Reduction of Induction Motor Energy Consumption via Variable Velocity and Flux References

Abstract

1. Introduction

2. System Model

2.1. The Model of the Induction Motor

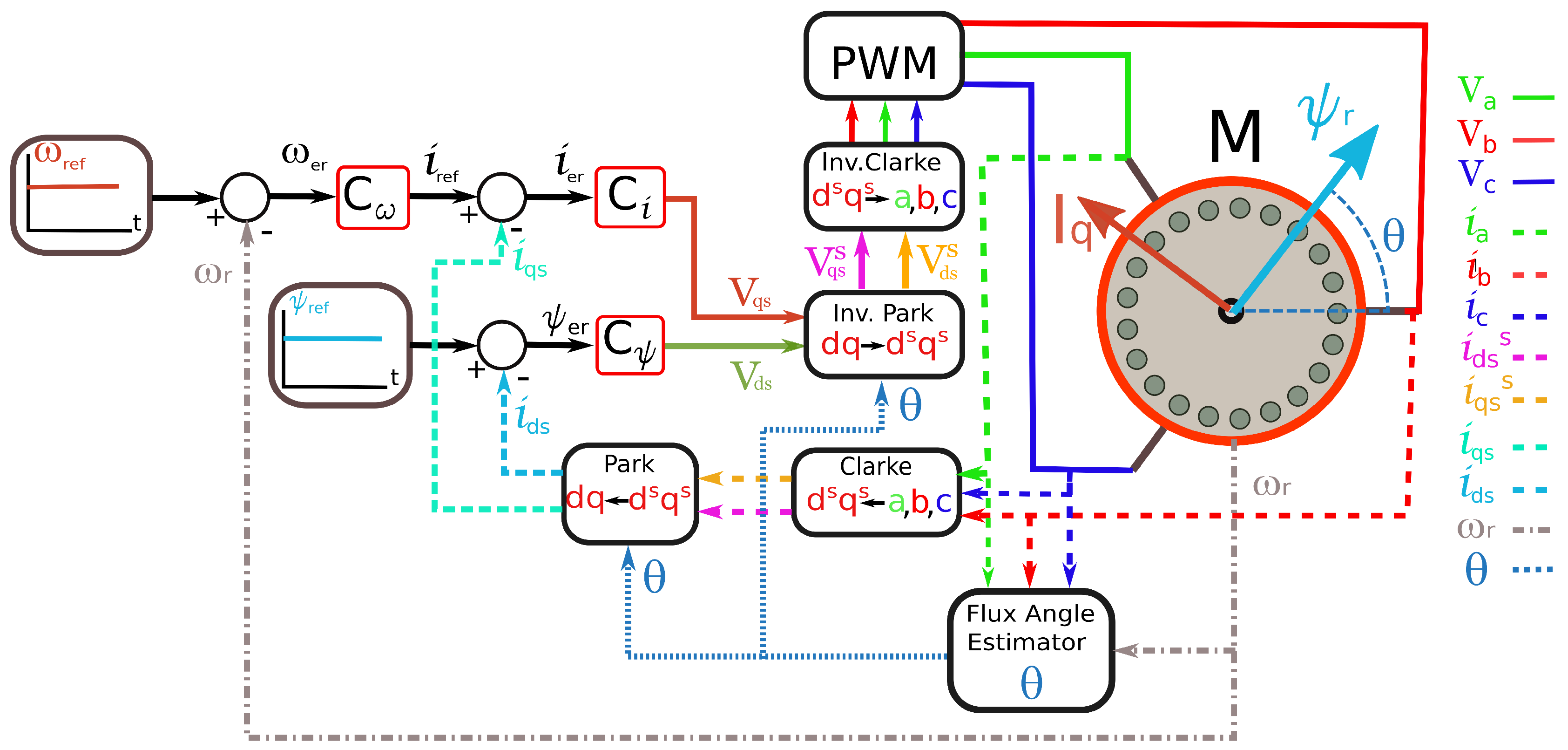

2.2. Field-Oriented Control of the Induction Motor

2.2.1. Estimation of the Magnetic Flux Angle

2.2.2. The Park Transformation

2.2.3. The PI Controllers

3. The Proposed Procedure to Find Variable References

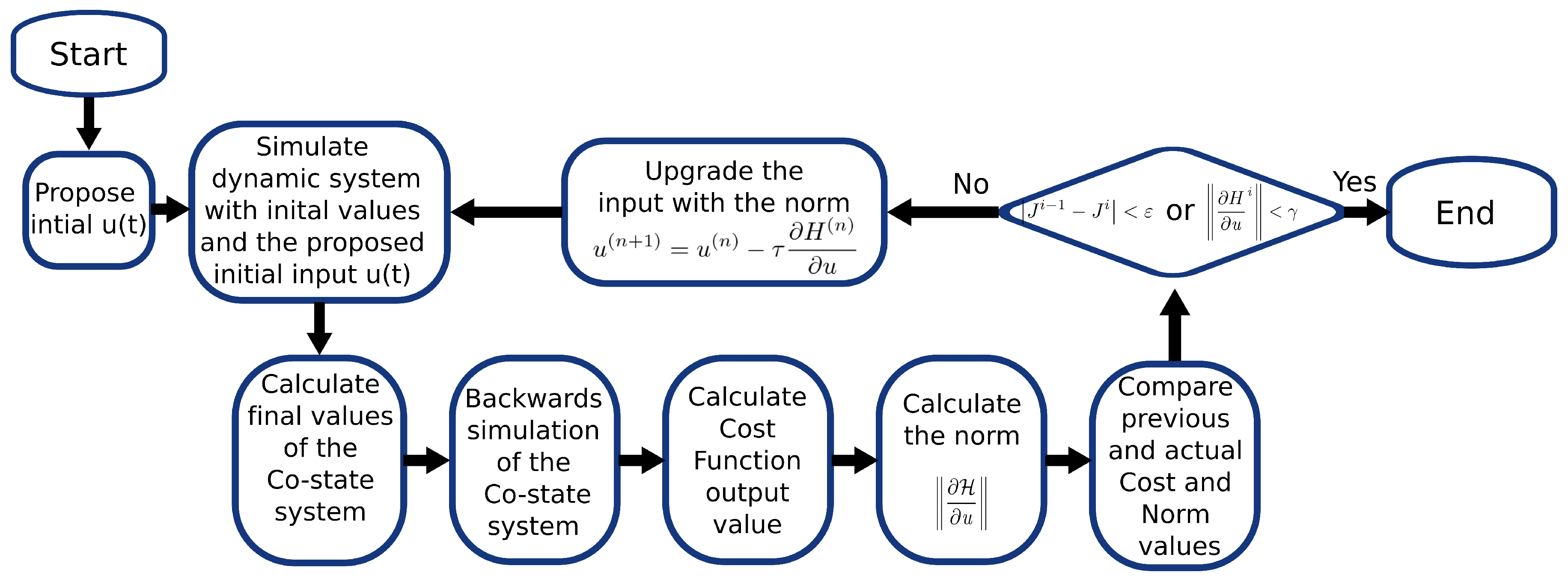

3.1. A Variational Tool

3.2. Finding Variable References

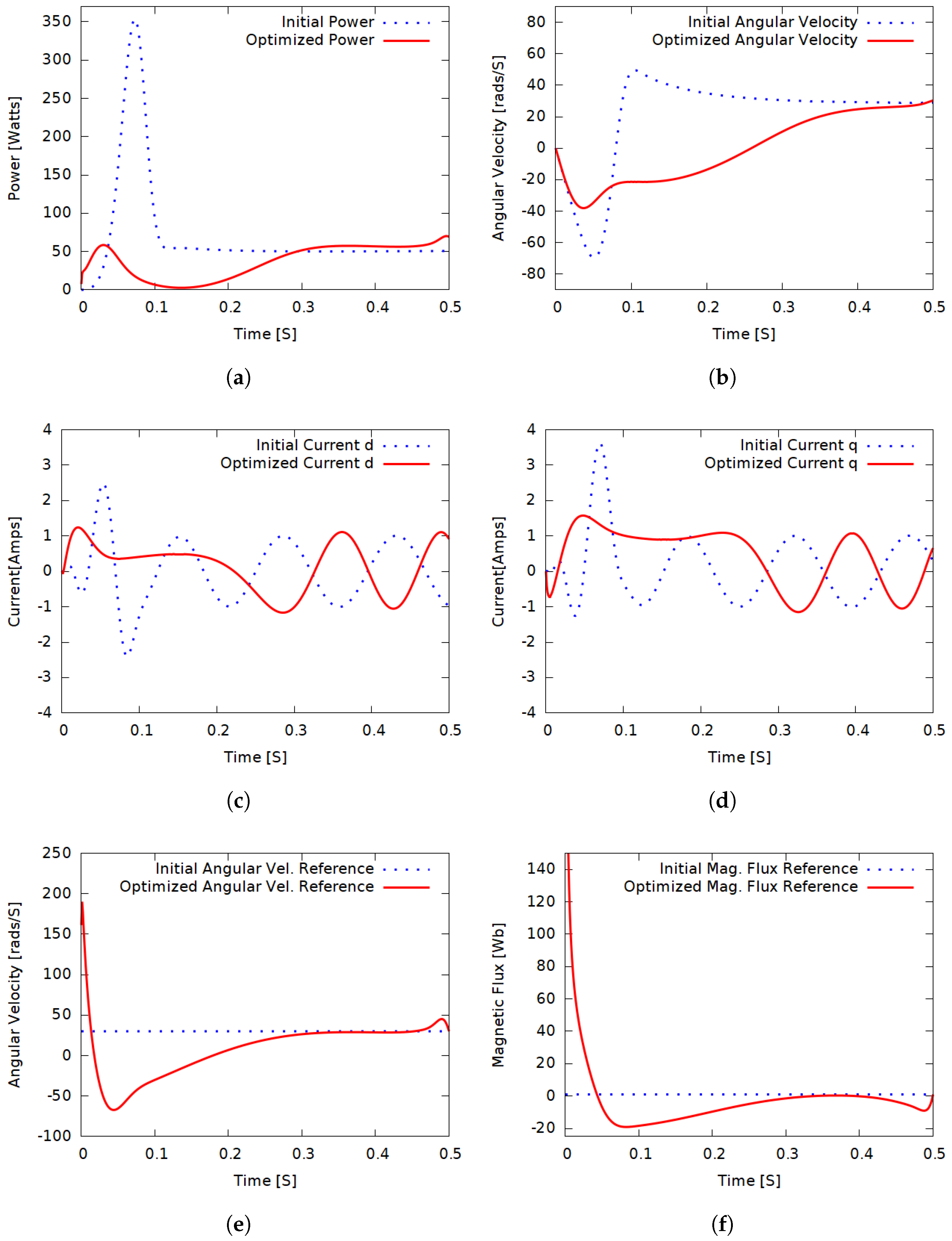

4. Simulation Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Waide, P.; Brunner, C.U. Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems; IEA Energy Papers 2011/7; OECD Publishing: Paris, France, 2011. [Google Scholar]

- Ferreira, F.J.T.E.; de Almeida, A.T. Overview on energy saving opportunities in electric motor driven systems—Part 1: System efficiency improvement. In Proceedings of the 2016 IEEE/IAS 52nd Industrial and Commercial Power Systems Technical Conference (I CPS), Detroit, MI, USA, 1–5 May 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Stumper, J.; Kennel, R. Real-time dynamic efficiency optimization for induction machines. In Proceedings of the 2013 American Control Conference, Washington, DC, USA, 17–19 June 2013; pp. 6589–6594. [Google Scholar] [CrossRef]

- Bazzi, A.M.; Krein, P.T. Review of Methods for Real-Time Loss Minimization in Induction Machines. IEEE Trans. Ind. Appl. 2010, 46, 2319–2328. [Google Scholar] [CrossRef]

- Ghozzi, S.; Jelassi, K.; Roboam, X. Energy optimization of induction motor drives. In Proceedings of the 2004 IEEE International Conference on Industrial Technology, 2004, Hammamet, Tunisia, 8–10 December 2004; Volume 2, pp. 602–610. [Google Scholar] [CrossRef]

- Thangaraj, R.; Chelliah, T.R.; Pant, M.; Abraham, A.; Grosan, C. Optimal gain tuning of PI speed controller in induction motor drives using particle swarm optimization. Log. J. IGPL 2011, 19, 343–356. [Google Scholar] [CrossRef][Green Version]

- Mitsukura, Y.; Yamamoto, T.; Kaneda, M. A design of self-tuning PID controllers using a genetic algorithm. In Proceedings of the 1999 American Control Conference (Cat. No. 99CH36251), San Diego, CA, USA, 2–4 June 1999; Volume 2, pp. 1361–1365. [Google Scholar] [CrossRef]

- Mohamed, H.A.F.; Lau, E.L.; Yang, S.S.; Moghavvemi, M. Fuzzy-SMC-PI Flux and Speed Control for Induction Motors. In Proceedings of the 2008 IEEE Conference on Robotics, Automation and Mechatronics, Chengdu, China, 21–24 September 2008; pp. 325–330. [Google Scholar] [CrossRef]

- Taheri, A.; Rahmati, A.; Kaboli, S. Efficiency Improvement in DTC of Six-Phase Induction Machine by Adaptive Gradient Descent of Flux. IEEE Trans. Power Electron. 2012, 27, 1552–1562. [Google Scholar] [CrossRef]

- Hung, N.T.; Thien, N.C.; Nguyen, T.P.; Le, V.S.; Tuan, D.A. Optimization of Electric Energy in Three-Phase Induction Motor by Balancing of Torque and Flux Dependent Losses; AETA 2013: Recent Advances in Electrical Engineering and Related Sciences; Zelinka, I., Duy, V.H., Cha, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 497–507. [Google Scholar]

- Melo, P.; de Castro, R.; Araujo, R.E. Evaluation of an Energy Loss-Minimization Algorithm for EVs Based on Induction Motor. In Induction Motors; IntechOpen: Rijeka, Croatia, 2012; Chapter 17. [Google Scholar] [CrossRef]

- Thanh Hung, N.; Chi Thien, N.; Phuong Nguyen, T.; Le, V.S.; Tuan, D.A. Optimization of Electric Energy in Three-Phase Induction Motor by Balancing of Torque and Flux Dependent Losses. Lect. Notes Electr. Eng. 2014, 282, 497–507. [Google Scholar] [CrossRef]

- Borisevich, A. Numerical Method for Power Losses Minimization of Vector-Controlled Induction Motor. Int. J. Power Electron. Drive Syst. 2015, 6, 486–497. [Google Scholar] [CrossRef]

- Ta, C.M.; Hori, Y. Convergence improvement of efficiency-optimization control of induction motor drives. IEEE Trans. Ind. Appl. 2001, 37, 1746–1753. [Google Scholar] [CrossRef]

- Ismail, M. Efficiency optimisation with PI gain adaptation of field-oriented control applied on five phase induction motor using AI technique. Int. J. Model. 2013, 20, 344–360. [Google Scholar] [CrossRef]

- Wilson, D. Teaching Your PI Controller to Behave. 2015. Available online: http://www.webcitation.org/78mq5YtqU (accessed on 31 May 2019).

- Bose, B. Modern Power Electronics and AC Drives; Prentice Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Krishnan, R. Electric Motor Drives: Modeling Analysis In addition, Control; Prentice-Hall Of India Pvt. Limited: New Delhi, India, 2008. [Google Scholar]

- De Doncker, R.; Pulle, D.; Veltman, A. Advanced Electrical Drives: Analysis, Modeling, Control; Power Systems; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Duesterhoeft, W.C.; Schulz, M.W.; Clarke, E. Determination of Instantaneous Currents and Voltages by Means of Alpha, Beta, and Zero Components. Trans. Am. Inst. Electr. Eng. 1951, 70, 1248–1255. [Google Scholar] [CrossRef]

- Kirk, D. Optimal Control Theory: An Introduction; Dover Books on Electrical Engineering; Dover Publications: Englewood Cliffs, NJ, USA, 2004. [Google Scholar]

- Cassel, K. Variational Methods with Applications in Science and Engineering; Cambridge University Press: New York, NY, USA, 2013. [Google Scholar]

- Liberzon, D. Calculus of Variations and Optimal Control Theory: A Concise Introduction; Princeton University Press: Princeton, NJ, USA, 2012. [Google Scholar]

- Reginatto, R.; Ramos, R.A. On electrical power evaluation in dq coordinates under sinusoidal unbalanced conditions. IET Gener. Transm. Distrib. 2014, 8, 976–982. [Google Scholar] [CrossRef]

| Parameter | Description |

|---|---|

| Supply current d-axis | |

| Supply current q-axis | |

| Rotor magnetic flux d-axis | |

| Rotor magnetic flux q-axis | |

| Supply voltage d-axis | |

| Supply voltage q-axis | |

| Motor angular velocity | |

| Mechanic load torque | |

| Rotor resistance | |

| Stator resistance | |

| Stator inductance | |

| Rotor inductance | |

| Mutual inductance | |

| J | Rotor inertia |

| P | Number of poles |

| Parameter | Value |

|---|---|

| 559.27 W | |

| P | 2 |

| 21.34 | |

| 4.19 | |

| 1.37 H | |

| 0.05 H | |

| 0.05 H | |

| 1.0 Nm | |

| J | 5.89 × 10 kg·m |

| Parameter | Original | Optimized | % |

|---|---|---|---|

| Peak Current | 3.62 A | 1.56 A | |

| Peak Power | 352.35 W | 70.18 W | |

| Energy | 34.83 J | 18.50 J | |

| Apparent Average Power | 103.73 VA | 51.59 VA | |

| Current Consumption | 1.32 As | 1.13 As |

| Parameter | Original | Optimized | % |

|---|---|---|---|

| Peak Current | 3.54 A | 2.62 A | |

| Peak Power | 378.01 W | 199.73 W | |

| Energy | 42.52 J | 32.58 J | |

| Apparent Average Power | 143.76 VA | 110.01 VA | |

| Current Consumption | 1.34 As | 1.24 As |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Resa, J.; Cortes, D.; Marquez-Rubio, J.F.; Navarro, D. Reduction of Induction Motor Energy Consumption via Variable Velocity and Flux References. Electronics 2019, 8, 740. https://doi.org/10.3390/electronics8070740

Resa J, Cortes D, Marquez-Rubio JF, Navarro D. Reduction of Induction Motor Energy Consumption via Variable Velocity and Flux References. Electronics. 2019; 8(7):740. https://doi.org/10.3390/electronics8070740

Chicago/Turabian StyleResa, Jorge, Domingo Cortes, Juan Francisco Marquez-Rubio, and David Navarro. 2019. "Reduction of Induction Motor Energy Consumption via Variable Velocity and Flux References" Electronics 8, no. 7: 740. https://doi.org/10.3390/electronics8070740

APA StyleResa, J., Cortes, D., Marquez-Rubio, J. F., & Navarro, D. (2019). Reduction of Induction Motor Energy Consumption via Variable Velocity and Flux References. Electronics, 8(7), 740. https://doi.org/10.3390/electronics8070740