Investigation of Seasonal Variation in Fatty Acid and Mineral Concentrations of Pecorino Romano PDO Cheese: Imputation of Missing Values for Enhanced Classification and Metabolic Profile Reconstruction

Abstract

1. Introduction

2. Materials and Methods

2.1. Analytical Methods

2.1.1. Cheese Composition and Nitrogen Fractions

2.1.2. Fatty Acid Methyl Ester Analysis

2.1.3. Elemental Analysis

2.2. Chemometric Techniques

2.3. Models’ Validation

- Step 1. Creation of the calibration set. The set is created by randomly selecting approximately 85% of the available complete samples. Further partial samples are added to the calibration set to constitute approximately 15 to 35% of the total calibration set.

- Step 2. Validation set construction. The remaining complete samples from step 1 are included for model cross-validation. Additional partial samples are included in the validation set, constituting approximately 30% to 65% of the total validation set. These samples are exclusively used for external validation, meaning that they are not replaced in the calibration set.

- Step 3. Calibrate the models. The entire calibration dataset is utilized to tune the PPCA and PLS-DA models.

- Step 4. Calculate the percentage of correctly classified samples (%CC). The PPCA and PLS-DA models are tested in reference to the validation samples, and their performance is assessed by determining their classification accuracy.

3. Results and Discussion

3.1. Pecorino Romano PDO Cheese Macro Composition Analysis

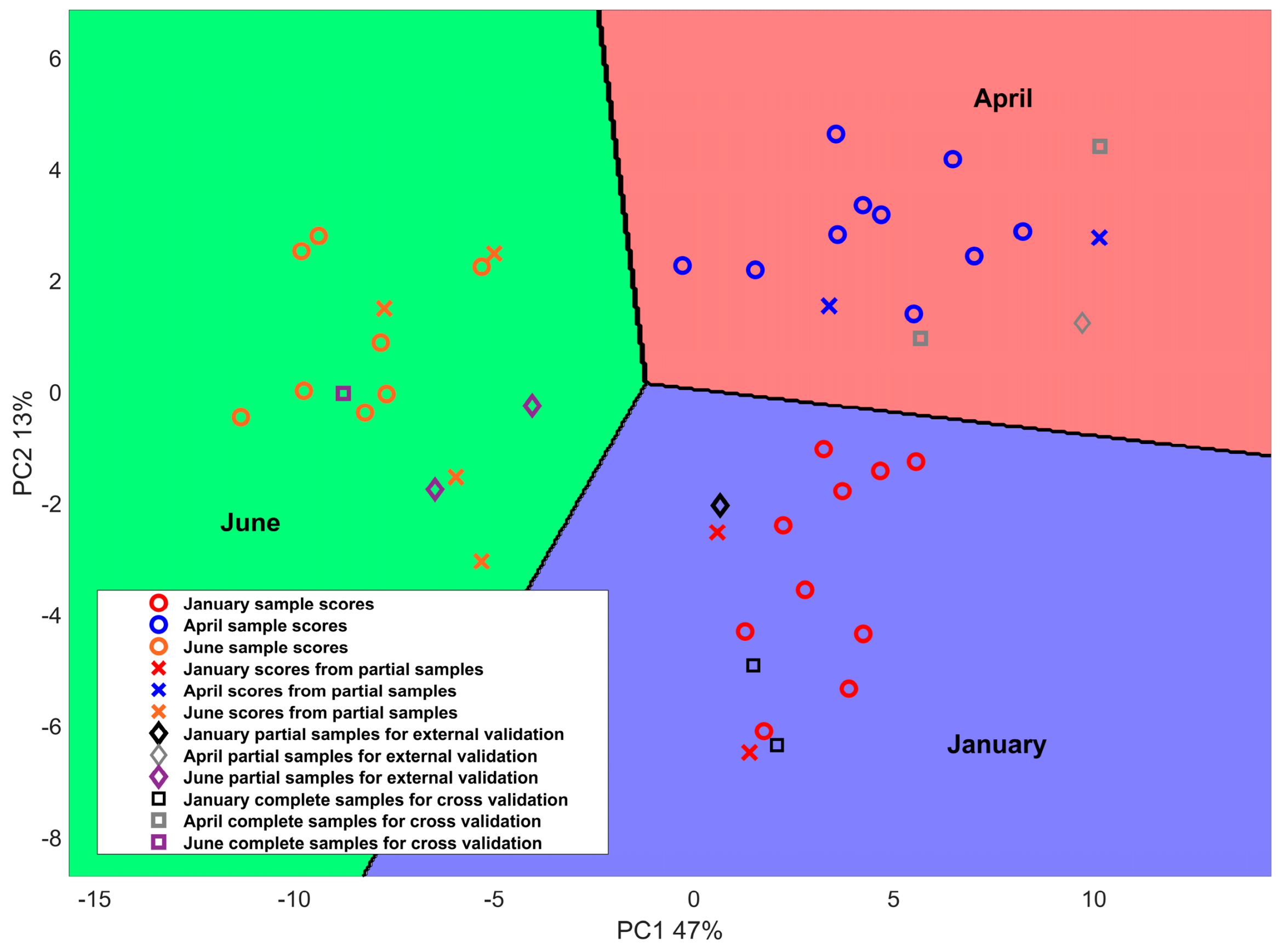

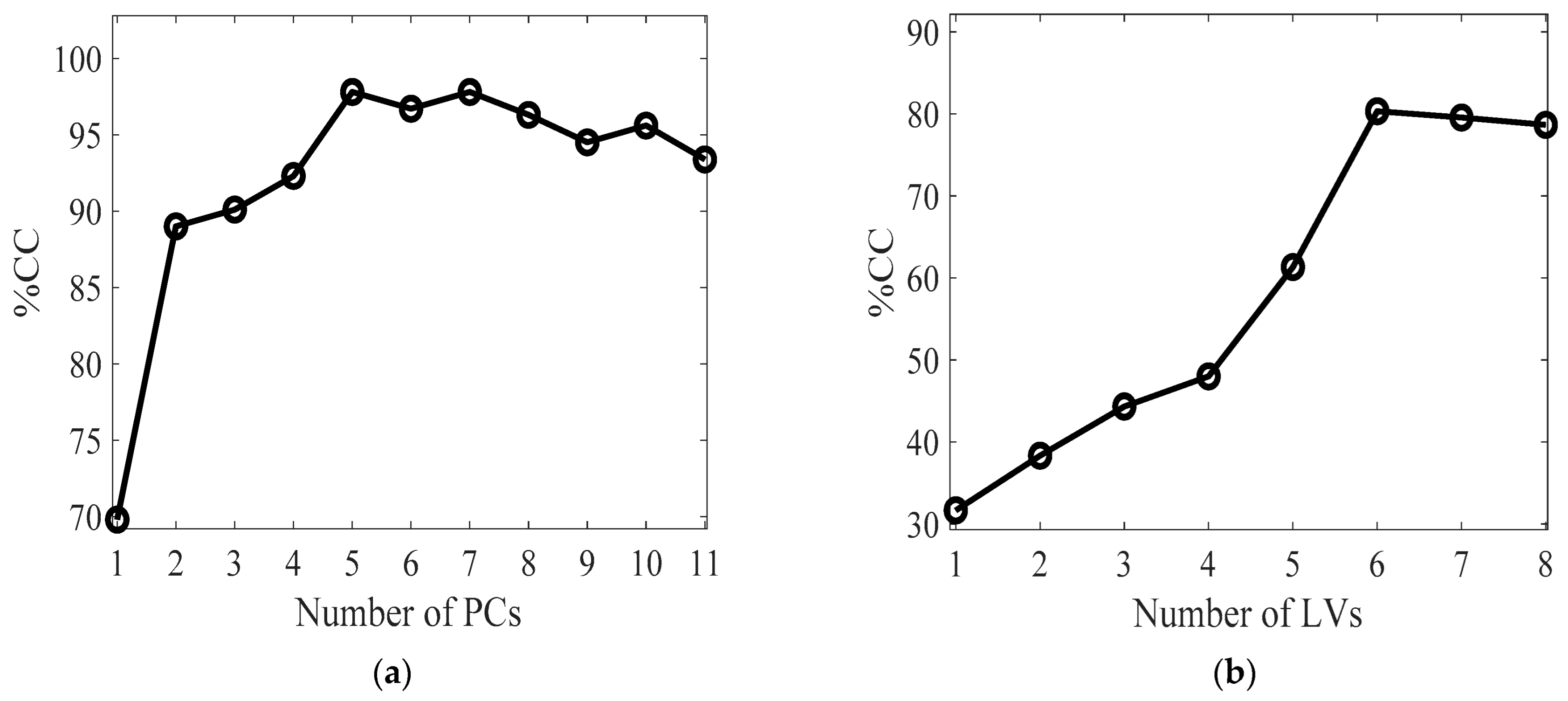

3.2. Multivariate Statistical Analysis on % FAME and Mineral Profiles

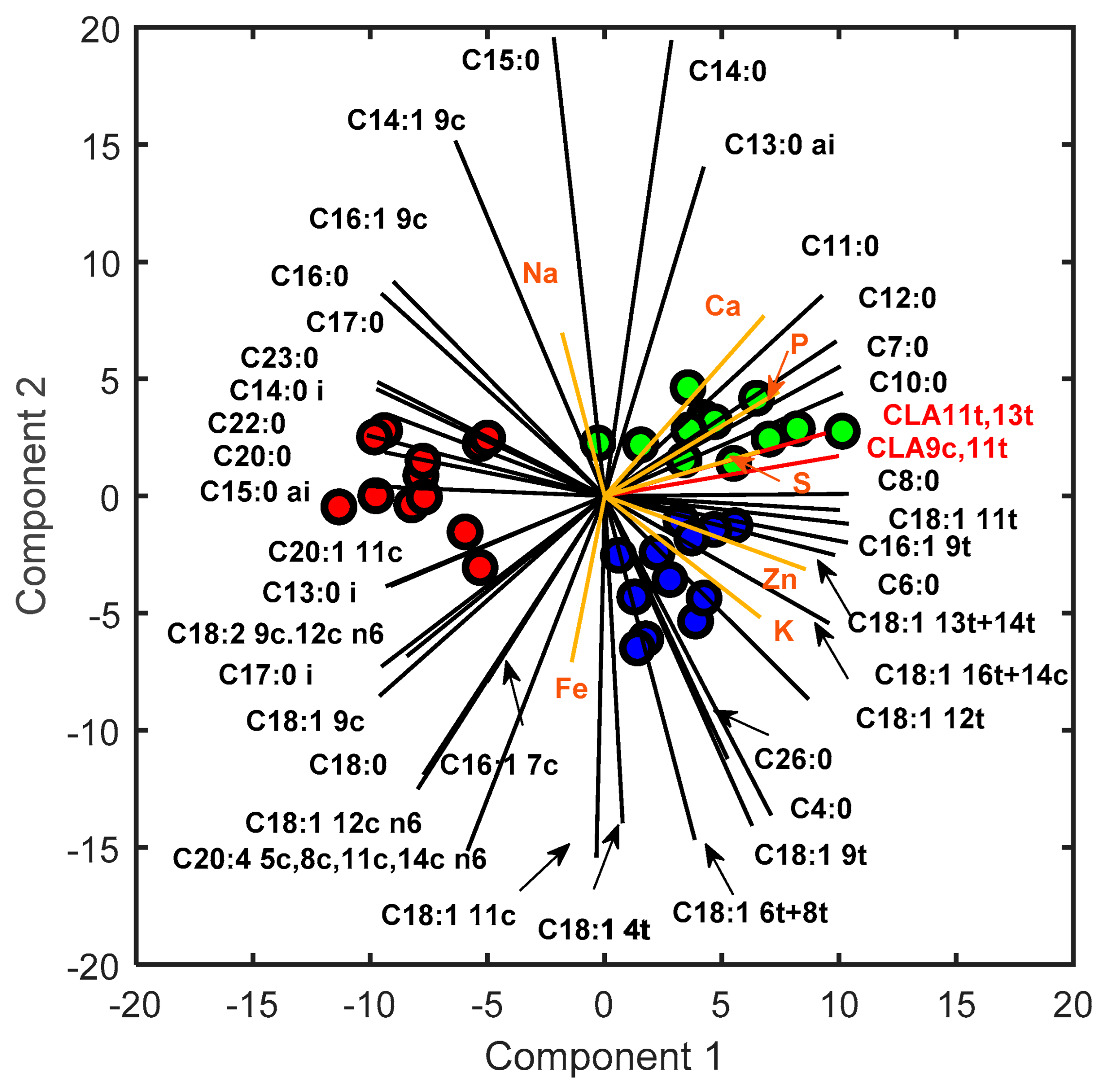

3.3. PPCA Loading Analysis

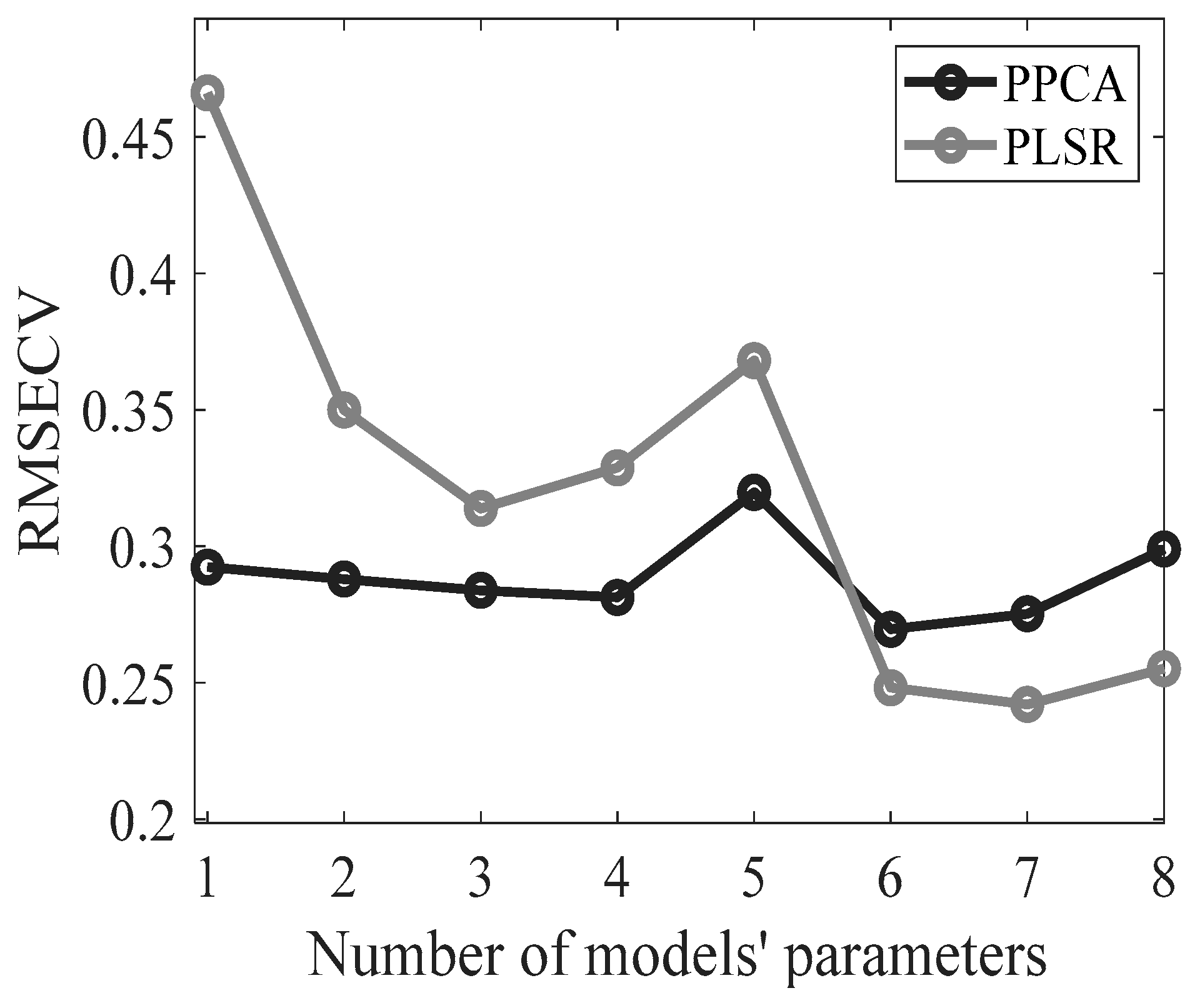

3.4. Missing Data Reconstruction

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- MacGregor, J.F.; Kourti, T. Statistical process control of multivariate processes. Control Eng. Pract. 1995, 3, 403–414. [Google Scholar] [CrossRef]

- Miletic, I.; Quinn, S.; Dudzic, M.; Vaculik, V.; Champagne, M. An industrial perspective on implementing on-line applications of multivariate statistics. J. Process Control 2004, 14, 821–836. [Google Scholar] [CrossRef]

- Renes, E.; Gómez-Cortés, P.; de la Fuente, M.A.; Linares, D.M.; Tornadijo, M.E.; Fresno, J.M. CLA-producing adjunct cultures improve the nutritional value of sheep cheese fat. Food Res. Int. 2019, 116, 819–826. [Google Scholar] [CrossRef] [PubMed]

- Mishra, B.; Mishra, A.K.; Kumar, S.; Mandal, S.K.; Lakshmayya, N.S.V.; Kumar, V.; Baek, K.H.; Mohanta, Y.K. Antifungal metabolites as food bio-preservative: Innovation, outlook, and challenges. Metabolites 2022, 12, 12. [Google Scholar] [CrossRef] [PubMed]

- Khattab, A.R.; Guirguis, H.A.; Tawfik, S.M.; Farag, M.A. Cheese ripening: A review on modern technologies towards flavor enhancement, process acceleration and improved quality assessment. Trends Food Sci. Technol. 2019, 88, 343–360. [Google Scholar] [CrossRef]

- Matera, J.; Luna, A.S.; Batista, D.B.; Pimentel, T.C.; Moraes, J.; Kamimura, B.A.; Ferreira, M.V.S.; Silva, H.L.A.; Mathias, S.P.; Esmerino, E.A.; et al. Brazilian cheeses: A survey covering physicochemical characteristics, mineral content, fatty acid profile and volatile compounds. Food Res. Int. 2018, 108, 18–26. [Google Scholar] [CrossRef]

- Addis, M.; Fiori, M.; Riu, G.; Pes, M.; Salvatore, E.; Pirisi, A. Physico-chemical characteristics and acidic profile of PDO Pecorino Romano cheese: Seasonal variation. Small Rumin. Res. 2015, 126, 73–79. [Google Scholar] [CrossRef]

- Nudda, A.; Correddu, F.; Cesarani, A.; Pulina, G.; Battacone, G. Functional Odd- and Branched-Chain Fatty Acid in Sheep and Goat Milk and Cheeses. Dairy 2021, 2, 79–89. [Google Scholar] [CrossRef]

- Caboni, P.; Murgia, A.; Porcu, A.; Manis, C.; Ibba, I.; Contu, M.; Scano, P. A metabolomics comparison between sheep’s and goat’s milk. Food Res. Int. 2019, 119, 869–875. [Google Scholar] [CrossRef]

- Suh, J.H. Critical review: Metabolomics in dairy science—Evaluation of milk and milk product quality. Food Res. Int. 2022, 154, 110984. [Google Scholar] [CrossRef]

- Karlsson, T.; Winkvist, A.; Rådjursöga, M.; Ellegård, L.; Pedersen, A.; Lindqvist, H.M. Identification of Single and Combined Serum Metabolites Associated with Food Intake. Metabolites 2022, 12, 908. [Google Scholar] [CrossRef] [PubMed]

- Cubero-Leon, E.; Peñalver, R.; Maquet, A. Review on metabolomics for food authentication. Food Res. Int. 2014, 60, 95–107. [Google Scholar] [CrossRef]

- Tipping, M.E.; Bishop, C.M. Probabilistic principal component analysis. J. R. Stat. Soc. Ser. B Stat. Methodol. 1999, 61, 611–622. [Google Scholar] [CrossRef]

- Mercier, S.; Mondor, M.; Marcos, B.; Moresoli, C.; Villeneuve, S. Estimation of missing values in a food property database by matrix completion using PCA-based approaches. Chemom. Intell. Lab. Syst. 2017, 166, 37–48. [Google Scholar] [CrossRef]

- Delaporte, G.; Cladière, M.; Camel, V. Missing value imputation and data cleaning in untargeted food chemical safety assessment by LC-HRMS. Chemom. Intell. Lab. Syst. 2019, 188, 54–62. [Google Scholar] [CrossRef]

- Gromski, P.; Xu, Y.; Kotze, H.; Correa, E.; Ellis, D.; Armitage, E.; Turner, M.; Goodacre, R. Influence of Missing Values Substitutes on Multivariate Analysis of Metabolomics Data. Metabolites 2014, 4, 433–452. [Google Scholar] [CrossRef]

- van Ginkel, J.R.; Linting, M.; Rippe, R.C.A.; van der Voort, A. Rebutting Existing Misconceptions About Multiple Imputation as a Method for Handling Missing Data. J. Pers. Assess. 2020, 102, 297–308. [Google Scholar] [CrossRef]

- Nyamundanda, G.; Brennan, L.; Gormley, I.C. Probabilistic principal component analysis for metabolomic data. BMC Bioinform. 2010, 11, 571. [Google Scholar] [CrossRef] [PubMed]

- Scano, E.A.; Grosso, M.; Pistis, A.; Carboni, G.; Cocco, D. An in-depth analysis of biogas production from locally agro-industrial by-products and residues. An Italian case. Renew. Energy 2021, 179, 308–318. [Google Scholar] [CrossRef]

- Kalivodová, A.; Hron, K.; Filzmoser, P.; Najdekr, L.; Janečková, H.; Adam, T. PLS-DA for compositional data with application to metabolomics. J. Chemom. 2015, 29, 21–28. [Google Scholar] [CrossRef]

- ISO5534:2004; Cheese and Processed Cheese—Determination of the Total Solids Content. ISO: Geneva, Switzerland, 2004.

- Soxhlet, F. Die gewichtsanalytische Bestimmung des Milchfettes. Dinglers Polytech. J. 1879, 232, 461–465. [Google Scholar]

- ISO 8968-12014 IDF 20-12014; IDF Milk and Milk Products—Determination of Nitrogen Content—Part 1: Kjeldahl Principle and Crude Protein Calculation. ISO: Geneva, Switzerland, 2014.

- Gripon, J.C.; Desmazeaud, M.J.; Le Bars, D.; Bergere, J.L. Etude du rôle des micro-organismes et des enzymes au cours de la maturation des fromages. II.—Influence de la présure commerciale. Lait 1975, 55, 502–516. [Google Scholar] [CrossRef]

- ISO 5943:2006 IDF 88:2006; Cheese and Processed Cheese Products—Determination of Chloride Content—Potentiometric Titration Method. ISO: Geneva, Switzerland, 2006.

- ISO 5545 IDF 90: 2008; Rennet Caseins and Caseinates, Determination of Ash. ISO: Geneva, Switzerland, 2008.

- Jiang, J.; Bjoerck, L.; Fondén, R.; Emanuelson, M. Occurrence of Conjugated Cis-9,Trans-11-Octadecadienoic Acid in Bovine Milk: Effects of Feed and Dietary Regimen. J. Dairy Sci. 1996, 79, 438–445. [Google Scholar] [CrossRef] [PubMed]

- Lai, G.; Caboni, P.; Piras, C.; Pes, M.; Sitzia, M.; Addis, M.; Pirisi, A.; Scano, P. Development and Chemico-Physical Characterization of Ovine Milk-Based Ingredients for Infant Formulae. Appl. Sci. 2023, 13, 653. [Google Scholar] [CrossRef]

- Brereton, R.G. Chemometrics for Pattern Recognition; Wiley: Hoboken, NJ, USA, 2009; ISBN 9780470987254. [Google Scholar]

- Xu, Q.S.; Liang, Y.Z. Monte Carlo cross validation. Chemom. Intell. Lab. Syst. 2001, 56, 1–11. [Google Scholar] [CrossRef]

- Ballabio, D.; Consonni, V. Classification tools in chemistry. Part 1: Linear models. PLS-DA. Anal. Methods 2013, 5, 3790–3798. [Google Scholar] [CrossRef]

- Guinee, T.P.; Mulholland, E.O.; Kelly, J.; Callaghan, D.J.O. Effect of protein-to-fat ratio of milk on the composition, manufacturing efficiency, and yield of cheddar cheese. J. Dairy Sci. 2007, 90, 110–123. [Google Scholar] [CrossRef] [PubMed]

- Altomonte, I.; Conte, G.; Serra, A.; Mele, M.; Cannizzo, L.; Salari, F.; Martini, M. Nutritional characteristics and volatile components of sheep milk products during two grazing seasons. Small Rumin. Res. 2019, 180, 41–49. [Google Scholar] [CrossRef]

- Serrapica, F.; Masucci, F.; Di Francia, A.; Napolitano, F.; Braghieri, A.; Esposito, G.; Romano, R. Seasonal variation of chemical composition, fatty acid profile, and sensory properties of a mountain pecorino cheese. Foods 2020, 9, 1091. [Google Scholar] [CrossRef]

- Todaro, M.; Bonanno, A.; Scatassa, M.L. The quality of Valle del Belice sheep’s milk and cheese produced in the hot summer season in Sicily. Dairy Sci. Technol. 2014, 94, 225–239. [Google Scholar] [CrossRef][Green Version]

- Verma, A.; Meitei, N.S.; Gajbhiye, P.U.; Raftery, M.J.; Ambatipudi, K. Comparative analysis of milk triglycerides profile between jaffarabadi buffalo and holstein friesian cow. Metabolites 2020, 10, 507. [Google Scholar] [CrossRef] [PubMed]

- Bontempo, L.; Barbero, A.; Bertoldi, D.; Camin, F.; Larcher, R.; Perini, M.; Sepulcri, A.; Zicarelli, L.; Piasentier, E. Isotopic and elemental profiles of Mediterranean buffalo milk and cheese and authentication of Mozzarella di Bufala Campana PDO: An initial exploratory study. Food Chem. 2019, 285, 316–323. [Google Scholar] [CrossRef] [PubMed]

- Lopez, C.; Briard-Bion, V.; Ménard, O. Polar lipids, sphingomyelin and long-chain unsaturated fatty acids from the milk fat globule membrane are increased in milks produced by cows fed fresh pasture based diet during spring. Food Res. Int. 2014, 58, 59–68. [Google Scholar] [CrossRef]

- Dar, A.A.; Jadhav, R.K.; Dimri, U.; Khan, A.A.; Khan, H.M.; Sharma, M.C. Effects of physiological status and seasonal variation on plasma mineral profile of sheep in Kashmir valley. Sci. Res. Essays 2014, 9, 69–76. [Google Scholar]

- Li, S.; Delger, M.; Dave, A.; Singh, H.; Ye, A. Seasonal Variations in the Composition and Physicochemical Characteristics of Sheep and Goat Milks. Foods 2022, 11, 1737. [Google Scholar] [CrossRef]

- García-Laencina, P.J.; Sancho-Gómez, J.L.; Figueiras-Vidal, A.R. Pattern classification with missing data: A review. Neural Comput. Appl. 2010, 19, 263–282. [Google Scholar] [CrossRef]

| January | April | June | ||||

|---|---|---|---|---|---|---|

| Number of Complete Samples | Number of Partial Samples | Number of Complete Samples | Number of Partial Samples | Number of Complete Samples | Number of Partial Samples | |

| Calibration set | 10 | 2 | 10 | 2 | 8 | 4 |

| Validation set | 2 a | 1 b | 2 a | 1 b | 1 a | 2 b |

| Total | 12 | 3 | 12 | 3 | 9 | 6 |

| Parameter | January | April | June |

|---|---|---|---|

| pH | 5.07 ± 0.12 a,b | 5.10 ± 0.12 a | 5.01 ± 0.14 b |

| Moisture (w/w %) | 31.86 ± 1.43 a | 31.51 ± 0.97 a | 31.57 ± 1.05 a |

| Fat/Dry matter (w/w %) | 49.54 ± 1.31 b | 47.60 ± 1.40 c | 50.58 ± 1.28 a |

| Protein/Dry matter (w/w %) | 36.65 ± 0.94 b | 38.22 ± 1.12 a | 35.43 ± 1.10 c |

| Fat/Protein ratio (-) | 1.35 ± 0.05 b | 1.25 ± 0.05 c | 1.43 ± 0.06 a |

| NaCl (w/w %) | 4.48 ± 0.88 c | 4.59 ± 0.83 b | 5.02 ± 0.98 a |

| Ash (w/w %) | 7.20 ± 0.83 a | 7.48 ± 0.81 a | 7.57 ± 0.95 a |

| SN/TN (%) | 14.95 ± 2.25 a | 14.28 ± 3.11 a | 13.99 ± 2.07 a |

| SN-TCA/TN (%) | 21.21 ± 2.13 a | 11.92 ± 2.36 a | 11.22 ± 2.24 a |

| SN-PTA/TN (%) | 9.71 ± 2.51 a | 9.27 ± 1.79 a | 9.08 ± 1.89 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sibono, L.; Grosso, M.; Tronci, S.; Errico, M.; Addis, M.; Vacca, M.; Manis, C.; Caboni, P. Investigation of Seasonal Variation in Fatty Acid and Mineral Concentrations of Pecorino Romano PDO Cheese: Imputation of Missing Values for Enhanced Classification and Metabolic Profile Reconstruction. Metabolites 2023, 13, 877. https://doi.org/10.3390/metabo13070877

Sibono L, Grosso M, Tronci S, Errico M, Addis M, Vacca M, Manis C, Caboni P. Investigation of Seasonal Variation in Fatty Acid and Mineral Concentrations of Pecorino Romano PDO Cheese: Imputation of Missing Values for Enhanced Classification and Metabolic Profile Reconstruction. Metabolites. 2023; 13(7):877. https://doi.org/10.3390/metabo13070877

Chicago/Turabian StyleSibono, Leonardo, Massimiliano Grosso, Stefania Tronci, Massimiliano Errico, Margherita Addis, Monica Vacca, Cristina Manis, and Pierluigi Caboni. 2023. "Investigation of Seasonal Variation in Fatty Acid and Mineral Concentrations of Pecorino Romano PDO Cheese: Imputation of Missing Values for Enhanced Classification and Metabolic Profile Reconstruction" Metabolites 13, no. 7: 877. https://doi.org/10.3390/metabo13070877

APA StyleSibono, L., Grosso, M., Tronci, S., Errico, M., Addis, M., Vacca, M., Manis, C., & Caboni, P. (2023). Investigation of Seasonal Variation in Fatty Acid and Mineral Concentrations of Pecorino Romano PDO Cheese: Imputation of Missing Values for Enhanced Classification and Metabolic Profile Reconstruction. Metabolites, 13(7), 877. https://doi.org/10.3390/metabo13070877