Review of Pulsed-Eddy-Current Signal Feature-Extraction Methods for Conductive Ferromagnetic Material-Thickness Quantification

Abstract

:1. Introduction

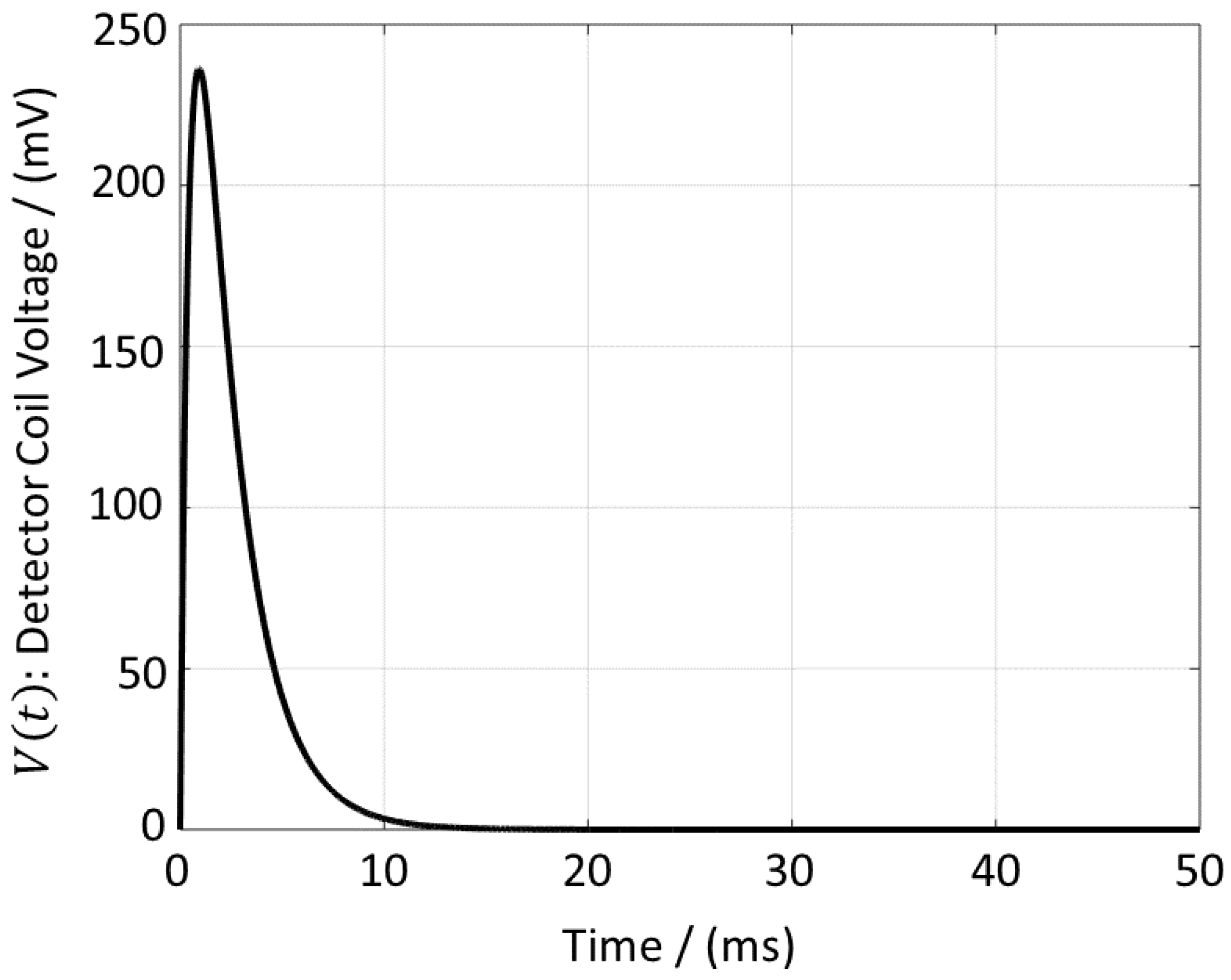

2. Detector Coil-Based PEC Sensors for Ferromagnetic Material-Thickness Quantification: Operating Principles

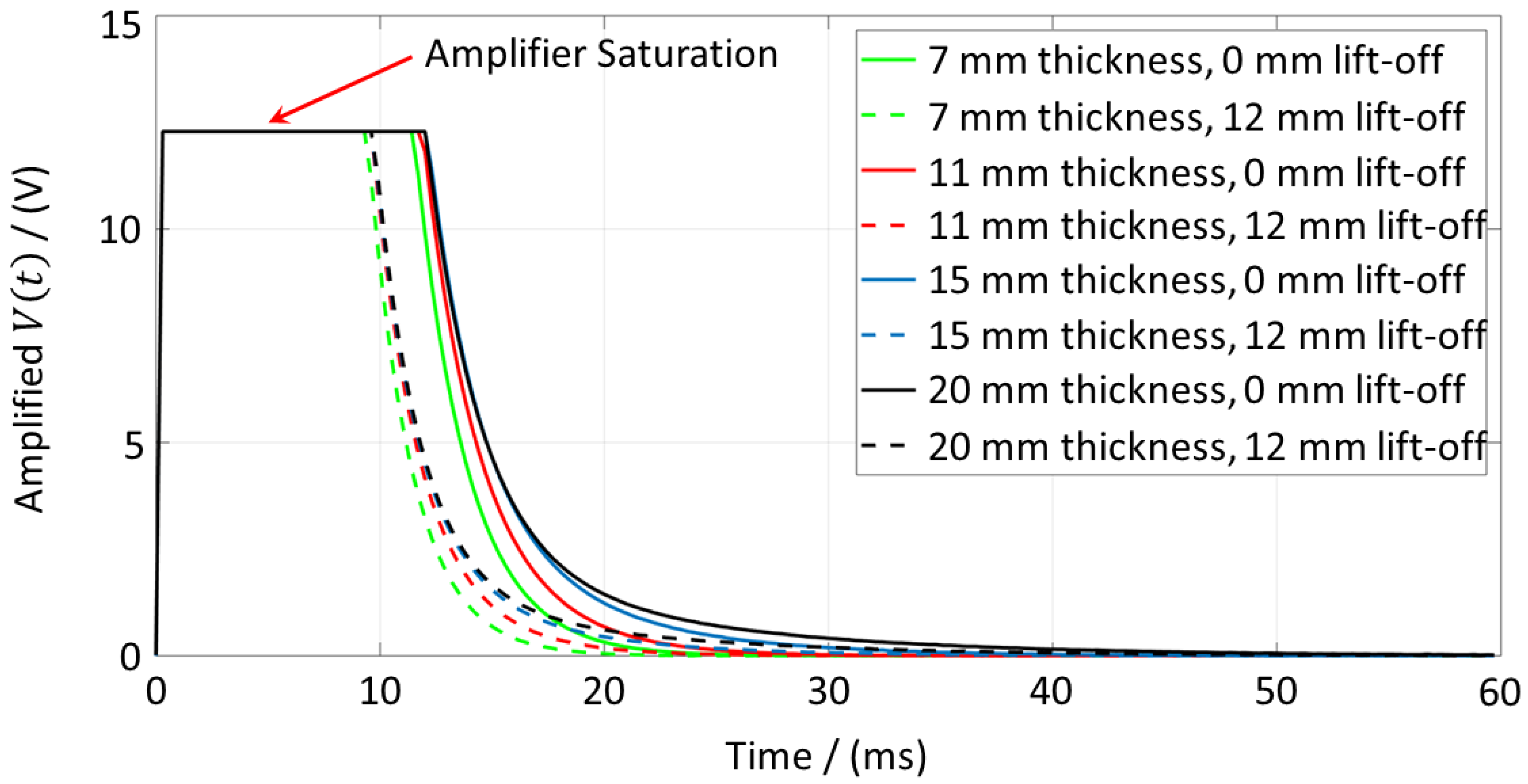

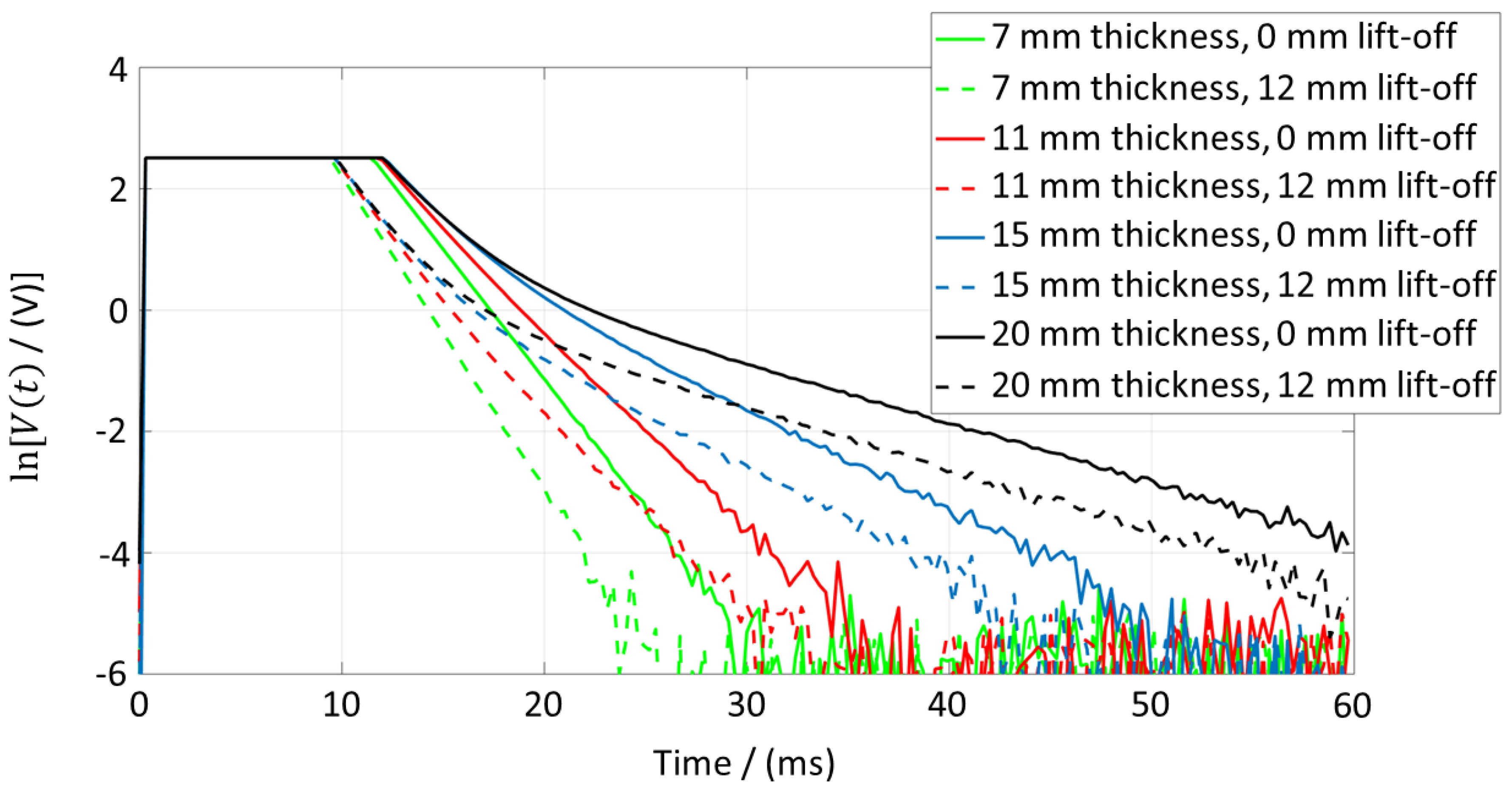

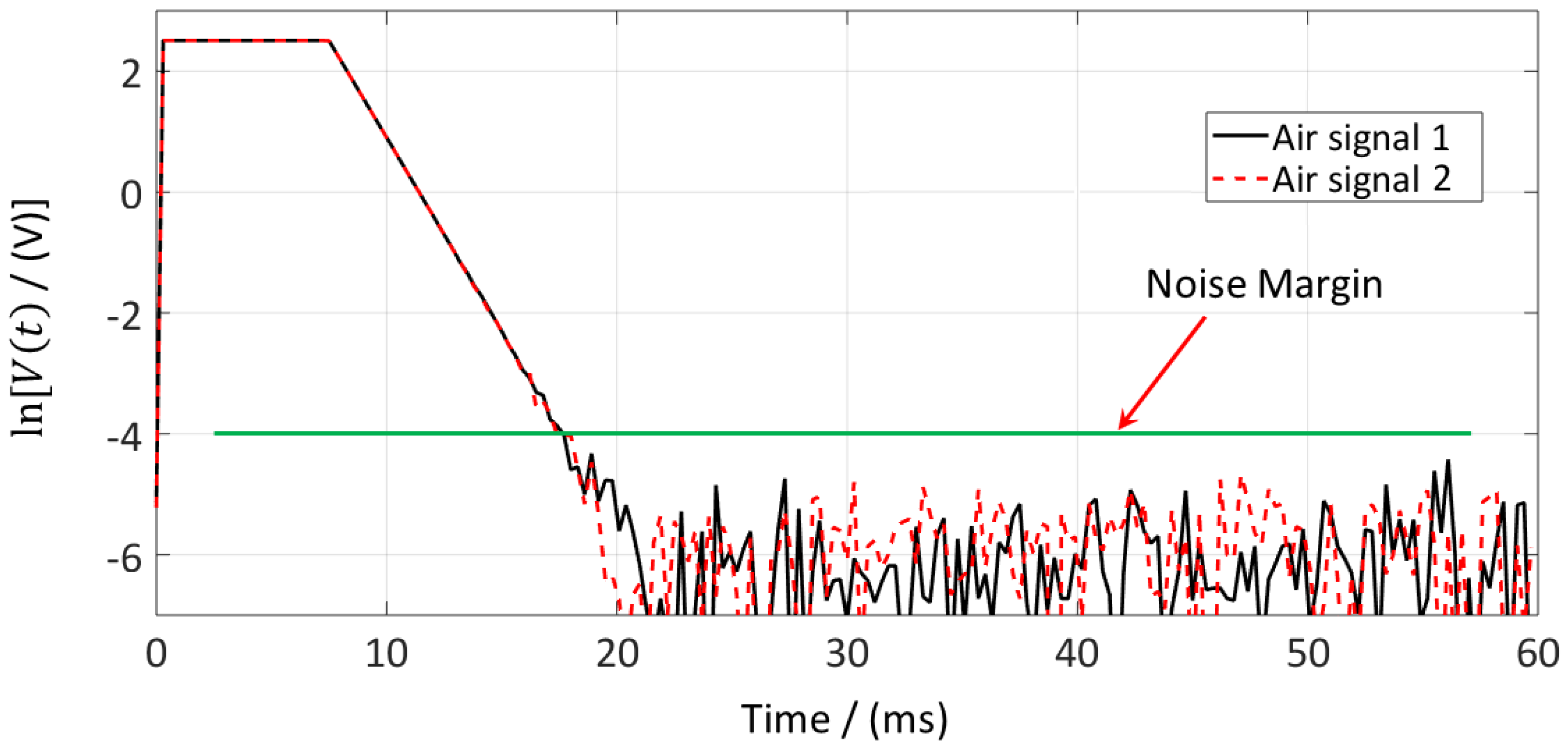

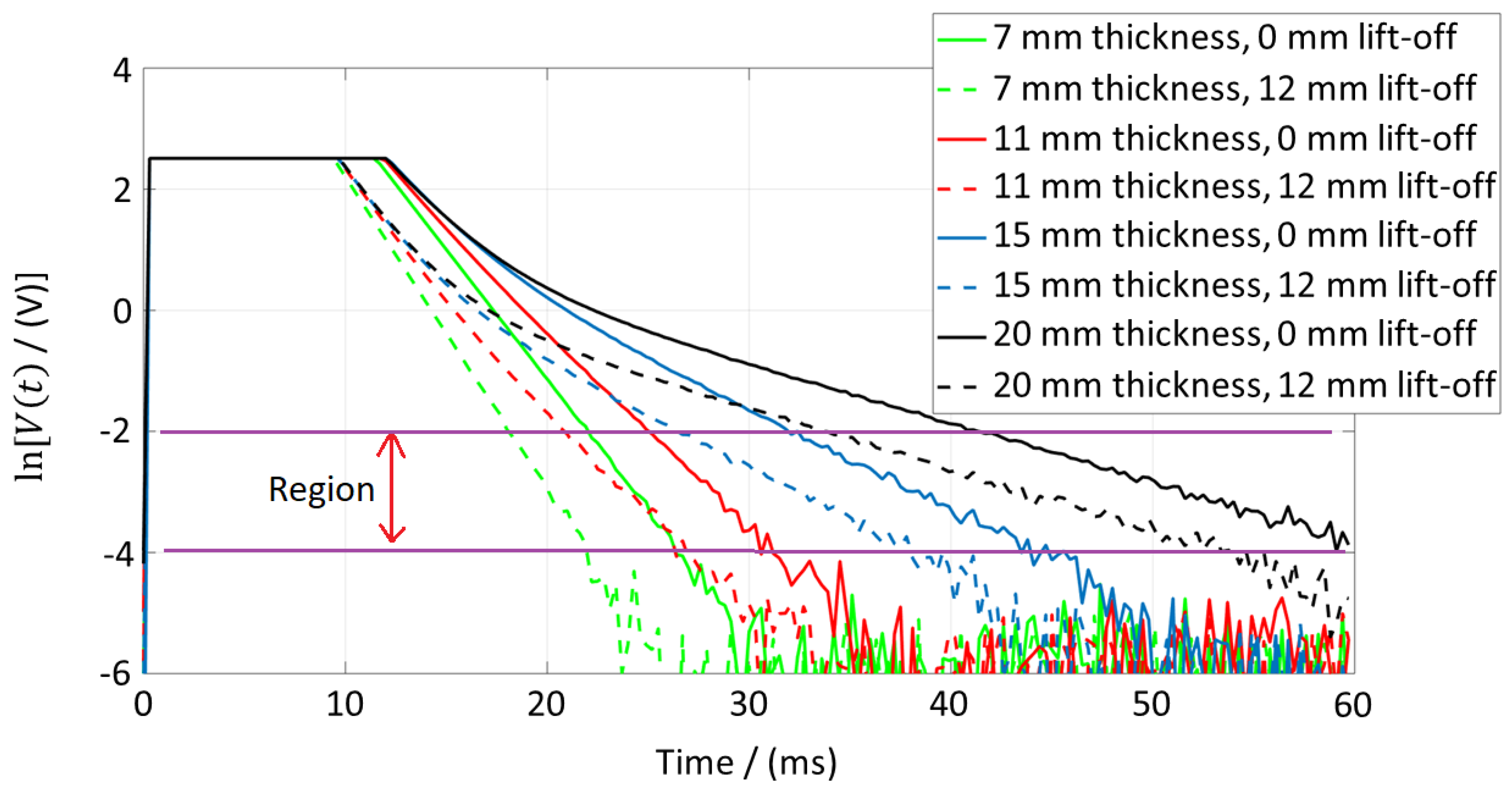

3. Experimental PEC Signals

4. Review of Feature-Extraction Methods

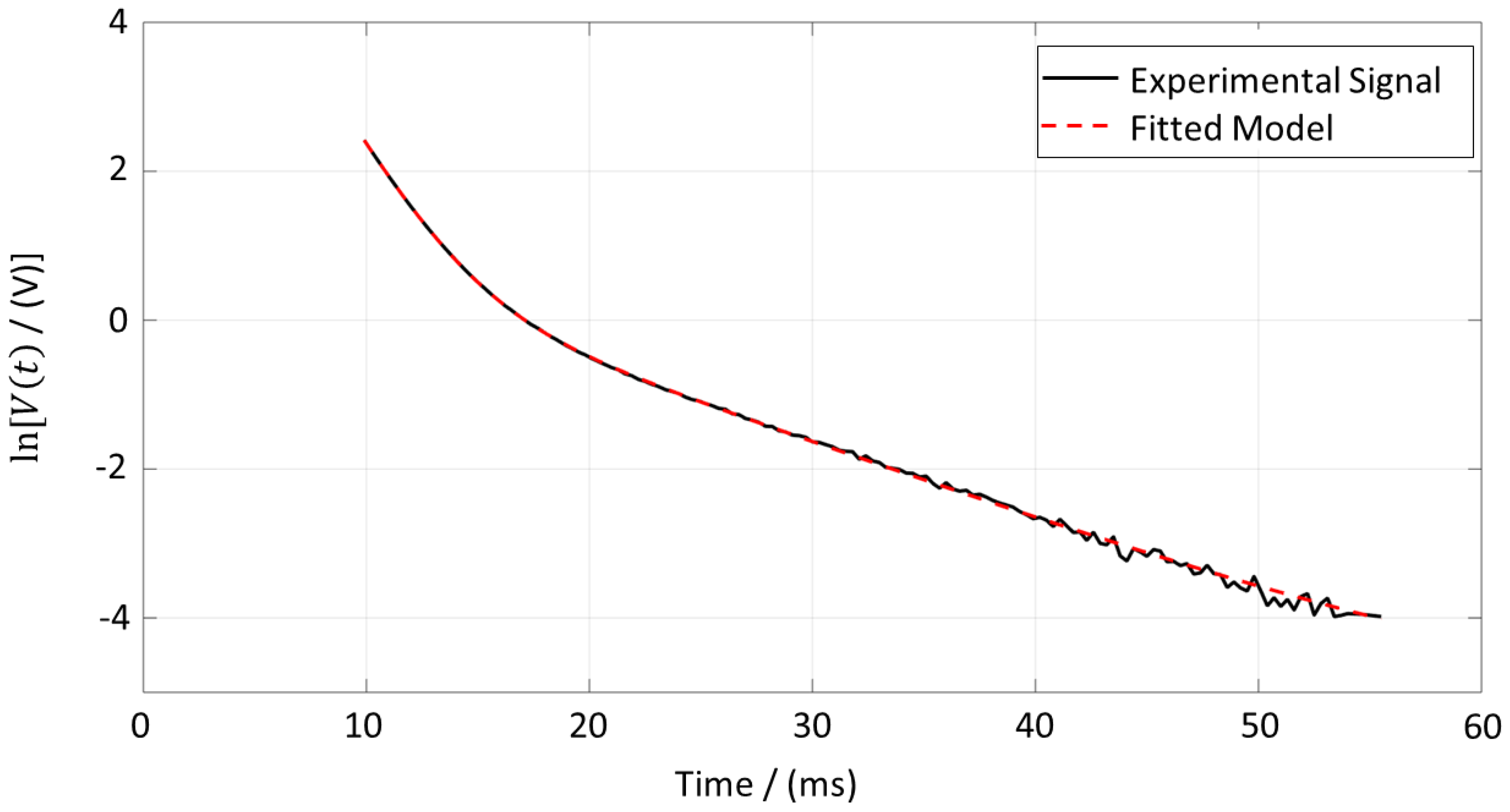

4.1. Fitting a Sum of Exponentials

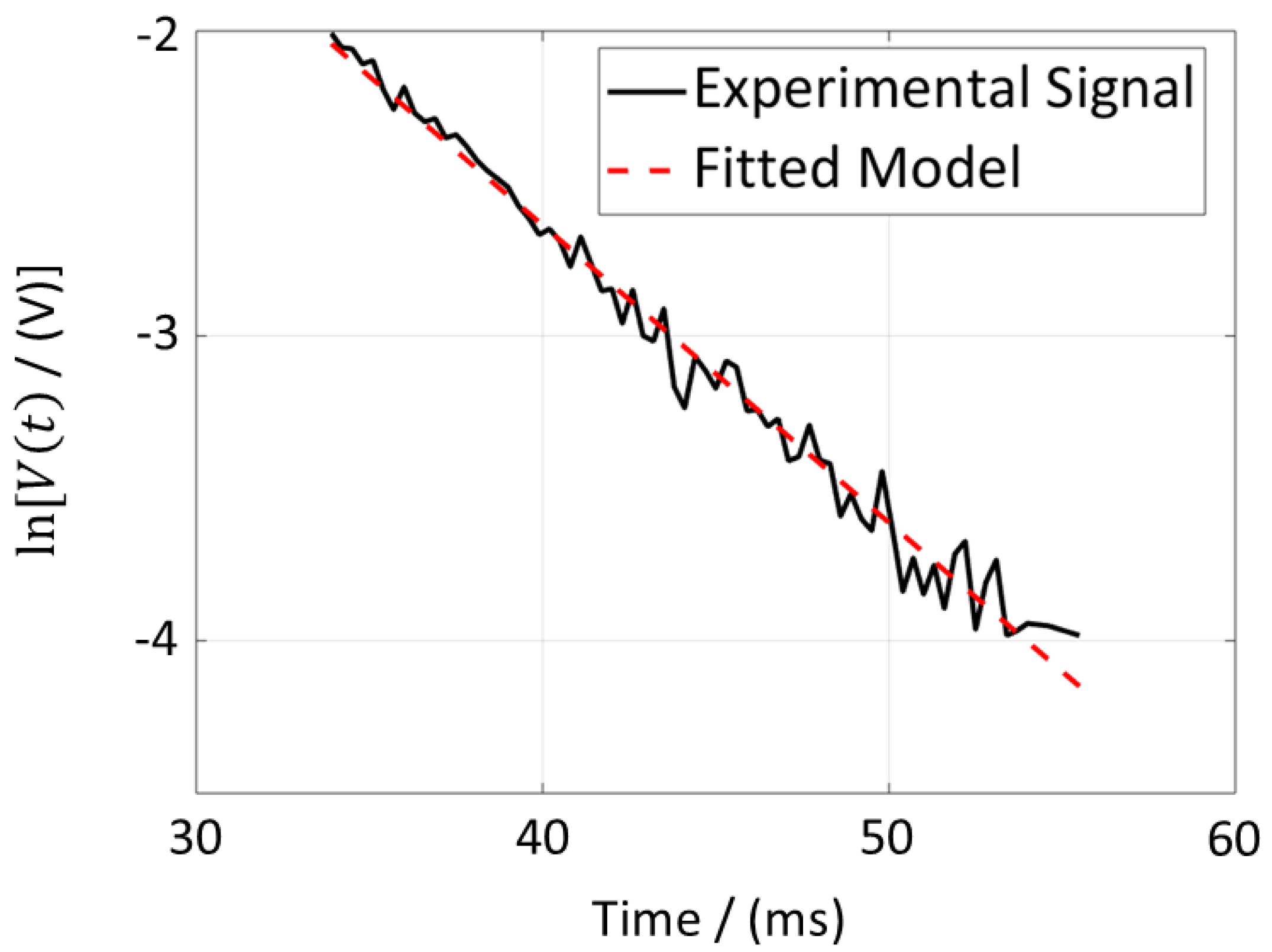

4.2. Fitting a Straight Line to the Later Stage

4.2.1. Least Squares-Based Fixed-Region Line-Fitting Method

4.2.2. Savitzky–Golay Filter and Adaptive Least-Squares Fitting-Line (ALSFL)-Based Method

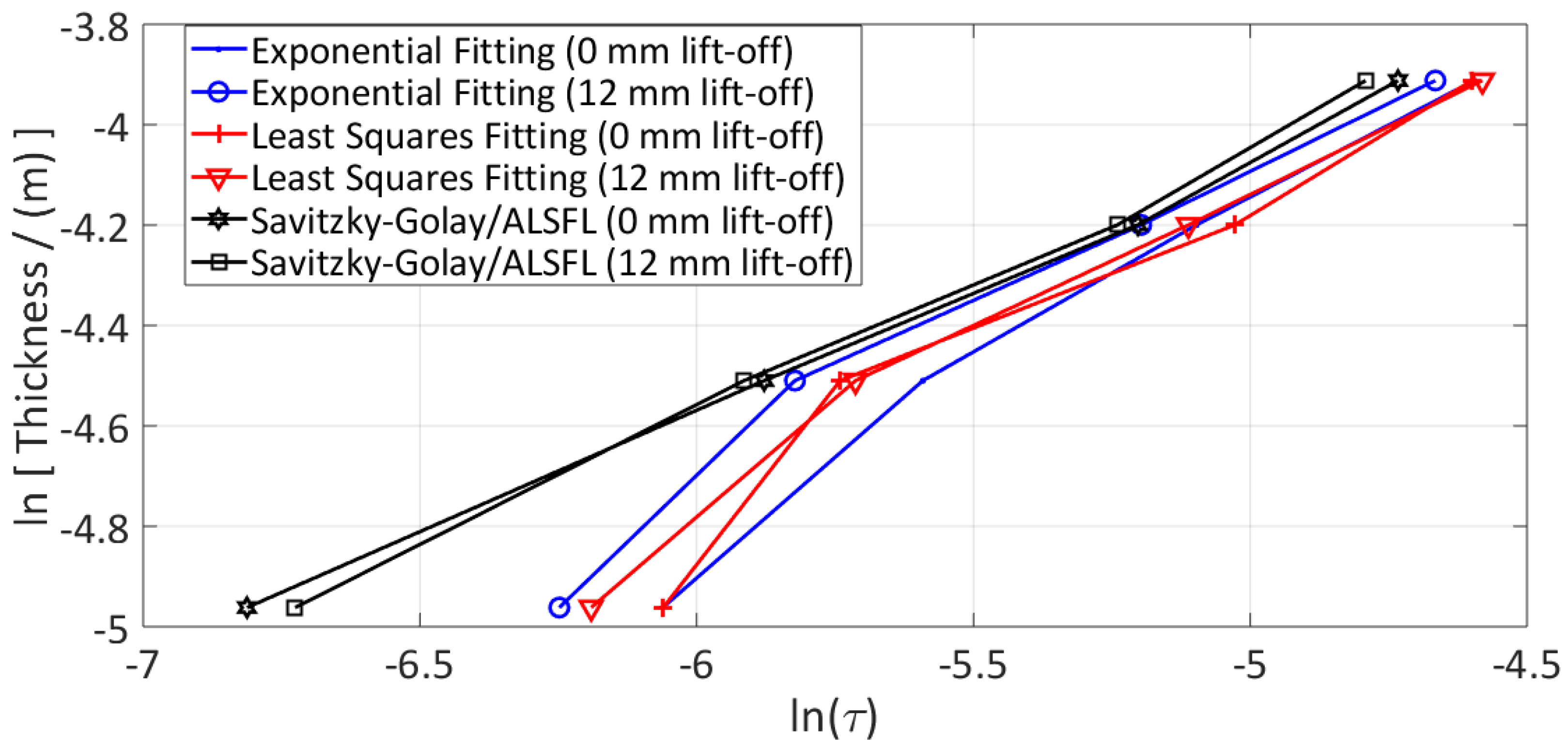

4.3. Results Comparison

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ALSFL | Adaptive Least Squares Fitting Line |

| CPU | Central Processing Unit |

| DC | Direct Current |

| EC | Eddy Current |

| NDE | Nondestructive Evaluation |

| NDT | Nondestructive Testing |

| PC | Personal Computer |

| PEC | Pulsed Eddy Current |

| RAM | Random Access Memory |

| RMSE | Root Mean Square Error |

References

- Luo, Q.; Shi, Y.; Wang, Z.; Zhang, W.; Li, Y. A Study of Applying Pulsed Remote Field Eddy Current in Ferromagnetic Pipes Testing. Sensors 2017, 17, 1038. [Google Scholar] [CrossRef] [PubMed]

- Melchers, R.E. Long-term immersion corrosion of steels in seawaters with elevated nutrient concentration. Corros. Sci. 2014, 81, 110–116. [Google Scholar] [CrossRef]

- Ji, J.; Robert, D.J.; Zhang, C.; Zhang, D.; Kodikara, J. Probabilistic physical modelling of corroded cast iron pipes for lifetime prediction. Struct. Saf. 2017, 64, 62–75. [Google Scholar] [CrossRef]

- Sophian, A.; Tian, G.Y.; Taylor, D.; Rudlin, J. Design of a pulsed eddy current sensor for detection of defects in aircraft lap-joints. Sens. Actuators A Phys. 2002, 101, 92–98. [Google Scholar] [CrossRef]

- Sophian, A.; Tian, G.Y.; Taylor, D.; Rudlin, J. A feature extraction technique based on principal component analysis for pulsed eddy current NDT. NDT&E Int. 2003, 36, 37–41. [Google Scholar]

- Sophian, A. Characterisation of Surface and Sub-Surface Discontinuities in Metals Using Pulsed Eddy Current Sensors. Ph.D. Thesis, University of Huddersfield, Huddersfield, UK, 2003. [Google Scholar]

- Li, Y.; Jing, H.; Zainal Abidin, I.M.; Yan, B. A Gradient-Field Pulsed Eddy Current Probe for Evaluation of Hidden Material Degradation in Conductive Structures Based on Lift-Off Invariance. Sensors 2017, 17, 943. [Google Scholar] [CrossRef]

- Li, Y.; Ren, S.; Yan, B.; Zainal Abidin, I.M.; Wang, Y. Imaging of Subsurface Corrosion Using Gradient-Field Pulsed Eddy Current Probes with Uniform Field Excitation. Sensors 2017, 17, 1747. [Google Scholar] [CrossRef] [PubMed]

- Rifai, D.; Abdalla, A.N.; Razali, R.; Ali, K.; Faraj, M.A. An Eddy Current Testing Platform System for Pipe Defect Inspection Based on an Optimized Eddy Current Technique Probe Design. Sensors 2017, 17, 579. [Google Scholar] [CrossRef]

- Liu, Z.; Kleiner, Y. State of the art review of inspection technologies for condition assessment of water pipes. Measurement 2013, 46, 1–15. [Google Scholar] [CrossRef]

- Li, Y.; Wilson, J.; Tian, G.Y. Experiment and simulation study of 3D magnetic field sensing for magnetic flux leakage defect characterisation. NDT&E Int. 2007, 40, 179–184. [Google Scholar]

- Sophian, A.; Tian, G.Y.; Zairi, S. Pulsed magnetic flux leakage techniques for crack detection and characterisation. Sens. Actuators A Phys. 2006, 125, 186–191. [Google Scholar] [CrossRef]

- Ivanov, P.A.; Zhang, V.; Yeoh, C.H.; Udpa, H.; Sun, Y.; Udpa, S.S.; Lord, W. Magnetic flux leakage modeling for mechanical damage in transmission pipelines. IEEE Trans. Magn. 1998, 34, 3020–3023. [Google Scholar] [CrossRef]

- Smith, J.W.K.; Hay, B.R. Magnetic Flux Leakage Inspection Tool for Pipelines. U.S. Patent US6023986A, 15 February 2000. [Google Scholar]

- Wijerathna, B.; Vidal-Calleja, T.; Kodagoda, S.; Zhang, Q.; Miro, J.V. Multiple defect interpretation based on gaussian processes for mfl technology. SPIE Proc. 2013, 8694, 86941Z. [Google Scholar]

- Wijerathna, B.; Kodagoda, S.; Miro, J.V.; Dissanayake, G. Iterative coarse to fine approach for interpretation of defect profiles using MFL measurements. In Proceedings of the 10th IEEE Conference on Industrial Electronics and Applications (ICIEA), Auckland, New Zealand, 15–17 June 2015; pp. 1099–1104. [Google Scholar]

- Kim, D.; Udpa, L.; Udpa, S. Remote field eddy current testing for detection of stress corrosion cracks in gas transmission pipelines. Mater. Lett. 2004, 58, 2102–2104. [Google Scholar] [CrossRef]

- Xu, X.; Liu, M.; Zhang, Z.; Jia, Y. A novel high sensitivity sensor for remote field eddy current non-destructive testing based on orthogonal magnetic field. Sensors 2014, 14, 24098–24115. [Google Scholar] [CrossRef] [PubMed]

- Falque, R.; Vidal-Calleja, T.; Miro, J. Defect Detection and Segmentation Framework for Remote Field Eddy Current Sensor Data. Sensors 2017, 17, 2276. [Google Scholar] [CrossRef] [PubMed]

- Su, D.; Miro, J.V.; Vidal-Calleja, T. Modelling in-pipe acoustic signal propagation for condition assessment of multi-layer water pipelines. In Proceedings of the 10th IEEE Conference on Industrial Electronics and Applications (ICIEA), Auckland, New Zealand, 15–17 June 2015; pp. 545–550. [Google Scholar]

- Huang, C.; Wu, X.; Xu, Z.; Kang, Y. Pulsed eddy current signal processing method for signal denoising in ferromagnetic plate testing. NDT&E Int. 2010, 43, 648–653. [Google Scholar]

- Huang, C.; Wu, X.; Xu, Z.; Kang, Y. Ferromagnetic material pulsed eddy current testing signal modeling by equivalent multiple-coil-coupling approach. NDT&E Int. 2011, 44, 163–168. [Google Scholar]

- Chen, X.; Lei, Y. Excitation current waveform for eddy current testing on the thickness of ferromagnetic plates. NDT&E Int. 2014, 66, 28–33. [Google Scholar]

- Huang, C.; Wu, X. An improved ferromagnetic material pulsed eddy current testing signal processing method based on numerical cumulative integration. NDT&E Int. 2015, 69, 35–39. [Google Scholar]

- Ulapane, A.M.N.N.B. Nondestructive Evaluation of Ferromagnetic Critical Water Pipes Using Pulsed Eddy Current Testing. Ph.D. Thesis, University of Technology Sydney, Sydney, Australia, 2016. [Google Scholar]

- Ulapane, N.; Alempijevic, A.; Vidal-Calleja, T.; Valls Miro, J. Pulsed eddy current sensing for critical pipe condition assessment. Sensors 2017, 17, 2208. [Google Scholar] [CrossRef] [PubMed]

- Ulapane, N.; Alempijevic, A.; Miro, J.V.; Vidal-Calleja, T. Non-destructive evaluation of ferromagnetic material thickness using Pulsed Eddy Current sensor detector coil voltage decay rate. NDT&E Int. 2018, 100, 108–114. [Google Scholar]

- Nguyen, L.; Ulapane, N.; Valls Miro, J.; Dissanayake, G.; Munoz, F. Improved Signal Interpretation for Cast Iron Thickness Assessment based on Pulsed Eddy Current Sensing. In Proceedings of the 12th IEEE Conference on Industrial Electronics and Applications, Siem Reap, Cambodia, 18–20 June 2017. [Google Scholar]

- Miro, J.V.; Hunt, D.; Ulapane, N.; Behrens, M. Towards automatic robotic ndt dense mapping for pipeline integrity inspection. In Field and Service Robotics; Springer: Cham, Switzerland, 2018; pp. 319–333. [Google Scholar]

- Valls Miro, J.; Ulapane, N.; Shi, L.; Hunt, D.; Behrens, M. Robotic pipeline wall thickness evaluation for dense nondestructive testing inspection. J. Field Robot. 2018, 35, 1293–1310. [Google Scholar] [CrossRef]

- García-Martín, J.; Gómez-Gil, J.; Vázquez-Sánchez, E. Non-destructive techniques based on eddy current testing. Sensors 2011, 11, 2525–2565. [Google Scholar] [CrossRef] [PubMed]

- Ulapane, N.; Nguyen, L.; Valls Miro, J.; Alempijevic, A.; Dissanayake, G. Designing A Pulsed Eddy Current Sensing Set-up for Cast Iron Thickness Assessment. In Proceedings of the 12th IEEE Conference on Industrial Electronics and Applications, Siem Reap, Cambodia, 18–20 June 2017. [Google Scholar]

- Ulapane, N.; Alempijevic, A.; Vidal-Calleja, T.; Miro, J.V.; Rudd, J.; Roubal, M. Gaussian process for interpreting pulsed eddy current signals for ferromagnetic pipe profiling. In Proceedings of the 9th IEEE Conference on Industrial Electronics and Applications, Hangzhou, China, 9–11 June 2014; pp. 1762–1767. [Google Scholar]

- Miro, J.V.; Rajalingam, J.; Vidal-Calleja, T.; de Bruijn, F.; Wood, R.; Vitanage, D.; Ulapane, N.; Wijerathna, B.; Su, D. A live test-bed for the advancement of condition assessment and failure prediction research on critical pipes. In Proceedings of the Leading-Edge Strategic Asset Management Conference (LESAM13), Sydney, Australia, 9–12 September 2013. [Google Scholar]

- Schafer, R.W.; Press, W.H.; Teukolsky, S.A. Savitzky-Golay smoothing filters. Comput. Phys. 1990, 4, 669–672. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ulapane, N.; Nguyen, L. Review of Pulsed-Eddy-Current Signal Feature-Extraction Methods for Conductive Ferromagnetic Material-Thickness Quantification. Electronics 2019, 8, 470. https://doi.org/10.3390/electronics8050470

Ulapane N, Nguyen L. Review of Pulsed-Eddy-Current Signal Feature-Extraction Methods for Conductive Ferromagnetic Material-Thickness Quantification. Electronics. 2019; 8(5):470. https://doi.org/10.3390/electronics8050470

Chicago/Turabian StyleUlapane, Nalika, and Linh Nguyen. 2019. "Review of Pulsed-Eddy-Current Signal Feature-Extraction Methods for Conductive Ferromagnetic Material-Thickness Quantification" Electronics 8, no. 5: 470. https://doi.org/10.3390/electronics8050470

APA StyleUlapane, N., & Nguyen, L. (2019). Review of Pulsed-Eddy-Current Signal Feature-Extraction Methods for Conductive Ferromagnetic Material-Thickness Quantification. Electronics, 8(5), 470. https://doi.org/10.3390/electronics8050470