Multi-Objective Intelligent Industrial Robot Calibration Using Meta-Heuristic Optimization Approaches

Abstract

1. Introduction

2. Problem Formulation

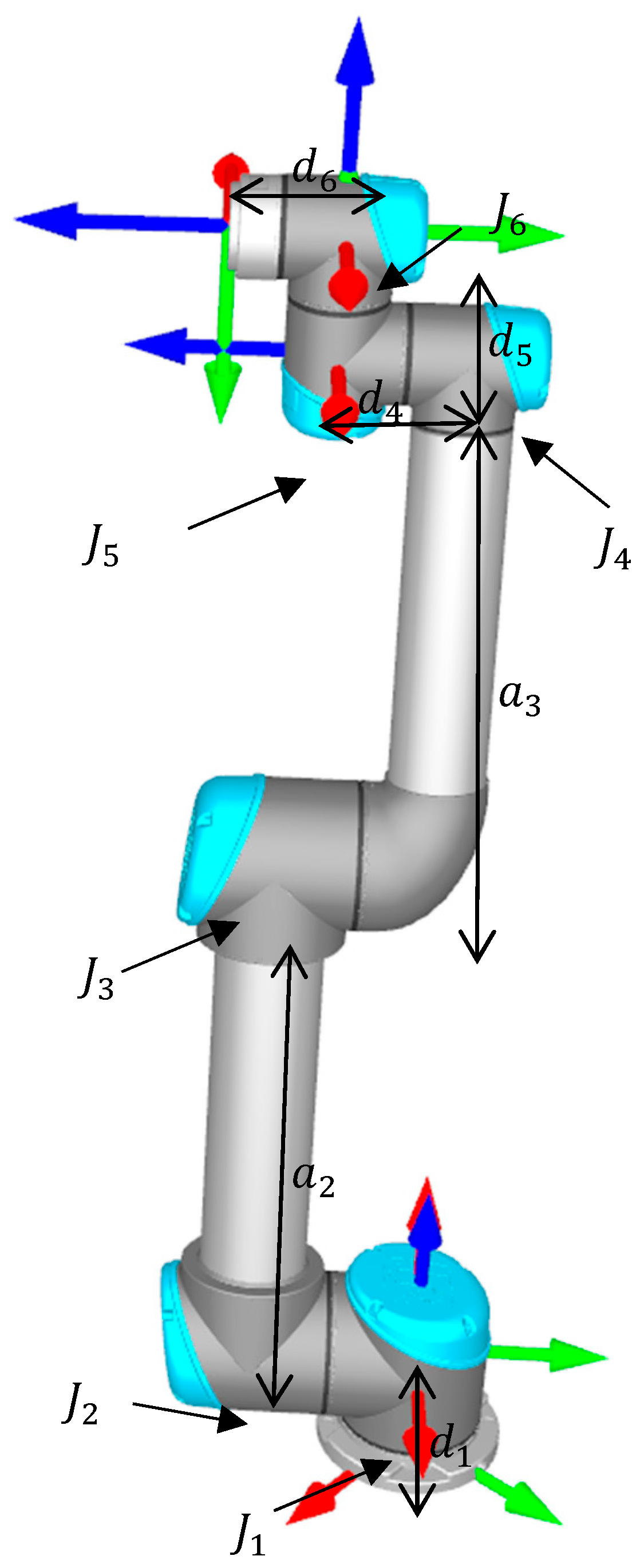

2.1. Industrial Robot DH Parameters

- Joint angle : This parameter is one of the DH parameters of the industrial robot which is usually measured online using joint encoders and it is defined as the angle between and axes about the axis, where , and are the x-axis and the z-axis of the i-th joint;

- Link offset : This parameter is the second DH parameter of the industrial robot which is defined as the distance from the origin of frame to the axis along the axis;

- Link length This parameter is the third DH parameter of the industrial robot which is defined as the distance between the and axis along the axis, where the intersecting axis is parallel to ;

- Link twist This parameter is the last parameter in the DH parameter list which is defined as the angle between the and axes about the axis.

2.2. Forward Kinematics of UR5

2.3. Multi-Objective Calibration

3. Multi-Objective Optimization Approaches

3.1. Nondominated Sorting Genetic Algorithm

- (1)

- Randomly initialize n-dimensional with in feasible space.

- (2)

- Apply a selection algorithm on the population and choose parents.

- (3)

- Apply genetic algorithm operators of crossover and mutations to the selected parents.

- (4)

- Combine the old population and the offspring and evaluate the whole population.

- (5)

- Apply nondominated sorting to the overall population.

- (6)

- Select N number of the population from the first Pareto fronts. For the last Pareto front, if selecting all members of the Pareto front, make the number of next generations more than N, apply a crowding distance measurement algorithm, and choose the individuals with the highest crowding distance index to maximize the diversity within the next generation.

- (7)

- If the STOP condition is not met GOTO 2, otherwise STOP the procedure.

3.2. Multi-Objective Particle Swarm Optimization Algorithm

- (1)

- Randomly initialize n-dimensional with in feasible space.

- (2)

- Initialize n-dimensional to zero vector.

- (3)

- Calculate the multi-objective cost function associated with each member of the swarm.

- (4)

- Construct the swarm repository out of nondominated solutions within the swarm.

- (5)

- Generate hypercubes out of particles in the repository in the objective function space. Locate particles in the repository in their respective hypercube.

- (6)

- Initialize the best experience for each particle by using their initial multi-objective cost function.

- (7)

- Compute the velocity matrix using the following equation: .

- (8)

- The position vector is then updated as .

- (9)

- Evaluate the new values of and update and with newly generated nondominated solutions.

- (10)

- GOTO (7) and iterate the algorithm until the STOP condition is met.

3.3. Multi-Objective Evolutionary Algorithm Based on Decomposition

- (1)

- Randomly initialize n-dimensional within feasible space.

- (2)

- Evaluate the randomly generated population and initialize the repository by adding the nondominated ones to the repository. Initialize ’s as the best solution obtained so far for the objective function ’s.

- (3)

- Find closest neighbors for each individual in terms of Euclidean distance within generated population : .

- (4)

- For each individual select two parents from their associated neighborhood and apply evolutionary operations to generate new offspring.

- (5)

- Update ’s as the best solution obtained so far in the case that a better is found.

- (6)

- Evaluate the new individuals if they dominate the repository members; update the repository by adding them and removing the dominated ones.

- (7)

- Update neighborhoods according to the newly obtained ’s.

- (8)

- If STOP criteria are not met, GOTO 4.

4. Experimental Setup

4.1. Laser Tracker

4.2. Industrial Robot

5. Experimental Results

6. Conclusions and Future Work

Author Contributions

Funding

Funding

Data Availability Statement

Conflicts of Interest

References

- Aggogeri, F.; Pellegrini, N.; Taesi, C. Towards Industrial Robots’ Maturity: An Italian Case Study. Robotics 2024, 13, 42. [Google Scholar] [CrossRef]

- Cong, Y.; Du, H.; Zhu, W.; Chen, C.-C. Position Regulation of Industrial Robots via Bounded Integral Terminal Sliding Mode Control Algorithm. IEEE Trans. Ind. Electron. 2023, 71, 7403–7412. [Google Scholar] [CrossRef]

- Toquica, J.S.; Motta, J.M.S. A methodology for industrial robot calibration based on measurement sub-regions. Int. J. Adv. Manuf. Technol. 2022, 119, 1199–1216. [Google Scholar] [CrossRef]

- Wang, H.; Qi, H.; Xu, M.; Tang, Y.; Yao, J.; Yan, X.; Li, M. Research on the relationship between classic denavit-hartenberg and modified denavit-hartenberg. In Proceedings of the 2014 Seventh International Symposium on Computational Intelligence and Design, Hangzhou, China, 13–14 December 2014; pp. 26–29. [Google Scholar]

- Jin, G.; Yu, X.; Chen, Y.; Li, J. SCARA+ System: Bin Picking System of Revolution-Symmetry Objects. IEEE Trans. Ind. Electron. 2024, 71, 10976–10986. [Google Scholar] [CrossRef]

- Rocha, C.; Tonetto, C.; Dias, A. A comparison between the Denavit–Hartenberg and the screw-based methods used in kinematic modeling of robot manipulators. Robot. Comput. Integr. Manuf. 2011, 27, 723–728. [Google Scholar] [CrossRef]

- Khanesar, M.A.; Yan, M.; Isa, M.; Piano, S.; Branson, D.T. Precision Denavit–Hartenberg Parameter Calibration for Industrial Robots Using a Laser Tracker System and Intelligent Optimization Approaches. Sensors 2023, 23, 5368. [Google Scholar] [CrossRef]

- Roth, Z.; Mooring, B.; Ravani, B. An overview of robot calibration. IEEE J. Robot. Autom. 1987, 3, 377–385. [Google Scholar] [CrossRef]

- Ke, X.; Yu, Y.; Li, K.; Wang, T.; Zhong, B.; Wang, Z.; Kong, L.; Guo, J.; Huang, L.; Idir, M. Review on robot-assisted polishing: Status and future trends. Robot. Comput.-Integr. Manuf. 2023, 80, 102482. [Google Scholar] [CrossRef]

- Sun, T.; Lian, B.; Yang, S.; Song, Y. Kinematic calibration of serial and parallel robots based on finite and instantaneous screw theory. IEEE Trans. Robot. 2020, 36, 816–834. [Google Scholar] [CrossRef]

- Chen, H.; Fuhlbrigge, T.; Choi, S.; Wang, J.; Li, X. Practical industrial robot zero offset calibration. In Proceedings of the 2008 IEEE International Conference on Automation Science and Engineering, Arlington, VA, USA, 23–26 August 2008; pp. 516–521. [Google Scholar]

- Gao, B.; Liu, Y.; Xi, N.; Shen, Y. Developing an efficient calibration system for joint offset of industrial robots. J. Appl. Math. 2014, 2014, 769343. [Google Scholar] [CrossRef]

- Kana, S.; Gurnani, J.; Ramanathan, V.; Turlapati, S.H.; Ariffin, M.Z.; Campolo, D. Fast kinematic re-calibration for industrial robot arms. Sensors 2022, 22, 2295. [Google Scholar] [CrossRef]

- Cao, H.Q.; Nguyen, H.X.; Tran, T.N.-C.; Tran, H.N.; Jeon, J.W. A robot calibration method using a neural network based on a butterfly and flower pollination algorithm. IEEE Trans. Ind. Electron. 2021, 69, 3865–3875. [Google Scholar] [CrossRef]

- Gao, T.; Meng, F.; Zhang, X.; Tian, Z.; Song, H. An operational calibration approach of industrial robots through a motion capture system and an artificial neural network ELM. Int. J. Adv. Manuf. Technol. 2023, 125, 5135–5147. [Google Scholar] [CrossRef]

- Maghami, A.; Imbert, A.; Côté, G.; Monsarrat, B.; Birglen, L.; Khoshdarregi, M. Calibration of Multi-Robot Cooperative Systems Using Deep Neural Networks. J. Intell. Robot. Syst. 2023, 107, 55. [Google Scholar] [CrossRef]

- Cao, H.Q.; Nguyen, H.X.; Nguyen, T.T.; Nguyen, V.Q.; Jeon, J.W. Robot Calibration Method Based on Extended Kalman Filter–Dual Quantum Behaved Particle Swarm Optimization and Adaptive Neuro-Fuzzy Inference System. IEEE Access 2021, 9, 132558–132568. [Google Scholar] [CrossRef]

- Bai, Y.; Zhuang, H. Modeless robots calibration in 3D workspace with an on-line fuzzy interpolation technique. In Proceedings of the 2004 IEEE International Conference on Systems, Man and Cybernetics (IEEE Cat. No. 04CH37583), Hague, The Netherlands, 10–13 October 2004; pp. 5233–5239. [Google Scholar]

- Bai, Y. On the comparison of model-based and modeless robotic calibration based on a fuzzy interpolation method. Int. J. Adv. Manuf. Technol. 2007, 31, 1243–1250. [Google Scholar] [CrossRef]

- Aoyagi, S.; Kohama, A.; Nakata, Y.; Hayano, Y.; Suzuki, M. Improvement of robot accuracy by calibrating kinematic model using a laser tracking system-compensation of non-geometric errors using neural networks and selection of optimal measuring points using genetic algorithm. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 5660–5665. [Google Scholar]

- Bai, M.; Zhang, M.; Zhang, H.; Li, M.; Zhao, J.; Chen, Z. Calibration method based on models and least-squares support vector regression enhancing robot position accuracy. IEEE Access 2021, 9, 136060–136070. [Google Scholar] [CrossRef]

- Duong, Q.K.; Trang, T.T.; Pham, T.L. Robot Control Using Alternative Trajectories Based on Inverse Errors in the Workspace. J. Robot. 2021, 2021, 9995787. [Google Scholar] [CrossRef]

- Nguyen, H.-N.; Zhou, J.; Kang, H.-J. A calibration method for enhancing robot accuracy through integration of an extended Kalman filter algorithm and an artificial neural network. Neurocomputing 2015, 151, 996–1005. [Google Scholar] [CrossRef]

- Hu, J.; Hua, F.; Tian, W. Robot positioning error compensation method based on deep neural network. J. Phys. Conf. Ser. 2020, 1487, 012045. [Google Scholar] [CrossRef]

- Kato, D.; Yoshitugu, K.; Maeda, N.; Hirogaki, T.; Aoyama, E.; Takahashi, K. Finding Features of Positioning Error for Large Industrial Robots Based on Convolutional Neural Network. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Online, 17–19 August 2021; American Society of Mechanical Engineers: New York, NY, USA, 2021; p. V002T002A022. [Google Scholar]

- Min, K.; Ni, F.; Chen, Z.; Liu, H.; Lee, C.-H. A robot positional error compensation method based on improved kriging interpolation and Kronecker products. IEEE Trans. Ind. Electron. 2023, 71, 3884–3893. [Google Scholar] [CrossRef]

- Robots, U. 100,000 Cobots: Proof That the Future of Manufacturing Is Collaborative! Available online: https://www.automate.org/news/100k-cobots-proof-that-the-future-of-manufacturing-is-collaborative-universal-robots (accessed on 11 September 2025).

- Wang, C.; Zhang, Z.; Han, J. Multiobjective Optimization of High Power Density Outer Rotor PM Starter Generator Considering Electromagnetic and Temperature Characteristics. IEEE Trans. Ind. Electron. 2023, 71, 8339–8350. [Google Scholar] [CrossRef]

- Kufieta, K. Force Estimation in Robotic Manipulators: Modeling, Simulation and Experiments. Diploma Thesis, Department of Engineering Cybernetics NTNU Norwegian University of Science and Technology, Trondheim, Norway, 2014. [Google Scholar]

- Sun, J.-D.; Cao, G.-Z.; Li, W.-B.; Liang, Y.-X.; Huang, S.-D. Analytical inverse kinematic solution using the DH method for a 6-DOF robot. In Proceedings of the 2017 14th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Jeju, Republic of Korea, 28 June–1 July 2017; pp. 714–716. [Google Scholar]

- Mahmoudian, A.; Niasati, M.; Khanesar, M.A. Multi objective optimal allocation of fault current limiters in power system. Int. J. Electr. Power Energy Syst. 2017, 85, 1–11. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef]

- Wang, D.; Tan, D.; Liu, L. Particle swarm optimization algorithm: An overview. Soft Comput. 2018, 22, 387–408. [Google Scholar] [CrossRef]

- Shami, T.M.; El-Saleh, A.A.; Alswaitti, M.; Al-Tashi, Q.; Summakieh, M.A.; Mirjalili, S. Particle swarm optimization: A comprehensive survey. IEEE Access 2022, 10, 10031–10061. [Google Scholar] [CrossRef]

- Tian, J.; Hou, M.; Bian, H.; Li, J. Variable surrogate model-based particle swarm optimization for high-dimensional expensive problems. Complex Intell. Syst. 2023, 9, 3887–3935. [Google Scholar] [CrossRef]

- Coello, C.A.C.; Pulido, G.T.; Lechuga, M.S. Handling multiple objectives with particle swarm optimization. IEEE Trans. Evol. Comput. 2004, 8, 256–279. [Google Scholar] [CrossRef]

- Han, W.; Yang, P.; Ren, H.; Sun, J. Comparison study of several kinds of inertia weights for PSO. In Proceedings of the 2010 IEEE International Conference on Progress in Informatics and Computing, Shanghai, China, 10–12 December 2010; pp. 280–284. [Google Scholar]

- Shi, Y.; Eberhart, R.C. Empirical study of particle swarm optimization. In Proceedings of the 1999 Congress on Evolutionary Computation-CEC99 (Cat. No. 99TH8406), Washington, DC, USA, 6–9 July 1999; pp. 1945–1950. [Google Scholar]

- Al-Hassan, W.; Fayek, M.; Shaheen, S. Psosa: An optimized particle swarm technique for solving the urban planning problem. In Proceedings of the 2006 International Conference on Computer Engineering and Systems, Cairo, Egypt, 5–7 November 2006; pp. 401–405. [Google Scholar]

- Zhang, Q.; Li, H. MOEA/D: A multiobjective evolutionary algorithm based on decomposition. IEEE Trans. Evol. Comput. 2007, 11, 712–731. [Google Scholar] [CrossRef]

- Jiao, R.; Nguyen, B.H.; Xue, B.; Zhang, M. A survey on evolutionary multiobjective feature selection in classification: Approaches, applications, and challenges. IEEE Trans. Evol. Comput. 2023, 28, 1156–1176. [Google Scholar] [CrossRef]

- Yazdani, D.; Omidvar, M.N.; Yazdani, D.; Branke, J.; Nguyen, T.T.; Gandomi, A.H.; Jin, Y.; Yao, X. Robust Optimization Over Time: A Critical Review. IEEE Trans. Evol. Comput. 2023, 28, 1265–1285. [Google Scholar] [CrossRef]

- Khanesar, M.A.; Yan, M.; Isa, M.; Piano, S.; Ayoubi, M.A.; Branson, D.T. Enhancing Positional Accuracy of the XY-Linear Stage Using Laser Tracker Feedback and IT2FLS. Machines 2023, 11, 497. [Google Scholar] [CrossRef]

- Kyle, S. Operational features of the Leica laser tracker. In Proceedings of the IEE Seminar Business Improvement Through Measurement, Sheffield, UK, 8 June 1999. [Google Scholar]

- He, N.; Li, Y.; Li, H.; He, D.; Cheng, F. PID-Based Event-Triggered MPC for Constrained Nonlinear Cyber-Physical Systems: Theory and Application. IEEE Trans. Ind. Electron. 2024, 71, 13103–13112. [Google Scholar] [CrossRef]

- Fu, Z.; Dai, J.S.; Yang, K.; Chen, X.; López-Custodio, P. Analysis of unified error model and simulated parameters calibration for robotic machining based on Lie theory. Robot. Comput. Integr. Manuf. 2020, 61, 101855. [Google Scholar] [CrossRef]

| Ref. No. | Main Calibration Approach | Industrial Robot | Metrology Equipment and Brand |

|---|---|---|---|

| [14] | Extended Kalman filter and an artificial neural network | Stewart Platform | Digital indicators |

| [15] | Extreme learning machine neural network | GSK RB03 robot | Nokov’s MARS 2H |

| [16] | Deep neural networks | KUKA KR300 R2500 ULTRA | Leica LT800 LT |

| [17] | Adaptive neuro-fuzzy inference system (ANFIS) | 2-DOF five-bar parallel robot | Digital indicators |

| [19] | Fuzzy interpolation method | PUMA 560 robot model | Single-beam LT system |

| [20] | Nonlinear least squares | PA10 robot arm | Leica SMART310 LT |

| [21] | Least squares support vector regression with radial basis function kernel | IRB1410 | Leica AT960 |

| [24] | Deep neural networks | KUKA KR500 | API Radian LT |

| [25] | Convolutional neural network | SRA166 | LT manufactured by IHI Scube |

| NSGAII | MOPSO | MOEAD | ||

|---|---|---|---|---|

| Cost function #1 | Min (mm) | 0.0094031 | 0.17594 | 0.84645 |

| Max (mm) | 19.0 | 0.80271 | 1.5 | |

| Range (mm) | 19.0 | 0.62677 | 0.60869 | |

| Standard deviation (mm) | 5.8 | 0.21223 | 0.11697 | |

| Mean (mm) | 9.3 | 0.42292 | 0.87284 | |

| Median (mm) | 9.1 | 0.33401 | 0.84645 | |

| Cost function #2 | Min (µm) | 70.713 | 74.603 | 74.824 |

| Max (µm) | 98.631 | 93.189 | 119.08 | |

| Range (µm) | 27.917 | 18.586 | 44.259 | |

| Standard deviation (µm) | 4.9674 | 6.1017 | 9.2482 | |

| Mean (µm) | 73.377 | 79.639 | 116.87 | |

| Median (µm) | 72.357 | 78.450 | 119.08 |

| Point A DH Parameters | Point B DH Parameters | Manufacturer’s Given Parameters | ||

|---|---|---|---|---|

| Train set | MAE (µm) | 55.025 | 56.290 | 70.221 |

| RMSE (µm) | 70.713 | 72.187 | 97.924 | |

| MDMP (mm) | 19 | 10 | 0 | |

| Test set | MAE (µm) | 60.842 | 61.370 | 75.381 |

| RMSE (µm) | 75.856 | 76.349 | 100.55 | |

| MDMP (mm) | 19 | 10 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanesar, M.A.; Karaca, A.; Yan, M.; Piano, S.; Branson, D. Multi-Objective Intelligent Industrial Robot Calibration Using Meta-Heuristic Optimization Approaches. Robotics 2025, 14, 129. https://doi.org/10.3390/robotics14090129

Khanesar MA, Karaca A, Yan M, Piano S, Branson D. Multi-Objective Intelligent Industrial Robot Calibration Using Meta-Heuristic Optimization Approaches. Robotics. 2025; 14(9):129. https://doi.org/10.3390/robotics14090129

Chicago/Turabian StyleKhanesar, Mojtaba A., Aslihan Karaca, Minrui Yan, Samanta Piano, and David Branson. 2025. "Multi-Objective Intelligent Industrial Robot Calibration Using Meta-Heuristic Optimization Approaches" Robotics 14, no. 9: 129. https://doi.org/10.3390/robotics14090129

APA StyleKhanesar, M. A., Karaca, A., Yan, M., Piano, S., & Branson, D. (2025). Multi-Objective Intelligent Industrial Robot Calibration Using Meta-Heuristic Optimization Approaches. Robotics, 14(9), 129. https://doi.org/10.3390/robotics14090129