Influence of Si Substrate Preparation Procedure on Polarity of Self-Assembled GaN Nanowires on Si(111): Kelvin Probe Force Microscopy Studies

Abstract

1. Introduction

2. Experiment

3. Results and Discussion

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ng, H.M.; Cho, A.Y. Investigation of Si doping and impurity incorporation dependence on the polarity of GaN by molecular beam epitaxy. J. Vac. Sci. Technol. B 2002, 20, 1217–1220. [Google Scholar] [CrossRef]

- Tuomisto, F.; Saarinen, K.; Lucznik, B.; Grzegory, I.; Teisseyre, H.; Suski, T.; Porowski, S.; Hageman, P.R.; Likonen, J. Effect of growth polarity on vacancy defect and impurity incorporation in dislocation-free GaN. Appl. Phys. Lett. 2005, 86, 031915. [Google Scholar] [CrossRef]

- Li, S.F.; Wang, X.; Fundling, S.; Erenburg, M.; Ledig, J.; Wei, J.D.; Wehmann, H.H.; Waag, A.; Bergbauer, W.; Mandl, M.; et al. Nitrogen-polar core-shell GaN light-emitting diodes grown by selective area metalorganic vapor phase epitaxy. Appl. Phys. Lett. 2012, 101, 032103. [Google Scholar] [CrossRef]

- Tang, H.; Haffouz, S.; Bardwell, J.A. Si(111) substrates as highly effective pseudomasks for selective growth of GaN material and devices by ammonia-molecular-beam epitaxy. Appl. Phys. Lett. 2006, 88, 172110. [Google Scholar] [CrossRef]

- Losurdo, M.; Giangregorio, M.M.; Capezzuto, P.; Bruno, G.; Namkoong, G.; Doolittle, W.A.; Brown, A.S. Interplay between GaN polarity and surface reactivity towards atomic hydrogen. J. Appl. Phys. 2004, 95, 8408–8418. [Google Scholar] [CrossRef]

- Mastro, M.A.; Kryliouk, O.M.; Anderson, T.J.; Davydov, A.; Shapiro, A. Influence of polarity on GaN thermal stability. J. Cryst. Growth 2005, 274, 38–46. [Google Scholar] [CrossRef]

- Monroy, E.; Sarigiannidou, E.; Fossard, F.; Gogneau, N.; Bellet-Amalric, E.; Rouvière, J.-L.; Monnoye, S.; Mank, H.; Daudin, B. Growth kinetics of N-face polarity GaN by plasma-assisted molecular beam epitaxy. Appl. Phys. Lett. 2004, 84, 3684–3686. [Google Scholar] [CrossRef]

- Fernández-Garrido, S.; Kong, X.; Gotschke, T.; Calarco, R.; Geelhaar, L.; Trampert, A.; Brandt, O. Spontaneous Nucleation and Growth of GaN Nanowires: The Fundamental Role of Crystal Polarity. Nano Lett. 2012, 12, 6119–6125. [Google Scholar] [CrossRef]

- Carnevale, S.D.; Kent, T.F.; Phillips, P.J.; Sarwar, A.T.M.G.; Selcu, C.; Klie, R.F.; Myers, R.C. Mixed Polarity in Polarization-Induced p−n Junction Nanowire Light-Emitting Diodes. Nano Lett. 2013, 13, 3029–3035. [Google Scholar] [CrossRef]

- Ambacher, O.; Smart, J.; Shealy, J.R.; Weimann, N.G.; Chu, K.; Murphy, M.; Schaff, W.J.; Eastman, L.F. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in N- and Ga-face AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 85, 3222–3233. [Google Scholar] [CrossRef]

- Alloing, B.; Vézian, S.; Tottereau, O.; Vennéguès, P.; Beraudo, E.; Zúñiga-Pérez, J. On the polarity of GaN micro- and nanowires epitaxially grown on sapphire (0001) and Si(111) substrates by metal organic vapor phase epitaxy and ammoniamolecular beam epitaxy. Appl. Phys. Lett. 2011, 98, 011914. [Google Scholar] [CrossRef]

- Bertness, K.A.; Memberaaa, S.; Sanford, N.A.; Davydov, A.V. GaN Nanowires Grown by Molecular Beam Epitaxy. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 847–858. [Google Scholar] [CrossRef]

- Geelhaar, L.; Chèze, C.; Jenichen, B.; Brandt, O.; Pfüller, C.; Münch, S.; Rothemund, R.; Reitzenstein, S.; Forchel, A.; Kehagias, T.; et al. Properties of GaN Nanowires Grown by Molecular Beam Epitaxy. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 878–888. [Google Scholar] [CrossRef]

- Carnevale, S.D.; Yang, J.; Phillips, P.J.; Mills, M.J.; Myers, R.C. Three-Dimensional GaN/AlN Nanowire Heterostructures by Separating Nucleation and Growth Processes. Nano Lett. 2011, 11, 866–871. [Google Scholar] [CrossRef]

- Trampert, A.; Ristić, J.; Jahn, U.; Calleja, E.; Ploog, K.H. TEM study of (Ga,Al)N nanocolumns and embedded GaN nanodiscs. Microsc. Semicond. Mater. 2003, 180, 167–170. [Google Scholar]

- Fernández-Garrido, S.; Grandal, J.; Calleja, E.; Sánchez-García, M.A.; López-Romero, D. A growth diagram for plasma-assisted molecular beam epitaxy of GaN nanocolumns on Si(111). J. Appl. Phys. 2009, 106, 126102. [Google Scholar] [CrossRef]

- Wierzbicka, A.; Zytkiewicz, Z.R.; Kret, S.; Borysiuk, J.; Dluzewski, P.; Sobanska, M.; Klosek, K.; Reszka, A.; Tchutchulashvili, G.; Cabaj, A.; et al. Influence of substrate nitridation temperature on epitaxial alignment of GaN nanowires to Si(111) substrate. Nanotechnology 2013, 24, 035703. [Google Scholar] [CrossRef]

- Sobanska, M.; Wierzbicka, A.; Klosek, K.; Borysiuk, J.; Tchutchulashvili, G.; Gieraltowska, S.; Zytkiewicz, Z.R. Arrangement of GaN nanowires grown by plasma-assisted molecular beam epitaxy on silicon substrates with amorphous Al2O3 buffers. J. Cryst. Growth 2014, 401, 657–660. [Google Scholar] [CrossRef]

- Borysiuk, J.; Zytkiewicz, Z.R.; Sobanska, M.; Wierzbicka, A.; Klosek, K.; Korona, K.P.; Perkowska, P.S.; Reszka, A. Growth by molecular beam epitaxy and properties of inclined GaN nanowires on Si(001) substrate. Nanotechnology 2014, 25, 135610. [Google Scholar] [CrossRef] [PubMed]

- Concordel, A.; Jacopin, G.; Gayral, B.; Garro, N.; Cros, A.; Rouviere, J.-L.; Daudin, B. Polarity conversion of GaN nanowires grown by plasma-assisted molecular beam epitaxy. Appl. Phys. Lett. 2019, 114, 172101. [Google Scholar] [CrossRef]

- Zhao, B.; Lockrey, M.N.; Caroff, P.; Wang, N.; Li, L.; Wong-Leung, J.; Tan, H.H.; Jagadish, C. The effect of nitridation on the polarity and optical properties of GaN self-assembled nanorods. Nanoscale 2018, 10, 11205. [Google Scholar] [CrossRef]

- Hetzl, M.; Kraut, M.; Hoffmann, T.; Stutzmann, M. Polarity Control of Heteroepitaxial GaN Nanowires on Diamond. Nano Lett. 2017, 17, 3582–3590. [Google Scholar] [CrossRef]

- de Souza Schiaber, Z.; Calabrese, G.; Kong, X.; Trampert, A.; Jenichen, B.; Dias da Silva, J.H.; Geelhaar, L.; Brandt, O.; Fernández-Garrido, S. Polarity-Induced Selective Area Epitaxy of GaN Nanowires. Nano Lett. 2017, 17, 63–70. [Google Scholar] [CrossRef]

- Green, D.S.; Haus, E.; Wu, F.; Chen, L.; Mishra, U.K.; Speck, J.S. Polarity control during molecular beam epitaxy growth of Mg-doped GaN. J. Vac. Sci. Technol. B 2003, 21, 1804. [Google Scholar] [CrossRef]

- Pezzagna, S.; Vennegues, P.; Grandjean, N.; Massies, J. Polarity inversion of GaN (0001) by a high Mg doping. J. Cryst. Growth 2004, 269, 249–256. [Google Scholar] [CrossRef]

- Rosa, A.; Neugebauer, J. Polarity inversion of GaN (0001) surfaces induced by Si adsorption. Surf. Sci. 2006, 600, 335–339. [Google Scholar] [CrossRef]

- Kong, X.; Li, H.; Albert, S.; Bengoechea-Encabo, A.; Sanchez-Garcia, M.A.; Calleja, E.; Draxl, C.; Trampert, A. Titanium induced polarity inversion in ordered (In,Ga)N/GaN nanocolumns. Nanotechnology 2016, 27, 065705. [Google Scholar] [CrossRef]

- Mohn, S.; Stolyarchuk, N.; Markurt, T.; Kirste, R.; Hoffmann, M.P.; Collazo, R.; Courville, A.; Di Felice, R.; Sitar, Z.; Vennéguès, P.; et al. Polarity Control in Group-III Nitrides beyond Pragmatism. Phys. Rev. Appl. 2016, 5, 054004. [Google Scholar] [CrossRef]

- Roshko, A.; Brubaker, M.; Blanchard, P.; Harvey, T.; Bertness, K. The role of Si in GaN/AlN/Si(111) plasma assisted molecular beam epitaxy: Polarity and inversion. Jpn. J. Appl. Phys. 2019, 58, SC1050. [Google Scholar] [CrossRef]

- Roshko, A.; Brubaker, M.D.; Blanchard, P.T.; Harvey, T.E.; Bertness, K.A. Eutectic Formation, V/III Ratio, and Controlled Polarity Inversion in Nitrides on Silicon. Phys. Status Solidi B 2020, 257, 1900611. [Google Scholar] [CrossRef]

- Zúñiga-Pérez, J.; Consonni, V.; Lymperakis, L.; Kong, X.; Trampert, A.; Fernández-Garrido, S.; Brandt, O.; Renevier, H.; Keller, S.; Hestroffer, K.; et al. Polarity in GaN and ZnO: Theory, measurement, growth, and devices. Appl. Phys. Rev. 2016, 3, 041303. [Google Scholar] [CrossRef]

- Minj, A.; Cros, A.; Garro, N.; Colchero, J.; Auzelle, T.; Daudin, B. Assessment of Polarity in GaN Self-Assembled Nanowires by Electrical Force Microscopy. Nano Lett. 2015, 15, 6770–6776. [Google Scholar] [CrossRef]

- Sobanska, M.; Klosek, K.; Borysiuk, J.; Kret, S.; Tchutchulasvili, G.; Gieraltowska, S.; Zytkiewicz, Z.R. Enhanced catalyst-free nucleation of GaN nanowires on amorphous Al2O3 by plasma-assisted molecular beam epitaxy. J. Appl. Phys. 2014, 115, 043517. [Google Scholar] [CrossRef]

- Sobanska, M.; Korona, K.P.; Zytkiewicz, Z.R.; Klosek, K.; Tchutchulashvili, G. Kinetics of self-induced nucleation and optical properties of GaN nanowires grown by plasma-assisted molecular beam epitaxy on amorphous AlxOy. J. Appl. Phys. 2015, 118, 184303. [Google Scholar] [CrossRef]

- Klosek, K.; Sobanska, M.; Tchutchulashvili, G.; Zytkiewicz, Z.R.; Teisseyre, H.; Klopotowski, L. Optimization of nitrogen plasma source parameters by measurements of emitted light intensity for growth of GaN by molecular beam epitaxy. Thin Solid Films 2013, 534, 107–110. [Google Scholar] [CrossRef]

- Ino, S. Some New Techniques in Reflection High Energy Electron Diffraction (RHEED) Application to Surface Structure Studies. Jpn. J. Appl. Phys. 1977, 16, 891–908. [Google Scholar] [CrossRef]

- Osakabe, N.; Yagi, K.; Honjo, G. Reflection Electron Microscope Observations of Dislocations and Surface Structure Phase Transition on Clean (111) Silicon Surfaces. Jpn. J. Appl. Phys. 1980, 19, L309–L312. [Google Scholar] [CrossRef]

- Cheze, C.; Geelhaar, L.; Trampert, A.; Riechert, H. In situ investigation of self-induced GaN nanowire nucleation on Si. Appl. Phys. Lett. 2010, 97, 043101. [Google Scholar] [CrossRef]

- Consonni, V.; Hanke, M.; Knelangen, M.; Geelhaar, L.; Trampert, A.; Riechert, H. Nucleation mechanisms of self-induced GaN nanowires grown on an amorphous interlayer. Phys. Rev. B 2011, 83, 035310. [Google Scholar] [CrossRef]

- Fernández-Garrido, S.; Zettler, J.K.; Geelhaar, L.; Brandt, O. Monitoring the Formation of Nanowires by Line-of-Sight Quadrupole Mass Spectrometry: A Comprehensive Description of the Temporal Evolution of GaN Nanowire Ensembles. Nano Lett. 2015, 15, 1930–1937. [Google Scholar] [CrossRef]

- Sobanska, M.; Fernández-Garrido, S.; Zytkiewicz, Z.R.; Tchutchulashvili, G.; Gieraltowska, S.; Brandt, O.; Geelhaar, L. Self-assembled growth of GaN nanowires on amorphous AlxOy: From nucleation to the formation of dense nanowire ensembles. Nanotechnology 2016, 27, 325601. [Google Scholar] [CrossRef]

- Gieraltowska, S.; Wachnicki, L.; Witkowski, B.S.; Mroczynski, R.; Dluzewski, P.; Godlewski, M. Characterization of dielectric layers grown at low temperature by atomic layer deposition. Thin Solid Films 2015, 577, 97–102. [Google Scholar] [CrossRef]

- Colchero, J.; Gil, A.; Baró, A.M. Resolution enhancement and improved data interpretation in electrostatic force microscopy. Phys. Rev. B 2001, 64, 245403. [Google Scholar] [CrossRef]

- Palacios-Lidón, E.; Abellán, J.; Colchero, J.; Munuera, C.; Ocal, C. Quantitative electrostatic force microscopy on heterogeneous nanoscale samples. Appl. Phys. Lett. 2005, 87, 154106. [Google Scholar] [CrossRef]

- Rodriguez, B.J.; Yang, W.-C.; Nemanich, R.J.; Gruverman, A. Scanning probe investigation of surface charge and surface potential of GaN-based heterostructures. Appl. Phys. Lett. 2005, 86, 112115. [Google Scholar] [CrossRef]

- Hestroffer, K.; Leclere, C.; Bougerol, C.; Renevier, H.; Daudin, B. Polarity of GaN nanowires grown by plasma-assisted molecular beam epitaxy on Si(111). Phys. Rev. B 2011, 84, 245302. [Google Scholar] [CrossRef]

- Hestroffer, K.; Daudin, B. A RHEED investigation of self-assembled GaN nanowire nucleation dynamics on bare Si and on Si covered with a thin AlN buffer layer. Phys. Status Solidi RRL 2013, 7, 835–839. [Google Scholar] [CrossRef]

- Largeau, L.; Dheeraj, D.L.; Tchernycheva, M.; Cirlin, G.E.; Harmand, J.C. Facet and in-plane crystallographic orientations of GaN nanowires grown on Si(111). Nanotechnology 2008, 19, 155704. [Google Scholar] [CrossRef]

- Furtmayr, F.; Vielemeyer, M.; Stutzmann, M.; Arbiol, J.; Estradé, S.; Peirò, F.; Morante, J.R.; Eickhoff, M. Nucleation and growth of GaN nanorods on Si(111) surfaces by plasma-assisted molecular beam epitaxy—The influence of Si- and Mg-doping. J. Appl. Phys. 2008, 104, 034309. [Google Scholar] [CrossRef]

- Furtmayr, F.; Vielemeyer, M.; Stutzmann, M.; Laufer, A.; Meyer, B.K.; Eickhoff, M. Optical properties of Si- and Mg-doped gallium nitride nanowires grown by plasma-assisted molecular beam epitaxy. J. Appl. Phys. 2008, 104, 074309. [Google Scholar] [CrossRef]

- Morita, Y.; Miki, K.; Tokumoto, H. Atomic Structure of Hydrogen-Terminated Si(111) Surfaces by Hydrofluoric Acid Treatments. Jpn. J. Appl. Phys. 1991, 30, 3570–3574. [Google Scholar] [CrossRef]

- Thornton, J.M.C.; Williams, R.H. A photoemission study of passivated silicon surfaces produced by etching in solutions of HF. Semicond. Sci. Technol. 1989, 4, 847. [Google Scholar] [CrossRef]

- Takahagi, T.; Nagai, I.; Ishitani, A.; Kuroda, H.; Nagasawa, Y. The formation of hydrogen passivated silicon single-crystal surfaces using ultraviolet cleaning and HF etching. J. Appl. Phys. 1988, 64, 3516. [Google Scholar] [CrossRef]

- Thornton, J.M.C.; Williams, R.H. An S/XPS study of hydrogen terminated, ordered silicon (100) and (111) surfaces prepared by chemical etching. Phys. Scr. 1990, 41, 1047. [Google Scholar] [CrossRef]

- Miki, K.; Sakamoto, K.; Sakamoto, T. Surface preparation of Si substrates for epitaxial growth. Surf. Sci. 1998, 406, 312–327. [Google Scholar] [CrossRef]

- Wierzbicka, A.; Tchutchulashvili, G.; Sobanska, M.; Klosek, K.; Minikayev, R.; Domagala, J.Z.; Borysiuk, J.; Zytkiewicz, Z.R. Arrangement of GaN nanowires on Si(001) substrates studied by X-ray diffraction: Importance of silicon nitride interlayer. Appl. Surf. Sci. 2017, 425, 1014–1019. [Google Scholar] [CrossRef]

- Wright, S.; Kroemer, H. Reduction of oxides on silicon by heating in a gallium molecular beam at 800 °C. Appl. Phys. Lett. 1980, 36, 210. [Google Scholar] [CrossRef]

- Chin, C.W.; Yam, F.K.; Beh, K.P.; Hassan, Z.; Ahmad, M.A.; Yusof, Y.; Mohd Bakhori, S.K. The growth of heavily Mg-doped GaN thin film on Si substrate by molecular beam epitaxy. Thin Solid Films 2011, 520, 756–760. [Google Scholar] [CrossRef]

- Limbach, F.; Caterino, R.; Gotschke, T.; Stoica, T.; Calarco, R.; Geelhaar, L.; Riechert, H. The influence of Mg doping on the nucleation of self-induced GaN nanowires. AIP Adv. 2012, 2, 012157. [Google Scholar] [CrossRef]

- Hussein, A.S.; Thahab, S.M.; Hassan, Z.; Chin, C.W.; Abu Hassan, H.; Ng, S.S. High Al-content AlxGa1−xN epilayers grown on Si substrate by plasma-assisted molecular beam epitaxy. J. Alloys Compd. 2009, 487, 24–27. [Google Scholar] [CrossRef]

- Lee, J.H.; Wang, Z.M.; Salamo, G.J. Ga-triggered oxide desorption from GaAs (100) and non-(100) substrates. Appl. Phys. Lett. 2006, 88, 252108. [Google Scholar] [CrossRef]

- Wasilewski, Z.R.; Baribeau, J.-M.; Beaulieu, M.; Wu, X.; Sproule, G.I. Studies of oxide desorption from GaAs substrates via Ga2O3 to Ga2O conversion by exposure to Ga flux. J. Vac. Sci. Technol. B 2004, 22, 1534. [Google Scholar] [CrossRef]

- Kern, W.; Puotinen, D.A. Cleaning solutions based on hydrogen peroxide for use in silicon semiconductor technology. RCA Rev. 1970, 31, 187–206. [Google Scholar]

- Ishizaka, A.; Shiraki, Y. Low Temperature Surface Cleaning of Silicon and Its Application to Silicon MBE. J. Electrochem. Soc. 1986, 133, 666. [Google Scholar] [CrossRef]

- Eftychis, S.; Kruse, J.; Koukoula, T.; Kehagias, T.; Komninou, P.; Adikimenakis, A.; Tsagaraki, K.; Androulidaki, M.; Tzanetakis, P.; Iliopoulos, E.; et al. Understanding the effects of Si(111) nitridation on the spontaneous growth and properties of GaN nanowires. J. Cryst. Growth 2016, 442, 8–13. [Google Scholar] [CrossRef]

- Calleja, E.; Sánchez-García, M.A.; Sánchez, F.J.; Calle, F.; Naranjo, F.B.; Muñoz, E.; Molina, S.I.; Sánchez, A.M.; Pacheco, F.J.; García, R. Growth of III-nitrides on Si(111) by molecular beam epitaxy Doping, optical, and electrical properties. J. Cryst. Growth 1999, 201/202, 296–317. [Google Scholar] [CrossRef]

- Mohd Yusoff, M.Z.; Hassan, Z.; Chin, C.W.; Abu Hassan, H.; Abdullah, M.J.; Ahmad, M.A.; Yusof, Y. Fabrication of GaN homo-junction on Si(111) substrate for sensor applications. J. Mol. Eng. Mater. 2013, 1, 1250006. [Google Scholar] [CrossRef]

- Kern, W. The Evolution of Silicon Wafer Cleaning Technology. J. Electrochem. Soc. 1990, 137, 1887. [Google Scholar] [CrossRef]

- Sobanska, M.; Zytkiewicz, Z.R.; Klosek, K.; Kruszka, R.; Golaszewska, K.; Ekielski, M.; Gieraltowska, S. Selective area formation of GaN nanowires on GaN substrates by the use of amorphous AlxOy nucleation layer. Nanotechnology 2020, 31, 184001. [Google Scholar] [CrossRef]

- Sobanska, M.; Zytkiewicz, Z.R.; Ekielski, M.; Klosek, K.; Sokolovskii, A.S.; Dubrovskii, V.G. Surface Diffusion of Gallium as the Origin of Inhomogeneity in Selective Area Growth of GaN Nanowires on AlxOy Nucleation Stripes. Cryst. Growth Des. 2020, 20, 4770–4778. [Google Scholar] [CrossRef]

- Sobanska, M.; Zytkiewicz, Z.R.; Calabrese, G.; Geelhaar, L.; Fernández-Garrido, S. Comprehensive analysis of the self-assembled formation of GaN nanowires on amorphous AlxOy: In situ quadrupole mass spectrometry studies. Nanotechnology 2019, 30, 154002. [Google Scholar] [CrossRef] [PubMed]

- Sobanska, M.; Dubrovskii, V.G.; Tchutchulashvili, G.; Klosek, K.; Zytkiewicz, Z.R. Analysis of Incubation Times for the Self-Induced Formation of GaN Nanowires: Influence of the Substrate on the Nucleation Mechanism. Cryst. Growth Des. 2016, 16, 7205–7211. [Google Scholar] [CrossRef]

- Corfdir, P.; Hauswald, C.; Zettler, J.K.; Flissikowski, T.; Lähnemann, J.; Fernández-Garrido, S.; Geelhaar, L.; Grahn, H.T.; Brandt, O. Stacking faults as quantum wells in nanowires: Density of states, oscillator strength, and radiative efficiency. Phys. Rev. B 2014, 90, 195309. [Google Scholar] [CrossRef]

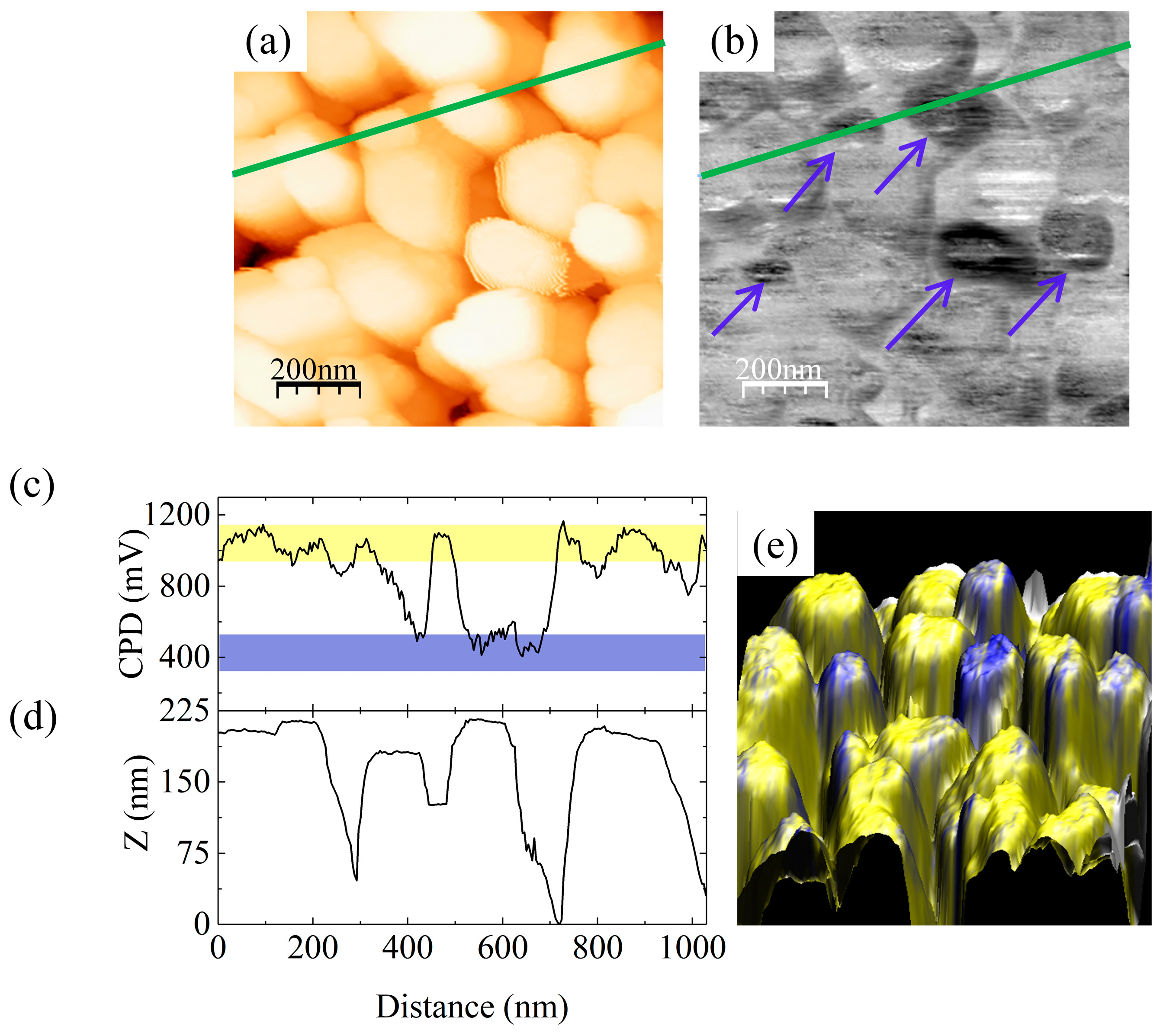

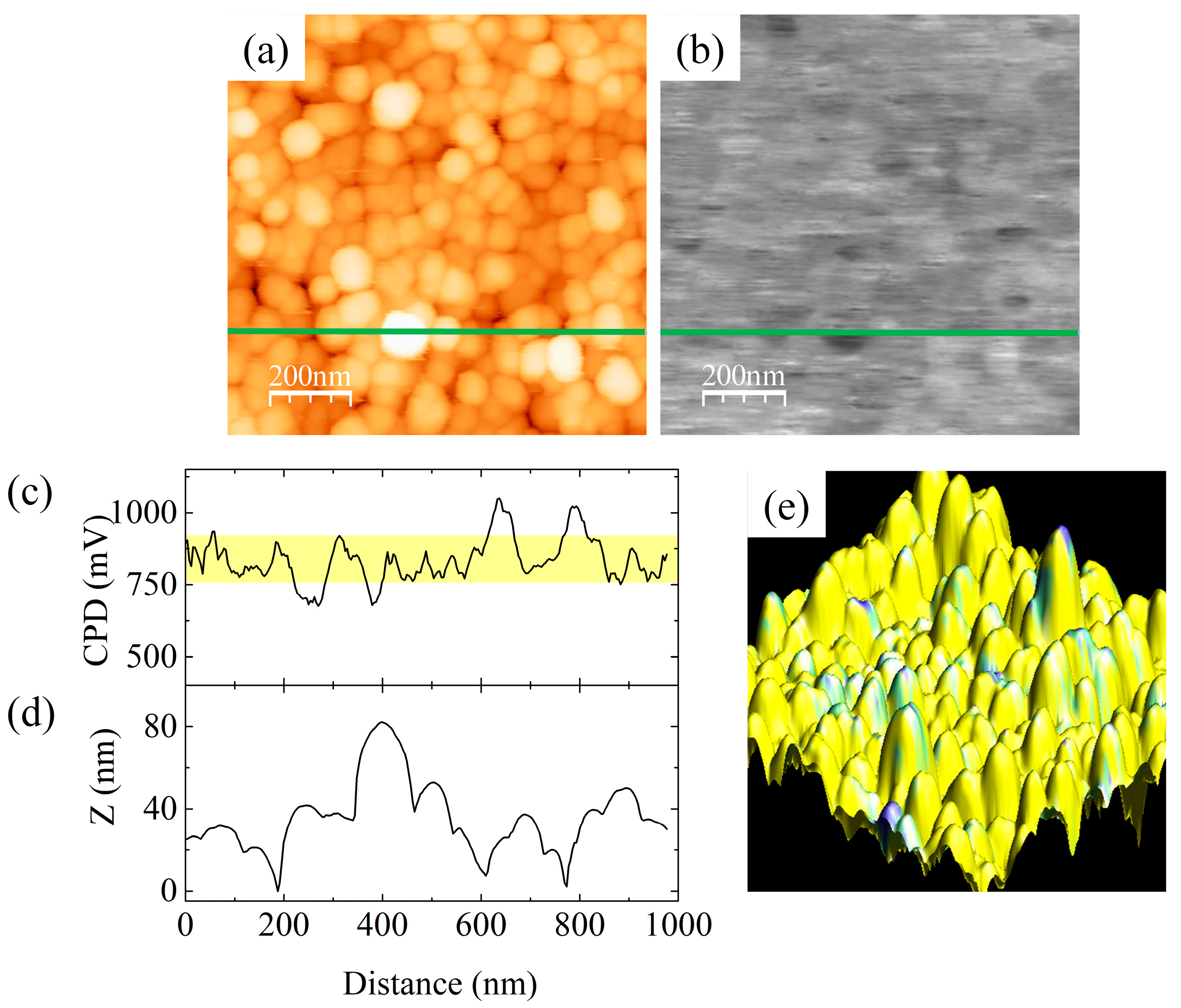

| Sample | Description of Si Substrate Processing Procedure | % of Ga-Polar NWs |

|---|---|---|

| A | Aqueous HF dip followed by thermal desorption of hydrogen passivation in the growth chamber at ~700 °C | 18% Ga-polar (125 NWs tested) |

| B | RCA clean followed by thermal removal of silicon oxide in the growth chamber at ~950 °C for 10 min | 4% Ga polar (50 NWs tested) |

| C | Procedure as for sample B followed by 2 × Ga-induced deoxidation steps in the growth chamber | <3% Ga-polar (180 NWs tested) |

| D | Thermal oxide desorption in UHV at ~1000 °C for 10 min followed by 2 × Ga-induced deoxidation steps as for sample C | 0% Ga-polar (225 NWs tested) |

| E | Thermal native oxide desorption in the growth chamber at ~1000 °C for 10 min | 0% Ga-polar (120 NWs tested) |

| F | Aqueous HF dip as for sample A followed by transfer in air to the ALD system for deposition of AlOy buffer | 0% Ga-polar (>400 NWs tested) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobanska, M.; Garro, N.; Klosek, K.; Cros, A.; Zytkiewicz, Z.R. Influence of Si Substrate Preparation Procedure on Polarity of Self-Assembled GaN Nanowires on Si(111): Kelvin Probe Force Microscopy Studies. Electronics 2020, 9, 1904. https://doi.org/10.3390/electronics9111904

Sobanska M, Garro N, Klosek K, Cros A, Zytkiewicz ZR. Influence of Si Substrate Preparation Procedure on Polarity of Self-Assembled GaN Nanowires on Si(111): Kelvin Probe Force Microscopy Studies. Electronics. 2020; 9(11):1904. https://doi.org/10.3390/electronics9111904

Chicago/Turabian StyleSobanska, Marta, Núria Garro, Kamil Klosek, Ana Cros, and Zbigniew R. Zytkiewicz. 2020. "Influence of Si Substrate Preparation Procedure on Polarity of Self-Assembled GaN Nanowires on Si(111): Kelvin Probe Force Microscopy Studies" Electronics 9, no. 11: 1904. https://doi.org/10.3390/electronics9111904

APA StyleSobanska, M., Garro, N., Klosek, K., Cros, A., & Zytkiewicz, Z. R. (2020). Influence of Si Substrate Preparation Procedure on Polarity of Self-Assembled GaN Nanowires on Si(111): Kelvin Probe Force Microscopy Studies. Electronics, 9(11), 1904. https://doi.org/10.3390/electronics9111904