Feasibility of Harvesting Solar Energy for Self-Powered Environmental Wireless Sensor Nodes

Abstract

1. Introduction

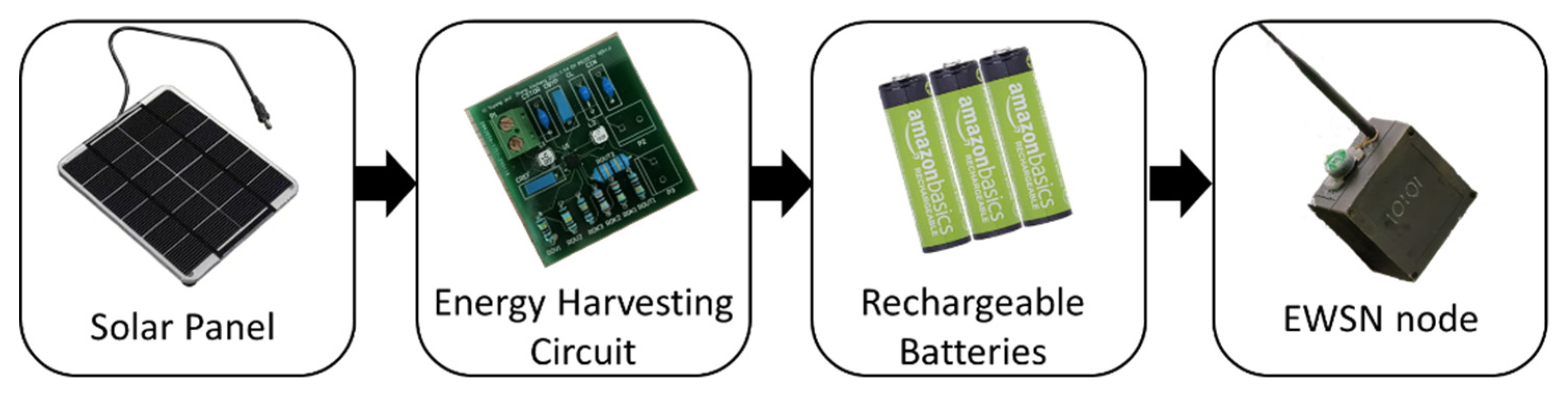

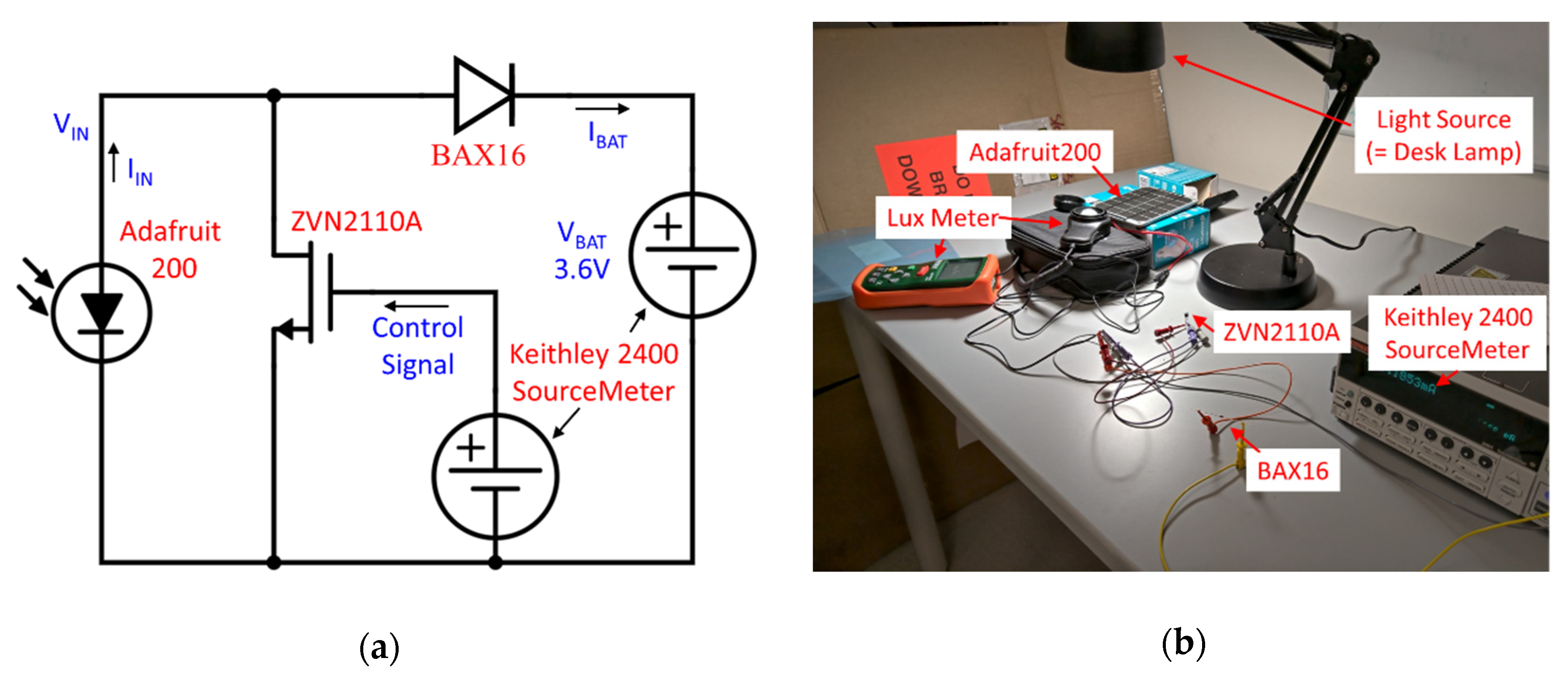

2. Primitive Solar Energy Harvester

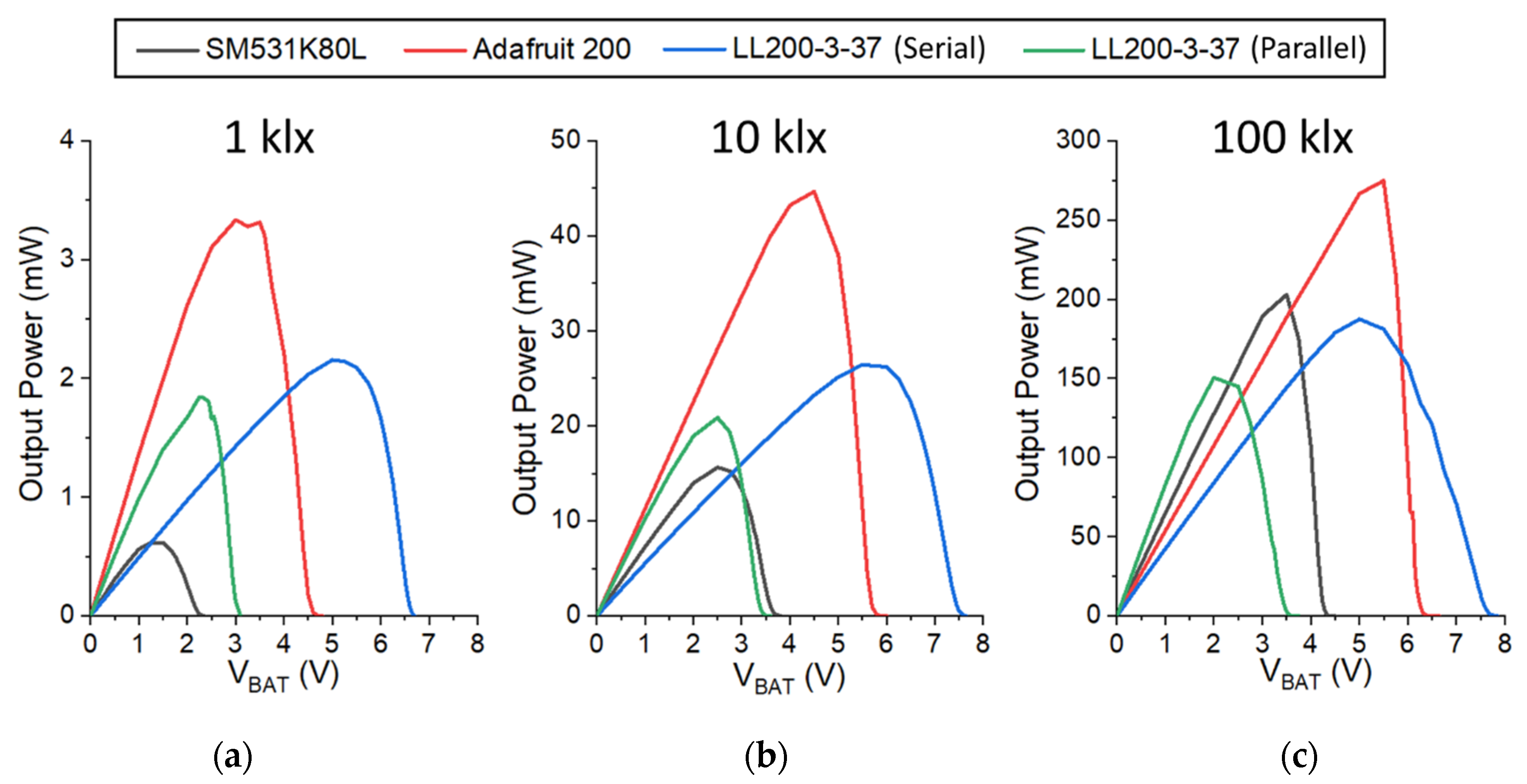

3. Solar Energy Harvester Based on bq25570 IC

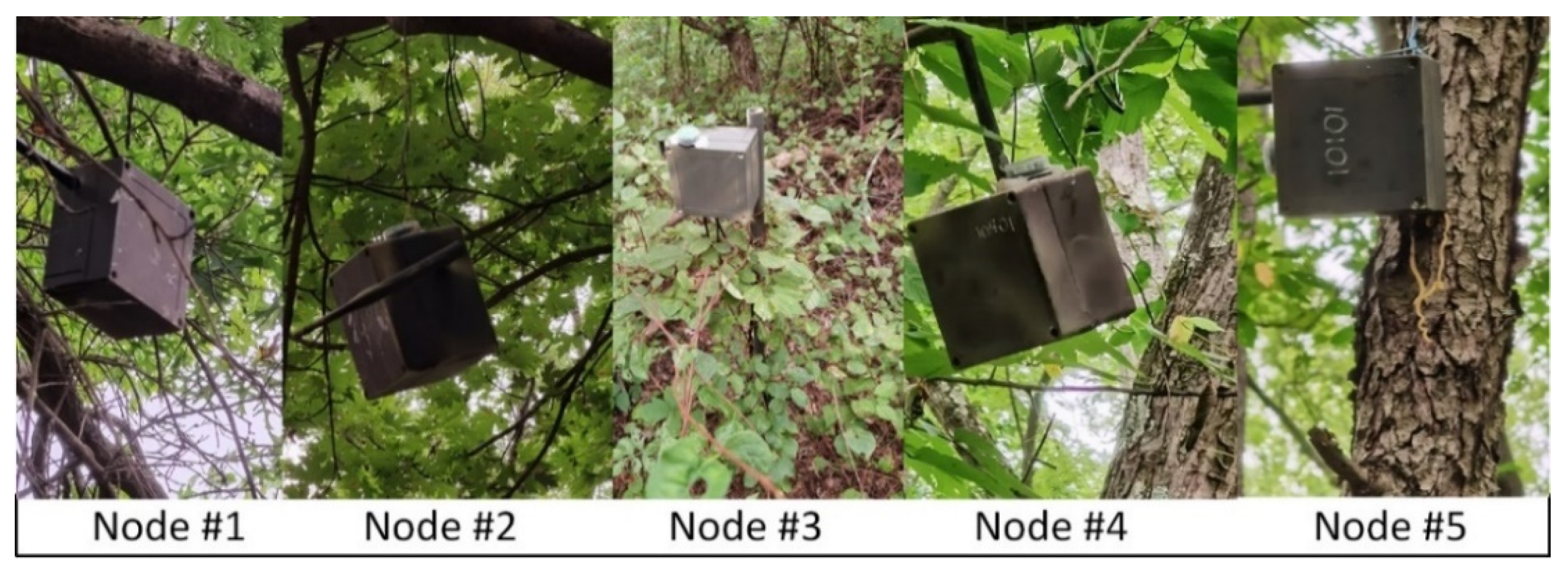

4. Measurement Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, H.; Li, W.; Xu, D.; Kan, J. A Hybrid Microenergy Storage System for Power Supply of Forest Wireless Sensor Nodes. Electronics 2019, 8, 1409. [Google Scholar] [CrossRef]

- Sharma, H.; Haque, A.; Jaffery, Z.A. Maximization of wireless sensor network lifetime using solar energy harvesting for smart agriculture monitoring. Ad Hoc Netw. 2019, 94, 101966. [Google Scholar] [CrossRef]

- Chammas, M.; Makhoul, A.; Demerjian, J. An efficient data model for energy prediction using wireless sensors. Comput. Electr. Eng. 2019, 76, 249–257. [Google Scholar] [CrossRef]

- Qian, J.; Jing, X. Wind-driven hybridized triboelectric-electromagnetic nanogenerator and solar cell as a sustainable power unit for self-powered natural disaster monitoring sensor networks. Nano Energy 2018, 52, 78–87. [Google Scholar] [CrossRef]

- Gaikwad, S.; Patil, R.; Khandare, A.; Rai, A. Design WSN node for protection of forest trees against poaching based on ZigBee. In Proceedings of the 2015 IEEE International Conference on Electronics, Computing and Communication Technologies (CONECCT), Bangalore, India, 10–11 July 2015. [Google Scholar]

- Prauzek, M.; Konecny, J.; Borova, M.; Janosova, K.; Hlavica, J.; Musilek, P. Energy harvesting sources, storage devices and system topologies for environmental wireless sensor networks: A review. Sensors 2018, 18, 2446. [Google Scholar] [CrossRef]

- Navarro, M.; Li, Y.; Liang, Y. Energy profile for environmental monitoring wireless sensor networks. In Proceedings of the 2014 IEEE Colombian Conference on Communications and Computing (COLCOM), Bogota, Colombia, 4–6 June 2014. [Google Scholar]

- Landsiedel, O.; Wehrle, K.; Gotz, S. Accurate prediction of power consumption in sensor networks. In Proceedings of the The Second IEEE Workshop on Embedded Networked Sensors, Sydney, Australia, 31 May 2005. EmNetS-II. [Google Scholar]

- Tang, X.; Wang, X.; Cattley, R.; Gu, F.; Ball, A.D. Energy harvesting technologies for achieving self-powered wireless sensor networks in machine condition monitoring: A review. Sensors 2018, 18, 4113. [Google Scholar] [CrossRef]

- Wang, H.; Jasim, A.; Chen, X. Energy harvesting technologies in roadway and bridge for different applications–A comprehensive review. Appl. Energy 2018, 212, 1083–1094. [Google Scholar] [CrossRef]

- Verma, G.; Sharma, V. A novel thermoelectric energy harvester for wireless sensor network application. IEEE Trans. Ind. Electron. 2018, 66, 3530–3538. [Google Scholar]

- Geballe, T.; Hull, G. Seebeck effect in silicon. Phys. Rev. 1955, 98, 940. [Google Scholar] [CrossRef]

- Van Herwaarden, A.; Sarro, P. Thermal sensors based on the Seebeck effect. Sens. Actuators 1986, 10, 321–346. [Google Scholar] [CrossRef]

- Goldsmid, H.J. Introduction to Thermoelectricity; Springer: Berlin/Heidelberg, Germany, 2010; Volume 121. [Google Scholar]

- Junior, O.A.; Maran, A.; Henao, N. A review of the development and applications of thermoelectric microgenerators for energy harvesting. Renew. Sustain. Energy Rev. 2018, 91, 376–393. [Google Scholar] [CrossRef]

- Nguyen, N.Q.; Pochiraju, K.V. Behavior of thermoelectric generators exposed to transient heat sources. Appl. Therm. Eng. 2013, 51, 1–9. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, J.; Chen, S.; Zuo, L. Thermo-element geometry optimization for high thermoelectric efficiency. Energy 2018, 147, 672–680. [Google Scholar] [CrossRef]

- Shaikh, F.K.; Zeadally, S. Energy harvesting in wireless sensor networks: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 55, 1041–1054. [Google Scholar] [CrossRef]

- Akhtar, F.; Rehmani, M.H. Energy replenishment using renewable and traditional energy resources for sustainable wireless sensor networks: A review. Renew. Sustain. Energy Rev. 2015, 45, 769–784. [Google Scholar] [CrossRef]

- Penella-López, M.T.; Gasulla-Forner, M. Powering Autonomous Sensors: An Integral Approach with Focus on Solar and RF Energy Harvesting; Springer Science & Business Media: Berlin, Germany, 2011. [Google Scholar]

- Lu, X.; Wang, P.; Niyato, D.; Kim, D.I.; Han, Z. Wireless networks with RF energy harvesting: A contemporary survey. IEEE Commun. Surv. Tutor. 2014, 17, 757–789. [Google Scholar] [CrossRef]

- Mishra, D.; De, S.; Jana, S.; Basagni, S.; Chowdhury, K.; Heinzelman, W. Smart RF energy harvesting communications: Challenges and opportunities. IEEE Commun. Mag. 2015, 53, 70–78. [Google Scholar] [CrossRef]

- Mouapi, A.; Hakem, N. A new approach to design autonomous wireless sensor node based on RF energy harvesting system. Sensors 2018, 18, 133. [Google Scholar] [CrossRef]

- Aparicio, M.P.; Bakkali, A.; Pelegri-Sebastia, J.; Sogorb, T.; Bou, V.L. Radio frequency energy harvesting-sources and techniques. Renew. Energy Util. Syst. Integr. 2016. [Google Scholar] [CrossRef]

- Raghunathan, V.; Kansal, A.; Hsu, J.; Friedman, J.; Srivastava, M. Design considerations for solar energy harvesting wireless embedded systems. In Proceedings of the IPSN 2005. Fourth International Symposium on Information Processing in Sensor Networks, Boise, ID, USA, 15 April 2005. [Google Scholar]

- Pimentel, D.; Musilek, P.; Knight, A.; Heckenbergerova, J. Characterization of a wind flutter generator. In Proceedings of the 2010 9th International Conference on Environment and Electrical Engineering, Prague, Czech Republic, 16–19 May 2010. [Google Scholar]

- Roundy, S.; Steingart, D.; Frechette, L.; Wright, P.; Rabaey, J. Power Sources for Wireless Sensor Networks. In European Workshop on Wireless Sensor Network; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Snyman, D.B.; Enslin, J.H.R. Novel technique for improved power conversion efficiency in systems with battery back-up. Renew. Energy 1994, 4, 349–357. [Google Scholar] [CrossRef]

- Milichko, V.A.; Shalin, A.S.; Mukhin, I.S.; Kovrov, A.E.; Krasilin, A.A.; Vinogradov, A.V.; Belov, P.A.; Simovski, C.R. Solar photovoltaics: Current state and trends. Physics-Uspekhi 2016, 59, 727. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Koh, S.C.; Reaney, I.M.; Acquaye, A.; Schileo, G.; Mustapha, K.B.; Greenough, R. Perovskite solar cells: An integrated hybrid lifecycle assessment and review in comparison with other photovoltaic technologies. Renew. Sustain. Energy Rev. 2017, 80, 1321–1344. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Y.; Guo, S.; Zhou, H. Solar energy storage in the rechargeable batteries. Nano Today 2017, 16, 46–60. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Mostafavi, E.S.; Jiao, P. Next generation prediction model for daily solar radiation on horizontal surface using a hybrid neural network and simulated annealing method. Energy Convers. Manag. 2017, 153, 671–682. [Google Scholar] [CrossRef]

- Navarro, M.; Davis, T.W.; Liang, Y.; Liang, X. ASWP: A long-term WSN deployment for environmental monitoring. In Proceedings of the 12th International Conference on INFORMATION Processing in Sensor Networks, Philadelphia, PA, USA, April 2013. [Google Scholar] [CrossRef]

- Navarro, M.; Davis, T.W.; Liang, Y.; Liang, X. A study of long-term WSN deployment for environmental monitoring. In Proceedings of the 2013 IEEE 24th annual international symposium on personal, indoor, and mobile radio communications (PIMRC), London, UK, 8–11 September 2013. [Google Scholar]

- Villalba, G.; Plaza, F.; Zhong, X.; Davis, T.W.; Navarro, M.; Li, Y.; Slater, T.A.; Liang, Y.; Liang, X. A networked sensor system for the analysis of plot-scale hydrology. Sensors 2017, 17, 636. [Google Scholar] [CrossRef] [PubMed]

- Texas Instrument. Bq25570 Nano Power Boost Charger and Buck Converter for Energy Harvester Powered Applications; Texas Instrument: Dallas, TX, USA, 2015. [Google Scholar]

- Habtoor, M.S.; Rowaihy, H. Performance evaluation of IRIS and LOTUS motes when communicating in real environments. Int. J. Distrib. Sens. Netw. 2016, 12, 7347158. [Google Scholar] [CrossRef][Green Version]

- MICAz, Wireless Measurement System; Crossbow Technology Inc.: San Jose, CA, USA, 2006.

- Davis, T.W.; Liang, X.; Kuo, C.M.; Liang, Y. Analysis of power characteristics for sap flow, soil moisture and soil water potential sensors in wireless sensor networking systems. IEEE Sens. J. 2012, 12, 1933–1945. [Google Scholar] [CrossRef]

- Davis, T.W.; Liang, X.; Navarro, M.; Bhatnagar, D.; Liang, Y. An Experimental Study of WSN Power Efficiency: MICAz networks with XMesh. Spec. Issue Smart Sens. Netw. Theory Pract. Int. J. Distrib. Sens. Netw. 2012, 8, 358238. [Google Scholar] [CrossRef]

- MDA300CA, MICA2 Data Acquistion Board; Crossbow Technology Inc.: San Jose, CA, USA, 2007.

| Model | Leakage Current (pA) | |

|---|---|---|

| 1st Sample | 2nd Sample | |

| TN5325N3 | 300 | 400 |

| BS270FS | 20 | 300 |

| ZVN2110A | 30 | 30 |

| Model | Voltage Drop (V) | Ileakage (nA) | ||

|---|---|---|---|---|

| 1 klx | 10 klx | 100 klx | 100 klx | |

| BAX16 | 0.59/0.58 | 0.72/0.71 | 0.82/0.81 | 4.72/3.78 |

| 1N4148FS | 0.62/0.61 | 0.73/0.73 | 0.82/0.82 | 3.12/3.03 |

| 1N4149 | 0.62/0.61 | 0.73/0.73 | 0.82/0.82 | 2.92/2.79 |

| FDH333 | 0.68/0.68 | 0.79/0.79 | 0.85/0.85 | 0.03/0.03 |

| Actual Resistors | Corresponding Voltages | ||

|---|---|---|---|

| ROV1 | 1.00 MΩ | VBAT_OV | 3.72 V |

| ROV2 | 1.05 MΩ | ||

| ROK1 | 2.00 MΩ | VBAT_OK VBAT_OK_HYST | 3.03 V 3.63 V |

| ROK2 | 3.00 MΩ | ||

| ROK3 | 1.00 MΩ | ||

| ROUT1 | 1.00 MΩ | VOUT | 2.90 V |

| ROUT2 | 1.40 MΩ | ||

| Operation | IRIS | MicaZ | ||

|---|---|---|---|---|

| Current Consumption (mA) | Duration (ms) | Current Consumption (mA) | Duration (ms) | |

| Sensor Sampling w/o external sensors | 6.3 | 341.8 | 6.8 | 337.0 |

| Sensor Sampling w/external sensors | 59.1 | 341.8 | 91.8 | 337.0 |

| Data Packet Transmission | 6.5 | 1.5 | 9.2 | 2.4 |

| Data Packet Reception | 21.1 | 23.6 | 22.7 | 24.0 |

| Idle Listening | 19.1 | 5.4 | 23.3 | 3.7 |

| Sleep (Relay/Reg.) | 0.1/1.0 | N/A | 0.3/1.1 | N/A |

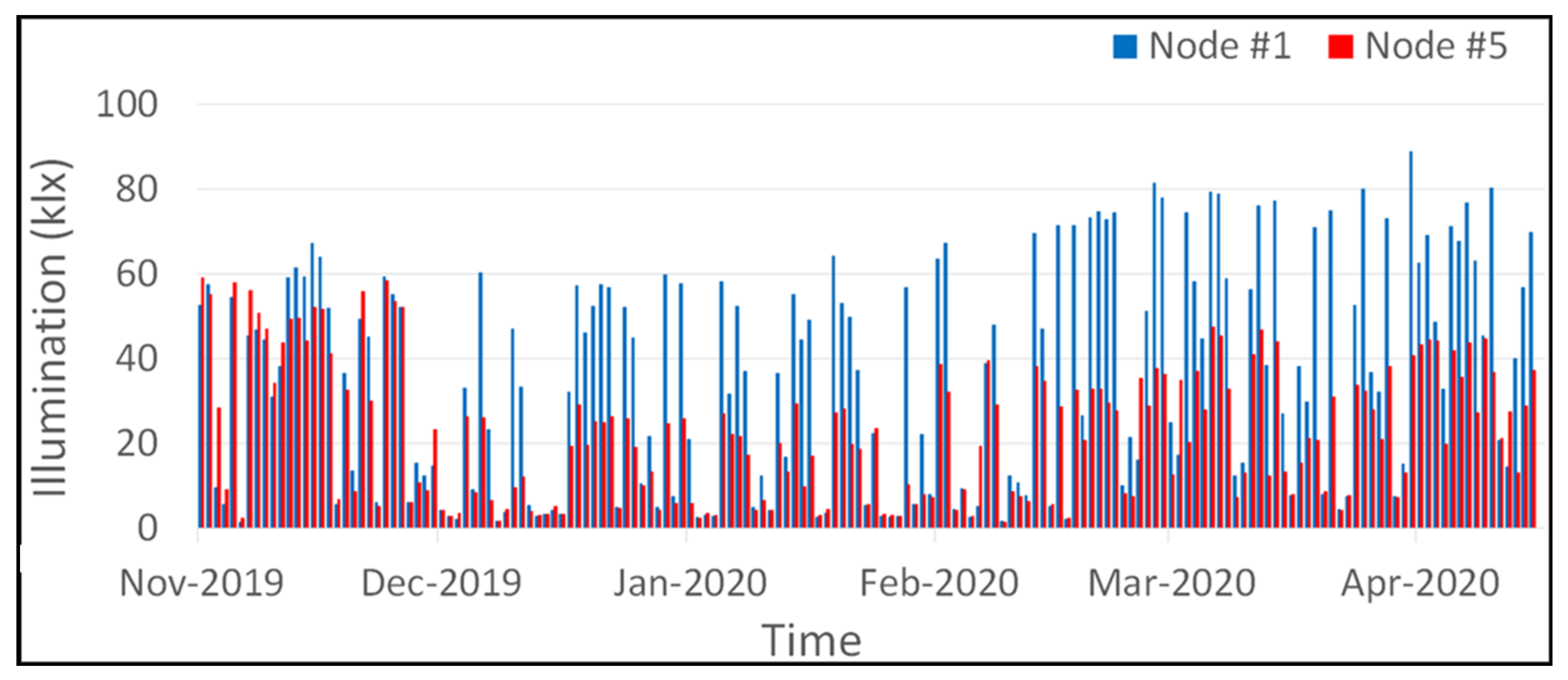

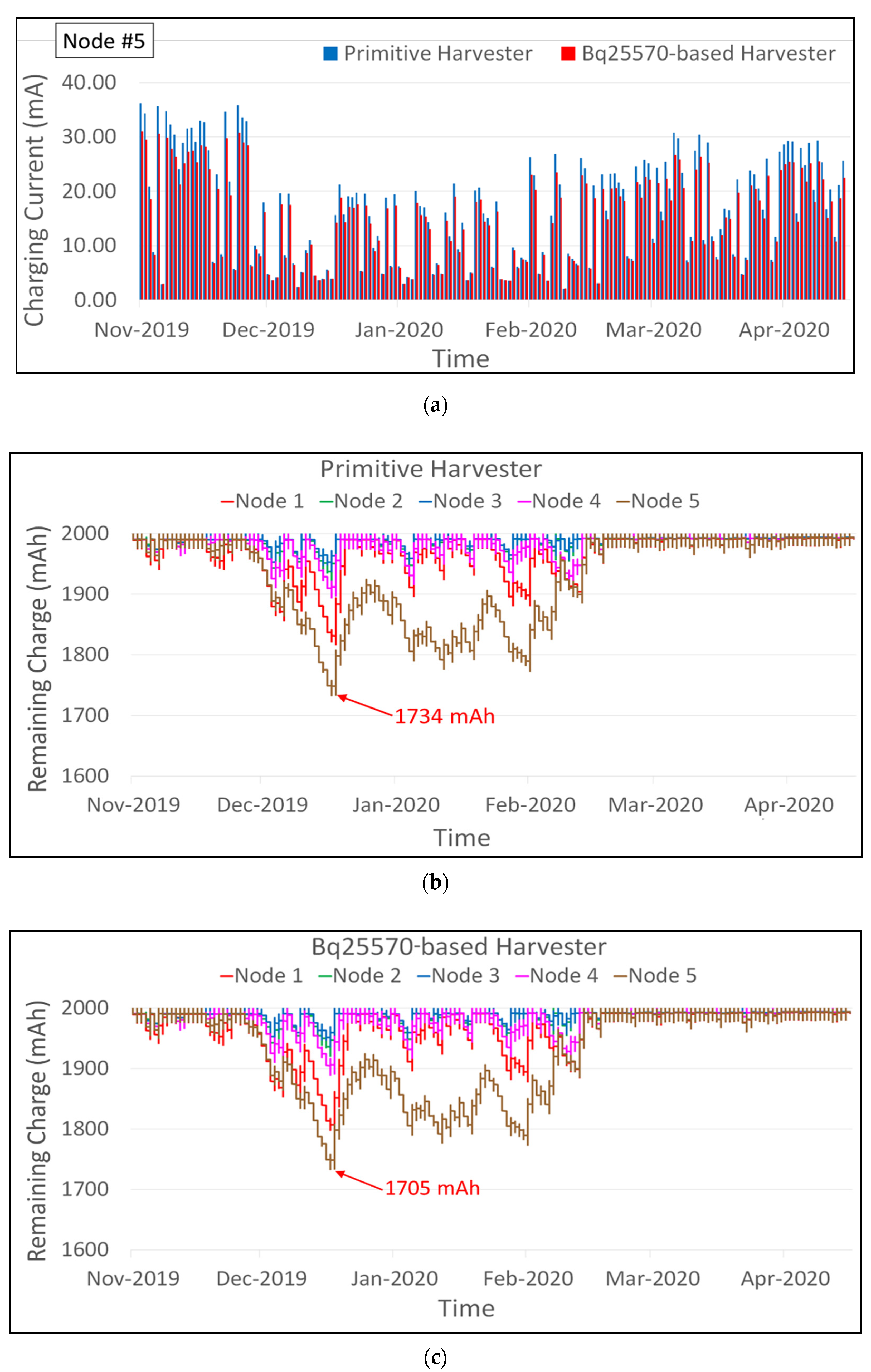

| Node | Illumination (Lux) | Avg. Charging Current (mA) | Max. Charging Current (mA) | Min. Remaining Battery Charge (mAh) | ||||

|---|---|---|---|---|---|---|---|---|

| Avg. | Max | Primitive | Bq25570 | Primitive | Bq25570 | Primitive | Bq25570 | |

| #1 | 3161 | 88,760 | 2.61 | 2.42 | 49.0 | 41.1 | 1818 | 1793 |

| #2 | 4814 | 85,852 | 3.86 | 3.54 | 47.8 | 40.1 | 1923 | 1921 |

| #3 | 3969 | 75,796 | 3.38 | 3.13 | 43.5 | 36.8 | 1938 | 1937 |

| #4 | 3627 | 77,087 | 3.05 | 2.83 | 44.1 | 37.2 | 1895 | 1890 |

| #5 | 2505 | 59,105 | 2.27 | 2.14 | 36.1 | 31.0 | 1734 | 1705 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Hamed, E.A.; Zhang, X.; Luna, D.; Lin, J.-S.; Liang, X.; Lee, I. Feasibility of Harvesting Solar Energy for Self-Powered Environmental Wireless Sensor Nodes. Electronics 2020, 9, 2058. https://doi.org/10.3390/electronics9122058

Li Y, Hamed EA, Zhang X, Luna D, Lin J-S, Liang X, Lee I. Feasibility of Harvesting Solar Energy for Self-Powered Environmental Wireless Sensor Nodes. Electronics. 2020; 9(12):2058. https://doi.org/10.3390/electronics9122058

Chicago/Turabian StyleLi, Yuyang, Ehab A. Hamed, Xincheng Zhang, Daniel Luna, Jeen-Shang Lin, Xu Liang, and Inhee Lee. 2020. "Feasibility of Harvesting Solar Energy for Self-Powered Environmental Wireless Sensor Nodes" Electronics 9, no. 12: 2058. https://doi.org/10.3390/electronics9122058

APA StyleLi, Y., Hamed, E. A., Zhang, X., Luna, D., Lin, J.-S., Liang, X., & Lee, I. (2020). Feasibility of Harvesting Solar Energy for Self-Powered Environmental Wireless Sensor Nodes. Electronics, 9(12), 2058. https://doi.org/10.3390/electronics9122058