Tree Search Fuzzy NARX Neural Network Fault Detection Technique for PV Systems with IoT Support

Abstract

1. Introduction

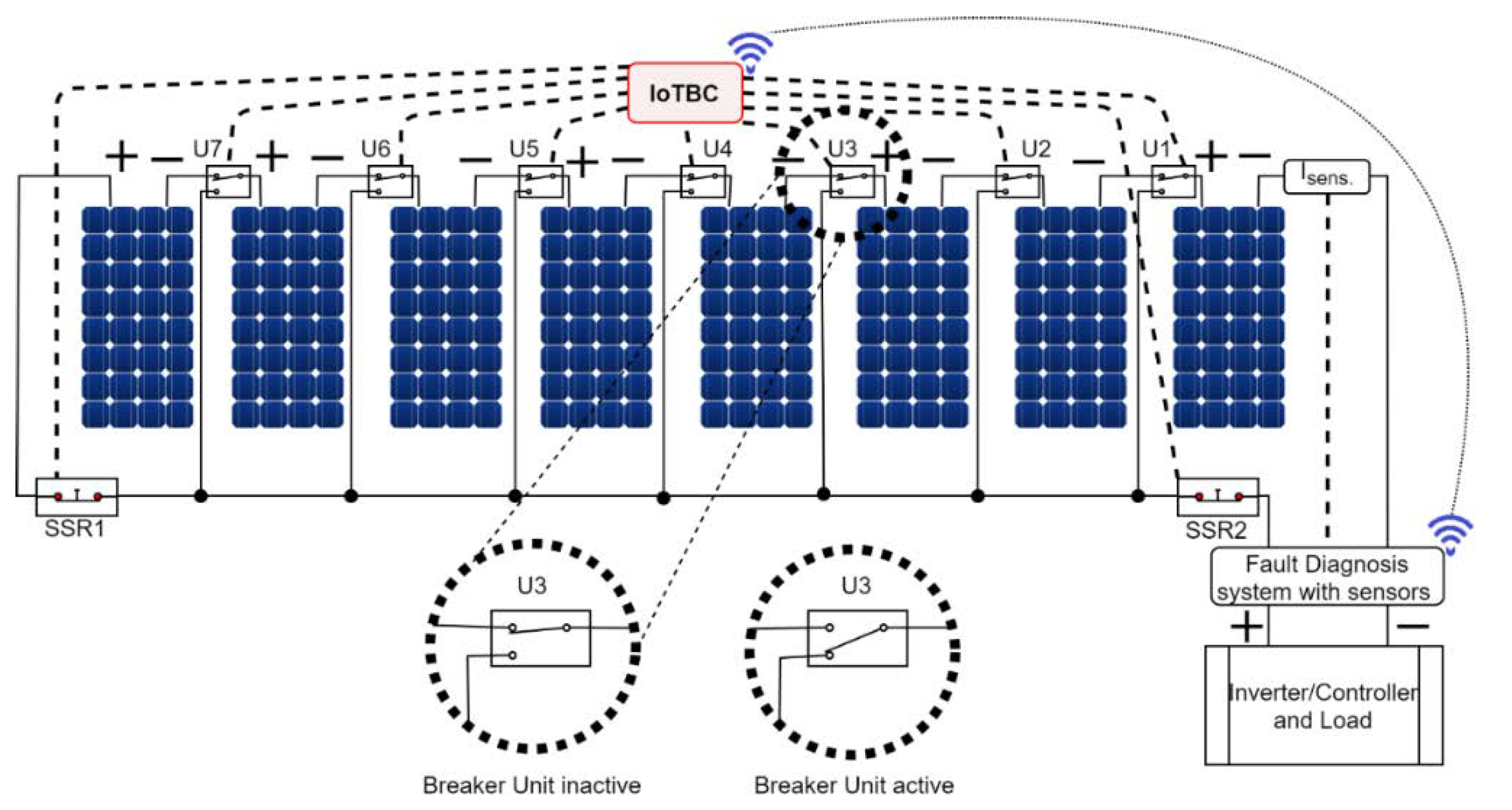

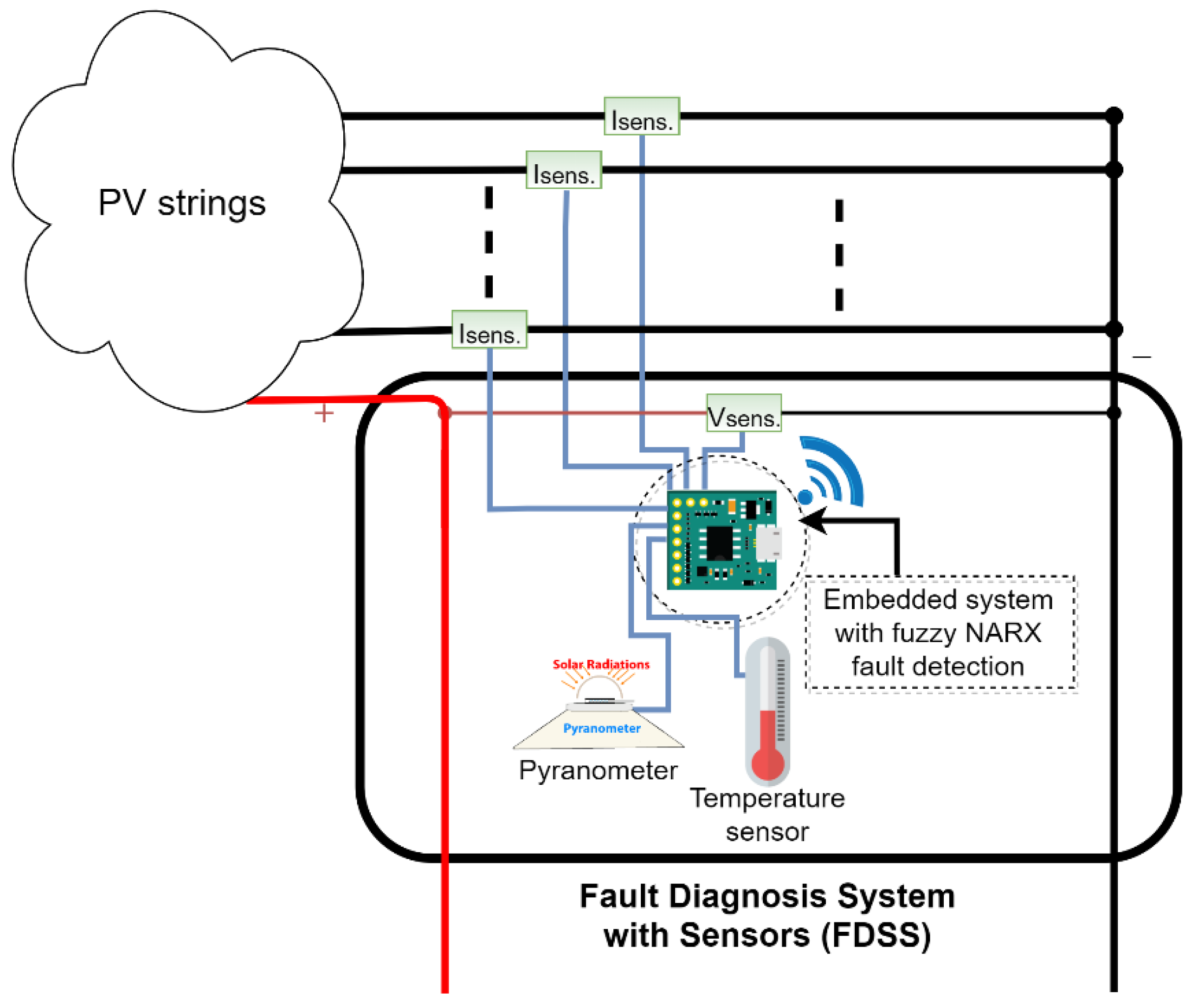

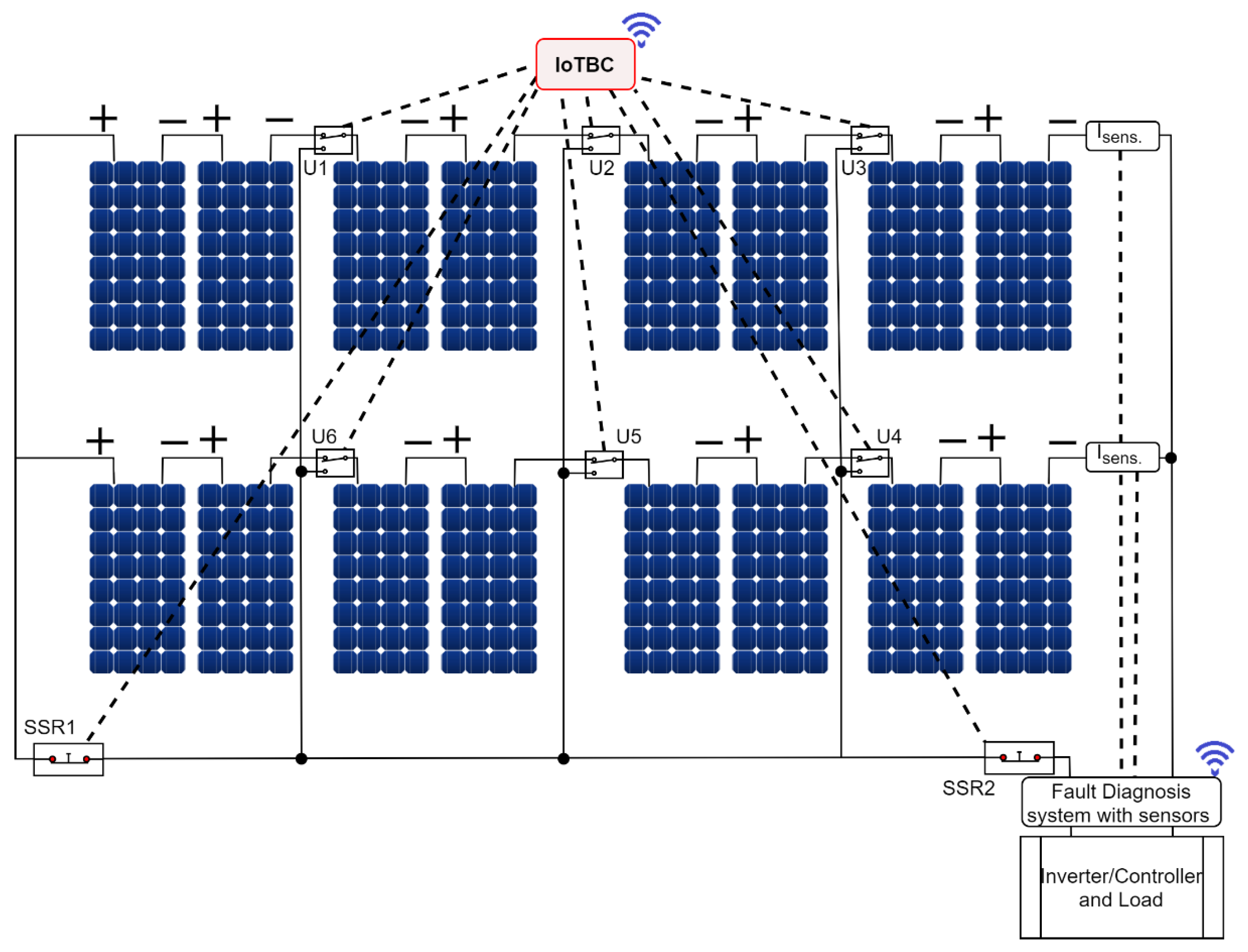

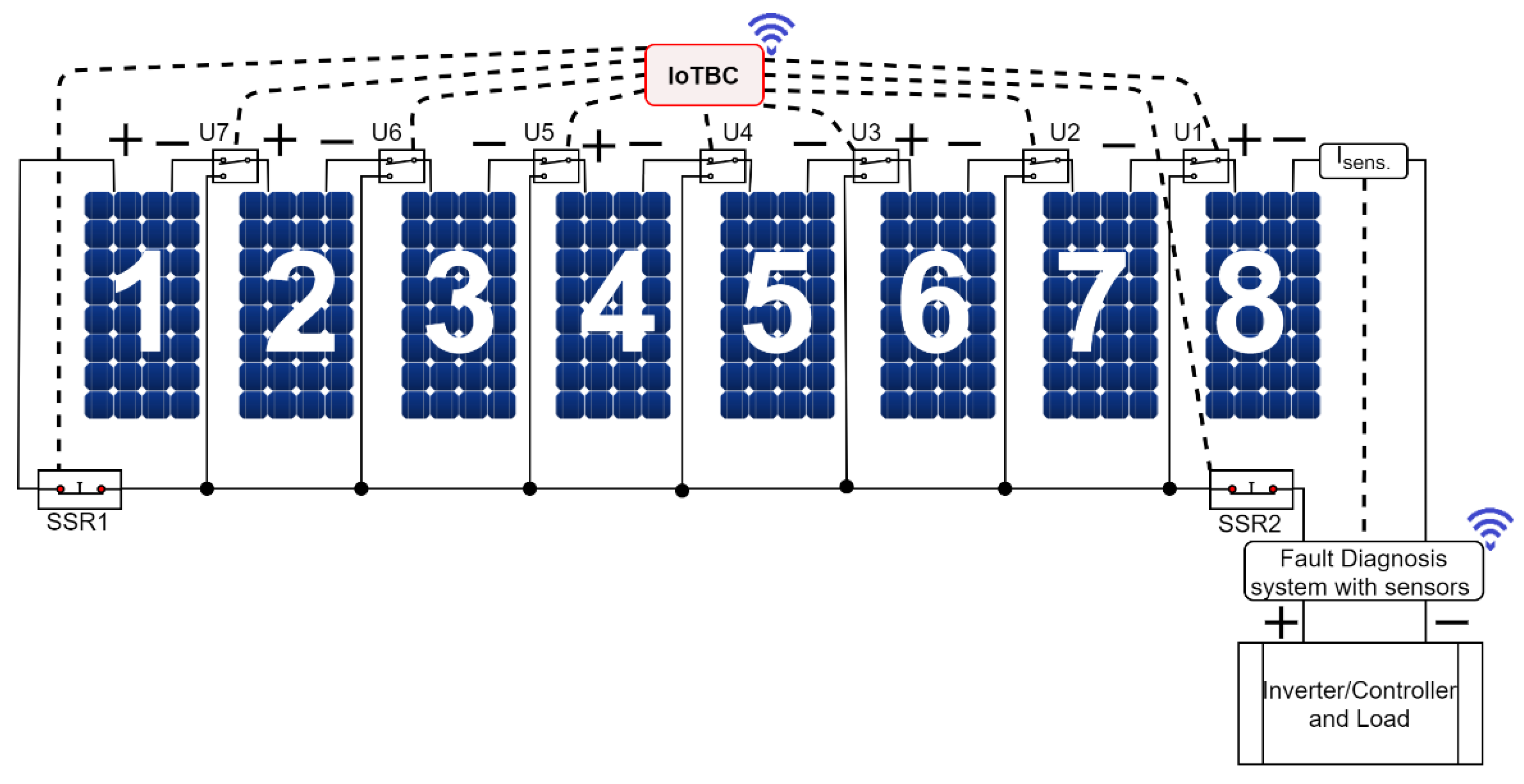

2. System Architecture

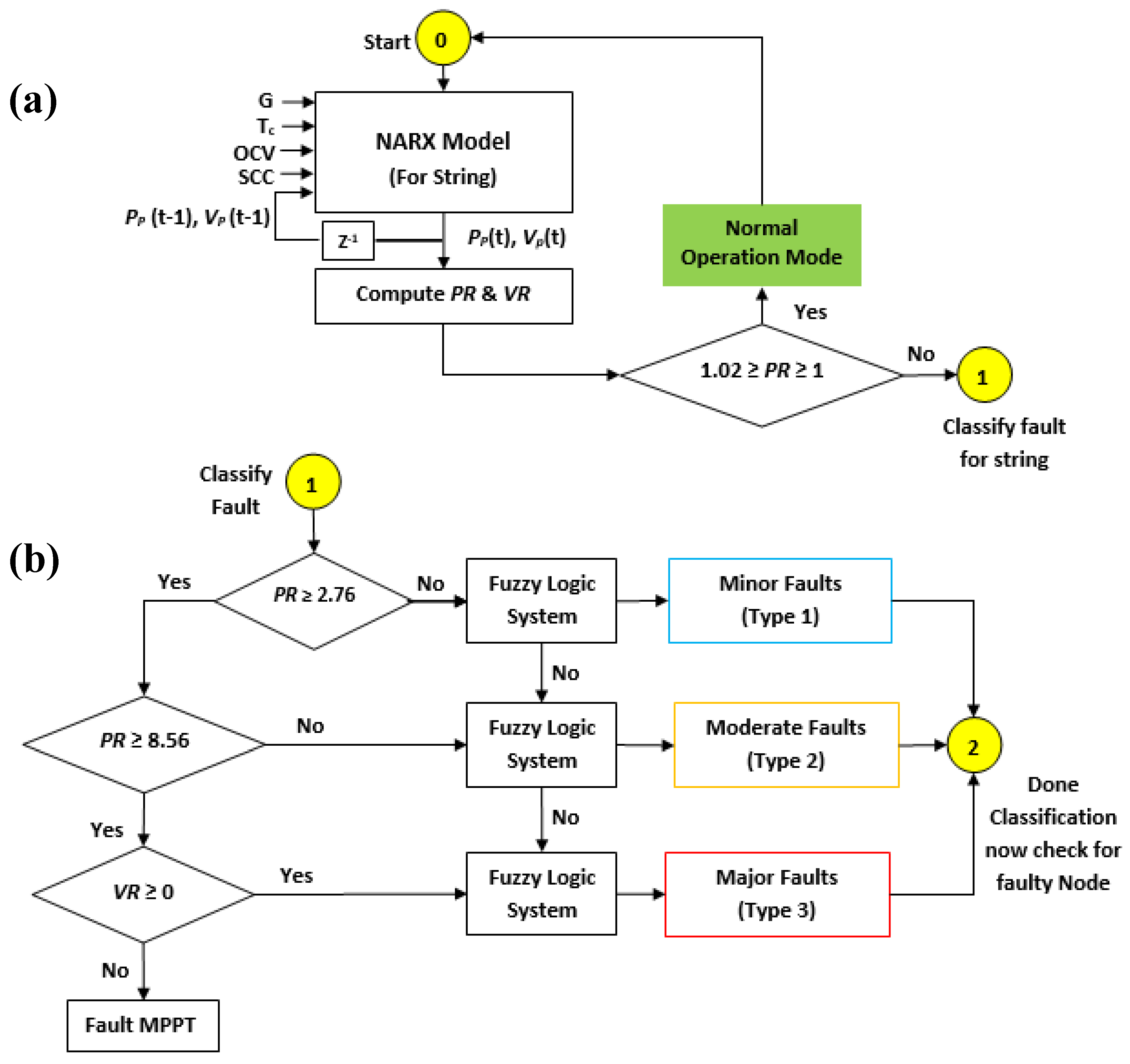

3. Methodology

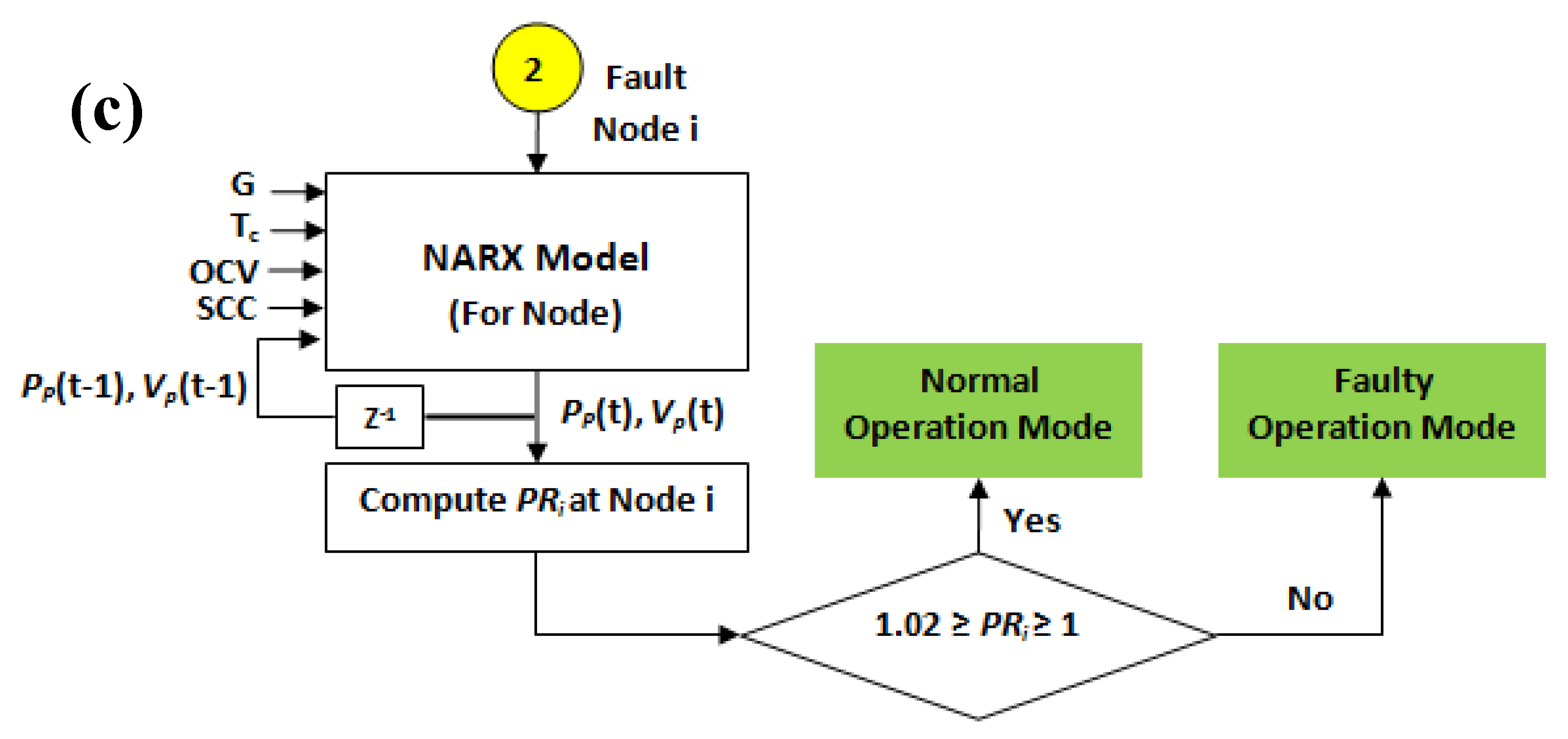

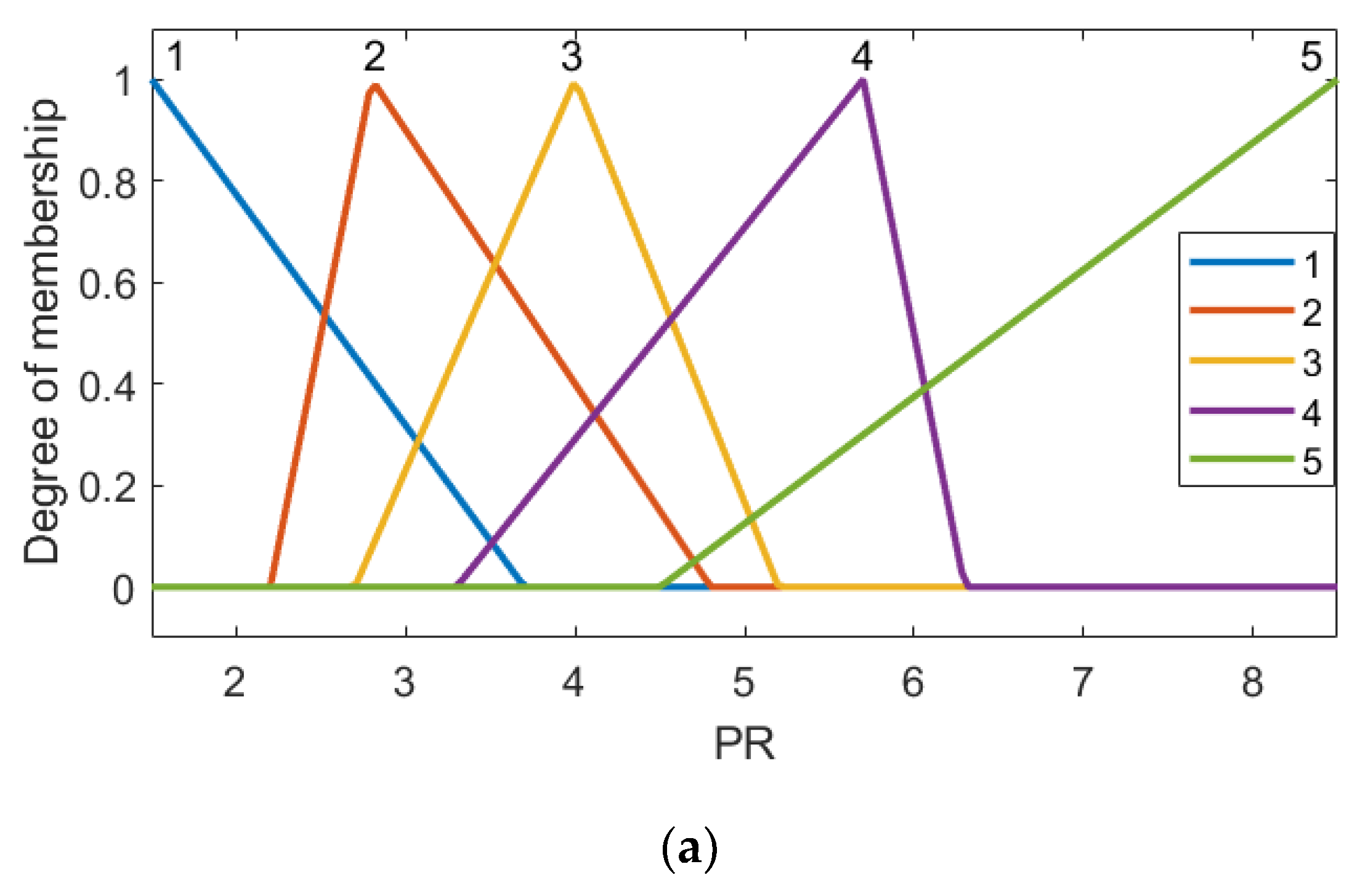

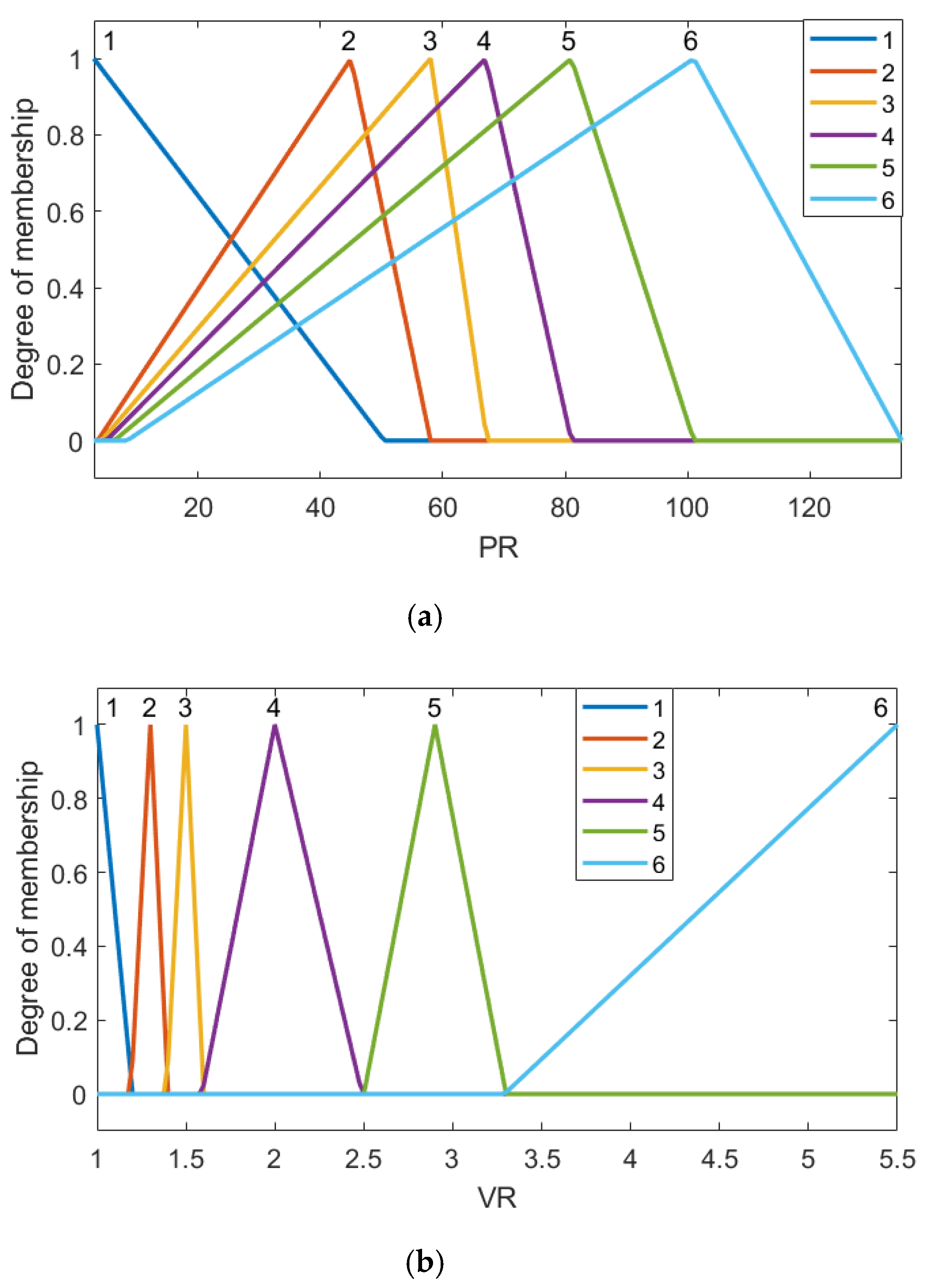

3.1. The Fuzzy NARX Fault Detection

- ▪

- Review the fuzzy sets

- ▪

- Revise shapes of the fuzzy sets

- ▪

- Review the existing rules

- ▪

- Adjust the rule execution weights

3.2. The Fault Source Identification Process

| Algorithm 1: The PV tree fault search (PTFS) algorithm. |

|

4. Results

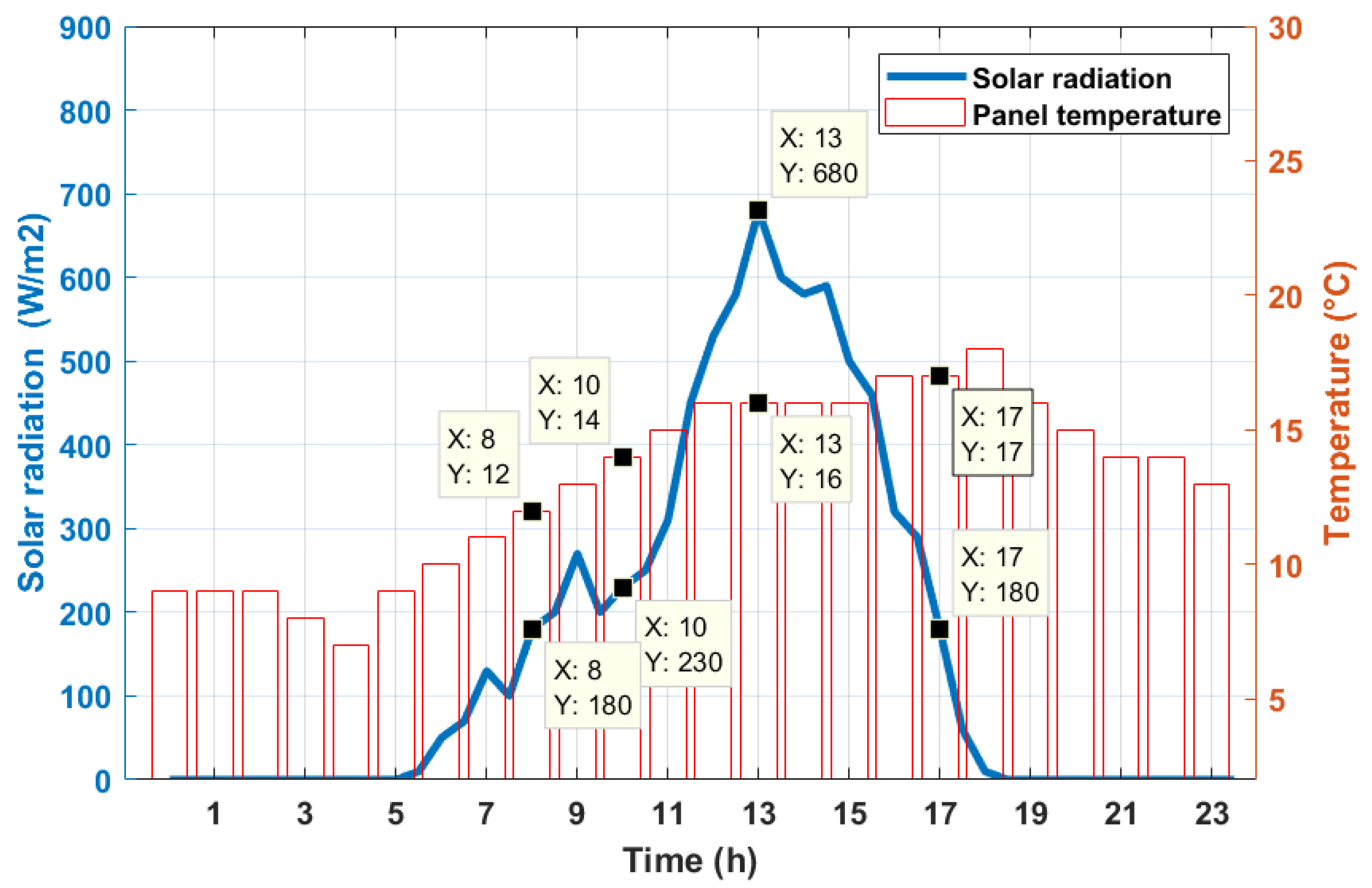

4.1. Meteorological Data

4.2. Implementing the Algorithm on a Low-Cost Microcontroller

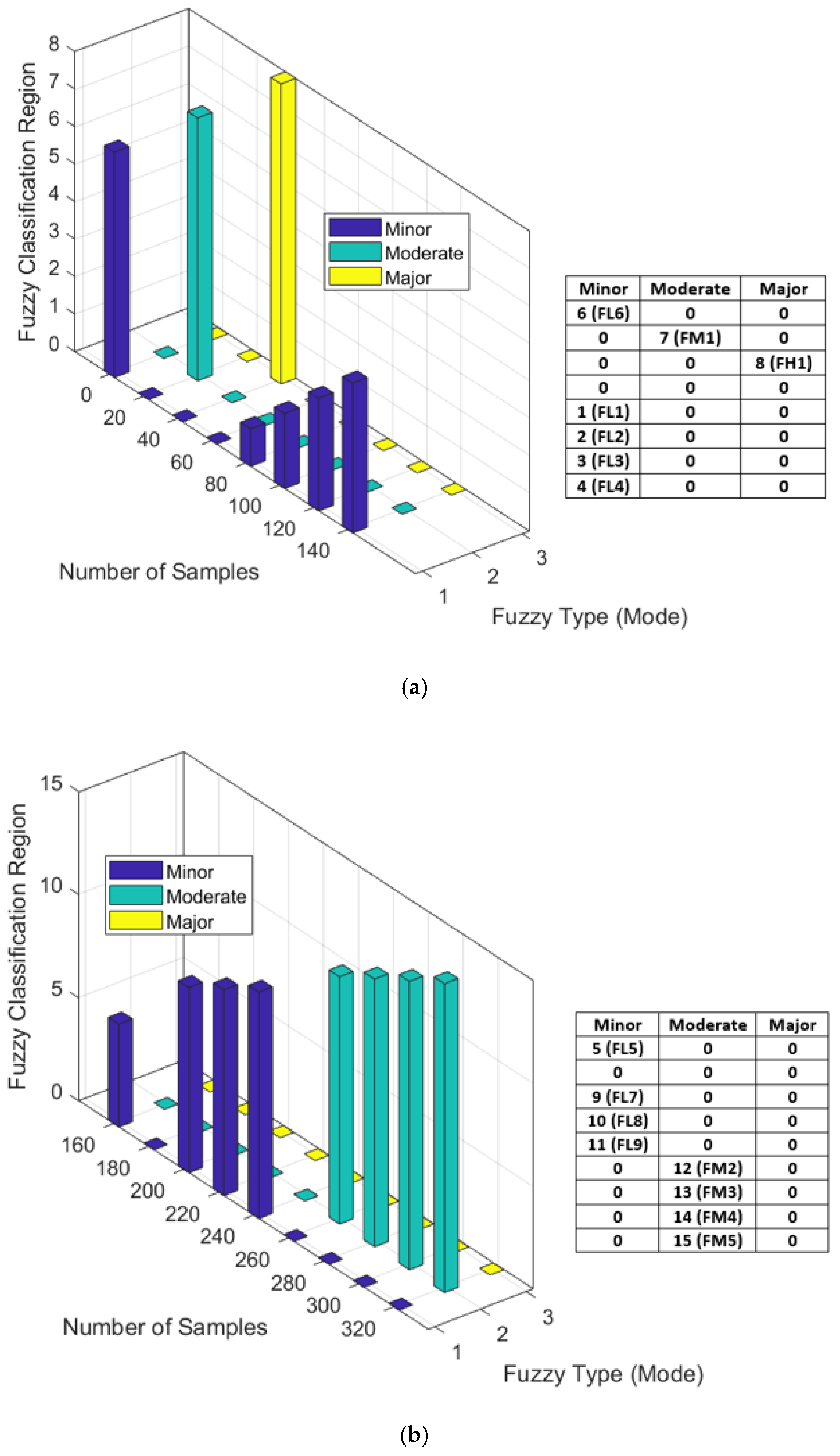

4.3. Evaluation of the Proposed Fault Detection Algorithm

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Alternating current |

| AVR | Alf and Vegard’s RISC |

| DC | Direct current |

| FCA | Fault classification algorithm |

| FDSS | Fault diagnosis system with sensors |

| FH | Fault high |

| FL | Fault low |

| FM | Fault moderate |

| GHI | Global horizontal irradiance |

| I | Current |

| IoT | Internet of Things |

| IoTBC | Internet of Things breaker connector |

| Isens | Current sensors |

| MLPNN | Multi-layer perceptron neural network |

| MPPT | Maximum power point tracking |

| NARX network | Nonlinear autoregressive network with exogenous inputs |

| OCV | Open-circuit voltage |

| PNN | Probabilistic neural network |

| PTFS | PV tree fault search |

| PV | Photovoltaic |

| SCC | Short circuit current |

| SCG | Scaled conjugate gradient |

| STC | Standard test condition |

| V | Voltage |

| Vsens | Voltage sensors |

References

- Gray, J.L. The Physics of the Solar Cell. In Handbook of Photovoltaic Science and Engineering; Luque, A., Hegedus, S., Eds.; John Wiley and Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Walker, G. Evaluating MPPT converter topologies using a MATLAB PV model. J. Electr. Electron. Eng. 2001, 21, 49–56. [Google Scholar]

- Natsheh, E.M.; Albarbar, A. Photovoltaic model with MPP tracker for standalone/grid connected applications. In Proceedings of the IET Conference on Renewable Power Generation, Edinburgh, UK, 6–8 September 2011; pp. 1–6. [Google Scholar]

- Patel, H.; Agarwal, V. MATLAB-Based Modelling to Study the Effects of Partial Shading on PV Array Characteristics. IEEE Trans. Energy Convers. 2008, 23, 302–310. [Google Scholar] [CrossRef]

- Daliento, S.; Di Napoli, F.; Guerriero, P.; d’Alessandro, V. A modified bypass circuit for improved hot spot reliability of solar panels subject to partial shading. Sol. Energy 2016, 134, 211–218. [Google Scholar] [CrossRef]

- Rajput, P.; Malvoni, M.; Kumar, N.M.; Sastry, O.S.; Tiwarie, G.N. Risk priority number forunderstanding the severity of photovoltaic failure modes and their impacts on performance degradation. Case Stud. Therm. Eng. 2019, 16, 100563. [Google Scholar] [CrossRef]

- Köntges, M.; Kunze, I.; Kajari-Schröder, S.; Breitenmoser, X.; Bjørneklett, B. Quantifying the risk of power loss in PV modules due to micro cracks. In Proceedings of the 25th European Photovoltaic Solar Energy Conference, Valencia, Spain, 6–10 September 2010; pp. 3745–3752. [Google Scholar]

- Kajari-Schršder, S.; Kunze, I.; Kšntges, M. Criticality of cracks in PV modules. Energy Procedia 2012, 27, 658–663. [Google Scholar] [CrossRef]

- Morlier, A.; Haase, F.; Köntges, M. Impact of cracks in multicrystalline silicon solar cells on PV module power: A simulation study based on field data. IEEE J. Photovolt 2015, 5, 1735–1741. [Google Scholar] [CrossRef]

- Hoffmann, S.; Koehl, M. Effect of humidity and temperature on the potential-induced degradation. Prog. Photovolt. Res. Appl. 2014, 22, 173–179. [Google Scholar] [CrossRef]

- Cristaldi, L.; Faifer, M.; Lazzaroni, M.; Khalil, M.M.A.F.; Catelani, M.; Ciani, L. Diagnostic architecture: A procedure based on the analysis of the failure causes applied to photovoltaic plants. Measurement 2015, 67, 99–107. [Google Scholar] [CrossRef]

- Caron, J.R.; Littmann, B. Direct monitoring of energy lost due to soiling on first solar modules in California. IEEE J. Photovolt. 2013, 3, 336–340. [Google Scholar] [CrossRef]

- Cova, P.; Delmonte, N.; Lazzaroni, M. Photovoltaic plant maintainability optimization and degradation detection: Modelling and characterization. Microelectron. Reliab. 2018, 88, 1077–1082. [Google Scholar] [CrossRef]

- Kim, K.A.; Krein, P.T. Hot spotting and second breakdown effects on reverse IV characteristics for mono-crystalline Si photovoltaics. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 1007–1014. [Google Scholar]

- García, M.; Marroyo, L.; Lorenzo, E.; Marcos, J.; Pérez, M. Observed degradation in photovoltaic plants affected by hot-spots. Prog. Photovolt. Res. Appl. 2014, 22, 1292–1301. [Google Scholar] [CrossRef]

- Mäki, A.; Valkealahti, S. Power losses in long string and parallel-connected short strings of series-connected silicon-based photovoltaic modules due to partial shading conditions. IEEE Trans. Energy Convers. 2012, 27, 173–183. [Google Scholar] [CrossRef]

- Takashima, T.; Yamaguchi, J.; Ishida, M. Fault detection by signal response in PV module strings. In Proceedings of the IEEE Photovoltaic Specialists Conference, San Diego, CA, USA, 11–16 May 2008. [Google Scholar]

- Takashima, T.; Yamaguchi, J.; Otani, K.; Oozeki, T.; Kato, K.; Ishida, M. Experimental studies of fault location in PV module strings. Sol. Energy Mater. Sol. Cells 2009, 93, 1079–1082. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Wu, C. Four parameter on-line fault diagnosis method for PV modules. Proc. CSEE 2014, 34, 2078–2087. [Google Scholar]

- Chouder, A.; Silvestre, S. Automatic supervision and fault detection of PV systems based on power losses analysis. Energy Convers. Manag. 2010, 51, 1929–1937. [Google Scholar] [CrossRef]

- Kang, B.K.; Kim, S.T.; Bae, S.H.; Park, J.W. Diagnosis of output power lowering in a PV array by using the Kalman-filter algorithm. IEEE Trans. Energy Convers. 2012, 27, 885–894. [Google Scholar] [CrossRef]

- Wang, P.; Zheng, S. Fault analysis of photovoltaic array based on infrared image. Acta Energiae Solaris Sinica 2010, 31, 197–202. [Google Scholar]

- Silvestre, S.; da Silva, M.A.; Chouder, A.; Guasch, D.; Karatepe, E. New procedure for fault detection in grid connected PV systems based on the evaluation of current and voltage indicators. Energy Convers. Manag. 2014, 86, 241–249. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V. Fault detection algorithm for grid-connected photovoltaic plants. Sol. Energy 2016, 137, 236–245. [Google Scholar] [CrossRef]

- Silvestre, S.; Chouder, A.; Karatepe, E. Automatic fault detection in grid connected PV systems. Sol. Energy 2013, 94, 119–127. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; DalesT, M. Simultaneous fault detection algorithm for grid-connected photovoltaic plants. IET Renew. Power Gener. 2017, 11, 1565–1575. [Google Scholar] [CrossRef]

- Chine, W.; Mellit, A.; Pavan, A.M.; Kalogirou, S.A. Fault detection method for grid-connected photovoltaic plants. Renew. Energy 2014, 66, 99–110. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Dales, M. Parallel fault detection algorithm for grid connected photovoltaic plants. Renew. Energy 2017, 113, 94–111. [Google Scholar] [CrossRef]

- Kim, K.A.; Seo, G.S.; Cho, B.H.; Krein, P.T. Photovoltaic hot-spot detection for solar panel substrings using ac parameter characterization. IEEE Trans. Power Electron. 2016, 31, 1121–1130. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhong, D.; Li, B.; Liu, Y. Research on fault detection of PV array based on data fusion and fuzzy mathematics. In Proceedings of the Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 25–28 March 2011; pp. 1–4. [Google Scholar]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M. The impact of cracks on photovoltaic power performance. J. Sci. Adv. Mater. Devices 2017, 2, 199–209. [Google Scholar] [CrossRef]

- Mellitab, A.; Tinac, G.M.; Kalogiroud, S.A. Fault detection and diagnosis methods for photovoltaic systems: A review. Renew. Sustain. Energy Rev. 2018, 91, 1–17. [Google Scholar] [CrossRef]

- Mellit, A.; Pavan, A.M. A 24-h forecast of solar irradiance using artificial neural network: Application for performance prediction of a grid-connected PV plant at Trieste, Italy. Sol. Energy 2010, 84, 807–821. [Google Scholar] [CrossRef]

- Mellit, A.; Kalogirou, S.A. Artificial intelligence techniques for photovoltaic applications: A review. Prog. Energy Combust. Sci. 2008, 34, 574–632. [Google Scholar] [CrossRef]

- Natsheh, E.; Natsheh, A.R.; Albarbar, A.H. Intelligent controller for managing power flow within standalone hybrid power systems. IET Sci. Meas. Technol. 2013, 7, 191–200. [Google Scholar] [CrossRef]

- Natsheh, E.; Samara, S. Toward Better PV Panel’s Output Power Prediction; a Module Based on Nonlinear Autoregressive Neural Network with Exogenous Inputs. Appl. Sci. 2019, 9, 3670. [Google Scholar] [CrossRef]

- Yona, A.; Senjyu, T.; Funabshi, T.; Sekine, H. Application of neural network to 24-h-ahead generating power forecasting for PV system. IEEE Trans. Power Energy 2008, 128, 33–39. [Google Scholar] [CrossRef]

- Natsheh, E.; Natsheh, A.; Khatib, T. Intelligent Controller for Tracking the MPP of a PV System under Partial Shaded Conditions. Appl. Sol. Energy 2019, 55, 282–290. [Google Scholar] [CrossRef]

- Mandal, P.; Madhira, S.T.S.; Ul haque, A.; Meng, J.; Pineda, R.L. Forecasting Power Output of Solar Photovoltaic System Using Wavelet Transform and Artificial Intelligence Techniques. Procedia Comput. Sci. 2012, 12, 332–337. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M. Comparing Mamdani Sugeno fuzzy logic and RBF ANN network for PV fault detection. Renew. Energy 2018, 117, 257–274. [Google Scholar] [CrossRef]

- Chowdhury, S.R.; Saha, H. Maximum power point tracking of partially shaded solar PV arrays. Sol. Energy Mater. Sol. Cells 2010, 94, 1441–1447. [Google Scholar] [CrossRef]

- Wang, X.; Wang, S.; Du, H.; Wang, P. Fault Diagnosis of Chemical Industry Process Based on FRS and SVM. Control Decis. 2015, 30, 353–356. [Google Scholar]

- Zhao, Q.; Shao, S.; Lu, L.; Liu, X.; Zhu, Y.H. A New PV Array Fault Diagnosis Method Using Fuzzy C-Mean Clustering and Fuzzy Membership Algorithm. Energies 2018, 11, 238. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M. Diagnostic method for photovoltaic systems based on six layer detection algorithm. Electr. Power Syst. Res. 2017, 151, 26–39. [Google Scholar] [CrossRef]

- Dhimish, M.; Holmes, V.; Mehrdadi, B.; Dales, M. Multi-layer photovoltaic fault detection algorithm. IET 2017, 2, 244–252. [Google Scholar] [CrossRef]

- Samara, S.; Natsheh, E. Intelligent PV Panels Fault Diagnosis Method Based on NARX Network and Linguistic Fuzzy Rule-Based Systems. Sustainability 2020, 12, 2011. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, L.; Lehman, B.; de Palma, J.F.; Mosesian, J.; Lyons, R. Decision tree-based fault detection and classification in solar PV arrays. In Proceedings of the 27th Annual IEEE Applied Power Electronics Conference and Exposition, Orlando, FL, USA, 5–9 February 2012; pp. 93–99. [Google Scholar]

- Gu, Y.; Wei, H.L.; Boynton, R.J.; Walker, S.N.; Balikhin, M.A. System identification and data-driven forecasting of AE index and prediction uncertainty analysis using a new cloud-NARX model. J. Geophys. Res. Space Phys. 2019, 124, 248–263. [Google Scholar] [CrossRef]

- Ul-Haq, A.; Sindi, H.F.; Gul, S.; Jalal, M. Modeling and Fault Categorization in Thin-Film and Crystalline PV Arrays Through Multilayer Neural Network Algorithm. IEEE Access 2020, 8, 102235–102255. [Google Scholar] [CrossRef]

- Cervone, G.; Clemente-Harding, L.; Alessandrini, S.; Monache, L.D. Short-term photovoltaic power forecasting using Artificial Neural Networks and an Analog Ensemble. Renew. Energy 2017, 108, 274–286. [Google Scholar] [CrossRef]

- Chine, W.; Mellit, A.; Lughi, V.; Malek, A.; Sulligoi, G.; Pavan, A.M. A novel fault diagnosis technique for photovoltaic systems based on artificial neural networks. Renew. Energy 2016, 90, 501–512. [Google Scholar] [CrossRef]

- Gul, S.; Ul Haq, A.; Jalal, M.; Anjum, A.; Khalil, I.U. A unified approach for analysis of faults in different configurations of PV arrays and its impact on power grid. Energies 2020, 13, 156. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Zhou, D.; Wu, C. An Intelligent Method for Fault Diagnosis in Photovoltaic Array. In System Simulation and Scientific Computing; Springer: Berlin/Heidelberg, Germany, 2012; pp. 10–16. [Google Scholar]

- Wang, Y.; Wu, C.; Fu, L.; Zhou, D.; Li, Z. Fault diagnosis of PV array based on BP neural network. Power Syst. Prot. Control 2013, 41, 108–114. [Google Scholar]

- Boussaada, Z.; Curea, O.; Remaci, A.; Camblong, H.; Bellaaj, N.M. A Nonlinear Autoregressive Exogenous (NARX) Neural Network Model for the Prediction of the Daily Direct Solar Radiation. Energies 2018, 11, 620. [Google Scholar] [CrossRef]

- Billings, S.A.; Wei, H.L. NARMAX model as a sparse, interpretable and transparent machine learning approach for big medical and healthcare data analysis. In Proceedings of the IEEE 21st International Conference on High Performance Computing and Communications; IEEE 17th International Conference on Smart City; IEEE 5th International Conference on Data Science and Systems (HPCC/SmartCity/DSS), Zhangjiajie, China, 10–12 August 2019; pp. 2743–2750. [Google Scholar]

- Solares, J.R.A.; Wei, H.L.; Billings, S.A. A novel logistic-NARX model as a classifier for dynamic binary classification. Neural Comput. Appl. 2019, 31, 11–25. [Google Scholar] [CrossRef]

- Negnevitsky, M. Artificial Intelligence: A Guide to Intelligent Systems; Addison Wesley: Essex, UK, 2004. [Google Scholar]

- Cömert, Z.; Kocamaz, A.F. A study of artificial neural network training algorithms for classification of cardiotocography signals. J. Sci. Technol. 2017, 7, 93–103. [Google Scholar] [CrossRef]

- Smith, S.W. Digital Signal Processing: A Practical Guide for Engineers and Scientists; Spectrum Inc.: San Diego, CA, USA, 2002. [Google Scholar]

- Natsheh, E.M.; Natsheh, A.R.; Albarbar, A.H. An automated tool for solar power systems. Appl. Sol. Energy 2014, 50, 221–227. [Google Scholar] [CrossRef]

- Samara, S.; Natsheh, E. Modeling the output power of heterogeneous photovoltaic panel’s based on artificial neural networks using low cost microcontrollers. Heliyon 2018, 4, 1–18. [Google Scholar] [CrossRef] [PubMed]

| Astronergy- CHSM6610P | Lorentz Mono-crystalline | Sharp’s- NUS0E3E | |

|---|---|---|---|

| Maximum power (Pm) | 225 W | 95 W | 180 W |

| Voltage at Pm (Vamp) | 29.76 V | 17.2 V | 23.7 V |

| Current at Pm (Iamp) | 7.55 A | 5.5 A | 7.6 A |

| Open circuit voltage (Voc) | 36.88 V | 20.6 V | 30 V |

| Short circuit current (Isc) | 8.27 A | 6.2 A | 8.37 A |

| Fault # | Symbol | Mode | Fault Scenario |

|---|---|---|---|

| 1 | FL1 | Minor | One faulty panel |

| 2 | FL2 | Minor | Two faulty panels |

| 3 | FL3 | Minor | Three faulty panels |

| 4 | FL4 | Minor | Four faulty panels |

| 5 | FL5 | Minor | Five faulty panels |

| 6 | FL6 | Minor | Low shading |

| 7 | FM1 | Moderate | Medium shading |

| 8 | FH1 | Major | High shading |

| 9 | FL7 | Minor | One faulty panel + low shading |

| 10 | FL8 | Minor | Two faulty panels + low shading |

| 11 | FL9 | Minor | Three faulty panels + low shading |

| 12 | FM2 | Moderate | Four faulty panels + low shading |

| 13 | FM3 | Moderate | Five faulty panels + low shading |

| 14 | FM4 | Moderate | One faulty panel + med shading |

| 15 | FM5 | Moderate | Two faulty panels + med shading |

| 16 | FM6 | Moderate | Three faulty panels + med shading |

| 17 | FM7 | Moderate | Four faulty panels + med shading |

| 18 | FM8 | Moderate | Five faulty panels + med shading |

| 19 | FH2 | Major | One faulty panel + high shading |

| 20 | FH3 | Major | Two faulty panels + high shading |

| 21 | FH4 | Major | Three faulty panels + high shading |

| 22 | FH5 | Major | Four faulty panels + high shading |

| 23 | FH6 | Major | Five faulty panels + high shading |

| Symbol | Fuzzy Classification Region | Partial Shading % | Min VR (V) | Max VR (V) | Min PR (W) | Max PR (W) |

|---|---|---|---|---|---|---|

| FL1 | 1 | - | 1.1444 | 1.1429 | 1.14 | 1.1638 |

| FL2 | 2 | 1.3351 | 1.3596 | 1.3334 | 1.3578 | |

| FL3 | 3 | 1.6021 | 1.6315 | 1.6000 | 1.6294 | |

| FL4 | 4 | 2.0027 | 2.0394 | 2.0000 | 2.0367 | |

| FL5 | 5 | 2.6702 | 2.7192 | 2.6667 | 2.7156 | |

| FL6 | 6 | Low | 0.9987 | 1.0149 | 1.1121 | 1.7257 |

| FL7 | 9 | 1.1414 | 1.1598 | 1.2710 | 1.9722 | |

| FL8 | 10 | 1.3316 | 1.4829 | 1.3531 | 2.3010 | |

| FL9 | 11 | 1.5980 | 1.7794 | 1.6238 | 2.7611 | |

| FM1 | 7 | Medium | 0.9904 | 1.0967 | 1.7201 | 3.1203 |

| FM2 | 12 | 1.9903 | 2.0585 | 2.276 | 3.4603 | |

| FM3 | 13 | 2.6493 | 2.7514 | 2.9531 | 4.6142 | |

| FM4 | 14 | 1.1802 | 1.3507 | 1.9507 | 3.5663 | |

| FM5 | 15 | Low | 1.3211 | 1.3899 | 2.2874 | 4.1601 |

| FM6 | 16 | Medium | 1.5704 | 1.7109 | 2.7453 | 5.1124 |

| FM7 | 17 | Low | 1.9554 | 2.1101 | 3.4 | 6.343 |

| FM8 | 18 | Medium | 2.6213 | 2.9656 | 4.5509 | 8.567 |

| FH1 | 8 | High | 1.0012 | 1.2056 | 3.0124 | 50.425 |

| FH2 | 19 | 1.1902 | 1.4045 | 3.6076 | 58.0092 | |

| FH3 | 20 | 1.3904 | 1.6091 | 4.2012 | 67.2024 | |

| FH4 | 21 | 1.5901 | 2.4902 | 5.0551 | 81.0214 | |

| FH5 | 22 | 2.5065 | 3.3023 | 6.3074 | 101.085 | |

| FH6 | 23 | 3.2905 | 5.5011 | 8.4091 | 135.056 |

| Mode | # | Rules |

|---|---|---|

| Minor | 1 | If PR is 1 and VR is 2, then the fault is 1 (1) |

| 2 | If PR is 2 and VR is 3, then the fault is 2 (0.01) | |

| 3 | If PR is 2 and VR is 4, then the fault is 3 (0.01) | |

| 4 | If PR is 4 and VR is 5, then the fault is 4 (1) | |

| 5 | If PR is 5 and VR is 6, then the fault is 5 (1) | |

| 6 | If PR is 2 and VR is 1, then the fault is 6 (1) | |

| 7 | If PR is 3 and VR is 2, then the fault is 9 (1) | |

| 8 | If PR is 4 and VR is 3, then the fault is 10 (1) | |

| 9 | If PR is 5 and VR is 4, then the fault is 11 (1) | |

| Moderate | 1 | If PR is 1 and VR is 1, then the fault is 7 (1) |

| 2 | If PR is 1 and VR is 5, then the fault is 12 (1) | |

| 3 | If PR is 2 and VR is 6, then the fault is 13 (1) | |

| 4 | If PR is 1 and VR is 2, then the fault is 14 (1) | |

| 5 | If PR is 2 and VR is 3, then the fault is 15 (1) | |

| 6 | If PR is 3 and VR is 4, then the fault is 16 (1) | |

| 7 | If PR is 4 and VR is 5, then the fault is 17 (0.01) | |

| 8 | If PR is 5 and VR is 6, then the fault is 18 (1) | |

| Major | 1 | If PR is 1 and VR is 1, then the fault is 8 (1) |

| 2 | If PR is 2 and VR is 2, then the fault is 19 (1) | |

| 3 | If PR is 3 and VR is 3, then the fault is 20 (1) | |

| 4 | If PR is 4 and VR is 4, then the fault is 21 (1) | |

| 5 | If PR is 5 and VR is 5, then the fault is 22 (1) | |

| 6 | If PR is 6 and VR is 6, then the fault is 23 (1) |

| # | PR | VR | Fault Mode | Fuzzy Classification Region | Diagnosis Time in ms |

|---|---|---|---|---|---|

| 1 | 1.8 | 2.0 | Minor | 4 | 4.02 |

| 2 | 1.4 | 1.1 | Minor | 9 | 4.03 |

| 3 | 5.3 | 2.7 | Moderate | 18 | 1.93 |

| 4 | 2.4 | 1.0 | Moderate | 7 | 3.04 |

| 5 | 116 | 4.5 | Major | 23 | 1.82 |

| 6 | 80.6 | 3.0 | Major | 22 | 2.01 |

| Input | Simulation | Hardware Implementation | |||||||

|---|---|---|---|---|---|---|---|---|---|

| # | Solar Radiation (W/m2) | Temperature (°C) | Open- Circuit Voltage (V) | Short- Circuit Current (A) | I | V | I | V | Tracking Time (ms) |

| 1 | 200 | 10 | 36.88 | 8.27 | 1.35 | 31.26 | 1.36 | 31.28 | 7.85 |

| 2 | 500 | 20 | 36.88 | 8.27 | 3.67 | 30.40 | 3.68 | 30.41 | 7.74 |

| 3 | 350 | 15 | 36.88 | 8.27 | 2.53 | 30.94 | 2.54 | 30.95 | 7.86 |

| 4 | 600 | 25 | 30 | 8.37 | 4.49 | 23.63 | 4.49 | 23.64 | 7.89 |

| 5 | 400 | 20 | 30 | 8.37 | 2.85 | 24.11 | 2.85 | 24.11 | 7.58 |

| 6 | 800 | 30 | 30 | 8.37 | 6.23 | 22.69 | 6.23 | 22.69 | 8.02 |

| Test Case | Start Time | End Time | Solar Radiation | Temp | Faulty Panel # | Partial Shading | PR | VR |

|---|---|---|---|---|---|---|---|---|

| 1 | 8:00 | 8:19 | 180 | 12 | - | 25% | 1.48 | 1.02 |

| 2 | 8:20 | 8:39 | 190 | 12 | - | 50% | 2.61 | 1.08 |

| 3 | 8:40 | 8:59 | 230 | 12 | - | 75% | 7.62 | 1.17 |

| 4 | 9:00 | 9:19 | 270 | 13 | Normal Mode | 1.01 | 1.01 | |

| 5 | 9:20 | 9:39 | 220 | 13 | 2 | - | 1.16 | 1.16 |

| 6 | 9:40 | 9:59 | 220 | 13 | 2,4 | - | 1.30 | 1.30 |

| 7 | 10:00 | 10:19 | 230 | 14 | 1,3,5 | - | 1.60 | 1.60 |

| 8 | 10:20 | 10:39 | 240 | 14 | 1,2,3,5 | - | 2.03 | 2.03 |

| 9 | 10:40 | 10:59 | 290 | 14 | 1,3,4,6,8 | - | 2.71 | 2.71 |

| 10 | 11:00 | 11:19 | 310 | 15 | Normal Mode | 1.01 | 1.01 | |

| 11 | 11:20 | 11:39 | 400 | 15 | 3 | 25% | 1.61 | 1.17 |

| 12 | 11:40 | 11:59 | 480 | 15 | 1,3 | 25% | 1.86 | 1.37 |

| 13 | 12:00 | 12:19 | 530 | 16 | 1,2,3 | 38% | 2.76 | 1.65 |

| 14 | 12:20 | 12:39 | 560 | 16 | 1,2,3,4 | 38% | 3.44 | 2.04 |

| 15 | 12:40 | 12:59 | 620 | 16 | 1,2,3,4,5 | 38% | 4.55 | 2.74 |

| 16 | 13:00 | 13:19 | 680 | 16 | 2 | 50% | 2.47 | 1.17 |

| 17 | 13:20 | 13:39 | 630 | 16 | 2,5 | 50% | 2.90 | 1.37 |

| 18 | 13:40 | 13:59 | 590 | 16 | 1,3,5 | 63% | 5.01 | 1.69 |

| 19 | 14:00 | 14:19 | 580 | 16 | 1,5,7,8 | 63% | 6.26 | 2.10 |

| 20 | 14:20 | 14:39 | 590 | 16 | 1,3,5,6,8 | 63% | 8.36 | 2.82 |

| 21 | 14:40 | 14:59 | 530 | 16 | Normal Mode | 1.01 | 1.01 | |

| 22 | 15:00 | 15:19 | 500 | 16 | 1 | 75% | 6.13 | 1.25 |

| 23 | 15:20 | 15:39 | 470 | 16 | 1,3 | 75% | 7.25 | 1.46 |

| 24 | 15:40 | 15:59 | 400 | 16 | 1,5,6 | 88% | 33.28 | 2.42 |

| 25 | 16:00 | 16:19 | 320 | 17 | 2,3,5,6 | 88% | 49.01 | 3.26 |

| 26 | 16:20 | 16:39 | 290 | 17 | 1,3,5,7,8 | 88% | 72.20 | 5.38 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Natsheh, E.; Samara, S. Tree Search Fuzzy NARX Neural Network Fault Detection Technique for PV Systems with IoT Support. Electronics 2020, 9, 1087. https://doi.org/10.3390/electronics9071087

Natsheh E, Samara S. Tree Search Fuzzy NARX Neural Network Fault Detection Technique for PV Systems with IoT Support. Electronics. 2020; 9(7):1087. https://doi.org/10.3390/electronics9071087

Chicago/Turabian StyleNatsheh, Emad, and Sufyan Samara. 2020. "Tree Search Fuzzy NARX Neural Network Fault Detection Technique for PV Systems with IoT Support" Electronics 9, no. 7: 1087. https://doi.org/10.3390/electronics9071087

APA StyleNatsheh, E., & Samara, S. (2020). Tree Search Fuzzy NARX Neural Network Fault Detection Technique for PV Systems with IoT Support. Electronics, 9(7), 1087. https://doi.org/10.3390/electronics9071087