir or wood pulp fiber were developed. | [30,37] |

| Coconut (Cocos nucifera L.) husk | Mechanical extraction or retting | Fine fibers were treated with a mild alkali solution and H2O2 for scouring and pre-bleaching, and then with a cationic softener for 10 min at 60 °C. Such process was effective in enabling spinning and weaving to a textile material. | [38] |

| Hemp (Cannabis sativa L.) stem | Mechanical extraction and degumming | Low-cost ethanol-assisted degumming diminished fiber degradation. Morphology and composition analyses showed a smooth, high tensile strength and whitened fiber. | [39] |

| Sugarcane (Saccharum officinarum L.) bagasse rind and inner pith | Water and alkali retting variating temperature, time and concentrations of NaOH, | Authors revised fiber recovery reports from sugarcane bagasse, summarizing common points in their routes. Rind-derived fibers were stronger and coarser than other natural fibers. Cellulose and nano cellulose recovery resulted in smaller and weaker fibers than rind-derived ones. | [27] |

| Kenaf (Hibiscus cannabinus L.) stem | Dew retting, water retting, enzyme retting, mechanical retting and acid and alkali retting | Comparative cost analysis revealed that kenaf fibers are potentially cost-effective alternatives to cotton, flax, aramid and other fibers, considering their low cost, low density, medium tensile strength and stiffness. Kenaf fibers or powder enhanced the tensile strength of composite products. | [40,41] |

| Malva (Malva sylvestris L.) stem; curauá (Ananas erectifolius L.B. Smith) leaves | Chemical retting | Alkali treatment with NaOH enhanced fibers’ roughness and bonding strength, although it failed in improving fibers’ tensile and flexural strength. Hemicellulose was totally removed from the malva fibers, but partially removed from the curauá fibers, as confirmed by Thermogravimetric (TGA) and SEM analysis. | [42] |

| Barley (Hordeum vulgare L.) straw | Water, dew, enzymes, acid or alkali retting | Recovered fibers had moisture regain higher than cotton fibers and tenacity was enough to endure yarning formation. | [43] |

| Areca (Areca catechu L.) nutshell husk and leaves | Chemical or water retting | Fiber extraction from husk was simple and reproducible. According to the authors, both coarse fibers from husk and weaker fibers from leaves can be applied as yarn, mixed yarns, composites and as alternatives to synthetic fibers. | [44] |

| Okra [Abelmoschus esculentus (L.) Moench] stem | Chemical, due or water retting | In this review, okra stem fibers were featured as holding tensile strength, dyeability, and colorfastness. Bleaching, alkalization, and graft copolymerization improved fibers’ characteristics as color, water absorption and smoothness. | [26] |

| Tucum (Bactris setosa Mart.) leaves | Manual extraction | Unusual palm tree leaflets fibers were extracted in a slow chemical-free process. Recovered fibers were characterized, bleached and dyed. Fiber properties such as length, high tensile strength and dyes absorption were similar to cotton. | [9] |

| Rice (Oryza sativa L.) straw | Water retting | A mixed yarn composed of 12% rice straw, 23% rayon and 65% polyesters was dyed and finished with Starguard FCS to achieve water repellency. The resulting yarn repelled water efficiently and color was maintained, although the resistance to pilling was reduced. | [45] |

| Canola (Brassica napus L.) stem | Water retting or manual extraction | Recovered fibers were light, hydrophilic and suitable for apparel, non-woven, composite and other applications. SEM analysis indicated a low-density bast fiber, corroborating its lightweight and low tensile strength features. | [46] |

| Mango (Mangifera indica L.) residue | Mechanical processing | Mango-starch was cast-tape dried to produce a vegetable leather-like fabric. Mango small-length fibers are suitable for non-woven textiles applications. | [47] |

| Pigment Source | Colorant Obtainment | Color Finishing, Fixation Technique and Outcomes | Reference |

|---|---|---|---|

| Poppy (Papaver spp.) flowers and leaves of sycamore (Platanus occidentalis L.); Linden (Tilia spp.); walnut (Juglans spp.) and rose (Rosa indica L.) | Mechanical pressure by rolling the fabrics on a tubular draping structure, tying and heating | Ecoprinting cotton fabric and leather using three different mordants: copper sulfate, iron sulfate and spurge plant (biomordant). The fixation and vivid colors of plants and flowers had better outcomes with biomordant application. | [58] |

| Indian rose leaves (Rosa indica L.) | Mechanical pressure by careful hammering, steaming rolled fabrics and post mordanting | Ecoprinting cotton and silk fabric with potassium aluminum sulfate (alum) as mordant. The pigment absorption was fast, easy and highly replicable. | [59] |

| Mangosteen (Garcinia mangostana L.) rind | Rinds were washed, shade dried and powdered | Authors investigated the dyeing outcomes of pretreated leather with the following mordants: calcium carbonate, ferrous sulfate, citric acid, zinc sulphate, chestnut, or aluminum sulphate resulting in different reflectance values and color shades. | [60] |

| Onion (Allium cepa L.) peel extract | Red onion peels were dried, crushed and prepared by decoction | Kanwal et al. (2025) [56] reported that the ultrasonic dyeing of polyester fabric with alum mordant resulted in a light to medium color shade. Islam et al. (2022) [61] compared banana peel and guava leave mordants in dyeing jute-cotton pretreated fabric. The first resulted in better color fixation after washing, whereas the second provided better color shade. | [56,61] |

| Spent coffee (Coffea spp.) grounds and spent black tea (Camellia sinensis L.) leaves | Decoction, centrifugation and filtered | Spent black tea leaves’ colorant resulted in a darker color shade and higher antioxidant capacity than the spent coffee’s colorant, possibly due to the tannin and flavonoid components in its leaves. | [62,63] |

| Coconut (Cocos nucifera L.) husk fibers | Fibers were washed, dried and powdered | Cotton fabrics were dyed using alum and vinegar as mordants under varying concentrations and methods. Optimal results were defined with specific dye-mordant combinations, resulting in satisfactory washing and light fastness, as assessed by gray scale evaluation. | [64] |

| Eucalyptus (Eucalyptus grandis W. Hill ex Maiden) wood liquid residue | Lumber steaming resulting in a colored liquid residue (colorant) | Exhaustion dyeing of a cotton fabric with no use of mordants resulting in a low color intensity dyeing. The reported process consumed less water and energy in comparison with dyeing with other plant-based dyes. | [65] |

| “Sangra-d’água” (Croton urucurana Baill) wood bark | Barks were washed, dried and milled | The tannin-rich extract was applied to dye cotton and wool textiles, producing shades ranging from beige to reddish brown. Optimization of the dyeing process was achieved through a 23-factorial experimental design. The dyeing wastewater requires treatment. | [66] |

| Black beans (Phaseolus vulgaris L.) skin | Filtration of wastewater from soaked beans; the obtained anthocyanin extract was directly applied as colorant | Exhaustion wool dyeing with iron and alum tested as mordants resulted in color gain and UV protection. Silk exhaustion dyeing had time, temperature and pH interfering with the color shades. Best conditions for pigmentation on silk was verified for pH 1, at 60 °C for 60 min. | [67] |

| Beetroot (Beta vulgaris L.) peels | Dissolution in water, under pressure or enzyme-assisted extraction | The tree extraction methods were compared to develop a colorant for wool dyeing. An acid environment, chelating agents and temperature variation result in different and possible new colors for textile pigments. | [68] |

| Black rice (Oryza sativa L.) bran extract | Filtration of wastewater from soaked rice grains. The recovered anthocyanin extract was diluted and directly applied | Wool dyeing with metal mordants resulted in brown color changing shades varying according to pH and mordant. The extract antibacterial features were reported. | [32] |

| Category | Description | Technical Feasibility | Examples and Impacts | References |

|---|---|---|---|---|

| Collection and transportation | Collection logistics in remote rural areas; adequate storage infrastructure. | Feasible, but requires efficient logistics planning to optimize costs. | Collection of pineapple peels for fiber extraction, promoting agricultural waste reduction and fostering the integration of rural communities. | [97] |

| Processing technology | Investment in machinery for fiber extraction, chemical processing, and the production of sustainable filaments. | Feasible with already available technologies but requires adaptation for specific materials. | Utilization of extruders for processing coconut shell fibers, enabling the replacement of synthetic fibers and reducing dependence on non-renewable resources. | [98] |

| Process adaptation | Modifications in textile equipment, including looms and spinning machines, to accommodate recycled or natural fibers derived from waste. | Feasible with technical training and adjustments in existing equipment. | Adaptation of looms for processing banana fibers, enhancing efficiency in the production of sustainable fabrics. | [5] |

| Research and development | Research focused on developing new materials and optimizing dyeing and finishing processes using agro-industrial waste. | Fundamental for investigating the technical and aesthetic properties of innovative products. | Development of biodegradable fabrics dyed with natural pigments extracted from fruit peels, fostering the creation of premium ecological products. | [99] |

| Governmental incentives | Tax incentives, subsidies, and specialized credit lines for companies implementing sustainable practices in textile production. | Enhances economic viability while driving the transition to a circular economy. | Incentives for natural dyeing projects, lowering initial costs and fostering a sustainable economy. | [100] |

| Environmental impacts | Decreased solid waste generation and reduced reliance on synthetic raw materials like polyester. | Highly feasible through clean processes and the integration of agro-industrial waste. | Production of biodegradable fabrics from plant-based fibers, reducing the environmental impact of textile product disposal. | [5,9,101] |

| Human resources training | Technical training for process adaptation and operation of advanced technologies tailored to the textile industry. | Feasible through partnerships between companies and educational institutions. | Training programs on using recycled fibers in weaving, enhancing workers qualifications and boosting sector competitiveness. | [102] |

| Marketing and positioning | Investments to showcase the environmental and social advantages of sustainable products in the textile market. | Essential for attracting conscious consumers and solidifying added value. | Development of eco-labels and certifications for recycled fabrics, enabling access to premium markets and boosting exports. | [103] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dantas, M.P.; de Oliveira, C.R.S.; Ueda Yamaguchi, N.; da Silva Júnior, A.H.; Peralta, R.M.; Bracht, A.; Corrêa, R.C.G. Pathways in Agro-Industrial Waste Upcycling: A Review of Sustainable Textile Innovations and Economic Perspectives. Plants 2025, 14, 3574. https://doi.org/10.3390/plants14233574

Dantas MP, de Oliveira CRS, Ueda Yamaguchi N, da Silva Júnior AH, Peralta RM, Bracht A, Corrêa RCG. Pathways in Agro-Industrial Waste Upcycling: A Review of Sustainable Textile Innovations and Economic Perspectives. Plants. 2025; 14(23):3574. https://doi.org/10.3390/plants14233574

Chicago/Turabian StyleDantas, Marina Proença, Carlos Rafael Silva de Oliveira, Natália Ueda Yamaguchi, Afonso Henrique da Silva Júnior, Rosane Marina Peralta, Adelar Bracht, and Rúbia Carvalho Gomes Corrêa. 2025. "Pathways in Agro-Industrial Waste Upcycling: A Review of Sustainable Textile Innovations and Economic Perspectives" Plants 14, no. 23: 3574. https://doi.org/10.3390/plants14233574

APA StyleDantas, M. P., de Oliveira, C. R. S., Ueda Yamaguchi, N., da Silva Júnior, A. H., Peralta, R. M., Bracht, A., & Corrêa, R. C. G. (2025). Pathways in Agro-Industrial Waste Upcycling: A Review of Sustainable Textile Innovations and Economic Perspectives. Plants, 14(23), 3574. https://doi.org/10.3390/plants14233574