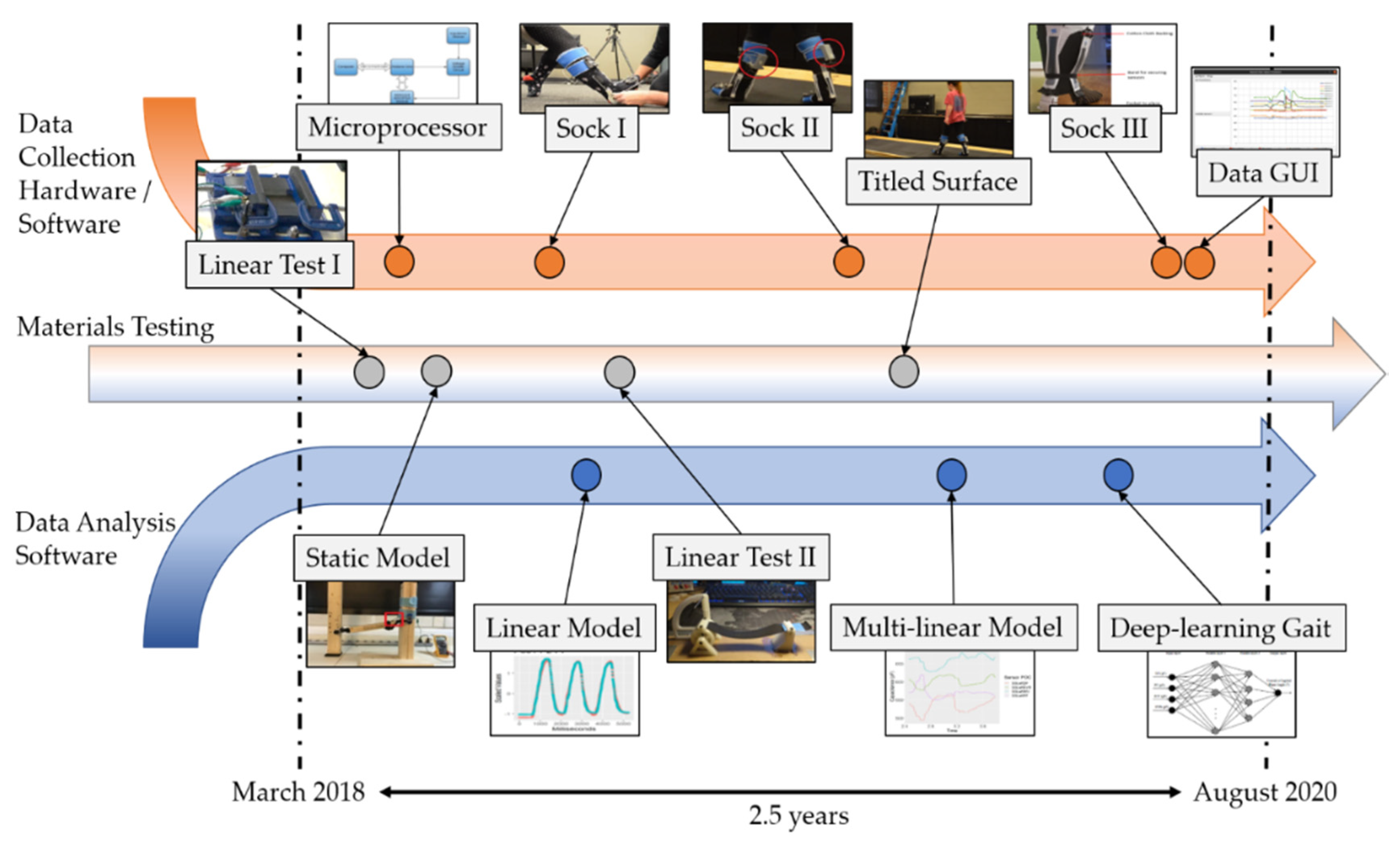

Closing the Wearable Gap-Part VII: A Retrospective of Stretch Sensor Tool Kit Development for Benchmark Testing

Abstract

:1. Introduction

1.1. Athlete Data Collection Limitations

1.2. Origins of Closing the Wearable Gap Research

1.3. SRS Validation Gaps

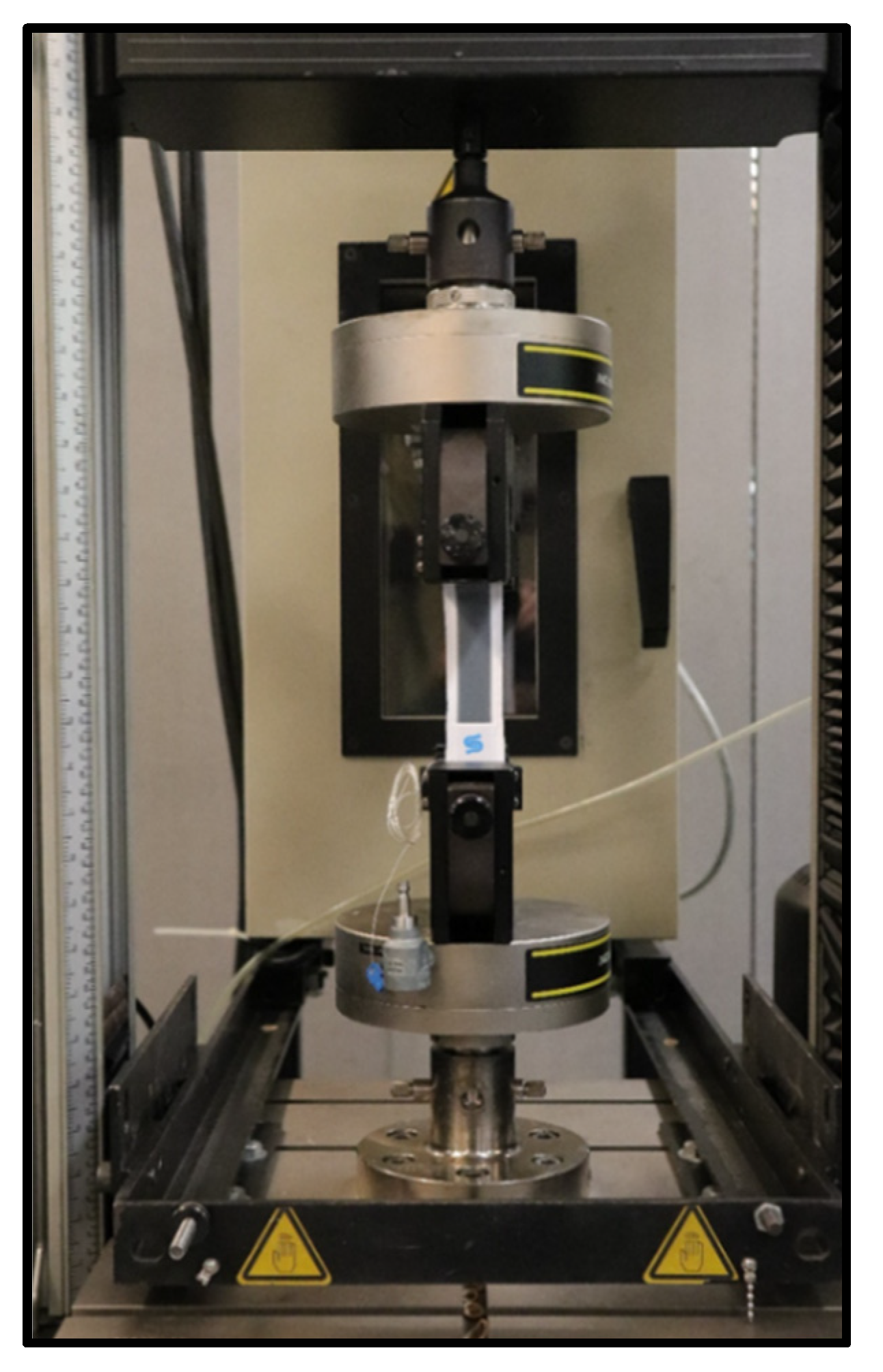

2. Material Testing Tools

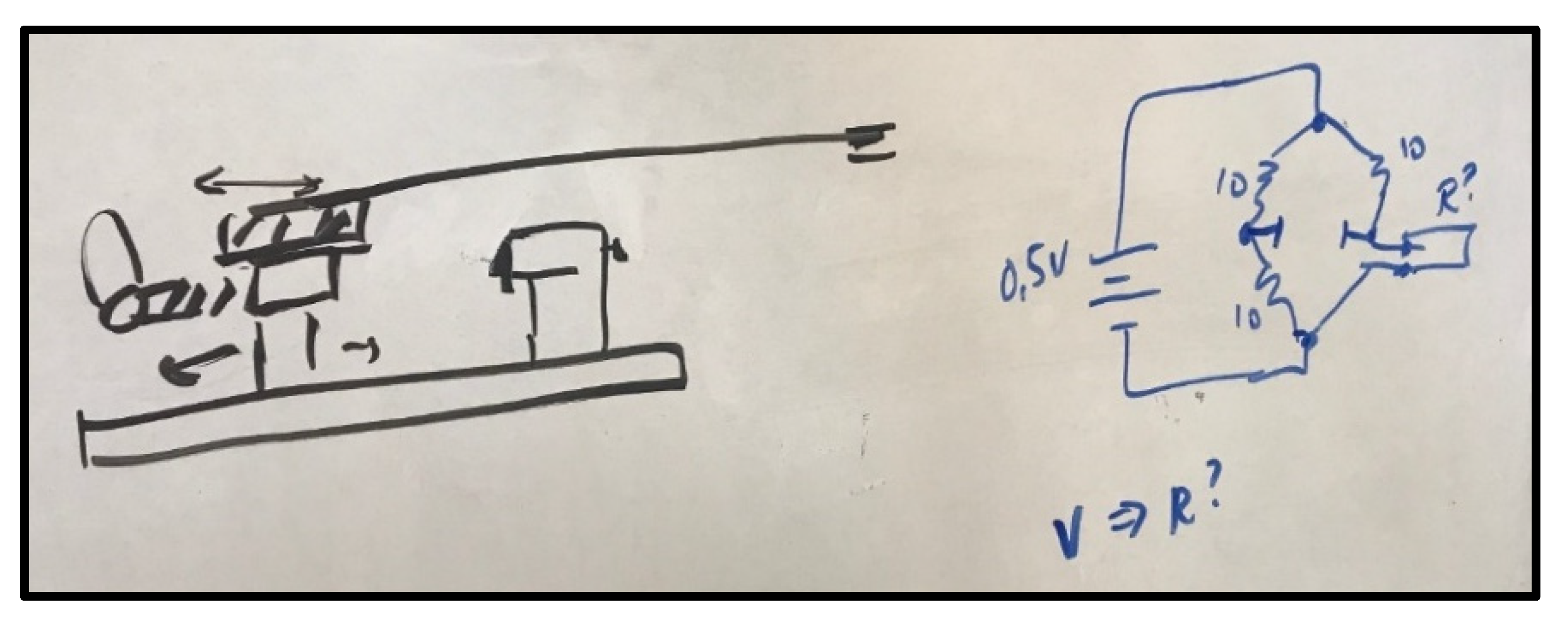

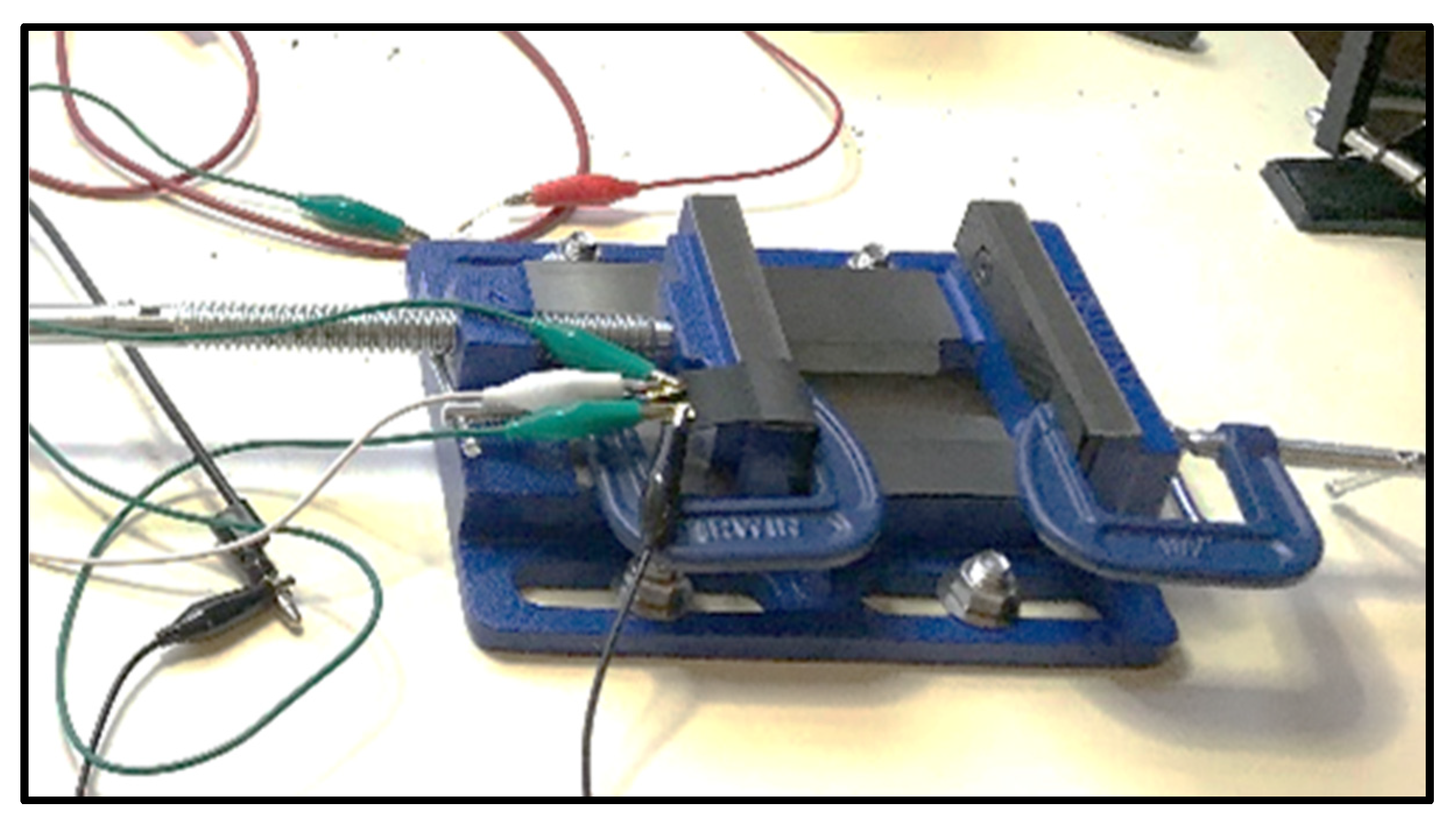

2.1. Linearity Testing Iteration I

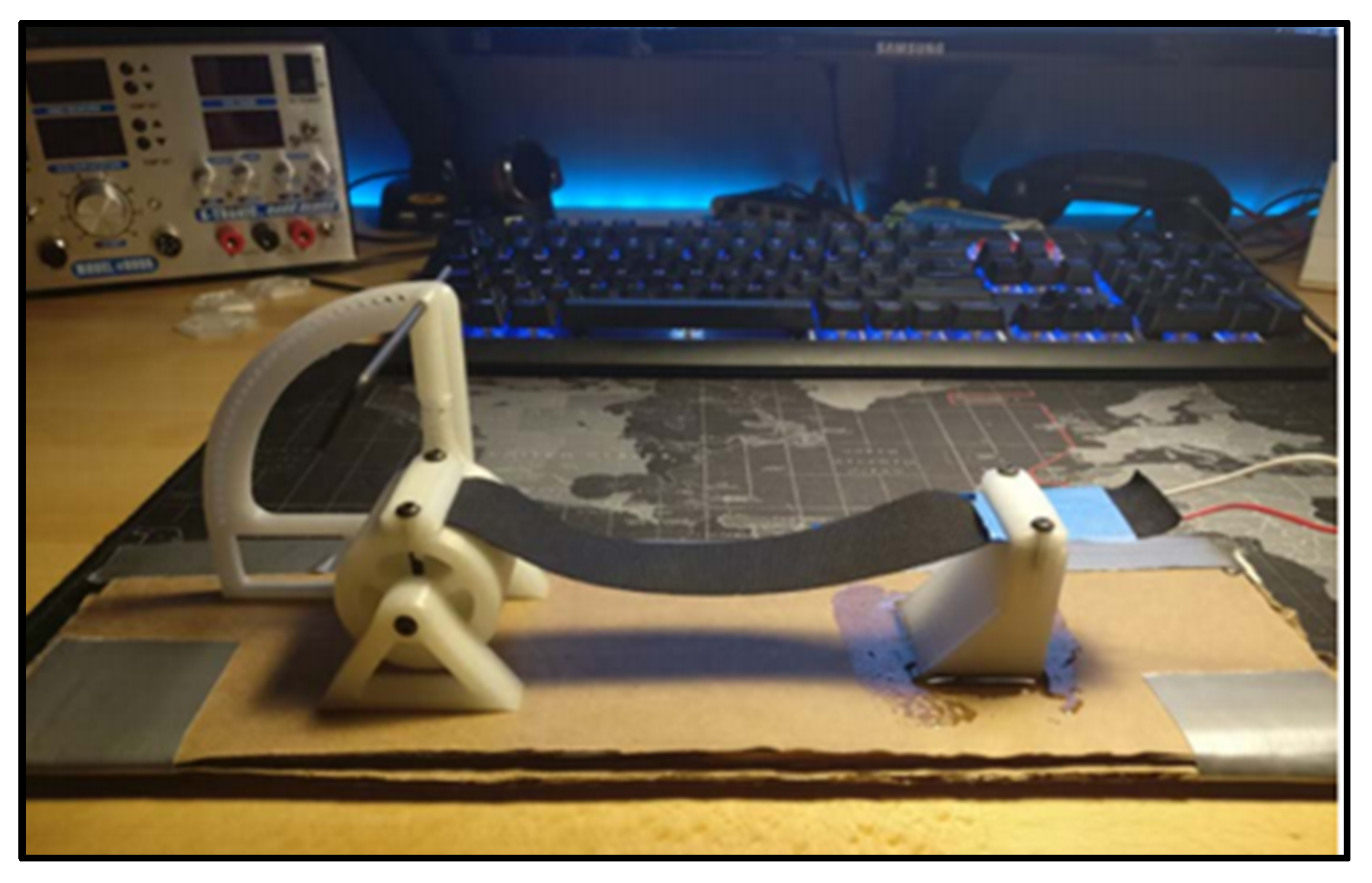

2.2. Linearity Testing Iteration II

2.3. Static Model Testing

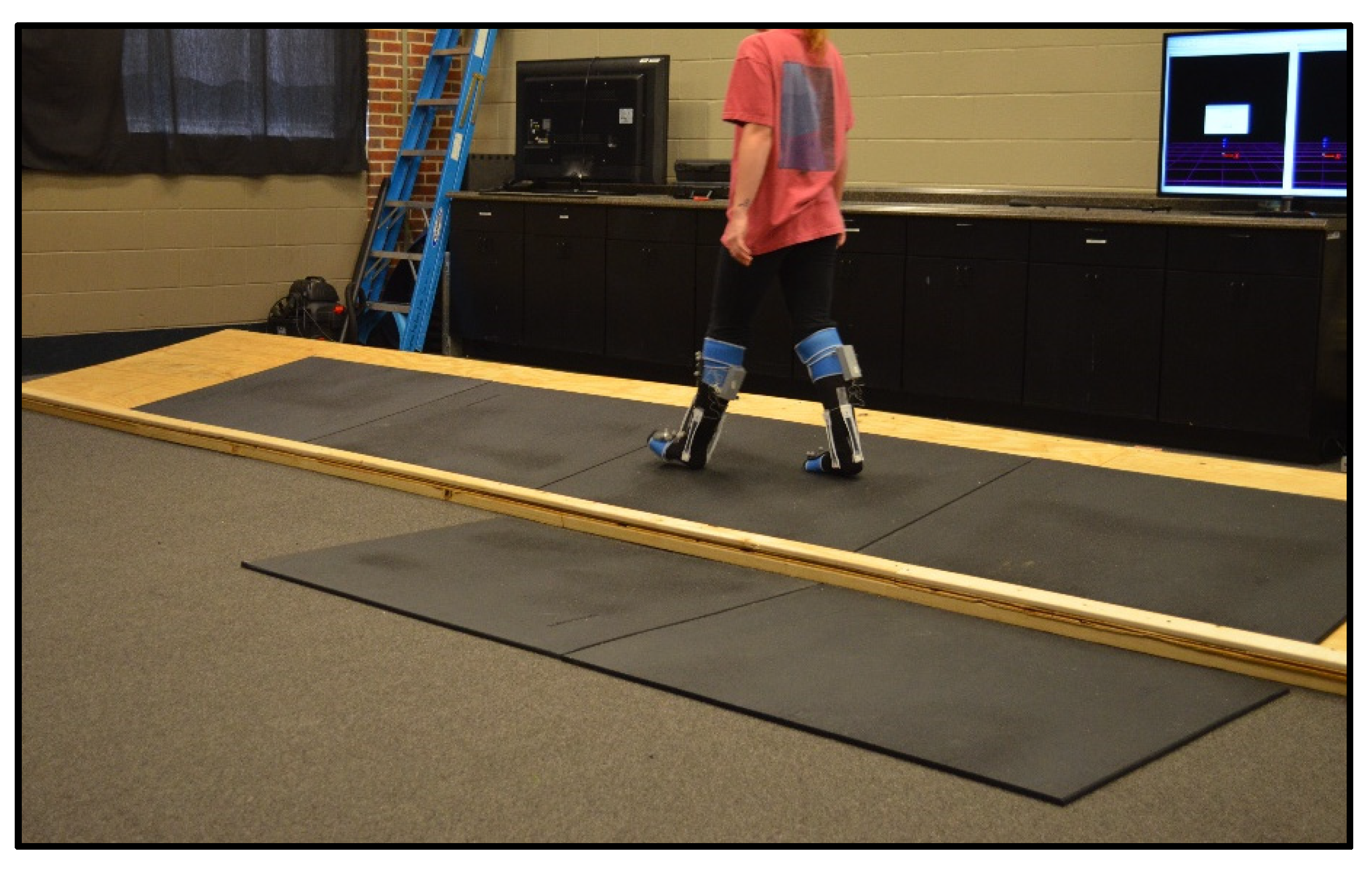

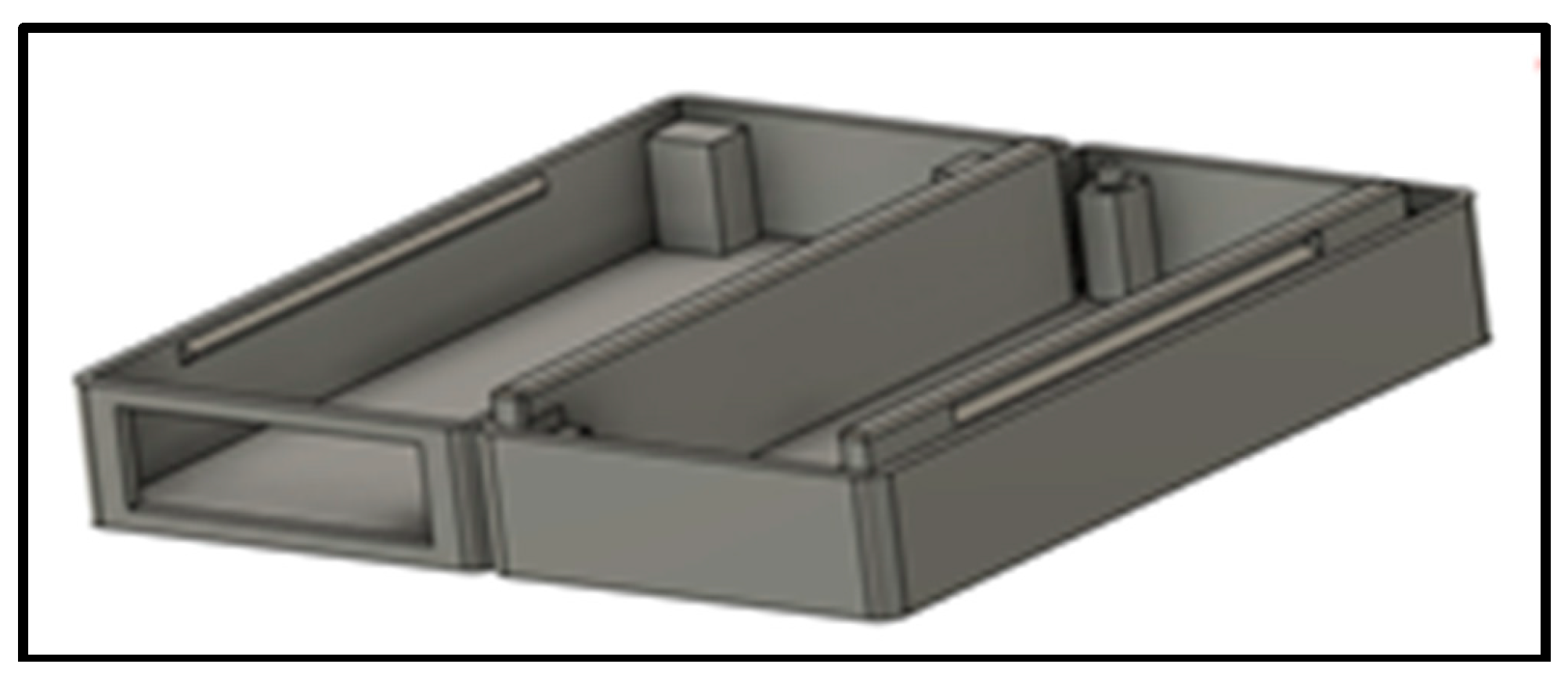

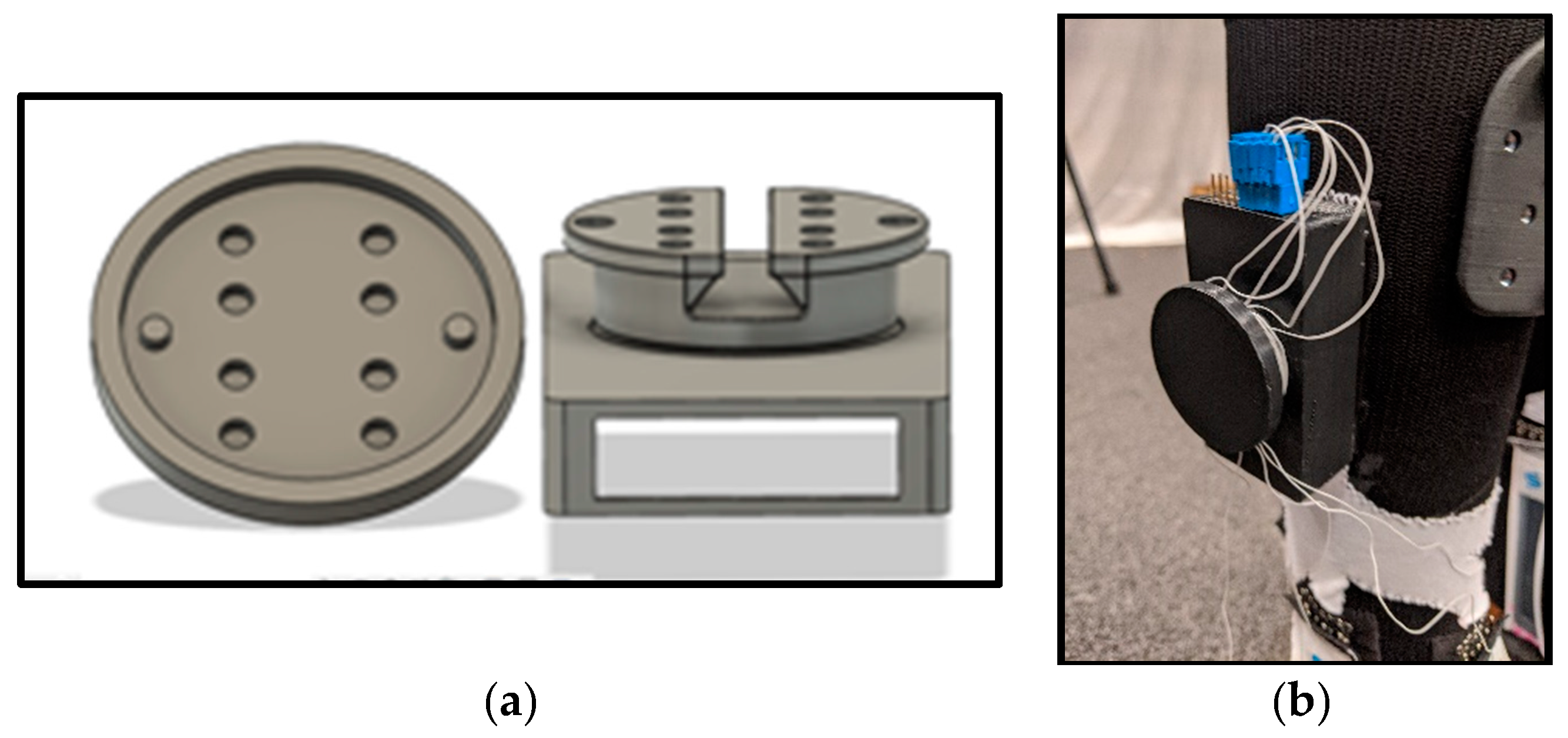

2.4. Tilted Surface Platform

3. Data Analysis Software

3.1. Simple Linear Modeling Analysis for SRS Placement on the Foot

3.2. Multiple Linear Modeling Analysis for Gait Analysis

3.3. Deep Learning Methods for Gait Analysis

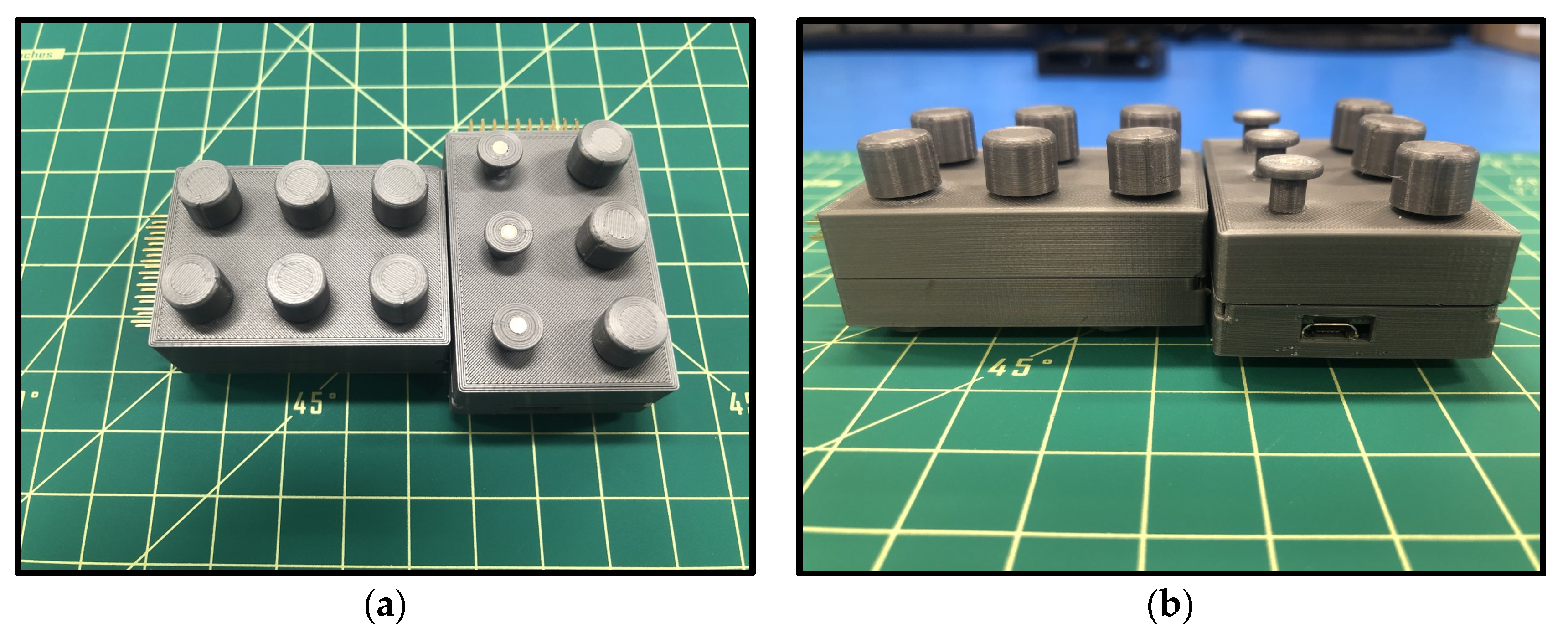

4. Data Collection Devices

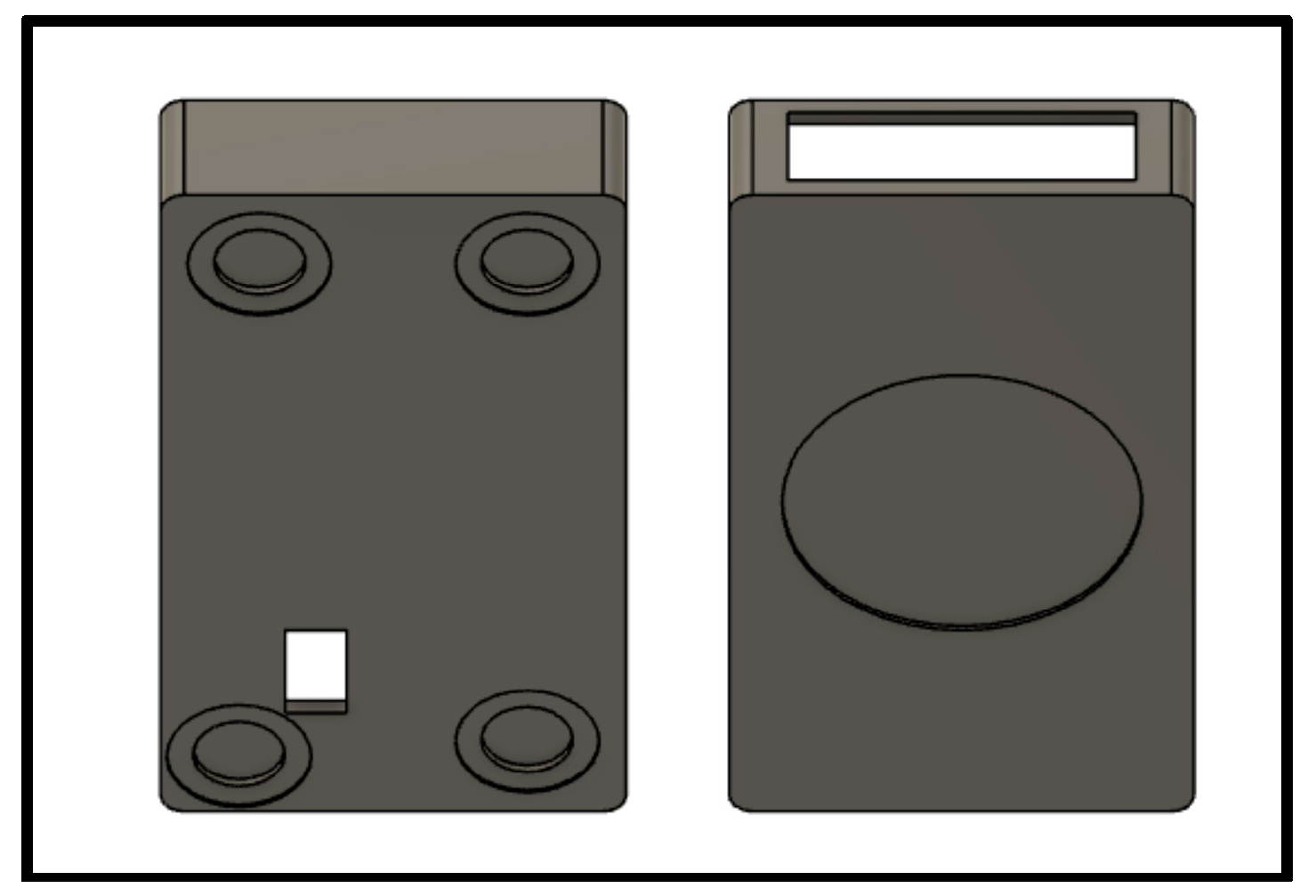

4.1. Initial Microprocessor Testing

4.2. Sock Prototype: Iteration I

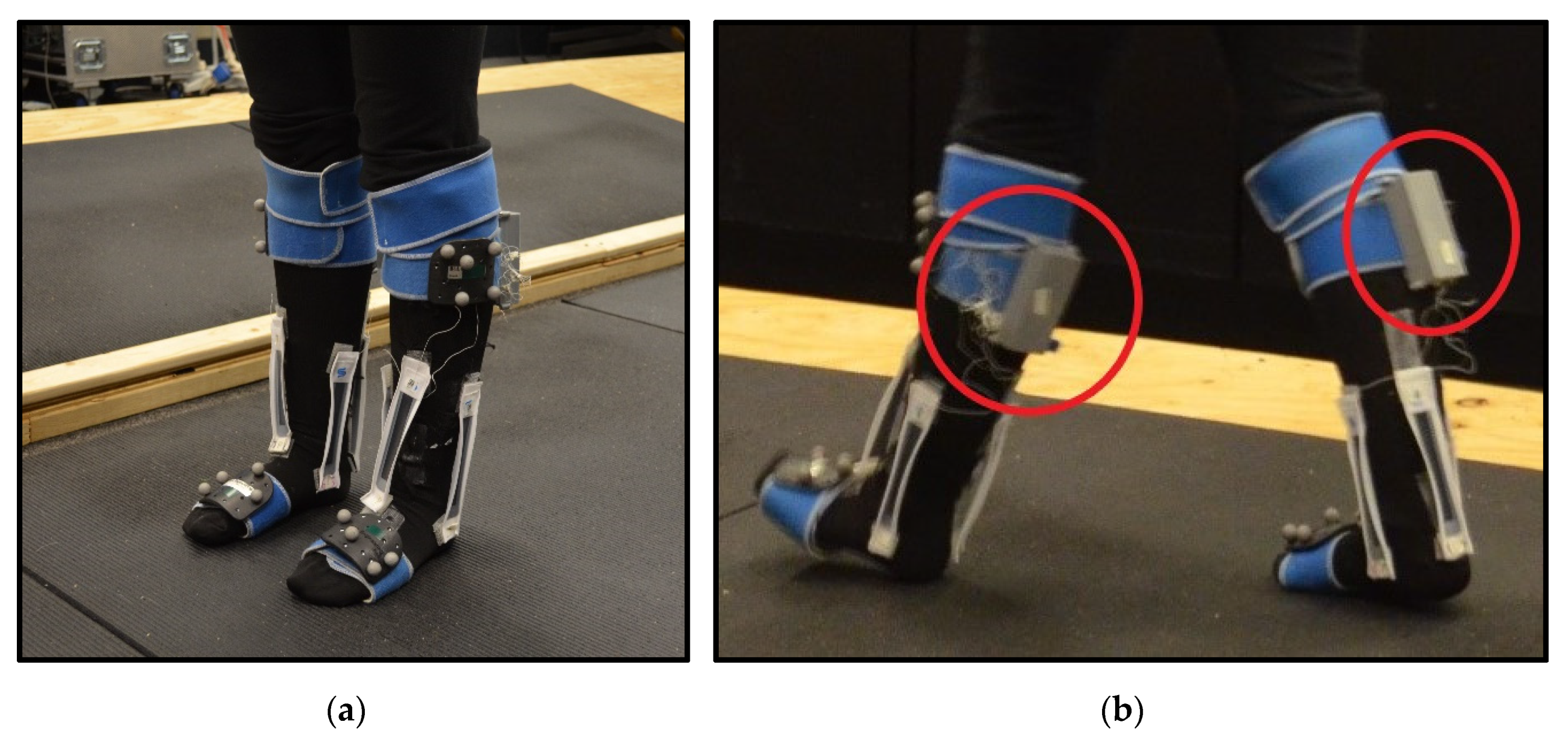

4.3. Sock Prototype: Iteration II

4.4. Sock Prototype: Iteration III/Current

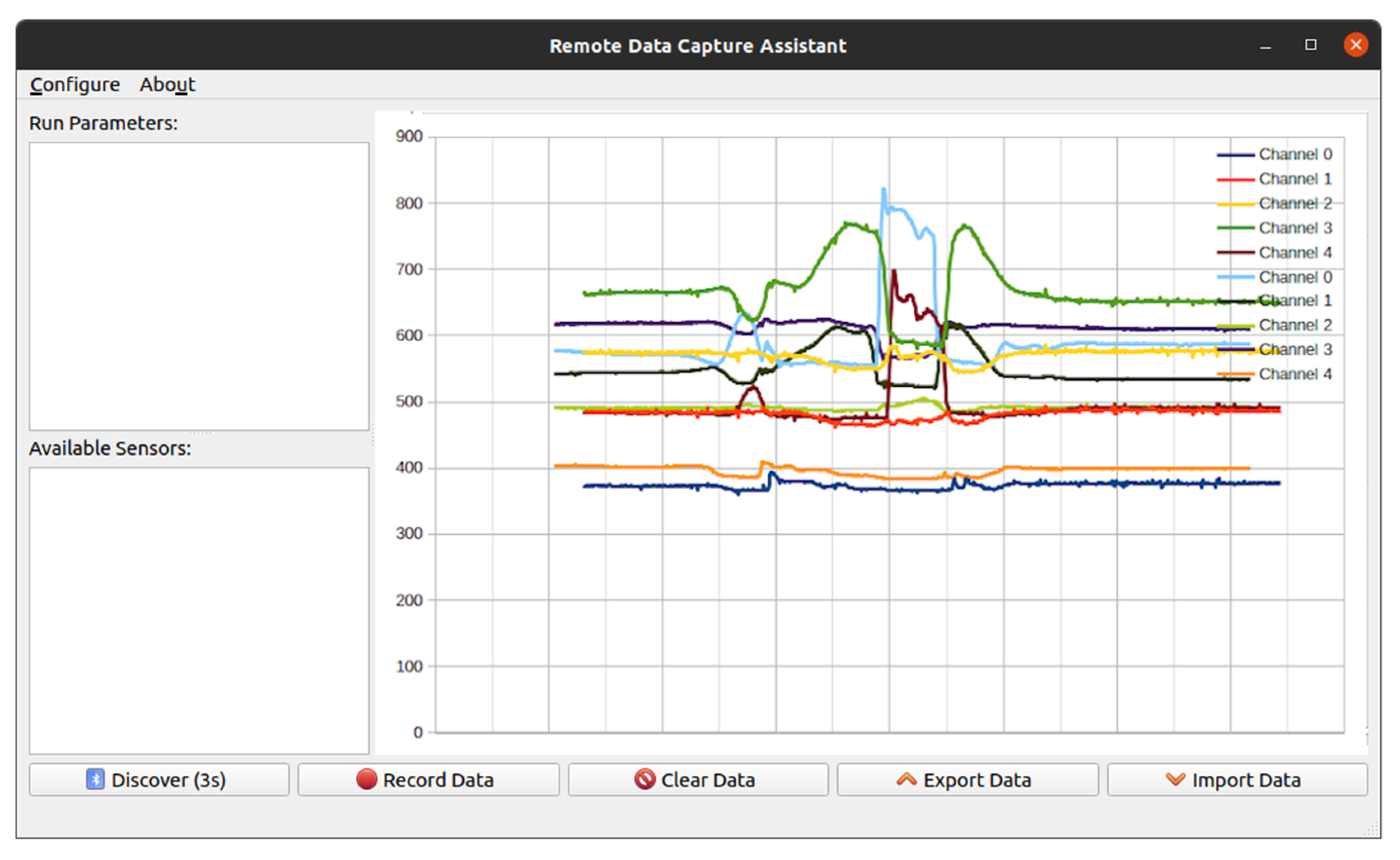

4.5. Data Collection Graphical User Interface (GUI)

5. Discussion of Limitations

- (a)

- The computing unit created for Closing the Wearable Gap Part I demonstrated minor noise levels, creating a variance in the electrical output at the time of data capture readings. The researchers recognized the importance of a breadboard during the initial design stages but suggested quickly moving to a PCB design.

- (b)

- The original wooden ankle model that was developed from an earlier model published in the literature [66] presented limitations. The rubber flooring material used to manipulate the wooden ankle joint for INV and EVR movements was problematic for the researchers during the experiment. A considerable amount of force had to be applied to manipulate the model to certain joint angles, which was a data collection issue, as well as an ergonomic concern, affecting the wrists and hands of the researchers. The researchers suggested the use of a more flexible material that would be easier to move and manipulate for future model developments.

- (c)

- Variance in participant’s gait patterns and stride lengths while walking on the flat surface and TSP created a lot of additional data cleaning. Gait research conducted by David Winter shows that every individual’s gait cycle is unique [67]. This variation in gait patterns made it more challenging to create prediction models that could generalize data well. The researchers transitioned to using multivariable linear models to minimize the effect of coupled movements, influencing the outputs of the SRS as well as deep learning techniques to improve predictability. The new sock prototype discussed in Section 4.2 was developed as a reliable SRS mounting approach to maintain consistency between different SRS data collection sessions and to avoid possible pre-strain problems. Sock prototype Iteration III will ensure that SRS can be mounted on the sock fabric only in one manner. Therefore, the deep learning model can be successfully trained as there is experimental confidence that all participant data collection sessions for SRS measurements are repeatable and reliable. Furthermore, deep learning needs a vast amount of data to properly train a model. To collect more data to train the deep learning algorithms, conducting longer trials to collect a higher number of gait cycles will be essential.

- (d)

- During the many initial linearity studies conducted by the researchers, numerous sensors were broken at the contact point after completing several measurement cycles while testing them on the drill vise fixture. Berlin et al. indicated that the conductive fibers might have mechanical properties somewhat different from those of normal textile fibers, causing them to react differently to deformation, bending, and extension. Chemical effects should also be considered. Because of certain deformations, gradual yet steady fiber migration eventually causes the SRS to crack at the point of contact [68]. Thus, depending upon the fiber type and fabric structure, having a reliable contact point was found to be critically important. Further, excellent flexibility and stretchability are crucial components that can provide monitoring systems with the ability to continuously track the human body’s physiological signals without being invasive. For this, researchers quickly found that it is necessary to consider the stretchability of the sensors based on the context of the area of research and the joint upon which the SRS is to be mounted. Most of the manufacturers provide a datasheet, indicating that the sensor can be stretched up to a certain proportion of its original length. Understanding the physical limitations of sensors became required learning for new members of the research team prior to experimentation.

- (e)

- The researchers used resistance-based SRS for Closing the Wearable Gap Part I, whereas capacitance-based sensors have been used to-date for the remaining Closing the Wearable Gap paper studies. Before swapping from resistance-based SRS to capacitance-based SRS, several factors were considered. The electrical properties of the sensors under applied strain were a primary reason for the change in the SRS type. Hysteresis is important to consider when using the sensor in real-life applications as it results in an increase in a change in the output of the SRS at rest, making it more difficult to predict with a model [69]. An important lesson learned by the experimenters is the desire for consistent and common resting resistances, that is when the SRS is not stretched. While all the sensors were linear in their movement-to-stretch output, not all sensors had comparable resistance values at rest. When developing a reliable model, variability in the resting resistance is not preferred. In this case, there were sensors that were the same length but had various resting resistances. To overcome this issue, the researchers suggested normalizing the data such that relative change is measured as opposed to absolute change. Nevertheless, the issue of resting resistance could still be considered problematic when reproducibility and consistency of sensors are desired, as they make circuit design more challenging. Resistivity itself is often susceptible to different environmental factors, such as temperature and damage [70]. Due to the variance in resistance, a flexibly designed circuit was needed, which would add more complexity to the computing unit’s programming to determine the resting resistance for the sensors. Thus, an SRS having consistent resting resistance with known minimal hysteresis is preferred when capturing complex joint movements.

- (f)

- Based on other literature in the field, resistive sensors possess strong sensitivity and excellent sensing efficiency. However, they suffer from poor long-term stability and linearity as well as substantial signal hysteresis. Alternatively, studies have suggested that capacitive sensors have better stability, lower hysteresis, and high stretchability [69,70,71,72]. One of the other factors to be addressed during the preliminary analysis was whether a commercial-off-the-shelf (COTS) product existed that could already measure the SRS. Having a COTS sensor module that supports Bluetooth and connects to a smartphone companion application for real-time data collection can help save a great deal of time when carrying out preliminary studies. It is also important to note the number of sensors a module can record simultaneously when measurements of multiple movements are desired, as well as the supported sampling rate and whether that sampling rate is consistent. There are some companies that have fully developed software applications with various raw data streaming functionalities, while others give basic demonstrations.

6. Future Scope

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Burch, R.F.; Strawderman, L.; Piroli, A.; Chander, H.; Tian, W.; Murphy, F. The importance of baselining division 1 football athlete jumping movements for performance, injury mitigation, and return to play. In Proceedings of the Advances in Intelligent Systems and Computing, Berkeley, CA, USA, 24–28 July 2009; Springer: Berlin/Heidelberg, Germany; 970, pp. 332–344. [Google Scholar]

- Luczak, T.; Burch, R.; Lewis, E.; Chander, H.; Ball, J. State-of-the-art review of athletic wearable technology: What 113 strength and conditioning coaches and athletic trainers from the USA said about technology in sports. Int. J. Sports Sci. Coach. 2019, 15, 26–40. [Google Scholar] [CrossRef]

- Coyle, S.; Morris, D.; Lau, K.-T.; Diamond, D.; Moyna, N. Textile-based wearable sensors for assisting sports performance. In Proceedings of the 2009 Sixth International Workshop on Wearable and Implantable Body Sensor Networks, Berkeley, CA, USA, 3–5 June 2009; pp. 307–311. [Google Scholar] [CrossRef] [Green Version]

- Carmines, E.G.; Zeller, R.A. Validity. In Reliability and Validity Assessment; Michael, S.L.-B., Ed.; SAGE Publications, Inc.: Iowa City, IA, USA, 1979; pp. 17–26. [Google Scholar]

- Van Der Kruk, E.; Reijne, M.M. Accuracy of human motion capture systems for sport applications; state-of-the-art review. Eur. J. Sport Sci. 2018, 18, 806–819. [Google Scholar] [CrossRef]

- Pueo, B.; Jimenez-Olmedo, J.M. Application of motion capture technology for sport performance analysis. Retos Nuevas Tend. Educ. Física Deporte Recreación 2017, 32, 241–247. [Google Scholar]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: A review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Fantozzi, S.; Giovanardi, A.; Magalhães, F.A.; Di Michele, R.; Cortesi, M.; Gatta, G. Assessment of three-dimensional joint kinematics of the upper limb during simulated swimming using wearable inertial-magnetic measurement units. J. Sports Sci. 2015, 34, 1073–1080. [Google Scholar] [CrossRef] [PubMed]

- Krüger, A.; Edelmann-Nusser, J. Biomechanical analysis in freestyle snowboarding: Application of a full-body inertial measurement system and a bilateral insole measurement system. Sports Technol. 2009, 2, 17–23. [Google Scholar] [CrossRef]

- Koda, H.; Sagawa, K.; Kuroshima, K.; Tsukamoto, T.; Urita, K.; Ishibashi, Y. 3D measurement of forearm and upper arm during throwing motion using body mounted sensor. J. Adv. Mech. Des. Syst. Manuf. 2010, 4, 167–178. [Google Scholar] [CrossRef] [Green Version]

- Bosch, S.; Shoaib, M.; Geerlings, S.; Buit, L.; Meratnia, N.; Havinga, P. Analysis of indoor rowing motion using wearable inertial sensors. In Proceedings of the 10th EAI International Conference on Body Area Networks, Sydney, Australia, 28–30 September 2015. [Google Scholar]

- Nakazato, K.; Scheiber, P.; Müller, E. Comparison between the force application point determined by portable force plate system and the center of pressure determined by pressure insole system during alpine skiing. Sports Eng. 2013, 16, 297–307. [Google Scholar] [CrossRef]

- Shepherd, J.B.; Giblin, G.; Pepping, G.-J.; Thiel, D.V.; Rowlands, D. Development and validation of a single wrist mounted inertial sensor for biomechanical performance analysis of an elite netball shot. IEEE Sens. Lett. 2017, 1, 1–4. [Google Scholar] [CrossRef]

- Akins, J.S.; Heebner, N.R.; Lovalekar, M.; Sell, T.C. Reliability and validity of instrumented soccer equipment. J. Appl. Biomech. 2015, 31, 195–201. [Google Scholar] [CrossRef]

- Blair, S.; Duthie, G.; Robertson, S.; Hopkins, W.; Ball, K.A. Concurrent validation of an inertial measurement system to quantify kicking biomechanics in four football codes. J. Biomech. 2018, 73, 24–32. [Google Scholar] [CrossRef] [PubMed]

- Philpott, L.K.; Weaver, S.; Gordon, D.; Conway, P.P.; West, A.A. Assessing wireless inertia measurement units for monitoring athletics sprint performance. IEEE Sens. 2014 Proc. 2014, 2199–2202. [Google Scholar] [CrossRef] [Green Version]

- Heikenfeld, J.; Jajack, A.; Rogers, J.; Gutruf, P.; Tian, L.; Pan, T.; Li, R.; Khine, M.; Wang, J.; Kim, J.; et al. Wearable sensors: Modalities, challenges, and prospects. Lab A Chip 2018, 18, 217–248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, S.L.P. Wearable sensors for sports performance. In Textiles for Sportswear; Elsevier: Amsterdam, The Netherlands, 2015; pp. 169–196. [Google Scholar]

- Luczak, T.; Saucier, D.; Burch, V.R.F.; Ball, J.; Chander, H.; Knight, A.; Wei, P.; Iftekhar, T. Closing the wearable gap: Mobile systems for kinematic signal monitoring of the foot and ankle. Electronics 2018, 7, 117. [Google Scholar] [CrossRef] [Green Version]

- Jamwal, P.K.; Hussain, S.; Tsoi, Y.H.; Ghayesh, M.H.; Xie, S.Q. Musculoskeletal modelling of human ankle complex: Estimation of ankle joint moments. Clin. Biomech. 2017, 44, 75–82. [Google Scholar] [CrossRef] [Green Version]

- Chinn, L.; Hertel, J. Rehabilitation of ankle and foot injuries in athletes. Clin. Sports Med. 2010, 29, 157–167. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hertel, J. Functional anatomy, pathomechanics, and pathophysiology of lateral ankle instability. J. Athl. Train. 2002, 37, 364–375. [Google Scholar]

- Amtmann, J.; Hegg, S. The industrial athlete and flexibility. Prim. Health Open Access 2016, 6. [Google Scholar] [CrossRef]

- Sevier, T.L. The industrial athlete? Occup. Environ. Med. 2000, 57, 285. [Google Scholar] [CrossRef]

- Chen, S.; Wei, Y.; Wei, S.; Lin, Y.; Liu, L. Ultrasensitive cracking-assisted strain sensors based on silver nanowires/graphene hybrid particles. ACS Appl. Mater. Interfaces 2016, 8, 25563–25570. [Google Scholar] [CrossRef]

- Din, S.; Xu, W.; Cheng, L.K.; Dirven, S. A stretchable multimodal sensor for soft robotic applications. IEEE Sens. J. 2017, 17, 5678–5686. [Google Scholar] [CrossRef]

- Jiao, Y.; Young, C.W.; Yang, S.; Oren, S.; Ceylan, H.; Kim, S.; Gopalakrishnan, K.; Taylor, P.C.; Dong, L. Wearable graphene sensors with microfluidic liquid metal wiring for structural health monitoring and human body motion sensing. IEEE Sens. J. 2016, 16, 7870–7875. [Google Scholar] [CrossRef]

- Lee, H.; Cho, J.; Kim, J. Printable skin adhesive stretch sensor for measuring multi-axis human joint angles. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 4975–4980. [Google Scholar]

- Liao, X.; Song, W.; Zhang, X.-Y.; Huang, H.; Wang, Y.; Zheng, Y. Directly printed wearable electronic sensing textiles towards human–machine interfaces. J. Mater. Chem. C 2018, 6, 12841–12848. [Google Scholar] [CrossRef]

- Park, Y.-L.; Chen, B.-R.; Wood, R.J. Design and fabrication of soft artificial skin using embedded microchannels and liquid conductors. IEEE Sens. J. 2012, 12, 2711–2718. [Google Scholar] [CrossRef]

- Kramer, R.K.; Majidi, C.; Sahai, R.; Wood, R.J. Soft curvature sensors for joint angle proprioception. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, Francisco, CA, USA, 25–30 September 2011; pp. 1919–1926. [Google Scholar]

- Yi, F.; Lin, L.; Niu, S.; Yang, P.K.; Wang, Z.; Chen, J.; Zhou, Y.; Zi, Y.; Wang, J.; Liao, Q.; et al. Stretchable-rubber-based triboelectric nanogenerator and its application as self-powered body motion sensors. Adv. Funct. Mater. 2015, 25, 3688–3696. [Google Scholar] [CrossRef]

- Shen, Z.; Yi, J.; Li, X.; Mark, L.H.P.; Hu, Y.; Wang, Z. A soft stretchable bending sensor and data glove applications. In Proceedings of the 2016 IEEE International Conference on Real-time Computing and Robotics (RCAR), Angkor Wat, Cambodia, 6–9 June 2016; pp. 88–93. [Google Scholar]

- Chander, H.; Burch V, R.F.; Talegaonkar, P.; Saucier, D.; Luczak, T.; Ball, J.; Turner, A.; Arachchige, S.N.K.K.; Carroll, W.; Smith, B.K.; et al. Wearable stretch sensors for human movement monitoring and fall detection in ergonomics. Int. J. Environ. Res. Public Health 2020, 17, 3554. [Google Scholar] [CrossRef]

- Giorgino, T.; Tormene, P.; Lorussi, F.; De Rossi, D.; Quaglini, S. Sensor evaluation for wearable strain gauges in neurological rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2009, 17, 409–415. [Google Scholar] [CrossRef]

- Helmer, R.; Farrow, D.; Ball, K.A.; Phillips, E.; Farouil, A.; Blanchonette, I. A pilot evaluation of an electronic textile for lower limb monitoring and interactive biofeedback. Procedia Eng. 2011, 13, 513–518. [Google Scholar] [CrossRef]

- Liu, C.-X.; Choi, J.-W. An embedded PDMS nanocomposite strain sensor toward biomedical applications. In Proceedings of the 2009 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Minneapolis, MN, USA, 2–6 September 2009; Volume 2009, pp. 6391–6394. [Google Scholar]

- Lorussi, F.; Scilingo, E.P.; Tesconi, M.; Tognetti, A.; DeRossi, D. Strain sensing fabric for hand posture and gesture monitoring. IEEE Trans. Inf. Technol. Biomed. 2005, 9, 372–381. [Google Scholar] [CrossRef]

- Dharap, P.; Li, Z.; Nagarajaiah, S.; Barrera, E.V. Nanotube film based on single-wall carbon nanotubes for strain sensing. Nanotechnology 2004, 15, 379–382. [Google Scholar] [CrossRef]

- Kang, I.; Schulz, M.; Kim, J.H.; Shanov, V.; Shi, D. A carbon nanotube strain sensor for structural health monitoring. Smart Mater. Struct. 2006, 15, 737–748. [Google Scholar] [CrossRef]

- Li, X.; Levy, C.; Elaadil, L. Multiwalled carbon nanotube film for strain sensing. Nanotechnology 2008, 19, 045501. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, J.; Zhuang, R.; Mäder, E.; Heinrich, G.; Gao, S.-L. Single MWNT-glass fiber as strain sensor and switch. Adv. Mater. 2011, 23, 3392–3397. [Google Scholar] [CrossRef] [PubMed]

- Helmer, R.; Farrow, D.; Lucas, S.; Higgerson, G.; Blanchonette, I. Can interactive textiles influence a novice’s throwing technique? Procedia Eng. 2010, 2, 2985–2990. [Google Scholar] [CrossRef] [Green Version]

- Lu, N.; Lu, C.; Yang, S.; Rogers, J.A. Highly sensitive skin-mountable strain gauges based entirely on elastomers. Adv. Funct. Mater. 2012, 22, 4044–4050. [Google Scholar] [CrossRef]

- Rautaray, S.S.; Agrawal, A. Interaction with virtual game through hand gesture recognition. In Proceedings of the 2011 International Conference on Multimedia, Signal Processing and Communication Technologies, Aligarh, India, 17–19 December 2011; pp. 244–247. [Google Scholar]

- Xiao, X.; Yuan, L.; Zhong, J.; Ding, T.; Liu, Y.; Cai, Z.; Rong, Y.; Han, H.; Zhou, J.; Wang, Z.L. High-strain sensors based on ZnO nanowire/polystyrene hybridized flexible films. Adv. Mater. 2011, 23, 5440–5444. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, Z.Y.; Zheng, F.Z.; Zhang, M.; Zhang, J.; Yao, Y.G. A high sensitivity single-walled carbon-nanotube-array-based strain sensor for weighing. In Proceedings of the TRANSDUCERS 2009—2009 International Solid-State Sensors, Actuators and Microsyst. Conference, Denver, CO, USA, 21–25 June 2009; pp. 1493–1496. [Google Scholar]

- Amjadi, M.; Park, I. Carbon nanotubes-ecoflex nanocomposite for strain sensing with ultra-high stretchability. In Proceedings of the 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 744–747. [Google Scholar] [CrossRef]

- Liang, A.; Stewart, R.; Bryan-Kinns, N. Analysis of sensitivity, linearity, hysteresis, responsiveness, and fatigue of textile knit stretch sensors. Sensors 2019, 19, 3618. [Google Scholar] [CrossRef] [Green Version]

- Campigotto, A.; Leahy, S.; Choudhury, A.; Zhao, G.; Lai, Y. A novel strain sensor using a microchannel embedded in PDMS. J. Biomed. Eng. Inform. 2018, 4, 1. [Google Scholar] [CrossRef]

- Guo, X.; Huang, Y.; Cai, X.; Liu, C.; Liu, P. Capacitive wearable tactile sensor based on smart textile substrate with carbon black/silicone rubber composite dielectric. Meas. Sci. Technol. 2016, 27, 045105. [Google Scholar] [CrossRef]

- Hu, S.; Dai, M.; Dong, T.; Liu, T. A textile sensor for long durations of human motion capture. Sensors 2019, 19, 2369. [Google Scholar] [CrossRef] [Green Version]

- Mattmann, C.; Clemens, F.; Tröster, G. Sensor for measuring strain in textile. Sensors 2008, 8, 3719–3732. [Google Scholar] [CrossRef] [PubMed]

- Nakamoto, H.; Ootaka, H.; Tada, M.; Hirata, I.; Kobayashi, F.; Kojima, F. Stretchable strain sensor with anisotropy and application for joint angle measurement. IEEE Sens. J. 2016, 16, 3572–3579. [Google Scholar] [CrossRef]

- Totaro, M.; Poliero, T.; Mondini, A.; Lucarotti, C.; Cairoli, G.; Ortiz, J.; Beccai, L. Soft smart garments for lower limb joint position analysis. Sensors 2017, 17, 2314. [Google Scholar] [CrossRef] [PubMed]

- Saucier, D.; Luczak, T.; Nguyen, P.; Davarzani, S.; Peranich, P.; Ball, J.E.; Burch, R.F.; Smith, B.K.; Chander, H.; Knight, A.; et al. Closing the wearable gap-Part II: Sensor orientation and placement for foot and ankle joint kinematic measurements. Sensors 2019, 19, 3509. [Google Scholar] [CrossRef] [Green Version]

- Saucier, D.; Davarzani, S.; Turner, A.; Luczak, T.; Nguyen, P.; Carroll, W.; Burch, V.R.F.; Ball, J.; Smith, B.K.; Chander, H.; et al. Closing the wearable gap—Part IV: 3D motion capture cameras versus soft robotic sensors comparison of gait movement assessment. Electronics 2019, 8, 1382. [Google Scholar] [CrossRef] [Green Version]

- Chan, C.W.; Rudins, A. Foot biomechanics during walking and running. Mayo Clin. Proc. 1994, 69, 448–461. [Google Scholar] [CrossRef] [Green Version]

- De Vries, G.; Roy, K.; Chester, V.L. Using three-dimensional gait data for foot/ankle orthopaedic surgery. Open Orthop. J. 2009, 3, 89–95. [Google Scholar] [CrossRef] [Green Version]

- Lundberg, A.; Goldie, I.; Kalin, B.; Selvik, G. Kinematics of the ankle/foot complex: plantarflexion and dorsiflexion. Foot Ankle 1989, 9, 194–200. [Google Scholar] [CrossRef]

- Doan-Johnson, S.; Veillette, C. Biomechanics of the foot and ankle. In OrthopaedicsOne—The Orthopaedic Knowledge Network; 2011; Available online: https://www.orthopaedicsone.com/display/Main/Biomechanics+of+the+foot+and+ankle (accessed on 6 August 2020).

- Kwon, Y.-H.; Hutcheson, L.; Casebolt, J.B.; Ryu, J.-H.; Singhal, K. The effects of railroad ballast surface and slope on rearfoot motion in walking. J. Appl. Biomech. 2012, 28, 457–465. [Google Scholar] [CrossRef]

- Rhudy, M. Time alignment techniques for experimental sensor data. Int. J. Comput. Sci. Eng. Surv. 2014, 5, 1–14. [Google Scholar] [CrossRef]

- Davarzani, S.; Saucier, D.; Peranich, P.; Carroll, W.; Turner, A.; Parker, E.; Middleton, C.; Nguyen, P.; Robertson, P.; Smith, B.K.; et al. Closing the wearable gap—Part VI: Human gait recognition using deep learning methodologies. Electronics 2020, 9, 796. [Google Scholar] [CrossRef]

- Luczak, T.; Burch V, R.F.; Smith, B.K.; Carruth, D.W.; Lamberth, J.; Chander, H.; Knight, A.; Ball, J.; Prabhu, R. Closing the wearable gap—Part V: Development of a pressure-sensitive sock utilizing soft sensors. Sensors 2019, 20, 208. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fuller, E. Center of pressure and its theoretical relationship to foot pathology. J. Am. Podiatr. Med. Assoc. 1999, 89, 278–291. [Google Scholar] [CrossRef] [PubMed]

- Winter, D.A. Biomechanical motor patterns in normal walking. J. Mot. Behav. 1983, 15, 302–330. [Google Scholar] [CrossRef]

- Berlin, A.A.; Joswik, R.; Ivanovich, V.N. Modern application of nanoengineered materials. In Engineering Textiles: Research Methodologies, Concepts, and Modern Applications, 1st ed.; Alexander, A.B., Roman, J., Nikolai, I.V., Eds.; CRC Press: New York, NY, USA, 2015; pp. 247–278. [Google Scholar]

- Atalay, O. Textile-based, interdigital, capacitive, soft-strain sensor for wearable applications. Materials 2018, 11, 768. [Google Scholar] [CrossRef] [Green Version]

- Homayounfar, S.Z.; Andrew, T.L. Wearable sensors for monitoring human motion: A review on mechanisms, materials, and challenges. SLAS Technol. Transl. Life Sci. Innov. 2019, 25, 9–24. [Google Scholar] [CrossRef]

- Jean-Mistral, C.; Iglesias, S.; Pruvost, S.; Duchet-Rumeau, J.; Chesné, S. Dielectric elastomer for stretchable sensors: Influence of the design and material properties. Proc. SPIE 2016, 9798. [Google Scholar] [CrossRef]

- Gu, J.; Kwon, D.; Ahn, J.; Park, I. Wearable strain sensors using light transmittance change of carbon nanotube-embedded elastomers with microcracks. ACS Appl. Mater. Interfaces 2019, 12, 10908–10917. [Google Scholar] [CrossRef]

| Item (Hyperlink) | Description |

|---|---|

| Soft Sensors Research Repository | Publicly available GitHub repository used to distribute and showcase hardware/software tools to the community (contains items listed below). |

| openSRS-manager GUI | A software tool used to communicate with/control custom hardware, assist with lab data collection, and visualize/export data. |

| openSRS-labkit-v1 Hardware/Firmware | PCB design files, 3D case models, and firmware source code for custom lab data collection kit. |

| Biomechanics Data Analysis Scripts (Statistical) | SRS/MOCAP data analysis using general statistical techniques. |

| Biomechanics Data Analysis Scripts (Deep Learning) | SRS/MOCAP data analysis using deep learning/machine learning techniques. |

| Publicly Available Datasets | Deidentified raw experiment data for public use. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Talegaonkar, P.; Saucier, D.; Carroll, W.; Peranich, P.; Parker, E.; Middleton, C.; Davarzani, S.; Turner, A.; Persons, K.; Casey, L.; et al. Closing the Wearable Gap-Part VII: A Retrospective of Stretch Sensor Tool Kit Development for Benchmark Testing. Electronics 2020, 9, 1457. https://doi.org/10.3390/electronics9091457

Talegaonkar P, Saucier D, Carroll W, Peranich P, Parker E, Middleton C, Davarzani S, Turner A, Persons K, Casey L, et al. Closing the Wearable Gap-Part VII: A Retrospective of Stretch Sensor Tool Kit Development for Benchmark Testing. Electronics. 2020; 9(9):1457. https://doi.org/10.3390/electronics9091457

Chicago/Turabian StyleTalegaonkar, Purva, David Saucier, Will Carroll, Preston Peranich, Erin Parker, Carver Middleton, Samaneh Davarzani, Alana Turner, Karen Persons, Landon Casey, and et al. 2020. "Closing the Wearable Gap-Part VII: A Retrospective of Stretch Sensor Tool Kit Development for Benchmark Testing" Electronics 9, no. 9: 1457. https://doi.org/10.3390/electronics9091457

APA StyleTalegaonkar, P., Saucier, D., Carroll, W., Peranich, P., Parker, E., Middleton, C., Davarzani, S., Turner, A., Persons, K., Casey, L., Burch V, R. F., Ball, J. E., Chander, H., Knight, A., Luczak, T., Smith, B. K., & Prabhu, R. K. (2020). Closing the Wearable Gap-Part VII: A Retrospective of Stretch Sensor Tool Kit Development for Benchmark Testing. Electronics, 9(9), 1457. https://doi.org/10.3390/electronics9091457