A Genome-Scale Metabolic Model of Anabaena 33047 to Guide Genetic Modifications to Overproduce Nylon Monomers

Abstract

1. Introduction

2. Results and Discussion

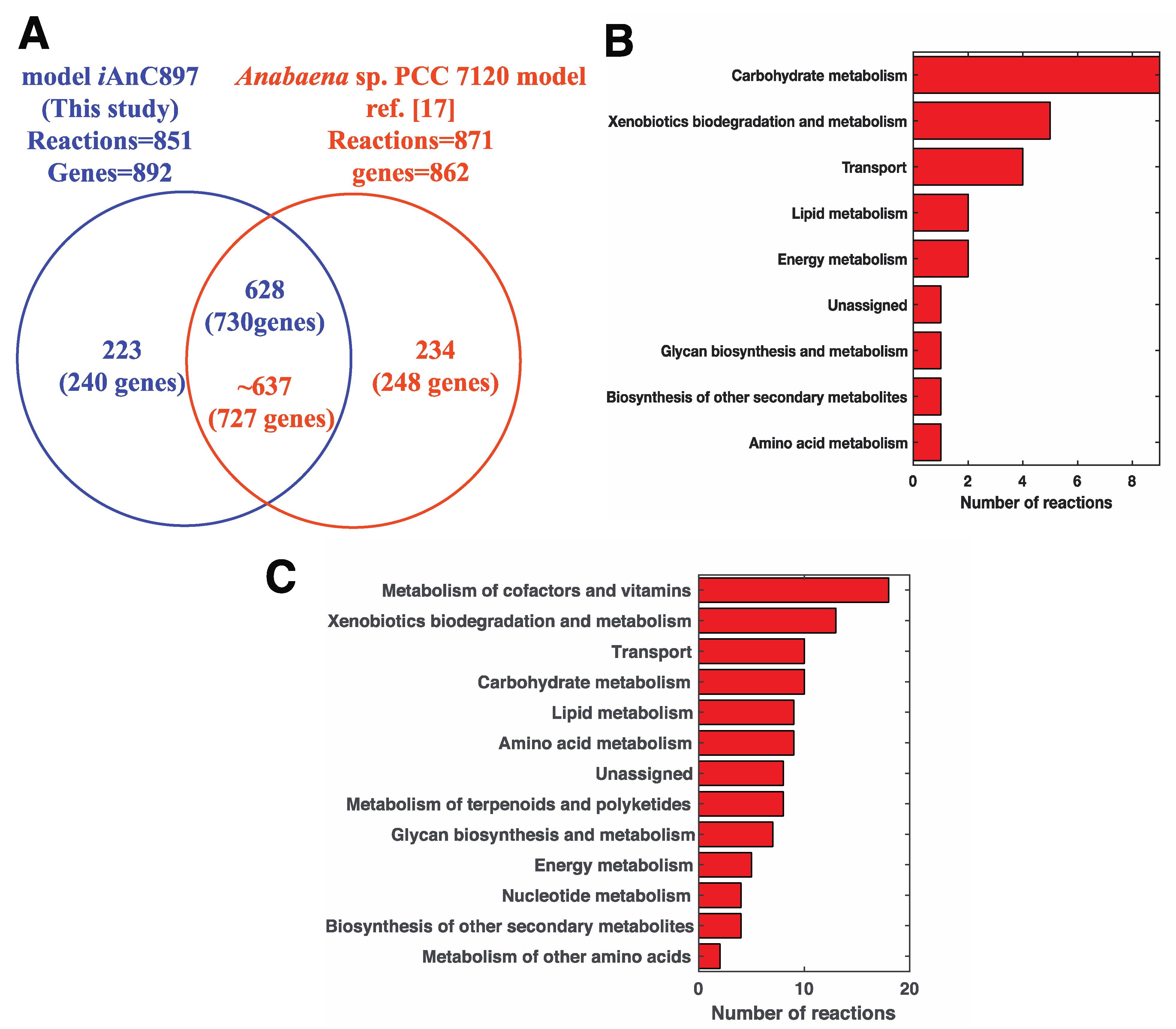

2.1. Genome Scale Metabolic Model of Anabaena 33047

2.2. Comparison with the Metabolic Network of Anabaena sp. PCC 7120

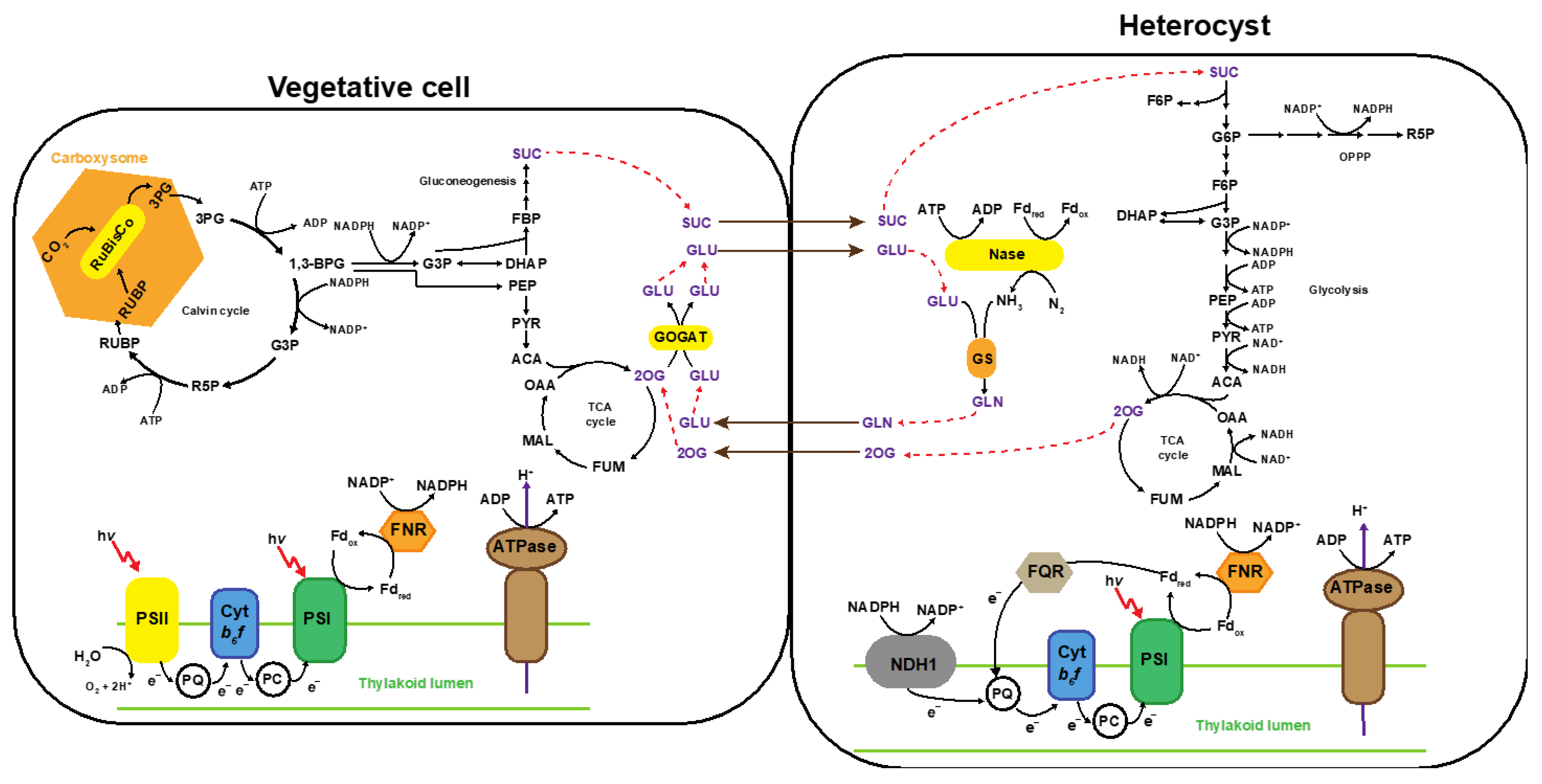

2.3. Flux Distribution Predicted by the Model

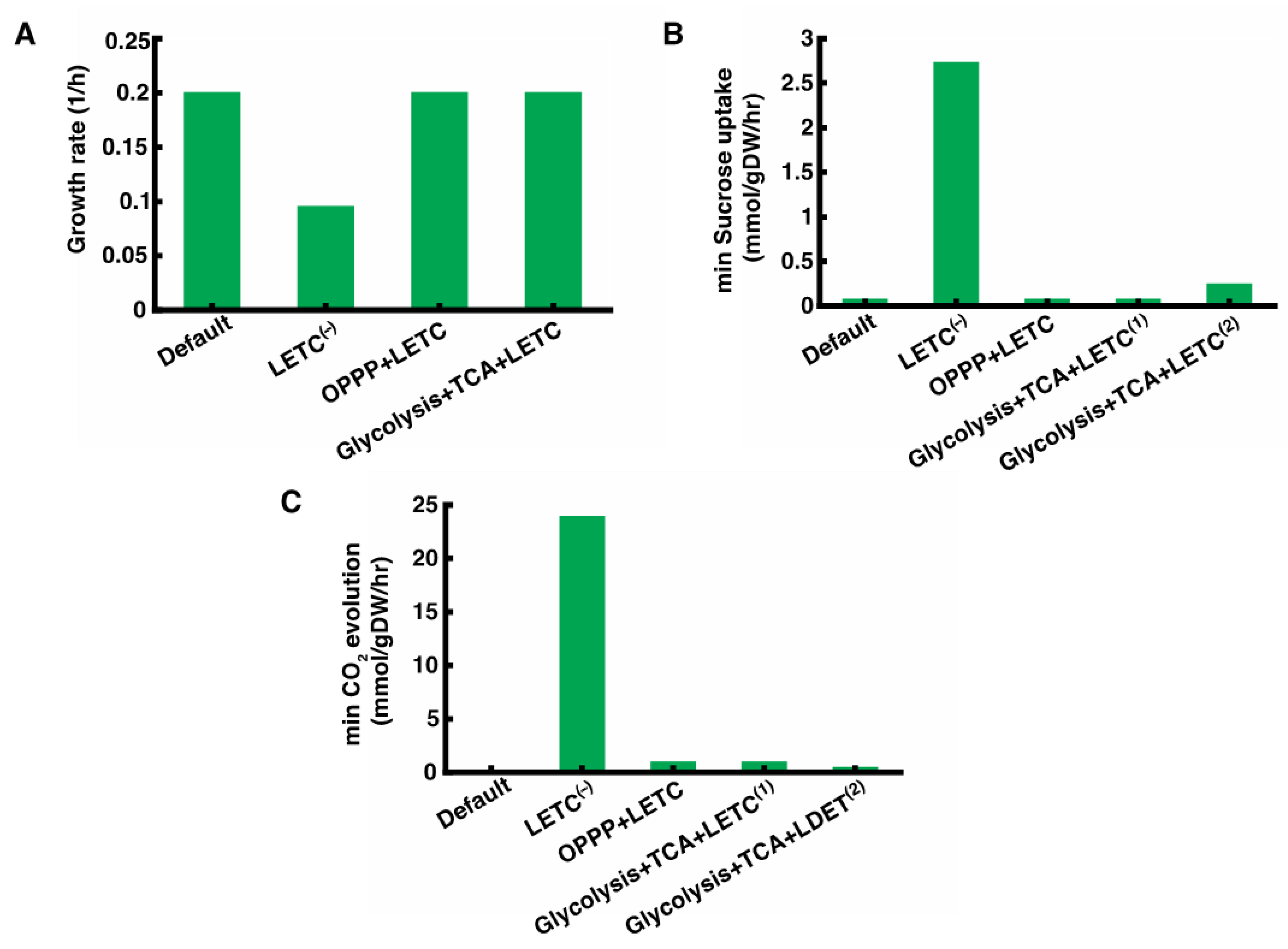

2.4. ATP/NAD(P)H Sources for N2 Fixation in Heterocyst

2.5. Strain Designs for Caprolactam and Valerolactam Overproduction

2.5.1. Interventions for the Overproduction for Valerolactam

2.5.2. Interventions for the Overproduction for Caprolactam

3. Materials and Methods

3.1. Genome Scale Metabolic Model

3.2. Model Simulation under Diazotrophic Condition

3.3. Analysis of ATP and NAD(P)H Sources in Heterocyst

3.4. Strain Design Using OptForce

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dismukes, G.C.; Carrieri, D.; Bennette, N.; Ananyev, G.M.; Posewitz, M.C. Aquatic phototrophs: Efficient alternatives to land-based crops for biofuels. Curr. Opin. Biotechnol. 2008, 19, 235–240. [Google Scholar] [CrossRef] [PubMed]

- Quintana, N.; Van der Kooy, F.; Van de Rhee, M.D.; Voshol, G.P.; Verpoorte, R. Renewable energy from Cyanobacteria: Energy production optimization by metabolic pathway engineering. Appl. Microbiol. Biotechnol. 2011, 91, 471–490. [Google Scholar] [CrossRef] [PubMed]

- Knoot, C.J.; Ungerer, J.; Wangikar, P.P.; Pakrasi, H.B. Cyanobacteria: Promising biocatalysts for sustainable chemical production. J. Biol. Chem. 2018, 293, 5044–5052. [Google Scholar] [CrossRef] [PubMed]

- Lai, C.M.; Lan, I.E. Advances in metabolic engineering of cyanobacteria for photosynthetic biochemical production. Metabolites 2015, 5, 636–658. [Google Scholar] [CrossRef]

- Yu, J.; Liberton, M.; Cliften, P.F.; Head, R.D.; Jacobs, J.M.; Smith, R.D.; Koppenaal, D.W.; Brand, J.J.; Pakrasi, H.B. Synechococcus elongatus UTEX 2973, a fast growing cyanobacterial chassis for biosynthesis using light and CO2. Sci. Rep. 2015, 5, 8132. [Google Scholar] [CrossRef] [PubMed]

- Ungerer, J.; Wendt, K.E.; Hendry, J.I.; Maranas, C.D.; Pakrasi, H.B. Comparative genomics reveals the molecular determinants of rapid growth of the cyanobacterium Synechococcus elongatus UTEX 2973. Proc. Natl. Acad. Sci. USA 2018, 115, E11761. [Google Scholar] [CrossRef]

- Pate, R.; Klise, G.; Wu, B. Resource demand implications for US algae biofuels production scale-up. Appl. Energy 2011, 88, 3377–3388. [Google Scholar] [CrossRef]

- Moreno, J.; Rodríguez, H.; Vargas, M.A.; Rivas, J.; Guerrero, M.G. Nitrogen-fixing cyanobacteria as source of phycobiliprotein pigments. Composition and growth performance of ten filamentous heterocystous strains. J. Appl. Phycol. 1995, 7, 17–23. [Google Scholar] [CrossRef]

- Clares, M.E.; Moreno, J.; Guerrero, M.G.; Garcia-Gonzalez, M. Assessment of the CO2 fixation capacity of Anabaena sp. ATCC 33047 outdoor cultures in vertical flat-panel reactors. J. Biotechnol 2014, 187, 51–55. [Google Scholar] [CrossRef] [PubMed][Green Version]

- González-López, C.V.; Acién Fernández, F.G.; Fernández-Sevilla, J.M.; Sánchez Fernández, J.F.; Molina Grima, E. Development of a process for efficient use of CO2 from flue gases in the production of photosynthetic microorganisms. Biotechnol. Bioeng. 2012, 109, 1637–1650. [Google Scholar] [CrossRef] [PubMed]

- Moreno, J.; Vargas, M.A.; Rodriguez, H.; Rivas, J.; Guerrero, M.G. Outdoor cultivation of a nitrogen-fixing marine cyanobacterium, Anabaena sp. ATCC 33047. Biomol Eng. 2003, 20, 191–197. [Google Scholar] [CrossRef]

- Gonzalez Lopez, C.V.; Acien Fernandez, F.G.; Fernandez Sevilla, J.M.; Sanchez Fernandez, J.F.; Ceron Garcia, M.C.; Molina Grima, E. Utilization of the cyanobacteria Anabaena sp. ATCC 33047 in CO2 removal processes. Bioresour. Technol. 2009, 100, 5904–5910. [Google Scholar] [CrossRef] [PubMed]

- Pfeffer, S.; Brown, R.M., Jr. Complete genome sequence of the cyanobacterium Anabaena sp. 33047. Genome Announc. 2016, 4, 4. [Google Scholar] [CrossRef] [PubMed]

- Orth, J.D.; Thiele, I.; Palsson, B.Ø. What is flux balance analysis? Nat. Biotechnol. 2010, 28, 245. [Google Scholar] [CrossRef] [PubMed]

- Mahadevan, R.; Schilling, C.H. The effects of alternate optimal solutions in constraint-based genome-scale metabolic models. Metab. Eng. 2003, 5, 264–276. [Google Scholar] [CrossRef] [PubMed]

- Hendry, J.I.; Bandyopadhyay, A.; Srinivasan, S.; Pakrasi, H.B.; Maranas, C.D. Metabolic model guided strain design of cyanobacteria. Curr. Opin. Biotechnol. 2020, 64, 17–23. [Google Scholar] [CrossRef] [PubMed]

- Malatinszky, D.; Steuer, R.; Jones, P.R. A comprehensively curated genome-scale two-cell model for the heterocystous cyanobacterium Anabaena sp. PCC 7120. Plant Physiol. 2017, 173, 509–523. [Google Scholar] [CrossRef]

- Ranganathan, S.; Suthers, P.F.; Maranas, C.D. OptForce: An optimization procedure for identifying all genetic manipulations leading to targeted overproductions. PloS Comput. Biol. 2010, 6, e1000744. [Google Scholar] [CrossRef]

- Bottomley, P.J.; Grillo, J.F.; Van Baalen, C.; Tabita, F.R. Synthesis of nitrogenase and heterocysts by Anabaena sp. CA in the presence of high levels of ammonia. J. Bacteriol. 1979, 140, 938–943. [Google Scholar] [CrossRef] [PubMed]

- Wolk, C.P.; Ernst, A.; Elhai, J. Heterocyst metabolism and development. In The Molecular Biology of Cyanobacteria; Bryant, D.A., Ed.; Springer: Dordrecht, The Netherlands, 1994; pp. 769–823. [Google Scholar] [CrossRef]

- Kumar, K.; Mella-Herrera, R.; Golden, J. Cyanobacterial heterocysts. Cold Spring Harb. Perspect. Biol. 2010, 2, a000315. [Google Scholar] [CrossRef] [PubMed]

- Martín-Figueroa, E.; Navarro, F.; Florencio, F.J. The GS-GOGAT pathway is not operative in the heterocysts. Cloning and expression of glsF gene from the cyanobacterium Anabaena sp. PCC 7120. FEBS Lett. 2000, 476, 282–286. [Google Scholar] [CrossRef]

- Nürnberg, D.J.; Mariscal, V.; Bornikoel, J.; Nieves-Morión, M.; Krauß, N.; Herrero, A.; Maldener, I.; Flores, E.; Mullineaux, C.W. Intercellular diffusion of a fluorescent sucrose analog via the septal junctions in a filamentous cyanobacterium. mBio 2015, 6, e02109-14. [Google Scholar] [CrossRef] [PubMed]

- Cumino, A.C.; Marcozzi, C.; Barreiro, R.; Salerno, G.L. Carbon cycling in Anabaena sp. PCC 7120. Sucrose synthesis in the heterocysts and possible role in nitrogen fixation. Plant Physiol. 2007, 143, 1385–1397. [Google Scholar] [CrossRef]

- Wolk, C.P.; Thomas, J.O.; Shaffer, P.W.; Austin, S.M.; Galonsky, A. Pathway of nitrogen metabolism after fixation of 13N-labeled nitrogen gas by the cyanobacterium. Anabaena cylindrica. J. Biol. Chem. 1976, 251, 5027–5034. [Google Scholar] [CrossRef]

- Thomas, J.; Meeks, J.C.; Wolk, C.P.; Shaffer, P.W.; Austin, S.M. Formation of glutamine from [13N]ammonia, [13N]dinitrogen, and [14C]glutamate by heterocysts isolated from Anabaena cylindrica. J. Bacteriol. 1977, 129, 1545–1555. [Google Scholar] [CrossRef] [PubMed]

- Böhme, H. Regulation of nitrogen fixation in heterocyst-forming cyanobacteria. Trends Plant Sci. 1998, 3, 346–351. [Google Scholar] [CrossRef]

- Deng, M.-D.; Coleman, J.R. Ethanol synthesis by genetic engineering in cyanobacteria. Appl. Environ. Microbiol. 1999, 65, 523–528. [Google Scholar] [CrossRef] [PubMed]

- Catalanotti, C.; Dubini, A.; Subramanian, V.; Yang, W.; Magneschi, L.; Mus, F.; Seibert, M.; Posewitz, M.C.; Grossman, A.R. Altered fermentative metabolism in Chlamydomonas reinhardtii mutants lacking pyruvate formate lyase and both pyruvate formate lyase and alcohol dehydrogenase. Plant Cell 2012, 24, 692–707. [Google Scholar] [CrossRef] [PubMed]

- Tamagnini, P.; Leitão, E.; Oliveira, P.; Ferreira, D.; Pinto, F.; Harris, D.J.; Heidorn, T.; Lindblad, P. Cyanobacterial hydrogenases: Diversity, regulation and applications. FEMS Microbiol. Rev. 2007, 31, 692–720. [Google Scholar] [CrossRef]

- Malek Shahkouhi, A.; Motamedian, E. Reconstruction of a regulated two-cell metabolic model to study biohydrogen production in a diazotrophic cyanobacterium Anabaena variabilis ATCC 29413. PLoS ONE 2020, 15, e0227977. [Google Scholar] [CrossRef] [PubMed]

- Smith, R.L.; Kumar, D.; Zhang, X.K.; Tabita, F.R.; Van Baalen, C. H2, N2, and O2 metabolism by isolated heterocysts from Anabaena sp. strain CA. J. Bacteriol. 1985, 162, 565–570. [Google Scholar] [CrossRef]

- Staal, M.; Lintel-Hekkert, S.t.; Harren, F.; Stal, L. Nitrogenase activity in cyanobacteria measured by the acetylene reduction assay: A comparison between batch incubation and on-line monitoring. Environ. Microbiol. 2001, 3, 343–351. [Google Scholar] [CrossRef] [PubMed]

- Magnuson, A. Heterocyst thylakoid bioenergetics. Life 2019, 9, 13. [Google Scholar] [CrossRef]

- Bottomley, P.J.; Stewart, W.D.P. ATP and nitrogenase activity in nitrogen-fixing heterocystous blue-green algae. New Phytol. 1977, 79, 625–638. [Google Scholar] [CrossRef]

- Ernst, A.; Böhme, H.; Böger, P. Phosphorylation and nitrogenase activity in isolated heterocysts from Anabaena variabilis (ATCC 29413). Biochim. et Biophys. Acta BBA Bioenerg. 1983, 723, 83–90. [Google Scholar] [CrossRef]

- Summers, M.L.; Wallis, J.G.; Campbell, E.L.; Meeks, J.C. Genetic evidence of a major role for glucose-6-phosphate dehydrogenase in nitrogen fixation and dark growth of the cyanobacterium Nostoc sp. strain ATCC 29133. J. Bacteriol. 1995, 177, 6184–6194. [Google Scholar] [CrossRef] [PubMed]

- Walsby, A.E. The Permeability of Heterocysts to the Gases Nitrogen and Oxygen. Proc. R. Soc. Lond. Ser. B Biol. Sci. 1985, 226, 345–366. [Google Scholar]

- Allen, J. Cyclic, pseudocyclic and noncyclic photophosphorylation: New links in the chain. Trends Plant Sci. 2003, 8, 15–19. [Google Scholar] [CrossRef]

- Magnuson, A.; Cardona, T. Thylakoid membrane function in heterocysts. Biochim. et Biophys. Acta BBA Bioenerg. 2016, 1857, 309–319. [Google Scholar] [CrossRef] [PubMed]

- Böhme, H.; Schrautemier, B. Electron donation to nitrogenase in a cell-free system from heterocysts of Anabaena variabilis. Biochim. et Biophys. Acta BBA Bioenerg. 1987, 891, 115–120. [Google Scholar] [CrossRef]

- Schrautemeier, B.; Böhme, H.; Böger, P. In vitro studies on pathways and regulation of electron transport to nitrogenase with a cell-free extract from heterocysts of Anabaena variabilis. Arch. Microbiol. 1984, 137, 14–20. [Google Scholar] [CrossRef]

- Zhang, S.; Bryant, D.A. The tricarboxylic acid cycle in cyanobacteria. Science 2011, 334, 1551–1553. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Barajas, J.F.; Burdu, M.; Wang, G.; Baidoo, E.E.; Keasling, J.D. Application of an Acyl-CoA ligase from Streptomyces aizunensis for lactam biosynthesis. ACS Synth. Biol 2017, 6, 884–890. [Google Scholar] [CrossRef] [PubMed]

- Turk, S.C.; Kloosterman, W.P.; Ninaber, D.K.; Kolen, K.P.; Knutova, J.; Suir, E.; Schurmann, M.; Raemakers-Franken, P.C.; Muller, M.; de Wildeman, S.M.; et al. Metabolic engineering toward sustainable production of Nylon-6. ACS Synth. Biol. 2016, 5, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Jakobsen, Ø.M.; Brautaset, T.; Degnes, K.F.; Heggeset, T.M.B.; Balzer, S.; Flickinger, M.C.; Valla, S.; Ellingsen, T.E. Overexpression of Wild-Type Aspartokinase Increases L-Lysine Production in the Thermotolerant Methylotrophic Bacterium Bacillus methanolicus. Appl. Environ. Microbiol. 2009, 75, 652. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Cremer, J.; Eggeling, L.; Sahm, H. Control of the lysine biosynthesis sequence in Corynebacterium glutamicum as analyzed by overexpression of the individual corresponding genes. Appl. Environ. Microbiol. 1991, 57, 1746. [Google Scholar] [CrossRef]

- Shin, J.H.; Park, S.H.; Oh, Y.H.; Choi, J.W.; Lee, M.H.; Cho, J.S.; Jeong, K.J.; Joo, J.C.; Yu, J.; Park, S.J.; et al. Metabolic engineering of Corynebacterium glutamicum for enhanced production of 5-aminovaleric acid. Microb. Cell Factories 2016, 15, 174. [Google Scholar] [CrossRef] [PubMed]

- Radmacher, E.; Eggeling, L. The three tricarboxylate synthase activities of Corynebacterium glutamicum and increase of L-lysine synthesis. Appl. Microbiol. Biotechnol. 2007, 76, 587–595. [Google Scholar] [CrossRef]

- Becker, J.; Zelder, O.; Häfner, S.; Schröder, H.; Wittmann, C. From zero to hero—Design-based systems metabolic engineering of Corynebacterium glutamicum for l-lysine production. Metab. Eng. 2011, 13, 159–168. [Google Scholar] [CrossRef]

- Chae, T.U.; Ko, Y.-S.; Hwang, K.-S.; Lee, S.Y. Metabolic engineering of Escherichia coli for the production of four-, five- and six-carbon lactams. Metab. Eng. 2017, 41, 82–91. [Google Scholar] [CrossRef]

- Yu, J.-L.; Xia, X.-X.; Zhong, J.-J.; Qian, Z.-G. Direct biosynthesis of adipic acid from a synthetic pathway in recombinant Escherichia coli. Biotechnol. Bioeng. 2014, 111, 2580–2586. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, X.; Qi, Q.; Hua, Q. Quantification and analysis of metabolic characteristics of aerobic succinate-producing Escherichia coli under different aeration conditions. Process. Biochem. 2012, 47, 1532–1538. [Google Scholar] [CrossRef]

- Gao, C.; Yang, X.; Wang, H.; Rivero, C.P.; Li, C.; Cui, Z.; Qi, Q.; Lin, C.S.K. Robust succinic acid production from crude glycerol using engineered Yarrowia lipolytica. Biotechnol. Biofuels 2016, 9, 179. [Google Scholar] [CrossRef] [PubMed]

- Sengupta, S.; Jaiswal, D.; Sengupta, A.; Shah, S.; Gadagkar, S.; Wangikar, P.P. Metabolic engineering of a fast-growing cyanobacterium Synechococcus elongatus PCC 11801 for photoautotrophic production of succinic acid. Biotechnol. Biofuels 2020, 13, 89. [Google Scholar] [CrossRef]

- Zhao, M.; Huang, D.; Zhang, X.; Koffas, M.A.G.; Zhou, J.; Deng, Y. Metabolic engineering of Escherichia coli for producing adipic acid through the reverse adipate-degradation pathway. Metab. Eng. 2018, 47, 254–262. [Google Scholar] [CrossRef]

- Lan, E.I.; Wei, C.T. Metabolic engineering of cyanobacteria for the photosynthetic production of succinate. Metab. Eng. 2016, 38, 483–493. [Google Scholar] [CrossRef]

- Krieger, C.J.; Zhang, P.; Mueller, L.A.; Wang, A.; Paley, S.; Arnaud, M.; Pick, J.; Rhee, S.Y.; Karp, P.D. MetaCyc: A multiorganism database of metabolic pathways and enzymes. Nucleic Acids Res. 2004, 32, D438–D442. [Google Scholar] [CrossRef] [PubMed]

- Kanehisa, M.; Goto, S.; Kawashima, S.; Okuno, Y.; Hattori, M. The KEGG resource for deciphering the genome. Nucleic Acids Res. 2004, 32, D277–D280. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Marcišauskas, S.; Sánchez, B.J.; Domenzain, I.; Hermansson, D.; Agren, R.; Nielsen, J.; Kerkhoven, E.J. RAVEN 2.0: A versatile toolbox for metabolic network reconstruction and a case study on Streptomyces coelicolor. PLoS Comput. Biol. 2018, 14, e1006541. [Google Scholar] [CrossRef]

- Aziz, R.K.; Bartels, D.; Best, A.A.; DeJongh, M.; Disz, T.; Edwards, R.A.; Formsma, K.; Gerdes, S.; Glass, E.M.; Kubal, M.; et al. The RAST Server: Rapid Annotations using Subsystems Technology. BMC Genom. 2008, 9, 75. [Google Scholar] [CrossRef]

- Henry, C.S.; DeJongh, M.; Best, A.A.; Frybarger, P.M.; Linsay, B.; Stevens, R.L. High-throughput generation, optimization and analysis of genome-scale metabolic models. Nat. Biotechnol. 2010, 28, 977–982. [Google Scholar] [CrossRef]

- Vargas, M.; Rodriguez, H.; Moreno, J.; Olivares, H.; Campo, J.D.; Rivas, J.; Guerrero, M. Biochemical composition and fatty acid content of filamentous nitrogen-fixing cyanobacteria. J. Phycol. 1998, 34, 812–817. [Google Scholar] [CrossRef]

- Nogales, J.; Gudmundsson, S.; Knight, E.M.; Palsson, B.O.; Thiele, I. Detailing the optimality of photosynthesis in cyanobacteria through systems biology analysis. Proc. Natl. Acad. Sci. USA 2012, 109, 2678. [Google Scholar] [CrossRef] [PubMed]

- Lieven, C.; Beber, M.E.; Olivier, B.G.; Bergmann, F.T.; Ataman, M.; Babaei, P.; Bartell, J.A.; Blank, L.M.; Chauhan, S.; Correia, K.; et al. MEMOTE for standardized genome-scale metabolic model testing. Nat. Biotechnol. 2020, 38, 272–276. [Google Scholar] [CrossRef]

- King, Z.A.; Dräger, A.; Ebrahim, A.; Sonnenschein, N.; Lewis, N.E.; Palsson, B.O. Escher: A web application for building, sharing, and embedding data-rich visualizations of biological pathways. PLoS Comput. Biol. 2015, 11, e1004321. [Google Scholar] [CrossRef]

- Heirendt, L.; Arreckx, S.; Pfau, T.; Mendoza, S.N.; Richelle, A.; Heinken, A.; Haraldsdóttir, H.S.; Wachowiak, J.; Keating, S.M.; Vlasov, V.; et al. Creation and analysis of biochemical constraint-based models using the COBRA Toolbox v.3.0. Nat. Protoc. 2019, 14, 639–702. [Google Scholar] [CrossRef]

- Chowdhury, A.; Zomorrodi, A.R.; Maranas, C.D. Bilevel optimization techniques in computational strain design. Comput. Chem. Eng. 2015, 72, 363–372. [Google Scholar] [CrossRef]

- Babele, P.K.; Young, J.D. Applications of stable isotope-based metabolomics and fluxomics toward synthetic biology of cyanobacteria. Wires Syst. Biol. Med. 2020, 12, e1472. [Google Scholar] [CrossRef]

- Batterton, J.C.; Van Baalen, C. Growth responses of blue-green algae to sodium chloride concentration. Arch. Mikrobiol. 1971, 76, 151–165. [Google Scholar] [CrossRef] [PubMed]

- Hendry, J.I.; Prasannan, C.; Ma, F.; Mollers, K.B.; Jaiswal, D.; Digmurti, M.; Allen, D.K.; Frigaard, N.U.; Dasgupta, S.; Wangikar, P.P. Rerouting of carbon flux in a glycogen mutant of cyanobacteria assessed via isotopically non-stationary 13C metabolic flux analysis. Biotechnol. Bioeng. 2017, 114, 2298–2308. [Google Scholar] [CrossRef] [PubMed]

| S.No | Reaction | Minimum Flux for Optimal Growth (mmol/gDW/h) |

|---|---|---|

| 1 | RuBisCo | 9.5 |

| 2 | Photosystem II | 20.7 |

| 3 | Thylakoid ATP synthase in vegetative cell | 10.3 |

| 4 | Sucrose uptake by heterocyst | 0.15 |

| 5 | N2ase | 0.68 |

| 6 | Photosystem I in heterocyst | 15.6 |

| 7 | Glutamate/glutamine exchange flux | 1.2 |

| S. No | Interventions a | Mutants | |||||

|---|---|---|---|---|---|---|---|

| k = 1 | k = 2 | k = 3 | |||||

| 1 | 2 | 3 | 4 b | 5 b | 6 b | ||

| 1. | ↑2-oxoglutarate decarboxylase | ↑ | ↑ | ||||

| 2. | ↑Aspartate Kinase | 1.2↑ | |||||

| 3. | ↓Citrate Synthase | 10↓ | 10↓ | 10↓ | |||

| 4. | ↑Dihydrodipicolinate synthase | 51↑ | |||||

| 5. | ↑Lysine 2-monooxygenase | ↑ | |||||

| 6. | ↑Phosphoenolpyruvate Carboxylase | 1.5↑ | 1.5↑ | ||||

| 7. | ΔPhosphoenolpyruvate Synthetase c | Δ | Δ | Δ | |||

| Valerolactam production flux (mmol/gDW/h) | 1.25 | 1.25 | 1.25 | 0.23 | 0.23 | 1.18 | |

| S. No | Interventions a | Mutants | ||||

|---|---|---|---|---|---|---|

| k = 1 | k = 2 | |||||

| 1 | 2 | 3 b | 4 b | 5 b | ||

| 1. | ↑2-oxoglutarate decarboxylase | ↑ | ||||

| 2. | ↑3-oxoadipyl-CoA thiolase | ↑ | ||||

| 3. | ↑Citrate Synthase | 6.3↑ | ||||

| 4. | ↑Succinate-CoA ligase | ↑ | ||||

| 5. | ↑Succinate-semialdehyde dehydrogenase | ↑ | ||||

| 6. | ΔSuccinate dehydrogenase | Δ | Δ | Δ | ||

| Caprolactam production flux (mmol/gDW/h) | 1.04 | 1.04 | 1.04 | 1.04 | 1.04 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hendry, J.I.; Dinh, H.V.; Sarkar, D.; Wang, L.; Bandyopadhyay, A.; Pakrasi, H.B.; Maranas, C.D. A Genome-Scale Metabolic Model of Anabaena 33047 to Guide Genetic Modifications to Overproduce Nylon Monomers. Metabolites 2021, 11, 168. https://doi.org/10.3390/metabo11030168

Hendry JI, Dinh HV, Sarkar D, Wang L, Bandyopadhyay A, Pakrasi HB, Maranas CD. A Genome-Scale Metabolic Model of Anabaena 33047 to Guide Genetic Modifications to Overproduce Nylon Monomers. Metabolites. 2021; 11(3):168. https://doi.org/10.3390/metabo11030168

Chicago/Turabian StyleHendry, John I., Hoang V. Dinh, Debolina Sarkar, Lin Wang, Anindita Bandyopadhyay, Himadri B. Pakrasi, and Costas D. Maranas. 2021. "A Genome-Scale Metabolic Model of Anabaena 33047 to Guide Genetic Modifications to Overproduce Nylon Monomers" Metabolites 11, no. 3: 168. https://doi.org/10.3390/metabo11030168

APA StyleHendry, J. I., Dinh, H. V., Sarkar, D., Wang, L., Bandyopadhyay, A., Pakrasi, H. B., & Maranas, C. D. (2021). A Genome-Scale Metabolic Model of Anabaena 33047 to Guide Genetic Modifications to Overproduce Nylon Monomers. Metabolites, 11(3), 168. https://doi.org/10.3390/metabo11030168