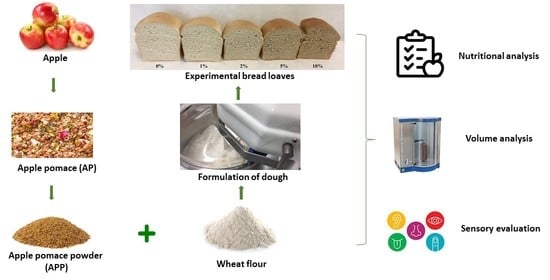

Selected Physico-Chemical, Nutritional, Antioxidant and Sensory Properties of Wheat Bread Supplemented with Apple Pomace Powder as a By-Product from Juice Production

Abstract

:1. Introduction

2. Results

2.1. Nutritional Analysis of the Apple Pomace Powder and Wheat Flour

2.2. Nutritional Analysis of the Bread Loaves

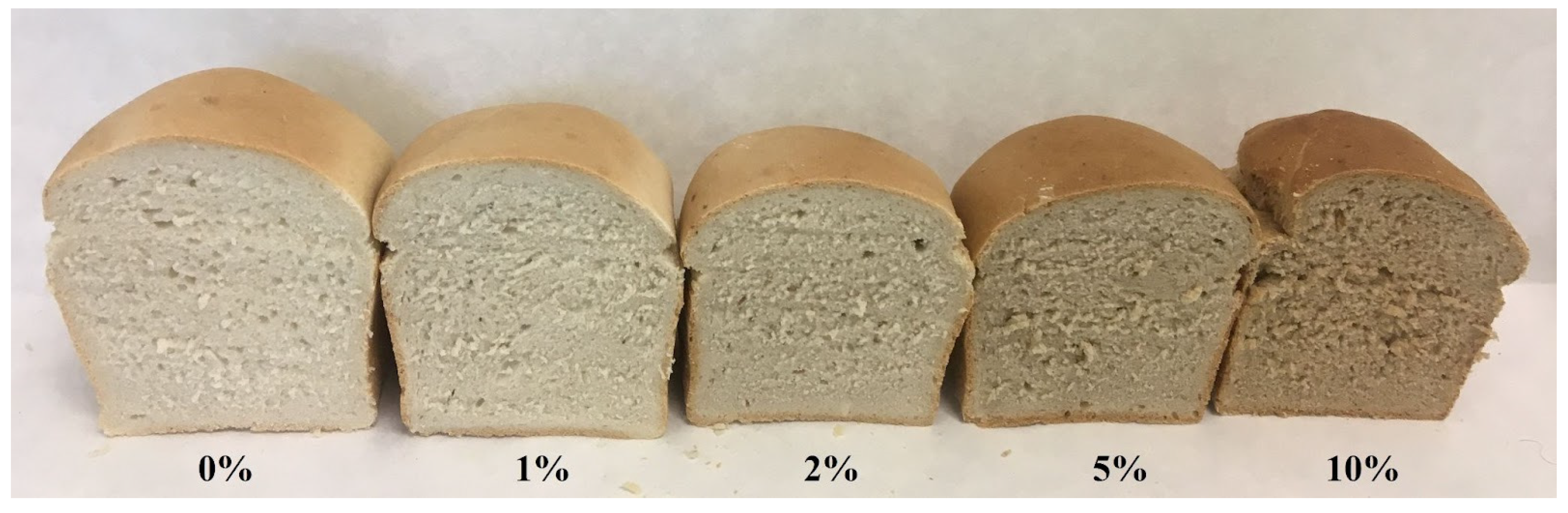

2.3. Bread Volume Analysis

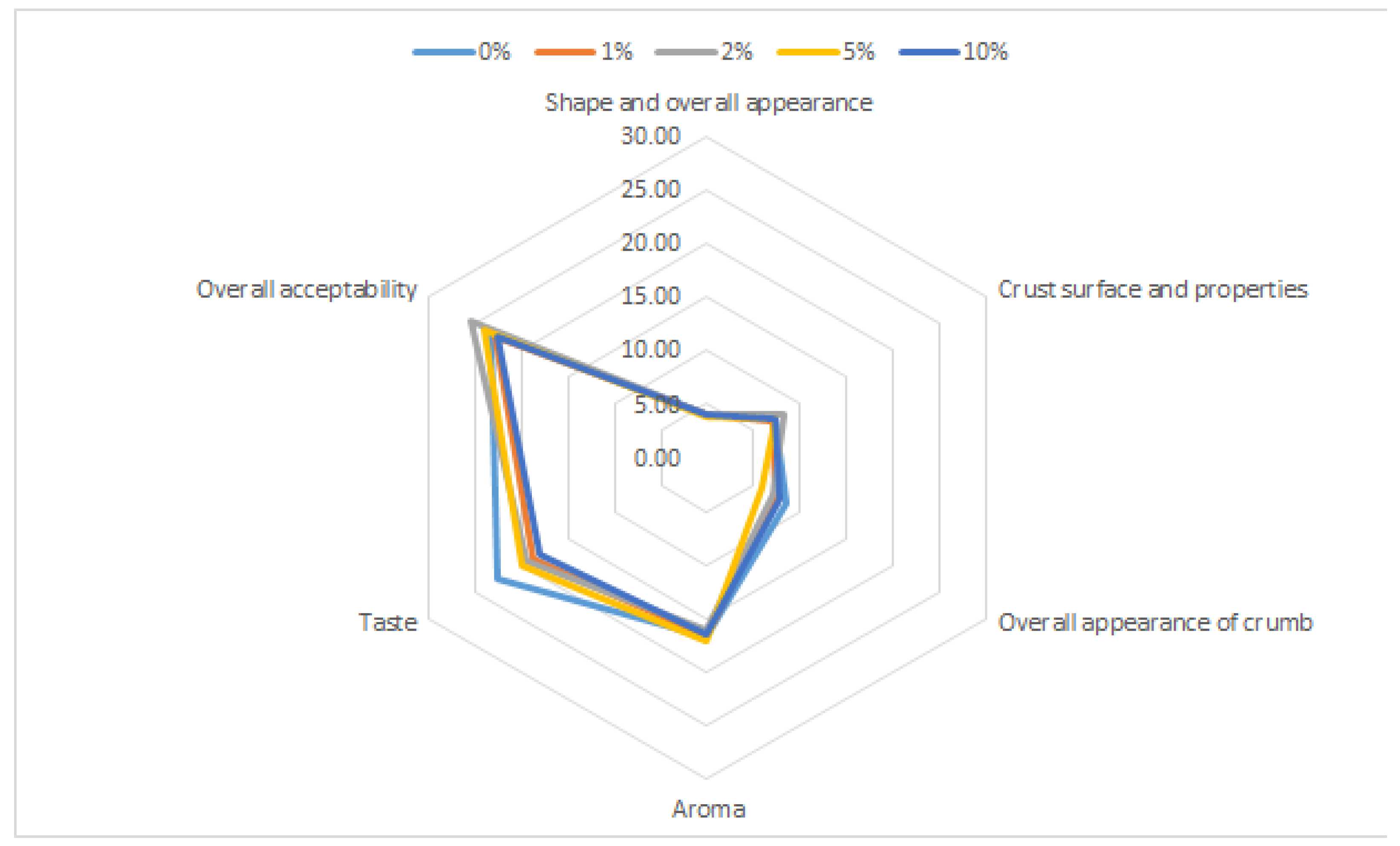

2.4. Sensory Evaluation of the Bread Loaves

3. Discussion

4. Materials and Methods

4.1. Obtaining the Apple Pomace Powder

4.2. Raw Materials

4.3. Chemicals

4.4. Flour Blend Preparation

4.5. Elaboration of Standard and Apple Pomace Powder-Enriched Bread Loaves

4.6. Assessment of Samples Nutritional and Energetic Values

4.7. Determination of Antioxidant Activity and Total Polyphenols Content

4.8. Evaluation of Bread Loaves Volume

4.9. Experimental Design of Bread Sensory Evaluation

4.10. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arraibi, A.A.; Liberal Dias, M.I.; Alves, M.J.; Ferreira, I.C.; Barros, L.; Barreira, J. Chemical and bioactive characterization of Spanish and Belgian apple pomace for its potential use as a novel dermocosmetic formulation. Foods 2021, 10, 1949. [Google Scholar] [CrossRef] [PubMed]

- Bhushan, S.; Kalia, K.; Sharma, M.; Singh, B.; Ahuja, P.S. Processing of apple pomace for bioactive molecules. Crit. Rev. Biotechnol 2008, 28, 285–296. [Google Scholar] [CrossRef] [PubMed]

- Cargnin, S.T.; Gnoatto, S.B. Ursolic acid from apple pomace and traditional plants: A valuable triterpenoid with functional properties. Food Chem. 2017, 220, 477–489. [Google Scholar] [CrossRef] [PubMed]

- Lyu, F.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, A.G.; Ajlouni, S.; Ranadheera, C.S. Apple pomace as a functional and healthy ingredient in food products: A Review. Processes 2020, 8, 319. [Google Scholar] [CrossRef] [Green Version]

- Curutchet, A.; Trias, J.; Tárrega, A.; Arcia, P. Consumer Response to Cake with Apple Pomace as a Sustainable Source of Fibre. Foods 2021, 10, 499. [Google Scholar] [CrossRef]

- Valková, V.; Ďúranová, H.; Ivanišová, E.; Kravárová, A.; Hillová, D.; Gabríny, L. Influence of variety on total polyphenols content and antioxidant activity in apple fruits (Malus domestica Borkh.). Agrobiodivers. Improv. Nutr. Health Life Qual. 2021, 5, 227–232. [Google Scholar] [CrossRef]

- Antonic, B.; Jancikova, S.; Dordevic, D.; Tremlova, B. Apple pomace as food fortification ingredient: A systematic review and meta-analysis. J. Food Sci. 2020, 85, 2977–2985. [Google Scholar] [CrossRef]

- Hussain, T.; Tan, B.; Yin, Y.; Blachier, F.; Tossou, M.C.; Rahu, N. Oxidative stress and inflammation: What polyphenols can do for us? Oxid. Med. Cell. Longev. 2016, 2016, 7432797. [Google Scholar] [CrossRef] [Green Version]

- Valková, V.; Ďúranová, H.; Štefániková, J.; Miškeje, M.; Tokár, M.; Gabríny, L.; Kowalczewski, P.L.; Kačániová, M. Wheat bread with grape seeds micropowder: Impact on dough rheology and bread properties. Appl Rheol 2020, 30, 138–150. [Google Scholar] [CrossRef]

- Gómez, M.; Martinez, M.M. Fruit and vegetable by-products as novel ingredients to improve the nutritional quality of baked goods. Crit. Rev. Food Sci. Nutr. 2017, 58, 2119–2135. [Google Scholar] [CrossRef]

- Padayachee, A.; Day, L.; Howella, K.; Gidley, M.J. Complexity and health functionality of plant cell wall fibers from fruits and vegetables. Crit. Rev. Food Sci. Nutr. 2017, 57, 59–81. [Google Scholar] [CrossRef]

- Garvey, E.C.; O’Sullivan, M.G.; Kerry, J.P.; Milner, L.; Gallagher, E.; Kilcawley, K.N. Characterising the sensory quality and volatile aroma profile of clean-label sucrose reduced sponge cakes. Food Chem. 2021, 342, 128124. [Google Scholar] [CrossRef]

- Bchir, B.; Rabetafika, H.N.; Paquot, M.; Blecker, C. Effect of pear, apple and date fibres from cooked fruit by-products on dough performance and bread quality. Food Bioproc. Technol. 2014, 7, 1114–1127. [Google Scholar] [CrossRef]

- He, Y.Q.; Lu, Q. Impact of apple pomace on the property of French bread. Adv. J. Food Sci. Technol. 2015, 8, 167–172. [Google Scholar] [CrossRef]

- Usman, M.; Ahmed, S.; Mehmood, A.; Bilal, M.; Patil, P.J.; Akram, K.; Farooq, U. Effect of apple pomace on nutrition, rheology of dough and cookies quality. J. Food Sci. Technol. 2020, 57, 3244–3251. [Google Scholar] [CrossRef]

- Djeghim, F.; Bourekoua, H.; Różyło, R.; Bieńczak, A.; Tanaś, W.; Zidoune, M.N. Effect of By-Products from Selected Fruits and Vegetables on Gluten-Free Dough Rheology and Bread Properties. Appl. Sci. 2021, 11, 4605. [Google Scholar] [CrossRef]

- Kalinowska, M.; Bielawska, A.; Lewandowska-Siwkiewicz, H.; Priebe, W.; Lewandowski, W. Apples: Content of phenolic compounds vs. variety, part of apple and cultivation model, extraction of phenolic compounds, biological properties. Plant Physiol. Biochem. 2014, 84, 169–188. [Google Scholar] [CrossRef]

- Martău, G.A.; Emoke, T.B.; Ranga, F.; Pop, I.D.; Vodnar, D.C. Apple pomace as a sustainable substrate in sourdough fermentation. Front. Microbiol. 2021, 12, 742020. [Google Scholar] [CrossRef]

- Rana, S.; Gupta, S.; Rana, A.; Bhushan, S. Functional properties, phenolic constituents and antioxidant potential of industrial apple pomace for utilization as active food ingredient. Food Sci. Hum. Wellness 2015, 4, 180–187. [Google Scholar] [CrossRef] [Green Version]

- Reis, S.F.; Rai, D.K.; Abu-Ghannam, N. Apple pomace as a potential ingredient for the development of new functional foods. J. Food Sci. Technol. 2014, 49, 1743–1750. [Google Scholar] [CrossRef]

- O’shea, N.; Ktenioudaki, A.; Smyth, T.P.; McLoughlin, P.; Doran, L.; Auty, M.A.E.; Arendt, E.; Gallagher, E. Physicochemical assessment of two fruit by-products as functional ingredients: Apple and orange pomace. J. Food Eng. 2015, 153, 89–95. [Google Scholar] [CrossRef]

- Dhillon, G.S.; Kaur, S.; Brar, S.K. Perspective of apple processing wastes as low-cost substrates for bioproduction of high value products: A review. Renew. Sust. Energ. Rev. 2013, 27, 789–805. [Google Scholar] [CrossRef]

- Li, W.; Yang, R.; Ying, D.; Yu, J.; Sanguansri, L.; Augustin, M.A. Analysis of polyphenols in apple pomace: A comparative study of different extraction and hydrolysis procedures. Ind. Crops Prod. 2020, 147, 112250. [Google Scholar] [CrossRef]

- Zielinska, M.; Michalska, A. Microwave-assisted drying of blueberry (Vaccinium corymbosum L.) fruits: Drying kinetics, polyphenols, anthocyanins, antioxidant capacity, colour and texture. Food Chem. 2016, 212, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Gumul, D.; Ziobro, R.; Korus, J.; Kruczek, M. Apple Pomace as a Source of Bioactive Polyphenol Compounds in Gluten-Free Breads. Antioxidants 2021, 10, 807. [Google Scholar] [CrossRef] [PubMed]

- Drożdż, W.; Tomaszewska-Ciosk, E.; Zdybel, E.; Boruczkowska, H.; Boruczkowski, T.; Regiec, P. Effect of apple and rosehip pomaces on colour, total phenolics and antioxidant activity of corn extruded snacks. Pol. J. Chem. Technol. 2014, 16, 7–11. [Google Scholar] [CrossRef] [Green Version]

- Tang, G.Y.; Zhao, C.N.; Xu, X.Y.; Gan, R.Y.; Cao, S.Y.; Liu, Q.; Shang, A.O.; Mao, G.G.; Li, H.B. Phytochemical composition and antioxidant capacity of 30 Chinese teas. Antioxidants 2019, 8, 180. [Google Scholar] [CrossRef] [Green Version]

- Šporin, M.; Avbelj, M.; Kovač, B.; Možina, S.S. Quality characteristics of wheat flour dough and bread containing grape pomace flour. Food Sci. Technol. Int. 2018, 24, 251–263. [Google Scholar] [CrossRef]

- Sudha, M.L.; Baskaran, V.; Leelavathi, K. Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem. 2007, 104, 686–692. [Google Scholar] [CrossRef]

- Torbica, A.; Škrobot, D.; Hajnal, E.J.; Belović, M.; Zhang, N. Sensory and physico-chemical properties of wholegrain wheat bread prepared with selected food by-products. LWT 2019, 114, 108414. [Google Scholar] [CrossRef]

- Gupta, R. Incorporation of dried apple pomace pulp powder in bread. J. Dairy Foods Home Sci. 2006, 25, 200–205. [Google Scholar]

- Wahyono, A.; Tifania, A.Z.; Kurniawati, E.; Kang, W.W.; Chung, S.K. Physical properties and cellular structure of bread enriched with pumpkin flour. IOP Conf. Ser. Earth Environ. Sci. 2018, 207, 12054. [Google Scholar] [CrossRef]

- Ivanišová, E.; Drevková, B.; Tokár, M.; Terentjeva, M.; Krajčovič, T.; Kačániová, M. Physicochemical and sensory evaluation of biscuits enriched with chicory fiber. Food Sci. Technol. Int. 2020, 26, 38–43. [Google Scholar] [CrossRef]

- Mildner-Szkudlarz, S.; Siger, A.; Szwengiel, A.; Bajerska, J. Natural compounds from grape by-products enhance nutritive value and reduce formation of CML in model muffins. Food Chem. 2015, 172, 78–85. [Google Scholar] [CrossRef] [Green Version]

- Alongi, M.; Melchior, S.; Anese, M. Reducing the glycemic index of short dough biscuits by using apple pomace as a functional ingredient. LWT 2019, 100, 300–305. [Google Scholar] [CrossRef]

- De Toledo, N.M.V.; Nunes, L.P.; da Silva, P.P.M.; Spoto, M.H.F.; Canniatti-Brazaca, S.G. Influence of pineapple, apple and melon by-products on cookies: Physicochemical and sensory aspects. Int. J. Food Sci. 2017, 52, 1185–1192. [Google Scholar] [CrossRef]

- Vijayaragavi, E.; Arivuchudar, R. Development and Characteristic Evaluation of Apple Pomace Powder Incorporated Breads. Infokara Res. 2019, 8, 30–37. [Google Scholar]

- American Association of Cereal Chemists. AACC Methods, Methods 08-01, 44-05A, 46-13, 54-20, 8th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 1996; pp. 200–210. [Google Scholar]

- Valková, V.; Ďúranová, H.; Miškeje, M.; Ivanišová, E.; Gabríny, L.; Kačániová, M. Physico-chemical, antioxidant and microbiological characteristics of bread supplemented with 1% grape seed micropowder. JFNR 2021, 60, 9–17. [Google Scholar]

| Parameters | APP | WF |

|---|---|---|

| Moisture (%) | 6.55 ± 0.16 a | 12.13 ± 0.19 b |

| Ash (%) | 1.65 ± 0.08 a | 0.61 ± 0.05 b |

| Protein (%) | 2.18 ± 0.09 a | 11.78 ± 0.13 b |

| Fat (%) | 1.58 ± 0.01 a | 2.01 ± 0.06 b |

| Carbohydrate (%) | 88.04 ± 0.09 a | 73.47 ± 0.11 b |

| Energetic value (kcal/100 g) | 375.10 ± 0.07 a | 359.09 ± 0.09 b |

| TPC (g/kg) | 9.53 ± 0.03 a | 0.41 ± 0.02 b |

| AA (g/kg) | 7.70 ± 0.17 a | 0.16 ± 0.03 b |

| Parameters | Additions of APP (%) | ||||

|---|---|---|---|---|---|

| 0 | 1 | 2 | 5 | 10 | |

| Moisture (%) | 13.69 ± 0.36 a | 13.74 ± 0.30 a | 13.72 ± 0.33 a | 13.67 ± 0.23 a | 13.15 ± 0.29 a |

| Ash (%) | 0.54 ± 0.03 a | 0.65 ± 0.02 b | 0.70 ± 0.03 b | 0.83 ± 0.04 c | 0.95 ± 0.02 d |

| Protein (%) | 17.40 ± 0.07 a | 16.18 ± 0.08 b | 16.08 ± 0.05 b | 13.15 ± 0.07 c | 12.73 ± 0.09 d |

| Fat (%) | 6.72 ± 0.06 a | 6.60 ± 0.03 b | 6.54 ± 0.05 b | 6.00 ± 0.07 c | 5.82 ± 0.02 d |

| Carbohydrate (%) | 61.65 ± 0.11 a | 62.83 ± 0.08 b | 62.96 ± 0.11 b | 66.35 ± 0.09 c | 67.35 ± 0.21 d |

| Energetic value (kcal/100 g) | 376.68 ± 0.10 a | 375.44 ± 0.08 b | 375.02 ± 0.15 c | 372.00 ± 0.12 d | 372.70 ± 0.19 e |

| TPC (g/kg) | 0.60 ± 0.07 a | 0.99 ± 0.02 b | 1.12 ± 0.04 c | 2.18 ± 0.02 d | 2.56 ± 0.03 e |

| AA (g/kg) | 1.65 ± 0.08 a | 1.99 ± 0.07 b | 2.14 ± 0.03 c | 2.61 ± 0.05 d | 2.79 ± 0.02 e |

| Additions of APP (%) | Volume (mL) |

|---|---|

| 0 | 610.42 ± 2.05 a |

| 1 | 542.77 ± 1.88 b |

| 2 | 510.07 ± 1.09 c |

| 5 | 495.12 ± 1.55 d |

| 10 | 482.77 ± 2.64 e |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valková, V.; Ďúranová, H.; Havrlentová, M.; Ivanišová, E.; Mezey, J.; Tóthová, Z.; Gabríny, L.; Kačániová, M. Selected Physico-Chemical, Nutritional, Antioxidant and Sensory Properties of Wheat Bread Supplemented with Apple Pomace Powder as a By-Product from Juice Production. Plants 2022, 11, 1256. https://doi.org/10.3390/plants11091256

Valková V, Ďúranová H, Havrlentová M, Ivanišová E, Mezey J, Tóthová Z, Gabríny L, Kačániová M. Selected Physico-Chemical, Nutritional, Antioxidant and Sensory Properties of Wheat Bread Supplemented with Apple Pomace Powder as a By-Product from Juice Production. Plants. 2022; 11(9):1256. https://doi.org/10.3390/plants11091256

Chicago/Turabian StyleValková, Veronika, Hana Ďúranová, Michaela Havrlentová, Eva Ivanišová, Ján Mezey, Zuzana Tóthová, Lucia Gabríny, and Miroslava Kačániová. 2022. "Selected Physico-Chemical, Nutritional, Antioxidant and Sensory Properties of Wheat Bread Supplemented with Apple Pomace Powder as a By-Product from Juice Production" Plants 11, no. 9: 1256. https://doi.org/10.3390/plants11091256

APA StyleValková, V., Ďúranová, H., Havrlentová, M., Ivanišová, E., Mezey, J., Tóthová, Z., Gabríny, L., & Kačániová, M. (2022). Selected Physico-Chemical, Nutritional, Antioxidant and Sensory Properties of Wheat Bread Supplemented with Apple Pomace Powder as a By-Product from Juice Production. Plants, 11(9), 1256. https://doi.org/10.3390/plants11091256