Abstract

This study presents a new path planning method based on Fuzzy Analytic Hierarchy Process (FAHP) for a mobile robot to be effectively operated through a multi-objective decision making problem. Unlike typical AHP, the proposed FAHP has a difference in using triangulation fuzzy number based extent analysis to derive weight vectors among the considerations. FAHP framework for finding the optimal position in this study is defined with the highest level (goal), middle level (objectives), and the lowest level (alternatives). It analytically selects an optimal position as a sub-goal among points on the sensing boundary of the mobile robot considering the three objectives: the travel distance to the target, robot’s rotation, and safety against collision between obstacles. Alternative solutions are evaluated by quantifying the relative importance for the objectives. Comparative results obtained from the artificial potential field, AHP, and FAHP simulations show that FAHP is much preferable for mobile robot’s path planning than typical AHP.

1. Introduction

Mobile robots are requested to perform their assignment under a variety of working environments such as smart factories, highly automated hospitals, and even homes. One of the important functions on mobile robots for the completion of the required tasks is to reach a target successfully by means of path planning. To this end, there have been many efforts to implement the capability of robot’s path planning [1,2,3,4,5,6]. Beyond the consideration on single objective aspect, i.e., traveling distance or collision safety with obstacles, the majority of current optimal path planning research has focused on multi-objective solving problems.

A number of studies have been conducted on the multi-objective path planning method. Castillo et al. [7] used multi-objective genetic algorithm considering length and travel difficulty of the path as the objectives. Masehian and Sedighizadeh [8] considered shortness and smoothness as the objectives by combining particle swarm optimization and probability road map. Kim and Langari [9] utilized Analytic Hierarchy Process (AHP) to plan an optimal path of mobile robot. Ahmed and Deb [10] modified Non-dominated Sorting Genetic Algorithm II taking into account travel distance, safety, and path smoothness simultaneously. Recently, [11,12,13] also suggested multi-objective considered path planning strategies. However, there are few approaches on preference based path optimization for mobile path planning, considering the diversity of a mobile robot’s working environment. To this end, Fuzzy-AHP based path planning based on the framework of AHP is studied in this study because it is a powerful method in multi-objective decision making under the user’s preference on objectives.

AHP is one of the most famous methods in multi-objective decision making and various multi-objective decision making problems [9,14,15,16]. Its optimization process, formulated as a multi-objective solution, selects optimal path on mobile robots among a variety of candidates (i.e., position in the sensing boundary) considering several factors (objectives) simultaneously. However, there is still weakness that AHP based decision making inevitably involves decision maker’s subjectivity in determining the preference for evaluation objectives [17].

To solve this difficulty, Fuzzy based AHP (FAHP) is proposed to address the issue of ambiguity and uncertainty resulting from this characteristic of AHP. There has been work in progress about performance improvement of AHP combined with fuzzy theory [18]. Chan and Kumar [19] showed that FAHP not only handles the uncertainty imposed by the decision maker during decision making process, but it also provides robustness and flexibility. Laarhoven and Pedrycz [20] developed FAHP to quantitatively include the subjectivity of the decision maker in the decision making process through a combination of triangular membership functions and triangular fuzzy numbers. Then, Chang [21] proposed the extent analysis method replacing Saaty’s nine-point pairwise scale to triangular fuzzy numbers. [22] applied FAHP to select the optimal path from preplanned paths considering safety of path, steepness, congestion, and roughness. However, this research is proposing FAHP based on-line path planning method. Therefore, it can be applied to various and dynamic working environments depending on the decision maker’s preferences or objectives.

In this paper, a multi-objective decision making strategy is applied to mobile robot path planning. The travel distance to the target, robot’s rotation, and safety against collision between obstacles are considered as the objectives. The performance of the proposed method is demonstrated under numerical simulations. A factory layout is defined and different priorities on the objectives are defined and simulated. Comparative results obtained from the artificial potential field, AHP, and FAHP simulations show that FAHP is much preferred for mobile robot’s path planning as compared to typical AHP. In addition, it is shown that the navigation results correspond to the defined priorities on objectives.

This paper is organized as follows. Section 2 provides a detailed explanation of AHP. The application of AHP to mobile robot path planning and the simulations are described in Section 3. In Section 4 and Section 5, Fuzzy based AHP is introduced and the sensitivity analysis of FAHP is investigated, respectively. AHP and FAHP based mobile robot navigation performance is compared with a conventional method and Artificial Potential Field based path planning in the following section. Finally, Section 7 concludes this paper.

2. Analytic Hierarchy Process

Normally, several objectives are simultaneously considered during the decision making process. Given the multitude of factors, it is difficult to choose a solution because decisions are not merely determined by using a single factor. To this end, a multi-objective decision making method aids in selecting an optimal solution among alternatives by considering a decision maker’s relative preference on each objective.

In this study, one of the famous multi-objective decision making methods, AHP, is applied on mobile robot path planning. As with everything, AHP has its advantages and disadvantages. The advantages of AHP are as follows [23,24]. The most powerful aspect of AHP is the ease of use. It provides a very simple and flexible model for a given problem. In addition, AHP based decision making can be either objective or subjective considerations, and either quantitative or qualitative, so various designs of decision making are possible. Additionally, the consistency measurement of the decision maker’s judgments allows for appropriateness of decision making.

Meanwhile, there are several weaknesses of the AHP such as the rank reversal problem, the priorities derivation method, and the comparison scale [25,26,27]; the rank reversal problem occurs due to the nature of comparisons between alternatives. The addition of alternatives at the end of the decision making process could change the ranking of the solution. However, this drawback can be ignored [27] in the alternatives to limited resource management problems. Another disadvantage of AHP is the priorities derivation method. Due to the fact that the different derivation method derives a different priority vector, extensive research has been taken to find the best method [28]. Lastly, the comparison scale is also an issue in AHP. Normally, Saaty’s one to nine scale is mostly utilized to generate a relative objective matrix [26]. Although it has these advantages and disadvantages, AHP provides a comprehensive and rational framework to structure a decision making process to quantify its objectives, relate the objectives into overall goals, and evaluate alternative solutions [14]. In order to implement AHP, it is necessary to standardize the problem as a hierarchy. In the AHP, the highest level of the hierarchy corresponds to the overall goal, and the lowest level corresponds to a list of alternatives (candidates). Problem initiator determines the relative importance of objectives, and all candidates are evaluated based on objectives. Subsequently, an alternative with the maximum value is selected as a solution. AHP based decision making complies with the following procedures as stated in Table 1.

Table 1.

Analytic Hierarchy Process (AHP) decision making process.

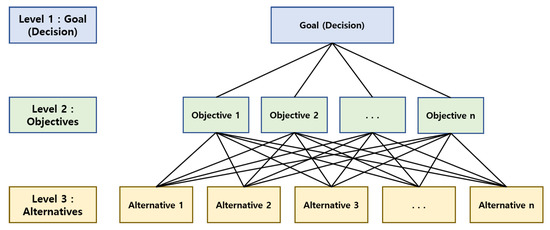

The first step is to complete an analysis of the problem wherein the purpose of the problem to be solved, the objectives considered, and the alternatives suggested are defined. Thus, three main hierarchies, namely goal, objectives, and alternatives are composed as in Figure 1.

Figure 1.

The structure of AHP decision making.

Following the generation of the AHP structure, the preferences (or priority among the entries) are determined based on the importance of each objective. In the AHP framework, a pairwise comparison scale is given in accordance with a previous study [29] to define a relative importance matrix (RM). A scale is defined from one to nine with the relative importance of an objective. Table 2 shows the pair-wise comparison scale in forming an RM.

Table 2.

Pairwise comparison scale.

Specifically, represent the n-th objectives. When three objectives are considered, the RM is formalized by using the following structure:

In Equation (1), RM represents a reciprocal matrix with only three elements, namely a, b, and c. To obtain a weighted objective matrix, the RM is normalized according to Equation (2) as follows:

Thus, as an example, where and n denotes the number of objectives. The average of each row of Equation (2) corresponds to the weighted objective matrix that is expressed as follows:

where denotes a row vector. The weighted objective matrix shows the importance of each objective that is derived from the preference for each objective.

However, the weight objective matrix could be inappropriate [29]. Therefore, consistency of relative importance matrix should be examined because of the limitation of Saaty’s discrete nine-value scale and the inconsistency of human judgment. Saaty [14] proposed a method to measure the inconsistency. Saaty [29] proved that the largest eigenvalue of the RM is equal to the size of the matrix, i.e., = n, under perfect consistency. It is also possible to estimate the departure from consistency by the consistency index (CI). Therefore, the CI is defined as follows:

After obtaining the CI value, it is divided by the random consistency (RC) index given in Table 3 to obtain the consistency ratio (CR) as follows:

Table 3.

Random consistency index.

Saaty [29] limits the appropriate measure as denoted by the fact that CR should not exceed 0.1. Thus, if this is not so, the result is not accepted and another relative importance matrix, RM, is assessed until the CR appropriately satisfies the condition CR < 0.1.

After the consistency is investigated, the given alternatives are evaluated with respect to each objective. The objective based alternative evaluation matrix is given as follows:

where represents the value of alternative when the objective is considered, and , where denotes the number of alternatives. Additionally, the same process of Equations (2) and (3) is used to obtain normalized matrices and the weighted alternative matrices of each corresponding objective. The normalized form of (6) is defined as follows:

Weighted alternative matrix of each objective is obtained by using the following equation:

All functions are considered to obtain the following weighted alternative matrix:

A optimal function with the highest value is derived by multiplying the two resulting matrices Equations (3) and (9) composed of weights as follows:

3. AHP-Based Mobile Robot Path Planning Framework

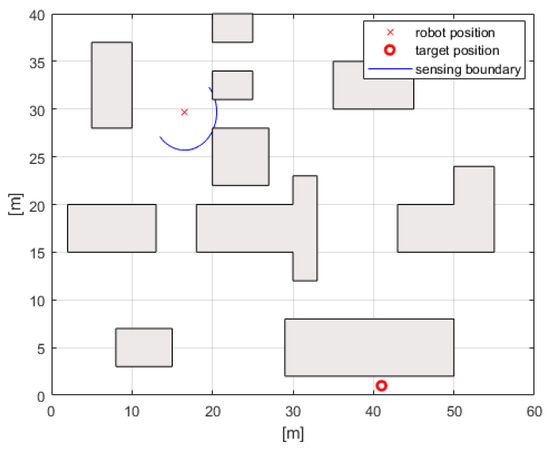

This section discusses an application of AHP to a mobile robot path planning. Prior to an analysis, it is assumed that the goal position and robot’s position in global map (working space) are broadcast. Furthermore, in the mobile robot working space, a few obstacles (can be a person or objects) are randomly located such that it is not possible to specify the position. The goal involves determining an optimal waypoint within the sensor’s field of view (FOV). To determine an optimal position, three objectives including distance to the target , angle to the target , and safety margin are considered. The alternatives for the FOV of a laser range finder (LRF) are given as follows:

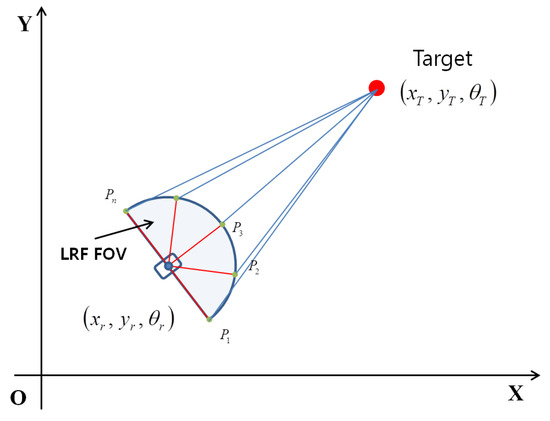

where, the candidates are among rad from the robot’s current orientation (). Furthermore, denotes an alternatives angle, (, ) denotes an alternative position on , represents the sensor’s detection range, and the robot’s current position corresponds to (, ,). Figure 2 shows the coordinate system of the mobile robot. The half circle represents the field of view of LRF. The alternatives can be changed based on the sensor angle resolution (in Figure 2, only five angles are considered).

Figure 2.

Coordinate system of a mobile robot with a laser range finder (LRF) sensor.

The relative importance (i.e., ) is defined by the user and represents that is four times as important as , is six-times as important as , and is twice as important as . Thus, the relative importance matrix among objectives is given as follows: . The following process is to calculate a weighted objective matrix () and the consistency index of the . Then the consistency is evaluated according to Equations (4) and (5). In the given relative importance matrix, the consistency ratio (CR = 0.0079 < 0.1) satisfies an appropriate measure for the consistency. The next step involves evaluating all the candidates (alternatives, ) with respect to the objectives, namely , , and . As shown in Figure 2, different angles exhibit different distances, robot rotation angles, and safety margins.

The first objective is the distance to the target, (, ,), and it is expressed as follows:

Subsequently, the RM of is given by the following expression:

The row vector weighted matrix, , is obtained based on Equations (2) and (3).

The second objective is the angle to the target and is expressed as follows:

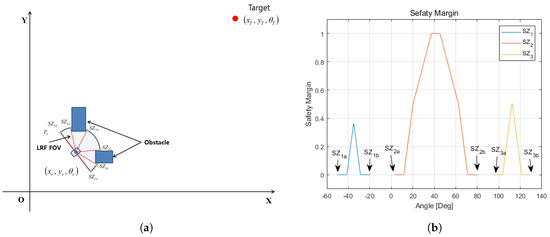

The final objective corresponds to the safety margin. Figure 3 depicts the situation when the mobile robot encounters obstacles.

Figure 3.

Safety margin under obstacles: (a) Description of safety zone (b) Function of safety margin.

Then the LRF sensor provides spaces, such as , , and , in which the robot can travel. Specifically, , , and represent the safety zone, starting angle of the safety zone, and ending angle of the safety zone, respectively. The basic idea of obtaining the safety margin involves utilizing the Gaussian function on two angles, and , as follows:

where denotes the safety margin, denotes arc length of alternative, and r denotes the sensing range of the robot’s distance sensor. For convenience, is defined.

4. Fuzzy Based AHP

In this section, Fuzzy based AHP (FAHP) is introduced and applied on mobile robot path planning to improve the performance of the AHP. In the framework of AHP, the pairwise comparisons are defined to select an optimal solution of the given problem using Satty’s nine-point scale. However, Kabir and Hasin [30] figured out the conventional AHP has the following disadvantages: (1) The AHP method creates and deals with a very unbalanced scale of judgment. (2) The AHP method does not take into account the uncertainty associated with the mapping of one’s judgment to a number. (3) Ranking of the AHP method is rather imprecise. (4) The subjective judgment, selection, and preference of decision makers have great influence on the AHP results. With these reasons, AHP is insufficient to explain uncertain conditions in pair-wise comparison scale.

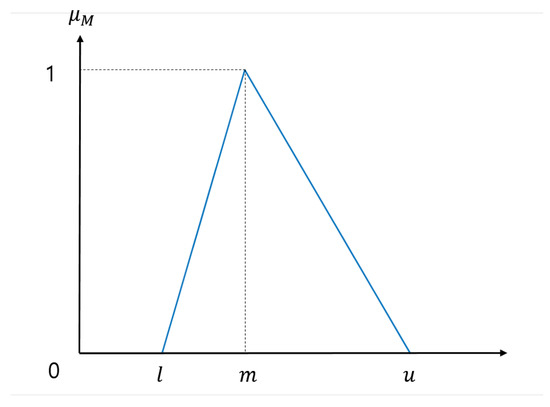

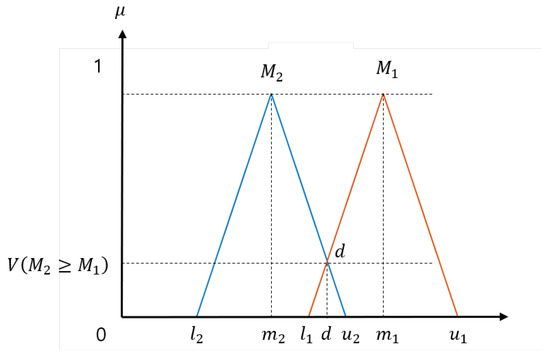

In order to cover these weak-points of the AHP, FAHP is introduced. Chang [21] proposed the extent analysis method on Fuzzy AHP using triangular fuzzy number as shown in Figure 4. As defined in [31], a fuzzy number M on R to be a triangular fuzzy number if its membership function is equal to

where . Furthermore, represent the lower, middle, and upper value of M, respectively. Table 4 shows the Fuzzified Satty’s nine-scale for triangular fuzzy number [32].

Figure 4.

Fuzzy number.

Table 4.

Fuzzified Satty’s Scale for Triangular Fuzzy Number.

In order to implement FAHP, the following steps are required [21]. In addition, all the following equations for FAHP are not covered in this research.

- Step 1: Fuzzification of the relative important matrix

Using the triangular fuzzy number, RM, Equation (1) is reformed as follows

where represents fuzzified relative importance matrix. According to Equation (19), the is converted to .

- Step 2: Calculation of fuzzy synthetic extent as follows

The fuzzy synthetic extent [33] of is calculated as follows

where is the ith synthetic extent and is triangular fuzzy number. The operator ⊙ is defined as

- Step 3: Calculation of priority vectors of fuzzy AHP

Once fuzzy synthetic extent is obtained, the vectors of weights under defined objectives is derived. By the principle of the comparison of fuzzy numbers [30], the degree of possibility of is defined as

and can be equivalently expressed as

where hgt and d represent the highest intersection point and x coordinate of the two fuzzy numbers as shown in Figure 5.

Figure 5.

The intersection between and .

The degree of possibility for a convex fuzzy number to be greater than k convex fuzzy numbers can be defined by

by assuming

for . Then the weight vector is given by

where are n elements. By normalizing Equation (27) the weight vector is given

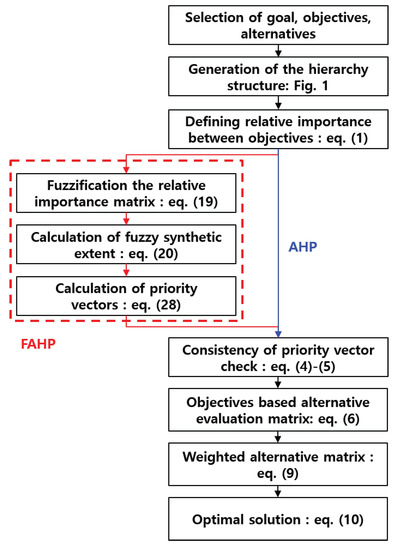

Figure 6 shows the step-wise algorithm of FAHP. Particularly, the blue box displays the AHP based decision making algorithm while the red box represents the Fuzzy based part that is different from the conventional AHP. The fuzzy part is implemented via Equations (19) and (28) and the consistency is checked by Equations (4) and (5).

Figure 6.

Step-wise algorithm of Fuzzy Analytic Hierarchy Process (FAHP).

5. Sensitivity Analysis of FAHP

In this section, the sensitivity analysis is conducted to examine the robustness of FAHP. When the optimal solution is derived from FAHP, it is important to provide information on the robustness of the selected method. In other words, the robustness of the solution to changes in the weightings of the objective needs to be discussed [26,34,35]. In FAHP based path planning problem, the optimal solution should be selected in every decision making cycle. In order to analyze the sensitivity of the suggested method, the following situation is considered: the mobile robot meets three gaps condition and the angle ranges of each gap are given; where the angle difference is 0.36 degrees a shown in the Figure 7. Therefore, there are 464 alternatives to select in this specific condition. In the sensitivity analysis, the fuzzification factor d in the triangular fuzzy number defined in Table 5 and Table 6 changes from 0.5 to 1.5 with 0.1 step.

Figure 7.

Three gap encountering situation for a mobile robot.

Table 5.

Sensitivity analysis result with .

Table 6.

Sensitivity analysis result with .

Table 5 and Table 6 show the decision making results from and , respectively. From 464 candidates, only the first five solutions are considered. From the results of , it is shown that the first three fuzzification factors have the same results while the others select the same results. based decision making shows the first five have the 24th candidate while the others choose the 170th alternative.

Table 7 displays the priority vector with respect to the fuzzification factor d. Each element stands for the traveling distance, rotation angle to the target, and the safety score change. has the highest priority in distance to the target while focuses on the safety. Due to each maintaining the priority manner while the fuzzification factor changes, the rank of the alternatives are not changes frequently. The robustness of the suggested path planning method is shown.

Table 7.

Priority vectors for and .

6. Simulation and Results

6.1. Simulation I (AHP Based Path Planning)

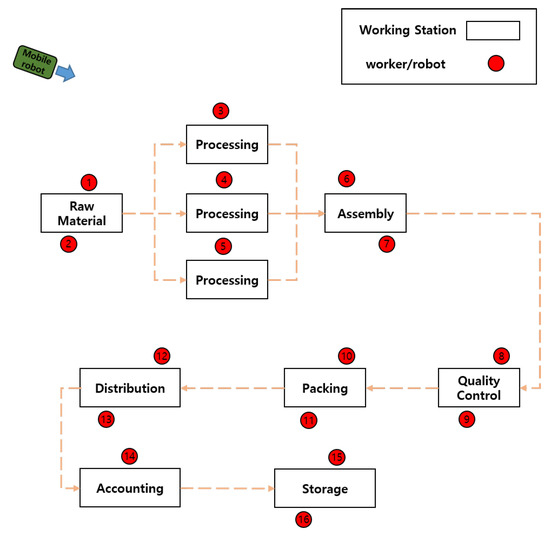

AHP based path planning method is simulated in a manufacturing plant. Figure 8 shows a factory layout consisting of several work stations. The manufacturing process follows the dashed line. It is assumed that the mobile robot delivers raw materials to each station on demand. All the following simulations are conducted in the same environment shown in Figure 8. In order to apply AHP on the path planning, the relative importance between the objectives (distance to the target, rotation of robot, and safety) should be defined. In the following simulations, two different preferences are considered, one with the highest weight on distance to the target and the other on safety.

Figure 8.

Factory layout.

In the manufacturing line, short traveling distance is sometimes an essential factor to improve productivity. Therefore, RM is defined based on the notion that the distance to the target is four times more important than the rotation and six times the safety, and the rotation is twice as important as the safety. Therefore, the RM is defined as

The second case is designed to place safety first over other objectives. It is assumed that distance to the target and rotation are the same priority, safety is four times more important than distance to the target, and safety is four times more important than rotation. The is defined as

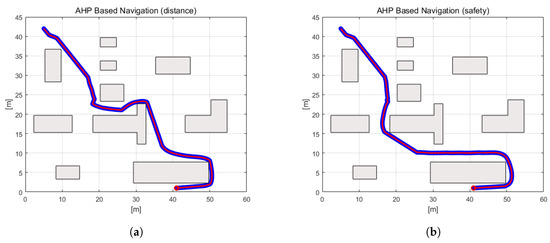

The simulation is conducted utilizing Equations (1) and (17). During the simulations, the total traveling distance, safety score, and amount of rotation steepness are investigated. This is because the traveling distance helps to increase working efficiency, safety score ensures collision free operation, and the number of steep turns is involved in the damage to the transporting material. Figure 9a shows the simulation result under while Figure 9b displays the result of path planning under . The based simulation results show that the total traveling distance is 81.46 m, safety score is 50.84, and the number of steep angles is 15. On the other hand, the based simulation results are 84.18 of the total traveling distance, 85.30 of the safety score, and 12 times of the occurrence of steep angles. As expected, short distance traveling strategy based RM has shorter distance travel results, whereas safety strategy based RM has higher safety scores, ensuring high safety margins against collisions with obstacles.

Figure 9.

Safety margin under obstacles: (a) AHP based path planning with short distance preference (b) AHP based path planning with high safety preference.

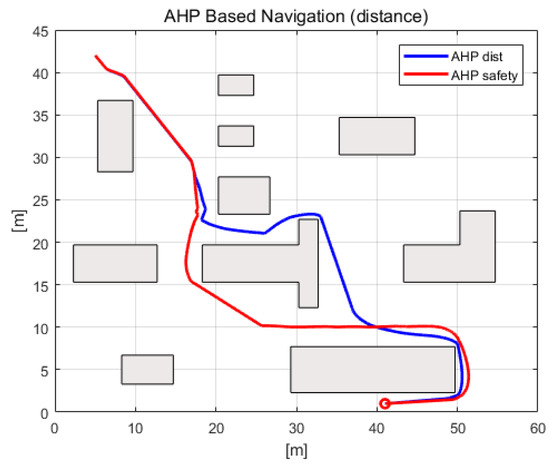

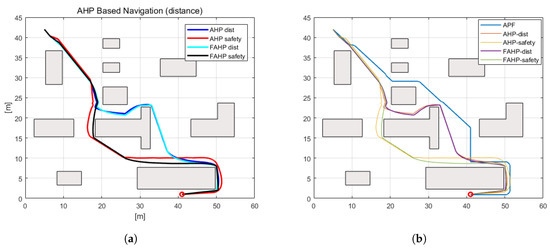

Figure 10 displays the trajectory of both . The blue line represents based path while the red line is for . According to the defined RM, one takes the shortest sub-target position while the other chooses the safest sub-target within sensing range.

Figure 10.

Comparison between short distance and high safety relative importance matrix (RM) based AHP path planning.

6.2. Simulation II (FAHP Based Path Planning)

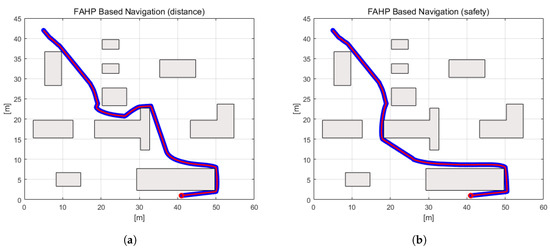

FAHP based mobile robot path planning is simulated in the same factory layout environment to overcome the aforementioned shortcomings of AHP. As the first step, and are converted to fuzzified relative importance matrices using Equation (19). Furthermore, FAHP based weight vector is calculated by following Equations (20) and (28). Then the multi-objective decision making is conducted according to the Equations (6) and (10). In Figure 11, FAHP based simulation results are displayed. It is shown that each of the fuzzified RMs plan different paths.

Figure 11.

Safety margin under obstacles: (a) FAHP based path planning with short distance preference (b) FAHP based path planning with high safety preference.

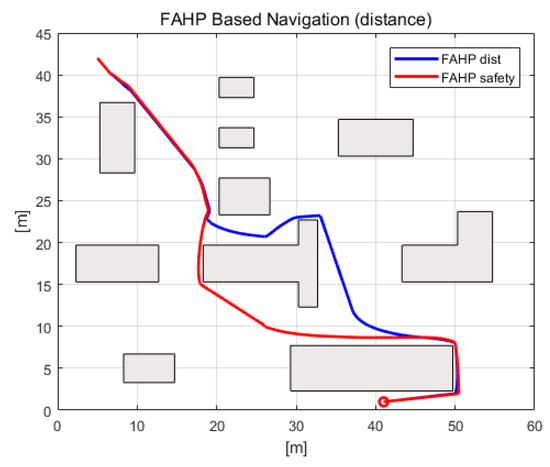

Through the analysis of the simulation results, the travel distance of 81.01 m, the safety score of 65.95, and 14 steep turns are found in the case of high weights for short distances. However, the safety priority strategy indicates 81.63 m, 98.11 safety scores, and 10 steep rotation performance for each investigating items. The FAHP with the highest weight on distance performs shorter travel than the other preference while the highest weight on the safety achieves the higher safety score than the other. Figure 12 shows the comparison path of the two path planning strategy. As with AHP, it is confirmed that FAHP based path planning follows the user’s intention well.

Figure 12.

Comparison between short distance and high safety RM based FAHP path planning.

6.3. Simulation III (Artificial Potential Field Based Path Planning)

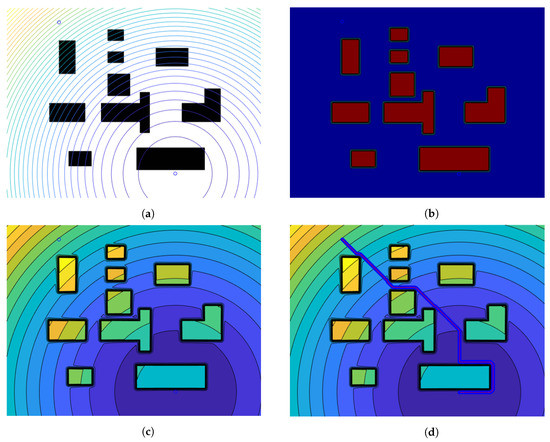

Finally, the performances of AHP and FAHP based path planning are compared with the conventional path planning strategy, Artificial Potential Field (APF) [36,37]. Because the details of the APF are explained well in [36,37], this paper does not cover them. The basic idea of APF is generating a vector for the robot to navigate by the summation of attractive field of the goal and the repulsive field of the obstacles. Figure 13 shows the simulation results with APF. Furthermore, APF is composed of attractive potential, repulsive potential, and potential field as shown in Figure 13. The upper circle represents starting position and the lower circle means the target.

Figure 13.

Artificial Potential Field (APF) based path planning results: (a) Attractive potential (b) Repulsive potential (c) Potential field (d) APF based navigation.

Table 8 indicates the performance comparison among AHP, FAHP, and APF. In most cases, AHP and FAHP have superior performance in traveling distance and the number of steep turns. When the navigation performances of AHP and FAHP are compared, travels shorter than .

Table 8.

Simulation results comparison between AHP, FAHP, and APF.

As shown in Figure 14a, an FAHP based decision takes a more sophisticated solution than AHP. For example, due to the AHP decision making utilizing a nine-point integer scale to describe the importance between objectives, it cannot handle the uncertainties. However, FAHP can decide under uncertain decision making conditions [22]. As shown in Table 8, path planning based on AHP is somewhat extreme in terms of the defined relative importance metrics. For example, distance-priority cases have lower safety performance, and safety-priority cases have lower distance performance. However, when FAHP is utilized for path planning under safety first strategy it also selects a solution that has high performance in distance reduction as shown in Table 8. Among all methods, short distance travel preference based FAHP can plan the minimum travel distance path. Furthermore, safety preference based FAHP plans a path that guarantees a safe logistics process. The superiority of AHP-based path planning is testified by comparing the performance of mobile robot navigation using the APF-based method. In addition, it is demonstrated that FAHP compensates the weaknesses of AHP.

Figure 14.

Navigation results: (a) Navigation path comparison between AHP and FAHP (b) Navigation path comparison among all methods.

7. Conclusions

In this paper, a mobile robot path planning strategy based on a multi-objective decision making framework, Analytic Hierarchy Process, has been studied. The main advantage of AHP is that decisions are made through relative importance among the objectives being considered. However, in the conventional AHP, a nine-point scale is utilized to apply the decision maker’s preference about relative importance between objectives. Therefore, AHP is inappropriate for making decisions under uncertain conditions. In this study, FAHP was proposed to compensate for the weakness of AHP. The main contribution of this research is to suggest a path planning method for a mobile robot, taking into account various objectives simultaneously. A path planning method using AHP is suggested firstly and the navigation performance is improved by applying FAHP. Through simulations, a mobile robot path planning performance based on AHP was verified. The application of the FAHP method also confirmed the overall improvement in navigation performances such as distance of travel, collision safety, and rapid rotation. This study is based on the simulation to verify the performance of the proposed path planning method. The following research will focus on the path planning method with a real mobile robot in various working environments. The results of this study can be applied to various mobile robot platforms working in dynamic working environments that require different paths according to the user’s preference such as traveling distance, collision safety, delicate material handling, etc.

Author Contributions

Conceptualization, C.K.; methodology and simulation, C.K.; validation, H.Y. and Y.K.; writing—original draft preparation, C.K.; writing—review and editing, H.Y. and Y.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science, ICT & Future Planning (No. 2017R1C1B2005512). And the APC was funded by the same source.

Acknowledgments

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP: Ministry of Science, ICT & Future Planning) (No. 2017R1C1B2005512).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Siegwart, R.; Nourbakhsh, I.R.; Scaramuzza, D. Introduction to Autonomous Mobile Robots; MIT Press: Cambridge, MA, USA, 2011. [Google Scholar]

- Raja, P.; Pugazhenthi, S. Optimal path planning of mobile robots: A review. Int. J. Phys. Sci. 2012, 7, 1314–1320. [Google Scholar] [CrossRef]

- Mac, T.T.; Copot, C.; Tran, D.T.; De Keyser, R. Heuristic approaches in robot path planning: A survey. Robot. Auton. Syst. 2016, 86, 13–28. [Google Scholar] [CrossRef]

- Garcia-Cruz, X.; Sergiyenko, O.Y.; Tyrsa, V.; Rivas-Lopez, M.; Hernandez-Balbuena, D.; Rodriguez-Quiñonez, J.; Basaca-Preciado, L.; Mercorelli, P. Optimization of 3D laser scanning speed by use of combined variable step. Opt. Lasers Eng. 2014, 54, 141–151. [Google Scholar] [CrossRef]

- Ivanov, M.; Sergiyenko, O.; Tyrsa, V.; Mercorelli, P.; Kartashov, V.; Hernandez, W.; Sheiko, S.; Kolendovska, M. Individual scans fusion in virtual knowledge base for navigation of mobile robotic group with 3D TVS. In Proceedings of the IECON 2018-44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 3187–3192. [Google Scholar]

- Ribeiro, J.; Silva, M.; Santos, M.; Vidal, V.; Honório, L.; Silva, L.; Rezende, H.; Neto, A.S.; Mercorelli, P.; Pancoti, A. Ant Colony Optimization Algorithm and Artificial Immune System Applied to a Robot Route. In Proceedings of the 2019 20th International Carpathian Control Conference (ICCC), Krakow-Wieliczka, Poland, 26–29 May 2019. [Google Scholar]

- Castillo, O.; Trujillo, L.; Melin, P. Multiple objective genetic algorithms for path-planning optimization in autonomous mobile robots. Soft Comput. 2007, 11, 269–279. [Google Scholar] [CrossRef]

- Masehian, E.; Sedighizadeh, D. A multi-objective PSO-based algorithm for robot path planning. In Proceedings of the 2010 IEEE International Conference on Industrial Technology, Vina del Mar, Chile, 14–17 March 2010; pp. 465–470. [Google Scholar]

- Kim, C.; Langari, R. Analytical Hierarchy Process and Brain Limbic System combined strategy for mobile robot navigation. In Proceedings of the 2010 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Montreal, QC, Canada, 6–9 July 2010; pp. 967–972. [Google Scholar]

- Ahmed, F.; Deb, K. Multi-objective optimal path planning using elitist non-dominated sorting genetic algorithms. Soft Comput. 2013, 17, 1283–1299. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, M.; Yan, X. Multi-objective path planning for unmanned surface vehicle with currents effects. ISA Trans. 2018, 75, 137–156. [Google Scholar] [CrossRef]

- Yunqiang, H.; Wende, K.; Lin, C.; Xiaokun, L. Research on multi-objective path planning of a robot based on artificial potential field method. Int. J. Wirel. Mob. Comput. 2018, 15, 335–341. [Google Scholar] [CrossRef]

- Kouzehgar, M.; Rajesh Elara, M.; Ann Philip, M.; Arunmozhi, M.; Prabakaran, V. Multi-Criteria Decision Making for Efficient Tiling Path Planning in a Tetris-Inspired Self-Reconfigurable Cleaning Robot. Appl. Sci. 2019, 9, 63. [Google Scholar] [CrossRef]

- Satty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Chen, P.Y.; Wu, J.K.; Pai, N.S.; Lai, Y.C. Design and Implementation of an Autonomous Parking Controller Using a Fuzzy controller and AHP for Car-Like Mobile Robot. Int. J. Comput. Consum. Control 2014, 3, 27–39. [Google Scholar]

- Kim, C.; Langari, R. Adaptive analytic hierarchy process-based decision making to enhance vehicle autonomy. IEEE Trans. Veh. Technol. 2012, 61, 3321–3332. [Google Scholar] [CrossRef]

- Bouyssou, D.; Marchant, T.; Pirlot, M.; Perny, P.; Tsoukias, A.; Vincke, P. Evaluation and Decision Models: A Critical Perspective; Springer: Berlin/Heidelberg, Germany, 2000; Volume 32. [Google Scholar]

- Saaty, T.L. The analytic hierarchy and analytic network measurement processes: Applications to decisions under risk. Eur. J. Pure Appl. Math. 2007, 1, 122–196. [Google Scholar]

- Chan, F.T.; Kumar, N. Global supplier development considering risk factors using fuzzy extended AHP-based approach. Omega 2007, 35, 417–431. [Google Scholar] [CrossRef]

- Van Laarhoven, P.J.; Pedrycz, W. A fuzzy extension of Saaty’s priority theory. Fuzzy Sets Syst. 1983, 11, 229–241. [Google Scholar] [CrossRef]

- Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Kilincci, O.; Onal, S.A. Fuzzy AHP approach for supplier selection in a washing machine company. Expert Syst. Appl. 2011, 38, 9656–9664. [Google Scholar] [CrossRef]

- Oguztimur, S. Why Fuzzy Analytic Hierarchy Process Approach for Transport Problems? In Proceedings of the 51st Congress of the European Regional Science Association: “New Challenges for European Regions and Urban Areas in a Globalised World”, Barcelona, Spain, 30 August–3 September 2011. [Google Scholar]

- Olson, D.L. Opportunities and limitations of AHP in multiobjective programming. Math. Comput. Modell. 1988, 11, 206–209. [Google Scholar] [CrossRef]

- Ziemba, P.; Watrobski, J. Selected issues of rank reversal problem in anp method. In Selected Issues in Experimental Economics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 203–225. [Google Scholar]

- Ishizaka, A.; Labib, A. Analytic hierarchy process and expert choice: Benefits and limitations. Or Insight 2009, 22, 201–220. [Google Scholar] [CrossRef]

- Velasquez, M.; Hester, P.T. An analysis of multi-criteria decision making methods. Int. J. Oper. Res. 2013, 10, 56–66. [Google Scholar]

- Lin, C.; Kou, G.; Ergu, D. A heuristic approach for deriving the priority vector in AHP. Appl. Math. Model. 2013, 37, 5828–5836. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision Making for Leaders: The Analytic Hierarchy Process for Decisions in a Complex World; RWS Publications: Pittsburgh, PA, USA, 1990. [Google Scholar]

- Kabir, G.; Akhtar Hasin, M.A. Multi-criteria inventory classification through integration of fuzzy analytic hierarchy process and artificial neural network. Int. J. Ind. Syst. Eng. 2013, 14, 74–103. [Google Scholar] [CrossRef]

- Anand, M.D.; Selvaraj, T.; Kumanan, S.; Johnny, M.A. Application of multicriteria decision making for selection of robotic system using fuzzy analytic hierarchy process. Int. J. Manag. Decis. Mak. 2008, 9, 75. [Google Scholar] [CrossRef]

- Noorul Haq, A.; Kannan, G. Design of an integrated supplier selection and multi-echelon distribution inventory model in a built-to-order supply chain environment. Int. J. Prod. Res. 2006, 44, 1963–1985. [Google Scholar] [CrossRef]

- Chang, D.Y. Extent analysis and synthetic decision. Optim. Tech. Appl. 1992, 1, 352–355. [Google Scholar]

- Srdjevic, Z.; Samardzic, M.; Srdjevic, B. Robustness of AHP in selecting wastewater treatment method for the coloured metal industry: Serbian case study. Civ. Eng. Environ. Syst. 2012, 29, 147–161. [Google Scholar] [CrossRef]

- Balusa, B.C.; Gorai, A.K. Sensitivity analysis of fuzzy-analytic hierarchical process (FAHP) decision-making model in selection of underground metal mining method. J. Sustain. Min. 2019, 18, 8–17. [Google Scholar] [CrossRef]

- Latombe, J.C. Robot Motion Planning; Springer: Berlin/Heidelberg, Germany, 2012; Volume 124. [Google Scholar]

- Rimon, E.; Koditschek, D.E. Exact robot navigation using artificial potential functions. IEEE Trans. Robot. Autom. 1992, 8, 501–518. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).