Abstract

New product development (NPD) is essential for large, as well as small and medium, enterprises (SMEs). Despite its importance for the economy, challenges remain in the NPD in SMEs. Product success is related with the NPD process, so it is important for SMEs to be able to design their NPD process. This paper aims to identify SME’s NPD research topics, the characteristics of the NPD process in SMEs, and important aspects to be considered for NPD process design. The literature review is done with the analysis of 99 selected academic articles from Scopus and ScienceDirect. Content analysis, bibliographic analysis, and clustering method (based on Pearson’s correlation coefficient) are used to conduct the identification. Less-formal processes, informal strategic planning, limited resources, need technology support, and lack of capabilities in certain fields are some of the characteristics of SME’s NPD. Collaborative product development, competitive advantage, information and communication technology (ICT), concurrent engineering, quality function deployment, and continuous improvement are important keywords based on previous research in SME’s NPD. Design activities in NPD, collaboration and source of innovation, and process modelling, tools, and techniques appear to be important aspects related with the SME’s NPD process.

1. Introduction

New product development (NPD) is essential for business. Development and commercialization of new products give competitive advantages and are very important for company’s growth and sustainability [1,2,3]. Nevertheless, achieving successful product development projects is still a challenge [4,5]. Prior studies identified that the NPD process is an important key success factor for product development [4,5,6,7,8,9,10,11]. The NPD process is defined as designed specific steps that describe how an organization transforms their product idea into marketable products [12]. While several issues on the NPD process; such as the NPD process in the context of Industry 4.0 [13], social product development process [14], how digital tools change the NPD process [15], knowledge sharing in NPD processes [16], and resource allocation in NPD processes [17]; have emerged and been studied, it is agreed that an organization needs to design their own NPD process that fits with their strategic goals and situations [3,18,19], and open innovation can help SMEs overcome their innovation issues [20].

The inevitability of NPD is not only relevant to large scale companies, but also for small and medium enterprises (SMEs) [21]. In fact, SMEs have a significant role in the economic development of a country [22]. NPD in SMEs may differ from large firms [23]. A recent literature study on NPD suggests that NPD processes outside large companies should be further studied [24]. It is important for SMEs to be able to design their NPD process. Although studies on the NPD process design have been done: Loch [19] addressed the NPD process design issue in a large firm and proposed technology newness and market newness as a base for NPD process; and Unger and Eppinger [18] proposed steps to design a NPD process based on risks, but a focus on designing a SME’s NPD process is still needed.

To be able to support the design of a NPD process for SME, it is important to conduct a literature study to gain a view of the previous research findings related to the SMEs’ NPD process. Horte [25] performed a literature study on SMEs’ NPD and organized the studies into three main areas: management (covering topics such as leadership, finance, and business environment), operations (covering topics such as methods and techniques, NPD process, and supply chain), and performance, i.e., link NPD with growth and performance. Based on the confidence that the literature concerning SMEs’ NPD has been carefully explored, this study aims to go one step further by exploring deeper and overlooked issues regarding the NPD process in SMEs. Therefore, the purpose of this review article was to identify the NPD process in SMEs with the following research questions:

RQ 1: What are the topics of previous studies on the NPD process in SMEs?

RQ 2: What are the characteristics of the NPD process in SMEs?

RQ 3: What are the important aspects to be considered for SMEs’ NPD process design?

2. Materials and Methods

2.1. Analytical Procedure

The research papers selected from the literature focus on the topic of NPD in SMEs. A review was conducted following the steps by Godinho Filho and Saes [26] as follows:

- Step 1: Find articles related to the topic.

The first step is to find relevant academic articles. The database is from Scopus and ScienceDirect. The search process is based on keywords that represent the NPD and SMEs and used to ensure the articles collected represent the topic discussed. Next, the articles are filtered to remove duplications. Two step filtering is then applied. Firstly, the articles are screened based on the titles and abstract. The abstract is a representation of the article, and consists of purpose, method, and results of the research, therefore it is a good approach for examining articles [27]. The inclusion criteria are that the articles discussed both the NPD process and SME. Secondly, after title and abstract screening, full-text review is conducted.

- Step 2: Decide the classification of articles.

Articles are classified to identify themes of research. The classification is performed using clustering based on words similarity. NVIVO 12 software is utilized to perform the clustering. The software detects the words in the article and clustered the articles based on its word similarity. In addition, descriptive analysis is also performed to identify the most cited articles, research approach, region of study, industry sectors, and keywords analysis.

- Step 3: Group the articles based on the classification.

Based on the clustering result, the articles are grouped.

- Step 4: Elaborate the result.

Content analysis is implemented to elaborate the classification result. The analysis is based on the article text, of which it is believed to be a valuable data source [28]. Each article is carefully read, and the themes of research are identified. Results from descriptive analysis are also elaborated.

- Step 5: Identify the opportunity for future research.

Finally, a future research opportunity is identified based on the elaboration result. We recommend some of the future research for SMEs’ NPD.

2.2. Data Collection

We use Scopus and Science Direct as the database of this study. The term used is based on the process (NPD) and organization (SME) side. There are 15 searches for articles and reviews based on the title, abstract, and author keywords. The searches are of “Product Development” AND “Small Medium Enterprise”, “Product Development” AND “Small and Medium Enterprise”, “Product Development” AND “SME”, “New Product Development” AND “Small Medium Enterprise”, “New Product Development” AND “Small and Medium Enterprise”, “New Product Development” AND “SME”, “Product Design” AND “Small Medium Enterprise”, “Product Design” AND “Small and Medium Enterprise”, “Product Design” AND “SME”, “Product Development Process” AND “Small Medium Enterprise”, “Product Development Process” AND “Small and Medium Enterprise”, “Product Development Process” AND “SME”, “New Product Development Process” AND “Small Medium Enterprise”, “New Product Development Process” AND “Small and Medium Enterprise”, and “New Product Development Process” AND “SME” keywords.

Previous literature studies on the NPD area have a diverse period of articles included in their analysis. In their study about intellectual structure of product innovation research, Durisin, Calabretta, and Parmeggiani [29] analyzed articles in a 20-years period. Guo [27] analyzed the streams of NPD research in a 22-years period. Papastathopoulou and Jan Hultink [30] used 27 years of articles to examine research on New Service Development (NSD), explaining that the time range is started at the time that the first article on NSD was published in an academic journal. There are also studies that have a shorter period, such as Perks and Roberts’ review on longitudinal studies of product innovation [31] (11 years), Horte et al.’s review on SME’s NPD (including management, operations, and performance) [25] that included articles in a 15-years period, and Marzi et al.’s [24] review on NPD research for the last ten years. Marzi et al. explain that the period is based on previous literature studies and intended to enrich the knowledge, especially in the engineering and business aspects, of NPD [24]. It seems that if the issues have been studied before, it is best to limit the period so that it can complement prior research. To our knowledge, a literature study of the NPD process in SMEs has not been explored yet. Therefore, there is no specific year restrictions for the articles in this study. It is expected that this will give more insight on the issues.

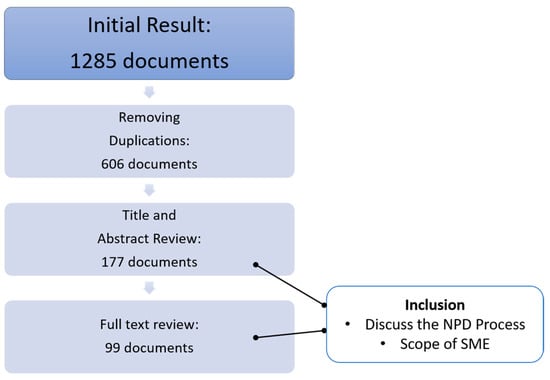

The initial search yielded 1285 documents. This vast collection of documents is filtered so that it aligned with the research questions. First the filter aimed to removing item duplications, reducing the portfolio to 606 documents. Discussions on SMEs are also linked with financial and organizational communication, supply chain, and production, which are not relevant with the focus on NPD. Based on the titles and abstract, a second filtering was conducted to select articles that focus on the NPD process, resulting in 177 documents. Next, using the same criteria that only articles focusing on the NPD process in SMEs will be further analyzed, we performed a full-text review. To ensure the scientific quality of the research, only articles published in journals with a double-blind review process were included. This is the most exhaustive filtering process, yielded 99 articles relevant to the NPD process pertaining to SMEs. The process is illustrated in Figure 1.

Figure 1.

Articles filtering process.

3. Descriptive Analysis Result

3.1. Articles Overview

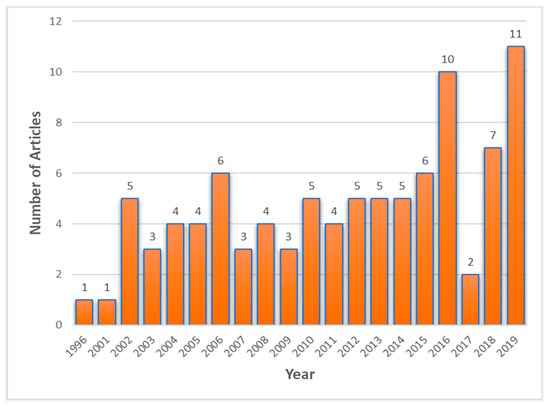

The database of articles consists of 99 papers, with the publication year from 1996 to 2019. The distribution of articles based on the year is shown in Table 1 and Figure 2.

Table 1.

Distribution of articles by years.

Figure 2.

Distribution of articles by years.

The articles have the total citations of 1838. Among them, the most cited articles are listed in Table 2.

Table 2.

Most Cited Articles.

3.2. Research Approach

The articles were categorized based on the methodological and analytical approaches used. This categorization is referred to in the literature review on SMEs’ NPD by Horte et al. [25]. The result is shown in Table 3.

Table 3.

Research approach.

Most of the studies’ analytical approach is descriptive (74.7%). Based on a methodological approach, 56.6% of research uses empirical qualitative and 34.4% of research uses empirical quantitative.

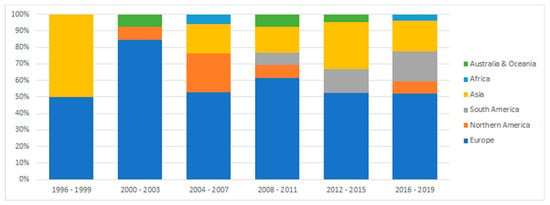

3.3. Region of Study

Most of the studies concern Europe, although trends show that since 2004, various regions have been investigated. The volume of studies that concern Asia remains mostly consistent over time. The region of study is shown in Figure 3.

Figure 3.

Region of study.

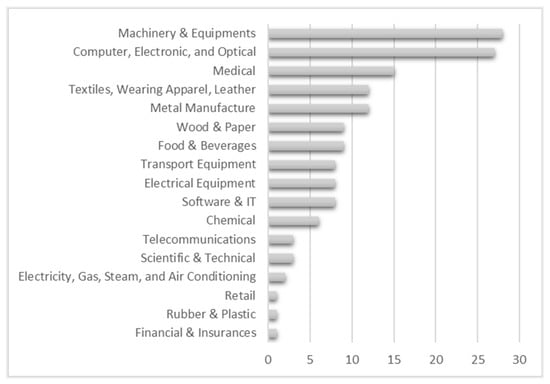

3.4. Industry Sectors

Numerous industry sectors have been studied, and the variation of the industry is growing. In the period 1996–2003, besides sectors such as machinery and equipment, medical, and manufacturing of computers, electronic, and optical products, there is also a concern in software and IT sectors. Starting from 2004, various sectors, including software and IT, telecommunications, even retail and financial and insurances are being studied. The industry sectors are shown in Table 4.

Table 4.

Industry Sectors.

In the period of 2016–2019, a wide variation of industries was studied. It included, to name a few, food and beverages, computer, electronic, and optical, software and IT, and medical. It seems that the NPD issues in technology-based SMEs and traditional manufacturing firms have gained more attention in research, as shown in Figure 4.

Figure 4.

Industry sectors.

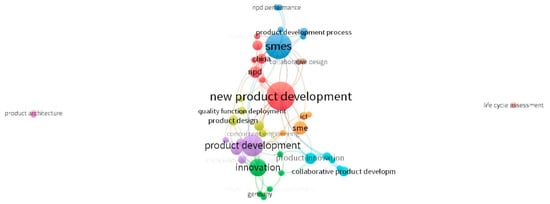

3.5. Keywords Analysis

To map the topics covered in the articles, a bibliographic analysis was conducted. Here, the co-occurrence of terms in author keywords was visualized based on the number of keywords that were used in the articles. Keywords that most likely emerged because of the search criteria (such as “new product development” or “SMEs”) are not further discussed. The result is shown in Figure 5.

Figure 5.

Keyword’s analysis.

Occurrence tells the number of documents that include a certain keyword [32], therefore it can help us identify what are the topics that which is of concern in previous studies. The result is shown in Table 5.

Table 5.

Keyword’s analysis.

Several terms that have high occurrence include “collaborative product development”, “competitive advantage”, “ICT”, “concurrent engineering”, “quality function deployment”, and “continuous improvement”. This may reflect the important issues that are faced by SME related to their NPD process. Collaboration is essential, as SMEs consider customers, suppliers, and other stakeholders crucial for their NPD process [33,34]. NPD is an important mean for competitive advantage. Quality Function Deployment is a powerful tool that has been extensively used in NPD process. ICT may reflect the needs of technological support in NPD process. Concurrent engineering can support development time efficiency. Continuous improvement may represent the awareness of process management in SMEs’ NPD.

4. Literature Review Result

4.1. Characteristics of SME’s NPD Process

SMEs’ NPD process is not the same as that in large firms [35,36]. Although there are numerous NPD process models, SMEs still experience difficulty in establishing the appropriate approach [21]. The characteristics of SMEs’ NPD process practices are identified to support the design process. The result is shown in Table 6.

Table 6.

Characteristics of SMEs’ NPD process.

The NPD process in SMEs tends to be less formal. This may influence the speed of development as the completeness of steps become an issue [38]. While the strategic direction is the starting point of the NPD process, it is found that SMEs practice informal strategic planning. Milward, Byrne, and Lewis [43] identified that the key person in SMEs sometimes handles various decision-making, including in technical and strategic aspects. Limited resources are one of the problems faced by SME. It may impact the design of the NPD process, as resources are important to process execution. Centralized decision-making may result in process inefficiency but may also support good monitoring and governance of the process. In addition, SMEs need to properly implement relevant design methods. Method of forecasting and prototyping can help to accomplish product design activities [36]. Priorities are another NPD issue that needs to be tackled by SMEs. The NPD process should be able to capture the dynamics of the environment that might force the company to rearrange its priorities. In a dynamic environment, it is important to be able to anticipate risks. The NPD process should accommodate the identification and anticipation of risks. Technology support can help SME in their NPD process. Kaljun and Dolšak [58] highlight the lack of existing computer tools for ergonomic design and propose the integration of ergonomic design knowledge in the decision support system. In executing the process, SME may experience a lack of milestones. It is important to have the aspects of completion in the NPD process. Issues on capabilities are also faced by SME. The NPD process involves various aspects and multidisciplinary analysis. Arfi, Enström, Sahut, and Hikkerova [45] proposed the knowledge-sharing platform to support a firm’s ability to perform its knowledge-sharing scheme. SMEs, due to their relatively small size, have the potential to be agile [37], and the autonomy of projects can be adapted [68]. Furthermore, external involvements are important to support the NPD process. The role of open innovation seems to be relevant with this matter. Integration [66,67] has been an interesting issue for SMEs’ NPD process. Limited data management and the requirement to consider various design aspects is another issue that needs to be addressed [69,70,71]. In addition, SMEs have utilized software tools involving a multidisciplinary team and have the potential to build a close relationship with the customer [33,41,42,49,51,57,73,74].

4.2. Themes of Research

To identify the theme of the research, a two-step analysis is conducted. Firstly, we perform a clustering analysis based on words similarity of the documents. A distinct word is important in clustering because words represent concepts [75]. The clustering is based on Pearson’s correlation coefficient using the NVIVO 12 software. There are 4851 correlation coefficients measured with the highest value of 0.8684 and the lowest value of 0.0847. Secondly, we perform a full-text analysis on the articles in each cluster to obtain the themes. There are three main themes in the SMEs’ NPD process that have been identified, i.e., design activities in NPD, collaboration and source of innovation, and process modelling, tools, and techniques. It is important to understand the themes as a research emphasis, rather than a strict topic categorization. For example, the article “Integrating EcoDesign by Conducting Changes in SMEs” [76] discusses the EcoDesign Integration Method for SMEs (EDIMS), a method developed as software program to facilitate integration of ecodesign in companies. The method is based on an environmental analysis tool called TEA (Typological Environmental Analysis). Emphasis on implementation of the method and tool is the reason that it seems logical to classify the study in the ‘process modelling, tools, and techniques’ theme; although the scope of the study is in the conceptual and detail design of the product development process, and discussion about the need of collaboration between purchasing, logistics, and marketing department is also covered.

4.2.1. Design Activities in NPD

Research on this category highlights the design phase or aspect of the NPD process, including the tools and techniques that relevant with this phase.

- (a)

- Simulation can be used to support design activities. Ma [77] discussed a web service-based multidisciplinary collaborative simulation platform that can support the Computer Aided Engineering (CAE) analysis. A simulation platform to support collaborative product design for engineering products is also considered important and has been proposed and tested [65].

- (b)

- Design evaluation should also be considered in NPD process. Cantó, Frasquet, and Irene [78]; Moultrie, Clarkson, and Albert [71] proposing approach to assess the design from the process and product point of view. Tan [79] elaborates AHP and Grey Relational Analysis’s implementation to support the green product design evaluation. The utilization of AHP, combined with Fuzzy Theory and Evidential Reasoning (ER), seems relevant to support the environmental impact evaluations of design options [80]. Not only environmental aspects, but consideration of economic and societal benefits also motivate the development of LICARA nanoSCAN—a modular web-based tool for assessing nanoproducts [81].

- (c)

- Customer’s consideration and involvement in the design process is pivotal for SMEs. A methodological framework supported by web-based software tools to support the user-centered design along the NPD process has been proved as “flexible, accessible, and easy-to-use” for SME [51]. Another user-centered design topic, related to ergonomic aspect, is discussed by Kaljun and Dolšak [58]. They present how ergonomic design knowledge is integrated in a decision support system. Germani, Mengoni, and Peruzzini [57,82], and Giannini et al. [83] explored the possibility of using the platform to support the co-design process, utilizing tools such as CAD, and methods such as quality function deployment (QFD). Zheng et al. [34] proposed a flexible design approach for robotic systems, accommodating the interactions between customers, designers, and component suppliers. To accommodate the standardization of the development process in the mold industry, the design chain operations reference model was developed by Lyu and Chang [84], enabling a more efficient collaborative design process. The design activities in the NPD process should be prepared so that it can result in desirable product design.

4.2.2. Collaboration and Source of Innovation

The NPD process is involving several stakeholders. Organization needs to collaborate and utilize their sources of innovation. The discussion of collaboration and source of innovation is found in the SMEs’ NPD literature. It seems that open innovation is pivotal for SMEs’ NPD. Interestingly, the source of innovation differs between large and small firms [33] or between regions [85]. Woodcock, Owen, and Woods [52], and Owens [86] studied the NPD process in the UK and found that a formalized process, formal competitor analysis, data management, involvement of manufacturing in the development process; senior management, environment, and resources support; and early collaboration between functions are required. From the perspective of open innovation, some issues that can be uncovered are:

- (a)

- Open Innovation—Collaboration with customers—considered as an important action for SME’s NPD. Morgan et al. [87] find that collaboration with the customer could speed up their NPD process. A study on Pakistan’s apparel industry revealed that customer collaboration is one way to avoid customer dissatisfaction, and its implementation is influenced by firm’s awareness and trust [88].

- (b)

- Technology’s role in collaboration and innovation sourcing also studied in several research. Innovation capability could be improved if SMEs are supported by IT systems [89] and capabilities, which include the e-collaboration capability [90]. In a study of SMEs’ NPD in Niagara region, Canada, Bagchi-Sen concludes that IT is beneficial for the firm’s NPD process. External collaborators of firms are those that included suppliers, distributors, and customers [63]. Adoption of technology from external sources, marketing skills, product strategy, and execution of activities; identified as one of the important factors for NPD’s success [91].

- (c)

- Collaboration and source of innovation in technology-based firms is a topic that also emerged. This may due to the rapid technological changes that forced companies to develop their products faster [38]. Formal communication within teams, process proficiency, filing, project deadlines, and information coding are critical for new product success in high-tech SMEs [62].

- (d)

- Collaboration between functions is considered important for NPD process. Cheng identified that marketing-manufacturing interaction may lead to successful NPD [92]. Mendes and Toledo studied concurrent engineering in Brazilian SMEs that do their business in medical device industry and use integration, cross-functional teams, and leadership to identify the organization characteristics [93]. Concurrent engineering is relevant for the SMEs in medical industry and “SMEs can use their informal meeting during the design process as a modified gate system to select winning concepts and monitor the project progress through the development cycle” [93]. Ledwidth [35] suggested that to increase their new product and organizational performance, “improving the product launch process, maintaining a high level of competitor and customer orientation, and inter-functional coordination” need to be done. In a framework of the new-to-market development process, Mosey [94] suggested the involvement of cross-functional teams with a senior manager’s participation for the four process area, i.e., product strategy, NPD management, market intelligence, and opportunity identification. It is also identified that external sources of technology and market opportunity can come from customers, suppliers, and competitors. Internal collaboration seems to be an important aspect for firms. A study on the Finnish metal industry SMEs indicates that closed NPD strategy and reliance on their internal resources may help achieve product performance [95]. Lindman, Scozzi, and Otero-Neira [73] studied SMEs in the furniture industry in Italy, Spain, and Finland and identified that management education and interest in design can be an important source of innovative designs. Gurau [54] explored the internal and external sources as the basis for flexible risk management in NPD. Chen [79] elaborated that intellectual capital is important for product development. Nicholas, Ledwith, and Perks [40] revealed that, beside strategy, a competent cross-functional team is considered a best practice for NPD. Besides collaboration with known parties such as suppliers and customers, interaction with other sources also have the potential to support the NPD process. Buganza, Colombo, and Landoni [96] conclude that by focusing on technology and project management capabilities, SME can have benefits from their collaborations with universities for their NPD.

4.2.3. Process Modeling, Tools and Techniques

The execution of process is related to the tools and techniques used. Research on this category is related with the insight on various tools and techniques in the NPD process.

- (a)

- It seems that there are tools that have the potential to support the NPD process, but have not been utilized. Linking NPD situations with tools needed may be a good way for designing the NPD process. In a study of NPD in multiple technology-based SMEs, Salgado, Salomon, Mello, and da Silva [97] identified that tools such as Technology Road mapping (TRM), QFD, Failure Mode and Effect Analysis (FMEA), Design for X (DFX), and others are not being fully utilized, but tools such as CAD and financial analysis are already being used. In an evaluation of product development methodologies of SMEs in metal-mechanic sector, Kaminski, Oliveira, and Lopes [42] identified that CAD and numeric computation software is utilized to support the creation and modification of the product, but PDM/PLM has not been utilized. In their study of NPD process of Swiss’ SMEs, Heck and Meboldt [70] conclude that “means are needed to support SMEs in tackling challenges in the product development process”.

- (b)

- Determining the specific NPD process for organizations is considered important as organizations’ NPD situations vary. Ocampo and Kaminski [98] suggest a 10 stages development process for SMEs in medical device business. The process includes strategic planning, feasibility study, detailed design, and discontinuance; grouped into pre-development, development, and post-development. In a study on NPD process of various SMEs in Spain, March-Chordà, Gunasekaran, and Lloria-Aramburo [99] discover that the NPD sequence is “rather simple and short: ‘original idea-brief development-prototype-fabrication’,” with an average development time of six months. Textile, electronics, and metallurgical are sectors with the most rapid changes in its products. Focusing on the pre-development process of food and beverages SME [37] uncovered that idea generation, a first pre-development activity, can be implemented with supporting tools such as creative technique, brainstorming, benchmarking, and QFD. Formal assessment technique might also give an advantage in development time and product quality.

- (c)

- Challenges in the implementation of tools, techniques, and approaches should also be considered in NPD process design. Filson and Lewis [61] address the cultural issues faced by the electronic component manufacturer’s in implementing concurrent engineering. Their study indicates that there should be awareness in all levels within the company that the current approach may not be reliable to deliver expected goals. Milward, Dorrington, and Lewis [100] studied the implementation of design-led technology in three manufacturing SMEs in the UK and revealed that CAD/CAM-based systems’ implementation has positively impacted product development time, cost, and product quality. Nevertheless, a systematic NPD process is still needed to overcome the firm’s dependency on the manager’s role.

- (d)

- Consideration of product architecture is also important. Ulonska and Welo [101] proposed Product Portfolio Map, a visual tool for structuring a product portfolio based on architecture analysis; Yan and Stewart [102] introduced GeMoCURE, a modular product design methodology that can help achieve modular product design, which is still a challenge for SMEs. The implementation in a manufacturing SME has uncovered the needs for a standardized system of interfaces. Knauber, Muthig, Schmid, and Widen applied the PulSE, a product line software engineering method. The concept of architecture is applied to software development to help the company introduce new products [103].

- (e)

- Approaches and Tools that enable the acceleration of NPD process is also an emerging issue. de Beer, Booysen, Barnard, and Truscott [104] implement rapid tooling to support accelerated NPD. Team and workgroup issues in applying concurrent engineering were studied by Kusar, Duhovnik, Grum, and Starbek [72]. Concurrent engineering is a potential approach to address development time reduction needs, resulting in a 52% reduction in development time and 13% reduction in development cost. They proposed a team configuration that consists of the core team’s permanent structure and the variable structure of the development team. Edwards, Cooper, Vedsmand, and Nardelli [105] apply the Agile–Stage-Gate Hybrid model, a development model combining the Stage-Gate and agile principles that intended to serve the needs of efficient development time and quality assurance, in three manufacturing SMEs. The result is promising as faster development time, higher success rates, and a generally improved development process are achieved.

- (f)

- Specific product requirements can be an important aspect of a company’s business. The environmental factor may play a strategic role for certain products. Le Pochat, Bertoluci, and Froelich [76] developed a software program called the EcoDesign Integration Method for SMEs (EDIMS). The software is used to facilitate the ecodesign implementation in an SME. Favi, Germani, Mandolini, and Marconi [106] studied the implementation of a software platform to support an ecodesign methodology. The study indicates that there are positive results, as it is applicable to be integrated in the existing process and can support the utilization of various tools. As technology advances, the approach on the development process also evolves. Niu, Qin, Vines, Wong, and Lu [60]; Qin, Van der Velde, Chatzakis, McStea, and Smith [107] elaborated a crowdsourcing approach for the product development process. Collaboration tools also emerged as important issues as scholars focus their research on this. David and Rowe [108], Aziz, Gao, Maropoulos, and Cheung [56], and Fagerstorm and Jackson [109] explored the collaboration aspects of SME’s NPD process. The elaboration of tools and techniques is important when conducting NPD process design for SME.

5. Conclusions

These are the conclusions of this study:

RQ 1: What are the topics of previous studies on the NPD process in SMEs? Topics related to SMEs’ NPD from previous studies include collaborative product development, competitive advantage, ICT, concurrent engineering, quality function deployment, and continuous improvement. Collaboration with stakeholders is important for SMEs’ NPD. Tool supporting quality and development time considerations are another issue that interest researchers regarding SMEs’ NPD. They also need technological support, and awareness of process management also emerged as an issue in SMEs’ NPD.

RQ 2: What are the characteristics of the NPD process in SMEs? The characteristics of SMEs’ NPD process include low formality, informal strategic planning, limited resources, centralized decision-making; need for adaptive, easy-to-use design methods; constantly changing priorities, need to anticipate risks and challenges, need for technological support, lack of milestones in processes, lack of capabilities in certain fields, having the potential to be agile and adaptive, external involvement is crucial in certain processes, the autonomy of projects, limited data management, need of considering various design aspects, utilize software tools, have multidisciplinary team involvement, and have close relationship with customers.

RQ 3: What are the important aspects to be considered for SMEs’ NPD process design? Important aspects that need to be considered in SMEs’ NPD process design are design activities, collaboration and source of innovation, and process modeling, tools, and techniques.

6. Future Research and Limitations

This article contributed to NPD literature on identification of topics studied in prior literature related to SMEs’ NPD, characteristics of SMEs’ NPD, and important aspects for the design of the NPD process. The limitation of this study is the themes of research that may not represent all the issues discussed in the articles, although obtained from the clustering based on words analysis. Therefore, we elaborate on the issues discussed within themes and present it as part of the themes. This article provides valuable insights as a starting point for future research agendas, i.e., modeling of SME’s NPD process design.

There are numerous aspects of SMEs’ NPD process. Investigating it from various perspectives will be a promising research opportunity. Related with design activities in NPD, research on simulation for design improvements and design evaluation approach will have substantial implications since some of the SMEs’ NPD characteristics are need for adaptive, easy-to-use design methods; need technology support, and need of considering various design aspect. Research on best practices of users’ consideration, lead users, and stakeholders’ role in concept generation and selection will give valuable insights since external involvement and close relationship with customers is crucial in SMEs’ NPD. Related with collaboration and source of innovation, research on customer’s feedback and needs identification is expected to give valuable information. The emerging issues on technology-based SMEs may lead to the need of research on technology-based SMEs’ NPD process. Research on technology to support open innovation may be linked to the SMEs’ NPD that need technology support, and experience lack of capabilities in certain fields.

Related with process modeling, tools, and techniques, research on addressing development time acceleration and quality assurance will be promising, since SMEs experience resource limitation. It is also interesting to elaborate on tools and technique identification for SMEs’ NPD process, as it is one of the considerations of designing the NPD process. Future research suggestions are listed in Table 7.

Table 7.

Future research recommendation.

Author Contributions

Validation, writing—review and editing, supervision, project administration, funding acquisition, A.S.; conceptualization, methodology, software, formal analysis, investigation, resources, data curation, visualization, writing—original draft preparation, M.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by research grant PUTI DOKTOR 2020 NKB-661/UN2.RST/HKP.05.00/2020 from Universitas Indonesia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data will be made available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Calantone, R.J.; Schmidt, J.B.; Song, X.M. Controllable Factors of New Product Success: A Cross-National Comparison. Mark. Sci. 1996, 15, 341–358. [Google Scholar] [CrossRef]

- Cooper, R.G. New Products—What Separates the Winners from the Losers and What Drives Success. In The PDMA Handbook of New Product Development; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Unger, D.W.; Eppinger, S.D. Comparing product development processes and managing risk. Int. J. Prod. Dev. 2009, 8. [Google Scholar] [CrossRef]

- Evanschitzky, H.; Eisend, M.; Calantone, R.J.; Jiang, Y. Success factors of product innovation: An updated meta-analysis. J. Prod. Innov. Manag. 2012, 29, 21–37. [Google Scholar] [CrossRef]

- Florén, H.; Frishammar, J.; Parida, V.; Wincent, J. Critical success factors in early new product development: A review and a conceptual model. Int. Entrep. Manag. J. 2018, 14, 411–427. [Google Scholar] [CrossRef]

- Cooper, R.G.; Kleinschmidt, E.J. Benchmarking the firm’s critical success factors in new product development. J. Prod. Innov. Manag. 1995, 12, 374–391. [Google Scholar] [CrossRef]

- Cooper, R.G.; Kleinschmidt, E.J. Winning businesses in product development: The critical success factors. Res. Technol. Manag. 2007, 50, 52–66. [Google Scholar] [CrossRef]

- Ernst, H. Success factors of new product development: A review of the empirical literature. Int. J. Manag. Rev. 2002, 4, 1–40. [Google Scholar] [CrossRef]

- Henard, D.H.; Szymanski, D.M. Why some new products are more successful than others. J. Mark. Res. 2001, 38, 362–375. [Google Scholar] [CrossRef]

- Lynn, G.S.; Abel, K.D.; Valentine, W.S.; Wright, R.C. Key factors in increasing speed to market and improving new product success rates. Ind. Mark. Manag. 1999, 28, 319–326. [Google Scholar] [CrossRef]

- Montoya-Weiss, M.M.; Calantone, R. Determinants of new product performance: A review and meta-analysis. J. Prod. Innov. Manag. 1994, 11, 397–417. [Google Scholar] [CrossRef]

- Kahn, K.B.; Kay, S.E.; Slotegraaf, R.; Uban, S. The PDMA Handbook of New Product Development; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Arromba, I.F.; Martin, P.S.; Ordoñez, R.C.; Anholon, R.; Rampasso, I.S.; Santa-Eulalia, L.A.; Martins, V.W.B.; Quelhas, O.L.G. Industry 4.0 in the product development process: Benefits, difficulties and its impact in marketing strategies and operations. J. Bus. Ind. Mark. 2020, 36, 522–534. [Google Scholar] [CrossRef]

- Abhari, K.; Davidson, E.J.; Xiao, B. Modeling Social Product Development Process, Technology, and Governance. IEEE Trans. Eng. Manag. 2020. [Google Scholar] [CrossRef]

- Marion, T.J.; Fixson, S.K. The Transformation of the Innovation Process: How Digital Tools are Changing Work, Collaboration, and Organizations in New Product Development. J. Prod. Innov. Manag. 2021, 38, 192–215. [Google Scholar] [CrossRef]

- Stock, G.N.; Tsai, J.C.-A.; Jiang, J.J.; Klein, G. Coping with uncertainty: Knowledge sharing in new product development projects. Int. J. Proj. Manag. 2021, 39, 59–70. [Google Scholar] [CrossRef]

- Zhao, C.; Ogura, M.; Kishida, M.; Yassine, A. Optimal resource allocation for dynamic product development process via convex optimization. Res. Eng. Des. 2021, 32, 71–90. [Google Scholar] [CrossRef]

- Unger, D.; Eppinger, S. Improving product development process design: A method for managing information flows, risks, and iterations. J. Eng. Des. 2011, 22, 689–699. [Google Scholar] [CrossRef]

- Loch, C. Tailoring product development to strategy: Case of a European technology manufacturer. Eur. Manag. J. 2000, 18, 246–258. [Google Scholar] [CrossRef]

- Bigliardi, B.; Ferraro, G.; Filippelli, S.; Galati, F. The past, present and future of open innovation. Eur. J. Innov. Manag. 2020. [Google Scholar] [CrossRef]

- Leithold, N.; Haase, H.; Lautenschläger, A. Stage-Gate® for SMEs: A qualitative study in Germany. Eur. J. Innov. Manag. 2015, 18, 130–149. [Google Scholar] [CrossRef]

- Salavou, H.; Avlonitis, G. Product innovativeness and performance: A focus on SMEs. Manag. Decis. 2008, 46, 969–985. [Google Scholar] [CrossRef]

- Huang, X.; Soutar, G.N.; Brown, A. Measuring new product success: An empirical investigation of Australian SMEs. Ind. Mark. Manag. 2004, 33, 117–123. [Google Scholar] [CrossRef]

- Marzi, G.; Ciampi, F.; Dalli, D.; Dabic, M. New product development during the last ten years: The ongoing debate and future avenues. IEEE Trans. Eng. Manag. 2020, 68, 330–344. [Google Scholar] [CrossRef]

- Horte, S.A.; Barth, H.; Chibba, A.; Florén, H.; Frishammar, J.; Halila, F.; Rundquist, J.; Tell, J. Product development in SMEs: A literature review. Int. J. Technol. Intell. Plan. 2008, 4, 299–325. [Google Scholar] [CrossRef]

- Godinho Filho, M.; Saes, E.V. From time-based competition (TBC) to quick response manufacturing (QRM): The evolution of research aimed at lead time reduction. Int. J. Adv. Manuf. Technol. 2013, 64, 1177–1191. [Google Scholar] [CrossRef]

- Guo, L. Perspective: An analysis of 22 years of research in JPIM. J. Prod. Innov. Manag. 2008, 25, 249–260. [Google Scholar] [CrossRef]

- Kleinheksel, A.; Rockich-Winston, N.; Tawfik, H.; Wyatt, T.R. Demystifying content analysis. Am. J. Pharm. Educ. 2020, 84, 7113. [Google Scholar] [CrossRef]

- Durisin, B.; Calabretta, G.; Parmeggiani, V. The intellectual structure of product innovation research: A bibliometric study of the journal of product innovation management, 1984–2004. J. Prod. Innov. Manag. 2010, 27, 437–451. [Google Scholar] [CrossRef]

- Papastathopoulou, P.; Hultink, E.J. New service development: An analysis of 27 years of research. J. Prod. Innov. Manag. 2012, 29, 705–714. [Google Scholar] [CrossRef]

- Perks, H.; Roberts, D. A review of longitudinal research in the product innovation field, with discussion of utility and conduct of sequence analysis. J. Prod. Innov. Manag. 2013, 30, 1099–1111. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual; Univeristeit Leiden: Leiden, The Netherlands, 2013; Volume 1, pp. 1–53. [Google Scholar]

- Bommer, M.; Jalajas, D.S. Innovation sources of large and small technology-based firms. IEEE Trans. Eng. Manag. 2004, 51, 13–18. [Google Scholar] [CrossRef]

- Zheng, C.; Qin, X.; Eynard, B.; Bai, J.; Li, J.; Zhang, Y. SME-oriented flexible design approach for robotic manufacturing systems. J. Manuf. Syst. 2019, 53, 62–74. [Google Scholar] [CrossRef]

- Ledwith, A.; O’Dwyer, M. Product launch, product advantage and market orientation in SMEs. J. Small Bus. Enterp. Dev. 2008, 15, 96–110. [Google Scholar] [CrossRef]

- Leithold, N.; Woschke, T.; Haase, H.; Kratzer, J. Optimising NPD in SMEs: A best practice approach. Benchmarking Int. J. 2016, 23, 262–284. [Google Scholar] [CrossRef]

- Abu, N.H.; Deros, B.M.; Wahab, D.A.; Rahman, N.A.; Mansor, M.F. The pre-development process implementation of product innovation: A Malaysian food and beverage manufacturing SMEs survey. Int. J. Bus. Manag. Sci. 2012, 5, 39. [Google Scholar]

- Allocca, M.A.; Kessler, E.H. Innovation speed in small and medium-sized enterprises. Creat. Innov. Manag. 2006, 15, 279–295. [Google Scholar] [CrossRef]

- De Toni, A.; Nassimbeni, G. Small and medium district enterprises and the new product development challenge. Int. J. Oper. Prod. Manag. 2003, 23, 678–697. [Google Scholar] [CrossRef]

- Nicholas, J.; Ledwith, A.; Perks, H. New product development best practice in SME and large organisations: Theory vs. practice. Eur. J. Innov. Manag. 2011, 14, 227–251. [Google Scholar] [CrossRef]

- Hernández Pardo, R.J.; Bhamra, T.; Bhamra, R. Sustainable product service systems in small and medium enterprises (SMEs): Opportunities in the leather manufacturing industry. Sustainability 2012, 4, 175–192. [Google Scholar] [CrossRef]

- Kaminski, P.C.; de Oliveira, A.C.; Lopes, T.M. Knowledge transfer in product development processes: A case study in small and medium enterprises (SMEs) of the metal-mechanic sector from Sao Paulo, Brazil. Technovation 2008, 28, 29–36. [Google Scholar] [CrossRef]

- Millward, H.; Byrne, C.; Lewis, A. Enhancing the design capabilities of small and medium-sized enterprises through knowledge transfer. Des. J. 2015, 9, 3–13. [Google Scholar] [CrossRef]

- Ale Ebrahim, N.; Ahmed, S.; Taha, Z. SMEs; Virtual research and development (R&D) teams and new product development: A literature review. Int. J. Phys. Sci. 2010, 5, 916–930. [Google Scholar]

- Arfi, W.B.; Enström, R.; Sahut, J.M.; Hikkerova, L. The significance of knowledge sharing platforms for open innovation success. J. Organ. Chang. Manag. 2019, 32, 496–516. [Google Scholar] [CrossRef]

- Caffyn, S.; Grantham, A. Enabling continuous improvement of new product development processes. Ind. High. Educ. 2000, 14, 235–243. [Google Scholar] [CrossRef]

- Chaochotechuang, P.; Mariano, S. Alignment of new product development and product innovation strategies: A case study of Thai food and beverage SMEs. Int. J. Glob. Small Bus. 2016, 8, 179–206. [Google Scholar] [CrossRef]

- Chen, Y.-S.; James Lin, M.-J.; Chang, C.-H. The influence of intellectual capital on new product development performance–the manufacturing companies of Taiwan as an example. Total Qual. Manag. Bus. Excell. 2006, 17, 1323–1339. [Google Scholar] [CrossRef]

- Cheng, J.-H.; Liu, S.-F. A study of innovative product marketing strategies for technological SMEs. J. Interdiscip. Math. 2017, 20, 319–337. [Google Scholar] [CrossRef]

- Delas, A.; Maranzana, N.; Mantelet, F.; Buisine, S. Encouraging innovation activity: In the specific context of small-and medium-sized retailers. Int. J. Des. Creat. Innov. 2015, 3, 211–238. [Google Scholar] [CrossRef]

- Gherardini, F.; Renzi, C.; Leali, F. A systematic user-centred framework for engineering product design in small-and medium-sized enterprises (SMEs). Int. J. Adv. Manuf. Technol. 2017, 91, 1723–1746. [Google Scholar] [CrossRef]

- Woodcock, D.; Mosey, S.; Wood, T. New product development in British SMEs. Eur. J. Innov. Manag. 2000, 3, 212–222. [Google Scholar] [CrossRef]

- Woschke, T.; Haase, H.; Lautenschläger, A. Waste in NPD processes of German SMEs. Int. J. Product. Perform. Manag. 2016, 65, 532–553. [Google Scholar] [CrossRef]

- Gurau, C.; Ranchhod, A. Flexible risk management in new product development: The case of small-and medium-sized biopharmaceutical enterprises. Int. J. Risk Assess. Manag. 2007, 7, 474–490. [Google Scholar] [CrossRef]

- Shekar, A.; Metikurke, S. An empirical study of important dimensions of new product development practices in small and medium enterprises in New Zealand. Int. J. Ind. Eng. Theory Appl. Pract. 2011, 18, 83–91. [Google Scholar]

- Aziz, H.; Gao, J.; Maropoulos, P.; Cheung, W.M. Open standard, open source and peer-to-peer tools and methods for collaborative product development. Comput. Ind. 2005, 56, 260–271. [Google Scholar] [CrossRef]

- Germani, M.; Mengoni, M.; Peruzzini, M. How to address virtual teamwork in SMEs by an innovative co-design platform. Int. J. Prod. Lifecycle Manag. 2011, 5, 54–72. [Google Scholar] [CrossRef]

- Kaljun, J.; Dolšak, B. Ergonomic design knowledge built in the intelligent decision support system. Int. J. Ind. Ergon. 2012, 42, 162–171. [Google Scholar] [CrossRef]

- Kühle, S.; Teischinger, A.; Gronalt, M. Connecting Product Design, Process, and Technology Decisions to Strengthen the Solid Hardwood Business with a Multi-Step Quality Function Deployment Approach. BioResources 2019, 14, 2229–2255. [Google Scholar]

- Niu, X.-J.; Qin, S.-F.; Vines, J.; Wong, R.; Lu, H. Key crowdsourcing technologies for product design and development. Int. J. Autom. Comput. 2019, 16, 1–15. [Google Scholar] [CrossRef]

- Filson, A.; Lewis, A. Cultural issues in implementing changes to new product development process in a small to medium sized enterprise (SME). J. Eng. Des. 2000, 11, 149–157. [Google Scholar] [CrossRef]

- Akgün, A.E.; Lynn, G.S.; Byrne, J.C. Taking the guesswork out of new product development: How successful high-tech companies get that way. J. Bus. Strategy 2004, 25, 41–46. [Google Scholar] [CrossRef]

- Bagchi-Sen, S. Product innovation and competitive advantage in an area of industrial decline: The Niagara region of Canada. Technovation 2001, 21, 45–54. [Google Scholar] [CrossRef]

- Corso, M.; Martini, A.; Paolucci, E.; Pellegrini, L. Knowledge management configurations in Italian small-to-medium enterprises. Integr. Manuf. Syst. 2003, 14, 46–56. [Google Scholar] [CrossRef]

- Seo, D.-W.; Lee, S.-M.; Park, K.-S.; Park, H.-W.; Jeong, S.-C. Integrated Engineering Product Design Simulation Platform for Collaborative Simulation under the User Experience of Sme Users. ICIC Express Lett. Part B Appl. 2015, 1, 2. [Google Scholar]

- Garengo, P.; Panizzolo, R. Supplier involvement in integrated product development: Evidence from a group of Italian SMEs. Prod. Plan. Control 2013, 24, 158–171. [Google Scholar] [CrossRef]

- Yan, W.; Pritchard, M.C.; Chen, C.-H.; Khoo, L.P. A strategy for integrating product conceptualization and bid preparation. Int. J. Adv. Manuf. Technol. 2006, 29, 616–628. [Google Scholar] [CrossRef]

- Christofol, H.; Delamarre, A.; Samier, H. Organisation of innovation projects in SMEs–contribution to concept products in the design process. Int. J. Prod. Dev. 2009, 8, 42–62. [Google Scholar] [CrossRef]

- Cherifi, A.; M’Bassègue, P.; Gardoni, M.; Houssin, R.; Renaud, J. Eco-innovation and knowledge management: Issues and organizational challenges to small and medium enterprises. Artif. Intell. Eng. Des. Anal. Manuf. 2019, 33, 129–137. [Google Scholar] [CrossRef]

- Heck, J.; Meboldt, M. Current Challenges in Product Development Processes of Swiss SMEs. Int. J. Innov. Manag. 2016, 20, 1640009. [Google Scholar] [CrossRef]

- Moultrie, J.; Clarkson, P.J.; Probert, D. A tool to evaluate design performance in SMEs. Int. J. Product. Perform. Manag. 2006, 55, 184–216. [Google Scholar] [CrossRef]

- Kusar, J.; Duhovnik, J.; Grum, J.; Starbek, M. How to reduce new product development time. Robot. Comput. Integr. Manuf. 2004, 20, 1–15. [Google Scholar] [CrossRef]

- Lindman, M.; Scozzi, B.; Otero-Neira, C. Low-tech, small- and medium-sized enterprises and the practice of new product development: An international comparison. Eur. Bus. Rev. 2008, 20, 51–72. [Google Scholar] [CrossRef]

- Sänn, A.; Krimmling, J.; Baier, D.; Ni, M. Lead user intelligence for complex product development: The case of industrial IT–security solutions. Int. J. Technol. Intell. Plan. 2013, 9, 232–249. [Google Scholar] [CrossRef]

- Chim, H.; Deng, X. Efficient Phrase-Based Document Similarity for Clustering. IEEE Trans. Knowl. Data Eng. 2008, 20, 1217–1229. [Google Scholar] [CrossRef]

- Le Pochat, S.; Bertoluci, G.; Froelich, D. Integrating ecodesign by conducting changes in SMEs. J. Clean. Prod. 2007, 15, 671–680. [Google Scholar] [CrossRef]

- Ma, S.; Tian, L. A web service-based multi-disciplinary collaborative simulation platform for complicated product development. Int. J. Adv. Manuf. Technol. 2014, 73, 1033–1047. [Google Scholar] [CrossRef]

- Cantó, M.; Frasquet, M.; Irene, G.-S. Design orientation in new product development and its measurement. Eur. J. Innov. Manag. 2019, 24, 131–149. [Google Scholar] [CrossRef]

- Tan, Y.-S.; Chen, H.; Wu, S. Evaluation and implementation of environmentally conscious product design by using AHP and grey relational analysis approaches. Ekoloji 2019, 28, 857–864. [Google Scholar]

- Ng, C.; Chuah, K. A hybrid approach for environmental impact evaluation of design options. Int. J. Sustain. Eng. 2016, 9, 141–151. [Google Scholar] [CrossRef]

- van Harmelen, T.; Zondervan-van den Beuken, E.K.; Brouwer, D.H.; Kuijpers, E.; Fransman, W.; Buist, H.B.; Ligthart, T.N.; Hincapié, I.; Hischier, R.; Linkov, I. LICARA nanoSCAN-a tool for the self-assessment of benefits and risks of nanoproducts. Environ. Int. 2016, 91, 150–160. [Google Scholar] [CrossRef]

- Germani, M.; Mengoni, M.; Peruzzini, M. A QFD-based method to support SMEs in benchmarking co-design tools. Comput. Ind. 2012, 63, 12–29. [Google Scholar] [CrossRef]

- Giannini, F.; Monti, M.; Biondi, D.; Bonfatti, F.; Monari, P.D. A modelling tool for the management of product data in a co-design environment. Comput. Aided Des. 2002, 34, 1063–1073. [Google Scholar] [CrossRef]

- Lyu, J.; Chang, L.-Y. A reference model for collaborative design in mould industry. Prod. Plan. Control 2010, 21, 428–436. [Google Scholar] [CrossRef]

- Baranano, A.M.; Bommer, M.; Jalajas, D.S. Sources of innovation for high-tech SMEs: A comparison of USA, Canada, and Portugal. Int. J. Technol. Manag. 2005, 30, 205–219. [Google Scholar] [CrossRef]

- Owens, J.D. Why do some UK SMEs still find the implementation of a new product development process problematical? Manag. Decis. 2007, 45, 235–251. [Google Scholar] [CrossRef]

- Morgan, T.; Anokhin, S.A.; Song, C.; Chistyakova, N. The role of customer participation in building new product development speed capabilities in turbulent environments. Int. Entrep. Manag. J. 2019, 15, 119–133. [Google Scholar] [CrossRef]

- Sheikh, M. Barriers to Customer Integration into New Product Development Process: A Case of Apparel Industry in Pakistan. Int. J. Supply Chain Manag. 2013, 2. [Google Scholar] [CrossRef]

- Zhang, M.; Hartley, J.L. Guanxi, IT systems, and innovation capability: The moderating role of proactiveness. J. Bus. Res. 2018, 90, 75–86. [Google Scholar] [CrossRef]

- Raymond, L.; Uwizeyemungu, S.; Fabi, B.; St-Pierre, J. IT capabilities for product innovation in SMEs: A configurational approach. Inf. Technol. Manag. 2018, 19, 75–87. [Google Scholar] [CrossRef]

- de Sousa Mendes, G.H.; Miller Devós Ganga, G. Predicting success in product development: The application of principal component analysis to categorical data and binomial logistic regression. J. Technol. Manag. Innov. 2013, 8, 83–97. [Google Scholar]

- Cheng, F.; Zhang, J. New product development period and competitive advantage resulting from manufacturing-marketing interaction: An empirical study of SMEs in the Yangtze Delta in China. Int. J. Mater. Struct. Integr. 2013, 7, 191–203. [Google Scholar] [CrossRef]

- de Sousa Mendes, G.H.; de Toledo, J.C. Organizational characteristics in concurrent engineering: Evidence from Brazilian small and medium enterprises in the medical device industry. Concurr. Eng. 2015, 23, 135–144. [Google Scholar] [CrossRef]

- Mosey, S. Understanding new-to-market product development in SMEs. Int. J. Oper. Prod. Manag. 2005, 25, 114–130. [Google Scholar] [CrossRef]

- Tapio Lindman, M. Open or closed strategy in developing new products? A case study of industrial NPD in SMEs. Eur. J. Innov. Manag. 2002, 5, 224–236. [Google Scholar] [CrossRef]

- Buganza, T.; Colombo, G.; Landoni, P. Small and medium enterprises’ collaborations with universities for new product development. J. Small Bus. Enterp. Dev. 2014, 21, 69–86. [Google Scholar] [CrossRef]

- Salgado, E.G.; Salomon, V.A.P.; Mello, C.H.P.; da Silva, C.E.S. New product development in small and medium-sized technology based companies: A multiple case study. Acta Sci. Technol. 2018, 40, 35242. [Google Scholar] [CrossRef]

- Ocampo, J.U.; Kaminski, P.C. Medical device development, from technical design to integrated product development. J. Med Eng. Technol. 2019, 43, 287–304. [Google Scholar] [CrossRef]

- March-Chordà, I.; Gunasekaran, A.; Lloria-Aramburo, B. Product development process in Spanish SMEs: An empirical research. Technovation 2002, 22, 301–312. [Google Scholar] [CrossRef]

- Millward, H.; Dorrington, P.; Lewis, A. Challenges in implementing design-led technologies in small manufacturing companies. Ind. High. Educ. 2004, 18, 377–384. [Google Scholar] [CrossRef]

- Ulonska, S.; Welo, T. Product portfolio map: A visual tool for supporting product variant discovery and structuring. Adv. Manuf. 2014, 2, 179–191. [Google Scholar] [CrossRef]

- Yan, X.-T.; Stewart, B. Developing modular product family using GeMoCURE within an SME. Int. J. Manuf. Res. 2010, 5, 449–463. [Google Scholar] [CrossRef]

- Knauber, P.; Muthig, D.; Schmid, K.; Widen, T. Applying product line concepts in small and medium-sized companies. IEEE Softw. 2000, 17, 88–95. [Google Scholar] [CrossRef]

- de Beer, D.; Booysen, G.; Barnard, L.; Truscott, M. Rapid tooling in support of accelerated new product development. Assem. Autom. 2005, 25, 306–308. [Google Scholar] [CrossRef]

- Edwards, K.; Cooper, R.G.; Vedsmand, T.; Nardelli, G. Evaluating the Agile-Stage-Gate Hybrid Model: Experiences From Three SME Manufacturing Firms. Int. J. Innov. Technol. Manag. 2019, 16, 1–32. [Google Scholar] [CrossRef]

- Favi, C.; Germani, M.; Mandolini, M.; Marconi, M. Implementation of a software platform to support an eco-design methodology within a manufacturing firm. Int. J. Sustain. Eng. 2018, 11, 79–96. [Google Scholar] [CrossRef]

- Qin, S.; Van der Velde, D.; Chatzakis, E.; McStea, T.; Smith, N. Exploring barriers and opportunities in adopting crowdsourcing based new product development in manufacturing SMEs. Chin. J. Mech. Eng. 2016, 29, 1052–1066. [Google Scholar] [CrossRef]

- David, M.; Rowe, F. What does PLMS (product lifecycle management systems) manage: Data or documents? Complementarity and contingency for SMEs. Comput. Ind. 2016, 75, 140–150. [Google Scholar] [CrossRef]

- Fagerström, B.; Jackson, M. Efficient collaboration between main and sub-suppliers. Comput. Ind. 2002, 49, 25–35. [Google Scholar] [CrossRef]

- Heck, J.; Steinert, M.; Meboldt, M.J.P.C. Conceptualizing ideation workshops for SMEs. Procedia CIRP 2015, 36, 248–253. [Google Scholar] [CrossRef][Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).