Response of Flavor Substances in Tomato Fruit to Light Spectrum and Daily Light Integral

Abstract

1. Introduction

2. Results

2.1. Effects of Light Spectrum and DLI on the Growth of Tomato Plants

2.2. Effects of Light Spectrum and DLI on Tomato Fruit Quality

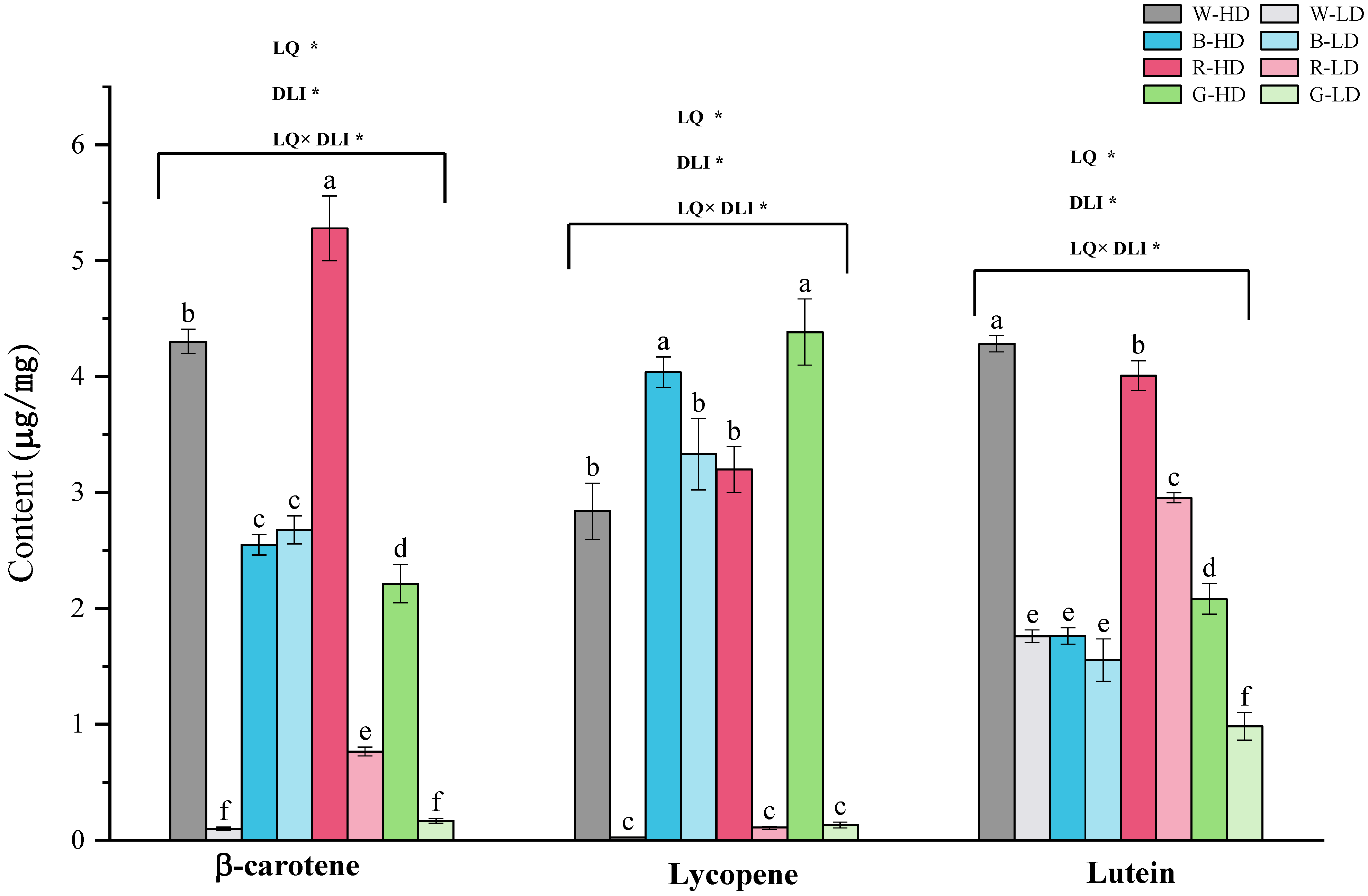

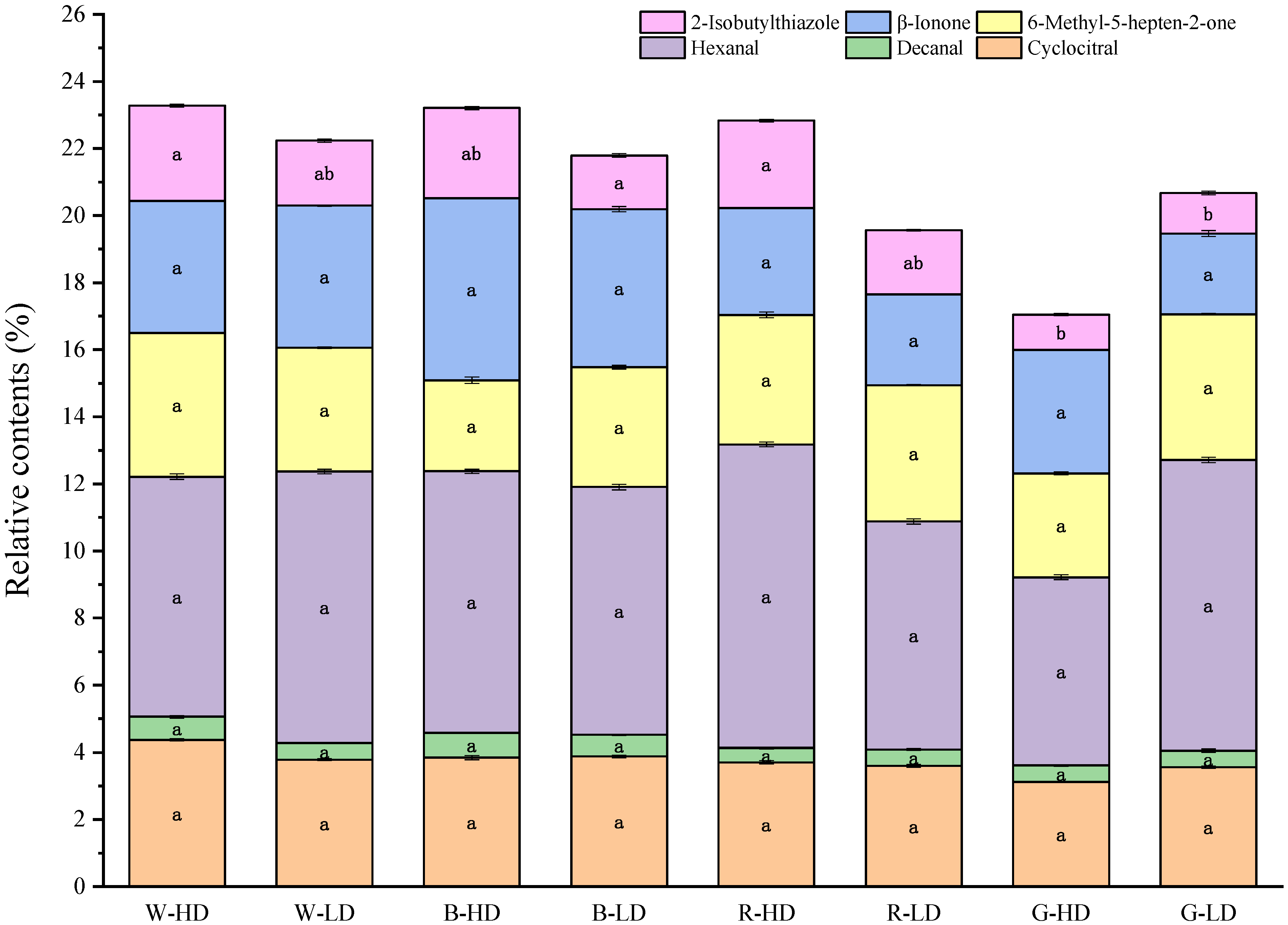

2.3. Effect of Light Spectrum and DLI on Flavor Substance Content of Tomato Fruits

2.4. Comprehensive Evaluation

3. Discussion

3.1. Effect of Light Spectrum and DLI on Growth of Tomato Plants

3.2. Effect of Light Spectrum and DLI on Nutritional Quality and Flavor Index of Tomato

4. Materials and Methods

4.1. Materials

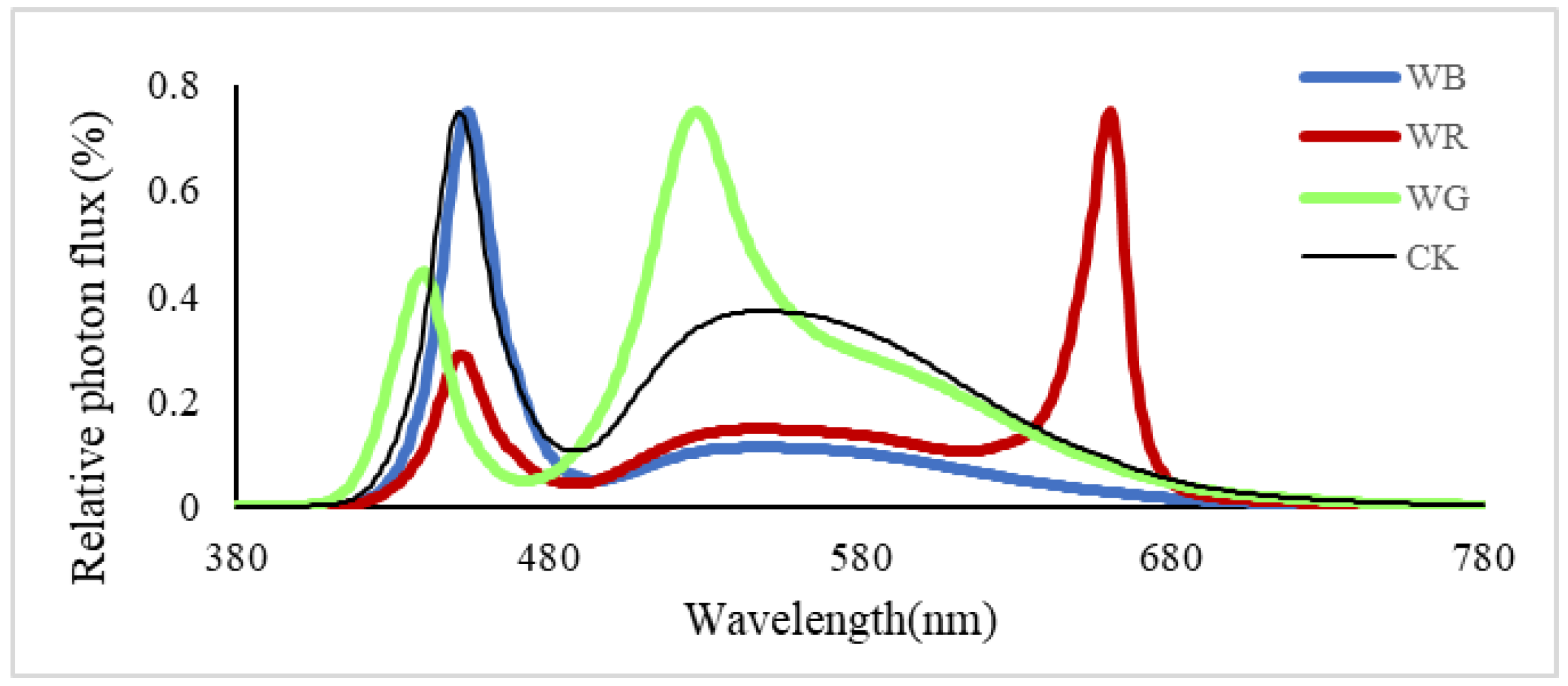

4.2. Light Treatments

4.3. Instruments and Measurement Methods

4.4. Calculation of Data

4.5. Data Analysis

- (1)

- Index dimensionless processing:

- (2)

- Data standardization:

- (3)

- Entropy value calculation of the jth:

- (4)

- Calculation of coefficient of difference:

- (5)

- Determine the weight wj of the indicator j and calculate the comprehensive score:

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Reservation Time (min) | Volatile Substance Composition | Chemical Formula | W-HD | W-LD | B-HD | B-LD | R-HD | R-LD | G-HD | G-LD | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100% | ||||||||||||||||||

| Aldehydes | ||||||||||||||||||

| 4.3 | Hexanal | C6H12O | 7.16 ± 0.01 | a | 8.10 ± 0.02 | a | 7.80 ± 0.01 | a | 7.39 ± 0.01 | a | 9.05 ± 0.01 | a | 6.80 ± 0.31 | a | 5.61 ± 0.02 | a | 8.66 ± 0.03 | a |

| 5.36 | 2-Hexenal | C6H10O | 22.28 ± 0.11 | a | 29.45 ± 0.07 | a | 22.76 ± 0.07 | a | 20.49 ± 0.02 | a | 25.04 ± 0.02 | a | 26.24 ± 0.03 | a | 24.48 ± 0.08 | a | 21.01 ± 0.08 | a |

| 7.69 | 2-Heptenal | C7H12O | 0.71 ± 0.01 | a | 0.39 ± 0.01 | a | 0.96 ± 0.01 | a | 0.66 ± 0.01 | a | 0.56 ± 0.01 | a | 0.53 ± 0.01 | a | 0.40 ± 0.01 | a | 0.65 ± 0.01 | a |

| 9.08 | 2,4-Heptadienal | C7H10O | 0.41 ± 0.01 | a | 0.23 ± 0.02 | a | 0.45 ± 0.01 | a | 0.49 ± 0.05 | a | 0.30 ± 0.01 | a | 0.43 ± 0.01 | a | 0.35 ± 0.02 | a | 0.25 ± 0.01 | a |

| 9.51 | 2-Nonenal | C9H16O | 0.07 ± 0.01 | b | 0.06 ± 0.01 | b | 0.22 ± 0.01 | ab | 0.27 ± 0.01 | a | 0.21 ± 0.01 | a | 0.05 ± 0.01 | b | 0.18 ± 0.01 | ab | 0.07 ± 0.01 | b |

| 10.12 | 5-Octen-2-yn-4-ol | C8H12O | 0.21 ± 0.01 | a | 0.24 ± 0.01 | a | 0.17 ± 0.01 | a | 0.16 ± 0.01 | a | 0.16 ± 0.01 | a | 0.16 ± 0.01 | a | 0.17 ± 0.01 | a | 0.20 ± 0.01 | a |

| 10.22 | 2-Octenal | C8H14O | 2.53 ± 0.02 | a | 1.33 ± 0.01 | a | 1.93 ± 0.01 | a | 1.67 ± 0.01 | a | 2.01 ± 0.01 | a | 2.27 ± 0.01 | a | 1.38 ± 0.01 | a | 2.3 ± 0.01 | a |

| 11.37 | Nonanal | C9H18O | 2.20 ± 0.01 | a | 1.31 ± 0.01 | a | 1.49 ± 0.01 | a | 1.20 ± 0.01 | a | 1.32 ± 0.01 | a | 1.21 ± 0.01 | a | 1.51 ± 0.01 | a | 1.79 ± 0.01 | a |

| 13.83 | Decanal | C10H20O | 1.27 ± 0.01 | a | 1.01 ± 0.01 | a | 1.17 ± 0.01 | a | 0.93 ± 0.01 | a | 0.70 ± 0.01 | a | 0.66 ± 0.01 | a | 1.21 ± 0.01 | a | 1.11 ± 0.01 | a |

| 14.06 | 2,4-Nonadienal | C9H14O | 0.32 ± 0.01 | ab | 0.19 ± 0.01 | ab | 0.47 ± 0.01 | ab | 0.51 ± 0.01 | a | 0.17 ± 0.01 | b | 0.18 ± 0.01 | b | 0.30 ± 0.01 | ab | 0.21 ± 0.01 | ab |

| 14.26 | 1-Cyclohexene-1-carboxaldehyde | C10H16O | 0.58 ± 0.01 | a | 0.59 ± 0.01 | a | 0.52 ± 0.01 | a | 0.51 ± 0.01 | a | 0.52 ± 0.01 | a | 0.38 ± 0.01 | a | 0.50 ± 0.01 | a | 0.46 ± 0.01 | a |

| 14.71 | 2,6-Octadienal | C10H16O | 1.21 ± 0.01 | a | 1.14 ± 0.01 | a | 0.99 ± 0.01 | a | 1.20 ± 0.01 | a | 1.14 ± 0.01 | a | 1.11 ± 0.01 | a | 0.88 ± 0.01 | a | 1.01 ± 0.01 | a |

| 14.82 | 4-Oxononanal | C9H16O2 | 0.20 ± 0.01 | ab | 0.19 ± 0.01 | ab | 0.31 ± 0.01 | a | 0.26 ± 0.01 | ab | 0.16 ± 0.01 | ab | 0.16 ± 0.01 | ab | 0.20 ± 0.01 | ab | 0.14 ± 0.01 | ab |

| 15.16 | 2-Decenal | C10H18O | 0.69 ± 0.01 | a | 0.48 ± 0.01 | a | 0.73 ± 0.01 | a | 0.64 ± 0.01 | a | 0.42 ± 0.01 | a | 0.48 ± 0.01 | a | 0.49 ± 0.01 | a | 0.49 ± 0.01 | a |

| 15.4 | Cyclocitral | C10H16O | 4.36 ± 0.01 | a | 3.79 ± 0.01 | a | 3.85 ± 0.01 | a | 3.88 ± 0.01 | a | 3.71 ± 0.01 | a | 3.60 ± 0.01 | a | 3.12 ± 0.01 | a | 3.56 ± 0.01 | a |

| 16.43 | 2,4-Decadienal | C10H16O | 0.97 ± 0.01 | a | 0.37 ± 0.01 | a | 0.65 ± 0.01 | a | 0.64 ± 0.01 | a | 0.67 ± 0.01 | a | 0.74 ± 0.01 | a | 0.34 ± 0.01 | a | 0.61 ± 0.01 | a |

| 17.81 | Hexadecyl 3-methylbut-3-enyl ester | C25H44O4 | 0.87 ± 0.01 | a | 0.80 ± 0.01 | a | 1.09 ± 0.01 | a | 1.07 ± 0.01 | a | 0.75 ± 0.01 | a | 0.60 ± 0.01 | a | 0.78 ± 0.01 | a | 0.60 ± 0.01 | a |

| 18.42 | Dodecanal | C12H24O | 0.22 ± 0.01 | a | 0.21 ± 0.01 | a | 0.22 ± 0.01 | a | 0.20 ± 0.01 | a | 0.18 ± 0.01 | a | 0.15 ± 0.01 | a | 0.21 ± 0.01 | a | 0.15 ± 0.01 | a |

| 19.64 | 8-Hexadecenal, 14-methyl-, (Z)- | C17H32O | 0.28 ± 0.01 | ab | 0.19 ± 0.01 | ab | 0.37 ± 0.01 | a | 0.32 ± 0.01 | ab | 0.21 ± 0.01 | ab | 0.17 ± 0.01 | ab | 0.20 ± 0.01 | ab | 0.14 ± 0.01 | b |

| Total | 45.27 | 49.06 | 44.98 | 41.56 | 41.10 | 42.30 | 46.58 | 45.26 | ||||||||||

| Ketone | ||||||||||||||||||

| 8.47 | 5-Hepten-2-one, 6-methyl- | C8H14O | 4.29 ± 0.02 | a | 3.69 ± 0.02 | a | 2.72 ± 0.01 | a | 3.57 ± 0.01 | a | 3.86 ± 0.01 | a | 4.07 ± 0.01 | a | 3.09 ± 0.01 | a | 4.35 ± 0.02 | a |

| 12.42 | 8-Decen-2-one | C12H20O | 0.19 ± 0.01 | b | 0.17 ± 0.01 | b | 0.18 ± 0.01 | b | 0.32 ± 0.01 | b | 0.20 ± 0.01 | b | 0.13 ± 0.01 | b | 0.14 ± 0.01 | a | 0.16 ± 0.01 | b |

| 18.89 | α-Ionone | C13H20O | 0.27 ± 0.01 | a | 0.16 ± 0.01 | a | 0.27 ± 0.01 | a | 0.24 ± 0.01 | a | 0.16 ± 0.01 | a | 0.12 ± 0.01 | a | 0.21 ± 0.01 | a | 0.09 ± 0.01 | a |

| 19.42 | 5,9-Undecadien-2-one, 6,10-dimethyl- | C13H22O | 23.27 ± 0.04 | ab | 17.95 ± 0.02 | b | 21.4 ± 0.02 | ab | 23.47 ± 0.02 | a | 21.02 ± 0.02 | ab | 19.80 ± 0.02 | ab | 15.26 ± 0.09 | b | 14.59 ± 0.04 | b |

| 20.14 | β-Ionone | C13H20O | 3.94 ± 0.02 | a | 4.24 ± 0.02 | a | 5.43 ± 0.02 | a | 4.71 ± 0.01 | a | 3.20 ± 0.02 | a | 2.70 ± 0.02 | a | 3.67 ± 0.02 | a | 2.41 ± 0.01 | a |

| 21 | 3,5,9-Undecatrien-2-one, 6,10-dimethyl-, (E,Z)- | C13H20O | 0.38 ± 0.01 | ab | 0.23 ± 0.001 | ab | 0.37 ± 0.01 | ab | 0.47 ± 0.01 | a | 0.28 ± 0.01 | ab | 0.26 ± 0.01 | ab | 0.23 ± 0.01 | ab | 0.18 ± 0.01 | b |

| 22.29 | Propanoic acid | C16H30O4 | 0.33 ± 0.01 | a | 1.36 ± 0.02 | a | 0.43 ± 0.01 | a | 0.28 ± 0.01 | a | 0.32 ± 0.01 | a | 1.30 ± 0.02 | a | 1.05 ± 0.01 | a | 0.45 ± 0.01 | a |

| 27.99 | 5,9,13-Pentadecatrien-2-one | C18H30O | 4.80 ± 0.02 | ab | 3.98 ± 0.03 | ab | 6.76 ± 0.01 | ab | 10.14 ± 0.01 | a | 7.01 ± 0.04 | ab | 4.37 ± 0.03 | ab | 5.66 ± 0.05 | ab | 3.37 ± 0.04 | b |

| Total | 37.47 | 31.78 | 37.56 | 43.2 | 29.31 | 25.6 | 36.05 | 32.75 | ||||||||||

| Esters | ||||||||||||||||||

| 15.91 | 2,4-Dodecadienal | C12H20O | 0.72 ± 0.01 | a | 0.23 ± 0.01 | a | 0.37 ± 0.01 | a | 0.38 ± 0.01 | a | 0.48 ± 0.01 | a | 0.60 ± 0.01 | a | 0.28 ± 0.01 | a | 0.53 ± 0.01 | a |

| 9.92 | Phenylacetic acid | C12H14O2 | 0.18 ± 0.01 | b | 0.19 ± 0.01 | b | 0.31 ± 0.01 | b | 0.29 ± 0.01 | b | 0.30 ± 0.01 | b | 0.31 ± 0.01 | b | 0.27 ± 0.01 | b | 0.62 ± 0.01 | a |

| 7.84 | E-2-Hexenyl benzoate | C13H16O2 | 1.11 ± 0.01 | a | 1.70 ± 0.01 | a | 1.13 ± 0.01 | a | 1.90 ± 0.01 | a | 1.67 ± 0.01 | a | 0.99 ± 0.01 | a | 1.05 ± 0.01 | a | 1.36 ± 0.01 | a |

| 11.12 | Ethanone, 1-(1-cyclohexen-1-yl) | C8H12O | 0.44 ± 0.01 | ab | 0.30 ± 0.01 | ab | 0.47 ± 0.01 | b | 0.63 ± 0.01 | ab | 0.70 ± 0.01 | ab | 0.44 ± 0.01 | ab | 1.03 ± 0.01 | b | 0.39 ± 0.01 | a |

| 12.73 | 6-Nonenal | C9H16O | 1.44 ± 0.01 | a | 1.15 ± 0.01 | a | 0.91 ± 0.01 | a | 1.38 ± 0.01 | a | 0.76 ± 0.01 | a | 1.44 ± 0.01 | a | 1.62 ± 0.01 | a | 0.95 ± 0.01 | a |

| 12.88 | 10,13-Octadecadiynoic acid | C19H30O2 | 0.19 ± 0.01 | b | 0.25 ± 0.01 | b | 0.30 ± 0.01 | ab | 0.23 ± 0.01 | b | 0.32 ± 0.01 | b | 0.19 ± 0.01 | b | 0.46 ± 0.01 | a | 0.24 ± 0.01 | b |

| 13.66 | Methyl salicylate | C8H8O3 | 5.48 ± 0.09 | a | 4.63 ± 0.07 | a | 3.04 ± 0.03 | a | 0.57 ± 0.01 | a | 5.78 ± 0.09 | a | 9.55 ± 0.10 | a | 18.65 ± 0.23 | a | 20.52 ± 0.13 | a |

| 16.18 | Undecanal | C11H22O | 0.31 ± 0.01 | a | 0.29 ± 0.01 | a | 0.37 ± 0.01 | a | 0.42 ± 0.01 | a | 0.32 ± 0.01 | a | 0.20 ± 0.01 | a | 0.27 ± 0.01 | a | 0.17 ± 0.01 | a |

| Total | 9.87 | 8.74 | 6.90 | 5.80 | 23.63 | 24.78 | 10.33 | 13.72 | ||||||||||

| Alcohols | ||||||||||||||||||

| 11.3 | 1,6-Octadien-3-ol | C10H18O | 0.34 ± 0.01 | a | 0.50 ± 0.01 | a | 0.20 ± 0.01 | a | 0.21 ± 0.01 | a | 0.31 ± 0.01 | a | 0.37 ± 0.01 | a | 0.35 ± 0.01 | a | 0.37 ± 0.01 | a |

| 17.71 | cis-4,5-Epoxy-(E)-2-decenal | C10H16O2 | 0.30 ± 0.01 | a | 0.33 ± 0.01 | a | 0.42 ± 0.01 | a | 0.34 ± 0.01 | a | 0.27 ± 0.01 | a | 0.29 ± 0.01 | a | 0.32 ± 0.01 | a | 0.27 ± 0.01 | a |

| 20.9 | trans-Geranylgeraniol | C20H34O | 0.29 ± 0.01 | ab | 0.23 ± 0.01 | ab | 0.34 ± 0.01 | ab | 0.39 ± 0.01 | a | 0.27 ± 0.01 | ab | 0.20 ± 0.01 | ab | 0.22 ± 0.01 | ab | 0.15 ± 0.01 | b |

| 22.53 | Cedrol | C15H26O | 0.24 ± 0.01 | a | 2.39 ± 0.04 | a | 0.48 ± 0.01 | a | 0.25 ± 0.01 | a | 0.33 ± 0.01 | a | 1.89 ± 0.03 | a | 1.06 ± 0.02 | a | 0.43 ± 0.01 | a |

| Total | 2.44 | 4.46 | 2.61 | 2.12 | 3.16 | 2.33 | 1.88 | 3.42 | ||||||||||

| Other chemical | ||||||||||||||||||

| composition | ||||||||||||||||||

| 9.63 | 2-Isobutylthiazole | C7H11NS | 2.84 ± 0.01 | a | 1.95 ± 0.01 | ab | 1.60 ± 0.01 | ab | 2.69 ± 0.02 | a | 2.60 ± 0.01 | a | 1.91 ± 0.01 | ab | 1.05 ± 0.01 | b | 1.20 ± 0.01 | b |

| 13.17 | 3-(1-Cyclopentenyl)furan | C9H10O | 0.14 ± 0.01 | a | 0.10 ± 0.01 | a | 0.14 ± 0.01 | a | 0.15 ± 0.01 | a | 0.11 ± 0.01 | a | 0.08 ± 0.01 | a | 0.09 ± 0.01 | a | 0.10 ± 0.01 | a |

| 16.49 | 3-Nonen-5-yne, 4-ethyl- | C11H18 | 1.06 ± 0.01 | ab | 0.45 ± 0.01 | b | 1.58 ± 0.01 | ab | 1.93 ± 0.01 | a | 1.17 ± 0.01 | ab | 0.91 ± 0.01 | ab | 0.92 ± 0.01 | ab | 0.56 ± 0.01 | b |

| 17.45 | 3-(1-Cyclopentenyl)furan | C11H20O | 0.66 ± 0.01 | ab | 2.28 ± 0.03 | ab | 3.19 ± 0.02 | a | 1.50 ± 0.01 | ab | 0.50 ± 0.01 | b | 1.18 ± 0.01 | ab | 0.66 ± 0.01 | ab | 0.38 ± 0.01 | b |

| 12.18 | 8-Decen-2-one, 9-methyl-5-methylene | C10H18 | 0.51 ± 0.01 | c | 0.54 ± 0.01 | c | 0.78 ± 0.01 | ab | 0.94 ± 0.01 | a | 0.59 ± 0.01 | bc | 0.62 ± 0.01 | abc | 0.56 ± 0.01 | c | 0.93 ± 0.01 | ab |

| 23.68 | Hexadecane, 1,1-bis(dodecyloxy)- | C40H82O2 | 0.18 ± 0.01 | ab | 0.12 ± 0.01 | ab | 0.28 ± 0.01 | a | 0.26 ± 0.01 | ab | 0.18 ± 0.01 | ab | 0.10 ± 0.01 | b | 0.15 ± 0.01 | ab | 0.09 ± 0.01 | b |

| 25 | 2,6,10-Dodecatrienal, 3,7,11-trimethyl | C15H24O | 4.80 ± 0.01 | a | 3.98 ± 0.01 | a | 6.76 ± 0.01 | a | 10.14 ± 0.01 | a | 7.01 ± 0.01 | a | 4.37 ± 0.01 | a | 5.66 ± 0.01 | a | 3.37 ± 0.01 | a |

| Total | 10.19 | 9.42 | 14.33 | 17.61 | 9.09 | 6.633 | 12.16 | 9.17 | ||||||||||

References

- Paolo, D.; Bianchi, G.; Morelli, C.F.; Speranza, G.; Campanelli, G.; Kidmose, U.; Scalzo, R. Lo Impact of drying techniques, seasonal variation and organic growing on flavor compounds profiles in two Italian tomato varieties. Food Chem. 2019, 298, 125062. [Google Scholar] [CrossRef] [PubMed]

- Tilahun, S.; Park, D.S.; Taye, A.M.; Jeong, C.S. Effect of ripening conditions on the physicochemical and antioxidant properties of tomato (Lycopersicon esculentum Mill.). Food Sci. Biotechnol. 2017, 26, 473–479. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.M.; Koutsidis, G.; Lodge, J.K.; Ashor, A.; Siervo, M.; Lara, J. Tomato and lycopene supplementation and cardiovascular risk factors: A systematic review and meta-analysis. Atherosclerosis 2017, 257, 100–108. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: http://www.fao.org/faostat/en/#home (accessed on 10 July 2023).

- Zhuang, Y.; Lu, N.; Shimamura, S.; Maruyama, A.; Kikuchi, M.; Takagaki, M. Economies of scale in constructing plant factories with artificial lighting and the economic viability of crop production. Front. Plant Sci. 2022, 13, 992194. [Google Scholar] [CrossRef]

- Fan, X.; Zang, J.; Xu, Z.; Guo, S.; Jiao, X.; Liu, X.; Gao, Y. Effects of different light quality on growth, chlorophyll concentration and chlorophyll biosynthesis precursors of non-heading Chinese cabbage (Brassica campestris L.). Acta Physiol. Plant. 2013, 35, 2721–2726. [Google Scholar] [CrossRef]

- Brechner, M.L.; Albright, L.D.; Weston, L. Impact of differing light integrals at a constant light intensity: Effects on biomass and production of secondary metabolites by Hypericum perforatum. In 2007 ASAE Annual Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007; p. 1. [Google Scholar]

- Larsen, D.H.; Woltering, E.J.; Nicole, C.C.S.; Marcelis, L.F.M. Response of basil growth and morphology to light intensity and spectrum in a vertical farm. Front. Plant Sci. 2020, 11, 597906. [Google Scholar] [CrossRef] [PubMed]

- Lu, N.; Mitchell, C.A. Supplemental Lighting for Greenhouse-Grown Fruiting Vegetables. In LED Lighting for Urban Agriculture; Kozai, T., Fujiwara, K., Runkle, E., Eds.; Springer: Singapore, 2016. [Google Scholar] [CrossRef]

- Lu, N.; Shimamura, S. Protocols, Issues and Potential Improvements of Current Cultivation Systems. In Smart Plant Factory; Kozai, T., Ed.; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Yue, D.; Zhang, J.; Zhao, J.; Zou, Z. Effect of CO2 enrichment and LED light supplementation on the quality and volatile compounds of tomato fruits. Shipin Kexue/Food Sci. 2018, 39, 124–130. [Google Scholar]

- Bian, Z.H.; Yang, Q.C.; Liu, W.K. Effects of light quality on the accumulation of phytochemicals in vegetables produced in controlled environments: A review. J. Sci. Food Agric. 2015, 95, 869–877. [Google Scholar] [CrossRef]

- Taulavuori, K.; Hyöky, V.; Oksanen, J.; Taulavuori, E.; Julkunen-Tiitto, R. Species-specific differences in synthesis of flavonoids and phenolic acids under increasing periods of enhanced blue light. Environ. Exp. Bot. 2016, 121, 145–150. [Google Scholar] [CrossRef]

- Xiang, N.; Hu, J.; Zhang, B.; Cheng, Y.; Wang, S.; Guo, X. Effect of light qualities on volatiles metabolism in maize (Zea mays L.) sprouts. Food Res. Int. 2022, 156, 111340. [Google Scholar] [CrossRef]

- He, Y.; Li, J.; Mei, H.; Zhuang, J.; Zhao, Z.; Jeyaraj, A.; Wang, Y.; Chen, X.; Li, X.; Liu, Z. Effects of leaf-spreading on the volatile aroma components of green tea under red light of different intensities. Food Res. Int. 2023, 168, 112759. [Google Scholar] [CrossRef]

- Watson, R.; Wright, C.J.; McBurney, T.; Taylor, A.J.; Linforth, R.S.T. Influence of harvest date and light integral on the development of strawberry flavour compounds. J. Exp. Bot. 2002, 53, 2121–2129. [Google Scholar] [CrossRef]

- Colquhoun, T.A.; Schwieterman, M.L.; Gilbert, J.L.; Jaworski, E.A.; Langer, K.M.; Jones, C.R.; Rushing, G.V.; Hunter, T.M.; Olmstead, J.; Clark, D.G. Light modulation of volatile organic compounds from petunia flowers and select fruits. Postharvest Biol. Technol. 2013, 86, 37–44. [Google Scholar] [CrossRef]

- Yang, J.; Liang, T.; Yan, L.; Zhang, K.; Xi, L.; Zou, Z. Effect of light quality on tomato fruit quality and volatile compounds. Shipin Kexue/Food Sci. 2019, 40, 55–61. [Google Scholar]

- Li, Y.; Wang, L.; Wen, L.; Wei, M.; Shi, Q.; Yang, F.; Wang, X. Effects of red and blue light qualities on main fruit quality of tomato during color-turning period. Acta Hortic. Sin. 2017, 44, 2372–2382. [Google Scholar]

- Li, Y.; Liu, C.; Shi, Q.; Yang, F.; Wei, M. Mixed red and blue light promotes ripening and improves quality of tomato fruit by influencing melatonin content. Environ. Exp. Bot. 2021, 185, 104407. [Google Scholar] [CrossRef]

- Liu, R.; Deng, Y.; Zheng, M.; Liu, Y.; Wang, Z.; Yu, S.; Nie, Y.; Zhu, W.; Zhou, Z.; Diao, J. Nano selenium repairs the fruit growth and flavor quality of tomato under the stress of penthiopyrad. Plant Physiol. Biochem. 2022, 184, 126–136. [Google Scholar] [CrossRef] [PubMed]

- Hogewoning, S.W.; Trouwborst, G.; Maljaars, H.; Poorter, H.; van Ieperen, W.; Harbinson, J. Blue light dose–responses of leaf photosynthesis, morphology, and chemical composition of Cucumis sativus grown under different combinations of red and blue light. J. Exp. Bot. 2010, 61, 3107–3117. [Google Scholar] [CrossRef]

- Naznin, M.T.; Lefsrud, M.; Azad, M.O.K.; Park, C.H. Effect of different combinations of red and blue LED light on growth characteristics and pigment content of in vitro tomato plantlets. Agriculture 2019, 9, 196. [Google Scholar] [CrossRef]

- Terashima, I.; Fujita, T.; Inoue, T.; Chow, W.S.; Oguchi, R. Green light drives leaf photosynthesis more efficiently than red light in strong white light: Revisiting the enigmatic question of why leaves are green. Plant Cell Physiol. 2009, 50, 684–697. [Google Scholar]

- Smith, H.L.; McAusland, L.; Murchie, E.H. Don’t ignore the green light: Exploring diverse roles in plant processes. J. Exp. Bot. 2017, 68, 2099–2110. [Google Scholar] [CrossRef] [PubMed]

- Johkan, M.; Shoji, K.; Goto, F.; Hahida, S.-N.; Yoshihara, T. Effect of green light wavelength and intensity on photomorphogenesis and photosynthesis in Lactuca sativa. Environ. Exp. Bot. 2012, 75, 128–133. [Google Scholar] [CrossRef]

- Kaiser, E.; Weerheim, K.; Schipper, R.; Dieleman, J.A. Partial replacement of red and blue by green light increases biomass and yield in tomato. Sci. Hortic. 2019, 249, 271–279. [Google Scholar] [CrossRef]

- Zou, J.; Fanourakis, D.; Tsaniklidis, G.; Cheng, R.; Yang, Q.; Li, T. Lettuce growth, morphology and critical leaf trait responses to far-red light during cultivation are low fluence and obey the reciprocity law. Sci. Hortic. 2021, 289, 110455. [Google Scholar] [CrossRef]

- Claypool, N.B.; Lieth, J.H. Modeling morphological adaptations of bell pepper (Capsicum annuum) to light spectra. Sci. Hortic. 2021, 285, 110135. [Google Scholar] [CrossRef]

- Li, F.; Li, Y.; Li, S.; Wu, G.; Niu, X.; Shen, A. Green light promotes healing and root regeneration in double-root-cutting grafted tomato seedlings. Sci. Hortic. 2021, 289, 110503. [Google Scholar] [CrossRef]

- Paik, I.; Huq, E. Plant photoreceptors: Multi-functional sensory proteins and their signaling networks. Semin. Cell Dev. Biol. 2019, 92, 114–121. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Zhou, Y.; Liu, Y.; Chen, H.; Ge, H. Volatile compound metabolism during cherry tomato fruit development and ripening. J. Food Meas. Charact. 2023, 17, 2162–2171. [Google Scholar] [CrossRef]

- Li, X.; Zeng, X.; Song, H.; Xi, Y.; Li, Y.; Hui, B.; Li, H.; Li, J. Characterization of the aroma profiles of cold and hot break tomato pastes by GC-O-MS, GC× GC-O-TOF-MS, and GC-IMS. Food Chem. 2023, 405, 134823. [Google Scholar] [CrossRef]

- Zhu, Y.; Sims, C.A.; Klee, H.J.; Sarnoski, P.J. Sensory and flavor characteristics of tomato juice from garden gem and roma tomatoes with comparison to commercial tomato juice. J. Food Sci. 2018, 83, 153–161. [Google Scholar] [CrossRef]

- Baldwin, E.A.; Goodner, K.; Plotto, A. Interaction of volatiles, sugars, and acids on perception of tomato aroma and flavor descriptors. J. Food Sci. 2008, 73, S294–S307. [Google Scholar] [CrossRef]

- Baldwin, E.A.; Scott, J.W.; Shewmaker, C.K.; Schuch, W. Flavor trivia and tomato aroma: Biochemistry and possible mechanisms for control of important aroma components. HortScience 2000, 35, 1013–1021. [Google Scholar] [CrossRef]

- Tremblay, N.; Wang, Z.; Cerovic, Z.G. Sensing crop nitrogen status with fluorescence indicators. A review. Agron. Sustain. Dev. 2012, 32, 451–464. [Google Scholar] [CrossRef]

- Ronga, D.; Rizza, F.; Badeck, F.-W.; Milc, J.; Laviano, L.; Montevecchi, G.; Pecchioni, N.; Francia, E. Physiological responses to chilling in cultivars of processing tomato released and cultivated over the past decades in Southern Europe. Sci. Hortic. 2018, 231, 118–125. [Google Scholar] [CrossRef]

- Gómez, C.; Izzo, L.G. Increasing efficiency of crop production with LEDs. AIMS Agric. Food. 2018, 3, 135–153. [Google Scholar] [CrossRef]

- Schouten, R.E.; Woltering, E.J.; Tijskens, L.M.M. Sugar and acid interconversion in tomato fruits based on biopsy sampling of locule gel and pericarp tissue. Postharvest Biol. Technol. 2016, 111, 83–92. [Google Scholar] [CrossRef]

- Davies, J.N.; Hobson, G.E.; McGlasson, W.B. The constituents of tomato fruit—The influence of environment, nutrition, and genotype. Crit. Rev. Food Sci. Nutr. 1981, 15, 205–280. [Google Scholar] [CrossRef]

- Ntagkas, N.; Woltering, E.; Nicole, C.; Labrie, C.; Marcelis, L.F.M. Light regulation of vitamin C in tomato fruit is mediated through photosynthesis. Environ. Exp. Bot. 2019, 158, 180–188. [Google Scholar] [CrossRef]

- Vogel, J.T.; Tieman, D.M.; Sims, C.A.; Odabasi, A.Z.; Clark, D.G.; Klee, H.J. Carotenoid content impacts flavor acceptability in tomato (Solanum lycopersicum). J. Sci. Food Agric. 2010, 90, 2233–2240. [Google Scholar] [CrossRef]

- Simkin, A.J.; Schwartz, S.H.; Auldridge, M.; Taylor, M.G.; Klee, H.J. The tomato carotenoid cleavage dioxygenase 1 genes contribute to the formation of the flavor volatiles β-ionone, pseudoionone, and geranylacetone. Plant J. 2004, 40, 882–892. [Google Scholar] [CrossRef]

- Xu, Y.; Barringer, S. Comparison of tomatillo and tomato volatile compounds in the headspace by selected ion flow tube mass spectrometry (SIFT-MS). J. Food Sci. 2010, 75, C268–C273. [Google Scholar] [CrossRef]

- Wang, L.; Baldwin, E.A.; Plotto, A.; Luo, W.; Raithore, S.; Yu, Z.; Bai, J. Effect of methyl salicylate and methyl jasmonate pre-treatment on the volatile profile in tomato fruit subjected to chilling temperature. Postharvest Biol. Technol. 2015, 108, 28–38. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, Y.; Sun, Y. Recent advances of flavor substance and its influencing factors of tomato fruits. Food Sci. 2022. (In Chinese with English Abstract). [Google Scholar]

- Ngcobo, B.L.; Bertling, I.; Clulow, A.D. Artificial daylength enhancement (pre-sunrise and post-sunset) with blue and red led lights affects tomato plant development, yield, and fruit nutritional quality. Hortic. Environ. Biotechnol. 2022, 63, 847–856. [Google Scholar] [CrossRef]

- Alba, R.; Cordonnier-Pratt, M.-M.; Pratt, L.H. Fruit-localized phytochromes regulate lycopene accumulation independently of ethylene production in tomato. Plant Physiol. 2000, 123, 363–370. [Google Scholar] [CrossRef]

- Xie, B.; Wei, J.; Zhang, Y.; Song, S.; Wei, S.U.; Sun, G.; Hao, Y.; Liu, H. Supplemental blue and red light promote lycopene synthesis in tomato fruits. J. Integr. Agric. 2019, 18, 590–598. [Google Scholar] [CrossRef]

- Wang, S.; Jin, N.; Jin, L.; Xiao, X.; Hu, L.; Liu, Z.; Wu, Y.; Xie, Y.; Zhu, W.; Lyu, J. Response of tomato fruit quality depends on period of LED supplementary light. Front. Nutr. 2022, 9, 833723. [Google Scholar] [CrossRef]

- Jiang, Y.; Joyce, D.C.; Macnish, A.J. Responses of cherry tomato fruit quality and antioxidant content to elevated CO2 and supplementary LED lighting. J. Amer. Soc. Hort. Sci. 2012, 137, 41–46. [Google Scholar]

- Khattak, A.B.; Zeb, A.; Bibi, N. Impact of germination time and type of illumination on carotenoidcontent, protein solubility and in vitro protein digestibility of chickpea (Cicer arietinum L.) sprouts. Food Chem. 2008, 109, 797–801. [Google Scholar] [CrossRef]

- Chung, I.-M.; Lee, C.; Hwang, M.H.; Kim, S.-H.; Chi, H.-Y.; Yu, C.Y.; Chelliah, R.; Oh, D.-H.; Ghimire, B.K. The Influence of Light Wavelength on Resveratrol Content and Antioxidant Capacity in Arachis hypogaeas L. Agronomy 2021, 11, 305. [Google Scholar] [CrossRef]

- Xu, Y.; Charles, M.T.; Luo, Z.; Mimee, B.; Veronneau, P.-Y.; Rolland, D.; Roussel, D. Preharvest ultraviolet C irradiation increased the level of polyphenol accumulation and flavonoid pathway gene expression in strawberry fruit. J. Agric. Food Chem. 2017, 65, 9970–9979. [Google Scholar] [CrossRef]

- Gu, S.; Xu, D.; Zhou, F.; Feng, K.; Chen, C.; Jiang, A. Repairing ability and mechanism of methyl jasmonate and salicylic acid on mechanically damaged sweet cherries. Sci. Hortic. 2022, 292, 110567. [Google Scholar] [CrossRef]

- Han, W.; Zhang, F.; Yang, C.; Chen, G. Analysis of volatile compounds from Rhizoma dioscoreae by SPME-GC-MS. Acta Agric. Jiangxi 2019, 31, 70–73. [Google Scholar] [CrossRef]

- Nelis, H.; De Leenheer, A.P. Isocratic nonaqueous reversed-phase liquid chromatography of carotenoids. Anal. Chem. 1983, 55, 270–275. [Google Scholar] [CrossRef]

- Chen, W.; Huang, L.; Zhang, K. Research on Comprehensive Performance Evaluation of Z Power Supply Branch of Jiangxi Power Grid. Master’s thesis, East China University of Technology, Nanchang, China, 2019. [Google Scholar]

| Treatment | Nitrogen Balance Index | Chlorophyll Index | Flavonoid Index | Proanthocyanidin Index | ||||

|---|---|---|---|---|---|---|---|---|

| W-HD | 49.26 ± 3.14 | a | 40.73 ± 8.15 | a | 0.82 ± 0.12 | b | 0.12 ± 0.47 | a |

| W-LD | 51.01 ± 5.37 | a | 40.50 ± 2.75 | a | 0.80 ± 0.06 | b | 0.14 ± 0.03 | a |

| B-HD | 48.56 ± 1.08 | a | 48.24 ± 6.23 | a | 1.01 ± 0.16 | ab | 0.10 ± 0.05 | ab |

| B-LD | 45.80 ± 6.28 | a | 45.61 ± 8.36 | a | 1.12 ± 0.38 | a | 0.10 ± 0.06 | ab |

| R-HD | 48.16 ± 1.30 | a | 43.30 ± 7.48 | a | 0.92 ± 0.11 | ab | 0.07 ± 0.03 | b |

| R-LD | 49.03 ± 9.70 | a | 38.05 ± 5.90 | a | 0.79 ± 0.09 | b | 0.15 ± 0.04 | a |

| G-HD | 53.13 ± 7.51 | a | 41.23 ± 8.70 | a | 0.77 ± 0.07 | b | 0.11 ± 0.05 | ab |

| G-LD | 47.90 ± 7.57 | a | 37.93 ± 4.96 | a | 0.77 ± 0.05 | b | 0.15 ± 0.06 | a |

| Light quality (LQ) | ns | ns | * | * | ||||

| Daily light integral (DLI) | * | * | * | * | ||||

| DLI×LQ | ns | ns | * | * | ||||

| Treatment | Soluble Sugar (%) | Titratable Acid (%) | Sugar/Acid Ratio | Vitamin C (mg/100 g) | ||||

|---|---|---|---|---|---|---|---|---|

| W-HD | 1.90 ± 0.09 | ab | 0.78 ± 0.03 | de | 2.43 ± 0.16 | ab | 22.21 ± 0.47 | bc |

| W-LD | 1.74 ± 0.20 | abc | 0.64 ± 0.04 | e | 2.73 ± 0.46 | a | 28.27 ± 0.90 | a |

| B-HD | 1.32 ± 0.28 | bcd | 1.23 ± 0.07 | b | 1.07 ± 0.19 | cd | 23.62 ± 4.30 | ab |

| B-LD | 2.06 ± 0.21 | a | 1.03 ± 0.04 | bc | 1.99 ± 0.13 | ab | 17.18 ± 4.05 | cd |

| R-HD | 2.05 ± 0.70 | a | 0.93 ± 0.13 | cd | 2.30 ± 0.06 | ab | 27.92 ± 2.79 | a |

| R-LD | 1.21 ± 0.42 | cd | 1.17 ± 0.03 | b | 1.04 ± 0.37 | cd | 16.39 ± 3.55 | d |

| G-HD | 0.74 ± 0.08 | d | 1.48 ± 0.29 | a | 0.52 ± 0.14 | d | 20.63 ± 1.27 | bcd |

| G-LD | 1.51 ± 0.06 | abc | 0.84 ± 0.05 | cde | 1.81 ± 0.16 | bc | 17.58 ± 0.50 | cd |

| Light quality (LQ) | * | * | * | * | ||||

| Daily light integral (DLI) | * | * | ns | * | ||||

| DLI×LQ | * | * | * | * | ||||

| Indicators | W-HD | W-LD | B-HD | B-LD | R-HD | R-LD | G-HD | G-LD |

|---|---|---|---|---|---|---|---|---|

| Soluble sugar content | 0.033 | 0.067 | 0.07 | 0.078 | 0.259 | 0.094 | 0 | 0.018 |

| Titratable acid | 0.009 | 0 | 0.06 | 0.031 | 0.079 | 0.033 | 0.311 | 0.021 |

| Sugar-to-acid ratio | 0.033 | 0.101 | 0.027 | 0.026 | 0.223 | 0.051 | 0 | 0.032 |

| Vitamin C content | 0.012 | 0.036 | 0.127 | 0.018 | 0.111 | 0 | 0.025 | 0.003 |

| β-carotene | 0.146 | 0.125 | 0.08 | 0.127 | 0.159 | 0.004 | 0 | 0.104 |

| Lycopene | 0.002 | 0 | 0.255 | 0.088 | 0.047 | 0.002 | 0.007 | 0.044 |

| Lutein | 0.004 | 0.221 | 0.045 | 0.15 | 0.142 | 0.002 | 0 | 0.095 |

| Total preferable flavor substances | 0.418 | 0.321 | 0.226 | 0.512 | 0.655 | 0.366 | 0.265 | 0.11 |

| Comprehensive evaluation value | 0.658 | 0.871 | 0.889 | 1.031 | 1.676 | 0.553 | 0.608 | 0.427 |

| Order | 5 | 4 | 3 | 2 | 1 | 7 | 6 | 8 |

| Light Treatment | Daily Light Integral | Main Peak Wavelength | Light Intensity | Photoperiod |

|---|---|---|---|---|

| (mol m−2 d−1) | of the Spectrum (nm) | (μmol m−2 s−1) | (h d−1) | |

| W-HD | 6.48 | 380–780 | 150 | 12 |

| W-LD | 12.96 | 300 | ||

| B-HD | 6.48 | 450–470 | 150 | 12 |

| B-LD | 12.96 | 300 | ||

| R-HD | 6.48 | 620–640 | 150 | 12 |

| R-LD | 12.96 | 300 | ||

| G-HD | 6.48 | 520–530 | 150 | 12 |

| G-LD | 12.96 | 300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, X.; Lu, N.; Xu, W.; Zhuang, Y.; Jin, J.; Mao, X.; Ren, N. Response of Flavor Substances in Tomato Fruit to Light Spectrum and Daily Light Integral. Plants 2023, 12, 2832. https://doi.org/10.3390/plants12152832

Fan X, Lu N, Xu W, Zhuang Y, Jin J, Mao X, Ren N. Response of Flavor Substances in Tomato Fruit to Light Spectrum and Daily Light Integral. Plants. 2023; 12(15):2832. https://doi.org/10.3390/plants12152832

Chicago/Turabian StyleFan, Xiaoxue, Na Lu, Wenshuo Xu, Yunfei Zhuang, Jing Jin, Xiaojuan Mao, and Ni Ren. 2023. "Response of Flavor Substances in Tomato Fruit to Light Spectrum and Daily Light Integral" Plants 12, no. 15: 2832. https://doi.org/10.3390/plants12152832

APA StyleFan, X., Lu, N., Xu, W., Zhuang, Y., Jin, J., Mao, X., & Ren, N. (2023). Response of Flavor Substances in Tomato Fruit to Light Spectrum and Daily Light Integral. Plants, 12(15), 2832. https://doi.org/10.3390/plants12152832