Assistive Control through a Hapto-Visual Digital Twin for a Master Device Used for Didactic Telesurgery

Abstract

1. Introduction

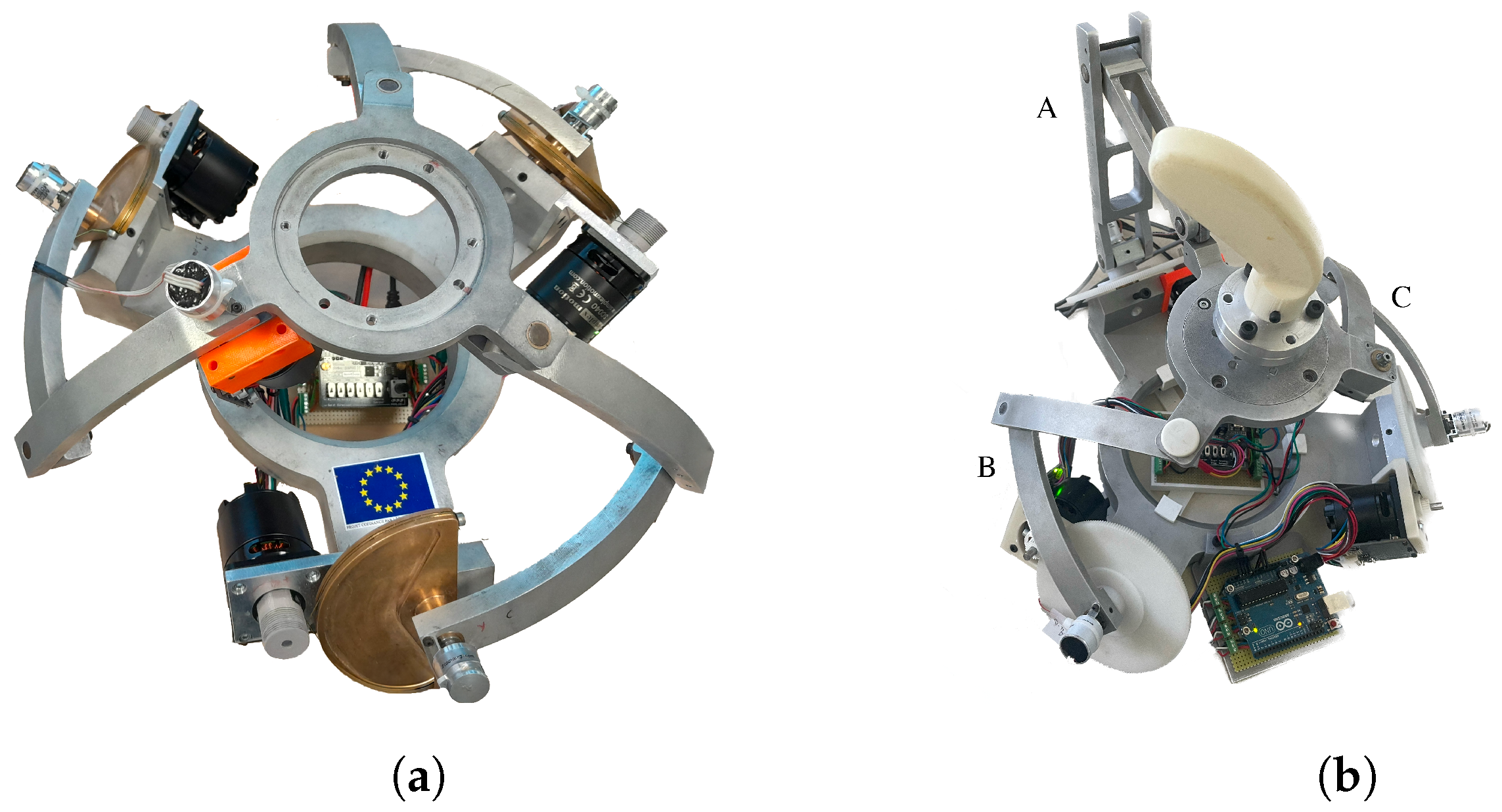

2. Materials and Methods

2.1. Kinematic Description, Jacobian, and Haptic Feedback

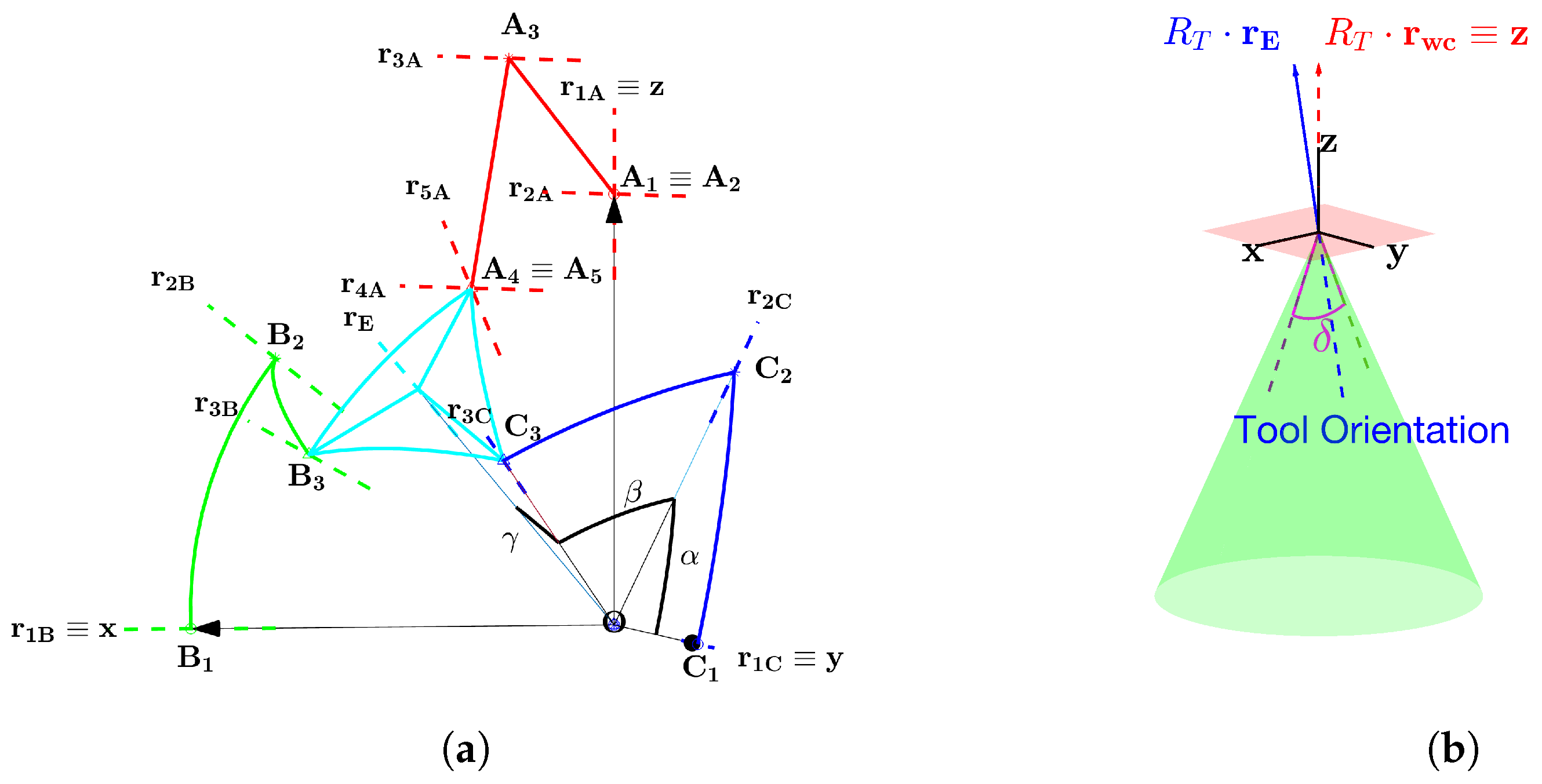

- We define the origin-based unit vectors as parallel to the axes of the R joints ;

- We define as the unit vector pointing to the platform’s center E. Its orientation is expressed by the Euler angles triplet , as in Equation (1):in which and denote rotation matrices around axes and ;

- We define the workspace center coincident to the bisector of the first octant, as in Equation (2):in which , being a self-rotation angle, we can assume any possible value within the operative workspace , and it is considered zero by default [25];

- According to the superposition principle, U joints on leg A can each be decomposed into two R joints sharing perpendicular axes, namely couples and , as in Figure 2a;

- Considering a symmetrical structure for simplicity, we define the geometrical angles as the ones describing the angular span of proximal links and , distal links and , and angle , respectively;

- As stated in Section 1, joints are each actuated by motors, and their revolution axes are perpendicular. Imposing , , , the actuated angle triplet is ;

- In the bilaterally teleoperated system, the platform’s orientation is transmitted to the slave’s instrumented tool for RCM control and transformed through a proper rotation matrix , as in Figure 2b.

2.2. Inverse and Forward Kinematics, Working Modes, and Self-Collision

2.3. Reachable Workspace and Best Working Mode

2.4. Hapto-Visual Digital Twin for Assistive Control

2.4.1. Haptic Assistive Control: Premises

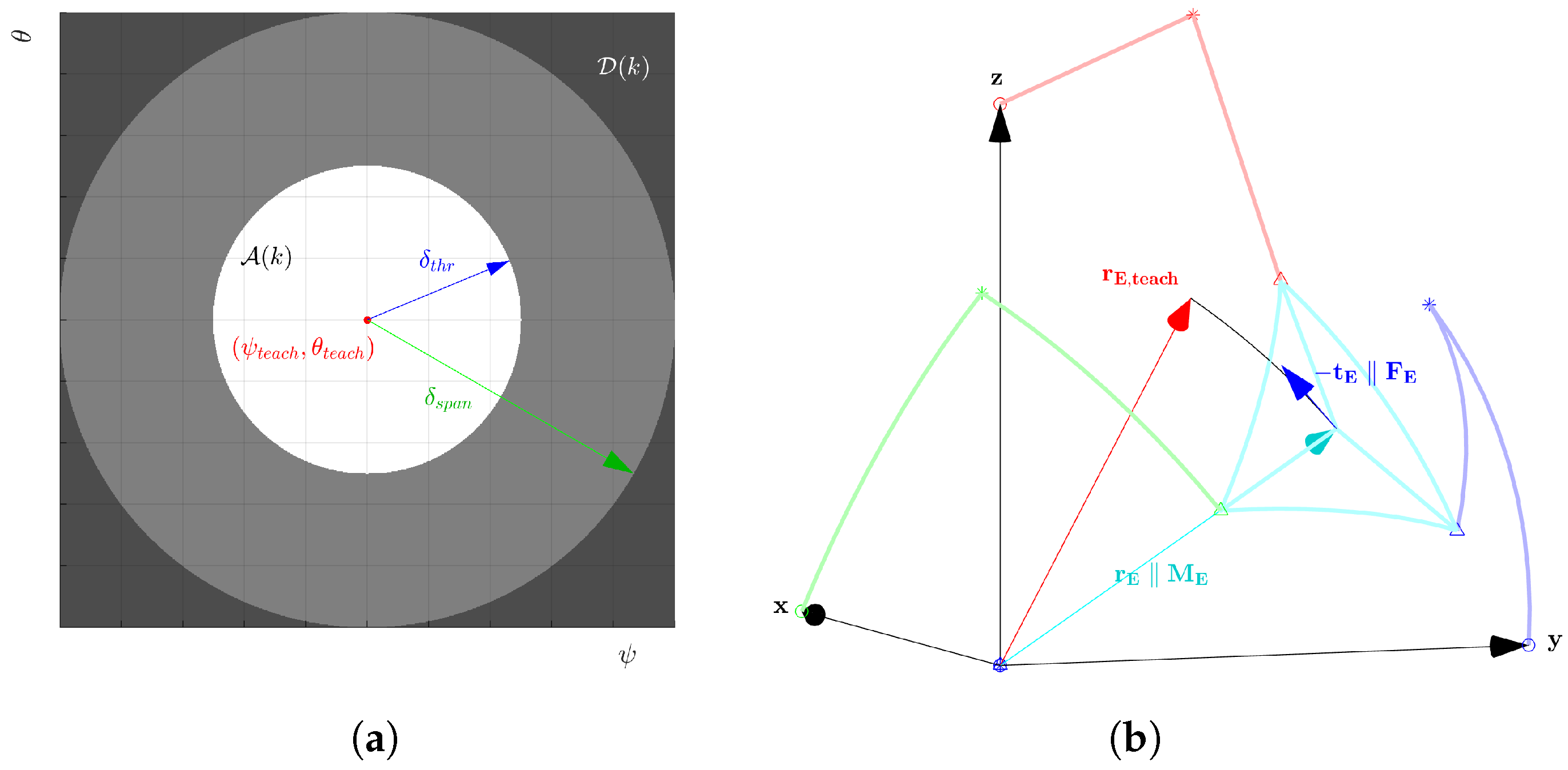

- For clarity of notation, given Equation (7), we define the instantaneous errors between student and teaching trajectories Equation (8):

- We define the time-varying cubic neighborhood as the subdominion of centered in , as in Equation (9a). As a first approach, the self-rotation angle can be neglected, defining the restricted squared neighborhood on plane , as in Equation (9b). All involved parameters’ value definitions can be found in Table A1.

- We finally define, neglecting and according to Equations (8) and (9b), the reduced euclidean distance , lying on the plane, between reduced and , as in Equation (10):

2.4.2. Haptic Assistive Control: Basic Description

2.4.3. Haptic Assistive Control: Modifications

- (I)

- To have a more fluid assistive action, we can consider not only the current but also for determining a suitable action associated with neighborhood . Admitted dominions should then depend on . The control algorithm can be easily modified between different admitted areas’ shapes by considering discrete numeric maps to apply on instead of analytic functions, as in Equations (11) and (13). Examples on are shown in Figure 5;

- (II)

- To have a less stringent and time-based assistive action, we can check whether the student has reached before updating to the next through a boolean condition . In this way, the effects of the control loop are drastically reduced, the performance is not evaluated in a time-based point of view, and the student is assisted only when actively leaves the current admitted dominion . Having adopted this strategy for the experimental part, from this point on the sampling index k will be removed for clarity;

- (III)

- To have an even less timely action, and with the aid of the visual feedback to be presented in Section 2.4.4, can toggle only on a subset of depending on , e.g., on , for a circular , such as the one presented in Figure 5b.

2.4.4. Visual Digital Twin

- The 3D mesh model of the object, processed in a digital asset exchange (.dae) format, referenced by a suitable relative reference frame (RF) centered in for all spherical elements (i.e., legs B and C, and platform), for non-spherical elements following the standard Denavit–Hartenberg convention;

- The pose of the object, contained by a quaternion computed from a suitable rotational matrix associated with the object and the relative RF described by the previous point.

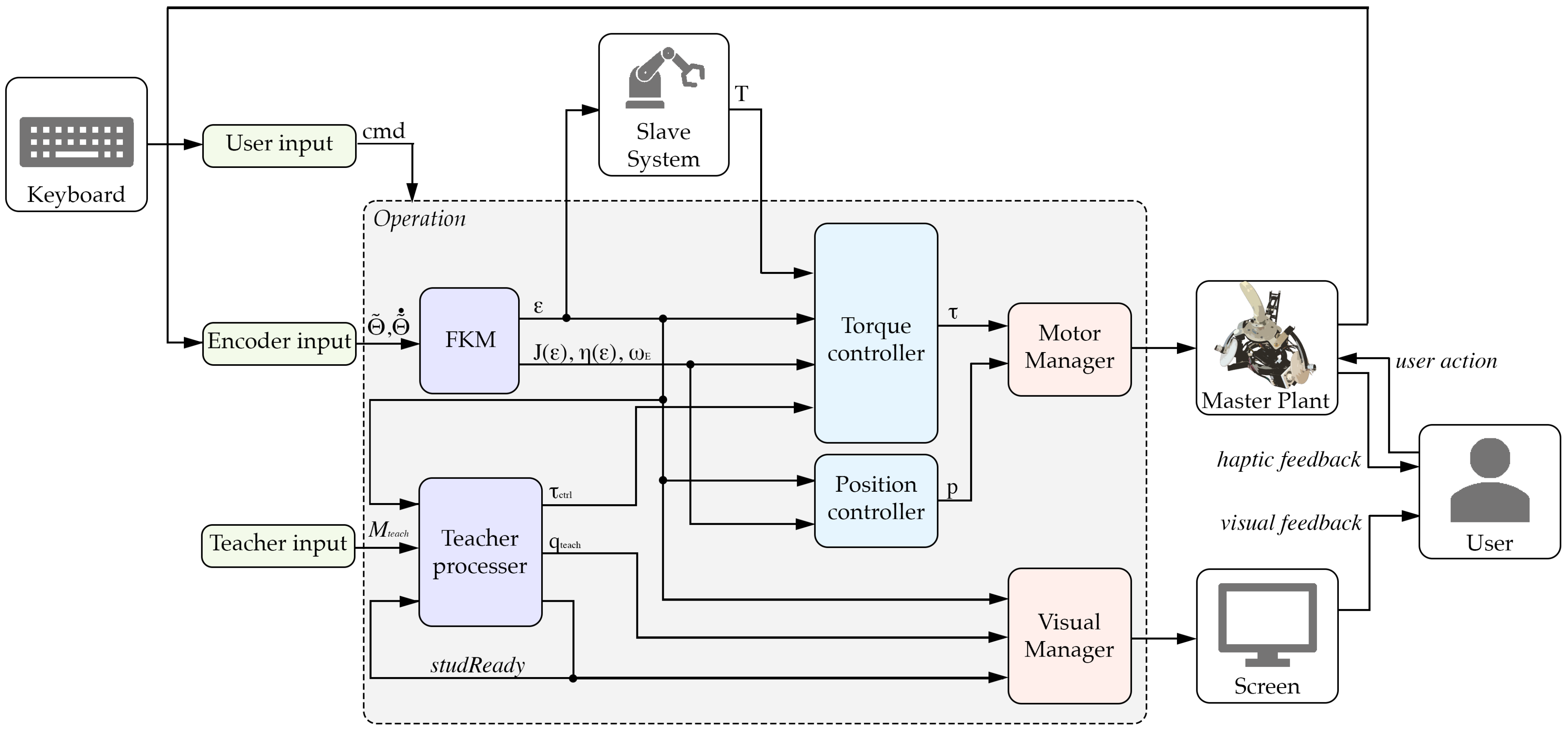

2.5. Overall Control Scheme Implementation

- Input blocks (Light green):

- –

- User input: Allowing an end user to toggle between control modes or shut off the device for emergency purposes via a keyboard. The device’s control modes, each corresponding to a suitable integer value inside topic , include different operational modes of the device: the free roaming and reset modes developed, respectively, in [25,26]; the stop mode, blocking the master device; the bilateral teleoperation mode, in which the operator interacts with a RCM slave device, such as the one described in [31], and receives haptic feedback; the assistive control mode, outlined in Section 2.4, in which the end user aims to follow a predefined path .

- –

- Encoder input: Interfacing with the absolute encoders measuring (MAB18A by Megatron [32], Table A2) through a microcontroller development board (Arduino Uno using Arduino [33]). The block is devoted to the encoders’ signal input and conditioning of , as outlined in Section 2.2. It also contains a signal differentiator to output the joint speed .

- –

- Teacher input: Outputting a predefined teaching path through the matrix , as described in Section 2.4.

- Processing blocks (dark blue):

- –

- FKM: Inputting the measured angles and outputting the estimated values of , , , and , as outlined in Section 2.1 and Section 2.2.

- –

- Teacher processer: Updating the current to feed into the system. The block checks whether has reached the current admitted dominion and updates only when said condition , as described in Section 2.4.3.

- Control blocks (light blue):

- –

- Position controller: Used by control modes such as the reset or stop modes, computing a suitable reference position or joint path.

- –

- Torque controller: Used by control modes such as the free roaming, bilateral teleoperation, or assistive control modes. Its purpose is to process and compute, basing on Equation (5), a suitable torque control input.

- Output blocks (light red):

- –

- –

- Visual manager: For pre-processing and visualizing the visual digital twin inside RViz environement, as described in Section 2.4.4.

- Keyboard input: Allowing the user to switch between different control modes;

- Slave plant: Interacting with the architecture by inputting for RCM position control, and outputting , as in Equation (5);

- Master plant: Detailed in the previous Sections, it allows said haptic feedback to reach the end user;

- Screen output: Allowing visual haptic feedback to reach the user.

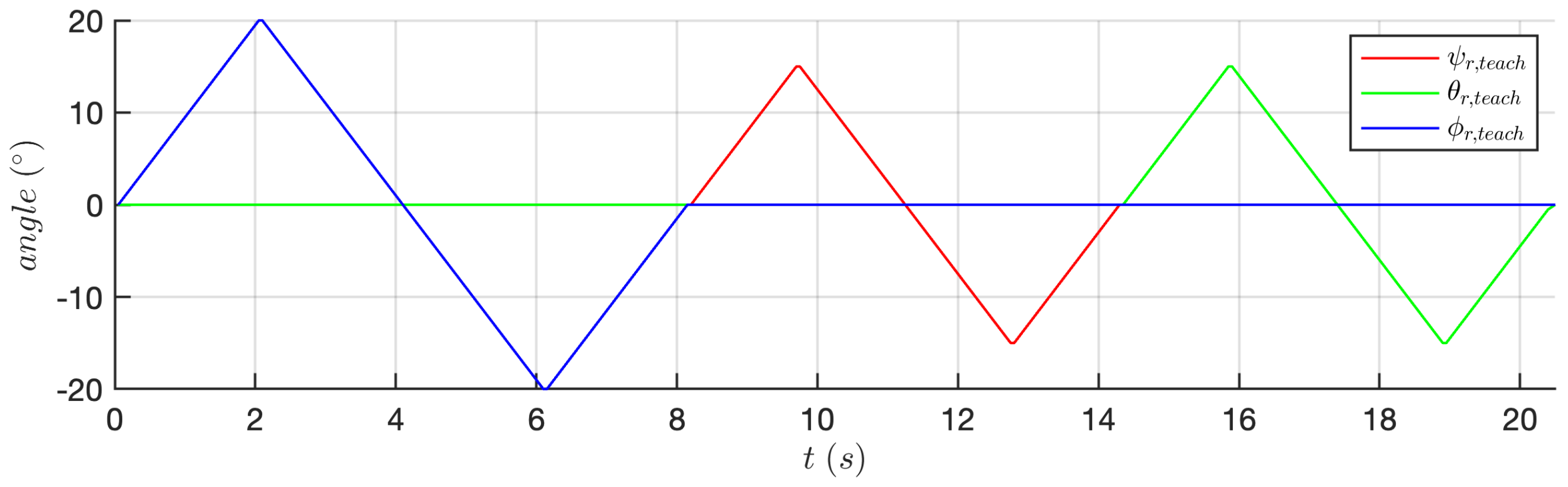

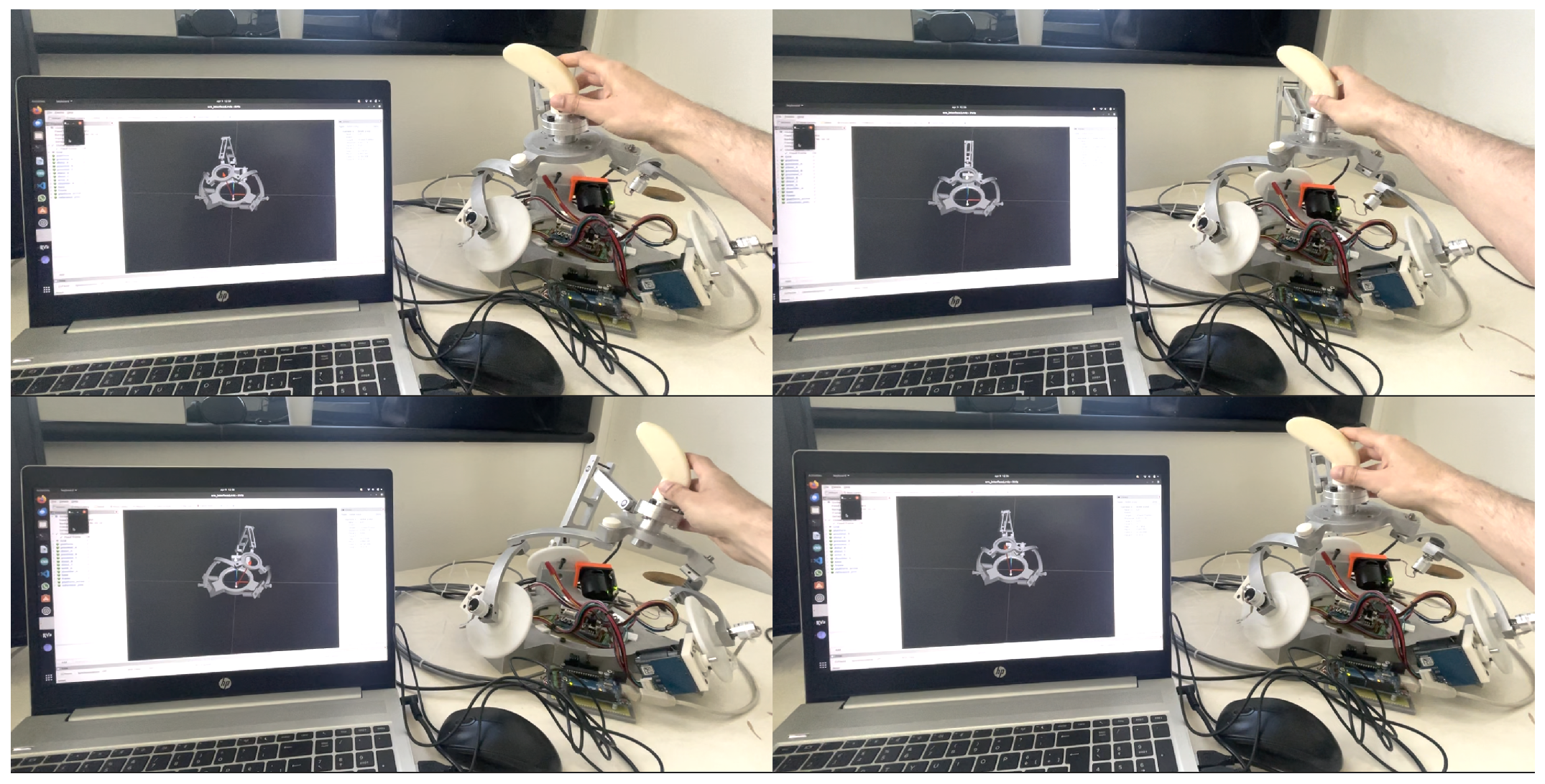

2.6. Testing Methods

- (Ex1)

- Four times the assistive control is composed only of Equation (11), neglecting self-rotation outside admitted Equation (13);

- (Ex2)

- One time the end user, not aiming to follow , actively moves the platform outside the admitted , as to prompt , neglecting self-rotation ;

- (Ex3)

- Four times the assistive action is fully implemented, taking into account all Euler angles and the full formula Equation (14).

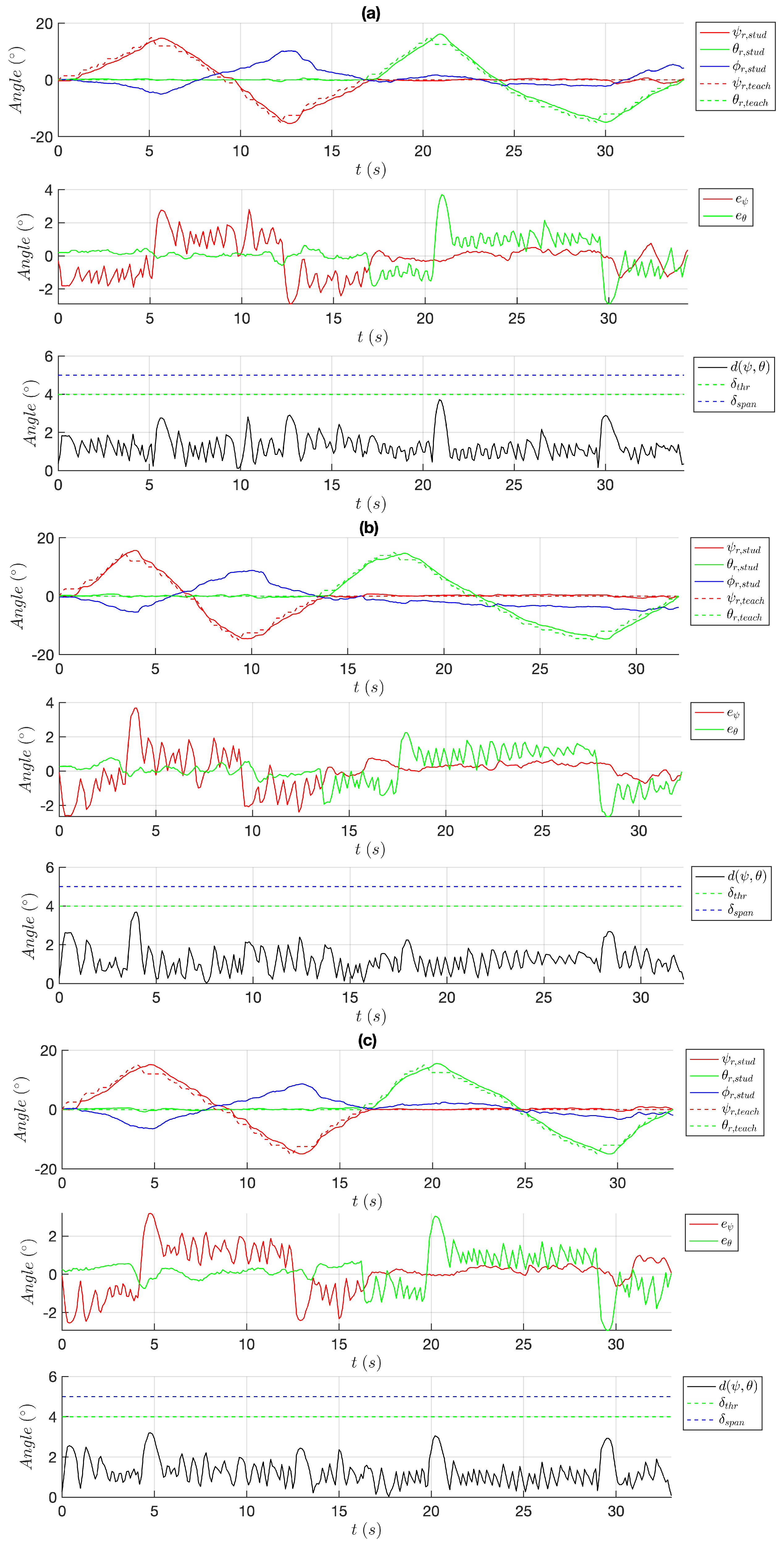

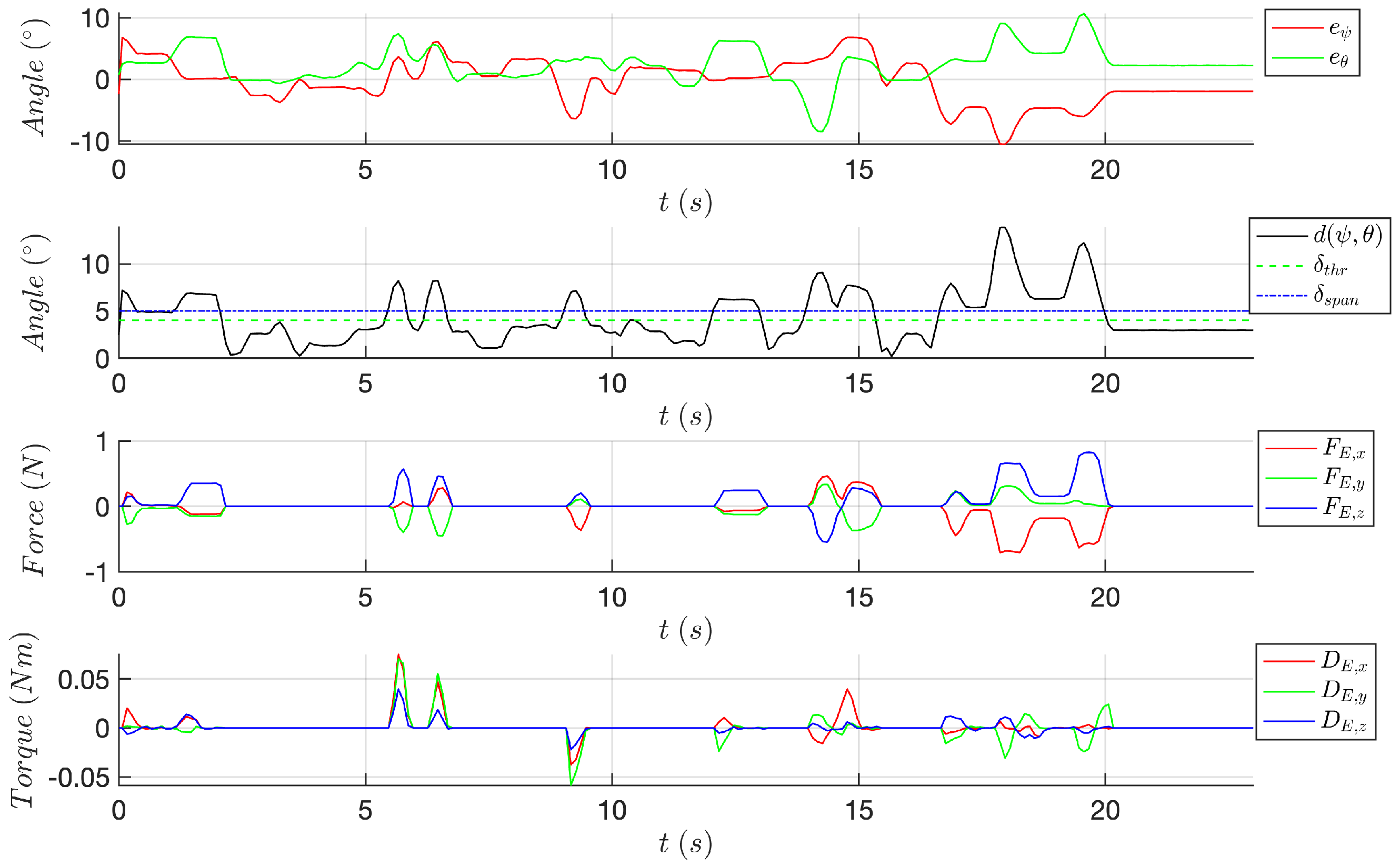

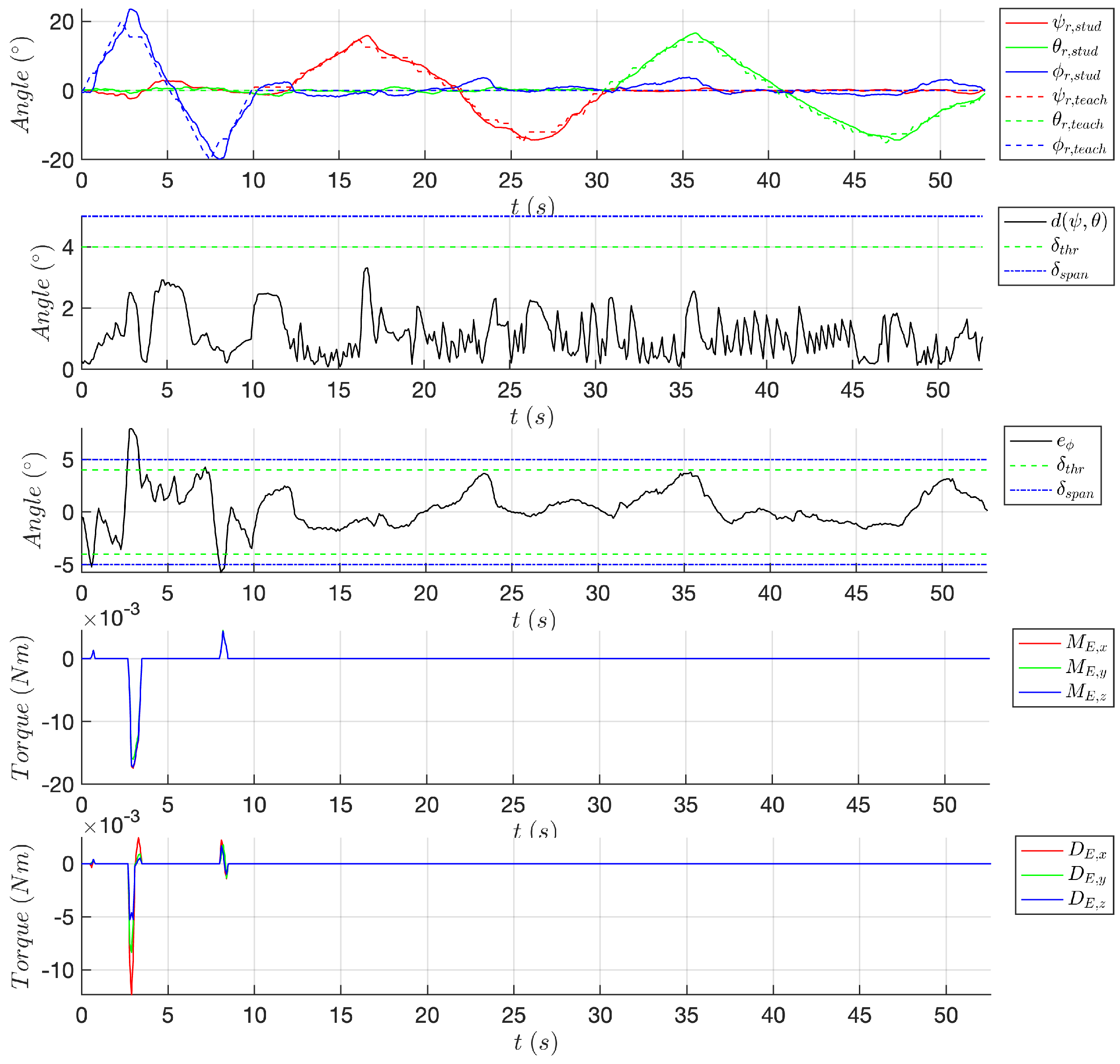

- The Euler angles triple , related to the student trajectory Equation (7a). The angles are offset to the workspace center Equation (2) for plotting clarity;

- The Euler angles triple , related to the teacher trajectory stored inside (7b). The angles are offset for clarity;

- The elements of the assistive force Equation (11) within the operative RF , defined in Section 2.1;

- The elements of the assistive torque Equation (13);

- The elements of the assistive damping Equation (14).

- Variables in Equation (8), described in Section 2.4.1;

- Variable in Equation (10), described in Section 2.4.1;

- Values and , described in Section 2.4.2 and reported in Table A1.

3. Results

3.1. Experiment 1

3.2. Experiment 2

3.3. Experiment 3

4. Discussion on the Experimental Results

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| R | Rotational Joint |

| U | Universal Joint |

| RF(s) | Reference Frame(s) |

| RCM | Remote Center of Motion |

| qSPM | Quasi-Spherical Parallel Manipulator |

| IKM | Inverse Kinematic Model |

| FKM | Forward Kinematic Model |

| ROS | Robotic Operating System |

Appendix A. Assistive Control Parameters

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Distance between operative RF origin and platform center | 0.208 | [m] | |

| Sampling Period | 0.01 | [s] | |

| Number of teacher trajectory’s samples | N | 376 | - |

| Neighborhood angular span | 5 | [∘] | |

| Neighborhood angular admissible threshold on | 4 | [∘] | |

| Maximum spring coefficient on reduced distance Equation (10) | 3 | [N/m] | |

| Maximum spring coefficient on self-rotation | 0.1 | [Nm/rad] | |

| Damping coefficient | 1 | [Nms/rad] |

Appendix B. Hardware Specifics

| Specific | Value | Unit |

|---|---|---|

| Angle range | 360 | [∘] |

| Angle resolution | 4096 | steps |

| Supply voltage | 5 | [V] |

| Supply current | <20 | [mA] |

| Signal load | >5 | [] |

| Output voltage range | 0–5 | [V] |

| Specific | Value | Unit |

|---|---|---|

| Maximum Speed (@24V) | 6000 | [rpm] |

| Maximum Torque | 0.8 | [Nm] |

| Rated Torque | 0.28 | [Nm] |

| Power supply input voltage | 24 | [V] |

| Maximum continuous mechanical output power | 120 | [W] |

| Gear-ratio (by crafted 3D-printed gears) | 200/23 | - |

Appendix C. Other Results

References

- Hokayem, P.F.; Spong, M.W. Bilateral teleoperation, An historical survey. Automatica 2006, 42, 2035–2057. [Google Scholar] [CrossRef]

- Goertz, R.C. Remote-Control Manipulator. U.S. Patent US2632574A, 24 March 1953. [Google Scholar]

- Bolopion, A.; Régnier, S. A Review of Haptic Feedback Teleoperation Systems for Micromanipulation and Microassembly. IEEE Trans. Autom. Sci. Eng. 2013, 10, 496–502. [Google Scholar] [CrossRef]

- Bayraktaroglu, Z.; Argin, O.; Haliyo, S. A modular bilateral haptic control framework for teleoperation of robots. Robotica 2019, 37, 338–357. [Google Scholar] [CrossRef]

- Jakuba, M.V.; German, C.R.; Bowen, A.D.; Whitcomb, L.L.; Hand, K.; Branch, A.; Chien, S.; McFarland, C. Teleoperation and robotics under ice, Implications for planetary exploration. In Proceedings of the 2018 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2018; pp. 1–14. [Google Scholar]

- Imaida, T.; Yokokohji, Y.; Doi, T.; Oda, M.; Yoshikawa, T. Ground-space bilateral teleoperation of ETS-VII robot arm by direct bilateral coupling under 7-s time delay condition. IEEE Trans. Robot. 2004, 20, 499–511. [Google Scholar] [CrossRef]

- Evans, C.R.; Medina, M.G.; Dwyer, A.M. Telemedicine and telerobotics, from science fiction to reality. Updates Surg. 2018, 70, 357–362. [Google Scholar] [CrossRef] [PubMed]

- Joshi, S.D. Smart Factory Digital Twin for Performance Measurement, Optimization, and Prediction. In Transforming Industry Using Digital Twin Technology; Mishra, A., El Barachi, M., Kumar, M., Eds.; Springer: Cham, Switzerland, 2024; pp. 115–143. [Google Scholar]

- Fan, W.; Guo, X.; Feng, E.; Lin, J.; Wang, Y.; Liang, J.; Garrad, M.; Rossiter, J.; Zhang, Z.; Lepora, N.; et al. Digital Twin-Driven Mixed Reality Framework for Immersive Teleoperation With Haptic Renderin. IEEE Robot. Auto. Lett. 2023, 8, 8494–8501. [Google Scholar] [CrossRef]

- Lopez Pulgarin, E.J.; Niu, H.; Herrmann, G.; Carrasco, J. Implementing and Assessing a Remote Teleoperation Setup with a Digital Twin Using Cloud Networking. In Towards Autonomous Robotic Systems; Cryer, A., Tugal, H., Caliskanelli, I., Pacheco-Gutierrez, S., Skilton, R., Eds.; Springer: Cham, Switzerland, 2022; pp. 238–250. [Google Scholar]

- Tiwari, S.; Shukla, A. Digital Twins in Industry: Real-World Applications and Innovations In Transforming Industry Using Digital Twin Technology; Mishra, A., El Barachi, M., Kumar, M., Eds.; Springer: Cham, Switzerland, 2024; pp. 1–18. [Google Scholar]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Bofill, J.; Abisado, M.; Villaverde, J.; Sampedro, G.A. Exploring Digital Twin-Based Fault Monitoring: Challenges and Opportunities. Sensors 2023, 23, 7087. [Google Scholar] [CrossRef]

- Choi, P.J.; Oskouian, R.J.; Tubbs, R.S. Telesurgery, Past, Present, and Future. Cureus 2018, 10, e2716. [Google Scholar] [CrossRef]

- Barba, P.; Stramiello, J.; Funk, E.K.; Richter, F.; Yip, M.C.; Orosco, R.K. Remote telesurgery in humans, a systematic review. Surg. Endosc. 2022, 36, 2771–2777. [Google Scholar] [CrossRef]

- Satcher, R.L.; Bogler, O.; Hyle, L.; Lee, A.; Simmons, A.; Williams, R.; Hawk, E.; Matin, S.; Brewster, A.M. Telemedicine and telesurgery in cancer care, Inaugural conference at MD Anderson Cancer Center. J. Surg. Oncol. 2014, 110, 353–359. [Google Scholar] [CrossRef] [PubMed]

- Rovetta, A.; Sala, R.; Wen, X.; Cosmi, F.; Togno, A.; Milanesi, S. Telerobotic surgery project for laparoscopy. Robotica 1995, 13, 397–400. [Google Scholar] [CrossRef]

- Meskini, M.; Saafi, H.; Mlika, A.; Arsicault, M.; Zeghloul, S.; Laribi, M.A. Development of a novel hybrid haptic (nHH) device with a remote center of rotation dedicated to laparoscopic surgery. Robotica 2023, 41, 3175–3194. [Google Scholar] [CrossRef]

- Tian, W.; Fan, M.; Zeng, C.; Liu, Y.; He, D.; Zhang, Q. Telerobotic Spinal Surgery Based on 5G Network, The First 12 Cases. Neurospine 2020, 17, 114–120. [Google Scholar] [CrossRef] [PubMed]

- Lopez, I.B.; Benzakour, A.; Mavrogenis, A.; Benzakour, T.; Ahmad, A.; Lemée, J.M. Robotics in spine surgery, systematic review of literature. Int. Orthop. 2023, 47, 447–456. [Google Scholar] [CrossRef]

- Saafi, H.; Laribi, M.A.; Zeghloul, S. Improvement of the direct kinematic model of a haptic device for medical application in real time using an extra sensor. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; pp. 1697–1702. [Google Scholar]

- Saafi, H.; Laribi, M.A.; Zeghloul, S. Redundantly actuated 3-RRR spherical parallel manipulator used as a haptic device, Improving dexterity and eliminating singularity. Robotica 2015, 33, 1113–1130. [Google Scholar] [CrossRef]

- Saafi, H.; Zeghloul, S.; Arsicault, M.; Laribi, M.A. On the Development of a New Master Device Used for Medical Tasks. J. Mech. Robot. 2018, 10, 044501. [Google Scholar] [CrossRef]

- Saafi, H.; Laribi, M.A.; Zeghloul, S. Forward Kinematic Model Resolution of a Special Spherical Parallel Manipulator: Comparison and Real-Time Validation. Robotics 2020, 9, 62. [Google Scholar] [CrossRef]

- Pacheco Quiñones, D.; Maffiodo, D.; Laribi, M.A. Kinematic Analysis, Workspace definition and Self-Collision avoidance of a quasi-Spherical Parallel Manipulator. Robotica 2025. accepted. [Google Scholar]

- Pacheco Quiñones, D.; Maffiodo, D.; Laribi, M.A. Joint Path Planning of the Quasi-Spherical Parallel Manipulator. In Advances in Italian Mechanism Science; Quaglia, G., Boschetti, G., Carbone, G., Eds.; Springer: Cham, Switzerland, 2024; pp. 242–248. [Google Scholar]

- Singh, S.K.; Yang, L.; Ma, H. Recent Challenges for Haptic Interface and Control for Robotic Assisted Surgical Training System: A Review. In Proceedings of the 2021 IEEE World AI IoT Congress (AIIoT), Seattle, WA, USA, 10–13 May 2021; pp. 0240–0249. [Google Scholar]

- Garudeswaran, S.; Cho, S.; Ohu, I.; Panahi, A.K.; Kavic, S. Teach and Playback Training Device for Minimally Invasive Surgery. Minim. Invasive Surg. 2018, 2018, 4815761. [Google Scholar] [CrossRef]

- Hong, K.; Sun, Y.; He, J.; Lei, Y.; Yang, L. Preliminary design of a robotic system for kinaesthetic training of surgical tasks. J. Eng. 2019, 2019, 490–494. [Google Scholar] [CrossRef]

- Chablat, D.; Wenger, P. Working modes and aspects in fully parallel manipulators. In Proceedings of the 1998 IEEE International Conference on Robotics and Automation, Leuven, Belgium, 20 May 1998; pp. 1964–1969. [Google Scholar]

- Trabelsi, A.; Sandoval, J.; Mlika, A.; Lahouar, S.; Zeghloul, S.; Cau, J.; Laribi, M.A. Optimal Multi-robot Placement Based on Capability Map for Medical Applications. In Advances in Service and Industrial Robotics; Müller, A., Brandstötter, M., Eds.; Springer: Cham, Switzerland, 2022; Volume 120, pp. 120–135. [Google Scholar]

- Megatron Hall-Effect Absolute Encoder Series MAB18A. Available online: https://www.megatron.de/en/products/more-products-angle-sensors/Hall-effect-absolute-encoder-series-mab18a.html (accessed on 8 June 2024).

- Arduino Uno Board. Available online: https://store.arduino.cc/products/arduino-uno-rev3 (accessed on 8 June 2024).

- Simplex Motion SC-Series. Available online: https://simplexmotion.com/integrated-servomotors/sc-series/ (accessed on 8 June 2024).

- Minimalmodbus Python Module. Available online: https://minimalmodbus.readthedocs.io/en/stable/ (accessed on 8 June 2024).

| Trial | Duration [s] | ||||||

|---|---|---|---|---|---|---|---|

| 1 | −0.34 | 1.246 | 0.238 | 1.010 | 1.459 | 0.782 | 26.8 |

| 2 | −0.164 | 1.06 | 0.113 | 0.937 | 1.291 | 0.610 | 34.3 |

| 3 | 0.002 | 0.968 | 0.110 | 0.943 | 1.202 | 0.626 | 32.2 |

| 4 | 0.161 | 1.083 | 0.176 | 0.889 | 1.269 | 0.636 | 33 |

| Average: | −0.074 | 1.082 | 0.155 | 0.941 | 1.298 | 0.657 | 31.6 |

| Trial | Admitted Points | Duration [s] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.002 | 0.869 | 0.155 | 0.716 | −0.229 | 1.905 | 0.957 | 0.613 | 94.62 | 55.7 |

| 2 | 0.036 | 0.765 | 0.029 | 1.065 | −0.524 | 2.516 | 1.036 | 0.805 | 92.46 | 50.3 |

| 3 | −0.095 | 1.037 | 0.183 | 0.772 | 0.392 | 1.880 | 1.109 | 0.696 | 97.15 | 52.6 |

| 4 | −0.134 | 1.229 | 0.192 | 0.922 | −0.693 | 2.663 | 1.291 | 0.864 | 85.13 | 63.2 |

| Average: | −0.052 | 0.988 | 0.144 | 0.867 | −0.281 | 2.254 | 1.106 | 0.747 | 92.03 | 55.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pacheco Quiñones, D.; Maffiodo, D.; Laribi, M.A. Assistive Control through a Hapto-Visual Digital Twin for a Master Device Used for Didactic Telesurgery. Robotics 2024, 13, 138. https://doi.org/10.3390/robotics13090138

Pacheco Quiñones D, Maffiodo D, Laribi MA. Assistive Control through a Hapto-Visual Digital Twin for a Master Device Used for Didactic Telesurgery. Robotics. 2024; 13(9):138. https://doi.org/10.3390/robotics13090138

Chicago/Turabian StylePacheco Quiñones, Daniel, Daniela Maffiodo, and Med Amine Laribi. 2024. "Assistive Control through a Hapto-Visual Digital Twin for a Master Device Used for Didactic Telesurgery" Robotics 13, no. 9: 138. https://doi.org/10.3390/robotics13090138

APA StylePacheco Quiñones, D., Maffiodo, D., & Laribi, M. A. (2024). Assistive Control through a Hapto-Visual Digital Twin for a Master Device Used for Didactic Telesurgery. Robotics, 13(9), 138. https://doi.org/10.3390/robotics13090138