Comprehensive Study on Dynamic Parameters of Symmetric and Asymmetric Ultracapacitors

Abstract

:1. Introduction

2. Experimental Setup and Methods

2.1. Charge–Discharge Cycling

2.2. EIS Measurements

3. Results

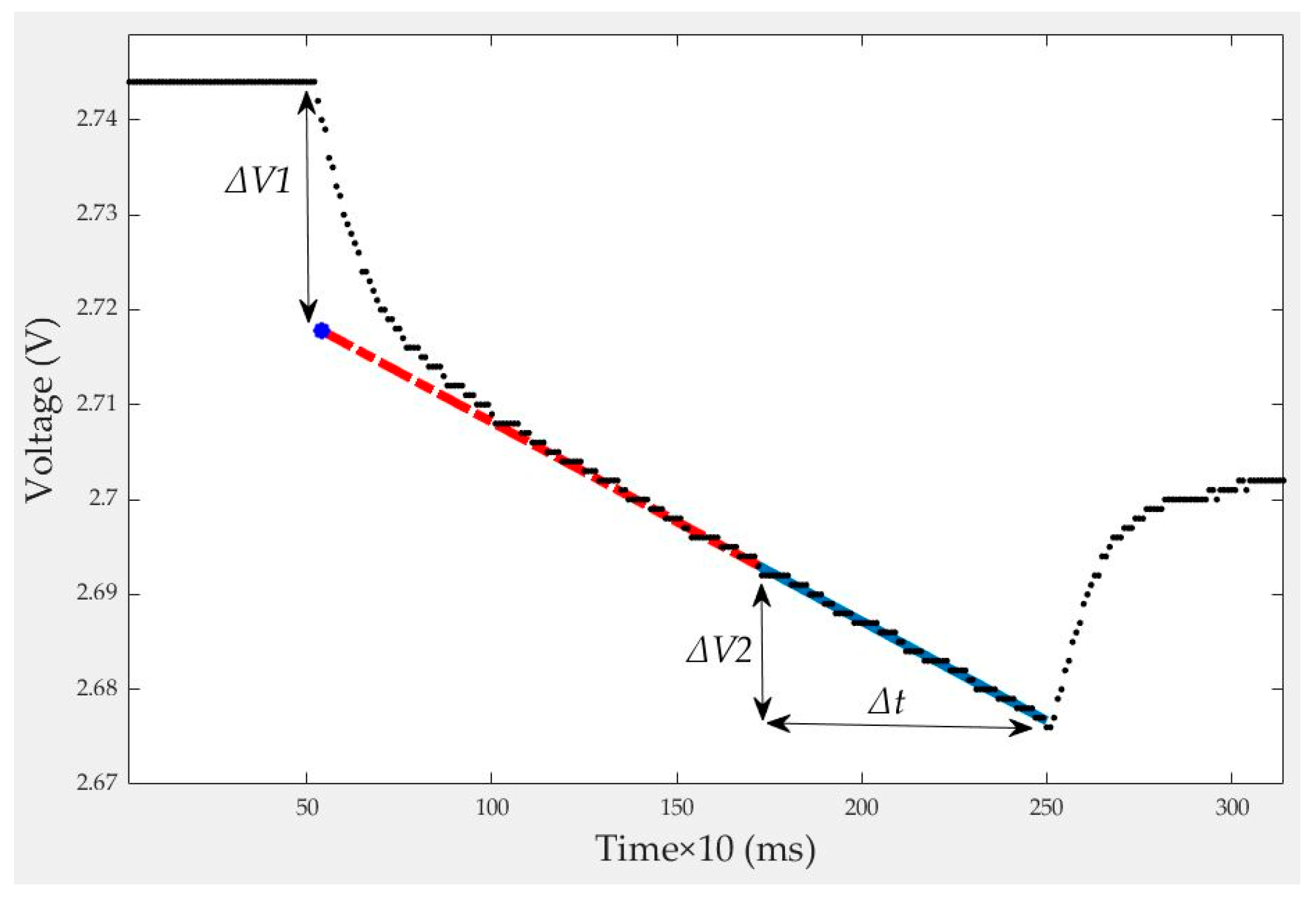

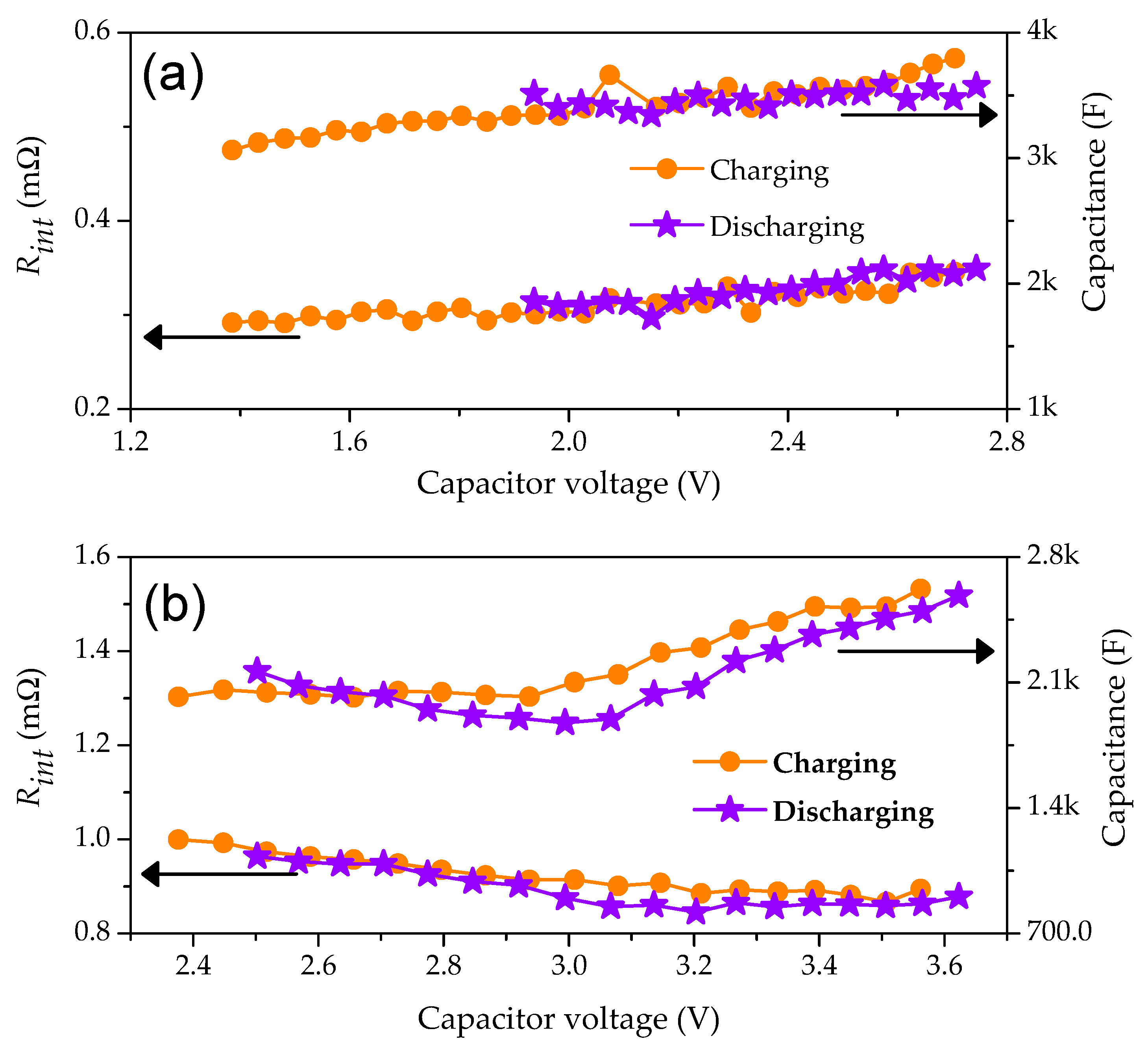

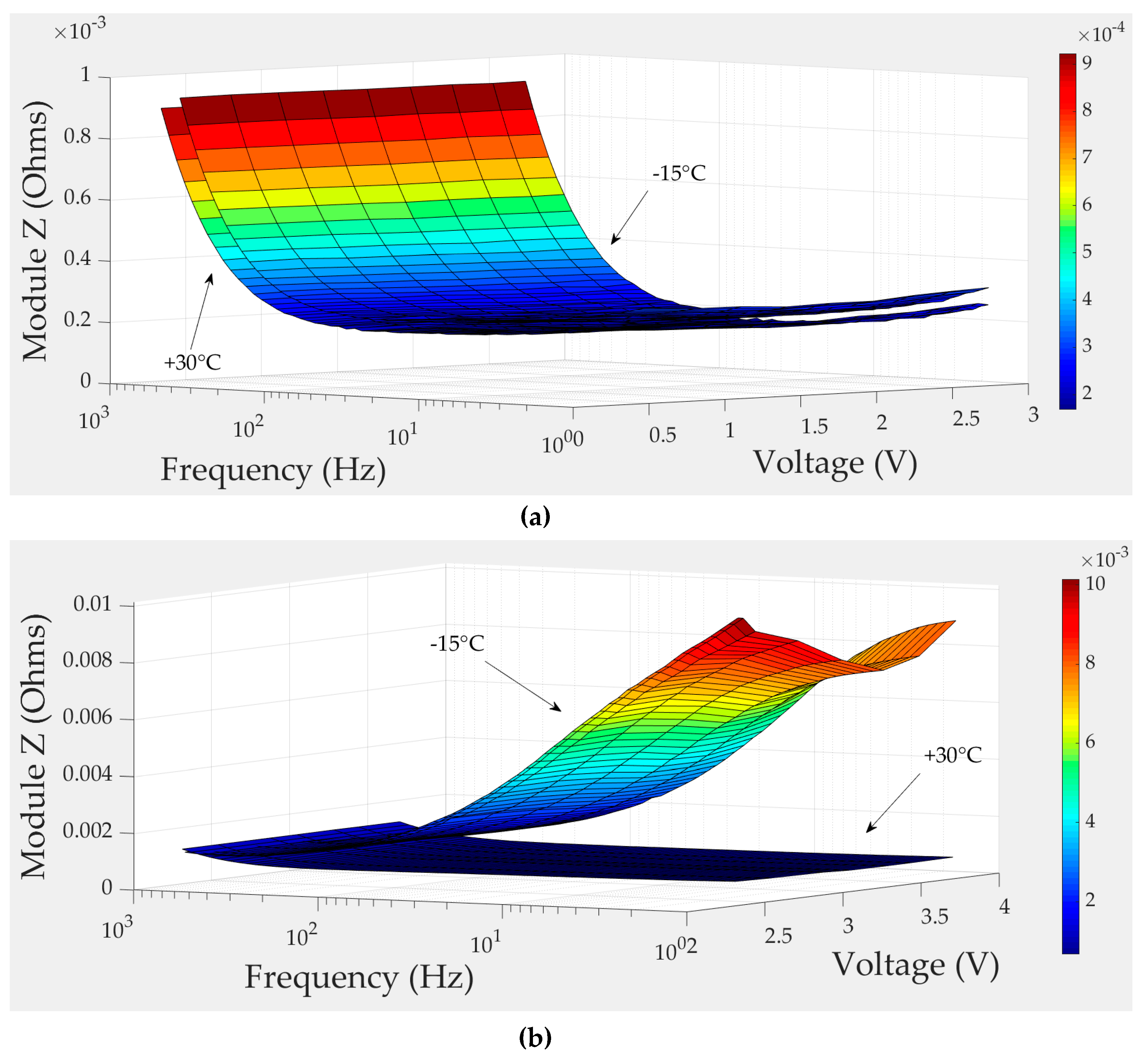

3.1. Measurements by Charge–Discharge Cycling

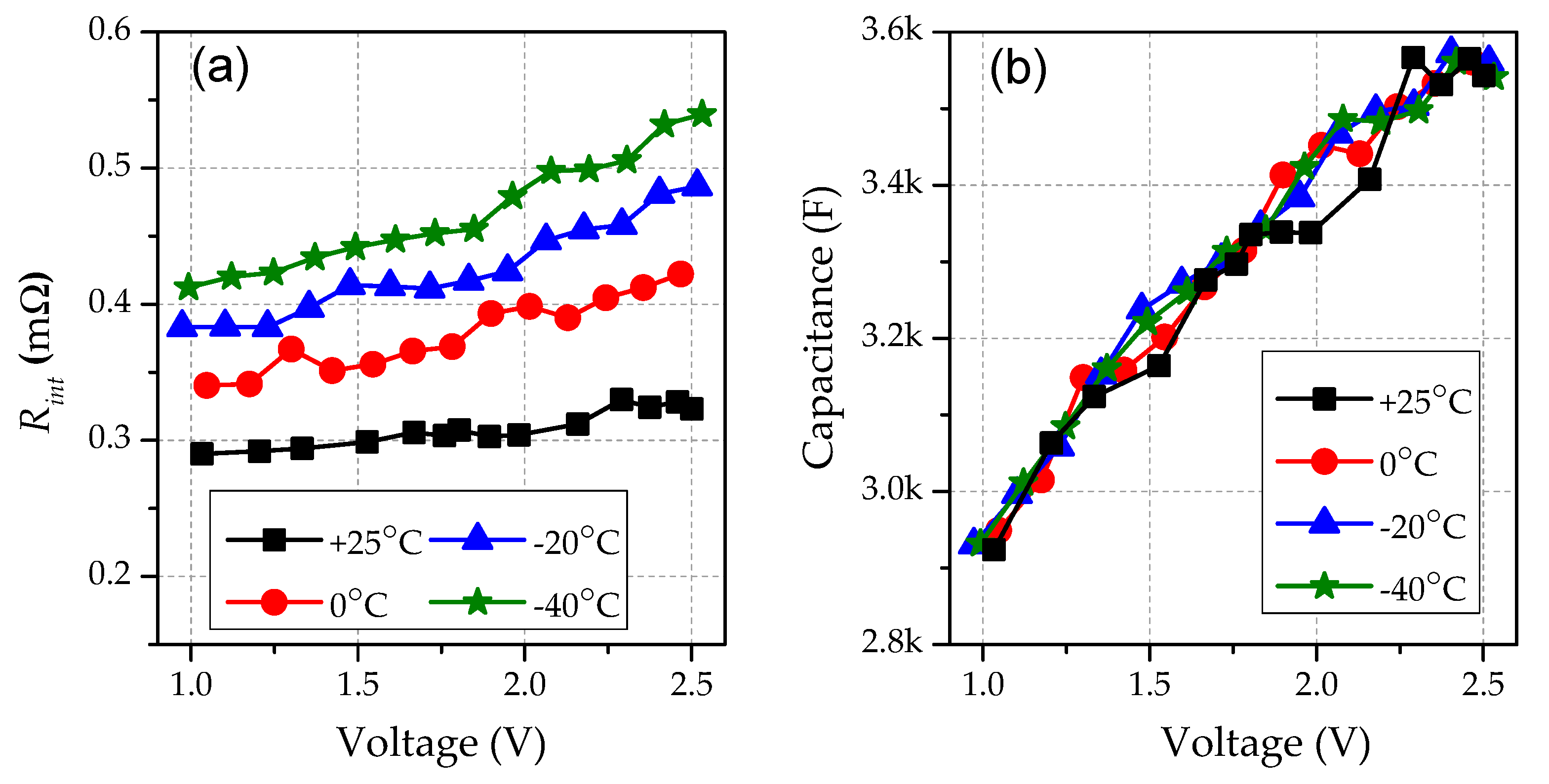

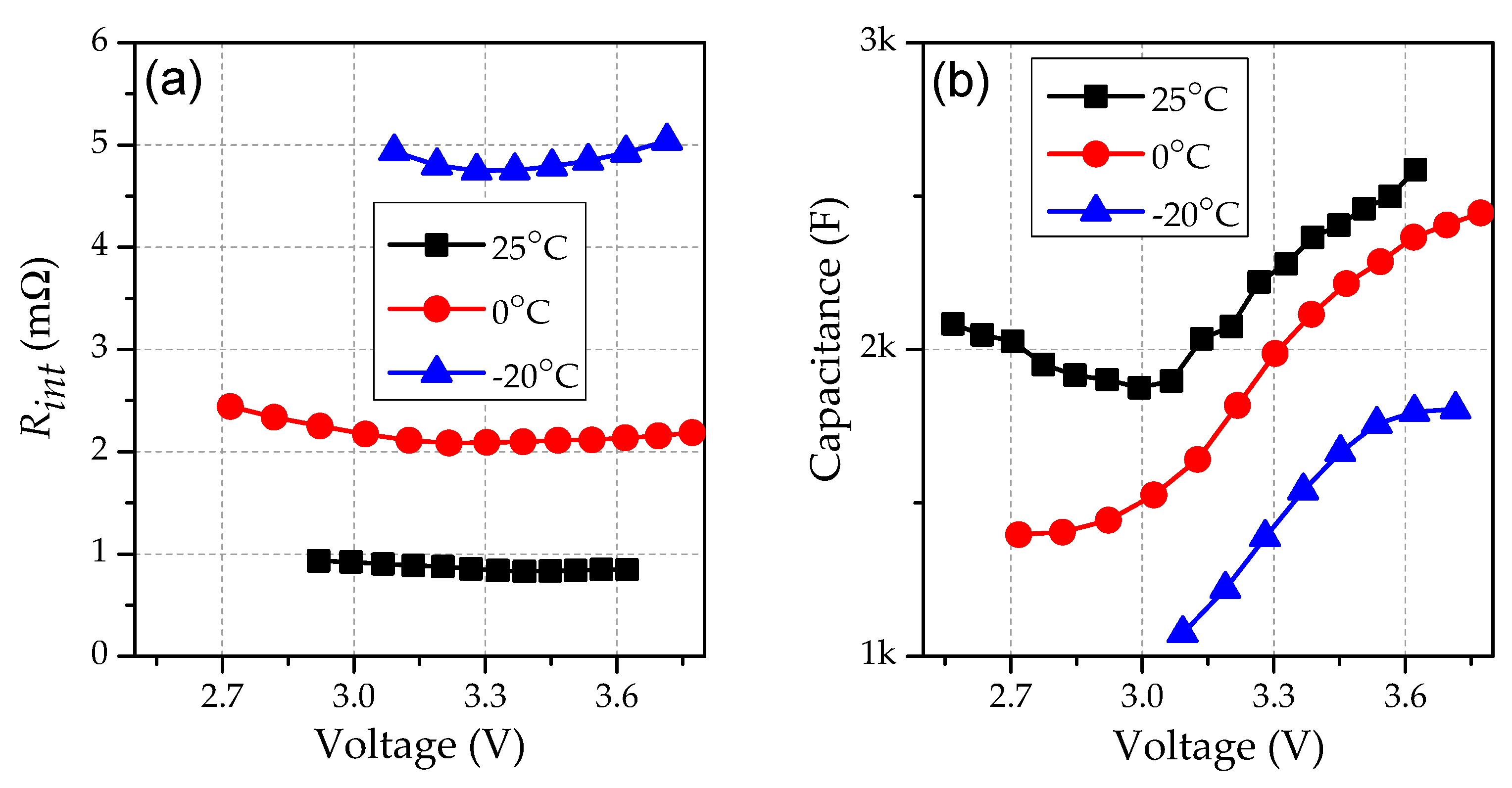

3.2. Measurements by EIS

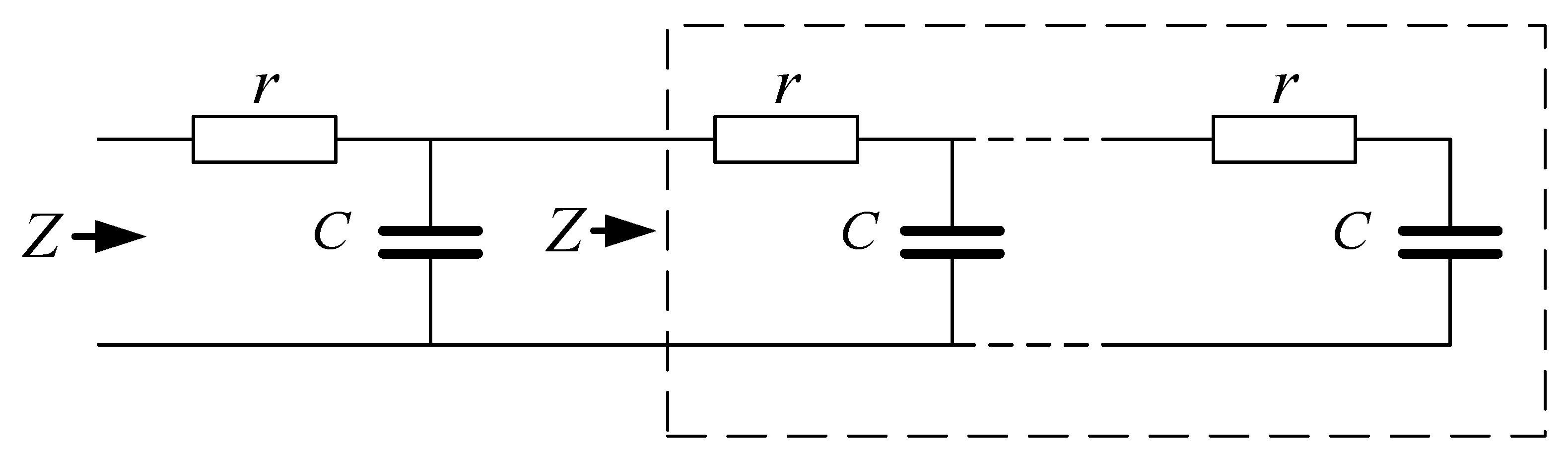

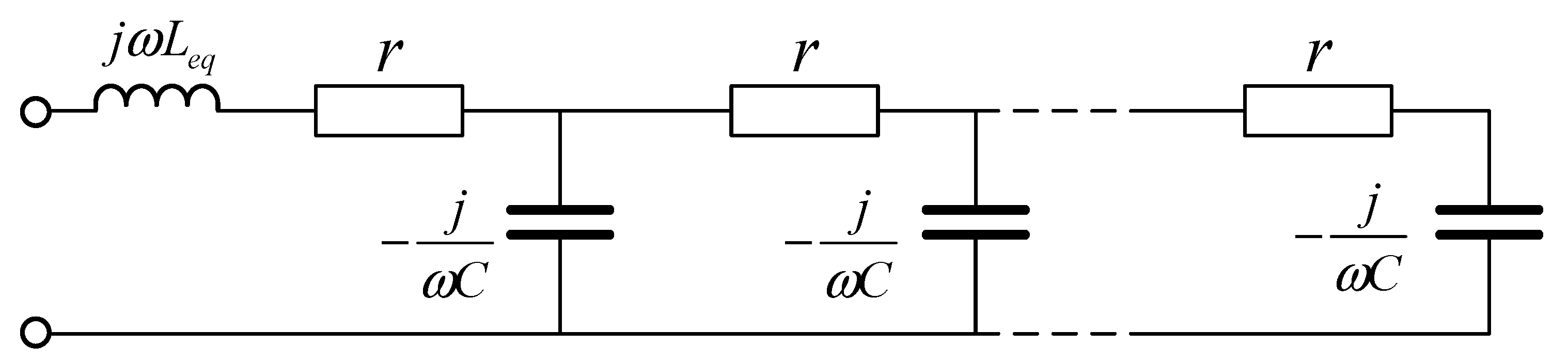

4. Equivalent Circuit Development

4.1. Mathematical Model

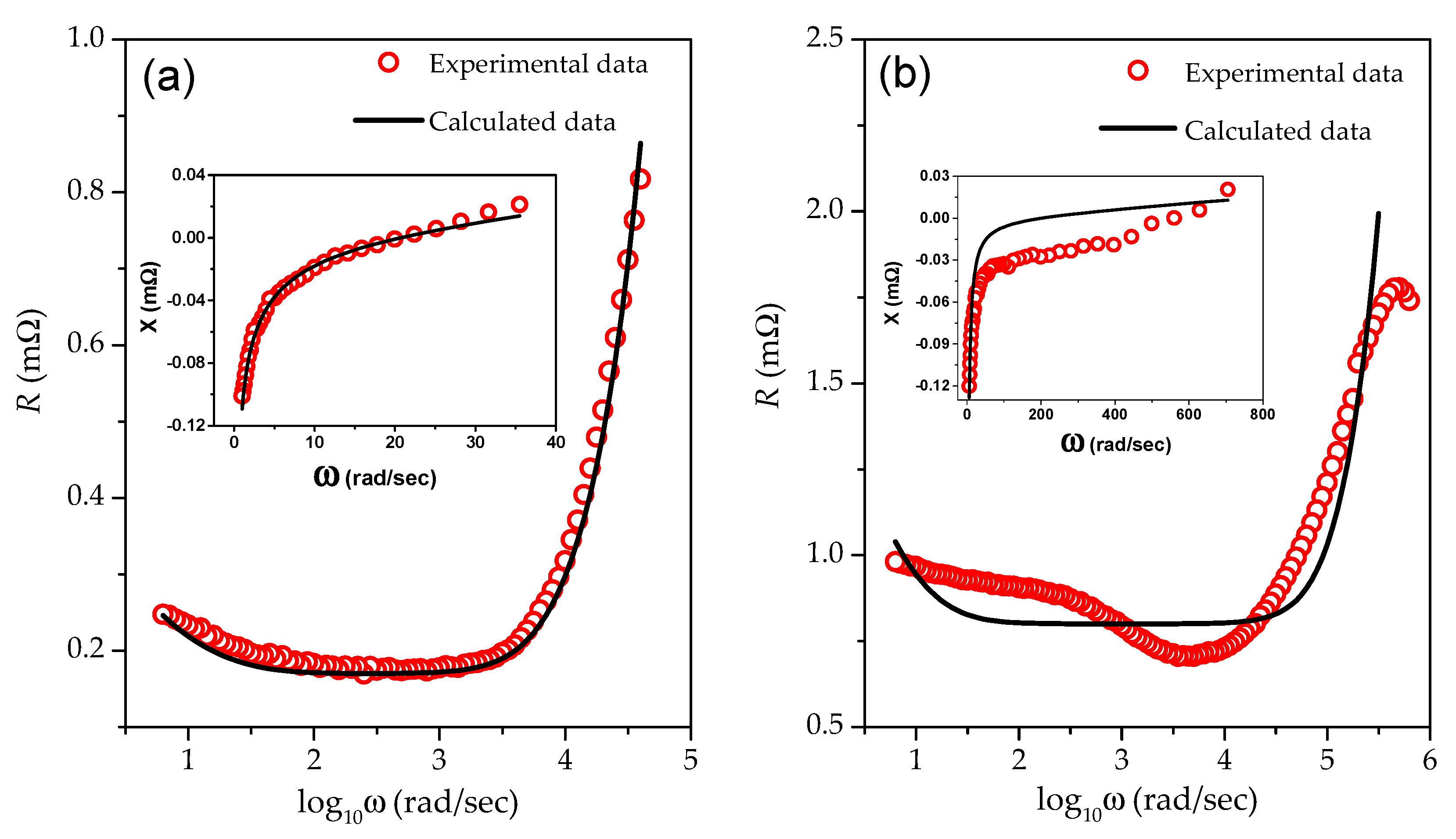

4.2. Fitting Results by Developed Theoretical Modeling

5. Application of UCs for Filtering Power Fluctuation

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Burke, A. Ultracapacitors: Why, how, and where is the technology. J. Power Sources 2000, 91, 37–50. [Google Scholar]

- Averbukh, M.; Lineykin, S.; Kuperman, A. Portable ultracapacitor based power source for emergency starting of internal combustion engines. IEEE Trans. Power Electron. 2015, 30, 4283–4290. [Google Scholar] [CrossRef]

- Sorkin, O.; Farber, E.; Averbukh, M. Selecting ultracapacitors for smoothing voltage deviations in local grids fed by transformer with tap-changer and distributed PV facilities. Electronics 2019, 8, 357. [Google Scholar] [CrossRef]

- Schultz, L.I.; Querques, N.P. Tracing the ultracapacitor commercialization pathway. Renew. Sustain. Energy Rev. 2014, 39, 1119–1126. [Google Scholar] [CrossRef]

- Sharma, P.; Bhatti, T.S. A review on electrochemical double-layer capacitors. Energ. Convers. Manage. 2010, 51, 2901–2912. [Google Scholar] [CrossRef]

- Campillo-Robles, J.M.; Artetxe, X.; del Teso Sánchez, K.; Gutiérrez, C.; Macicior, H.; Röser, S.; Wagner, R.; Winter, M. General hybrid asymmetric capacitor model: Validation with a commercial lithium ion capacitor. J. Power Sources 2019, 425, 110–120. [Google Scholar] [CrossRef]

- Manla, E.; Mandic, G.; Nasiri, A. Testing and modeling of lithium-ion ultracapacitors. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 17–22 September 2011; pp. 2957–2962. [Google Scholar]

- Hamidi, S.A.; Manla, E.; Nasiri, A. Li-ion batteries and Li-ion ultracapacitors: Characteristics, modeling and grid applications. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 4973–4979. [Google Scholar]

- Seyedmahmoudian, M.; Horan, B.; Soon, T.K.; Rahmani, R.; Oo, A.M.T.; Mekhilef, S.; Stojcevski, A. State of the art artificial intelligence-based MPPT techniques for mitigating partial shading effects on PV systems-A review. Renew. Sustain. Energy Rev. 2016, 64, 435–455. [Google Scholar] [CrossRef]

- Dou, X.; Quan, X.; Wu, Z.; Hu, M.; Sun, J.; Yang, K.; Xu, M. Improved control strategy for microgrid ultracapacitor energy storage systems. Energies 2014, 7, 8095–8115. [Google Scholar] [CrossRef]

- Alizadeh, G.A.; Rahimi, T.; Nozadian, B.; Hasan, M.; Sanjeevi kumar, P.; Leonowicz, Z. Improving microgrid frequency regulation based on the virtual inertia concept while considering communication system delay. Energies 2019, 12, 2016. [Google Scholar] [CrossRef]

- Sepe, R.B., Jr.; Steyerl, A.; Bastien, S.P. Lithium-ion supercapacitors for pulsed power applications. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 17–22 September 2011; pp. 1813–1818. [Google Scholar]

- Zhu, W.H.; Tatarchuk, B.J. Characterization of asymmetric ultracapacitors as hybrid pulse power devices for efficient energy storage and power delivery applications. Appl. Energy. 2016, 169, 460–468. [Google Scholar] [CrossRef]

- Piórkowski, P.; Chmielewski, A.; Bogdziński, K.; Możaryn, J.; Mydłowski, T. Research on ultracapacitors in hybrid systems: Case study. Energies 2018, 11, 2551. [Google Scholar] [CrossRef]

- Wang, L.; Guo, J.; Xu, C.; Wu, T.; Lin, H. Hybrid Model Predictive Control Strategy of Supercapacitor Energy Storage System Based on Double Active Bridge. Energies 2019, 12, 2134. [Google Scholar] [CrossRef]

- Yahalom, A.; Dahan, Y.; Prihodko, V.; Averbukh, M. Experimental verification of internal resistance and capacitance of CPQ2300S li-ion ultracapacitors (JSR Co.). In Proceedings of the 2016 IEEE International Conference on the Science of Electrical Engineering (ICSEE), Eilat, Israel, 16–18 November 2016; pp. 1–3. [Google Scholar]

- Zhao, S.; Wu, F.; Yang, L.; Gao, L.; Burke, A.F. A measurement method for determination of dc internal resistance of batteries and supercapacitors. Electrochem. Commun. 2010, 12, 242–245. [Google Scholar] [CrossRef]

- Vicentini, R.; Da Silva, L.M.; Cecilio Junior, E.P.; Alves, T.A.; Nunes, W.G.; Zanin, H. How to Measure and Calculate Equivalent Series Resistance of Electric Double-Layer Capacitors. Molecules 2019, 24, 1452. [Google Scholar] [CrossRef] [PubMed]

- Galla, S.; Szewczyk, A.; Smulko, J.; Przygocki, P. Methods of Assessing Degradation of Supercapacitors by Using Various Measurement Techniques. Appl. Sci. 2019, 9, 2311. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Ayadi, M.; Vinassa, J. Ultracapacitor performance determination using dynamic model parameter identification. In Proceedings of the 2013 IEEE International Symposium on Industrial Electronics, Taipei, Taiwan, 28–31 May 2013; pp. 1–5. [Google Scholar]

- Devillers, N.; Jemei, S.; Péra, M.; Bienaimé, D.; Gustin, F. Review of characterization methods for supercapacitor modelling. J. Power Sources 2014, 246, 596–608. [Google Scholar] [CrossRef]

- Miniguano, H.; Barrado, A.; Fernández, C.; Zumel, P.; Lázaro, A. A General Parameter Identification Procedure Used for the Comparative Study of Supercapacitors Models. Energies 2019, 12, 1776. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Z.; Hu, X.; Sun, F.; Dorrell, D.G. A comparative study of equivalent circuit models of ultracapacitors for electric vehicles. J. Power Sources 2015, 274, 899–906. [Google Scholar] [CrossRef]

- Fletcher, S.; Black, V.J.; Kirkpatrick, I. A universal equivalent circuit for carbon-based supercapacitors. J. Solid State Electrochem. 2014, 18, 1377–1387. [Google Scholar]

- Jiya, I.; Gurusinghe, N.; Gouws, R. Electrical circuit modelling of double layer capacitors for power electronics and energy storage applications: A review. Electronics 2018, 7, 268. [Google Scholar] [CrossRef]

- Manla, E.; Mandic, G.; Nasiri, A. Development of an electrical model for lithium-ion ultracapacitors. IEEE Trans. Emerg. Sel. Top. Power Electron. 2015, 3, 395–404. [Google Scholar] [CrossRef]

- Drummond, R.; Valmorbida, G.; Duncan, S.R. Equivalent circuits for electrochemical supercapacitor models. IFAC-Pap. OnLine 2017, 50, 2671–2676. [Google Scholar] [CrossRef]

- Pozo, B.; Garate, J.I.; Ferreiro, S.; Fernandez, I.; de Gorostiza, E.F. Supercapacitor Electro-Mathematical and Machine Learning Modelling for Low Power Applications. Electronics 2018, 7, 44. [Google Scholar] [CrossRef]

- Wu, C.H.; Hung, Y.H.; Hong, C.W. On-line supercapacitor dynamic models for energy conversion and management. Energy Convers. Manag. 2012, 53, 337–345. [Google Scholar] [CrossRef]

- Shi, L.; Crow, M. Comparison of ultracapacitor electric circuit models. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting-Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008; pp. 1–6. [Google Scholar]

- Li, J.; Xu, M.; Li, X.; Yuan, C. Preparation and Electrochemical Characterization of Li-ion Supercapacitor. Adv. Mater. Res. 2015, 482, 535–538. [Google Scholar] [CrossRef]

- Allu, S.; Asokan, B.V.; Shelton, W.A.; Philip, B.; Pannala, S. A generalized multi-dimensional mathematical model for charging and discharging processes in a supercapacitor. J. Power Sources 2014, 256, 369–382. [Google Scholar] [CrossRef]

- Sedlakova, V.; Sikula, J.; Majzner, J.; Sedlak, P.; Kuparowitz, T.; Buergler, B.; Vasina, P. Supercapacitor equivalent electrical circuit model based on charges redistribution by diffusion. J. Power Sources 2015, 286, 58–65. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Dorrell, D.G. A review of supercapacitor modeling, estimation, and applications: A control/management perspective. Renew. Sustain. Energy Rev. 2018, 81, 1868–1878. [Google Scholar] [CrossRef]

- Freeborn, T.J.; Maundy, B.; Elwakil, A.S. Fractional-order models of supercapacitors, batteries and fuel cells: A survey. Mater. Renew. Sustain. Energy 2015, 4, 9. [Google Scholar] [CrossRef]

- Zubieta, L.; Bonert, R. Characterization of double-layer capacitors for power electronics applications. IEEE Trans. Ind. Appl. 2000, 36, 199–205. [Google Scholar] [CrossRef]

- Buller, S.; Karden, E.; Kok, D.; Doncker, R.W.D. Modeling the dynamic behavior of supercapacitors using impedance spectroscopy. IEEE Trans. Ind. Appl. 2002, 38, 1622–1626. [Google Scholar] [CrossRef]

- K2 ULTRACAPACITORS: 2.85V/3400F. Available online: https://www.maxwell.com/images/documents/K2_2_85V_DS_3000619EN_3_.pdf (accessed on 20 March 2019).

- ULTIMO Lithium Ion Capacitor Prismatic Cells. Available online: https://www.jsrmicro.be/emerging-technologies/lithium-ion-capacitor/products/ultimo-lithium-ion-capacitor-prismatic-cells (accessed on 10 May 2019).

- Variable-switching Multi Range DC Power Supply PWR 1600W. Available online: https://www.kikusui.co.jp/en/product/detail.php?IdFamily=0064 (accessed on 1 February 2019).

- Midi logger GL900. Available online: http://www.graphteccorp.com/instruments/gl900/index.html (accessed on 21 February 2019).

- Gualous, H.; Bouquain, D.; Berthon, A.; Kauffmann, J.M. Experimental study of supercapacitor serial resistance and capacitance variations with temperature. J. Power Sources 2003, 123, 86–93. [Google Scholar] [CrossRef]

- EchemLab XM Potentiostat Galvanostat. Available online: https://www.ameteksi.com/products/potentiostats/single-channel/apps-xm-series/echemlab-xm-potentiostat-galvanostat (accessed on 21 May 2019).

- Lunaire Steady State Testing Chamber. Available online: https://www.thermalproductsolutions.com/brands/tenney-lunaire-environmental-test-chambers-and-rooms (accessed on 12 February 2019).

- Liu, H.; Akhtar, Z.; Li, P.; Wang, K. Mathematical Modeling Analysis and Optimization of Key Design Parameters of Proton-Conductive Solid Oxide Fuel Cells. Energies 2014, 7, 173–190. [Google Scholar] [CrossRef]

- Capizzi, G.; Sciuto, G.L.; Napoli, C.; Tramontana, E. Advanced and adaptive dispatch for smart grids by means of predictive models. IEEE Trans. Smart Grid 2017, 9, 6684–6691. [Google Scholar] [CrossRef]

| Double-Layer UC | Li-ion UC | |||||||

|---|---|---|---|---|---|---|---|---|

| Current (A) | Rint (mΩ) | Capacitance (F) | Rint (mΩ) | Capacitance (F) | ||||

| Charge | Discharge | Charge | Discharge | Charge | Discharge | Charge | Discharge | |

| 20 | 0.319 | 0.323 | 3465 | 3494 | 0.924 | 0.918 | 2206 | 2244 |

| 50 | 0.311 | 0.308 | 3381 | 3381 | 0.963 | 0.909 | 2198 | 2161 |

| 75 | 0.311 | 0.326 | 3411 | 3472 | 0.923 | 0.891 | 2218 | 2154 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abetbool, Y.; Rajput, S.; Yahalom, A.; Averbukh, M. Comprehensive Study on Dynamic Parameters of Symmetric and Asymmetric Ultracapacitors. Electronics 2019, 8, 891. https://doi.org/10.3390/electronics8080891

Abetbool Y, Rajput S, Yahalom A, Averbukh M. Comprehensive Study on Dynamic Parameters of Symmetric and Asymmetric Ultracapacitors. Electronics. 2019; 8(8):891. https://doi.org/10.3390/electronics8080891

Chicago/Turabian StyleAbetbool, Yakov, Shailendra Rajput, Asher Yahalom, and Moshe Averbukh. 2019. "Comprehensive Study on Dynamic Parameters of Symmetric and Asymmetric Ultracapacitors" Electronics 8, no. 8: 891. https://doi.org/10.3390/electronics8080891

APA StyleAbetbool, Y., Rajput, S., Yahalom, A., & Averbukh, M. (2019). Comprehensive Study on Dynamic Parameters of Symmetric and Asymmetric Ultracapacitors. Electronics, 8(8), 891. https://doi.org/10.3390/electronics8080891