1. Introduction

Commercially mass-produced electric vehicles (EVs) are mainly battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs). BEVs, sometimes which are also called blade electric vehicles, or pure electric vehicles, only have a drive motor and power battery as the energy source, so the parameter matching of the powertrain system is relatively simple [

1,

2,

3,

4,

5]. Unlike BEVs, HEVs have more complex structures. According to the structure and energy flow of the powertrain, HEVs are mainly divided into series HEVs, parallel HEVs, and series-parallel HEVs; while according to whether the battery can be externally charged, HEVs are divided into plug-in HEVs [

6] and non-plug-in HEVs. The parameters of the powertrain system have a high coupling degree. According to the latest research results, the relationship between the system parameters and the control strategy of the HEV is complicated. The parameter matching between the power components (including the engine, drive motor, and power battery, etc.) and the transmission system directly affects the overall performance of the vehicle’s power, fuel consumption and emissions [

5,

7,

8,

9,

10]. Therefore, it is very important to study the parameter matching optimization of the powertrain system of HEVs.

In ref. [

2], according to the design targets, the parameters of the drive motor, battery pack, and reducer of a pure electric vehicle were analyzed; and the simulation and parts matching experiment of a pure electric vehicle under AVL Cruise were focused in analysis in ref. [

4]. The parameter matching of the electric motor drive system for electric and series hybrid electric vehicles is studied in ref. [

5], and the feasibility and effectiveness of the proposed procedure were verified by a calculation example. The traditional methods of parameter matching of HEVs have problems such as large computational complexity and poor reliability, because the numerical ranges of the calculated matching parameters are generally broad, and there are no valid further restrictions [

2,

4]. Thus, several different parameter matching optimization methods were proposed under certain restrictions. A SHEV powertrain was developed by initial parameter matching and component sizing, followed by its optimization for given design constraints [

10]; while a multi-objective optimization algorithm in combination with boundary condition regulation was applied in a loop [

11], so that a new approach was developed to optimize the engine and hydraulic element size and their corresponding parameters. At the same time, most of the current research is focused on single-objective optimization (SOO) that only reduces fuel consumption or certain emissions. However, the ideal parameter matching optimization is to solve the optimal solution satisfying multiple targets by the optimization algorithm under certain constraints [

12,

13], that is, according to the vehicle basic parameters and performance indicators, the system parameters of the engine, motor, and power battery are determined, and the fuel consumption and emissions are also optimized simultaneously through theoretical analysis and calculation, while ensuring the vehicle’s power performance. In ref. [

12], a multi-objective genetic algorithm was adopted to find the optimization solutions in the feasible region, and the Pareto optimal solution set was solved as an optional variant set for both transmission with a fixed gear ratio and two-gear transmission. Furthermore, an efficient multi-objective genetic algorithm was proposed to optimize powertrain component sizes as well as fuel economy and emissions, including HC, CO, and NOx, for a parallel HEV in ref. [

13]. However, there is a strong coupling and even contradiction between the system parameters and performance indicators, and it is very difficult to optimize these goals at the same time. In engineering practice, it is difficult to judge which is the best matching under unrestricted conditions, and generally, only a compromise scheme can be selected. In addition, the traditional methods are only for the optimization matching of the components of the powertrain system and do not consider the optimization matching problem between the system parameters and control variables, so control optimization cannot be achieved [

2,

5]. Therefore, it is of great significance to study the parallel optimization of system parameters and control variables of HEVs, and it is also the first problem to be solved in the design and development of electric vehicles.

Aiming at the problems of large computational complexity and poor reliability, a parameter matching optimization method of the powertrain system of HEVs based on multi-objective optimization (MOO) is proposed. The research ideas and arrangement of the rest of the paper are as follows. In

Section 2, the vehicle basic parameters and performance indicators are designed. According to the above parameters and indicators, the parameter ranges of the components, including the engine, drive motor, and power battery, etc., are analyzed and calculated in

Section 3. Then in

Section 4, the transmission system modeling of HEVs in AVL Cruise is described in detail. The weight coefficient method is applied to convert the MOO problem of fuel consumption and emission into an SOO problem in

Section 5. Finally, the co-simulation of AVL Cruise and Matlab/Simulink is used to evaluate the effects of system parameter matching by the objective function in

Section 6, followed by the conclusion in

Section 7.

3. Parameter Matching Analysis of the Powertrain System

In practice, subject to the constraint of vehicle demand power, the power ranges of the engine and motor need to be determined first; then, according to the maximum speed and maximum torque of the engine and the motor, the speed ratio of the shifting mechanism is optimized to meet the indicators of the maximum velocity and maximum gradability. In order to ensure that the HEV has sufficient power performance and driving range in different drive modes such as pure electric drive mode and hybrid drive mode, it is generally necessary to select a motor with larger power and a battery pack with higher specific energy and power. The power of the engine can be appropriately reduced and matched to the motor power according to the control strategy [

14,

15,

16,

17].

3.1. Parameter Matching of Drive Motor

According to the performance indicators of the vehicle, the performances such as acceleration time and maximum gradability, are mainly considered to meet the power performance required for the vehicle in pure electric drive mode, and the parameters such as rated power, peak power, maximum speed and peak torque of the motor can be determined [

2,

5].

(1) Motor rated power and peak power

The motor power should take into account the rated power during continuous operation and the peak power for short-term operation. The rated power can generally be determined by the power of the vehicle when driving at the highest velocity on a horizontal road, which can be expressed as follows:

where

m is the curb weight, in kg;

g is the gravitational acceleration, 9.8 m/s

2;

f is the friction coefficient of tire;

Af is the front area, in m

2;

CD is the drag coefficient;

Vmax is the maximum velocity, in km/h;

ηt is the total transfer efficiency of the mechanical transmission device between the motor output shaft to the drive wheel.

When the vehicle is driving at the maximum gradability for a short period of time or driving at full acceleration, the motor runs at peak power. The short-time output power of the motor at the maximum gradability can be expressed as:

where

αmax is the maximum gradability;

Vα is the vehicle velocity, in km/h. In addition, it should meet the basic requirements of the climb performance of the vehicle in the national standards of the People’s Republic of China GB/T28382-2012: on 4% gradability, the maximum velocity is not less than 60 km/h; on 12% gradability, the maximum velocity is not less than 30 km/h.

When the vehicle is fully accelerating, it is necessary to meet the requirements of the acceleration time, of which the power can be expressed as follows:

where

δ is the rotation mass conversion factor;

td is the acceleration time, in s;

Vend is the acceleration target velocity, in km/h.

In summary, the peak power of the motor should meet the requirements of the above powers Equations (1)–(3), i.e.,. In addition, 1% to 2% margin of the peak power should also be considered.

(2) Motor maximum speed

The drive motor of the vehicle is generally selected from medium and high-speed motors. The rated speed is generally above 4000 r/min. The maximum speed has no special limit, but it is subject to the maximum velocity and total gear ratio. In addition, it is also necessary to consider the factor of expanding the constant power zone, that is, the limit of the ratio of the maximum speed to the rated speed.

(3) Motor peak torque

When the motor is running at maximum power with rated speed, its output torque is the peak torque:

where

nrat is the rated speed of the motor, in r/min.

3.2. Parameter Matching of Engine

According to the main and auxiliary power, parallel HEVs (PHEVs) mainly have engine-assisted and motor-assisted drive modes. The engine-assisted drive mode mainly uses the power battery and the motor to drive the vehicle, for example, the HEV generally starts from electric drive mode, and only switches to the hybrid drive mode at the appropriate timing when driving at high speed, climbing and rushing; while the motor-assisted mode mainly uses the internal combustion engine to drive the vehicle, and the motor only works when it is instantaneously accelerating, climbing and decelerating, so it does not have the electric drive mode. The advantage of the engine-assisted mode is that the vehicle can use the power of the battery in most cases, with fewer emissions and fuel consumption, while the engine can be started with the motion of the vehicle without the need to install an additional starter motor.

In this paper, the HEV adopts engine-assisted drive mode, so that the vehicle mainly works in pure electric drive mode and hybrid drive mode. The power selection of the engine can be substantially matched to the power of the drive motor as needed. For the specific choice of how much power of the engine is more suitable, it is necessary to take the engine power as one of the variables in the later research of MOO parameter matching.

3.3. Parameter Matching of the Power Battery

The power and capacity of the battery pack have a great impact on the vehicle’s power and driving range, especially BEVs and plug-in HEVs. At present, most of the power batteries used are nickel-metal hydride (NiMH) batteries and lithium-ion batteries (LiBs). The specific energy and power of NiMH batteries are relatively moderate with a good fast charging ability, and the suitable temperature range is wide, but the cycle life is short; LiBs have high specific energy and power, long cycle life, short charging time, and relatively good safety, however, the price is high [

18,

19,

20,

21].

First, the power of the battery pack must meet the power requirements, that is, the maximum power of the motor. The number of battery packs can be expressed as:

where

Rb_dis is the discharged internal resistance of the battery pack, in Ω;

Voc is the open circuit voltage of the battery pack, in

V.

Secondly, the capacity of the battery pack should meet the driving range of the vehicle, so the number of battery packs can be calculated as:

where

Ebat is the energy consumed of the battery per km, in kW/km;

Ldis is the driving range, in km;

Ubat is the voltage of battery pack, in V;

Dsoc is the battery discharge depth, in %;

ηm is the assembly efficiency of the motor and controller;

Cbat is the rated capacity of a battery cell, in Ah.

If the discharge depth of the battery is 70%, 100 LiB cells with 3.2 V are selected in series, that is, the average operating voltage of the battery pack is 320 V, and the number of battery packs in parallel takes the larger value of Equations (5) and (6). Considering the battery efficiency and attenuation, the number of power battery packs can be slightly larger, and the specific number in parallel also needs to be one of the variables in the later research of MOO parameter matching.

4. Transmission System Modeling of HEVs in AVL Cruise

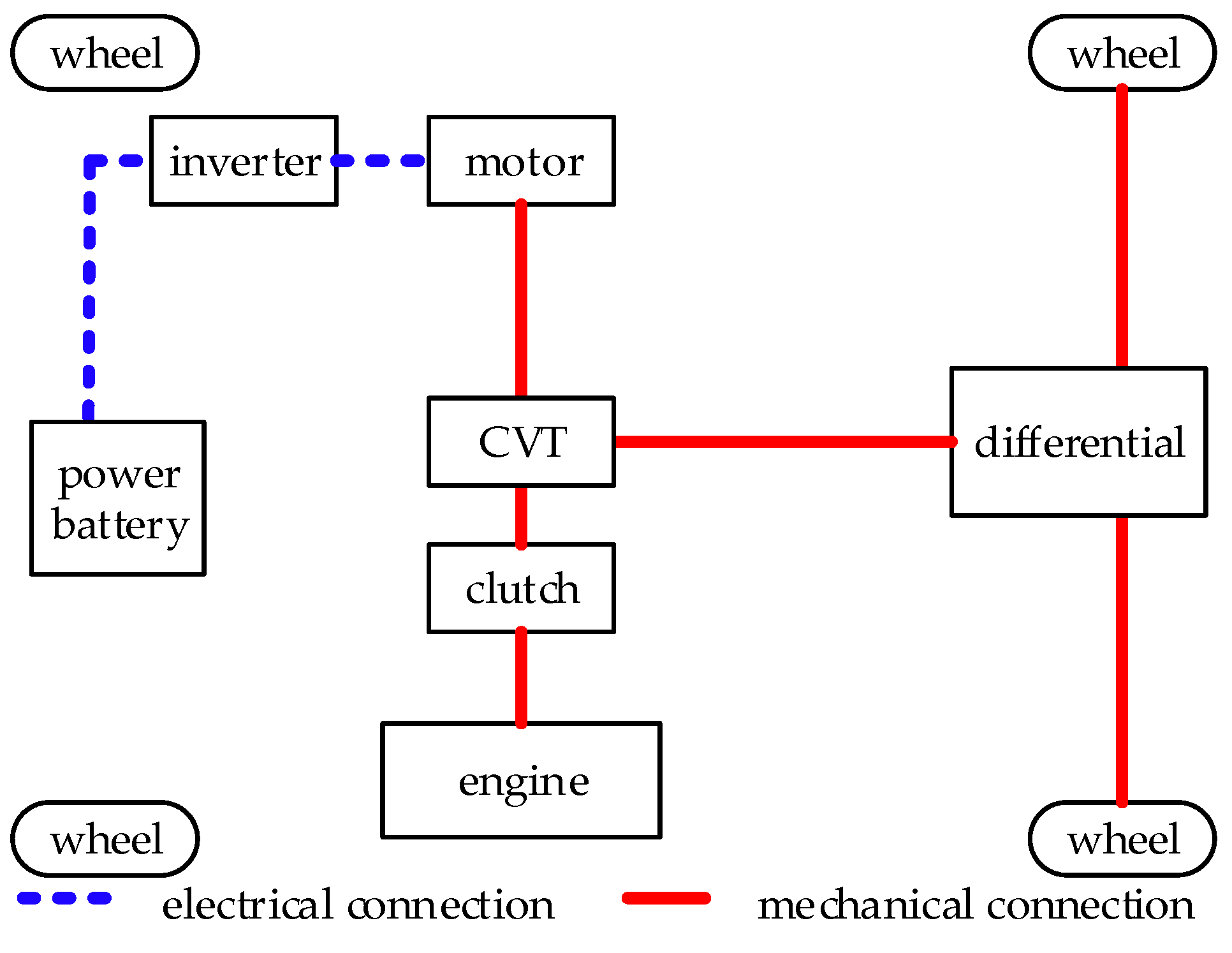

Compared with series HEVs, PHEVs do not need to select components of high power, large size, and heavy weight, and the energy conversions are less, because there is no conversion process of mechanical-electric-mechanical energy, and the overall energy efficiency is higher. Compared with the series-parallel HEVs, the structure of PHEVs is simple and reasonable, effectively reducing the weight and cost of components, and is conducive to commercial development and mass production. Therefore, the research in this paper is mainly based on the two-axis PHEVs, as shown in

Figure 1.

EVs, especially HEVs, are a highly nonlinear and complex system, which have a wide variety of components with different characteristics. It is difficult to directly model them. To this end, many research institutes and commercial companies have developed electric vehicle simulation software, such as Advisor, AVL Cruise, CarSim, PSAT, HEVSim, and Matlab [

22,

23,

24,

25,

26,

27,

28]. Among them, AVL Cruise is an EV simulation software developed by the AVL Company after the acquisition of Advisor (which has been discontinued). Currently, AVL Cruise has become one of the most widely used softwares for automakers and research institutes, in component parameter matching, performance prediction optimization, and control strategy development, and other aspects [

27,

28].

According to the power synthesis method and the presence or absence of the clutch, PHEVs can be divided into speed coupling type and torque coupling type, single shaft type, and double shaft type.

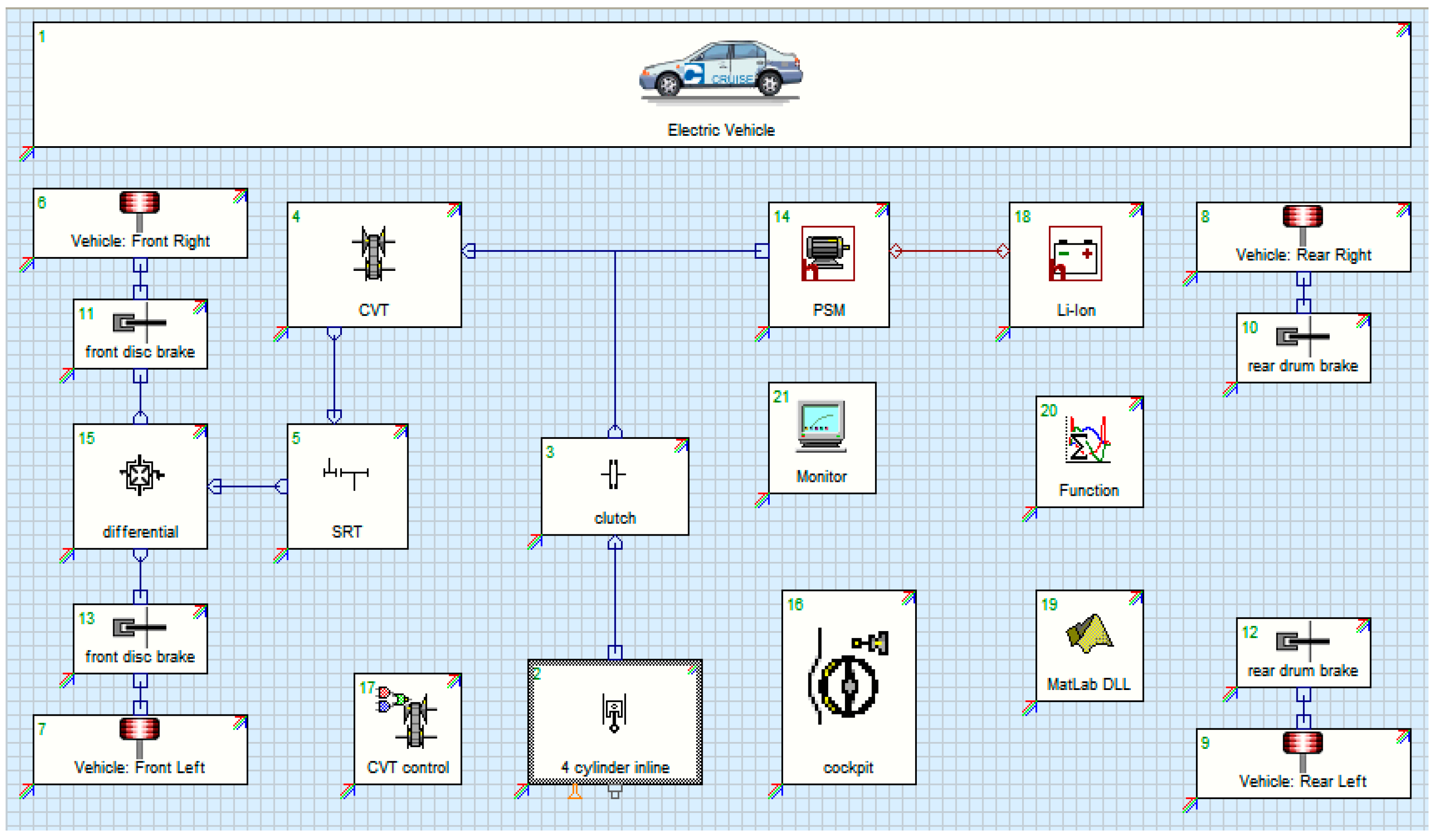

Figure 2 shows the designed HEV model in AVL Cruise. According to the configuration, the parallel structure of the drive system is a torque-coupled, single-shaft hybrid drive system with the transmission behind the motor, while the torque and speed transmitted by the engine and the motor to the drive axle are adjusted by the gearbox, which is a continuously variable transmission (CVT). Therefore, the engine and the motor must have the same speed range. The motor plays multiple functions such as driving the vehicle, starting the engine, and generating regenerative braking. The models of motor, engine, and power batteries in AVL Cruise are mainly based on the look-up table method, which can greatly improve the computing speed. In practice, the characteristic curves of these components can be obtained through experiments, and then achieved in models by the look-up table method.

The CVT has neither the numerous gear pairs of the manual transmission (MT) nor the complex planetary gear set of the automatic transmission (AT), which is simple in structure and small in size. Because the CVT transmission ratio can be continuously changed, it is easy to operate and to achieve the best match of the engine, transmission system, and driving conditions, thereby improving the vehicle’s power, fuel economy, and driving comfort. Thus, it is an ideal vehicle transmission. In this paper, we specified the specific architecture of HEC with a CVT that was used here as a case study. Of course, the research of this paper can also be used for the HEV with a configuration of MT or AT, but the gear ratio of the gearbox should be a parameter that is optimized according to the selection of the powertrain components. The optimization procedures of parameter matching are common under the premise of considering the difference between different transmission structures.

The CVT dynamic model without considering the friction phase can be simplified to:

where

Tcin and

Tcout are the input and output torque of CVT, respectively, in Nm;

ic represents the current transmission ratio of CVT;

wcin and

wcout are the input and output speed of CVT, respectively, in rad/s.

The main reducer is a stable ratio transmission (SRT), which is mainly used for deceleration and twisting. The SRT model can be expressed as:

where

Tsin and

Tsout are the input and output torque of the SRT, respectively, in Nm;

wsin and

wsout are the input and output speed of the SRT, respectively, in rad/s.

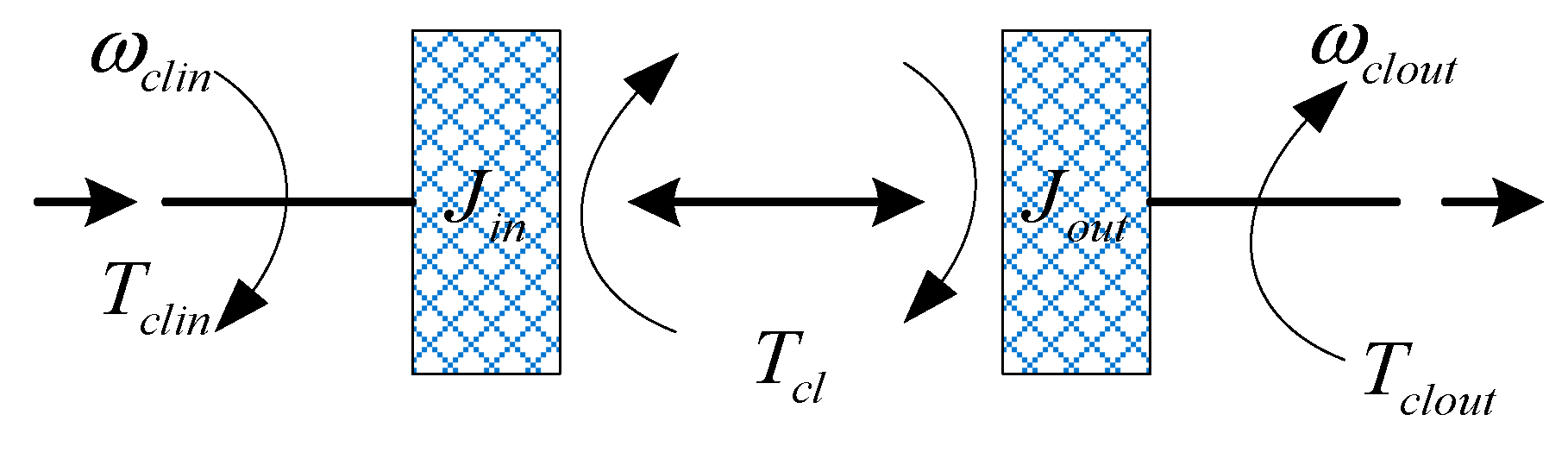

The clutch connection process mainly includes the sliding friction phase and the full meshing phase. The simplified clutch model is shown in

Figure 3.

In the sliding friction phase, the clutch input and output angular velocities are different, and the relationship between input and output torque can be expressed as:

where

Tclin and

wclin are the torque and angular velocity of the driving end, respectively;

Tclout and

wclout are the output torque and angular velocity, respectively;

Tcl is the transmitting torque;

Jin is the total moment of inertia of the rotating part of the engine and the active part of the clutch, in kg.m

2;

Jout is the equivalent moment of inertia of the driven portion of the clutch, in kg.m

2.

The input and output angular velocities are the same during the clutch full engagement phase. The relationship between input and output torque can be expressed as:

The transmitted torque by the clutch is determined by the demand of the drive system:

Of course, it is also limited by the clutch friction torque:

where

ucl is the actual friction coefficient,

rcl is the average effective radius of the clutch,

Fcl is the actual contact friction, and

Ncl is the friction surface factor.

5. Parameter Matching Based on Multi-Objective Optimization

5.1. Multi-Objective Optimization

There are many ways to solve multi-objective optimization (MOO) problems [

29,

30]. The basic idea is to map multiple targets to a single target through several rules and turn it into a single-objective optimization (SOO) problem. Researchers should clarify the relative importance of each optimization goal in order to better solve the MOO problem because the global optimal solution is sometimes not unique. The traditional methods mainly include weighted measurement method, ε-constraint method, and target programming method, while the modern heuristic intelligent algorithms mainly include the genetic algorithm, the particle swarm algorithm, the simulated annealing algorithm, reinforcement learning, etc. [

30,

31,

32,

33,

34,

35,

36,

37].

At present, as one of the hot issues in current research, intelligent algorithms have been applied to solve MOO problems [

30,

31,

32,

33,

34,

35,

36,

37], in most cases, the algorithm implementation program is relatively intuitive and easy to modify, but the algorithm depends on the actual problem, the designer’s experience, and technology, so there are still many problems. For example, in some cases it cannot be guaranteed that the solution is the optimal one, while some global optimal solutions may not be available in practice, or the performance is not stable. The traditional method requires several assumptions, and practical application is limited. However, it is easy to understand and implement, because of simple design, small calculation, fast calculation, and full theoretical support. These unique advantages have made it widely used in engineering design, financial management, and other fields.

The mathematical description of the MOO problem can use the following expression:

where

x is the d-dimensional spatial decision vector, and

xdmin and

xdmax are the upper and lower limits of the d-dimensional vector search,

X is the decision space formed by

x;

is the

ith of

p inequality constraints;

is the

jth of the

q equality constraints;

y is the target vector.

It can be known from (13) that the MOO problem can be expressed as a solution problem consisting of D decision variable parameters and N objective function variables under p + q constraints. The essential difference from the SOO problem is that, in general, MOO deals with conflicting sub-goals that are mutually conflicting and constrained. Therefore, the solution to the problem is not a unique solution, but a family of the optimal solution set consisting of numerous effective solutions.

5.2. Multi-Objective Optimization of HEV

Similarly, the parameter optimization problem of HEVs also involves MOO such as vehicle power, fuel economy, and emissions. These sub-goals are contradictory, and the improvements in power performance may cause fuel consumption or emission degradations. Coordination and trade-offs need to be performed to optimize the overall performance of HEVs. What is more, some parameters have been determined or optional in an actual vehicle configuration, so a reasonable selection of optimized parameters can greatly reduce the complexity of the optimization process.

In practice, the optimization goal is not to fully optimize these metrics, but to optimize a certain performance based on specific needs, while all other performances meet the design metrics. As for the MOO parameter matching of HEVs in this paper, the vehicle power such as acceleration time and maximum gradability are selected as the constraints, and several key parameters affecting the overall performance of the vehicle are selected as the optimized goal, including system parameters such as maximum motor power, maximum engine power, number of power batteries, and control variables such as battery and SOC working interval. The ultimate goal is to achieve optimal fuel consumption and emissions.

The optimization parameter

is defined as shown in

Table 3. It can be calculated that there is a total of 108 matching options.

Due to the complexity of the HEV system, each performance indicator under a matching scheme must be obtained through different multiple simulation experiments. Therefore, for matching optimization calculations, the conventional algorithm seems to be powerless and the calculation time is too long. It is necessary to design an optimization algorithm to realize automatic variable assignment, conditional judgment, and achieve the resulting output of the objective function. Therefore, the combination matrix method is designed and used to realize the automatic combination and matching calculation of the parameter variables.

The method first needs to design the database of the variables to be optimized. When co-simulation of AVL Cruise and Matlab/Simulink starts, it will call the values of a set of variable combinations from the database, and assign the values to the optimized component parameters in AVL Cruise through the interface; then load the test cycle conditions (such as NEDC, UDDS or customized conditions) and different test tasks (such as climbing test, acceleration time test, maximum cruise velocity test, fuel and emissions cycle test). The current performance indicator is obtained by the vehicle model in AVL Cruise and the control model in Matlab/Simulink, and the final function value is calculated by the defined objective function. The current termination condition is judged by the running time or the cycle number of the working conditions, and the next set of parameter variables is called. Finally, the result of the parameter matching optimization of HEV is judged by the objective function.

Considering the HEV dynamics indicator as a constraint in the MOO problem, the above MOO function can be expressed as:

where

Fuel(

x),

CO(

x),

HC(

x), and

NOx(

x) are functions representing fuel consumption and exhaust emissions of CO, HC, and NOx;

Vmax is the maximum velocity, in km/h;

t1 is the acceleration time from 0 to 60 km/h, in s;

θ is the maximum gradability, in %.

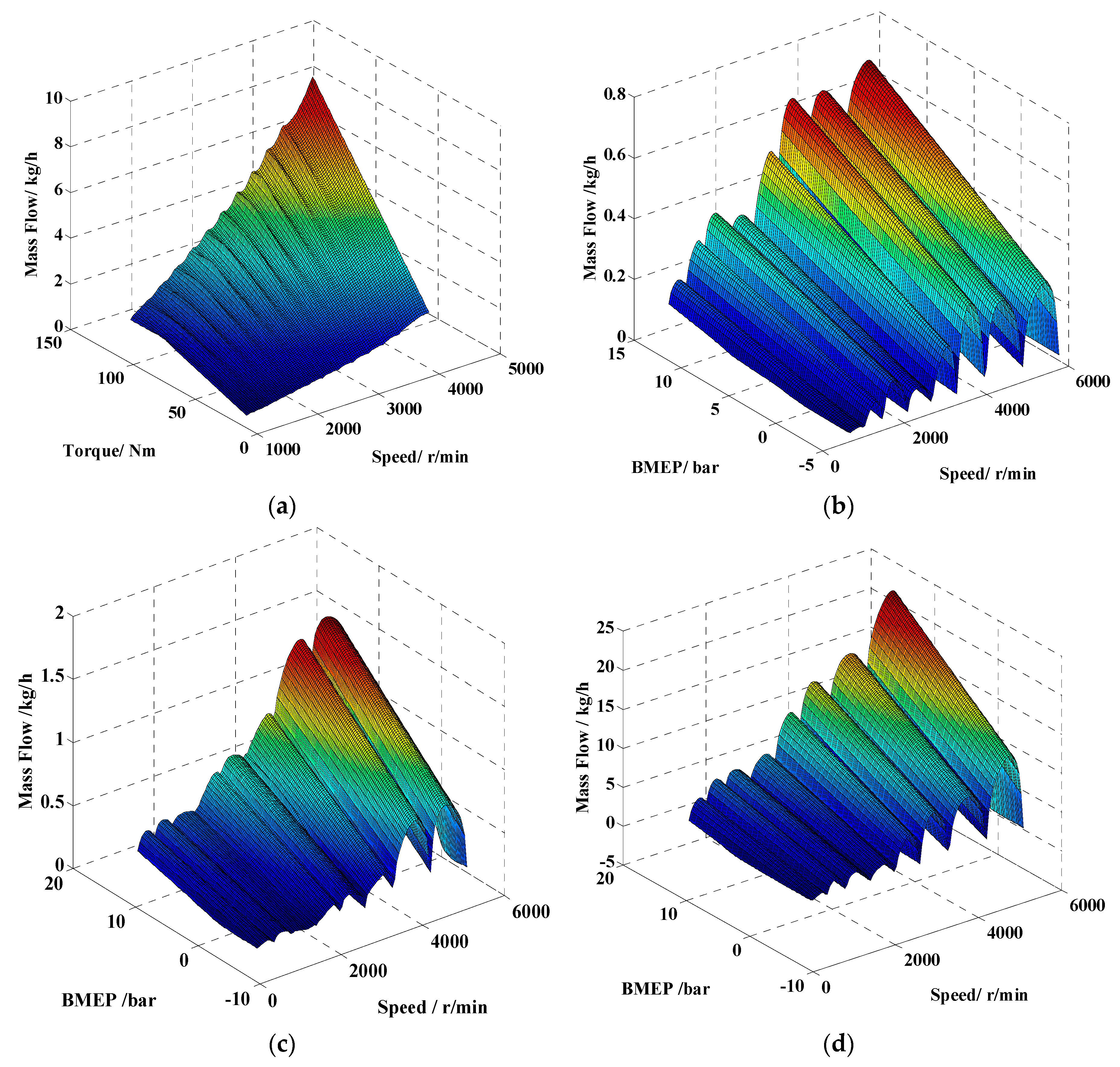

As a kind of nonlinear system with multiple input variables and multiple constraints, it is difficult to determine the mapping relationship between the multiple variables of the fuel consumption model and the emission model of the engine, thus, it is difficult to apply to control programs. Therefore, this paper establishes a description model of specific fuel consumption and exhaust emissions of the engine. The fuel consumption model, and CO, HC, and NOx emission models of the engine are shown in

Figure 4.

Define the objective function:

where

ki is the weighting factor for each fuel and emission optimization target;

fFuel(

x),

fCO(

x),

fHC(

x) and

fNOx(

x) are the actual fuel consumption and exhaust emissions of CO, HC, and NOx, respectively;

Fuel* is the target fuel consumption per 100 km, and

CO*,

HC*,

NOx* are the target emissions per kilometer, respectively.

The selection of the weighting factor is still an extremely difficult problem, but generally, the weight factor of the main optimization goal is larger than that of other secondary targets. Here, mainly to optimize the fuel economy of the vehicle and balance the emissions, the weighting factors

k1,

k2,

k3,

k4 take 0.4, 0.2, 0.2, and 0.2, respectively. The target value of fuel consumption can be customized according to the actual situation of the vehicle designed by the user, and the target value of emission generally needs to be based on the national standard of the vehicle exhaust emission. Equation (15) is used as an optimization indicator for both fuel consumption and emissions. The targets use the concept of relative fuel consumption and relative emissions, directly dividing the actual value of fuel consumption and emissions by the reference target value. In summary, the objective function of the defined parameter matching optimization of HEV is:

6. Analysis of Results

The EU standard steady-state driving condition NEDC is selected as the tested driving conditions, and different tasks are loaded to test the vehicle’s power, fuel and emissions performance, including driving condition cycle test, full force acceleration test, climbing test, and maximum speed test, etc.

Table 4 shows the partial test results (12 of the 108 matching schemes) of different matching parameters on vehicle fuel economy and emission performance under NEDC conditions. It can be seen that according to the matching calculation of the basic requirements of the motor demand power and the number of battery packs in the previous period, the constraints such as the maximum vehicle velocity

Vmax, acceleration time

t1, and maximum gradability

θ under different parameters are all satisfied. Among them, the maximum vehicle speed

Vmax of the vehicle is defined as the maximum speed of the continuous working area of the motor. At this time, the required power of the motor corresponds to the rated power of the motor and meets the requirements of pure electric drive mode; while the acceleration time

t1 and maximum gradability

θ of the vehicle are determined by the combined power of the motor and the engine, and not simply the sum of the power. It can be seen from the simulation test results that although the previous matching calculation does not limit the upper power of the motor and the engine, it does not mean that their power is selected as much as possible, because as the power increases, the volume and quality will also increase, and excessive power selection will cause the vehicle to not operate in an efficient area, resulting in economic deterioration.

It can be seen from

Table 4 that the optimization matching of the powertrain system parameters and the control variables has a direct impact on vehicle performance. When the design indicators are not clear or there are many optional component schemes, the optimization effect of the overall performance of the vehicle will be more significant.

The combined matrix experimental method is used to compare the proposed different parameter matching schemes. The statistical results of the range of fuel economy and emission performance are shown in

Table 5. The defined optimization percentage is the maximum percentage of optimization that the indicator can achieve over the entire matching range. It can be seen from

Table 5 that through MOO parameter matching, HEV can optimize 3.45% of fuel consumption per 100 km, while NO

x, CO, and HC emissions can be optimized by 6.15%, 3.71%, and 3.57%, respectively. The results show that the fuel economy and emissions of the vehicle can be significantly improved by optimizing the matching under the premise of power constraints, which also reflects the importance of system parameter matching and optimization design in the early stage of HEV development.

The indicators of fuel consumption and emission are as small as possible. Therefore, the value of the MOO function

F(x) defined by Equation (16) is also as small as possible. By evaluating each scheme, the minimum min

F(x) is Scheme 7 in

Table 4 when the maximum motor power is 48 kW, the maximum engine power is 35 kW, the number of battery packs is six, and the upper limit of the battery SOC is 90%., in which the overall performance of fuel consumption and emissions is optimal.

The following are the results of the various performance tests of the HEV in Scheme 7, in which

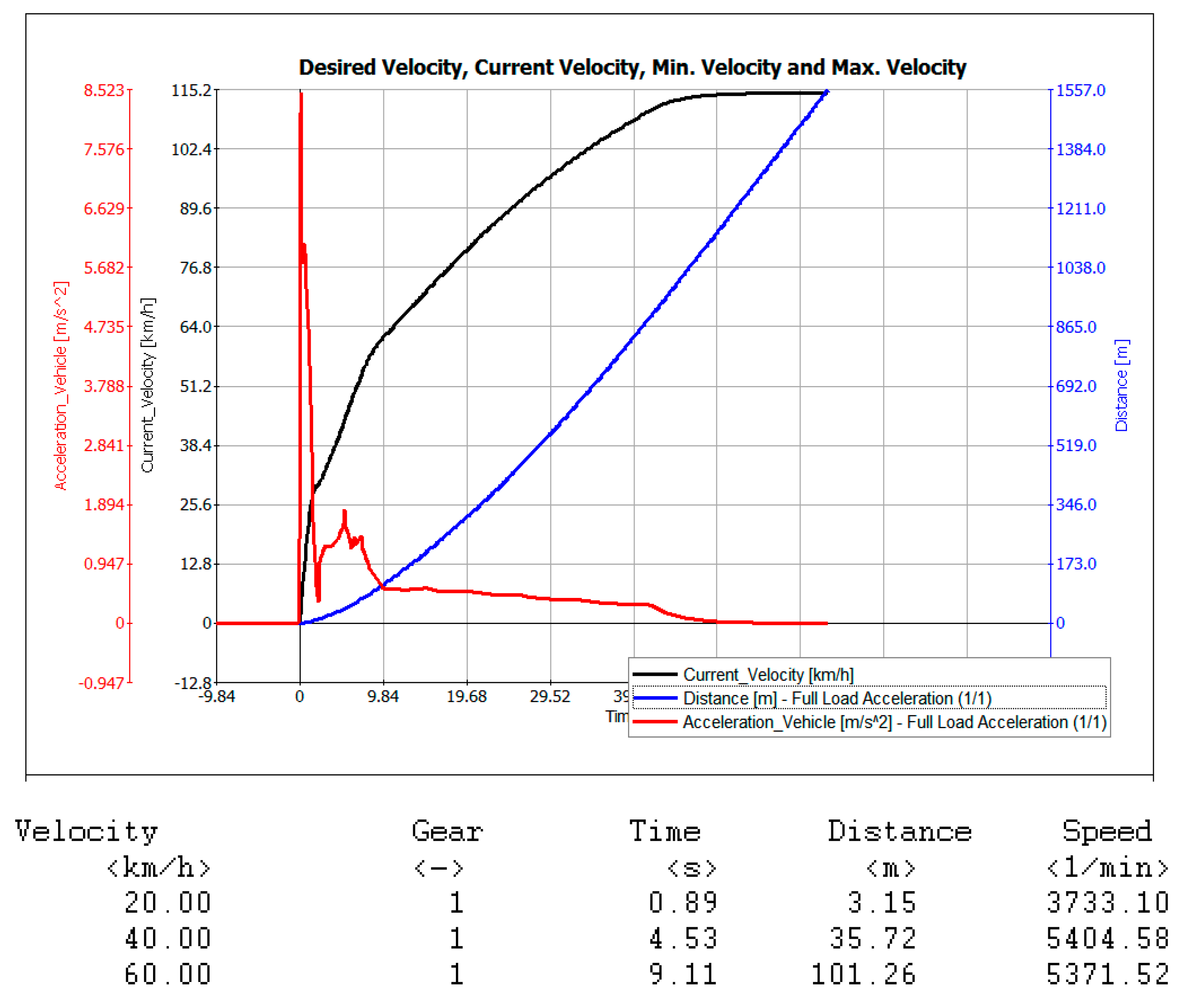

Figure 5 shows the test results of the full-load acceleration performance of the vehicle. It can be seen from the figure that under the full load condition, the acceleration time of the vehicle from the start to 60 km/h is 9.11 s, while the driving distance is 101.26 m, which meets the design of the vehicle’s acceleration performance indicator.

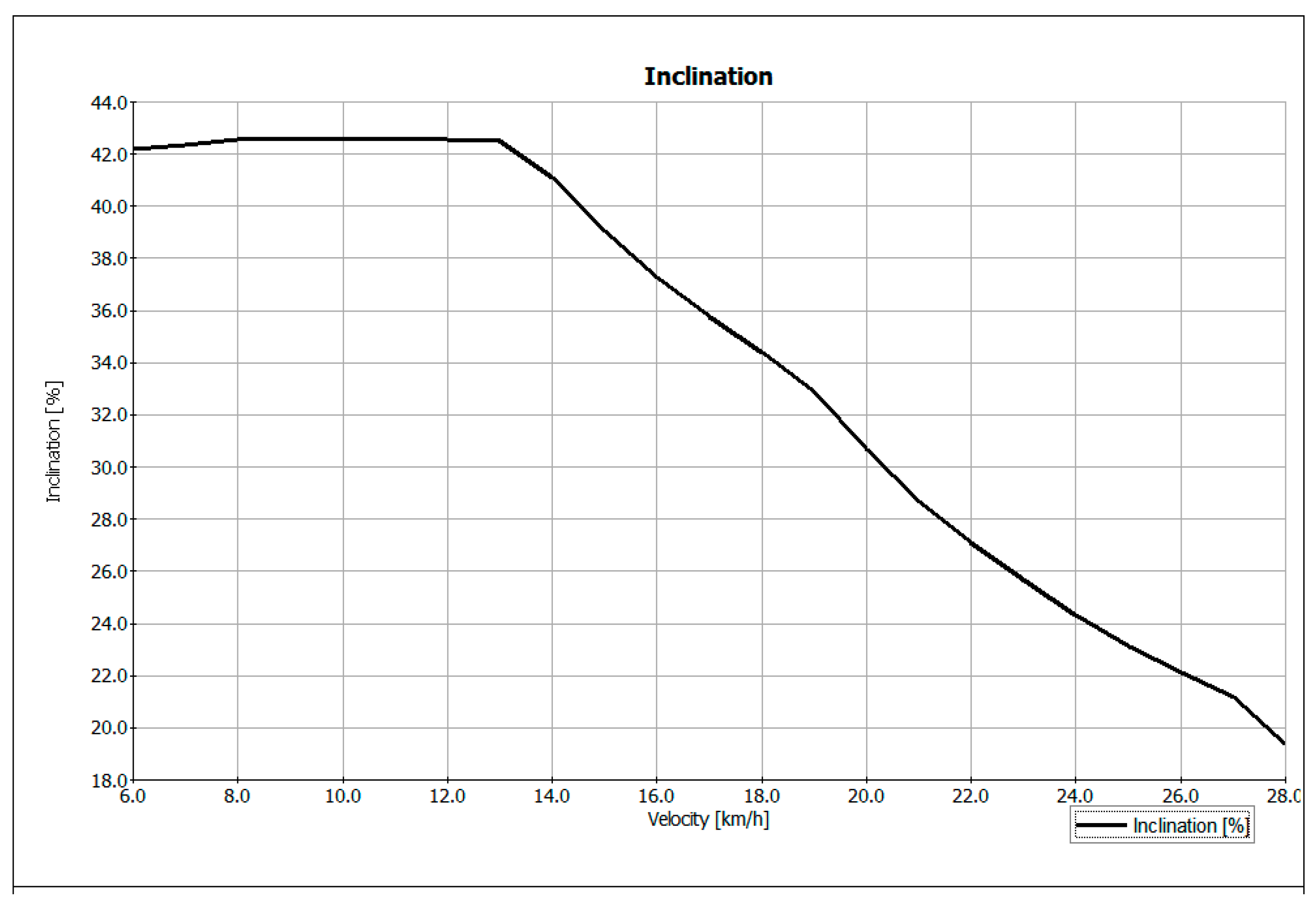

Figure 6 shows the maximum gradability performance of the HEV. Wherein, the slope percentage of the ordinate refers to the percentage of the road height difference to its horizontal distance, that is,

θ% = tan

γ × 100%, where

γ is the angle between the slope and the horizontal plane. The maximum gradability reflects the maximum gradability of the vehicle that can travel for a long time on a certain gradient. Generally, the maximum gradability of a small car in first gear is about 30% (16.7 degrees), while the off-road vehicle can reach 60% (31 degrees). From the test results, it can be seen that the HEV can meet the design performance indicator at a gradient of 42.66% (23 degrees) at 11 km/h.

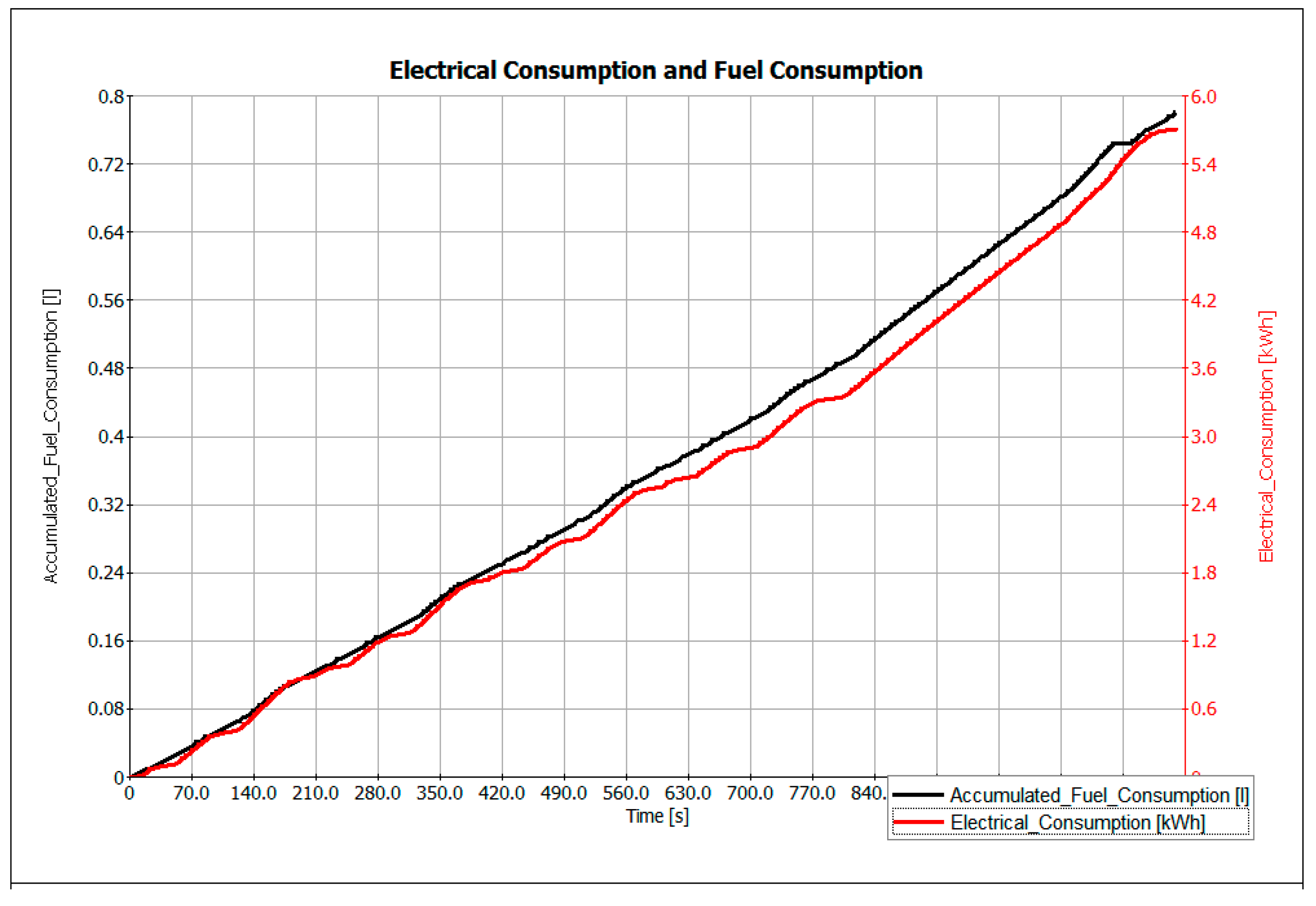

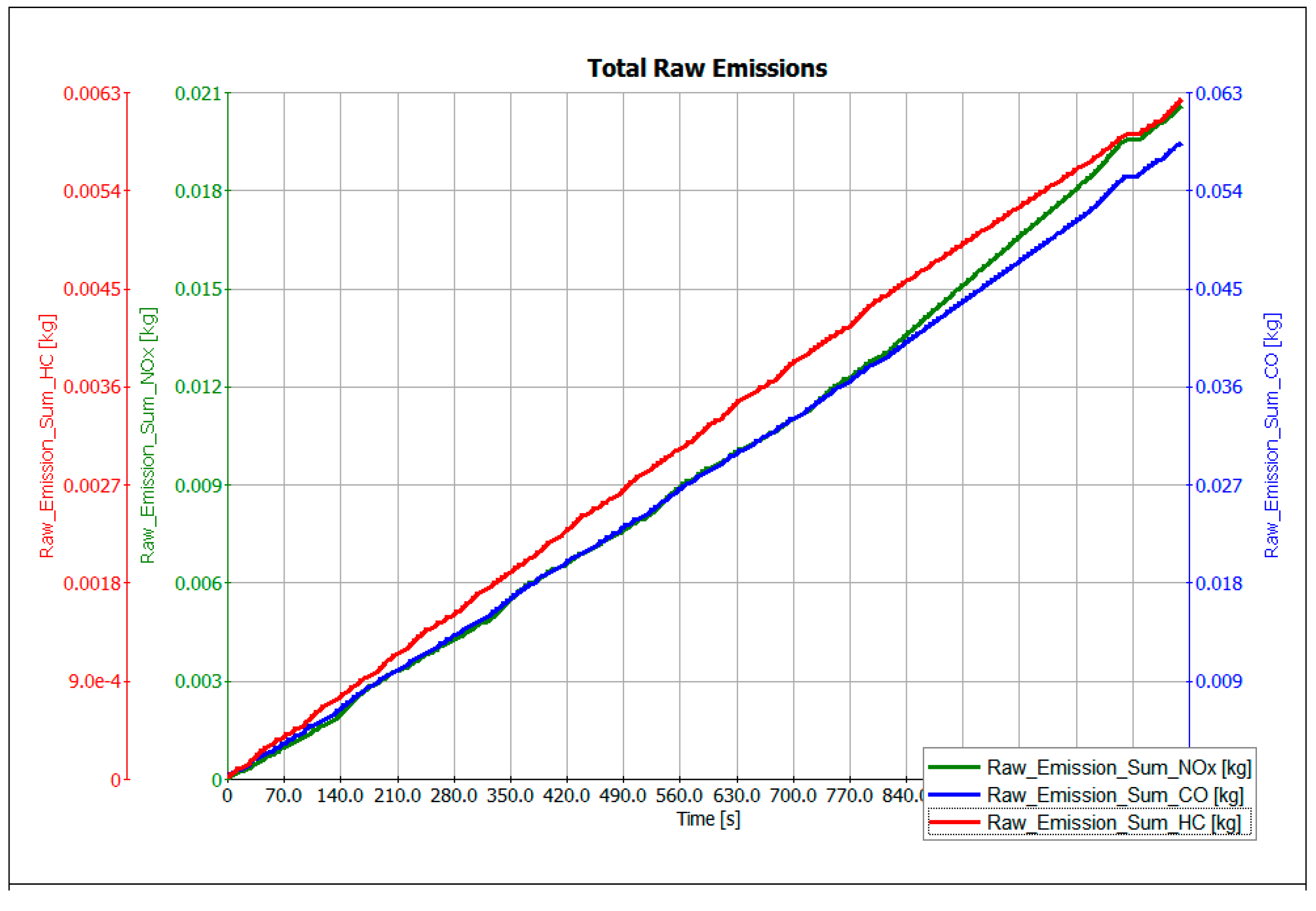

Figure 7 and

Figure 8 are the total fuel consumption, total power consumption curve and total emission curves of the HEV under NEDC tests. Through these curves, it can be calculated that the average fuel consumption per 100 km and the emission performance per km under NEDC conditions are NOx 1.83 g/km, CO 5.19 g/km, HC 0.56 g/km, 6.94 L/100 km, respectively.

In addition, AVL Cruise can analyze the impact of the three most important system parameters on HEV performance while other parameters are consistent.

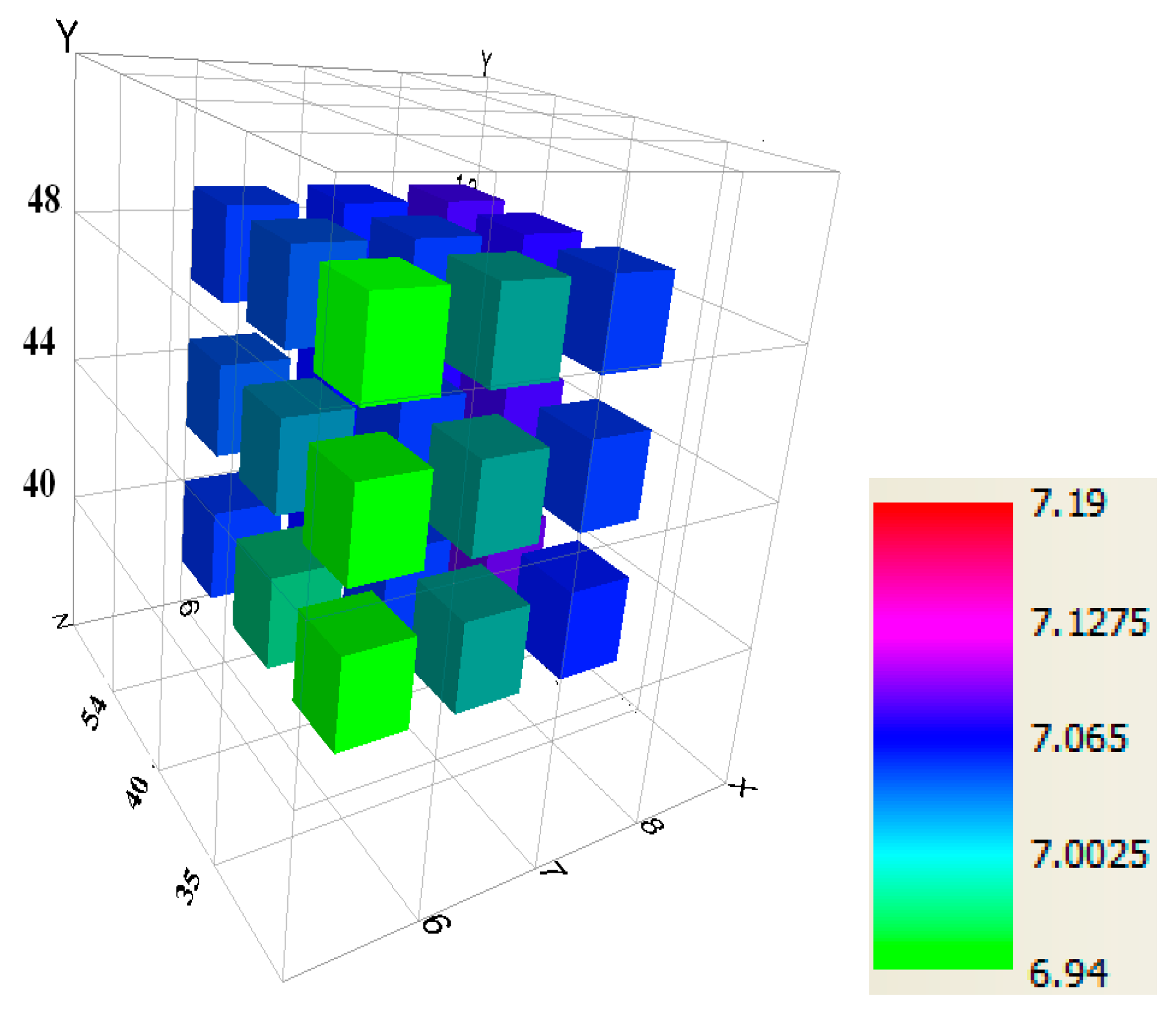

Figure 9 shows the effects of motor power, engine power, and the number of battery packs on fuel consumption per 100 km.

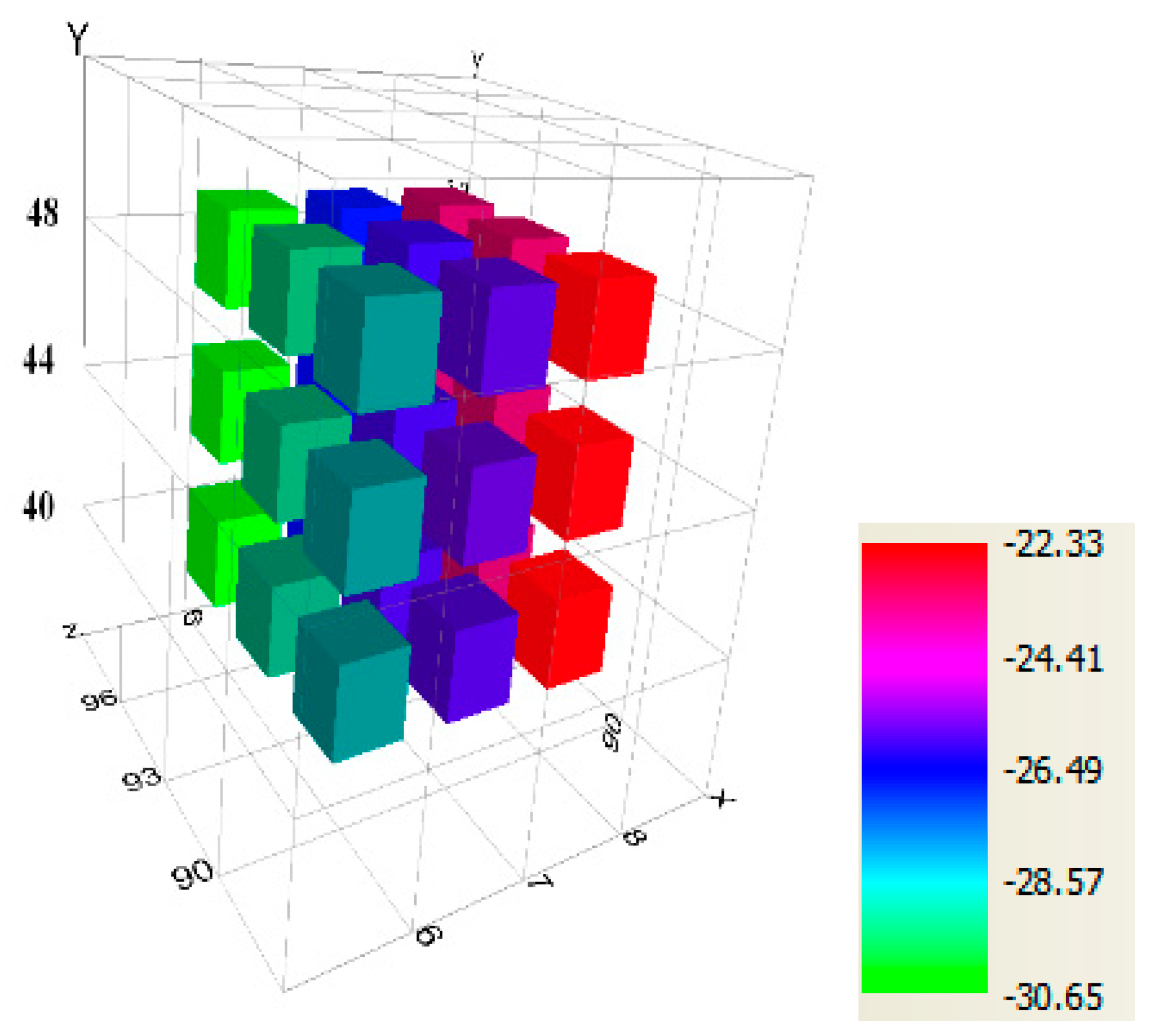

Figure 10 shows the effects of motor power, the number of battery packs and battery SOC operating upper limit on battery SOC. The analysis can determine the key factors affecting the performance of electric vehicles and further optimize the vehicle design.

In summary, the parameter matching of an electric vehicle powertrain system is a complex MOO problem. Only on the basis of establishing an accurate and complete vehicle model, can the best results be achieved after repeated optimization calculations. The vehicle configuration, system parameter matching, and EMS are three important factors affecting the performance of vehicle power, economy, and emissions, and the correlation between them is inseparable, in other words, the intelligent energy management strategy, which is one of research hotspots, can only exert its proper functions on the basis of a well-configured vehicle and parameter-matched powertrain system.

7. Conclusions

This paper provides theoretical guidance for the engineering optimization design of HEVs. That is to say, for a given powertrain system configuration in HEV research and design, first of all, we need to know the vehicle basic parameters and the vehicle performance indicators. Then, with the comprehensive optimization of fuel economy and emission as the goal, we can carry out the parameter matching research of the vehicle; finally, the powertrain system configuration can be optimized to study the parameter matching problem in each configuration. In this way, the configuration, parameter matching, and EMS are decoupled, so that the performance of the HEV can be further optimized.

The parameter matching optimization is indispensable in the design of HEVs. This problem is essentially a MOO problem with constraints. In this paper, an HEV parameter matching method based MOO is proposed. According to the vehicle basic parameters and performance indicators, the parameter ranges of the components were analyzed. The weight coefficient method was applied to convert the MOO problem of fuel consumption and emission into an SOO problem, and the parameter matching effect evaluated by the objective function. The research results of this paper provide an optimized vehicle configuration for EMS research and provide guidance for obtaining the best match between powertrain system parameters and control variables to improve fuel economy and reduce emissions. Additionally, it has high application value in the optimization design of electric vehicle engineering. It should be pointed out that the purpose of parameter matching optimization is to reduce the blindness of component selection and avoid the risk of increasing cost due to unreasonable selection. Simultaneously, parameter matching optimization is a necessary stage of pre-validation before bench tests and vehicle integration tests; and it is necessary to adjust the parameters of the motor, the engine or the gear ratio according to the actual tested results to achieve the optimal overall performance.

Compared with the traditional method, the proposed parameter matching optimization method of HEVs can significantly reduce fuel consumption and emissions of a vehicle simultaneously, and provides an optimized vehicle configuration for the study of an energy management strategy (EMS). It has high application value in the optimization design of electric vehicle engineering. In addition, the parameter matching optimization in this paper also takes into account the control variables in the EMS and provides a solution for the parallel optimization of system parameters and control variables. It should be noted that whether it is traditional parameter matching or intelligent algorithms, such as genetic algorithms, to achieve parameter matching of the powertrain system, the theoretical results may be ideal, but in practice if cost and other factors are taken into account on the market, the parameters of the selected components such as motors and gearboxes may not be optimally matched, but in the vicinity thereof; however, small changes in parameters can sometimes result in a lower overall system performance. Thus, further comprehensive cost considerations should be made to finally decide which product or components to choose.