1. Introduction

Generally, the pulse power capability, a term that is commonly used in energy storage systems such as batteries and supercapacitors, is the maximum output power that does not exceed the over- and under-voltage limit conditions in the current state of charge (SOC) of the energy storage. Therefore, even in the case of batteries and supercapacitors that are used in hybrid cars, battery, and hydrogen-electric vehicles, the pulse power capability is a very important parameter in terms of electrical stability as well as driving performance [

1,

2,

3,

4,

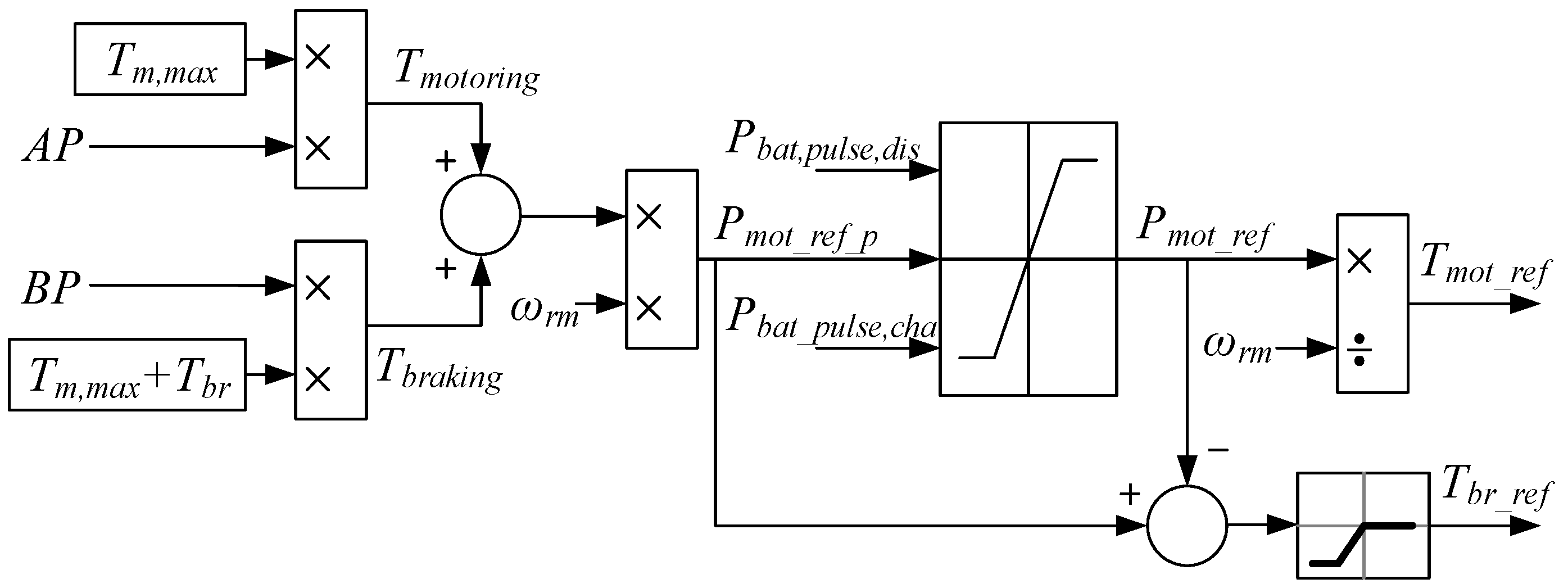

5]. The relationship between pulse power and the driving performance and safety of an electric vehicle is represented by the block diagram shown in

Figure 1.

Figure 1 shows a basic control block used to generate a torque command for a traction motor and the mechanical brake which is implemented in the vehicle control unit (VCU) of an electric vehicle. The VCU determines the torque command, denoted

Tmot_ref, that allows the battery to be driven by the power it can supply without operating at a low voltage, based on the motor speed, denoted ω

rm, as the vehicle’s accelerator pedal (AP) is pressed. Similarly, in the braking mode, the VCU calculates the regenerative torque command of the traction motor and the torque command value of the mechanical brake. This is performed so that the traction motor can be operated within the maximum chargeable power value without exceeding the overvoltage of the battery, based on the degree of depression of the brake pedal (BP). The available power of the battery for determining the torque command can be defined as the pulse power, which is represented as the variables

Pbat,pulse,dis and

Pbat,pulse,cha in

Figure 1. Therefore, to maximize the driving performance of a vehicle and to stabilize the system, it is necessary to estimate the maximum pulse power that energy storage devices such as batteries and supercapacitors can charge and discharge in the current state.

Studies on the pulse power capability of auxiliary storage devices and their estimation have been conducted [

6,

7,

8,

9,

10,

11]. In a previous paper [

6], a method for calculating the pulse power and an experimental approach for measuring the lumped resistance were described. However, this work did not consider an approach for vehicle driving control and the effect on the duration time when pulse power is applied. In related studies [

7,

8], the magnitude of the pulse power was estimated over a period of 10 seconds, considering the acceleration and deceleration of the electric vehicle. Bjorn Fridholm [

9] proposed an adaptive power capability estimation method that considered the communication time delay between controllers. This study focused mainly on stability analysis of the feedback system with batteries. Rui X. [

10] presented a recursive least square method for estimating peak power capability based on the dynamic battery model. However, the effects of the pulse duration were not fully considered. In addition, there are no known studies on the supercapacitors that are typically used to assist the peak power. Studies on the pulse power of a supercapacitor over a 5 second or 10 second duration are presented in references [

11,

12]. However, the magnitude of the lumped resistance measured based on the experimental results for the hybrid pulse power characterization (HPPC) test [

6] was used, and there was no consideration of the change of the pulse duration.

Therefore, in this investigation, we propose a method to estimate the pulse power of a battery and supercapacitor according to the sampling period of the power control algorithm of each application. Firstly, a method for estimating the magnitude of the lumped resistance according to the pulse duration is presented to determine the pulse power of a battery and a supercapacitor. It is subsequently shown that a battery and supercapacitor can be used in the stable voltage range for pulse power operation when the proposed method is applied. In this paper, pulse power estimation results for a 44.4 V, 11 Ah lithium battery module, and a 36 Vmax, 30 F supercapacitor module are presented to demonstrate the validity of the proposed method.

4. Experimental Results

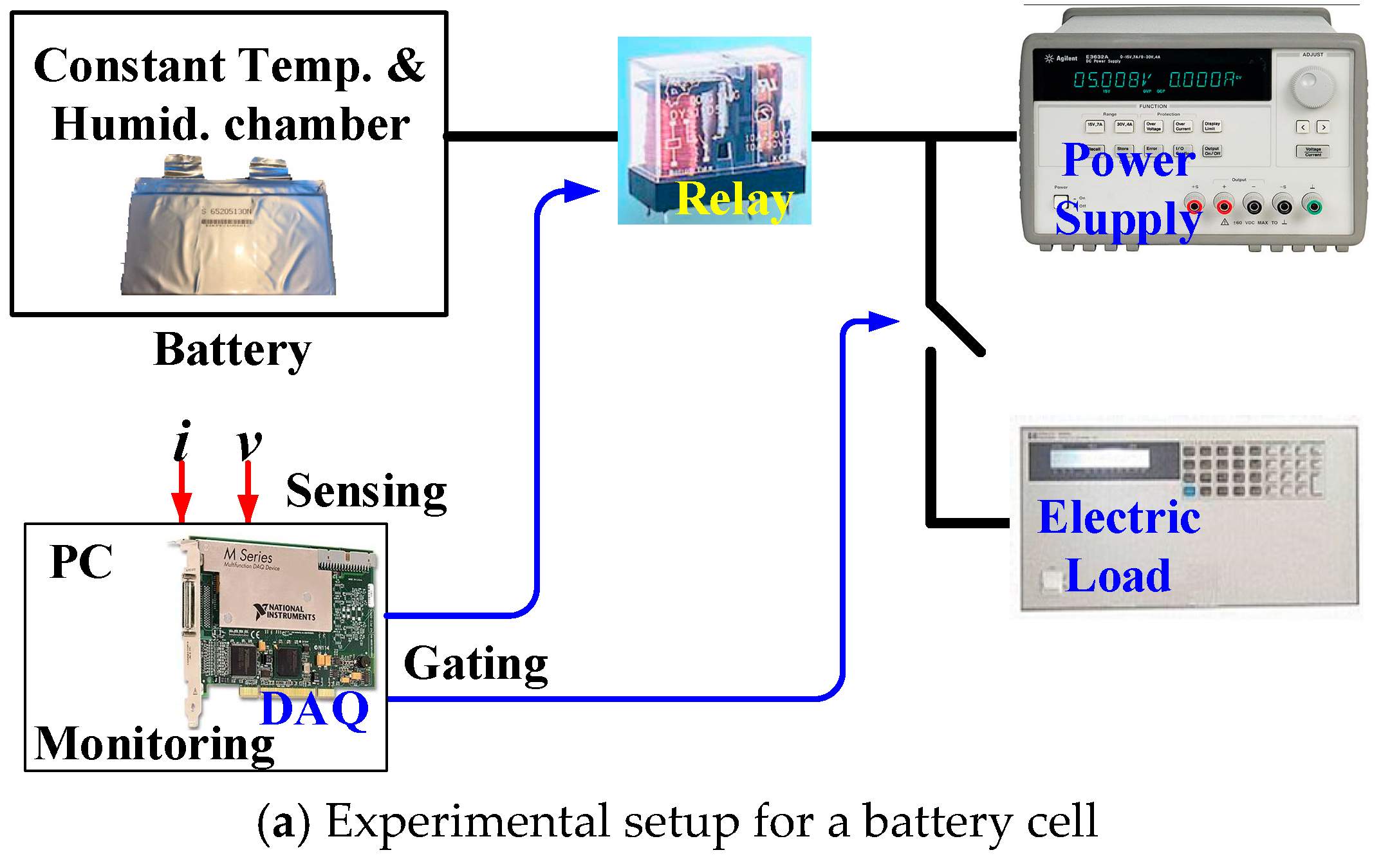

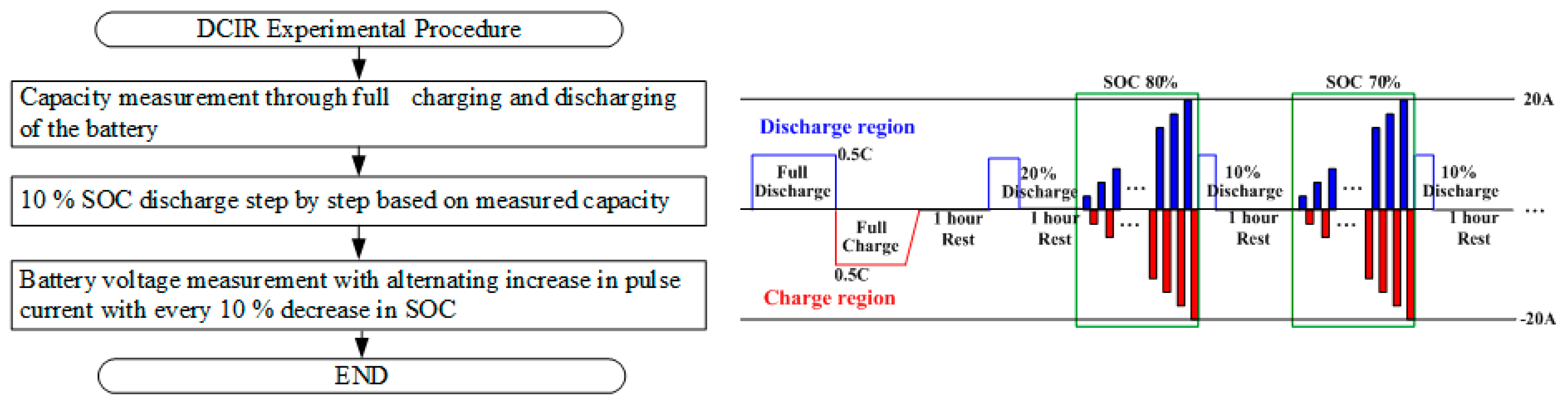

The charge and discharge tests, and the pulse power verification of the battery and supercapacitor were performed using the experimental setup shown in

Figure 6.

Figure 6a represents the equipment used for the charge and discharge experiments to model the battery’s cells, whereas

Figure 6b shows the experimental configuration of the battery and supercapacitor modules.

Table 1 lists the batteries, and supercapacitors used in the experiment, in addition to equipment used for charging and discharging.

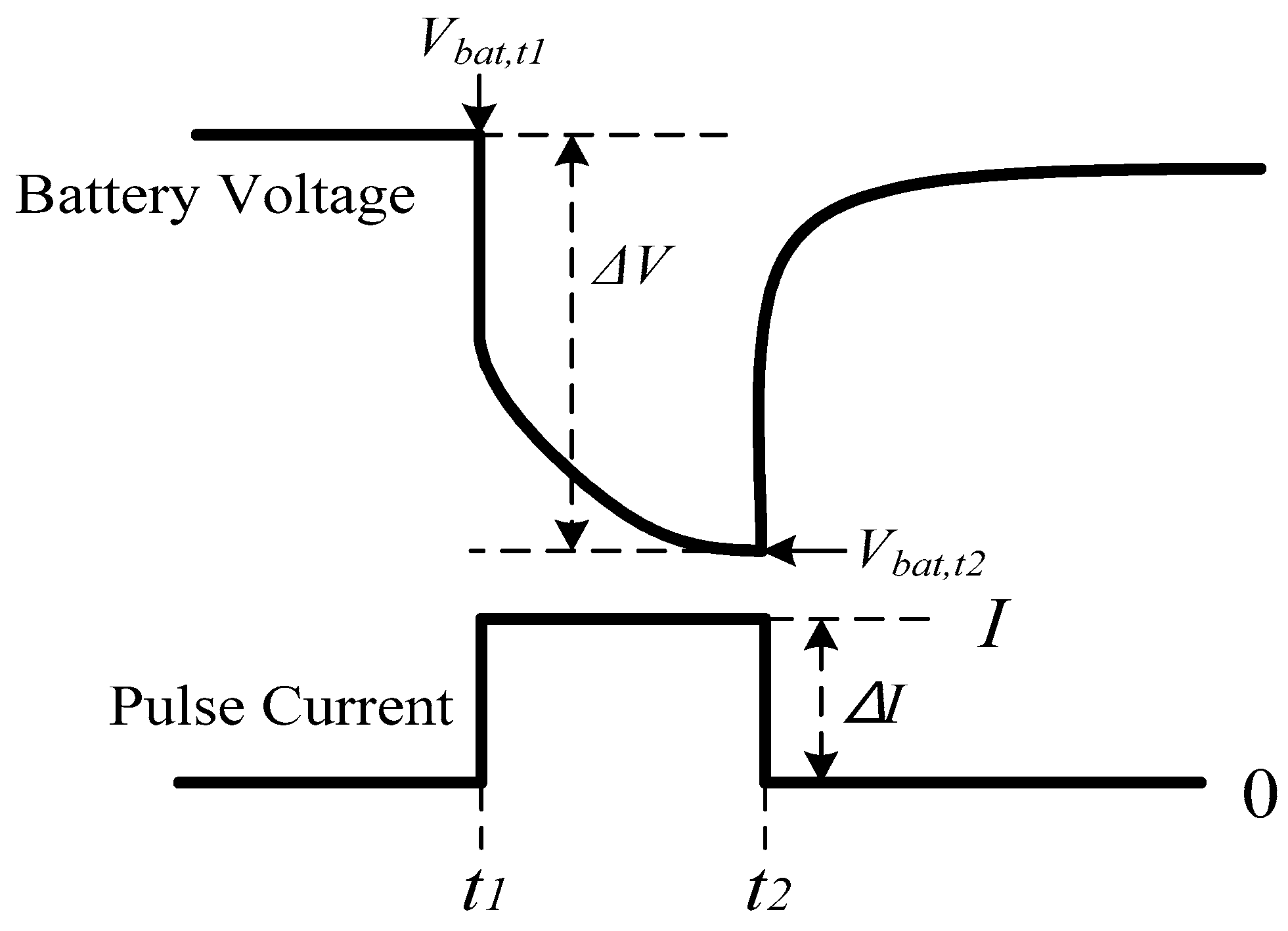

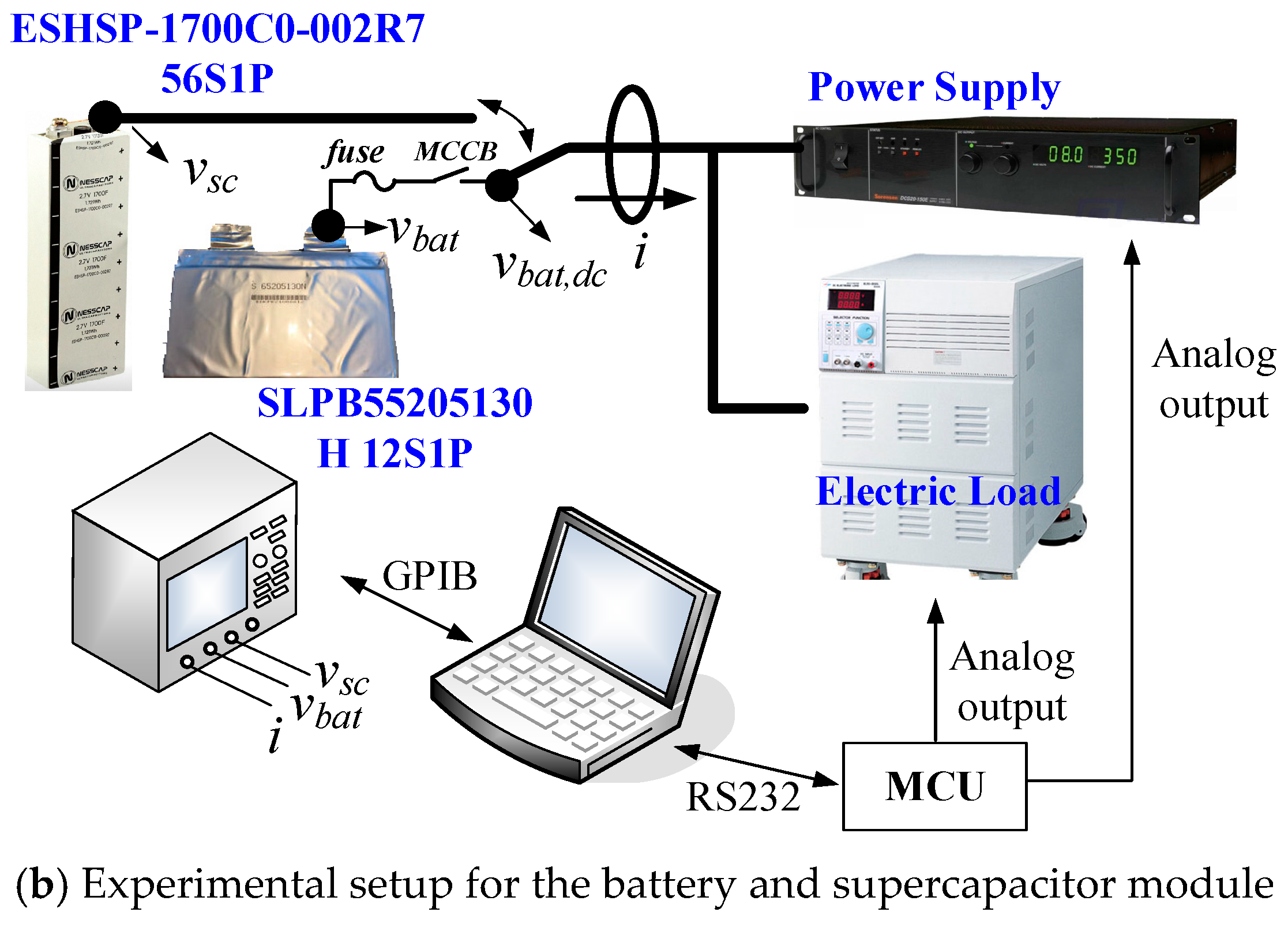

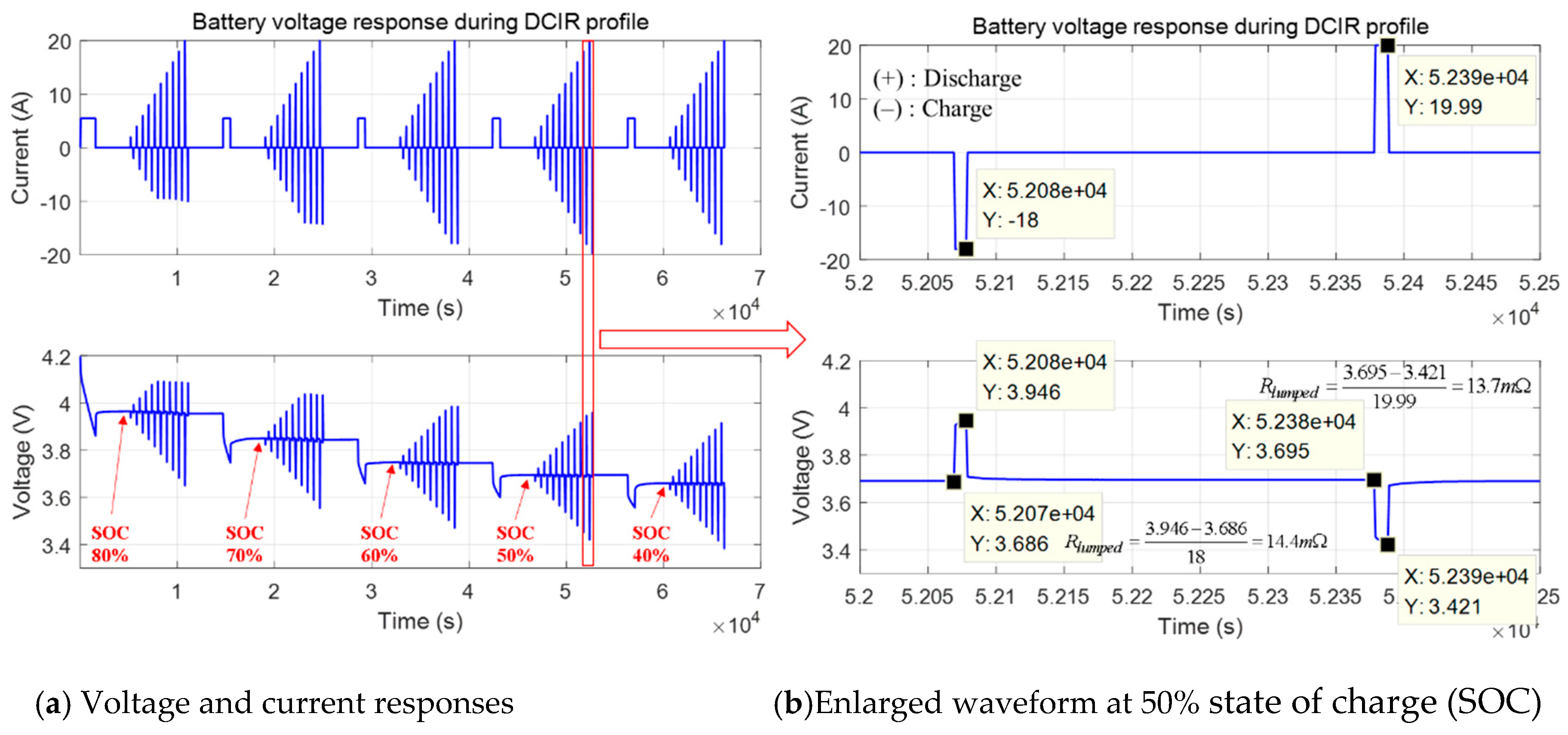

To obtain the pulse power of the battery as described in

Section 2, it is necessary to measure or estimate the lumped resistance of the battery. An example of an experimental method for measuring this resistance is the direct current internal resistance (DCIR) method, similar to the current profile and experimental procedure in

Figure 7 [

15]. In this method, when the discharge (denoted using a positive sign) and charge current (denoted using a negative sign) are increased stepwise for each SOC point of the battery, the voltage response can be obtained.

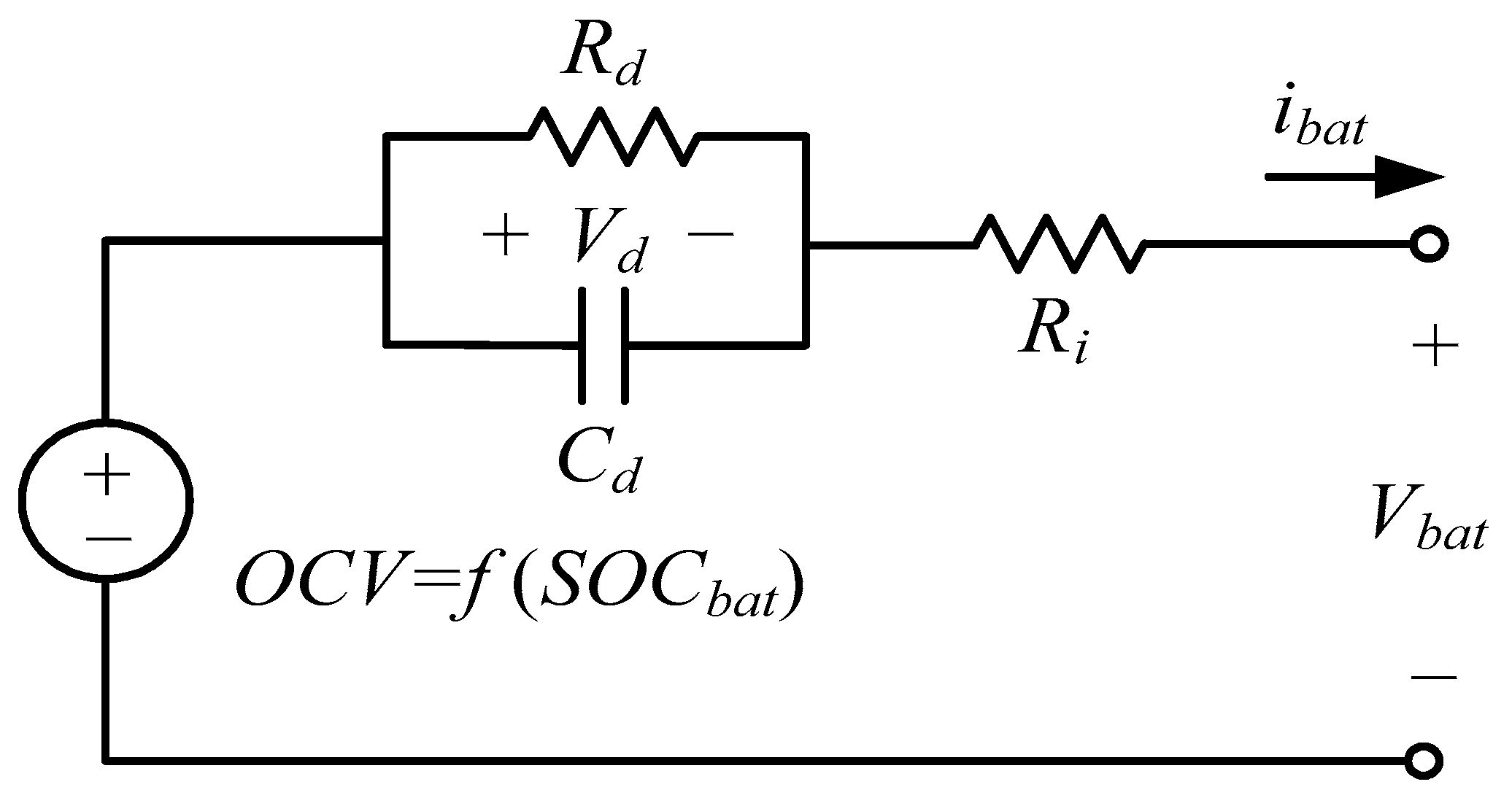

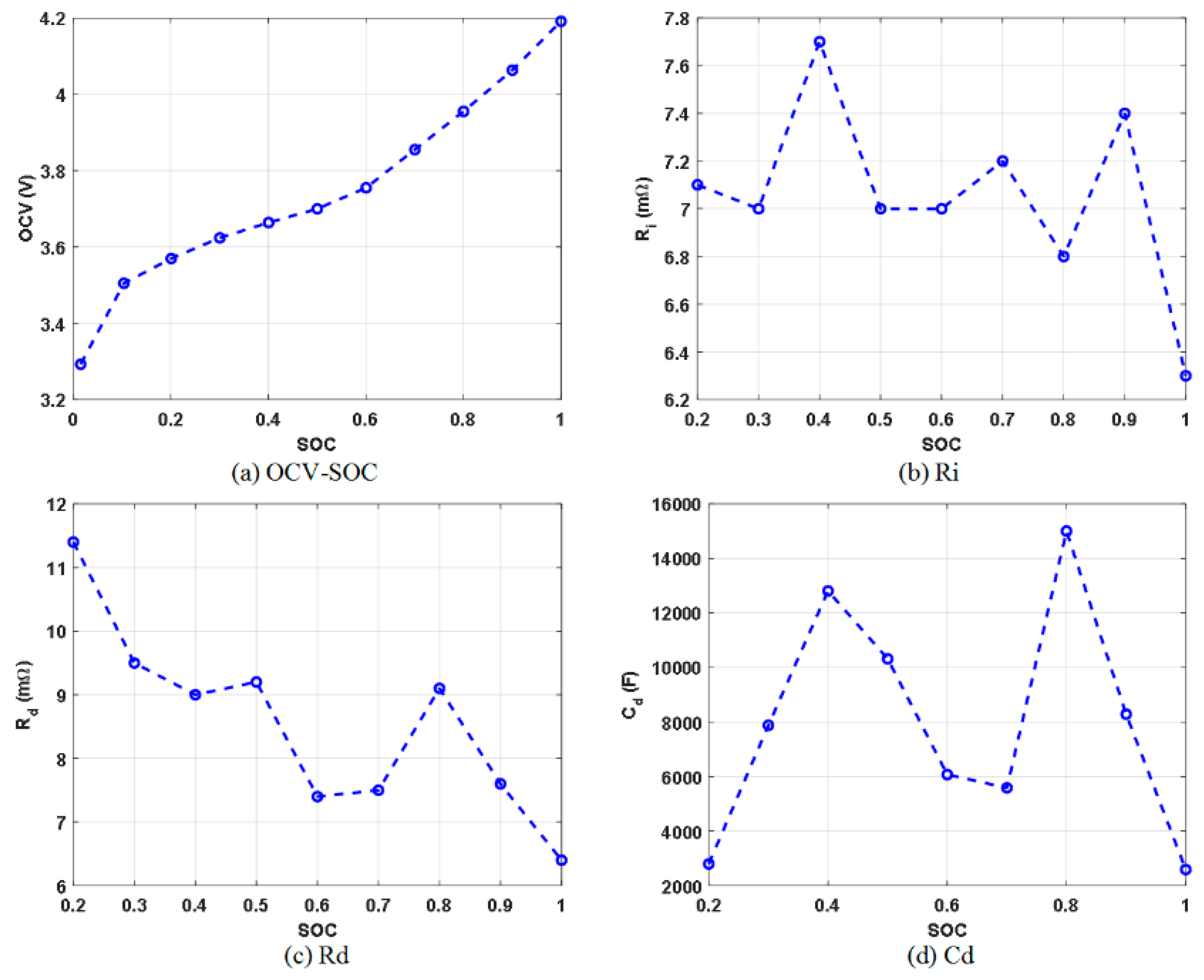

Figure 8 shows the results for a battery’s cell when the DCIR current profile is applied. The battery model parameters in

Figure 3 are extracted as shown in

Figure 9a–d.

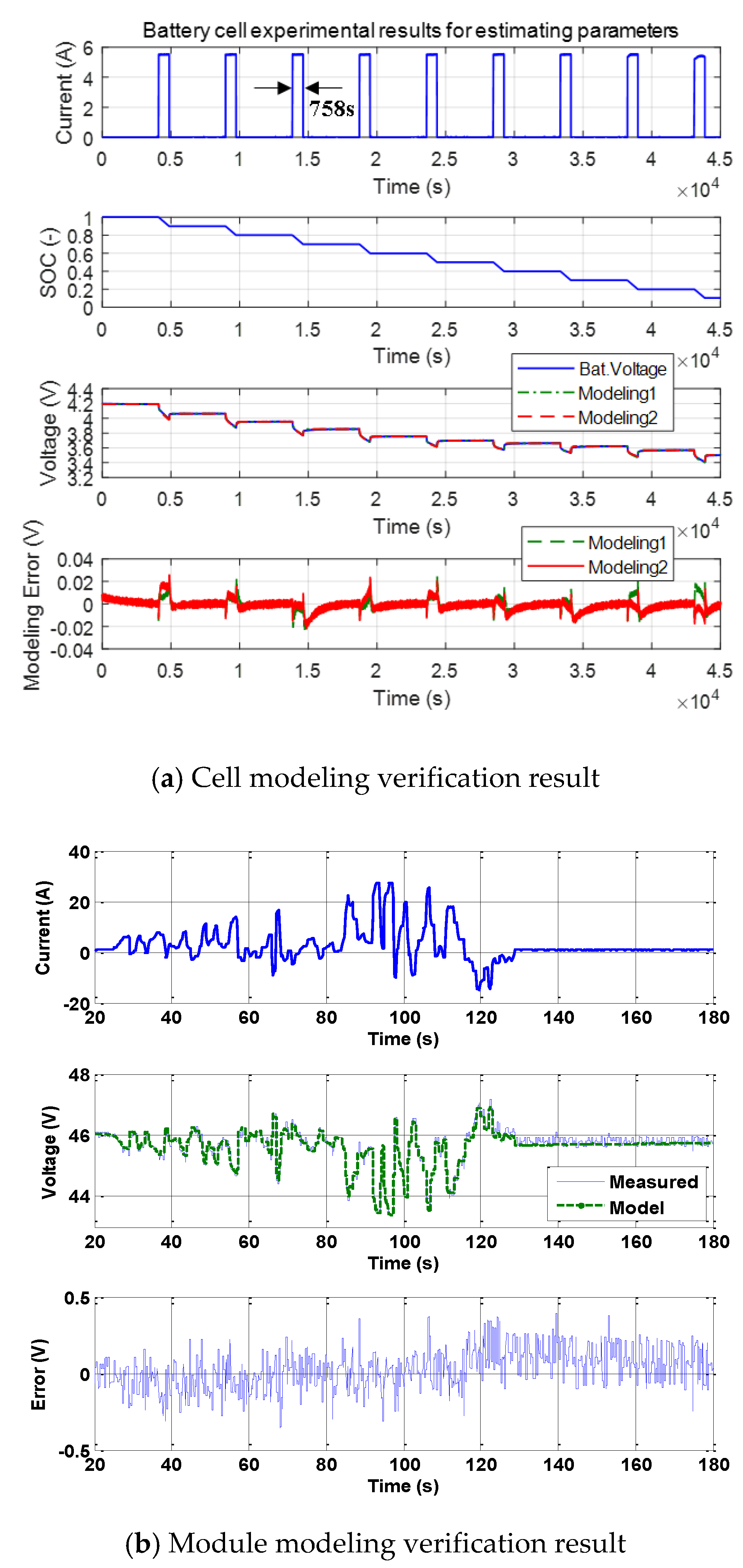

The accuracy of battery modeling using the extracted modeling parameters was verified under pulse current and dynamic current conditions as shown in

Figure 10. The upper waveform in

Figure 10a shows the current profile, and the SOC estimation result using the ampere-hour (Ah) counting method is shown in the second figure. The capacity measured at room temperature before the experiment was 11.58 Ah. Thus, to discharge the SOC at 10% intervals, a current of 5.5 A was applied for 758 seconds. In the experimental results, it can be seen that the discharge is performed in nine steps from 100% to 10% of SOC. In the third waveform, the solid line represents the measured voltage of the battery. The dash-dotted line shows the battery voltage (denoted as Modeling 1) when the parameters in

Figure 9 are configured as the lookup table according to each SOC. The dashed line represents the battery voltage (Modeling 2) that was modeled using the average value of the extracted parameters. The last waveform shows the modeling error for Modeling 1 and 2. It is evident from the experimental results that even when the average model of the extracted battery model is used, the modeling error is smaller than ± 0.03 V. Therefore, parameters of the battery use the average value. The 12-series battery module was modeled using the average value of the battery’s cell parameters, and the modeling accuracy of the battery module was determined to comparable to the cell modeling. The modeling accuracy of the battery module is shown in

Figure 10b.

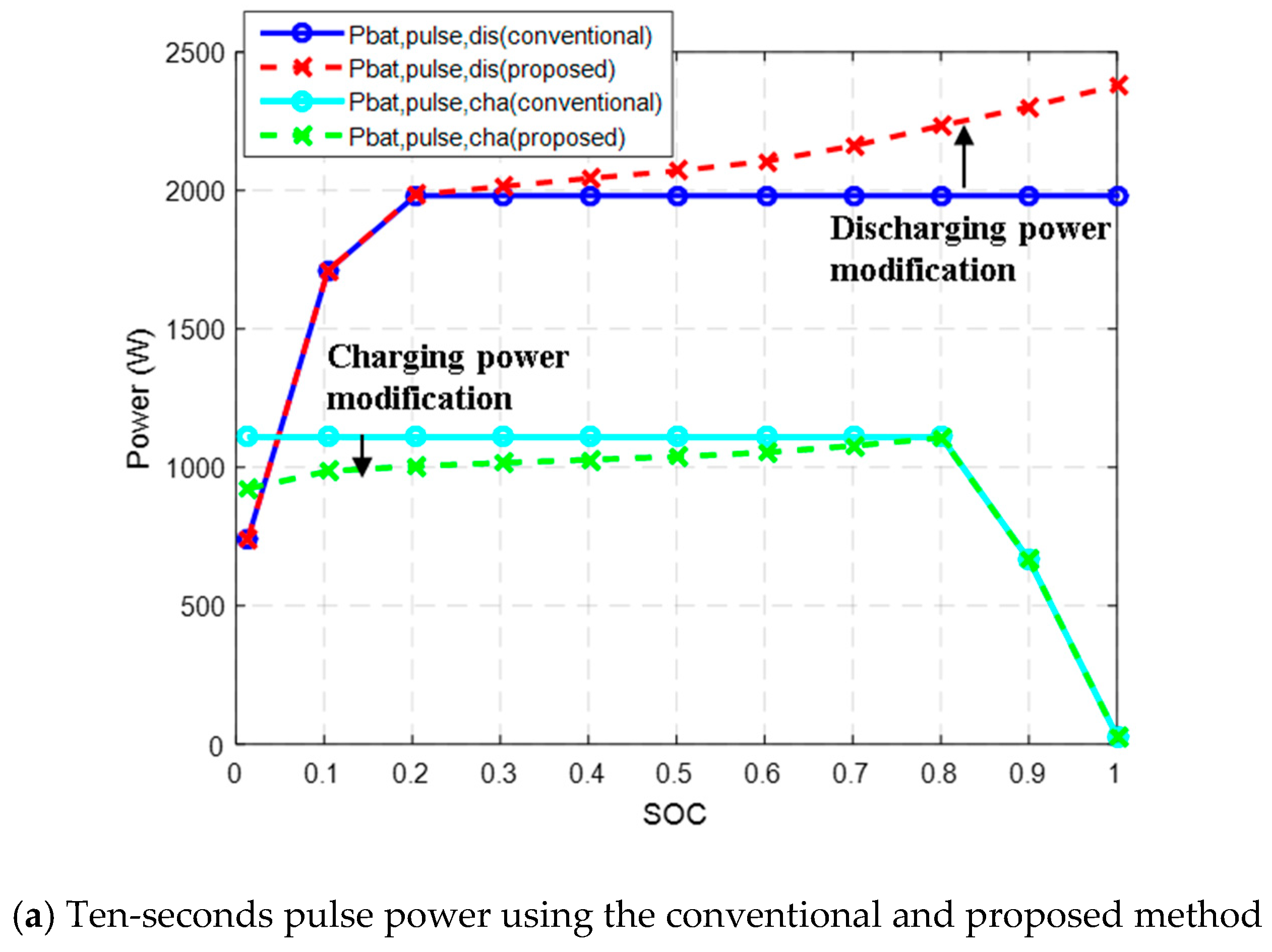

Equations (1)–(5) can be used to calculate the lumped resistance for 10 seconds, and the results of the estimated lumped resistance are shown in

Table 2. The lumped resistance of the battery’s cell shows a small deviation according to the SOC, but has a value of approximately 14 mΩ. The pulse power according to the SOC of the battery module can be obtained using Equations (10) and (11) as shown in

Figure 11.

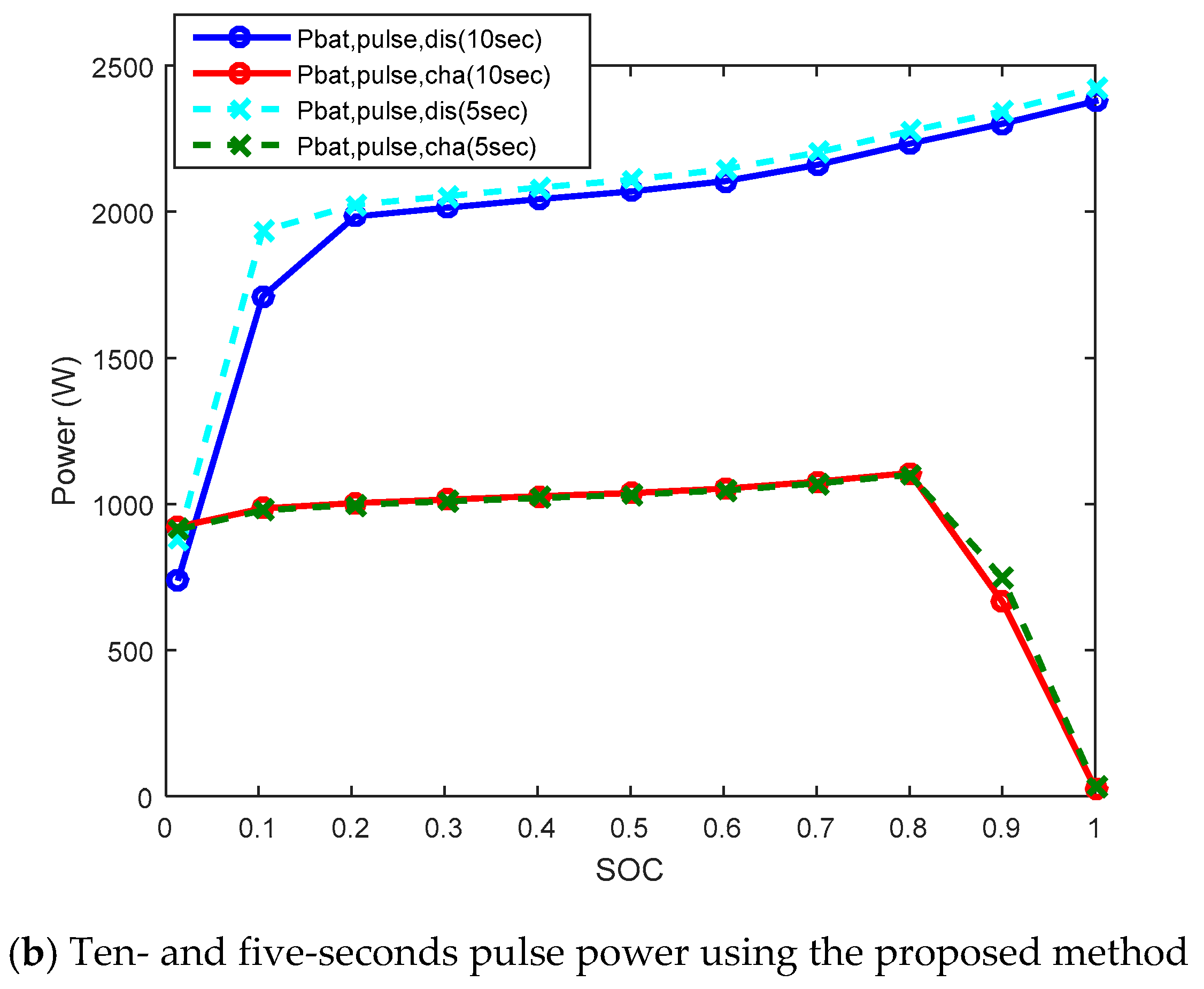

Figure 11a shows the magnitude of the discharging pulse power of the conventional method and the proposed method. The conventional method calculates the pulse power using only the second equation of Equation (10). Therefore, when the pulse current of the battery estimated from Equations (6) to (9) is limited, the pulse power is fixed to a constant value. However, if the battery current is fixed at the maximum value, the pulse current must be calculated from the voltage calculated from Equations (2)–(5). Therefore, the pulse power can be calculated as described in the first Equation of (10), which is larger than the conventional method. On the contrary, in the case of charging, as the state of charge of the battery is lowered, the magnitude of the charging current is fixed to the maximum current from the Equations (6)–(9). At this time, the conventional method calculates the pulse power based on the maximum voltage even if the pulse charging current is limited. However, the proposed method predicts the magnitude of the pulse power based on the estimated voltage when the pulse current is applied, and this value shows a smaller pulse power value than the conventional method.

Figure 11b shows the charge/discharge pulse power capability during the sampling period of 10 seconds and 5 seconds using the proposed method. Because batteries have more energy than supercapacitors, which will be discussed in the next section, there is no significant difference in the amount of pulse power with respect to the sampling period. However, if we want to use the battery for maximum performance in the stable voltage range, we need to calculate the pulse power considering the sampling period of the algorithm.

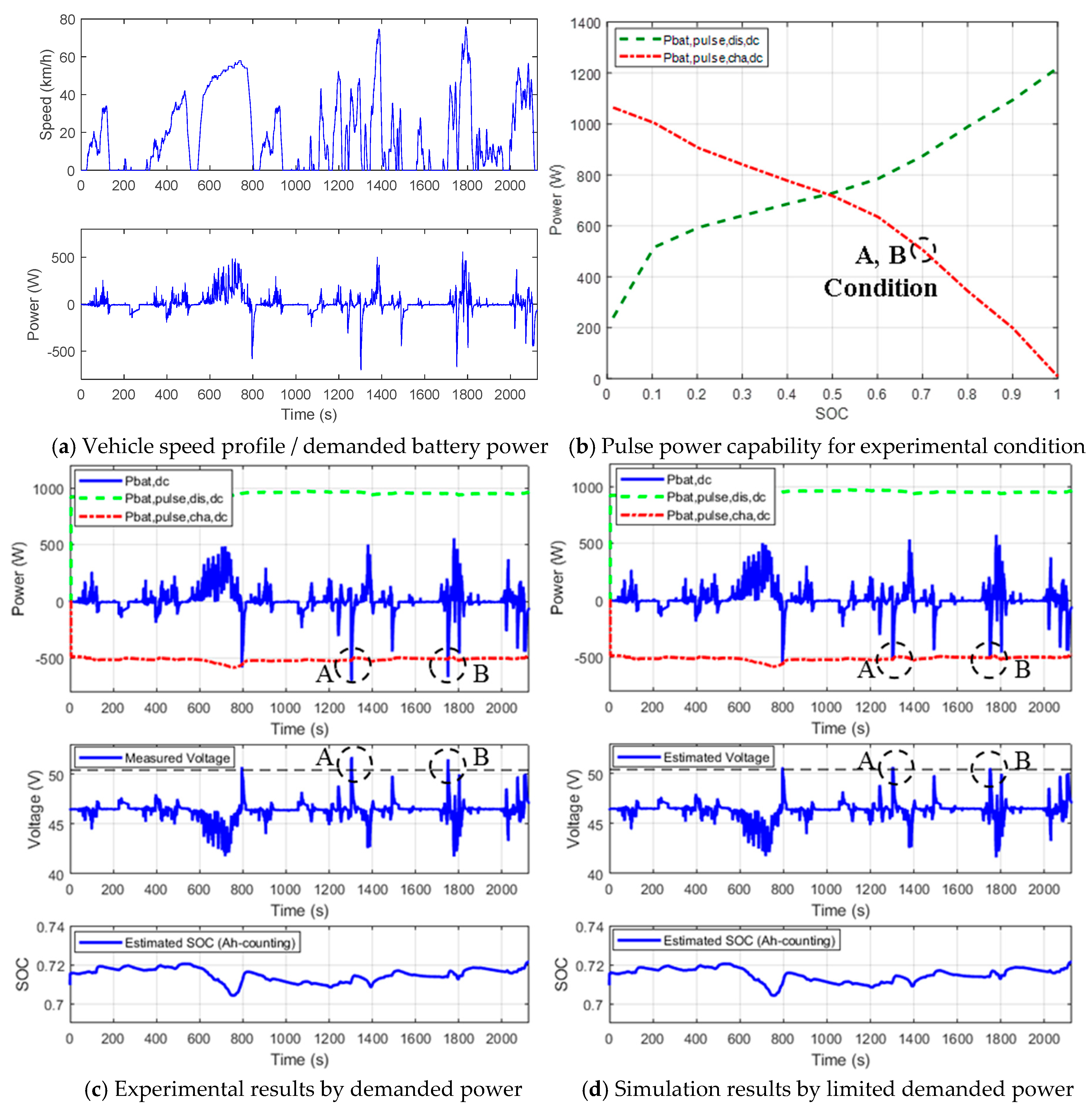

The simulation results obtained when the proposed method was applied to the power management algorithm of the electric vehicle are shown in

Figure 12. This figure shows the result of charging and discharging the battery with the power scaled down according to the experimental setup, assuming that the ten-ton electric vehicle continuously drives the heavy duty-urban dynamometer driving schedule (HD-UDDS) and the city driving profile [

16,

17]. The upper waveform in

Figure 12a shows the speed profile, and the lower waveform shows the demanded power required from the battery. In this experiment, we conducted a power test on the demanded power profile at 70% of the SOC of the battery, and predicted the magnitude of the pulse power considering the voltage at the point indicated by

Vbat,dc in

Figure 6b as the voltage of the battery. Thus, the magnitude of the pulse power due to the lumped resistance, which includes a 30 mΩ resistor representing the effects of the fuse, the molded case circuit breaker (MCCB) and the cable impedance, was calculated. In this case, the charging pulse power not exceeding the maximum voltage of 50.4 V and the discharging pulse power not exceeding 36V are shown in

Figure 12b. The green dashed line represents the discharging pulse power, and the red dash-dotted line shows the charging pulse power.

Figure 12c shows the results of a charge/discharge test when the battery is not used within the magnitude of the pulse power estimated by the battery management system (BMS). In

Figure 12c, points A and B represent the intervals in which the battery is used in excess of the charging pulse power, and during this period, it can be seen that the battery exceeds the overvoltage range of 50.4 V. On the other hand,

Figure 12d shows the simulation result for the case that the charging power is limited to the estimated charging pulse power by the BMS. In this case, since the power of the battery is limited to the available charging power, it can be seen that no overvoltage occurs in the A and B points.

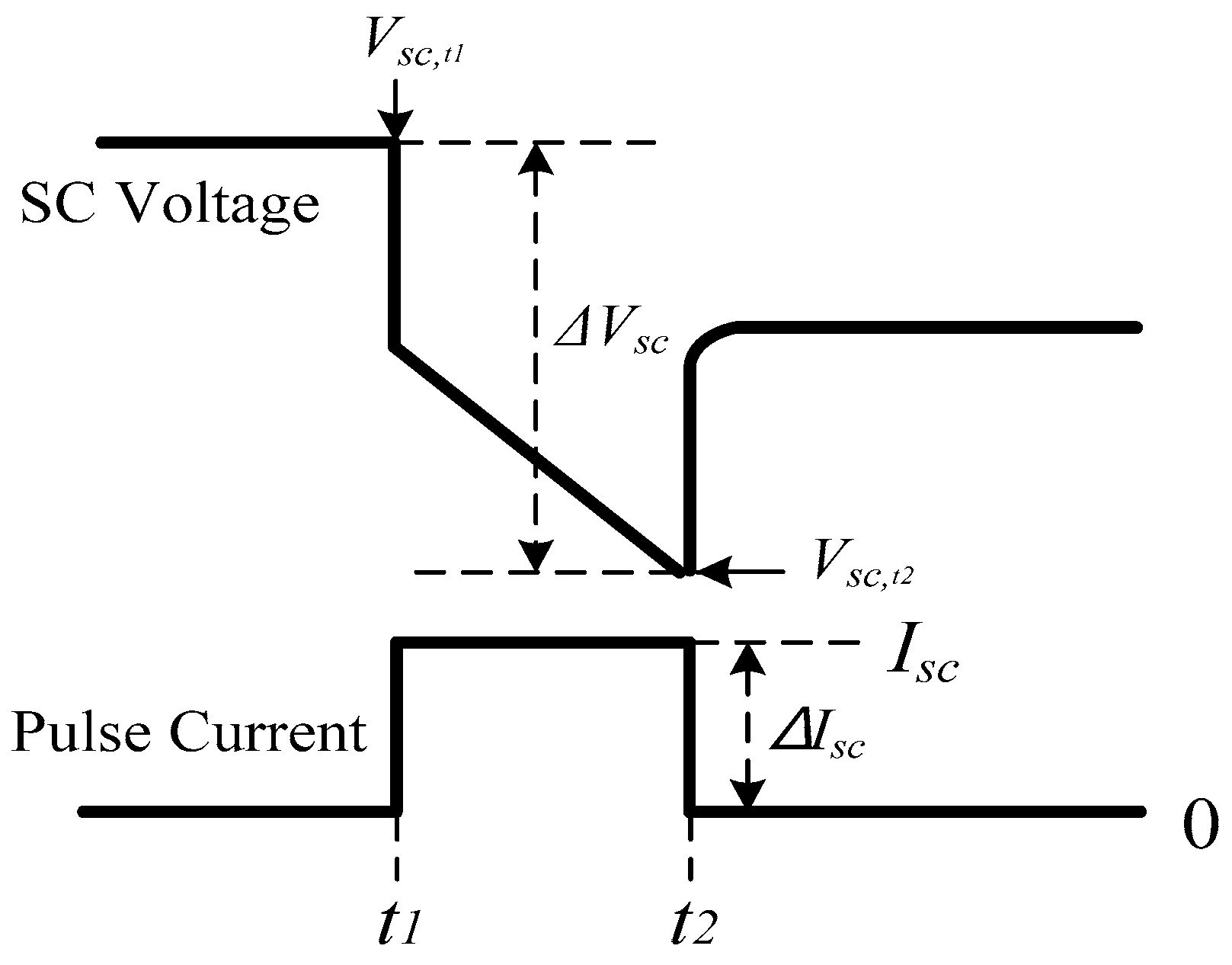

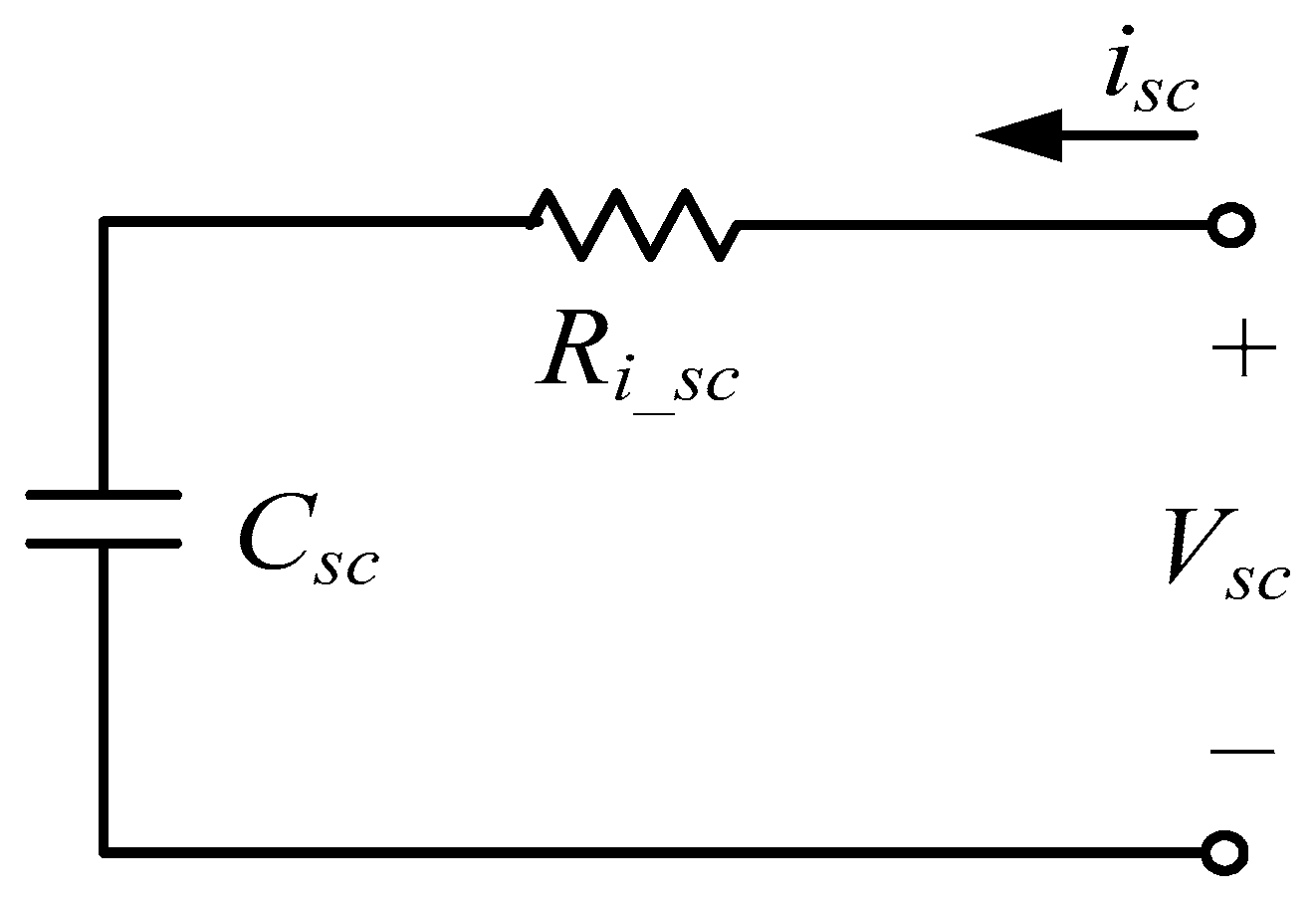

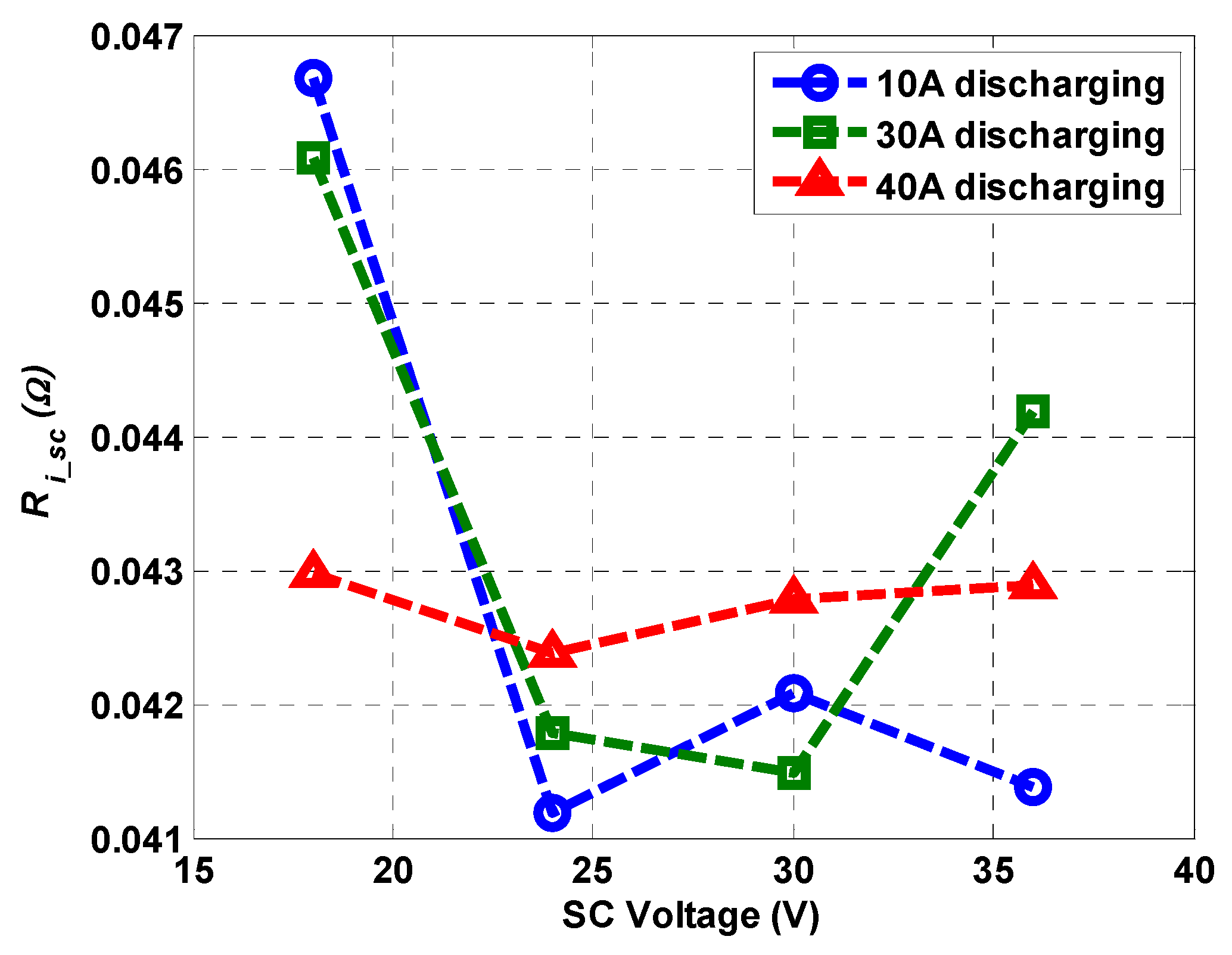

The parameters of the supercapacitor (SC) can be obtained from the voltage response characteristics for a pulse current, similar to the battery. The series resistance parameter of

Figure 5, which is the electrical equivalent circuit of the supercapacitor, can be obtained from the voltage drop of the applied pulse current. The resistance was obtained as shown in

Figure 13. The series resistance component of the supercapacitor did not exhibit a significant difference according to the magnitude of the current. An average value of 42.3 mΩ was determined as the series resistance value.

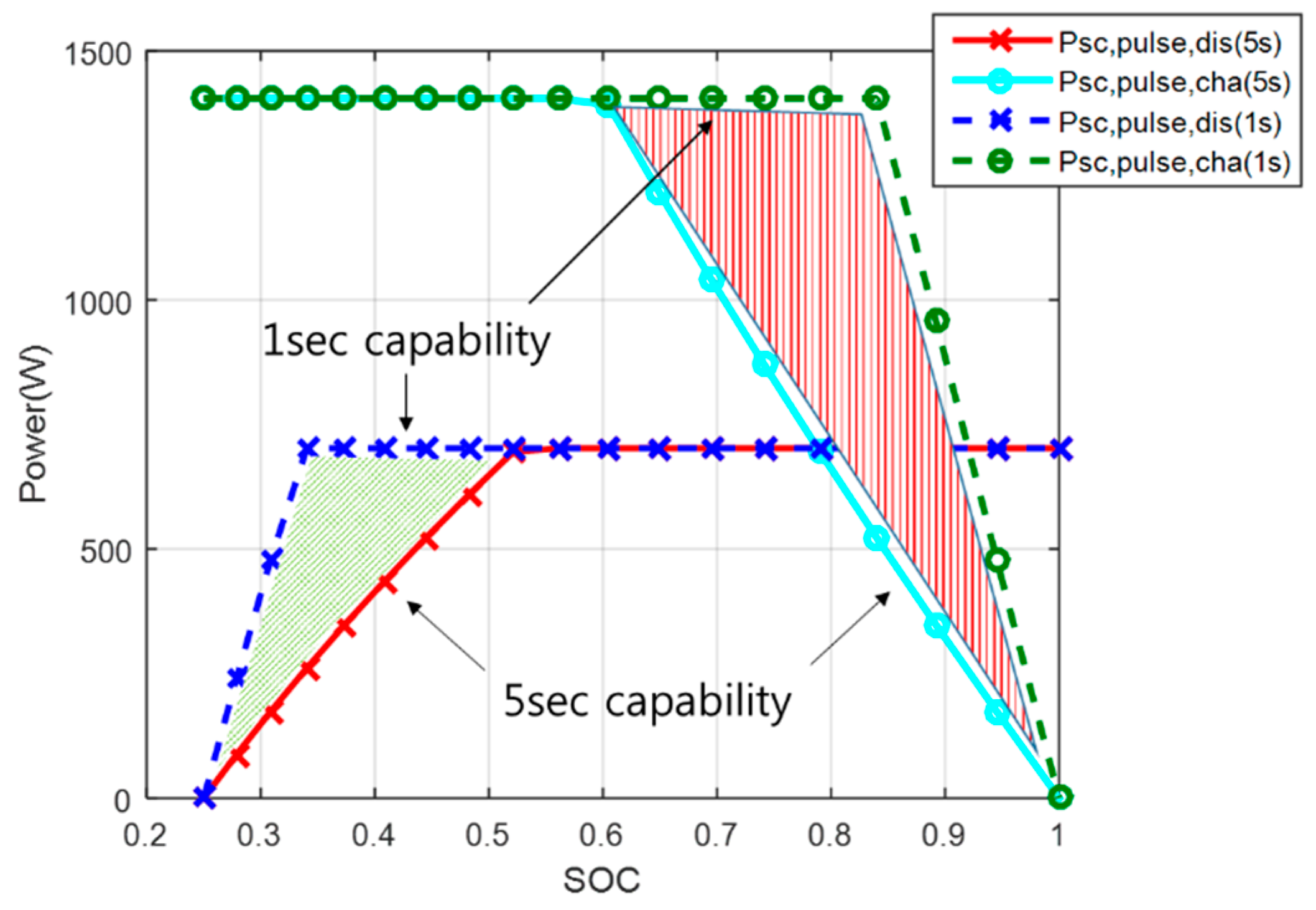

Because of the high power density of super-capacitors, the power capability of the super-capacitors is higher than that of the battery. However, since the energy density is low, the magnitude that can maintain the pulse power for a certain period fluctuates depending on the conditions such as the energy state. Therefore, the pulse power must be estimated considering the sampling period for estimating the pulse power.

The supercapacitor used in the experiments in this report has a value of 36 Vmax and an equivalent series resistance of 42.3 mΩ.

Figure 14 shows the pulse power estimation results when the sampling period was set to 5 seconds or 1 second using Equations (12)–(16). It is evident from the two shaded areas shown in the figure that the pulse output power of the supercapacitor for 5 seconds and 1 second varies depending on the required time.

As previously indicated, the power distribution algorithm of electric vehicles as shown in

Figure 1 uses the power capability of the energy storage device to calculate the torque command reference of the traction motor. Therefore, it is possible to influence the acceleration performance and the regenerative braking energy of the system, according to the algorithm’s sampling period, to calculate the power capability of the supercapacitor. In addition, if the lumped resistance used to calculate the pulse power of the supercapacitor is not calculated based on the sampling period, it is evident that a larger pulse power can be output during discharge. However, it cannot be used, as shown in

Figure 14. During the charging process, an issue arises in that it is assumed that the energy storage device can accept an output larger than the actual power capacity.

To predict the pulse power of the supercapacitor, the discharge power capability can be estimated using Equations (17)–(19), considering the characteristics of the cell and the current limitation according to the current specification of the power conversion unit, and the protection relay. Assuming that the pulse power lasts for a certain period (ΔT), the lumped resistance is calculated using the parameters of the supercapacitor. The voltage generated after the duration of the pulse power is then estimated, and the discharge pulse power is estimated using this value.

The charging pulse power capacity of the supercapacitor can be derived using Equations (20)–(22), as in the previous case.

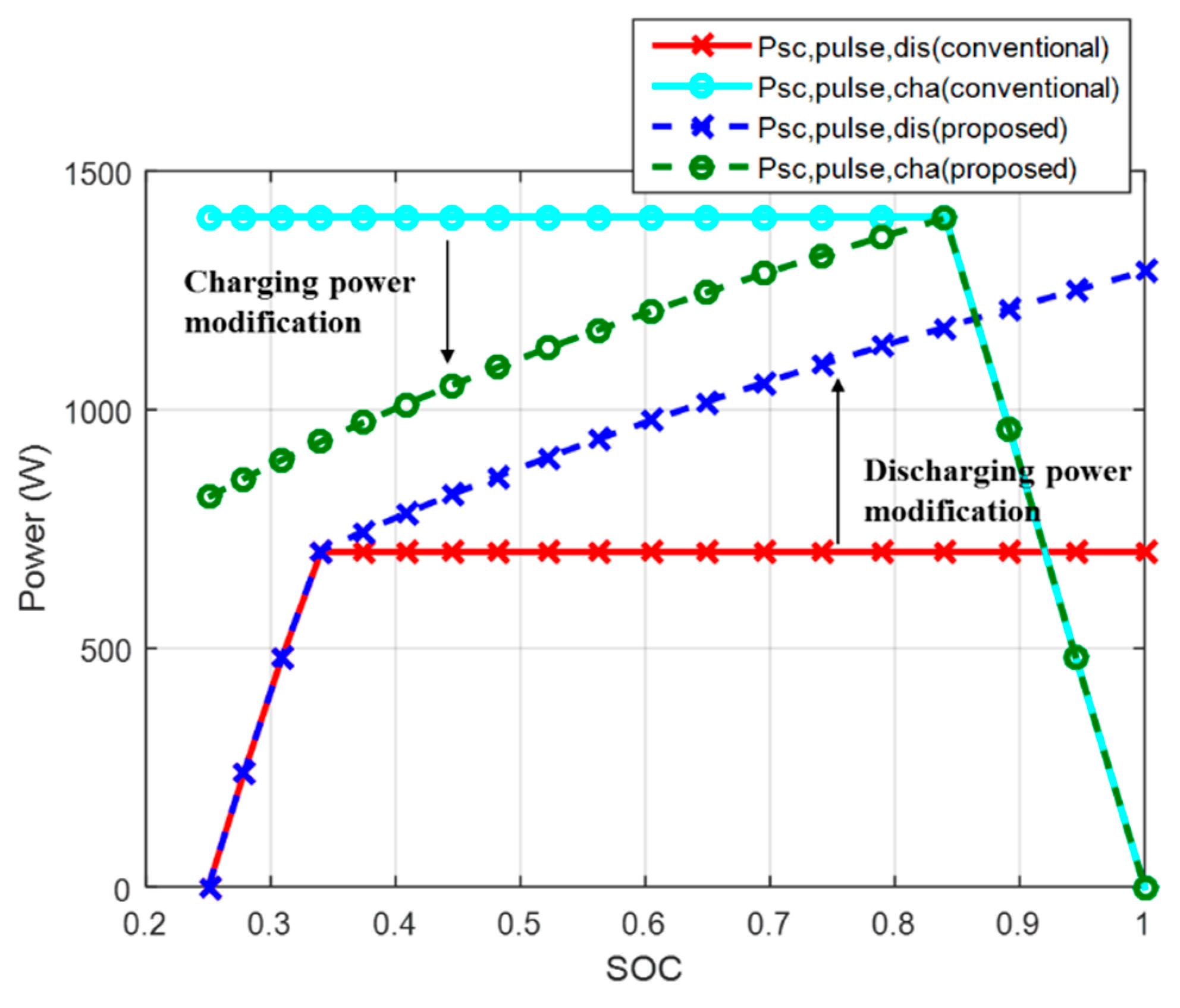

As previously indicated, the pulse power capability for the case where the sampling period of the pulse power of the supercapacitor is set to 1 second is shown in

Figure 15, for comparison of the conventional method and the proposed method. In this case,

Psc_pulse,dis(conventional) and

Psc_pulse,cha(conventional) represent the discharging and charging pulse power capability for 1 second for the conventional method. The power parameters with ‘proposed’ in the notation represent the charging and discharging pulse power capability for the proposed method. As the SOC of the supercapacitor increases in the discharge period, more power can be supplied using the proposed method compared to the conventional method. Moreover, in the charging period, the proposed method has a lower charge at a smaller SOC compared to the conventional method. Therefore, when the proposed method is applied to the power distribution algorithm of an electric vehicle, the output capability is increased during acceleration, and the performance and stability of the system can be increased by restricting the chargeable power during regenerative braking.

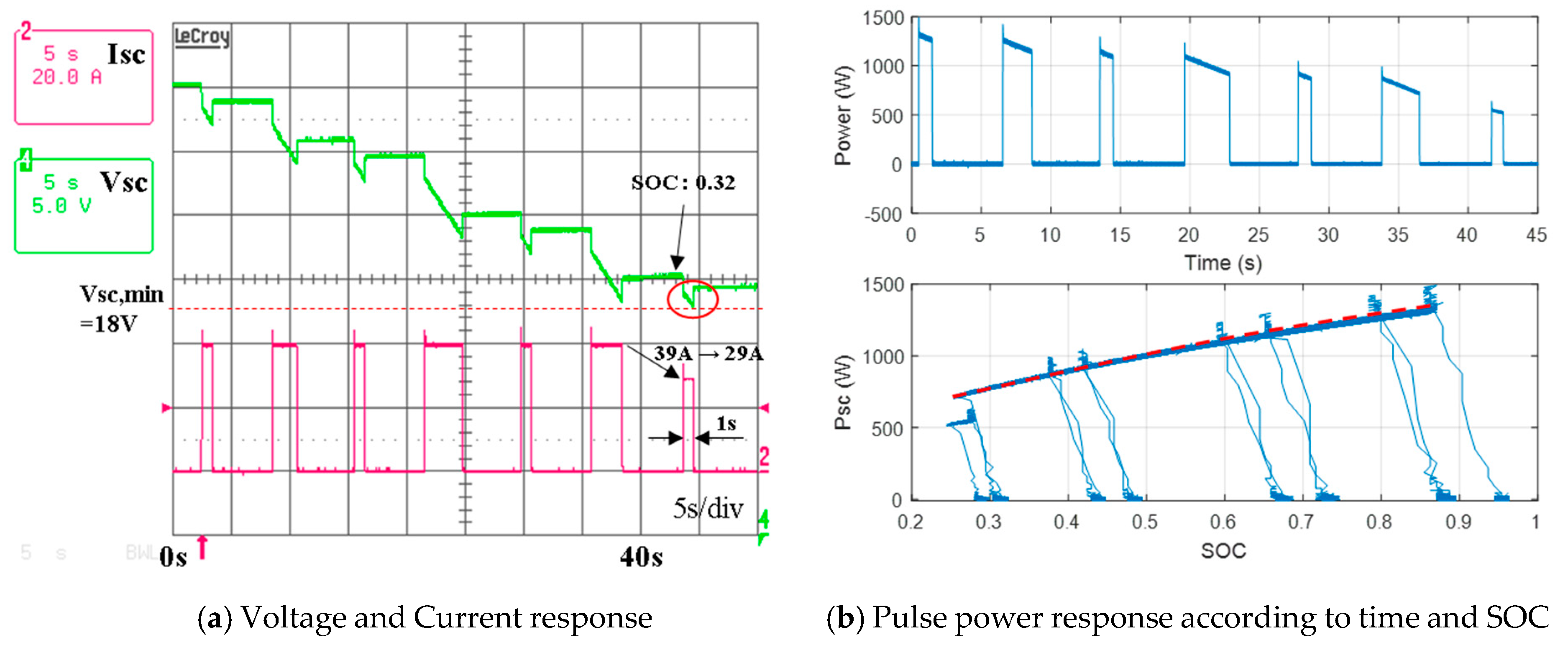

The pulse current prediction results of the supercapacitor are verified in

Figure 16. After the supercapacitor was charged to 36 V, an experiment was conducted to facilitate discharge to the lowest possible voltage with a pulse current of 39 A within a specified period. The controller unit was used to calculate the pulse power of the supercapacitor with a sampling period of 1 second and serves to limit the current command when a value that exceeds the available pulse power is applied. In

Figure 16a, since a current command of 39 A is greater than the pulse power that can be discharged at 43 seconds, it is evident that the magnitude of the pulse current changed to 29 A. This value is the predicted one-second pulse current. Since the voltage of the supercapacitor after the one-second pulse current of 29 A was applied became 18 V, which is a low voltage setting value, it can be seen that the magnitude of the estimated one-second pulse current is accurate. The top waveform of

Figure 16b shows the magnitude of the power of the supercapacitor during the experiment, and the bottom waveform shows the powers based on the state of charge of the supercapacitor. The red dashed line indicates the magnitude of the discharging pulse power of

Figure 15, and it can be seen that the pulse power estimation result and the experimental result are almost the same.