Optimizing Management of Alfalfa (Medicago sativa L.) Nitrogen Fertilizer Based on Critical Nitrogen Concentration Dilution Curve Model

Abstract

1. Introduction

2. Results and Analysis

2.1. Modeling of Critical Nitrogen Concentration Dilution Curves in Alfalfa

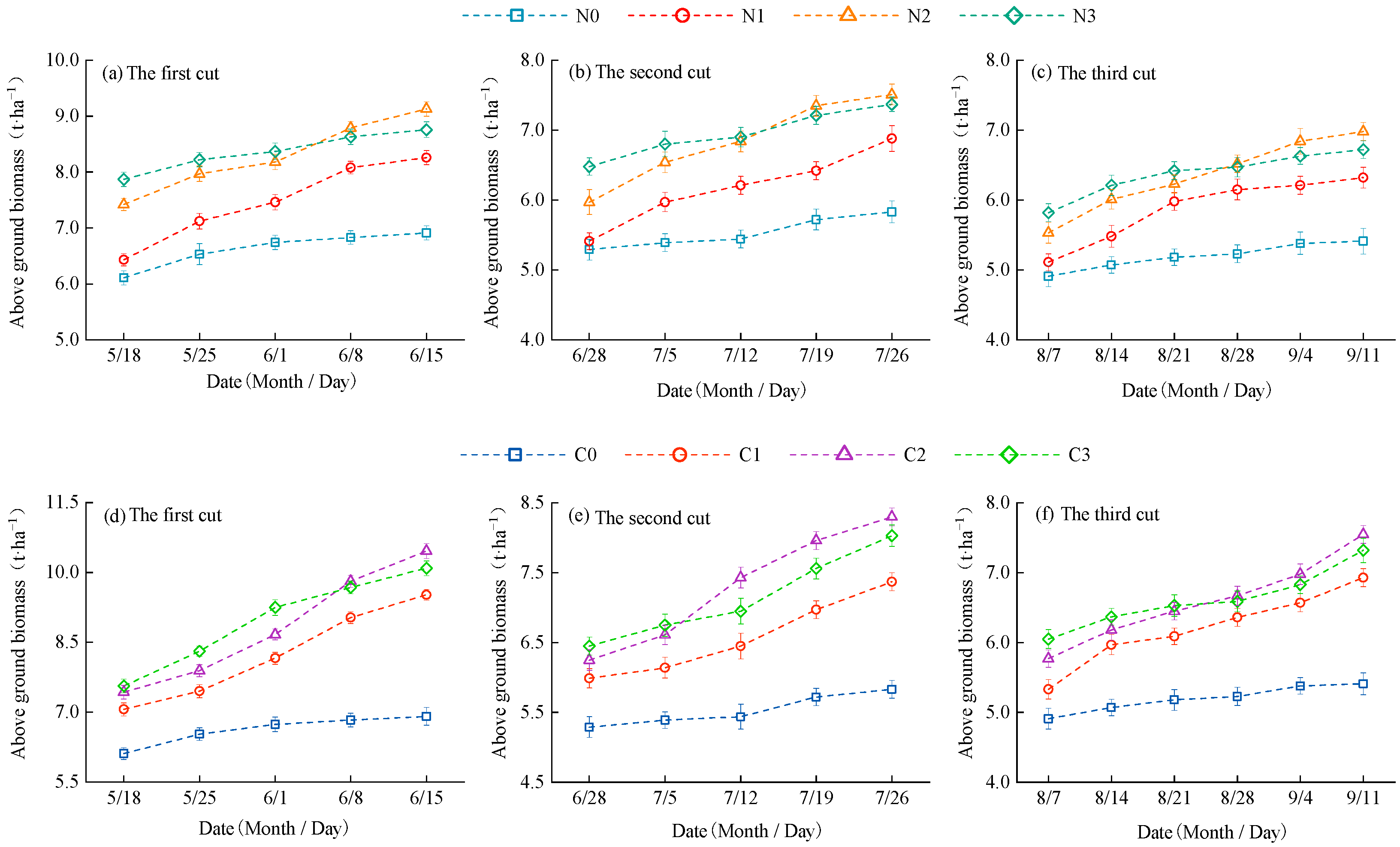

2.1.1. Effect of Nitrogen Fertilizer Management on Alfalfa Aboveground Biomass

2.1.2. Effects of Nitrogen Fertilizer Management on Alfalfa Plant Nitrogen Concentration

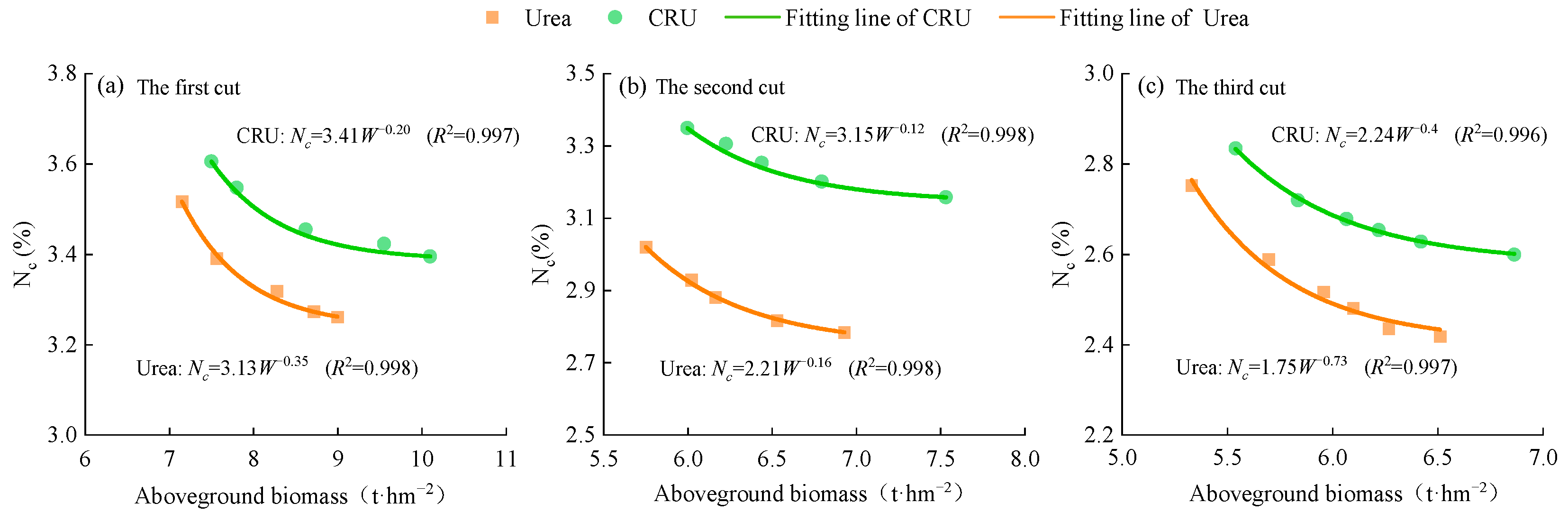

2.1.3. Construction of Critical Nitrogen Dilution Curve Models for Alfalfa

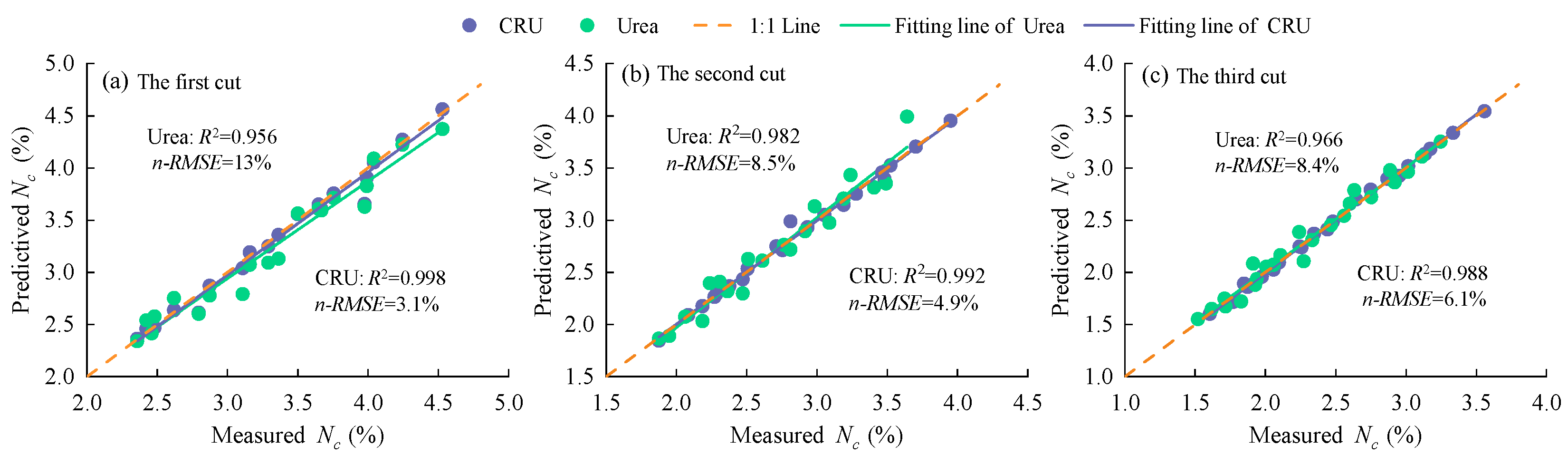

2.2. Validation of the Critical Nitrogen Dilution Curve Model for Alfalfa

2.3. Nitrogen Nutrition Diagnosis of Alfalfa Plants Under Different Nitrogen Fertilizer Management Strategies

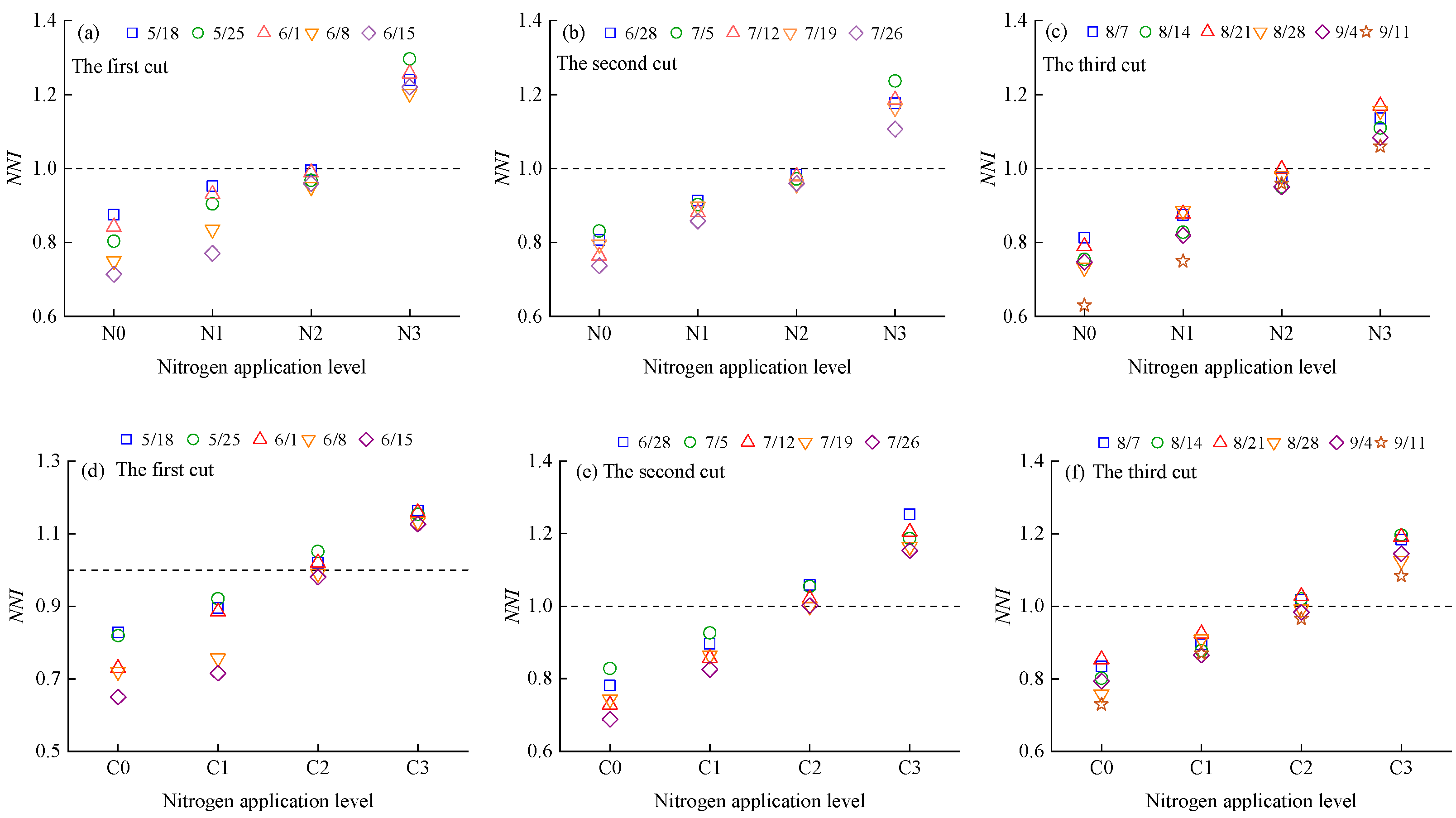

2.3.1. Nitrogen Nutrition Diagnosis Based on NNI

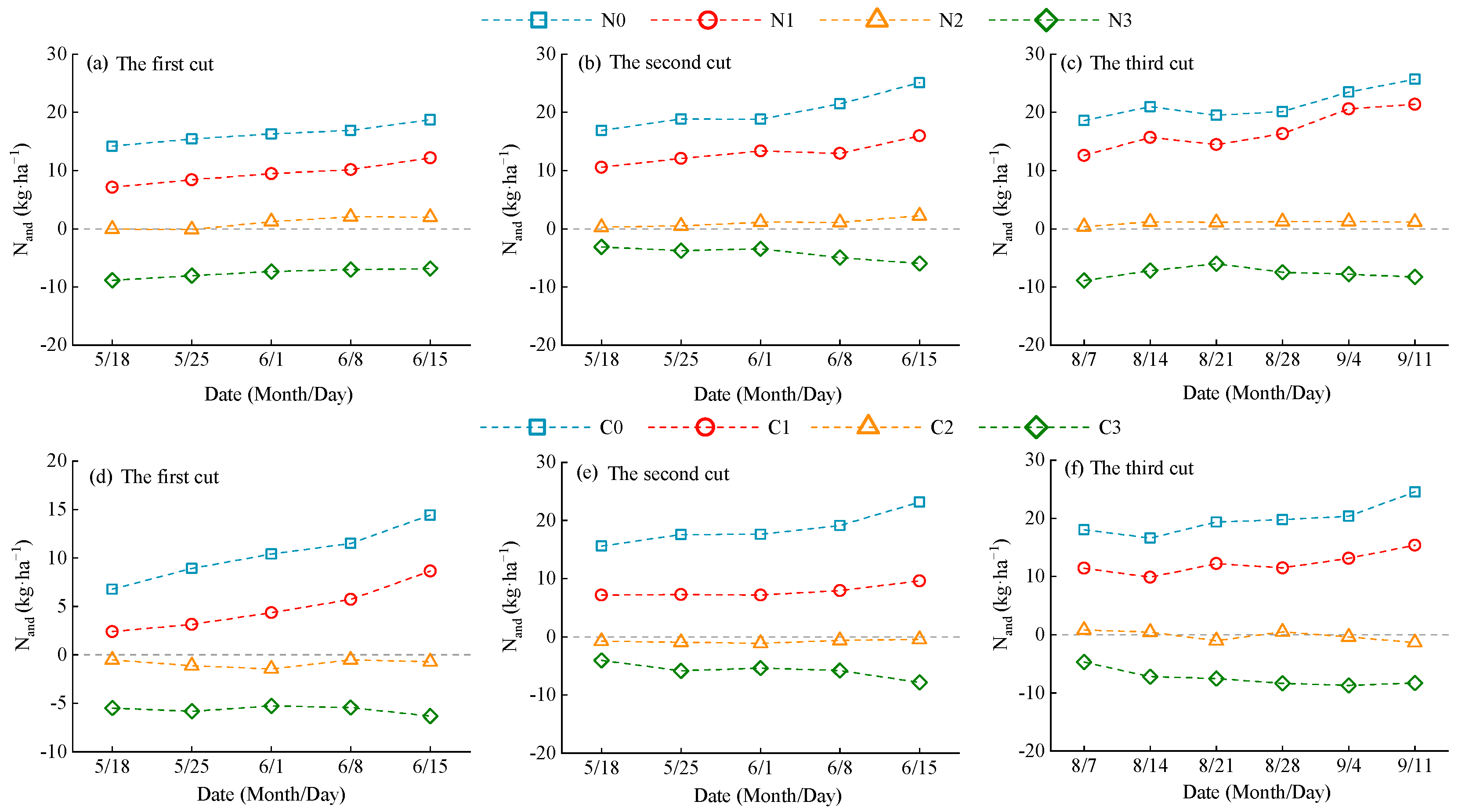

2.3.2. Nitrogen Nutrition Diagnosis of Alfalfa Based on Nand

2.4. Effects of Nitrogen Fertilizer Management on Alfalfa Yield

3. Discussion

3.1. Critical Nitrogen Dilution Curve Model for Alfalfa

3.2. Diagnosis of Nitrogen Nutrition in Alfalfa Plants

3.3. Yield-Increasing and Nitrogen-Saving Potential of Controlled Release Urea

4. Materials and Methods

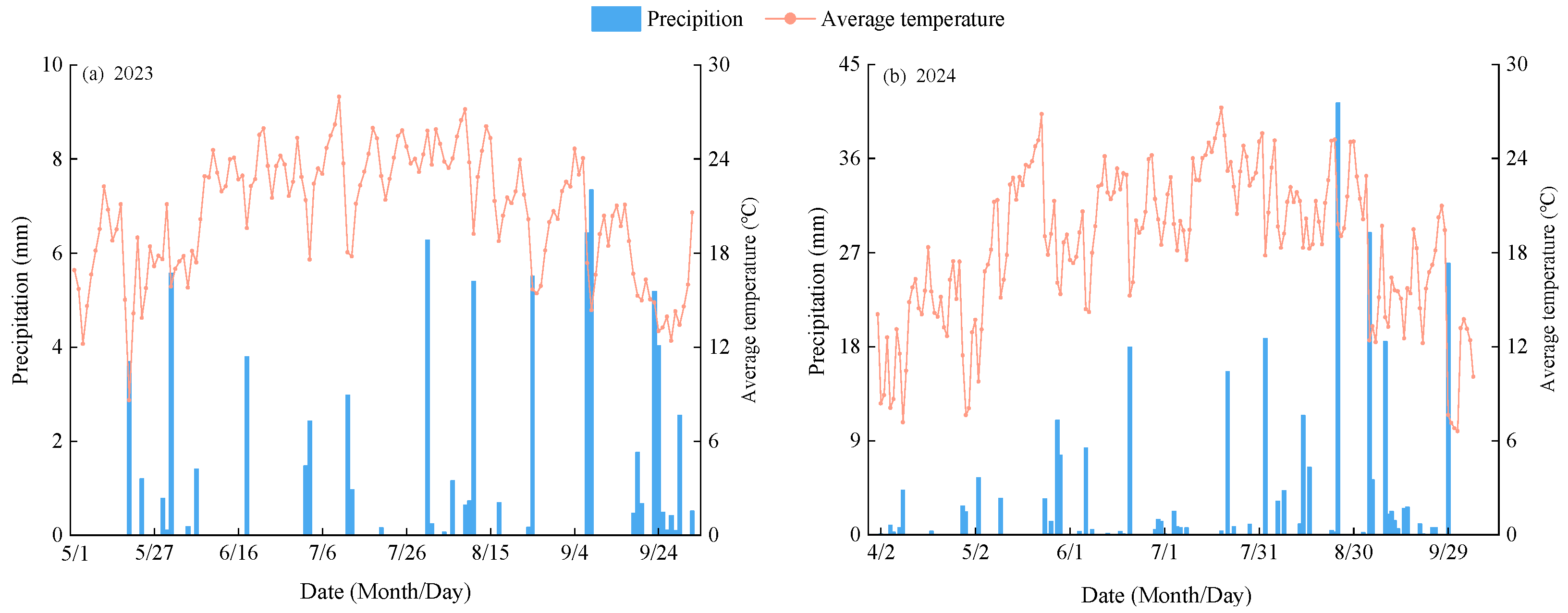

4.1. Experimental Site

4.2. Experimental Design

4.3. Measurement Items and Methods

4.3.1. Yield

4.3.2. Aboveground Biomass and Nitrogen Concentration

4.4. Model Description

4.4.1. Construction of the Critical Nitrogen Dilution Curve Model

- (1)

- Analysis of variance (ANOVA) was performed on the aboveground biomass data from each sampling date under different nitrogen treatments. Based on whether alfalfa growth was limited by nitrogen, the treatments were classified into nitrogen-limited (where increasing nitrogen significantly enhanced biomass accumulation) and non-nitrogen-limited groups (where further nitrogen application did not significantly increase biomass accumulation).

- (2)

- A linear regression was conducted between aboveground biomass and nitrogen concentration for the nitrogen-limited group.

- (3)

- The average aboveground biomass of the non-nitrogen-limited group was taken as the maximum attainable aboveground biomass.

- (4)

- For each sampling date, the theoretical critical nitrogen concentration was determined as the y-value (nitrogen concentration) at the intersection point of the linear regression line and a vertical line drawn at the maximum aboveground biomass on the x-axis.

4.4.2. Validation of the Critical Nitrogen Concentration Dilution Curve Model

4.5. Nitrogen Nutrition Diagnostic Models

4.5.1. Nitrogen Nutrition Index Model

4.5.2. Accumulated Nitrogen Deficit Model

4.5.3. Relative Yield

4.6. Statistics and Analysis of Data

5. Conclusions

- (1)

- The relationship between aboveground biomass and nitrogen concentration in alfalfa followed a power function. The critical nitrogen concentration dilution curve (CNDC) models constructed for the application of urea and controlled-release urea (CRU) to alfalfa all have R2 values > 0.99 and normalized root mean square errors (n-RMSE) ranging from 3.1~13%, indicating strong model reliability.

- (2)

- The nitrogen nutrition index (NNI) and cumulative nitrogen deficit (Nand) models constructed based on the CNDC effectively diagnosed nitrogen nutritional status in alfalfa, with consistent results between the two models. Treatments N2 and C2 were identified as optimal in maintaining nitrogen balance and crop performance.

- (3)

- Compared to urea, CRU application increased alfalfa yield by 6.60~23.19%. The optimal nitrogen application rates were 175.44~181.71 kg·ha−1 for urea and 145.63~153.40 kg·ha−1 for CRU. At theoretical maximum yield, CRU saved 18.41~20.47% of nitrogen input relative to urea.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cassman, K.G.; Dobermann, A. Nitrogen and the future of agriculture: 20 years on: This article belongs to ambio’s 50th anniversary collection. theme: Solutions-oriented research. Ambio 2022, 51, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.S.; Ye, H.H.; Yang, C.F.; Zhang, Y.; Pu, J.W.; Ren, Y.H.; Xie, K.; Wang, L.X.; Zeng, D.C.; He, H.Q.; et al. OsNLP3 and OsPHR2 orchestrate direct and mycorrhizal pathways for nitrate uptake by regulating NAR2.1-NRTs complexes in rice. Proc. Natl. Acad. Sci. USA 2025, 122, e2416345122. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.Z.; Hao, G.; Li, H.Y. Effects of availability and form of exogenous nitrogen on plant growth and physiology: Progress and prospects. Chin. J. Ecol. 2024, 43, 878–887. (In Chinese) [Google Scholar]

- Zhao, Y.; Wang, Y.Q.; Sun, S.N.; Liu, W.T.; Zhu, L.; Yan, X.B. Different Forms and Proportions of Exogenous Nitrogen Promote the Growth of Alfalfa by Increasing Soil Enzyme Activity. Plants 2022, 11, 1057. [Google Scholar] [CrossRef]

- Tyagi, J.; Ahmad, S.; Malik, M. Nitrogenous fertilizers: Impact on environment sustainability, mitigation strategies, and challenges. Int. J. Environ. Sci. Technol. 2022, 19, 49–72. [Google Scholar] [CrossRef]

- Gu, B.J.; Zhang, X.M.; Lam, S.K.; Yu, Y.L.; van Grinsven, H.J.M.; Zhang, S.H.; Wang, X.X.; Bodirsky, B.L.; Wang, S.T.; Duan, J.K.; et al. Publisher correction: Cost-effective mitigation of nitrogen pollution from global croplands. Nature 2023, 614, E19. [Google Scholar] [CrossRef]

- You, L.C.; Ros, G.H.; Chen, Y.L.; Shao, Q.; Young, M.D.; Zhang, F.S.; de Vries, W. Global mean nitrogen recovery efficiency in croplands can be enhanced by optimal nutrient, crop and soil management practices. Nat. Commun. 2023, 14, 5747. [Google Scholar] [CrossRef]

- Ullah, A.; Li, M.X.; Noor, J.; Tariq, A.; Liu, Y.; Shi, L.X. Effects of salinity on photosynthetic traits, ion homeostasis and nitrogen metabolism in wild and cultivated soybean. PeerJ 2019, 7, e8191. [Google Scholar] [CrossRef]

- Barłóg, P. Improving fertilizer use efficiency—Methods and strategies for the future. Plants 2023, 12, 3658. [Google Scholar] [CrossRef]

- Mishra, S.; Levengood, H.; Fan, J.P.; Zhang, C.K. Plants Under Stress: Exploring Physiological and Molecular Responses to Nitrogen and Phosphorus Deficiency. Plants 2024, 13, 3144. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, Z.D.; Syed, T.A.U.K.; Xiao, J.F.; Liu, Z.G.; Qi, A.Z.; Ning, D.F.; Nan, J.Q.; Duan, A.W. Rapid and nondestructive estimation of the nitrogen nutrition index in winter barley using chlorophyll measurements. Field Crops Res. 2016, 185, 59–68. [Google Scholar] [CrossRef]

- Kumar, K.; Parihar, C.M.; Nayak, H.S.; Sena, D.R.; Godara, S.; Dhakar, R.; Patra, K.; Sarkar, A.; Bharadwaj, S.; Ghasal, P.C.; et al. Modeling maize growth and nitrogen dynamics using ceres-maize (dssat) under diverse nitrogen management options in a conservation agriculture-based maize-wheat system. Sci. Rep. 2024, 14, 11743. [Google Scholar] [CrossRef] [PubMed]

- Xiong, D.L.; Chen, J.; Yu, T.T.; Gao, W.L.; Ling, X.X.; Li, Y.; Peng, S.B.; Huang, J.L. SPAD-based leaf nitrogen estimation is impacted by environmental factors and crop leaf characteristics. Sci. Rep. 2015, 5, 13389. [Google Scholar] [CrossRef] [PubMed]

- Xue, L.H.; Cao, W.X.; Luo, W.H.; Dai, T.B.; Zhu, Y. Monitoring leaf nitrogen status in rice with canopy spectral reflectance. Agron. J. 2004, 96, 135–142. [Google Scholar] [CrossRef]

- Zhao, Q.; Qu, Y.H. The retrieval of ground NDVI (normalized difference vegetation index) data consistent with remote-sensing observations. Remote Sens. 2024, 16, 1212. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Y.Y.; Xu, B.; Yang, G.J.; Feng, H.K.; Yang, X.D.; Yang, H.; Liu, C.B.; Cheng, Z.D.; Feng, Z.H. Study on the Estimation of leaf area index in rice based on UAV RGB and multispectral data. Remote Sens. 2024, 16, 3049. [Google Scholar] [CrossRef]

- Liu, C.; Liu, J.J.; Wang, J.; Ding, X.Y. Effects of Short-Term Nitrogen Additions on Biomass and Soil Phytochemical Cycling in Alpine Grasslands of Tianshan, China. Plants 2024, 13, 1103. [Google Scholar] [CrossRef]

- Dessureault-Rompré, J. Soil Nitrogen Supply: Linking Plant Available N to Ecosystem Functions and Productivity. Nitrogen 2022, 3, 5–7. [Google Scholar] [CrossRef]

- Ulrich, A. Physiological bases for assessing the nutritional requirements of plants. Annu. Rev. Plant Physiol. 1952, 3, 207–228. [Google Scholar] [CrossRef]

- Lei, H.J.; Fan, Y.M.; Xiao, Z.Y.; Jin, C.C.; Chen, Y.Y.; Pan, H.W. Comprehensive evaluation of tomato growth status under aerated drip irrigation based on critical nitrogen concentration and nitrogen nutrient diagnosis. Plants 2024, 13, 270. [Google Scholar] [CrossRef]

- Tang, L.; He, Z.Y.; Qiu, X.L.; Syed, T.A.U.K.; Li, Y.D.; Liu, X.J.; Cao, Q.; Zhu, Y.; Cao, W.X. Development of a critical nitrogen dilution curve of double cropping rice in south china. Front. Plant Sci. 2017, 8, 638. [Google Scholar]

- Yue, S.C.; Meng, Q.F.; Zhao, R.F.; Li, F.; Chen, X.P.; Zhang, F.S.; Cui, Z.L. Critical nitrogen dilution curve for optimizing nitrogen management of winter wheat production in the north china plain. Agron. J. 2012, 104, 523–529. [Google Scholar] [CrossRef]

- Du, L.J.; Li, Q.; Li, L.; Wu, Y.W.; Zhou, F.; Liu, B.X.; Zhao, B.; Li, X.L.; Liu, Q.L.; Kong, F.L.; et al. Construction of a critical nitrogen dilution curve for maize in southwest china. Sci. Rep. 2020, 10, 13084. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.; Xi, Q.L.; Zhang, S.Q.; He, J.; Liu, G.X.; Xue, G.; Xu, S.X.; Yang, T.Z. Critical nitrogen concentration dilution curve and nitrogen nutrition diagnosis of flue-cured tobacco under conditions of integration of water and fertilizer in tobacco-growing areas in central Henan. Acta Tabacaria Sin. 2019, 25, 58–66. (In Chinese) [Google Scholar]

- Sandaña, P.; Lobos, I.A.; Pavez, P.B.; Moscoso, C.J. Validation of a critical nitrogen dilution curve for hybrid ryegrasses. Grass Forage Sci. 2019, 74, 370–380. [Google Scholar] [CrossRef]

- De Oliveira, E.C.A.; De Castro Gava, G.J.; Trivelin, P.C.O.; Otto, R.; Franco, H.C.J. Determining a critical nitrogen dilution curve for sugarcane. J. Plant Nutr. Soil Sci. 2013, 176, 712–723. [Google Scholar] [CrossRef]

- Shlevin, E.; Zilberman, A.; Ben-Asher, J. Theoretical determination of a critical nitrogen dilution curve based on the carrot case study. Agric. Res. 2018, 7, 239–244. [Google Scholar] [CrossRef]

- Giletto, C.M.; Reussi Calvo, N.I.; Sandaña, P.; Echeverría, H.E.; Bélanger, G. Shoot and tuber-based critical nitrogen dilution curves for the prediction of the N status in potato. Eur. J. Agron. 2020, 119, 126114. [Google Scholar] [CrossRef]

- Mou, S.W.; Xie, J.; Luo, C.; Liu, T.N.; Yang, B.P.; Han, Q.F.; Liu, X.X. Establishment and verification of critical nitrogen concentration dilution curve of garlic in Guanzhong plain. Trans. Chin. Soc. Agric. Eng. 2019, 35, 126–133. (In Chinese) [Google Scholar]

- Feng, W.N.; Li, X.F.; Dong, H.L.; Qin, Y.K.; Sun, M.; Shao, J.J.; Zheng, C.S.; Li, P.C. Fruits-based critical nitrogen dilution curve for diagnosing nitrogen status in cotton. Front. Plant Sci. 2022, 13, 801968. [Google Scholar] [CrossRef]

- He, F.; Chen, S.; Zhang, Y.Y.; Chai, K.; Zhang, Q.; Kong, W.L.; Qu, S.Y.; Chen, L.; Zhang, F.; Li, M.N.; et al. Pan-genomic analysis highlights genes associated with agronomic traits and enhances genomics-assisted breeding in alfalfa. Nat. Genet. 2025, 57, 62–73. [Google Scholar] [CrossRef] [PubMed]

- Yu, T.F.; Hao, F.; Gao, K.; Xiong, M.; An, H.B. Productivity, soil fertility and enzyme activity of mixed forage grasslands improved by alfalfa and nitrogen addition in horqin sandy land, china. Sci. Rep. 2025, 15, 10748. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.; Sun, L.; Mao, L.N.; Li, J.Y.; Yan, B.H.; Li, B.; Li, X. Combined effects of cropping alfalfa (Medicago sativa L.) on the soil pore structure, microbial communities and organic carbon fractions in saline soils. Appl. Soil Ecol. 2025, 208, 105993. [Google Scholar] [CrossRef]

- Chen, D.D.; Wang, Y.R.; Han, Y.H. Effects of irrigation frequency and fertilizer rate on alfalfa seed yields in the Yellow River irrigated region. Acta Pratacult. Sin. 2016, 25, 154–163. (In Chinese) [Google Scholar]

- Liu, M.G.; Wang, Z.K.; Mu, L.; Xu, R.; Yang, H.M. Effect of regulated deficit irrigation on alfalfa performance under two irrigation systems in the Inland Arid Area of Midwestern China. Agric. Water Manag. 2021, 248, 106764. [Google Scholar] [CrossRef]

- Jing, B.; Shi, W.J.; Zhai, Z.M.; Chen, T. Optimizing nitrogen supply for maize based on critical nitrogen concentration and nitrogen residual effect under different irrigation levels. Plant Soil 2025, 1–17. [Google Scholar] [CrossRef]

- Lu, J.S.; Hu, T.T.; Li, Y.; Cui, X.L.; Cheng, M.H.; Yan, S.C.; Xiang, Y.Z.; Fan, J.L.; Zhang, F.C.; Xiong, Y.C. Effects of different water management strategies on critical nitrogen concentration dilution curves, nitrogen accumulation, and grain yield in winter wheat. Agric. Commun. 2024, 2, 100052. [Google Scholar] [CrossRef]

- Deng, L.J.; Xu, X.M.; Zhu, Y.M.; He, W.C.; Jin, M.H.; Liu, Y.H.; Lu, G.Q.; Lv, Z.F. Changes in dilution curves of critical nitrogen concentration in sweet potato under different potassium conditions. Field Crops Res. 2023, 303, 109130. [Google Scholar] [CrossRef]

- Lemaire, G.; Oosterom, E.V.; Sheehy, J.; Jeuffroy, M.H.; Massignam, A.; Rossato, L. Is crop N demand more closely related to dry matter accumulation or leaf area expansion during vegetative growth? Field Crops Res. 2007, 100, 91–106. [Google Scholar] [CrossRef]

- Gastal, F.; Lemaire, G. N uptake and distribution in crops: An agronomical and ecophysiological perspective. J. Exp. Bot. 2002, 53, 789–799. [Google Scholar] [CrossRef] [PubMed]

- Lemaire, G.; Cruz, P.; Gosse, G.; Chartier, M. Etude des relations entre la dynamique de prélèvement d’azote et la dynamique de croissance en matière sèche d’un peuplement de luzerne (Medicago Sativa L.). Agronomie 1985, 5, 685–692. [Google Scholar] [CrossRef]

- Chen, L.L.; Cheng, H.; Mao, P.S.; Yang, X.F.; Liang, Q.W.; Na, R.S. Establishment and Application of Critical Nitrogen Dilution Curve in Alfalfa (Medicago sativa L.) Seed Production. Chin. J. Grassl. 2017, 39, 13–18. [Google Scholar]

- Tkacz, A.; Ledermann, R.; Martyn, A.; Schornack, S.; Oldroyd, G.E.D.; Poole, P.S. Nodulation and nitrogen fixation in Medicago truncatula strongly alters the abundance of its root microbiota and subtly affects its structure. Environ. Microbiol. 2022, 24, 24–33. [Google Scholar] [CrossRef] [PubMed]

- Pislariu, C.E.; Murray, J.D.; Wen, J.Q.; Cosson, V.; Muni, R.R.D.; Wang, M.; Benedicto, V.A.; Andriankaja, A.; Cheng, X.F.; Jerez, I.T.; et al. A Medicago truncatula tobacco retrotransposon insertion mutant collection with defects in nodule development and symbiotic nitrogen fixation. Plant Physiol. 2012, 159, 86–99. [Google Scholar] [CrossRef]

- Qi, Z.L.; He, M.R.; Dai, X.L.; Dong, Y.J. The effect of controlled release of urea coated with natural rubber and biochemical inhibitor on soil nitrogen supply and winter wheat growth. Acta Pedol. Sin. 2022, 59, 08–19. [Google Scholar]

- Shaviv, A. Advances in controlled-release fertilizers. Adv. Agron. 2001, 71, 1–49. [Google Scholar]

- Liu, X.Y.; Han, H.H.; Gu, S.X.; Gao, R. Effects of urea application on soil organic nitrogen mineralization and nitrogen fertilizer availability in a rice–broad bean rotation system. Sustainability 2023, 15, 6091. [Google Scholar] [CrossRef]

- Sentek, V.; Velescu, A.; Wilcke, W.; Henke, C.; Peters, N.; Welp, G.; Amelung, W. Nitrogen release from different polymer-coated urea fertilizers in soil is affected by soil properties. Soil Use Manag. 2023, 39, 77–90. [Google Scholar] [CrossRef]

- Peoples, M.B.; Brockwell, J.; Herridge, D.F.; Rochester, I.J.; Alves, B.J.R.; Urquiaga, S.; Boddey, R.M.; Dakota, F.D.; Bhattarai, S.; Maskey, S.L.; et al. The contributions of nitrogen-fixing crop legumes to the productivity of agricultural systems. Symbiosis 2009, 48, 1–17. [Google Scholar] [CrossRef]

- Chang, C.; Yin, Q.; Liu, H.L. Study on cutting periods and cutting times of alfalfa. Chin. J. Grassl. 2013, 35, 53–56. (In Chinese) [Google Scholar]

- Alkhayri, J.M.; Ramakrishnan, R.; Toppo, V.; Chole, P.B.; Banadka, A.; Sudheer, W.N.; Nagella, P.; Shehata, W.F.; AlMssallem, M.Q.; Alessa, F.M.; et al. Plant secondary metabolites: The weapons for biotic stress management. Metabolites 2023, 13, 716. [Google Scholar] [CrossRef]

- Wang, M.Y.; Wang, H.; Hou, L.Y.; Zhu, Y.Q.; Zhang, Q.; Chen, L.L.; Mao, P.S. Development of a critical nitrogen dilution curve of Siberian wildrye for seed production. Field Crops Res. 2018, 219, 250–255. [Google Scholar]

- Ye, T.Y.; Zhang, Y.; Xuan, J.Y.; Wang, X.T.; Li, Y.; Xu, J.H.; Xiao, L.J.; Liu, L.L.; Tang, L.; Cao, W.X.; et al. Development of a novel critical nitrogen concentration–cumulative transpiration curve for optimizing nitrogen management under varying irrigation conditions in winter wheat. Crop J. 2024, 12, 42–51. [Google Scholar]

- Wang, R.Z.; Dijkstra, F.A.; Han, X.G.; Jiang, Y. Root nitrogen reallocation: What makes it matter? Trends Plant Sci. 2024, 29, 77–88. [Google Scholar]

- Brown, R.W.; Chadwick, D.R.; Zang, H.; Jones, D.L. Use of metabolomics to quantify changes in soil microbial function in response to fertiliser nitrogen supply and extreme drought. Soil Biol. Biochem. 2021, 160, 108351. [Google Scholar] [CrossRef]

- Yang, Y.T.; Dong, J.Q.; Gu, R.; Shi, R.R.; Shi, F.L. Effects of low temperature on distribution and metabolism enzyme activity of carbon and nitrogen of Medicago ruthenica (L.). Grassl. Sci. 2023, 69, 42–50. [Google Scholar] [CrossRef]

- Ma, H.M.; Jia, Y.; Wang, W.Q.; Wang, J.; Zou, D.T.; Wang, J.G.; Gong, W.B.; Han, Y.M.; Dang, Y.X.; Wang, J.; et al. Effects of low-temperature stress during the grain-filling stage on carbon–nitrogen metabolism and grain yield formation in rice. Agronomy 2025, 15, 417. [Google Scholar] [CrossRef]

- Sharma, S.; Bhatt, U.; Sharma, J.; Kalaji, H.M.; Mojski, J.; Soni, V. Ultrastructure, adaptability, and alleviation mechanisms of photosynthetic apparatus in plants under waterlogging: A review. Photosynthetica 2022, 60, 430–444. [Google Scholar] [CrossRef]

- Du, K.; Zhao, W.Q.; Lv, Z.W.; Xu, B.; Hu, W.; Zhou, Z.G.; Wang, Y.H. Optimal rate of nitrogen fertilizer improves maize grain yield by delaying the senescence of ear leaves and thereby altering their nitrogen remobilization. Field Crops Res. 2024, 310, 109359. [Google Scholar] [CrossRef]

- Cui, X.Q.; Bo, Y.; Adalibieke, W.; Winiwarter, W.; Zhang, X.; Davidson, E.A.; Sun, Z.X.; Tian, H.; Smith, P.; Zhou, F. The global potential for mitigating nitrous oxide emissions from croplands. One Earth 2024, 7, 401–420. [Google Scholar] [CrossRef]

- Rubel, R.I.; Wei, L.; Alanazi, S.; Aldekhail, A.; Cidreira, A.M.; Yang, X.F.; Wasti, S.; Bhagia, S.; Zhao, X.H. Biochar-compost-based controlled-release nitrogen fertilizer intended for an active microbial community. Front. Agric. Sci. Eng. 2024, 11, 326–343. [Google Scholar]

- Li, H.F.; An, S.D.; Zhang, L.Y.; Peng, H.; Ma, W.Z.; Meng, X.Y.; Ye, H.M. Urea fertilizer with precisely regulable slow-release performance by complexing with random copolyester. J. Environ. Chem. Eng. 2021, 9, 105120. [Google Scholar]

- Ransom, C.J.; Jolley, V.D.; Blair, T.A.; Sutton, L.E.; Hopkins, B.G. Nitrogen release rates from slow- and controlled-release fertilizers influenced by placement and temperature. PLoS ONE 2020, 15, e0234544. [Google Scholar]

- Duff, A.M.; Forrestal, P.; Ikoyi, I.; Brennan, F. Assessing the long-term impact of urease and nitrification inhibitor use on microbial community composition, diversity and function in grassland soil. Soil Biol. Biochem. 2022, 170, 108709. [Google Scholar]

- Mendonca Cidreira, A.C.; Wei, L.; Aldekhail, A.; Islam Rubel, R. Controlled-release nitrogen fertilizers: A review on bio-based and smart coating materials. J. Appl. Polym. Sci. 2025, 142, e56390. [Google Scholar] [CrossRef]

- Gao, L.M.; Su, J.; Tian, Q.; Shen, Y.X. Effects of nitrogen application on nitrogen accumulation and root nitrogenase activity in Medicago sativa at different soil water contents. Acta Pratacult. Sin. 2020, 29, 130–136. (In Chinese) [Google Scholar]

- Ma, Q.; Qian, C.C.; Jia, W.X.; Wu, Y.L.; Li, C.Y.; Ding, J.F.; Zhu, M.; Guo, W.S.; Zhu, X.K. Effect of coated urea type and fertilization pattern on lodging resistance and yield of wheat following rice. Chin. J. Eco-Agric. 2022, 30, 74–83. (In Chinese) [Google Scholar]

- Yin, M.H.; Li, Y.N.; Gu, X.B.; Zhou, C.M.; Dong, L.L.; Zhang, T.L. Effects of nitrogen application rates on nitrogen surplus and nitrogen use efficiency of summer maize. Trans. Chin. Soc. Agric. Eng. 2015, 46, 167–176. (In Chinese) [Google Scholar]

- Justes, E. Determination of a critical nitrogen dilution curve for winter wheat crops. Ann. Bot. 1994, 74, 397–407. [Google Scholar] [CrossRef]

- Greenwood, D.J.; Gastal, F.; Lemaire, G.; Draycott, A.; Millard, P.; Neeteson, J.J. Growth rate and %N of field grown crops: Theory and experiments. Ann. Bot. 1991, 67, 181–190. [Google Scholar]

- Brendel, A.E. Some comments on the evaluation of transducer performance. Exp. Tech. 1983, 7, 20–21. [Google Scholar] [CrossRef]

| Nitrogen Fertilizer Type | Nitrogen Application Rate (kg·ha−1) | The First Cut (%) | The Second Cut (%) | The Third Cut (%) |

|---|---|---|---|---|

| Urea | N0 | 2.96 e | 2.59 d | 2.35 d |

| N1 | 3.17 d | 2.76 cd | 2.49 cd | |

| N2 | 3.35 cd | 2.90 c | 2.63 cb | |

| N3 | 3.61 ab | 3.11 b | 2.79 ab | |

| CRU | C0 | 2.96 e | 2.59 d | 2.35 d |

| C1 | 3.23 d | 2.87 c | 2.53 cd | |

| C2 | 3.49 bc | 3.13 b | 2.72 b | |

| C3 | 3.79 a | 3.36 a | 2.94 a |

| Year | Nitrogen Fertilizer Type | Regression Equation | R2 | Maximum Yield (t·ha−1) | Optimum Nitrogen Rate (kg·ha−1) |

|---|---|---|---|---|---|

| 2023 | Urea | y = −9.96 × 10−5x2 + 0.04x + 11.47 | 0.925 | 14.76 | 181.71 |

| CRU | y = −2.22 × 10−4x2 + 0.07x + 11.54 | 0.987 | 16.76 | 153.46 | |

| 2024 | Urea | y = −1.14 × 10−4x2 + 0.04x + 13.89 | 0.846 | 17.40 | 175.44 |

| CRU | y = −3.09 × 10−4x2 + 0.09x + 14.11 | 0.998 | 20.66 | 145.63 |

| Nitrogen Type | Nitrogen Application Rate (kg·ha−1) |

|---|---|

| Urea | 0 (N0) |

| 80 (N1) | |

| 160 (N2) | |

| 240 (N3) | |

| CRU | 0 (C0) |

| 80 (C1) | |

| 160 (C2) | |

| 240 (C3) |

| Year | The First Cut | The Second Cut | The Third Cut |

|---|---|---|---|

| 2023 | 18 May | 28 June | 7 August |

| 25 May | 5 July | 14 August | |

| 1 June | 12 July | 21 August | |

| 8 June | 19 July | 28 August | |

| 15 June | 26 July | 4 September | |

| − | − | 11 September | |

| 2024 | 16 May | 25 June | 5 August |

| 23 May | 2 July | 12 August | |

| 30 May | 9 July | 18 August | |

| 6 June | 16 July | 21 August | |

| 13 June | 22 July | 2 September | |

| − | − | 9 Septemper |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Y.; Ling, Y.; Li, H.; Chang, W.; Lu, J.; Yin, M.; Kang, Y.; Ma, Y.; Wang, Y.; Qi, G.; et al. Optimizing Management of Alfalfa (Medicago sativa L.) Nitrogen Fertilizer Based on Critical Nitrogen Concentration Dilution Curve Model. Plants 2025, 14, 1782. https://doi.org/10.3390/plants14121782

Duan Y, Ling Y, Li H, Chang W, Lu J, Yin M, Kang Y, Ma Y, Wang Y, Qi G, et al. Optimizing Management of Alfalfa (Medicago sativa L.) Nitrogen Fertilizer Based on Critical Nitrogen Concentration Dilution Curve Model. Plants. 2025; 14(12):1782. https://doi.org/10.3390/plants14121782

Chicago/Turabian StyleDuan, Yaya, Yi Ling, Haiyan Li, Wenjing Chang, Jiandong Lu, Minhua Yin, Yanxia Kang, Yanlin Ma, Yayu Wang, Guangping Qi, and et al. 2025. "Optimizing Management of Alfalfa (Medicago sativa L.) Nitrogen Fertilizer Based on Critical Nitrogen Concentration Dilution Curve Model" Plants 14, no. 12: 1782. https://doi.org/10.3390/plants14121782

APA StyleDuan, Y., Ling, Y., Li, H., Chang, W., Lu, J., Yin, M., Kang, Y., Ma, Y., Wang, Y., Qi, G., & Shen, G. (2025). Optimizing Management of Alfalfa (Medicago sativa L.) Nitrogen Fertilizer Based on Critical Nitrogen Concentration Dilution Curve Model. Plants, 14(12), 1782. https://doi.org/10.3390/plants14121782