1. Introduction

Motors are used in a wide variety of applications, from washing machine [

1] in homes to electric vehicles [

2] in the transport sector. Modern control systems generally require more efficient techniques to execute the instructions at high velocity and get more accurate results. According to [

3], the best way to achieve high performance in servo control is to remove the servo control loop implemented in a Digital Signal Processor (DSP) or in a microcontroller and transfer it to a high-velocity control loop in an Field-Programmable Gate Array (FPGA). The statement takes into account the advantages of using the FPGA as a controller. For example, FPGAs are flexible devices that have the ability of reconfigurable parallel processing [

4,

5] and, it is precisely the aforementioned aspect that allows the realization of a system of logical operations in parallel, which considerably reduces the computation time [

6]. Finally, the FPGA has a comparatively simpler design cycle to be managed and requires less manual intervention [

7,

8].

FPGAs have established as a competitive option for the control of processes that require high-processing velocity. Examples of certain applications carried out with FPGA can be found in the literature [

9,

10,

11,

12]. In specific applications that use servo motors, lower cost of FPGA hardware is required to reduce the price of the system [

13]. The use of an FPGA enables a greater scale of control loop integration, which is one of the premises of the modern industry. In this sense, achieving a high-level integration and density of the used Printed Circuit Board (PCB) for the control implementation is defined as one of the most important criteria in the sector [

14]. The authors in [

15] discuss the block architecture and strategy that must be implemented in the FPGA to connect a speed profile to a controller.

Currently, position control loops on motors employ a design that allows tracking of a reference. These designs, also called velocity profiles, are presented as piece wise finite order polynomials [

16] and they play an important role in motion control applications. The main advantage of using velocity profiles is the reduction of vibrations and energy consumption [

17]. The most used profiles are: trapezoidal [

18] and parabolic [

19]. The use of the mentioned velocity profiles is not limited to the control of electric motors but is applied in a wide range of applications [

20,

21]. This type of polynomial has essential parameters: velocity, acceleration, distance, trajectory to follow and the time of the route. The relationship between distance and time allows establishing other concepts such as jerk (derived from acceleration) [

22].

According to [

23], the planning of trajectories in machines and robots with multiple actuators began with the design of mechanical cams capable of generating the desired movements. The movements were synchronized with the mechanical couplings. Presently, trajectory planning is committed to the design of electronic cameras that allow servo-assisted mechanisms to be controlled in a more flexible way and where synchronization is completely achieved with software tools [

24]. Therefore, it is possible to avoid repetitive design and manufacture of mechanical cams for each type of trajectory. On the other hand, movement is simplified by focusing solely on the control of the electric motor to generate different movement profiles.

Generally, position control in electric motors combines a position controller and a velocity profile generator. Heo et al. in [

25] present a trapezoidal velocity profile generator and a position P-PI controller to produce a trajectory from a reference. The trapezoidal profile causes a certain level of stress in the motors. Some research develops smoother profiles to avoid affecting the motor function. For example, [

26] presents a curve velocity profile S to eliminate the aforementioned disadvantages. The authors in [

27] shows an optimized S-curve model that reduces positioning time. The main advantage of the work is the proposal of a robust model.

In certain industrial applications, energy consumption is not considered to be a key element for the selection of profiles. This aspect represents an increase in production costs and pollution levels that the industrial sector generates, because it is precisely electric motors that represent the highest percentage of energy consumption. According to [

28], the electricity consumption for electric motors up to 0.75 kW represents 9% of the total, between 0.75 kW and 375 kW is 68% and the rest 23%. This work presents a use case for DC motors with a power consumption up to 0.75 kW. However, it can be scaled to higher power motors. Currently, the reduction of energy consumption is an urgent need and the participation of the industry is essential [

29]. Precisely, to advance in this regard, in 2012, the Energy Efficiency Directives of the European Union were approved. These directives establish a way forward to achieve greater energy efficiency [

30].

Although smoother profiles have been developed, such as the S-curve velocity profile, it has been shown that flexibility in the trapezoidal and parabolic profile can be achieved with the proper selection of its parameters [

31]. For this reason, the aforementioned profiles constitute the focus of this investigation.

Table 1 shows a brief comparison of the main characteristics of the velocity profiles treated at work. Although the S profile is not addressed in the present investigation, its inclusion in the previous table was considered important. Furthermore,

Table 2 presents a summary of similar works.

It is important to mention that greater efficiency in production chains is not the only justification for the development of this research. In addition, a correct modulation must be made in the maximum velocity of the actuators, since it allows the prevention of collisions or overheating in moving parts. The regulation of energy consumption directly affects production costs and it is precisely this characteristic that highlights the parabolic profile versus the trapezoidal profile, reducing the rate of change in acceleration with respect to time. The objective of the work is the practical FPGA-based implementation of a control for servo motors for industrial use, in addition to establishing a comparative analysis that results in the selection of the most suitable profile for the application. For this, a separate implementation of each module is carried out. The paper is structured as follows.

Section 2 presents the analytical model of velocity profiles. In

Section 3, the development and implementation of the modules that make up the motion control system is documented. The experimental results and the comparative analysis of the trapezoidal and parabolic profiles are presented in

Section 4. A list of the acronyms used in this paper is presented at the end of the document and in the

Table A3 is shown the main signals used in the diagrams.

3. Design and Implementation of Modules

According to [

36], modeling a physical system consists of obtaining and solving equations that describe the behavior through its variables. The components of the system are modeled separately and finally connected according to their configuration and the laws of nature that govern them. However, one of the main advantages of using velocity profiles is that it is not required to obtain the motor model to carry out its motion control.

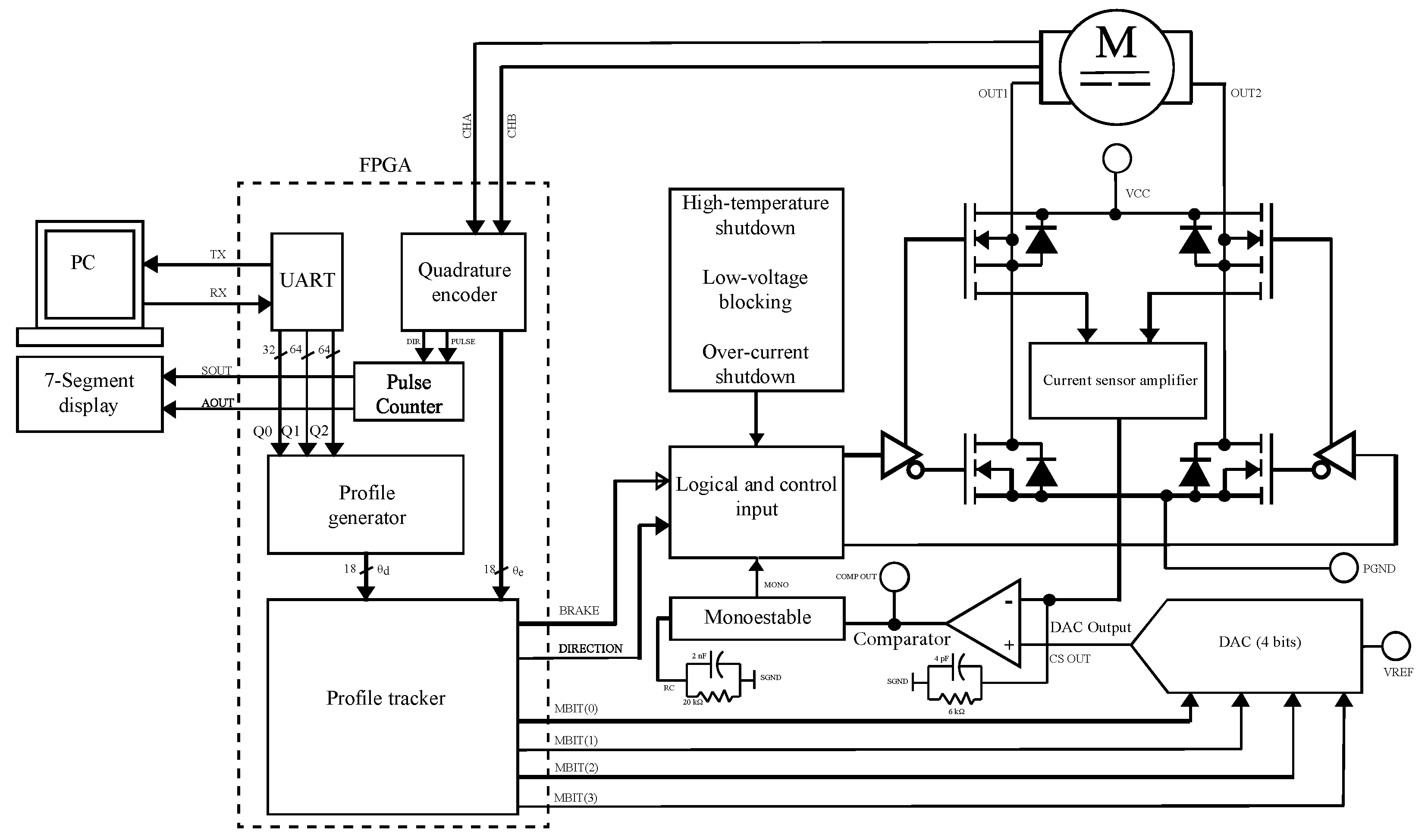

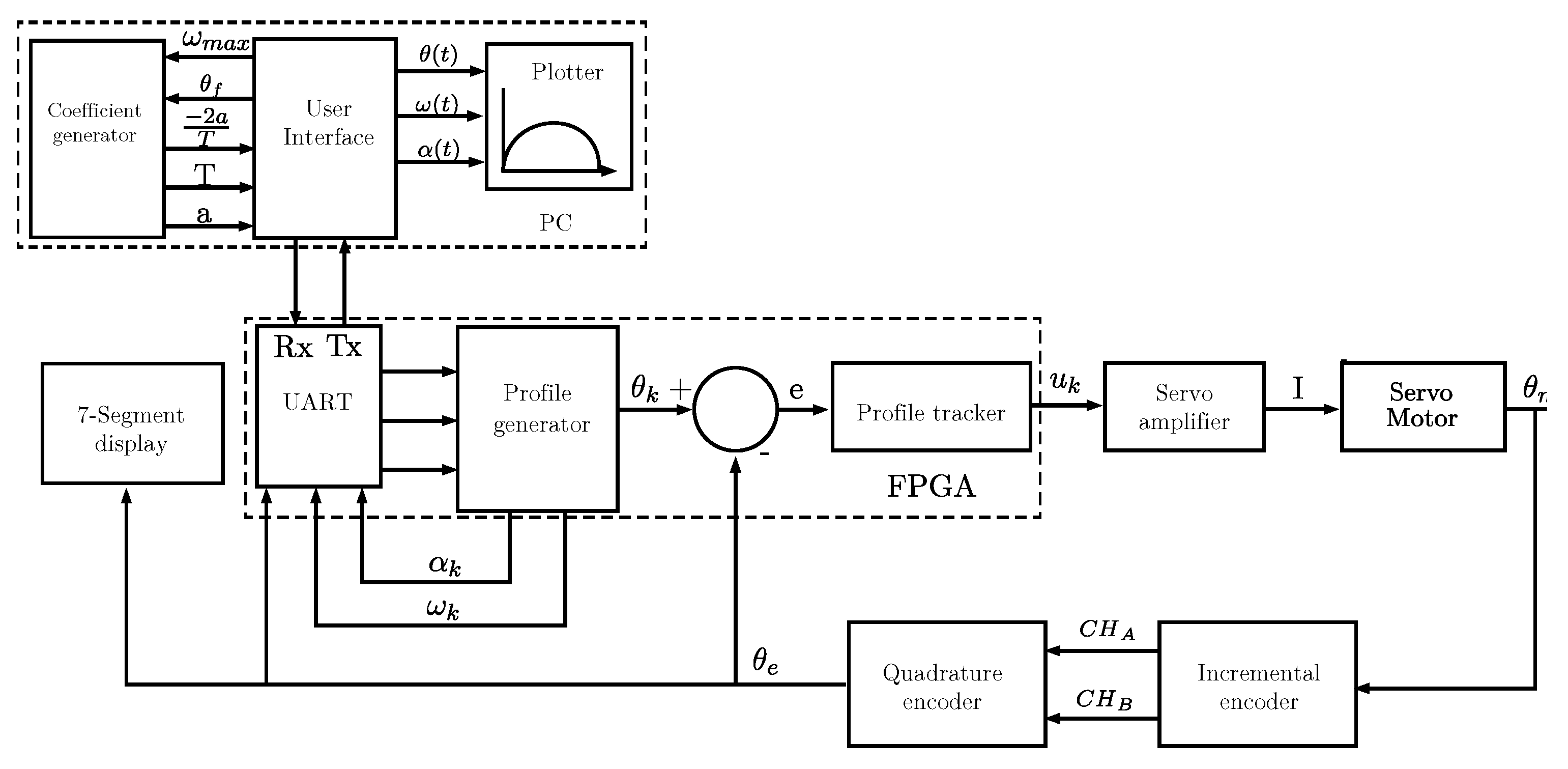

Figure 3 and

Figure 4 show the system proposed and the general hardware architecture for this work, respectively. The Artix-7 FPGA family is used, which optimized for low power applications requiring serial transceivers and high DSP and logic throughput. Provides the lowest total bill of materials cost for high-throughput, cost-sensitive applications. Also, this FPGA family offers high-end performance at the lowest cost and achievable power. The main characteristics of the device used are presented in

Table 5. The selection of the sampling period was made after carrying out some experiments with higher values. It was also decided to establish a sampling period of 1 ms to simplify the calculations in the internal blocks since it avoids the use of extra blocks (multiplication blocks) when working with the value of 1. Furthermore, in previous investigations the use of this value has been formally justified [

37,

38].

Block programming is done using VHDL. The blocks are implemented in a flexible and modular way to enable easy customization. It was decided to take advantage of this language advantage due to its magnitude. In this way, if any correction is necessary for any of the blocks, it is not necessary to modify the entire system.

The control flow begins with the user interface, where the type of profile, the maximum velocity and the desired position are selected. Then, the coefficient generator sends the values to the FPGA through a UART transmission-reception module. The profile generator calculates for each instant of time a portion of the final position according to the selected profile. The difference between the profile generator position and the current motor position is sent to the profile tracker; this block induces a current in the motor. The direction of the current is determined by a bit in the received frame and it depends on the sign of the error. The current motor position is measured with the motor encoder and processed with a quadrature module described in the FPGA. The result is used in three ways in the system: as feedback to the profile tracker, as a decimal value displayed on a seven-segment display and as a vector of data transmitted to the interface to graph the motor path.

A Finite State Machine allows control of the two signals given by the encoder. The main clock of the system feeds this component in order to generate a count that could be decremental or incremental, depending on the direction of the shaft of the motor. The two signals from the encoder could reach some MHz, in this sense, when a multi-axe system is requires, the FPGA is a good choice.

The implementation of the profile tracker is done after obtaining a discrete model to add it to the design in the FPGA. As in the velocity profiles, the sampling time is 1 ms. The difference can be expressed as the error and rewrite the equation as: . The block input is the difference between the encoder reading and the desired position. With this circuit, the necessary operations are performed, thus tracing the position requested by the velocity profile generator. The output of the circuit is saturated to couple the result to a 4-bit control action for the motor driver.

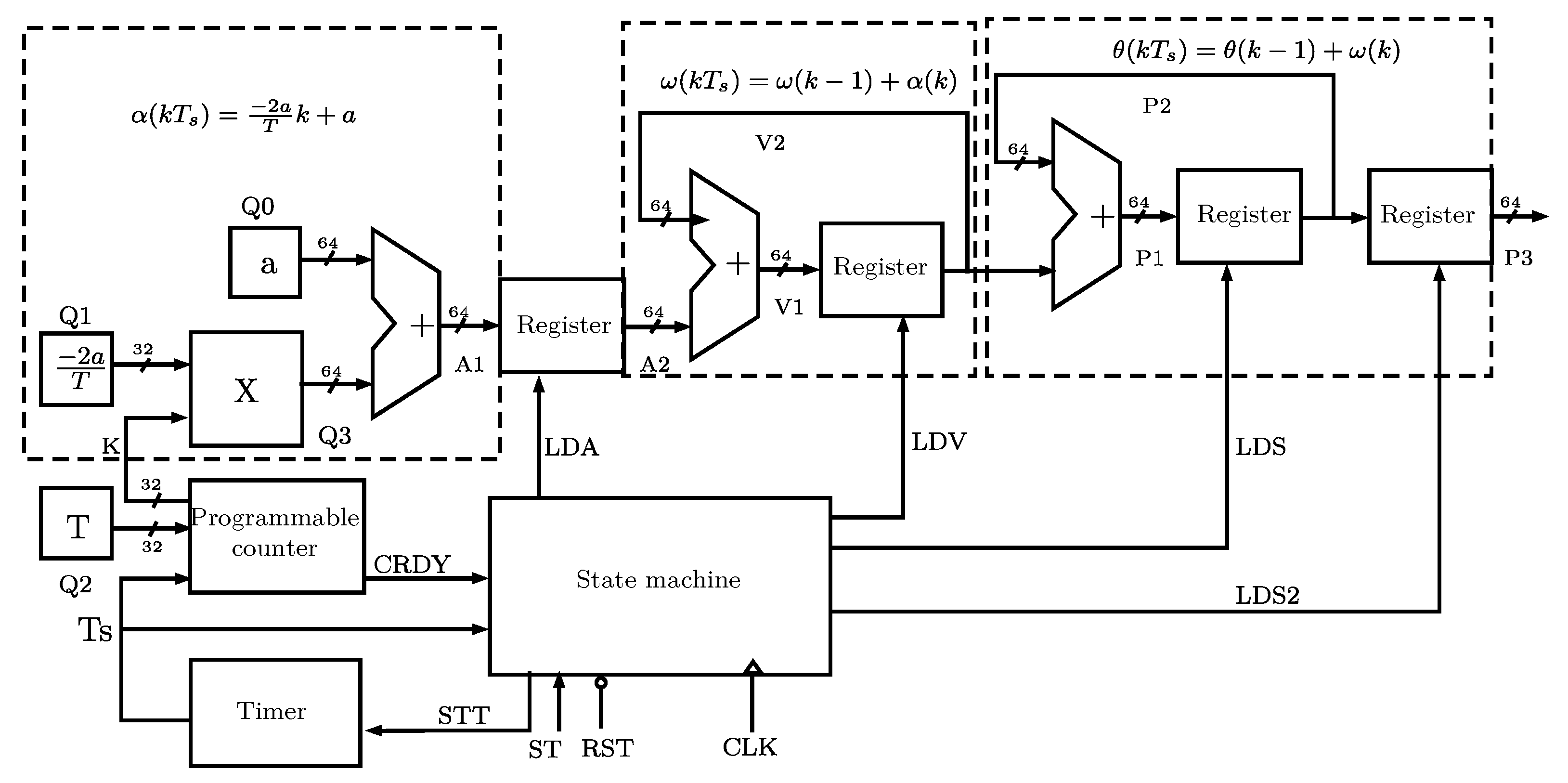

3.1. Implementation of the Parabolic Profile

The calculation of the velocity profiles develops by integrating the acceleration curve once to obtain the velocity and twice to obtain the position. The implementation in the digital system occurs under the same logic, but instead of solving through an analytical integration, numerical integration is used to approximate the desired value at each instant of time. The discrete acceleration equation is obtained by substituting in Equation (

1) the value of

t for

, where

k is an integer value that increases by 1 for each instant of time and

is the sampling period. To simplify operations, it is convenient to select a unit sampling period, in this case 1 ms. The discrete equations are expressed as:

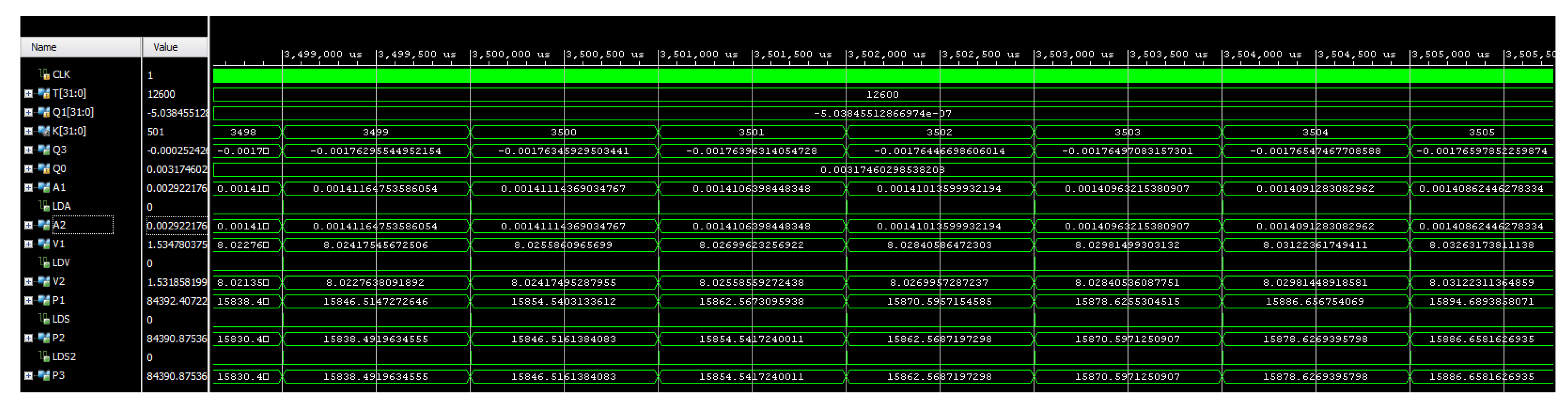

The circuit implemented in the FPGA is described in

Figure 5. The inputs for this component are the acceleration curve coefficients (Q0, Q1, Q2), a master clock (CLK), a start signal (ST) and a master reset (RST). The circuit performs the operations established by the numerical integration and gives the output an angular position for each instant of time. The components of the circuit are:

Time Base: Set the frequency of operations to 1 ms.

One Programmable counter: Increases its value every millisecond to establish the instant of time the circuit.

One-State machine: Controls the sequential flow of operations.

One Multiplier: In conjunction with an adder, it calculates the acceleration.

Three Adders: Perform the iterative operations for acceleration, velocity and position.

Four Registers: According to the state machine

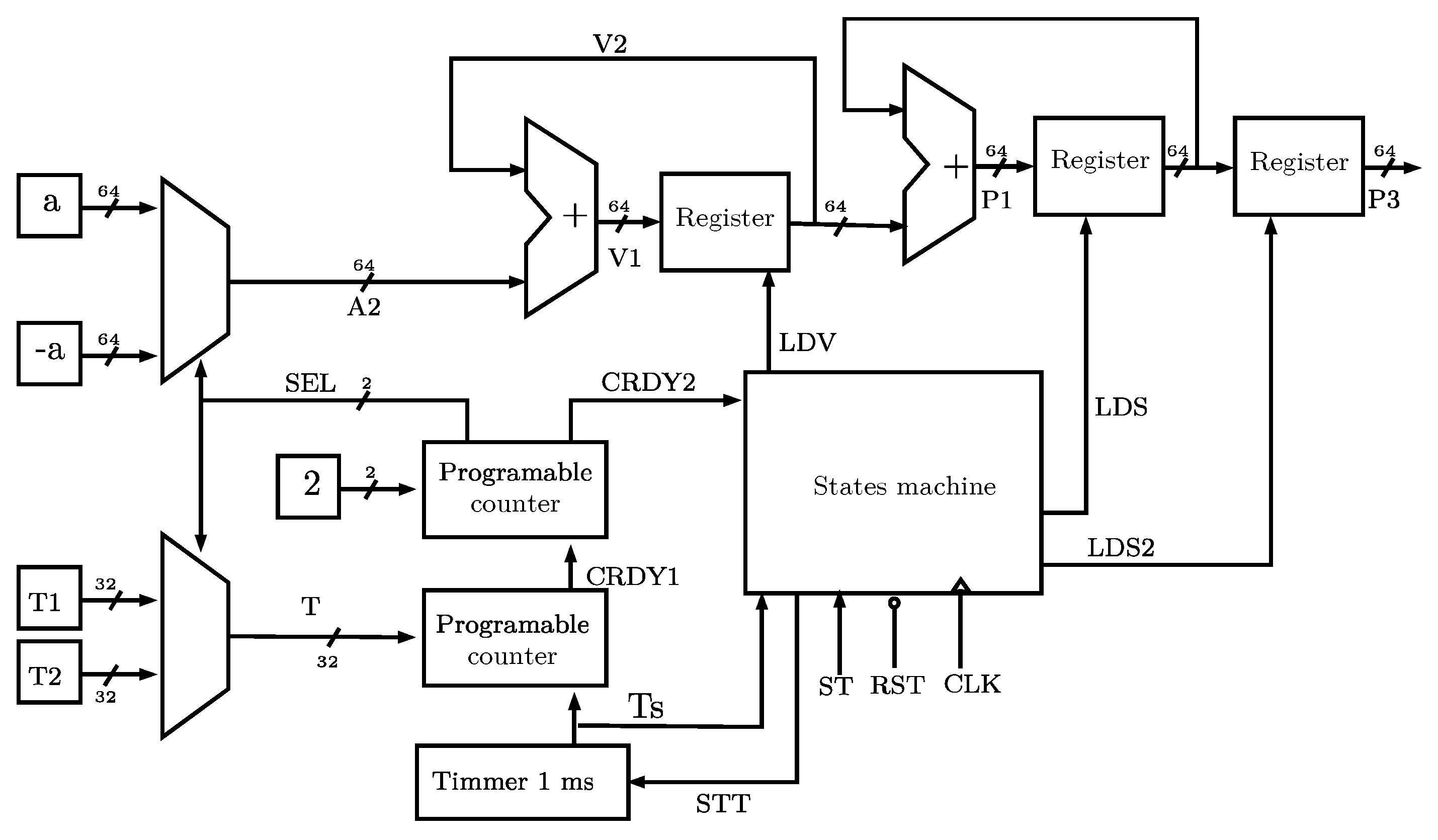

3.2. Implementation of the Trapezoidal Profile

The implementation of the trapezoidal profile is carried out in a similar way to

Section 3.1 and is shown in

Figure 6. The component inputs are acceleration and time period coefficients, a CLK, a ST and an RST. With this circuit it is possible to carry out the rectangular integration that allows us to obtain the angular position of the profile starting from its acceleration. The circuit components are:

Two-Multiplexers (MUX): The first select the constant value of the acceleration and the second one the constant of time.

Time Base: Set the sampling period to 1 ms.

Two-Programmable Counters: The first increase its value every millisecond to establish the instant of time the circuit and the second counter indicates the position in the third part of the trapezoid and serves as a selector for the acceleration and time constants.

One-State Machine: Controls the sequential flow of operations.

Two Adders: Perform the iterative operations for velocity and position.

Three-Registers: According to the state machine they store the data for each instant of time.

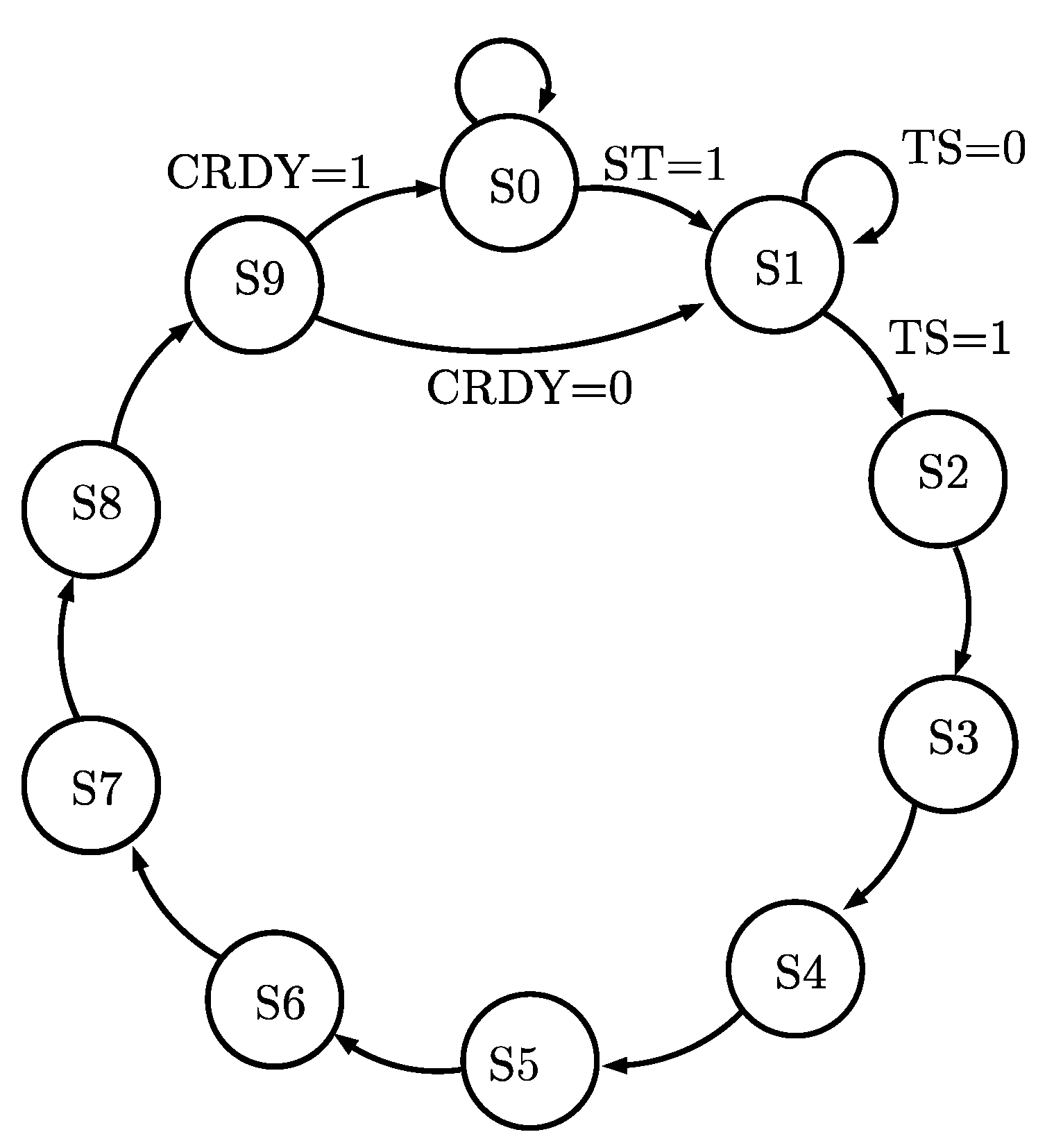

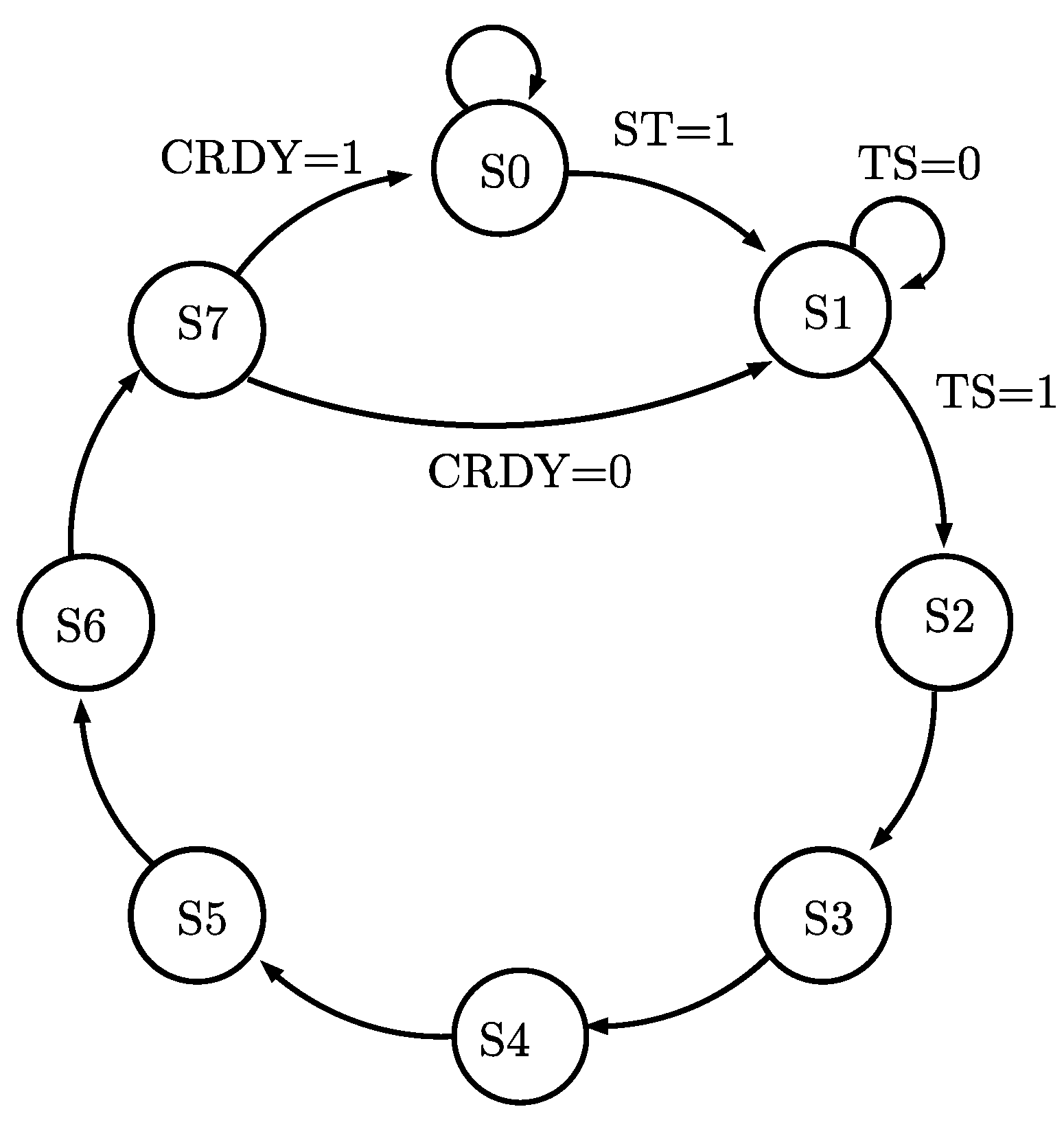

The behavior of the state machine of the trapezoidal and parabolic profiles is described in

Figure A1 and

Figure A2. The flow of states determines the activation and deactivation of the registers that store the velocity and position values. The only difference between both machines is that for the trapezoidal profile, there is no acceleration register that must be activated and consequently, it consists of only seven states.

3.3. Implementation of the Servo Amplifier

The coupling of the DC motor with the digital controller is achieved through the LMD18245 driver. According to the reference datasheet of the manufacturer, a four-bit digital-to-analog converter (DAC) provides a digital path for controlling the motor current, and, by extension, simplifies implementation of full, half and microstep stepper motor drives. For higher resolution applications, an external DAC can be used. However, the accuracy that is achieved with 4 bits is sufficient for the application developed. The main function of the driver is to control the current supply that the DC motor receives at each instant of time, which modifies its velocity. The main characteristics of the DC motor and driver used for the experiments in this work are mentioned in

Table 6.

The current that the driver supplies to the servo motor varies in correspondence to the reference voltage VREF. This voltage is proportionally limited by the decimal value of the 4-bit word formed by pins M4 to M1, where M4 is the most significant bit. This reference is sensed and amplified by the CS OUT pin in combination with the Rs resistor.

The current required to overcome the motor resistance and cause movement is 75 mA. When it reaches the nominal velocity (without load), 150 mA is consumed, and the reference voltage may be less than 5 V. The voltage is adjusted to 1.8 V to take full advantage of the 4-bit resolution that the DAC provides for more precise velocity changes. In the event that a load is added to the motor or replaced by a motor that requires more current, it is only necessary to readjust the reference voltage to increase the range of current supplied.

4. Experimental Results

The FPGA assembled on the built PCB is illustrated in

Figure 7. Some surface mount components were used to compact the component distribution and increase its wear resistance. The control system interface presented in

Figure A5 allow the user to simulate 4 different velocity profiles where they can modify: the maximum motor velocity (given by its specifications), the final angular position and the sampling time. The GUI has been introduced as follows. The GUI helps to the user to set values of the system such as PID gains. Moreover, it permits plotting in real time or offline of the power consumption, and the behavior of the position, among other graphs. It is used the transmitter and receiver virtual serial port from the PC and connected to the FPGA by using three wires.

The precision of a numerical method depends on the iterations that are carried out, the experiment is performed with 15 turns of the parabolic profile and compared with the position obtained through Equation (

5). The rectangular numerical method is the one used for the iterations. Before analyzing the results achieved through hardware, studying the error that exists when calculating the angular position with a numerical method is convenient. The results are shown in

Figure 8, where the analytical and numerical method is compared with different sampling times by simulation. It is important to note that even with a sampling period 10 times slower than the one used at work (1 ms), the average error remains less than 1%. In a range of 100 ms up to 1 s, the error becomes more significant. The processing velocity in this system is of utmost importance to achieve the results closest to the desired values.

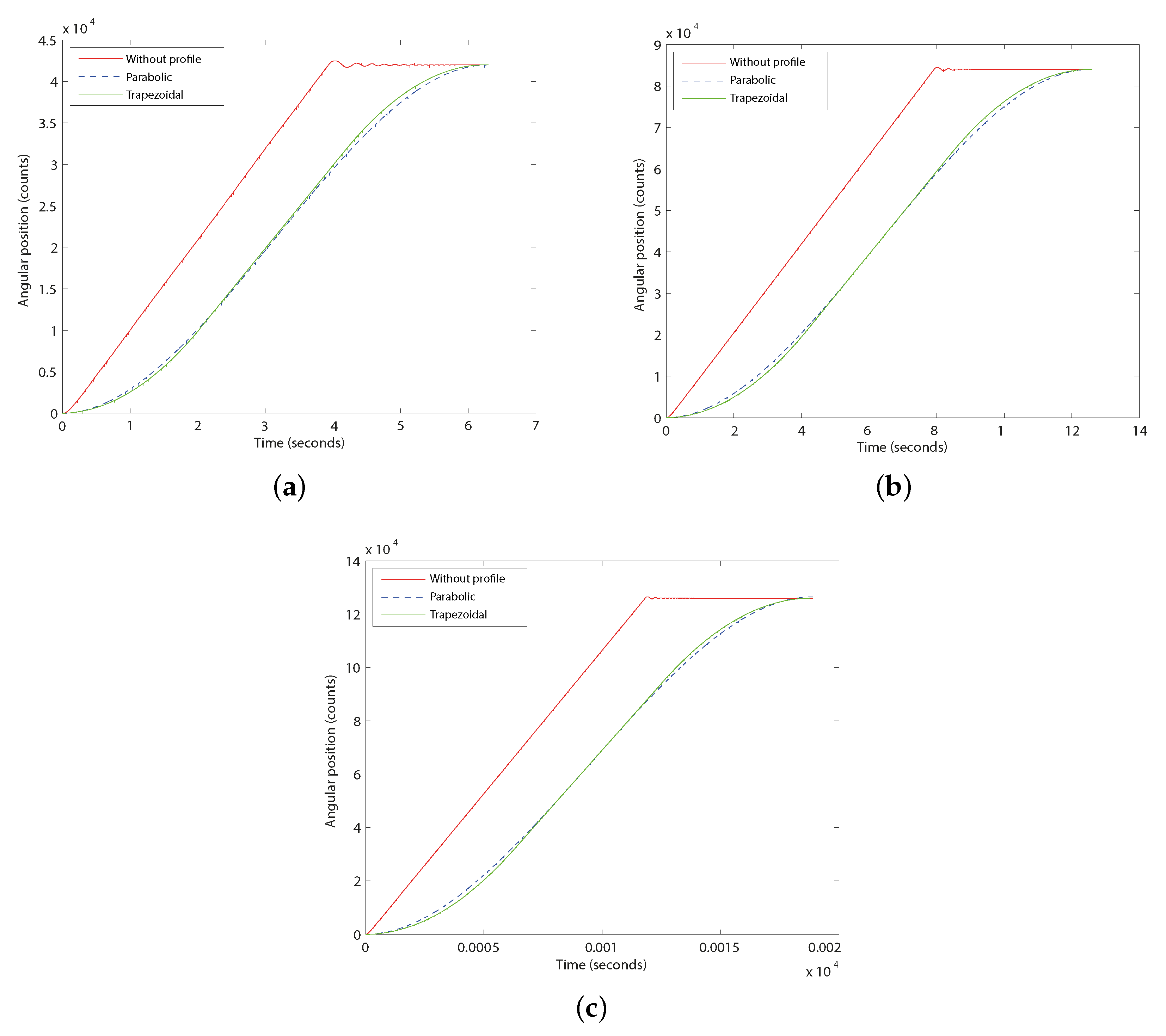

Each test shown in

Figure 9 delivers a vector of monitored angular positions in a millisecond. Therefore, it is necessary to adjust the velocity of the RS232 protocol to the maximum supported by the MATLAB IDE: 115200 bps. The interface is not able to graph the received data in real time due to the high-reception velocity. It is important to note that the expected times to reach each angular position are the same for both profiles.

Within the tests carried out on the system, the profile tracker is monitored when velocity profiles are used at its input and when the user directly assigns the position. Maximum engine velocity is a factor that path planning takes into account when calculating the position vector. For this experiment, the velocity is set to 10 per ms, equivalent to 71.4286 rpm, in order not to push the motor operation to the limit. The path followed by the profile tracker without the profile will use the 80 rpm of the engine. The experiments performed are presented in

Figure 10.

The results obtained show that the implemented control reaches the established setpoint. Comparisons between the parabolic profile, the trapezoidal profile and a non-profile response are also presented. It can be seen that the parabolic profile reaches the desired position through a smoother curve in an average time of 5 s. It is important to mention that with the implemented control, it is not necessary to use an additional control loop to decrease the steady-state error. The error under standard system operation is less than 1%.

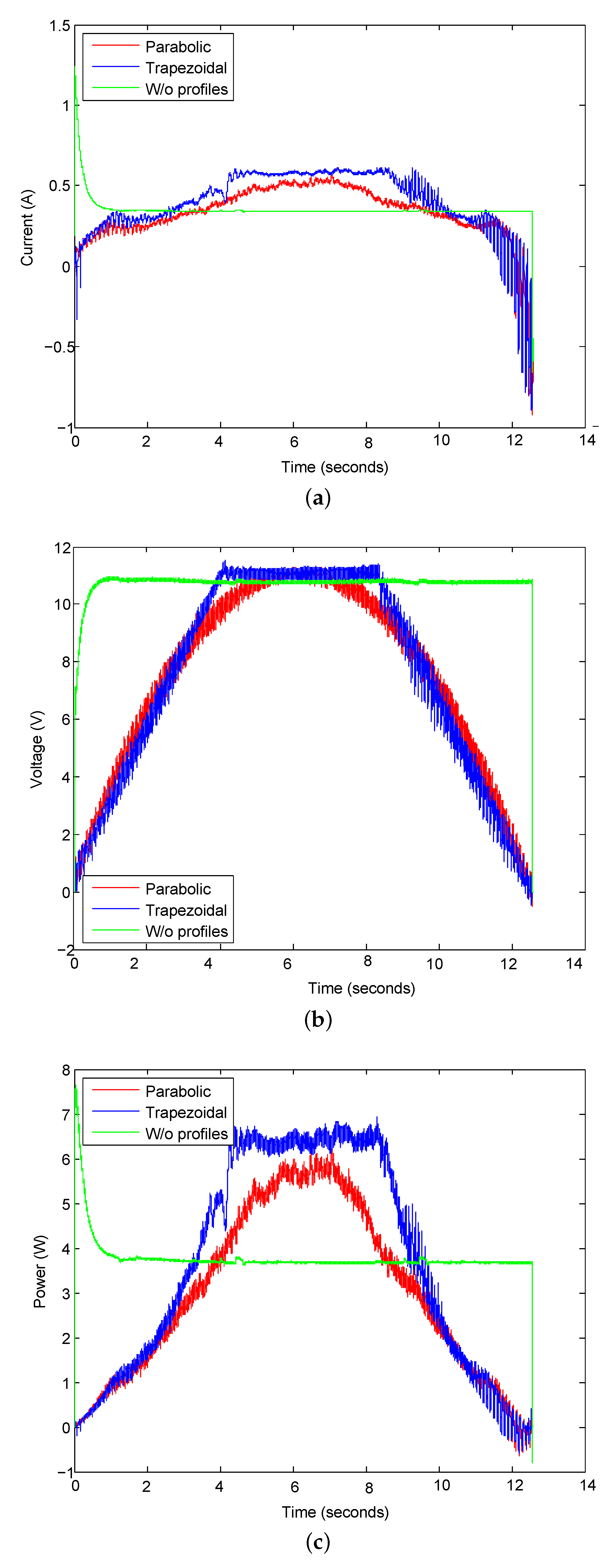

Figure 11 show the current measurement made with the Analog Discovery oscilloscope and MAX471 sensor to measure the power consumption of 10 turns. It should be noted that the function described by the voltages of both experiments is very similar to the velocity curve of each profile.

Table 7 presents a comparison of the values of current, voltage and average power for both profiles. Finally, the percentage of use of FPGA resources is shown in

Figure 8. It is observed that the consumption of FPGA resources is not excessive, even if improvements are required, they can be carried out without exceeding half the available resources.

The results in the table above show a saving in power consumption of 0.85 W between the trapezoidal profile and the system without a profile. Similarly, 1.38 W is saved using the parabolic profile compared to the system without a profile. For its part, the parabolic profile represents an energy saving of 0.53 W compared to the use of the trapezoidal profile.

Consumption in the FPGA can be reduced by applying different techniques. From a programming standpoint, techniques such as one-hot encoding for state machines and protected evaluation can be implemented while ensuring that logical loops that oscillate are not created. In addition, I/O standards must be chosen appropriately to avoid excessive use of static energy. Finally, an important technique to prevent excessive power usage in the FPGA is to suspend the part of the FPGA that is not in use.

It is important to note that the system responds satisfactorily to tracking the trajectory proposed by both profiles. The average error of the experiments ranges from 2.24% to 4.9%. Although the average error might seem considerable, it is interesting to note that the average error is very high at motor start because the theoretical value vector starts with very small decimal values less than 1 and the encoder gives counts per unit, not per fraction. Therefore, the errors at the beginning of the trajectory are up to almost 100%. However, after approximately the first sixth of the journey, the error is below 1%. The experiment was carried out for three different distances (5, 10 and 15 turns) to verify that the system remains stable at small or long distances and does not increase the value of the error. Regarding energy consumption, it can be seen that as shown in theory, it was significantly lower in the parabolic profile case than the trapezoidal one.

It can be seen that the voltage in both cases (parabolic and trapezoidal profile) was practically the same. However, the significant difference came from the current consumption, being considerably less in the parabolic profile. It can be concluded that the energy consumption in the parabolic profile was 17.3% less than the trapezoidal one. On the other hand, the behavior of energy consumption without a speed profile is considerably higher.

Table 8 shows the consumption of FPGA resources. Furthermore,

Table 9 shows a comparison of resources used by the FPGA for similar work. It can be seen that the developed design notably reduces the use of FPGA resources by using multipliers. This aspect enables the implementation of the proposed project in a wide range of similar devices and does not limit its use to devices with high performance.

5. Conclusions

In the paper, a motion control system based on the parabolic velocity profile is developed and implemented and a comparative analysis with the trapezoidal profile is performed. In the selection of the parabolic profile, the behavior of a planned trajectory is observed. The theoretical estimates that address the characteristics of each profile, such as the velocity of response and energy consumption, were verified through experimentation. The difference between the forecast of the mathematical model and the practical example was very low. Among the advantages of the work presented, its modularity stands out. This prototype can be replicated for motors with a consumption of up to 3 A and only requires minor modifications in case of using motors with higher consumption.

Due to the versatility offered by the implementations in digital logic, it was possible to reconfigure the system to observe the behavior with and without the assistance of velocity profiles. The previous approach is verified when the theoretical curve of the profile is very similar to that of the experiment for different angular positions. The main reason for this behavior was the sampling time at 1 ms, which allowed the profiles to show changes of position so small that they did not represent a complication for the profile tracker.

A comparison of the characteristics between the parabolic and trapezoidal profile with a special focus on response time and energy consumption was carried out. Finally, one of the greatest advantages of the parabolic profile compared to the trapezoidal one was demonstrated: a lower energy consumption necessary to complete the desired path. It is important to note that the response time for both profiles was the same and consequently, saving energy did not represent a loss in velocity. With this conclusion, the importance of planning trajectories based on mathematical models that contemplate the focus on variables that significantly impact different mobility applications can be highlighted, in this case: the reduction of costs due to energy savings.