Effect of the High-Temperature Off-State Stresses on the Degradation of AlGaN/GaN HEMTs

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

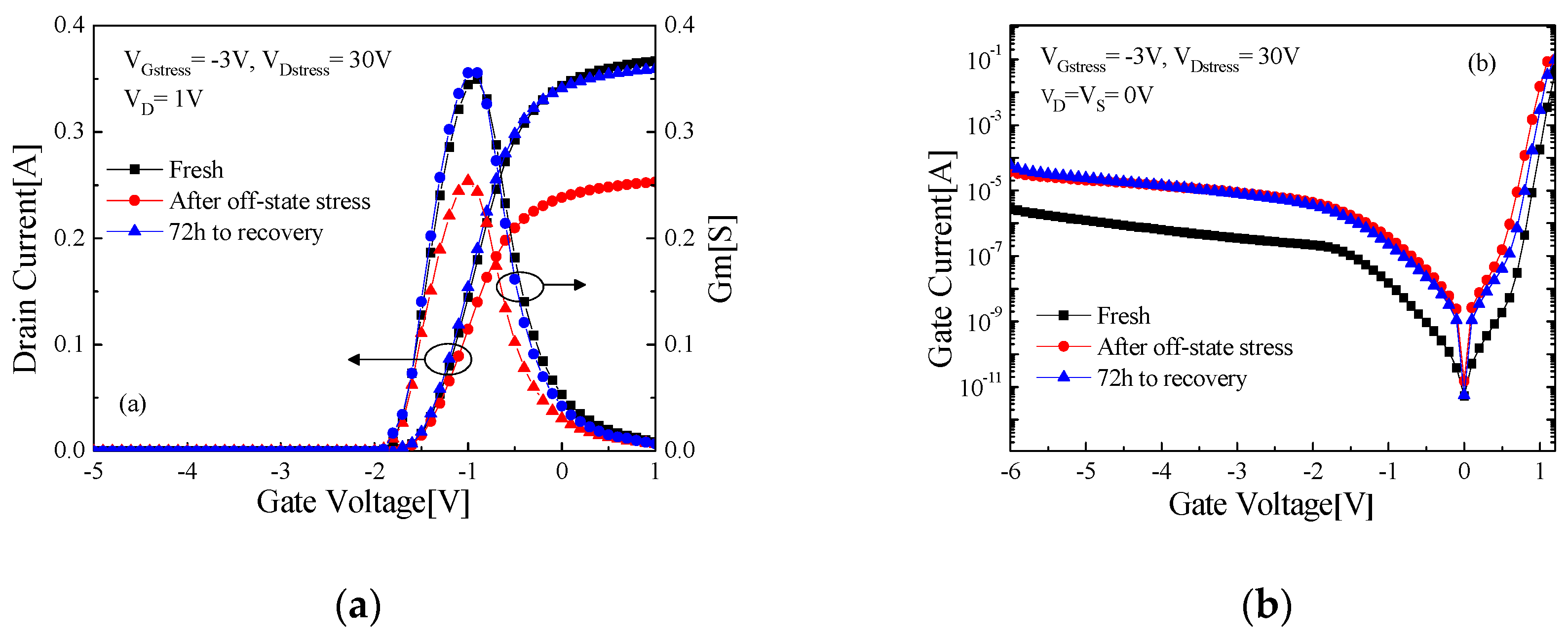

3.1. Off-State Stress

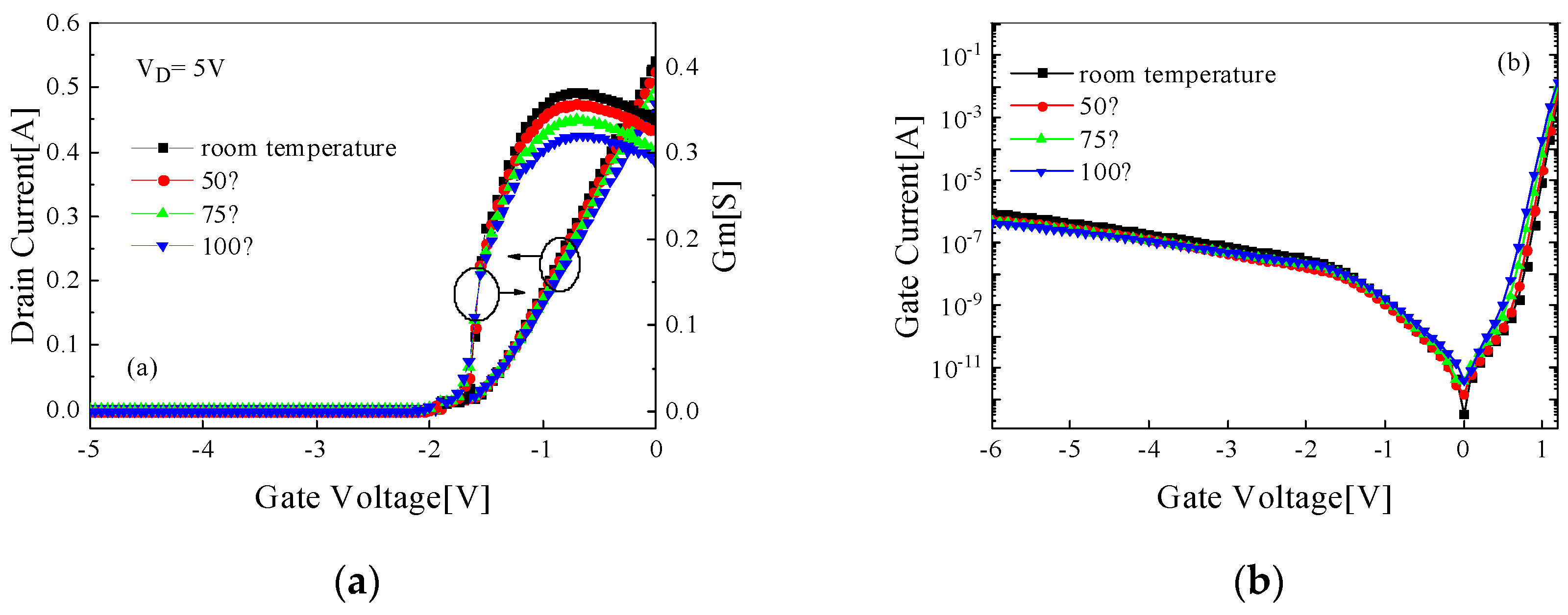

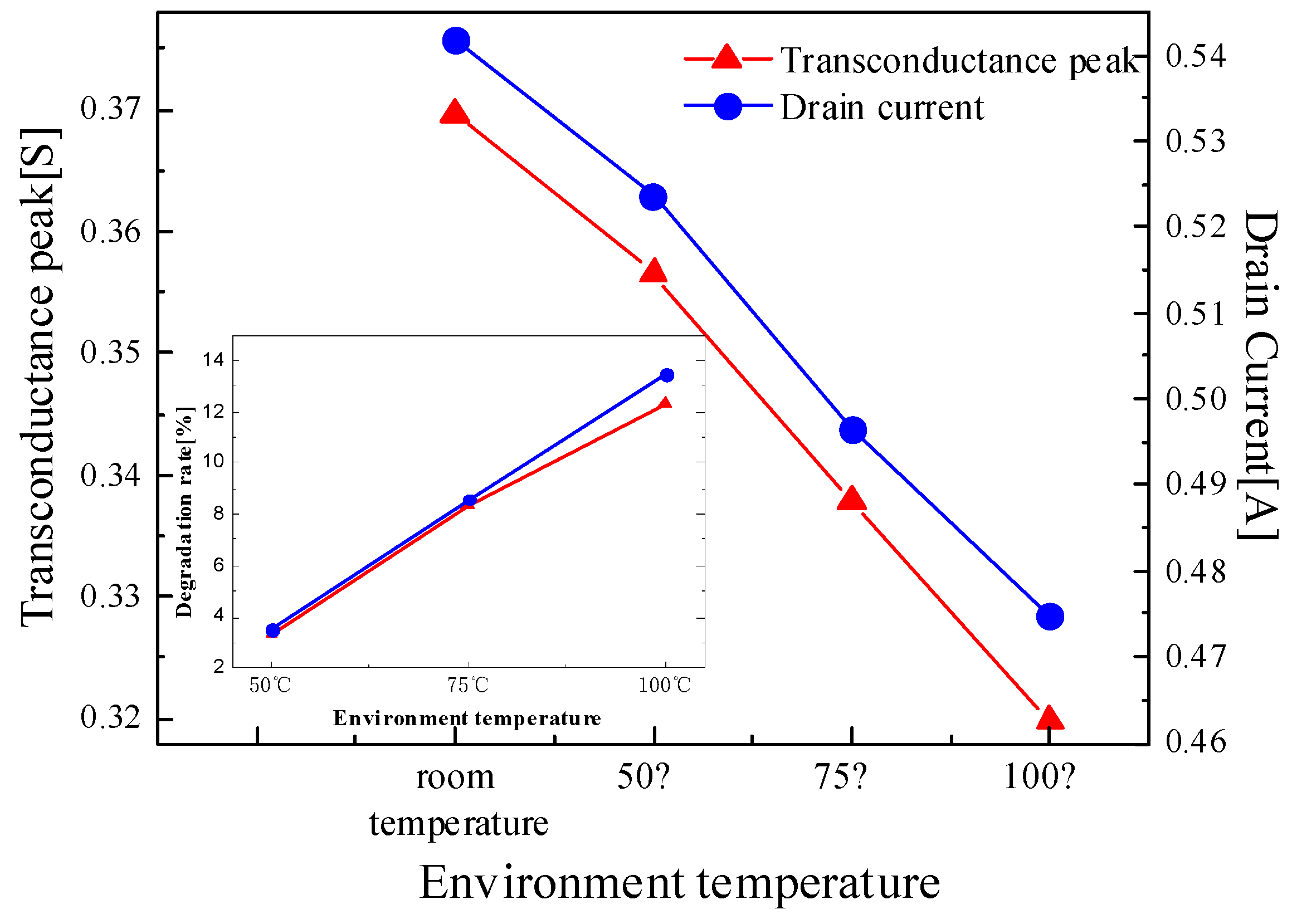

3.2. High-Temperature Stress

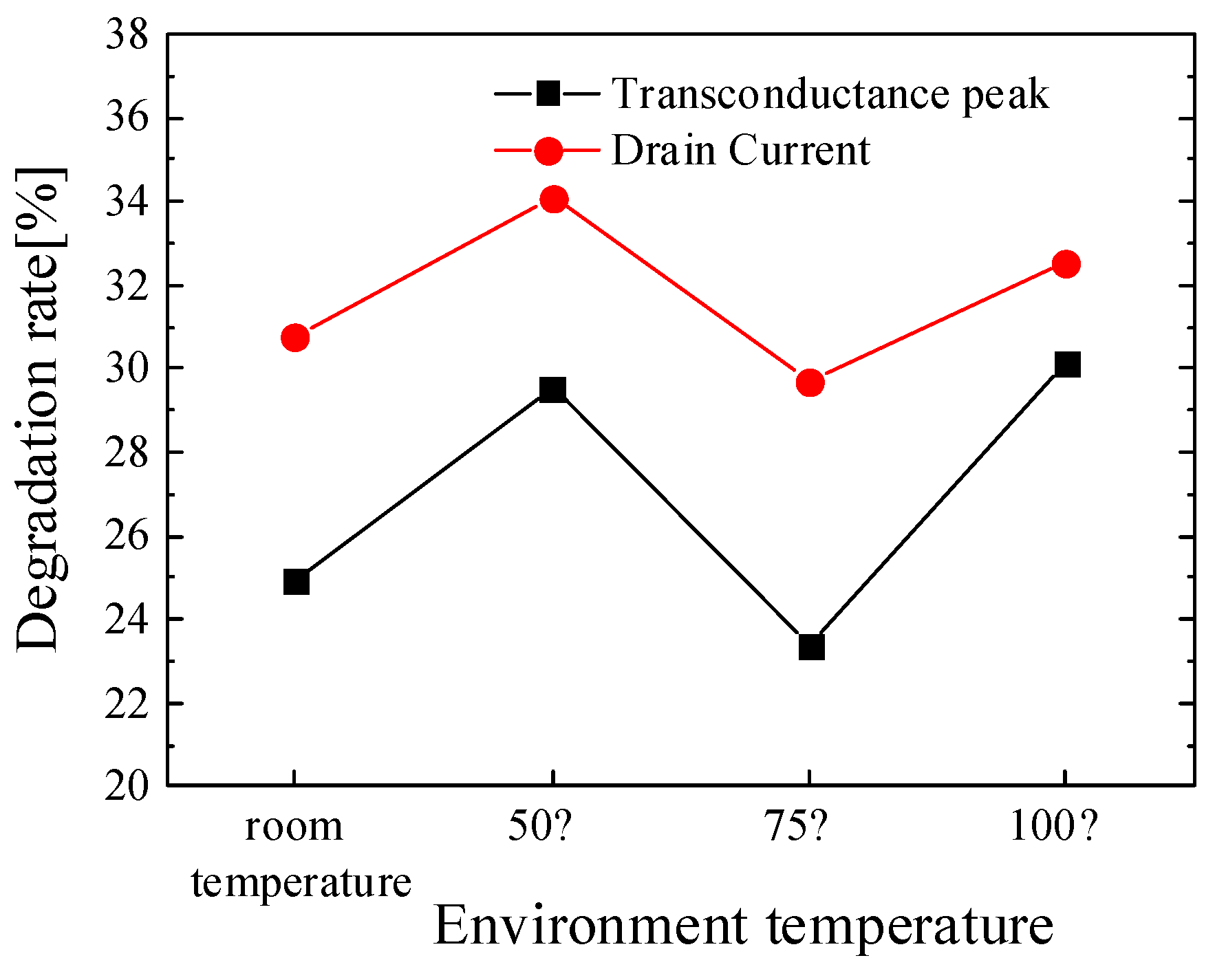

3.3. Off-State Stress at High Temperature

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pengelly, R.S.; Wood, S.M.; Milligan, J.W. A review of GaN on SiC high electron-mobility power transistors and MMICs. IEEE Trans. Microw. Theory Tech. 2012, 60, 1764–1783. [Google Scholar] [CrossRef]

- Akita, M.; Kishimoto, S.; Mizutani, T. High-frequency measurements of AlGaN/GaN HEMTs at high temperatures. IEEE Electron Device Lett. 2001, 22, 376–377. [Google Scholar] [CrossRef]

- Palacios, T.; Chakraborty, A.; Rajan, S. High-power AlGaN/GaN HEMTs for Ka-band applications. IEEE Electron Device Lett. 2005, 26, 781–783. [Google Scholar] [CrossRef]

- Kim, H.; Tilak, V.; Green, B.M. Reliability Evaluation of High Power AlGaN/GaN HEMTs on SiC Substrate. Phys. Status Solidi 2001, 188, 203–206. [Google Scholar] [CrossRef]

- Valizadeh, P.; Pavlidis, D. Effects of RF and DC stress on AlGaN/GaN MODFETs: A low-frequency noise-based investigation. IEEE Device Mater. Reliab. 2005, 5, 555–563. [Google Scholar] [CrossRef]

- Makaram, P.; Joh, J.; Jesús, A.D.A. Evolution of structural defects associated with electrical degradation in AlGaN/GaN high electron mobility transistors. Appl. Phys. Lett. 2010, 96, 756–758. [Google Scholar] [CrossRef]

- Joh, J.; Alamo, J.A.D. A Current-Transient Methodology for Trap Analysis for GaN High Electron Mobility Transistors. IEEE Trans. Electron Devices 2011, 58, 132–140. [Google Scholar] [CrossRef]

- Omar, C.; Loic, T.; Alain, B. Effect of HTRB lifetest on AlGaN/GaN HEMTs under different voltages and temperatures stresses. Microelectron. Reliab. 2018, 88–90, 402–405. [Google Scholar]

- Malik, A.; Sharma, C.; Laishram, R. Role of AlGaN/GaN interface traps on negative threshold voltage shift in AlGaN/GaN HEMT. Solid-State Electron. 2018, 142, 8–13. [Google Scholar] [CrossRef]

- Douglas, E.A.; Chang, C.Y.; Cheney, D.J. AlGaN/GaN High Electron Mobility Transistor degradation under on- and off-state stress. Microelectron. Reliab. 2011, 51, 207–211. [Google Scholar] [CrossRef]

- Rong, J.; Xiao, S.; Jingtian, F. Multiple Defects Cause Degradation After High Field Stress in AlGaN/GaN HEMTs. IEEE Trans. Device Mater. Reliab. 2018, 18, 364–376. [Google Scholar]

- Joh, J.; Del, A. A model for the critical voltage for electrical degradation of GaN high electron mobility transistors. Microelectron. Reliab. 2010, 50, 767–773. [Google Scholar] [CrossRef]

- Darwish, A.M.; Bayba, A.J.; Hung, H.A. Thermal resistance calculation of AlGaN-GaN devices. IEEE Trans. Microw. Theory Tech. 2004, 52, 2611–2620. [Google Scholar] [CrossRef]

- Oxley, C.H.; Uren, M.J.; Coates, A. On the temperature and carrier density dependence of electron saturation velocity in an AlGaN/GaN HEMT. IEEE Trans. Electron Devices 2006, 53, 565–567. [Google Scholar] [CrossRef]

- Lee, J.M.; Min, B.G.; Ju, C.W. High temperature storage test and its effect on the thermal stability and electrical characteristics of AlGaN/GaN high electron mobility transistors. Curr. Appl. Phys. 2017, 17, 157–161. [Google Scholar] [CrossRef]

- Husna, F.; Lachab, M.; Sultana, M. High-temperature performance of AlGaN/GaN MOSHEMT with SiO2 gate insulator fabricated on Si (111) substrate. IEEE Trans. Electron Devices 2012, 59, 2424–2429. [Google Scholar] [CrossRef]

- Alim, M.A.; Rezazadeh, A.A.; Gaquiere, C. Temperature Effect on DC and Equivalent Circuit Parameters of 0.15-μm Gate Length GaN/SiC HEMT for Microwave Applications. IEEE Trans. Microw. Theory Tech. 2016, 64, 3483–3491. [Google Scholar] [CrossRef]

- Zhao, M.; Wang, X.; Liu, X. Thermal storage of AlGaN/GaN high-electron-mobility transistors. IEEE Trans. Device Mater. Reliab. 2010, 10, 360–365. [Google Scholar] [CrossRef]

- Omar, C.; Loic, T.; Eric, W. Temperature and voltage effects on HTRB and HTGB stresses for AlGaN/GaN HEMTs. In Proceedings of the 2018 IEEE International Reliability Physics Symposium, Burlingame, CA, USA, 11–15 March 2018, ISSN 1938-1891. [Google Scholar]

- Meneghesso, G.; Meneghini, M.; Stocco, A. Degradation of AlGaN/GaN HEMT devices: Role of reverse-bias and hot electron stress. Microelectron. Eng. 2013, 109, 257–261. [Google Scholar] [CrossRef]

- Chang, Y.; Tong, K.Y.; Surya, C. Numerical simulation of current–voltage characteristics of AlGaN/GaN HEMTs at high temperatures. Semicond. Sci. Technol. 2015, 20, 188–192. [Google Scholar] [CrossRef]

- Sun, H.; Bajo, M.M.; Uren, M.J. Progressive failure site generation in AlGaN/GaN high electron mobility transistors under OFF-state stress: Weibull statistics and temperature dependence. Appl. Phys. Lett. 2015, 106, 7261. [Google Scholar] [CrossRef]

| Degradation Rate [%] | Temperature of 75 °C | Off-state Stress Under 75 °C | Return to Room Temperature | 72 h to Recovery |

|---|---|---|---|---|

| Threshold voltage | 1.71 | 33.15 | 26.51 | 27.62 |

| Transconductance peak | 11.52 | 32.20 | 13.61 | 11.26 |

| Drain current (VG =1V /VD = 1 V) | 15.00 | 40.26 | 22.11 | 18.68 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Liu, H.; Wang, S.; Liu, C.; Li, M.; Wu, L. Effect of the High-Temperature Off-State Stresses on the Degradation of AlGaN/GaN HEMTs. Electronics 2019, 8, 1339. https://doi.org/10.3390/electronics8111339

Lin J, Liu H, Wang S, Liu C, Li M, Wu L. Effect of the High-Temperature Off-State Stresses on the Degradation of AlGaN/GaN HEMTs. Electronics. 2019; 8(11):1339. https://doi.org/10.3390/electronics8111339

Chicago/Turabian StyleLin, Jinfu, Hongxia Liu, Shulong Wang, Chang Liu, Mengyu Li, and Lei Wu. 2019. "Effect of the High-Temperature Off-State Stresses on the Degradation of AlGaN/GaN HEMTs" Electronics 8, no. 11: 1339. https://doi.org/10.3390/electronics8111339

APA StyleLin, J., Liu, H., Wang, S., Liu, C., Li, M., & Wu, L. (2019). Effect of the High-Temperature Off-State Stresses on the Degradation of AlGaN/GaN HEMTs. Electronics, 8(11), 1339. https://doi.org/10.3390/electronics8111339