2.1. Sensor Test Bench

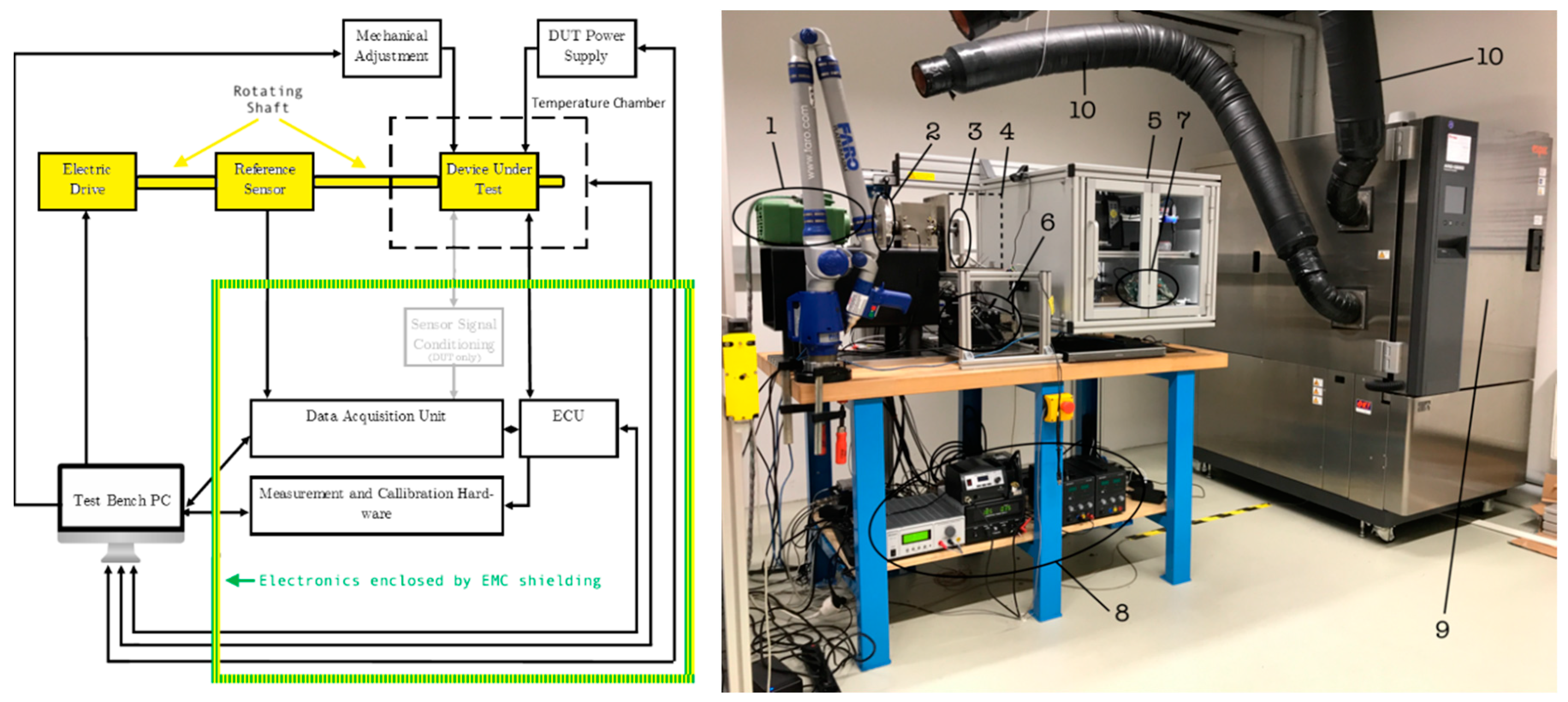

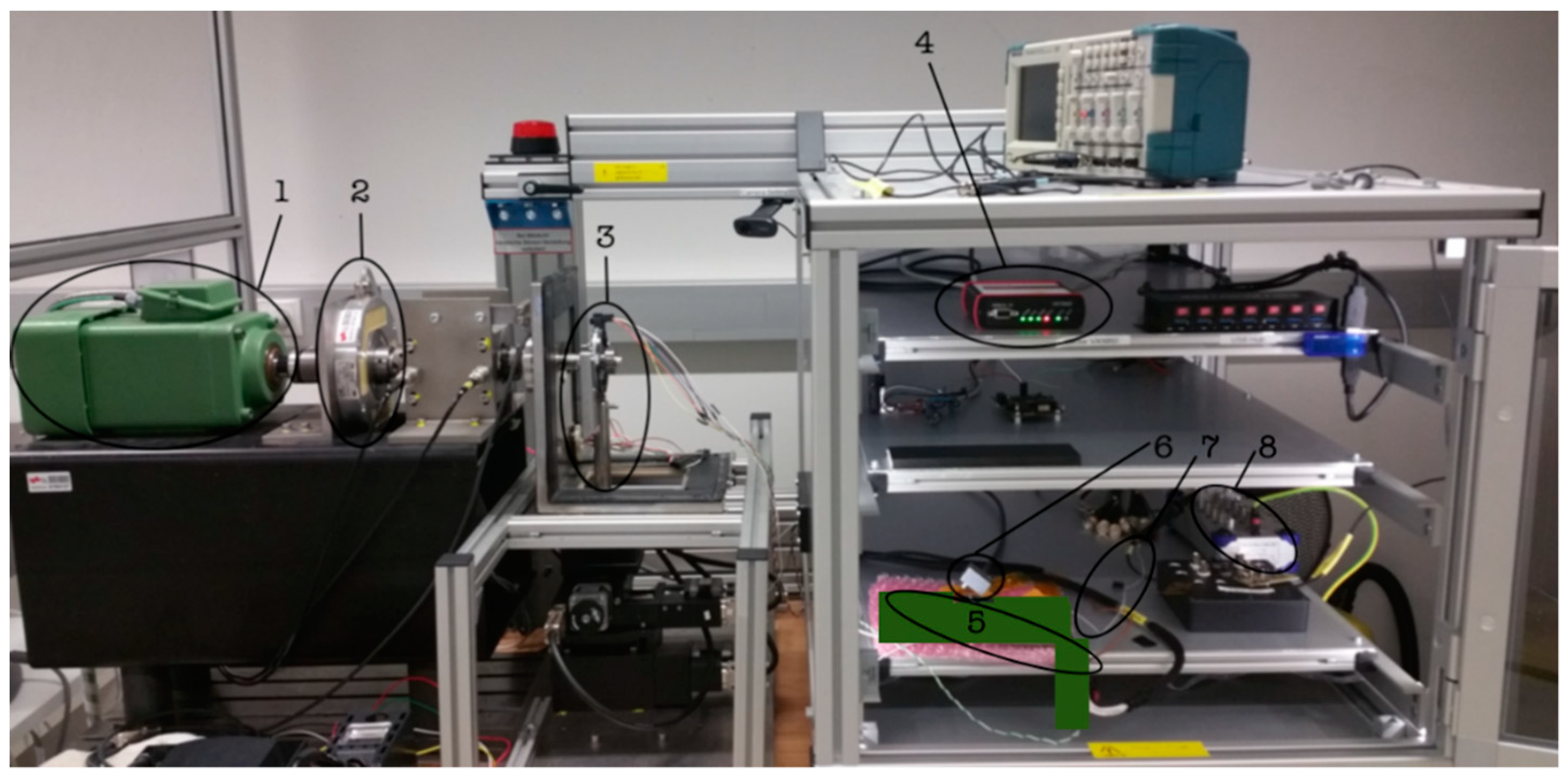

The experimental parts of the research activities have been conducted on a specifically developed test bench for position and speed sensor systems [

2,

6,

7]. The test bench consists of an electric drive (induction motor), providing a maximum speed of 24,000 rpm in both directions with a maximum acceleration of 10,000 rpm/s. This enables realistic test conditions as they occur in different automotive driving profiles. Furthermore, an ambient temperature can be applied to the device under test (DUT) within the range of −40 °C to +160 °C using a temperature chamber surrounding the DUT and a climatic chamber used as a thermal generator. To investigate the effects of mechanical misalignment between the sensor rotor relative to the stator, the DUT can be adjusted in four axes (

x,

y,

z, and tilt-angle) by a multiple set of precise motorized positioning actuators. The influence of supply voltage variations can be tested by a controlled power supply from zero to 40 V. Besides these parameters, a high precision Hall-based reference sensor with an angular resolution of <0.1° at 24,000 rpm is connected with a state-of-the-art 5 mega samples per second (MS/s) Field Programmable Gate Array (FPGA)-based data acquisition unit feeding an rpm-dependent transistor-transistor-logic (TTL) signal. Three signal tracks are available, namely A- and B-tracks for detecting the rotation direction, as well as a Z-track for zero position detection. The counter of the data acquisition unit increments every sensor step and resets the counter when the Z-track rises. Based on the counter information and knowledge of the reference sensor’s maximum increments per revolution (here: 8192 increments), a rotor position angle can be computed online. This process plays an important role; hence it represents the experimental fundament to determine the reference position. Furthermore, the reference sensor is used for control of the electric test bench machine.

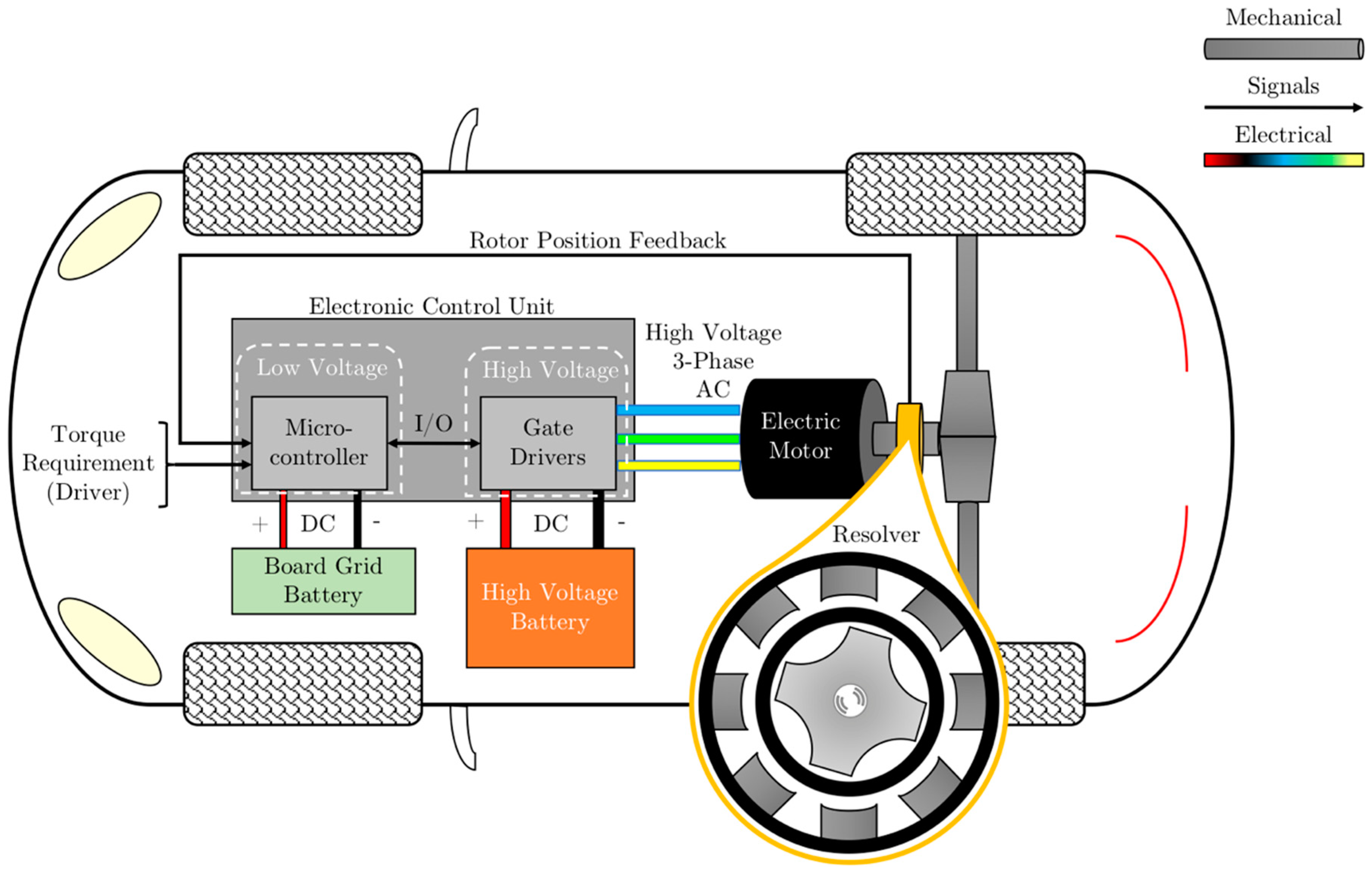

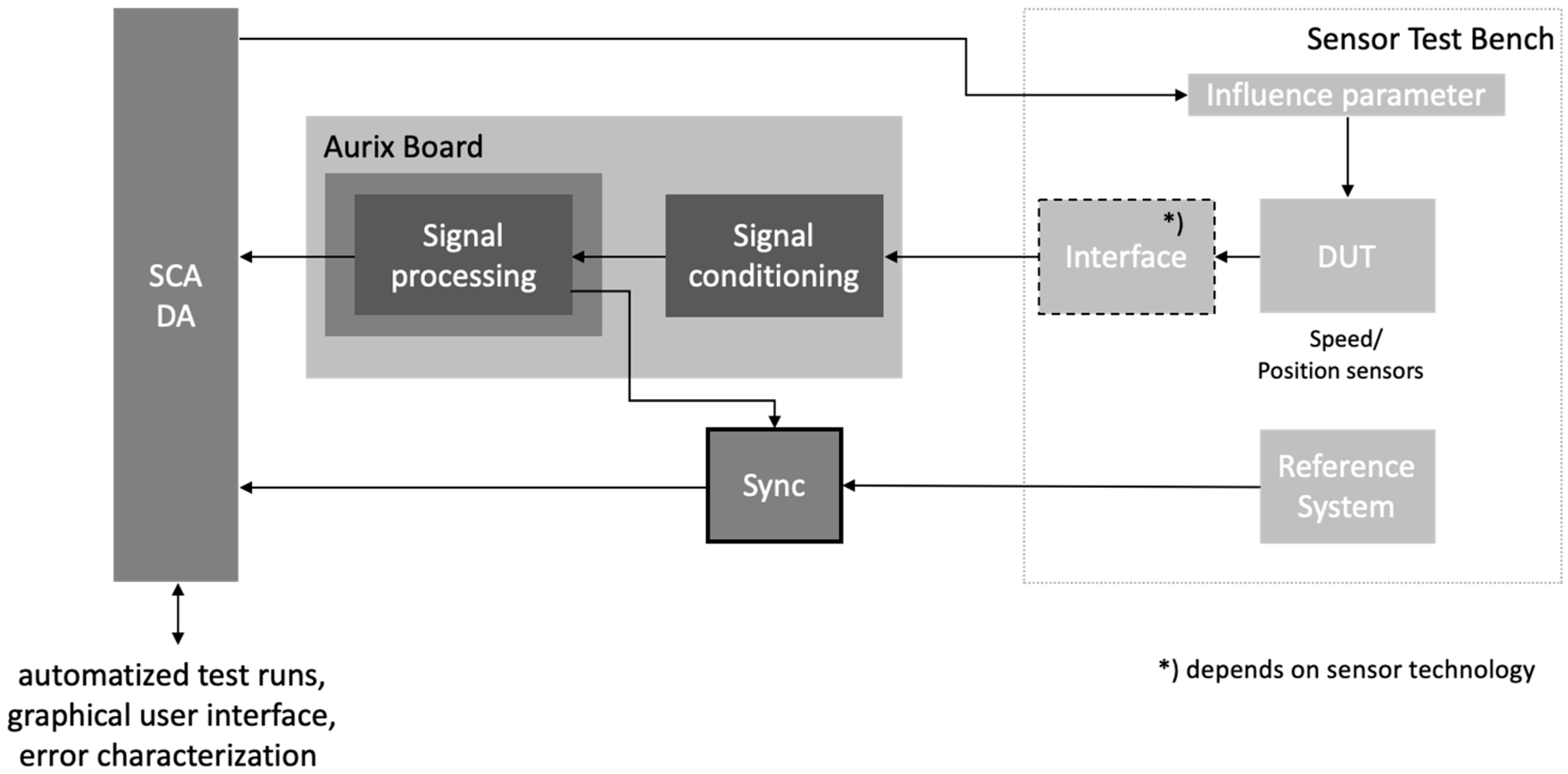

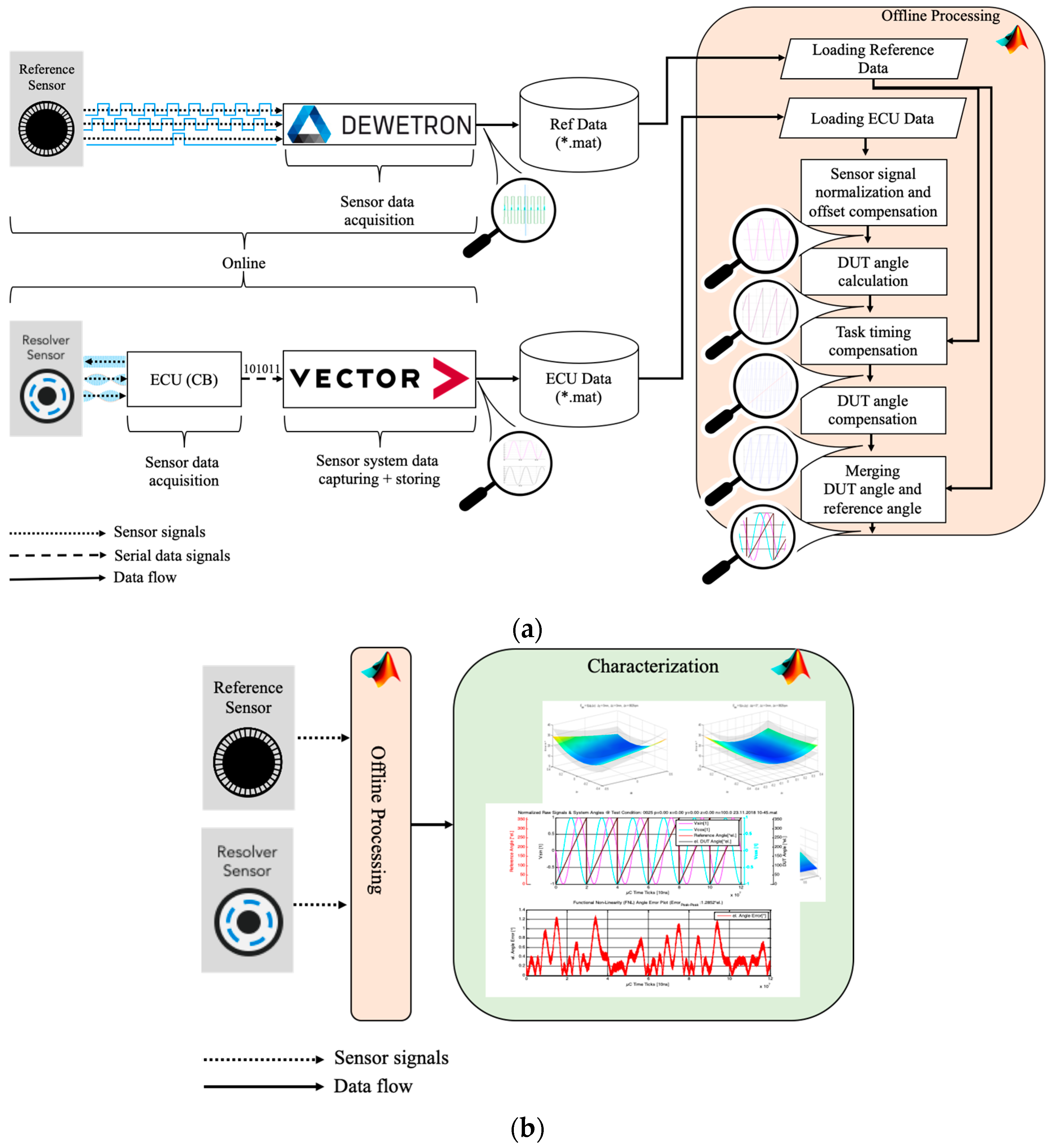

Considering a complete vehicle sensor system comprising a position sensor and a microcontroller for signal processing (see

Figure 1). The output of the investigated system is read out through a set of FPGAs, polling the desired data (e.g., raw sensor signals, estimated rotor position) without having an influence on the microcontroller’s processing time; therefore, the desired information is only available internally. Of course, the evaluated system has to be synchronized with the reference sensor system to enable a comparison between both systems (see

Section 2.4). For an adequate signal accuracy, all electronic components and measurement systems are shielded to prevent electromagnetic compatibility (EMC) influence [

2,

3,

6,

15].

Figure 2 shows an overview and the relevant components of the sensor test bench. As shown in

Figure 2, a climatic stress chamber is used for temperature conditioning, transferring the climate via thermal tubes into the DUT-temperature chamber. The special designed data acquisition housing comprises the total data acquisition (ECU + reference measurement unit) and is capable of being placed as close as possible to the DUT.

2.2. System under Test

The evaluated drive train sensor system comprises two main parts, namely a rotor position sensor and an ECU (see

Figure 1), including the microcontroller only. In this way, the rotation is set by the test bench and not by the gate drivers of the ECU (open-loop architecture). In this work, the investigated rotor position sensor type is a resolver, which will be explained in the following section.

2.2.1. Resolver

Resolver technology is known as a state-of-the-art sensor when it comes to applications that need reliable performance under rough conditions, e.g., high temperature, shocks and vibrations, radiation and contamination. This recommends the resolver as a suitable alternative compared to other sensor types e.g., magnetic or optical systems for shaft angle encoding.

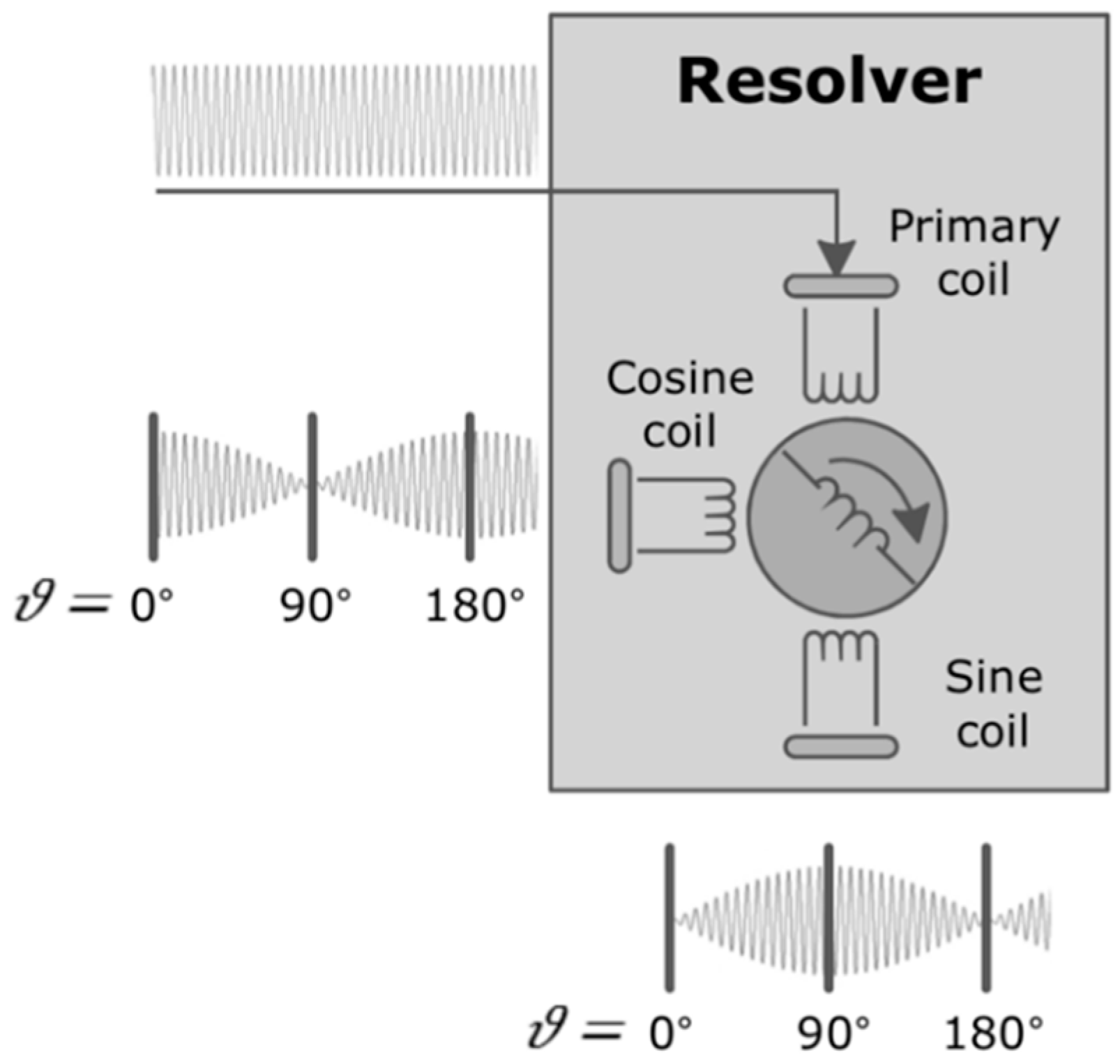

The variable reluctance resolver applied in this work, also called an eddy current resolver, is considered as a rotating electric transformer. It consists of one primary winding and two secondary windings (sine and cosine coil), where the primary winding is acting as the resolver’s rotor and the two secondary windings represent the stator, where they are physically displaced from each other by 90° as shown in

Figure 3 [

2,

3,

6,

7,

15,

16,

17,

18]. The sensor itself is excited by a high frequency sinusoidal signal of usually

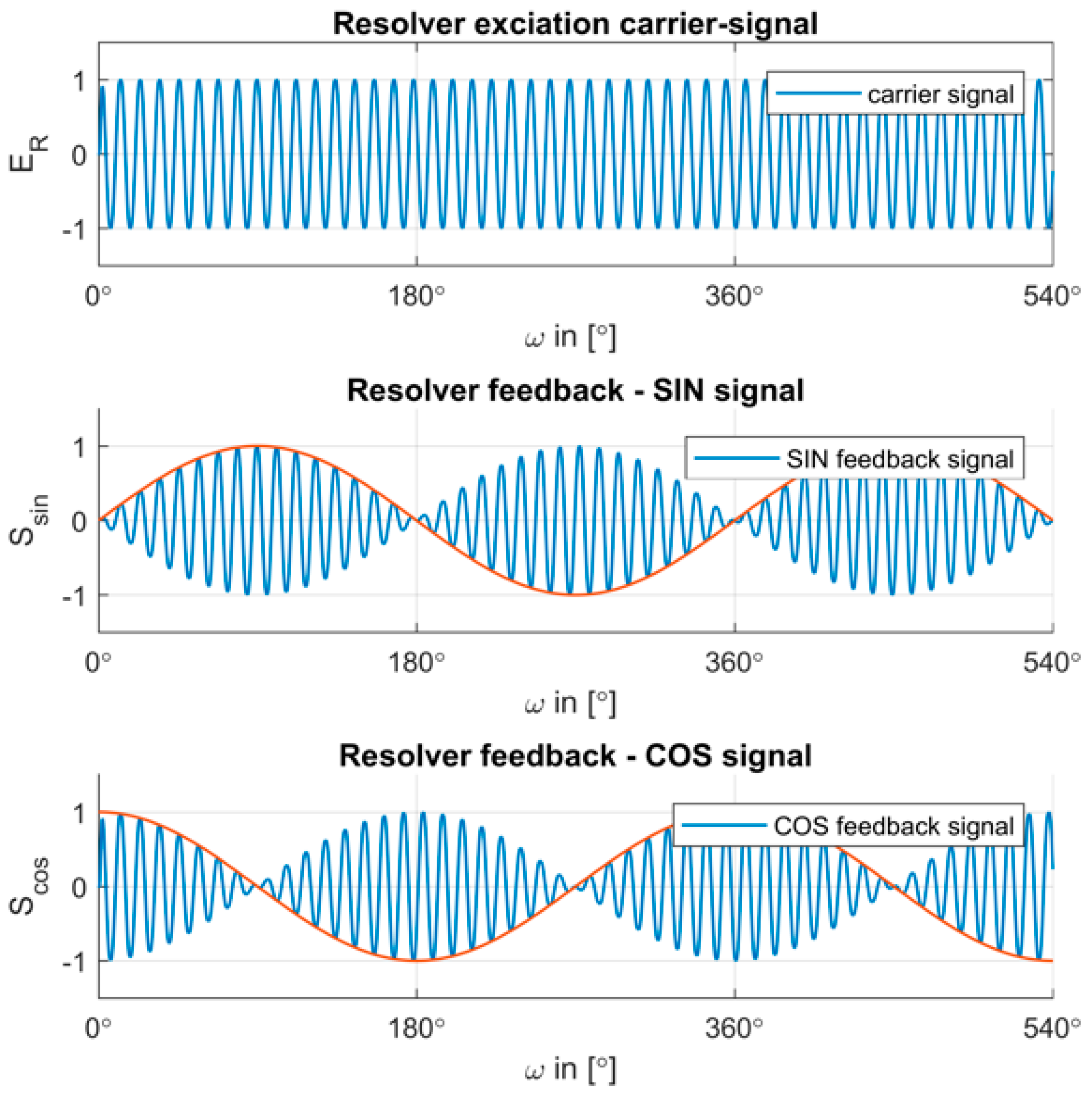

f = 10 kHz. This signal is also called the carrier signal. While the shaft rotates, the inductive coupling between the windings changes according to the position of the rotary part of the resolver. From this change of the inductive coupling, the shaft position is determined. The resulting signals on the sine and cosine coil are amplitude modulated sinusoidal signals with the same frequency as the carrier signal, shown in

Figure 4. With these signals only, it is not possible to establish a correct angular rotor position. To determine the actual rotor position, first a demodulation unit in the microcontroller computes the envelope of the resolver feedback signals by extracting the carrier signal (shown in

Figure 4 as the red line) before calculating the resolver angle. The sensor signal acquisition by analog-to-digital conversion, as well as the demodulation process, are stated in more detail in [

3].

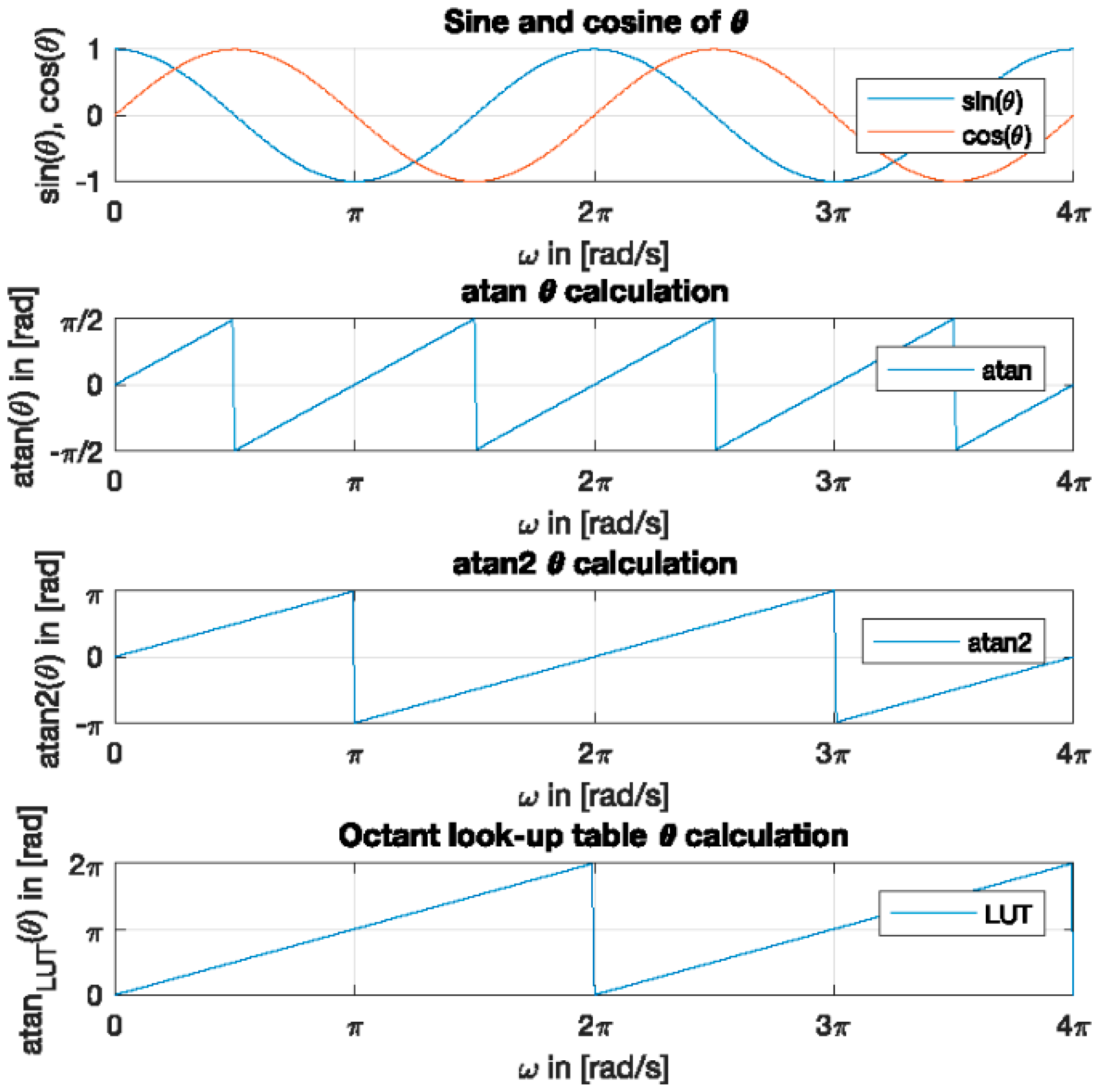

Processing of the sine and cosine signal is performed by use of a mathematical operation of the sine value over the cosine value and then applied to a four-quadrant inverse tangent (

ATAN2) function, which also enables a noise reduction process considering the ambient noise that has the same effect on both windings [

6]. This mechanism also provides adequate temperature compensation. Thereby the arguments of the Cartesian coordinates (sine and cosine), stated in Equations (1) and (2), are passed through the trigonometric-based

ATAN2 function extracting the root of the quadratic arguments (Equation (3)). As a result, the polar angle represents the position of the resolver’s rotor (

Figure 5). With an octant look-up table, a position resolution from 0 to 2π (in polar coordinates) can be achieved, which represents the mechanical resolution from 0° to 360° (in Cartesian coordinate system) [

2,

3].

An important term characterizing the resolver working principle is the electric zero (EZ), which is defined as the position of the rotor that gives a maximum amplitude for the resolver output cosine windings and at the same time gives a minimum amplitude of the resolver sine output windings (ideal: Vsin = 0 V) under the condition of a rated carrier signal voltage.

Resolvers, as stated before, come in many types. In order to specify the type of the resolver, the design should be addressed that determines the resolver type.

Regarding the design of the resolver windings, the coils are wound over a slotted lamination, which is wound with one of two types of windings: a constant pitch-variable turn or a variable pitch-variable turn pattern. In both types of windings, the windings are distributed in a sinusoidal pattern. This winding type introduces what is called the resolver’s speed. The resolver’s speed encompasses the number of electrical cycle periods that are there as an output in the sine and the cosine windings for each complete mechanical rotation. For the case of single speed, a single electrical period at the output sine and cosine winding is generated for each mechanical revolution. For a multi-speed resolver, more than one electrical period for each mechanical revolution can be obtained [

8]. Design criteria of resolver systems involve the speed of the resolver and the effort of control involved, where the multi-speed resolver is normally used when high accuracy is required. If the application deals with a very small change of velocity over time steps, the multi-speed resolver technology might be an ideal choice. For typical automotive electric motor control, the resolver speed is determined based on the number of poles of the motor, as for a 10-pole electric motor, a 5-speed resolver is adequate.

Generally, single-speed resolvers consist of a simple and affordable design and they are used in lots of daily applications of electric machines. They are able to provide an absolute rotor position in the range of 0° to 360° and are used in servo motors, actuators and robotics [

18].

Multi-speed resolvers are generally equipped with a certain number of windings to generate several electrical cycles per one mechanical revolution. The benefit of having a higher-speed resolver over the single speed resolver is that the increased number of windings reduces the contribution of possible mechanical error to the overall system error. On the other hand, the complex winding pattern in multi-speed resolvers increases the resolver costs. This is the reason why higher speed resolvers are generally preferred only for applications with high requirements on sensor system performance.

As stated above, a specific processing unit is used to process the sensor signals and thus to determine the rotor position.

2.2.2. Electronic Control Unit

In this section, the functionalities of the ECU used for resolver signal processing are introduced.

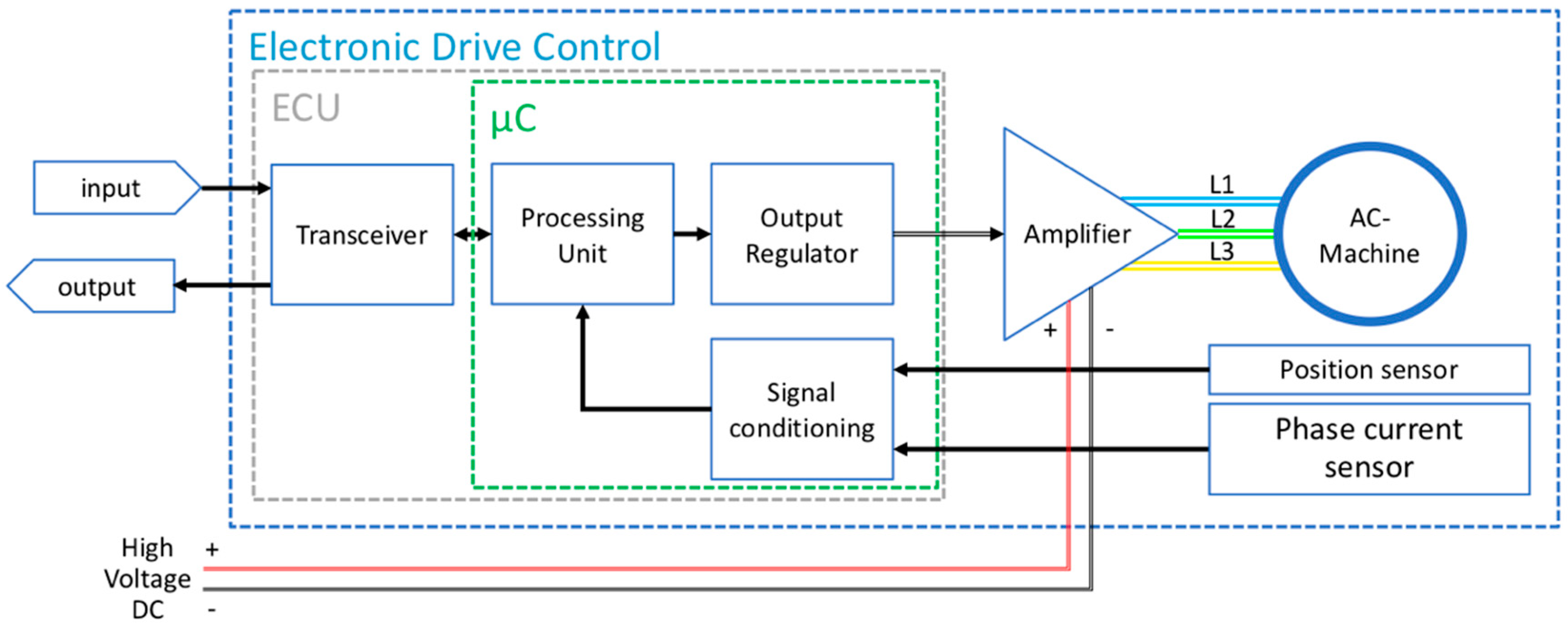

Figure 6 gives an overview of the electric drive control architecture using an induction motor (AC-machine) as an example. The integrated microcontroller (µC) represents the heart of the ECU that manages different tasks, e.g., interpreting the driver input (torque request), monitoring of relevant parameters (e.g., temperature, phase current, speed and rotor shaft position) and controlling electric parameters to drive the motor. The processing unit contains the motor control algorithm. The output signals, usually low-voltage pulse-width modulation (PWM) electrical signals, are sent through an output regulator to a separate driver stage (amplifier) comprising the gate drivers (e.g., bi-polar transistors), which actually supplies the three phases of the electric machine. The focus of this work in terms of the ECU focusses on the rotor shaft position sensor feedback signal conditioning and processing procedure within the µC. These procedures represent components of the control algorithm as well as the readout sequences of the internal sensor signals for angle error evaluation. Detailed investigations of the resolver-to-digital conversion (R2D, RDC) and conditioning have been carried out in previous research [

3].

The specific ECU applied in the present work includes a µC as well as signal conditioning circuits. Because there was no need to operate the electric machine from the ECU for the present investigations, the driver stage of the controller was removed during the measurement series on test bench. Under these laboratory conditions, the electric machine of the test bench provided the desired mechanical rotation of the rotor shaft independently from the investigated sensor system related controller.

The investigated µC represents a standard automotive device supplied by Infineon [

20]. The so-called AURIX µC is a powerful 32-bit microcontroller that provides a high level of functional safety features and at the same time high performance capabilities [

10]. AURIX stands for AUtomotive Real-time Integrated neXt generation architecture and has a multicore architecture [

20] based on up to three independent Central Processing Units (CPUs).

AURIX is available in several configurations where it comes with different memory sizes as well as a different number of cores. For investigating the rotor angle position, only one core is utilized executing the main operating system (OS) and performing the data acquisition. Since state-of-the-art algorithms for R2D are applied, the data conversion between ECU and test bench environment represents the focus of the present work.

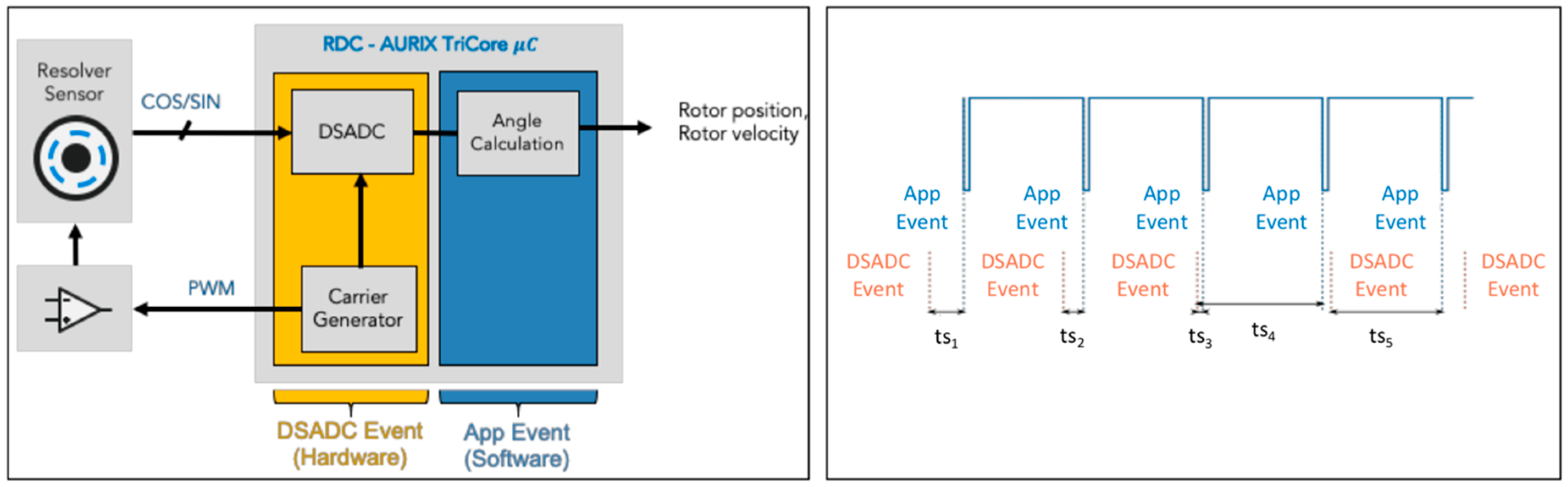

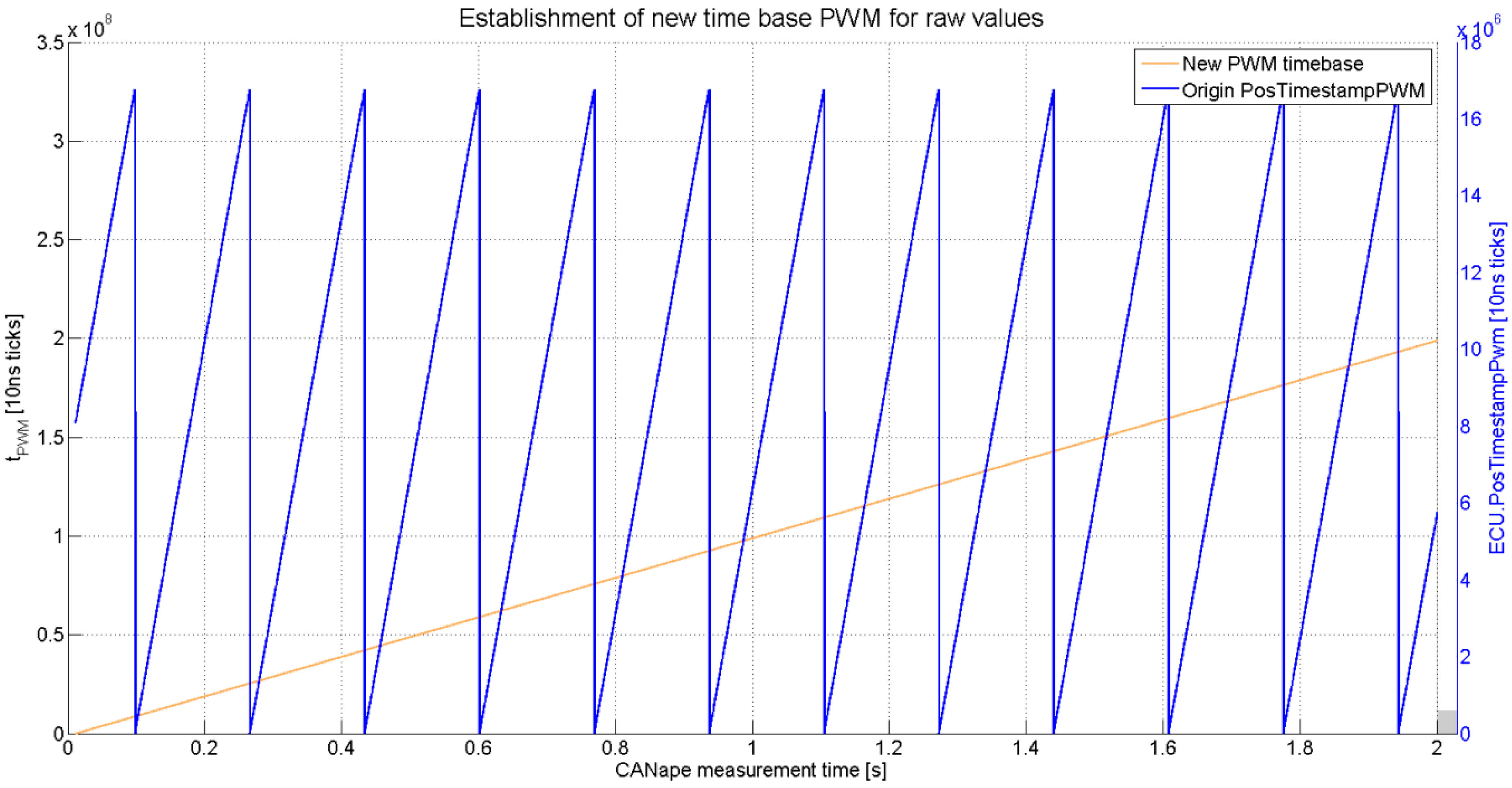

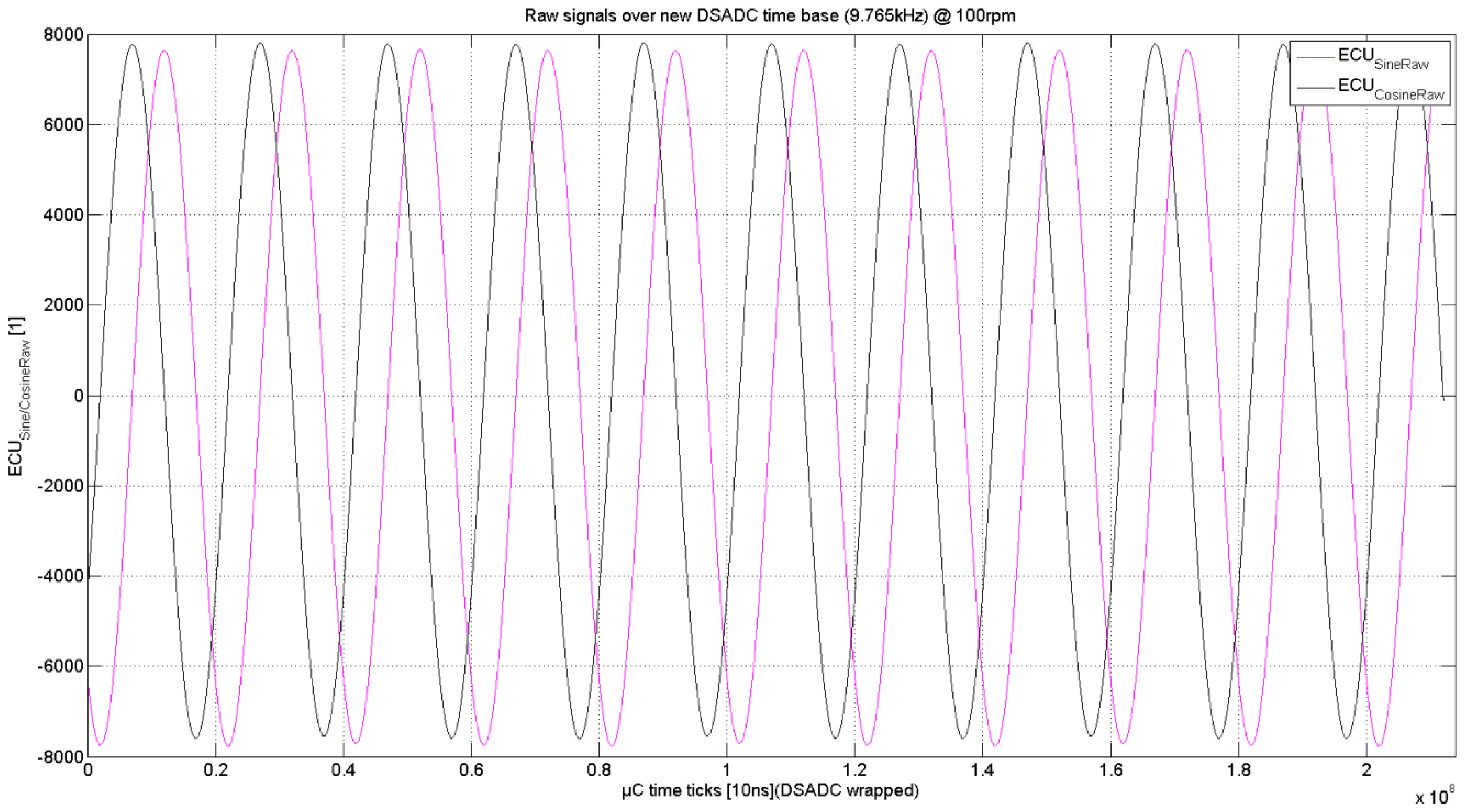

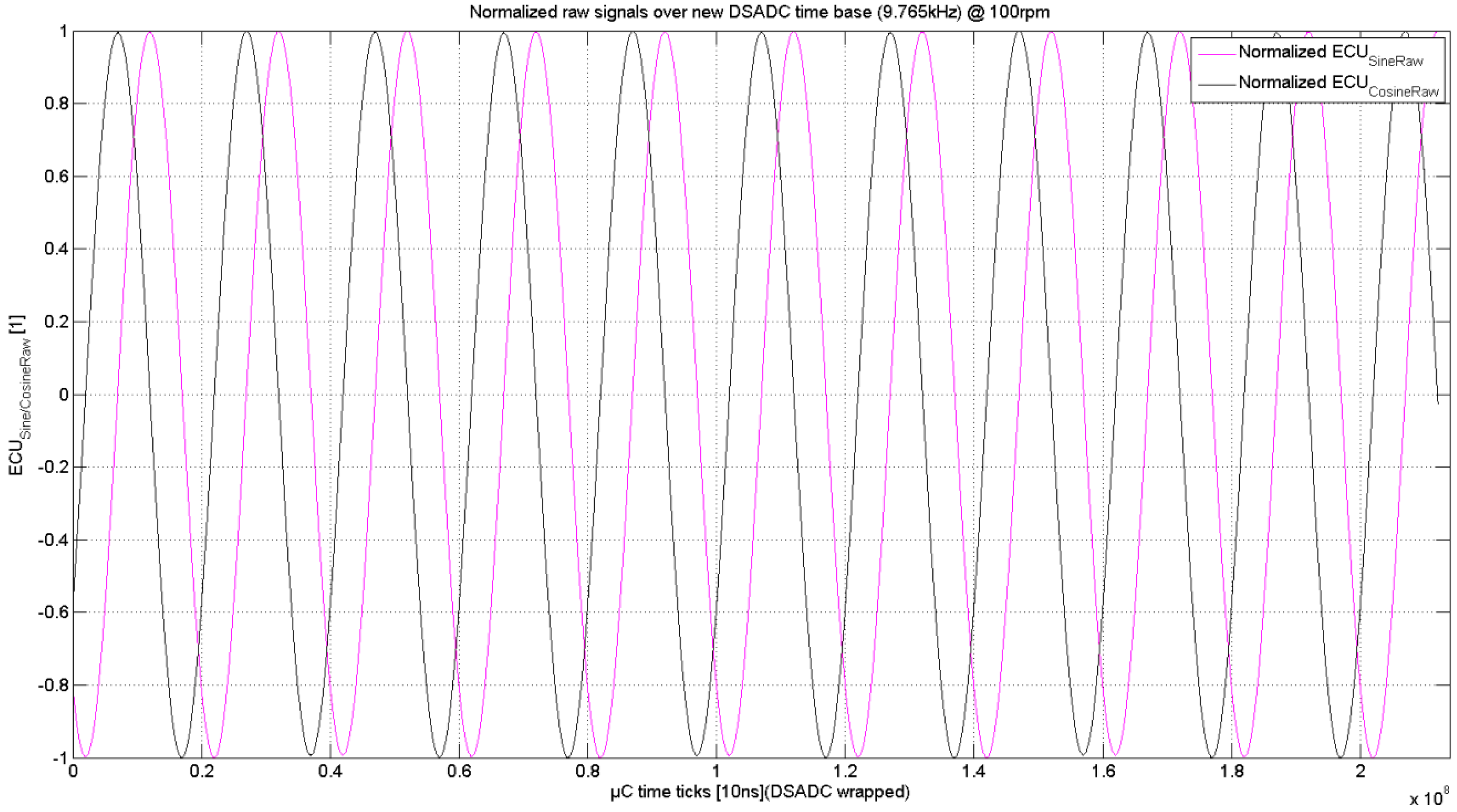

One characteristic of the AURIX µC is the asynchronous sampling of the resolver data, which is schematically shown in

Figure 7. This has to be considered when it comes to reading out the sensor’s sampled raw values and performing further evaluation, e.g., angle calculation and angle error analysis. The sampling of the resolver feedback signals is done by a delta-sigma-analog-to-digital-converter (∆Σ-ADC) [

17] under a constant, invariable frequency (a so-called

DSADC Event). In this work, the applied controller has a frequency set to

fDSADC Event = 9.765 kHz. This means, every

tDSADC Event = 102.4 µs one amplitude value of the resolver feedback signals per channel (two in sum: sine and cosine) is available for the angle calculation algorithm on the ECU. Also, the carrier generator works within the same event due to carrier cancelation reasons. This strategy was investigated in previous work [

3]. The second stage in the µC is the so-called

App Event. This event has a configurable frequency, which is set to

fApp Event = 9 kHz for the present investigations based on the requirements of the actual motor control algorithm. In more detail, this pre-defined frequency is linked with the pulse-width modulation (PWM) base frequency of the gate drivers to control the electric machine. That means the whole software and hardware control is operating at a timestamp of

tApp Event = 111 µs. In this way it can be stated that an inconstant task timing difference occurs between sampling and processing of the resolver signals, hence the sampled signals are available at every

tDSADC Event = 102.4 µs, while the software only collects and processes the values every

tApp Event = 111 µs.

This specific characteristic needs to be considered when further angle evaluation is performed, since the measured resolver signals, containing the information for angle computation, are not synchronous with the software-based angle determination. That means the angular information processed in software and used for the motor control is not the actual angle value. For that reason, an approach had to be developed within this work that enables the computation of the correct angle value at a constant rotational speed. This enables a more accurate angle error evaluation of the whole drive train system. The procedure is introduced in

Section 2.4.

2.3. Measurement and Calibration Hardware

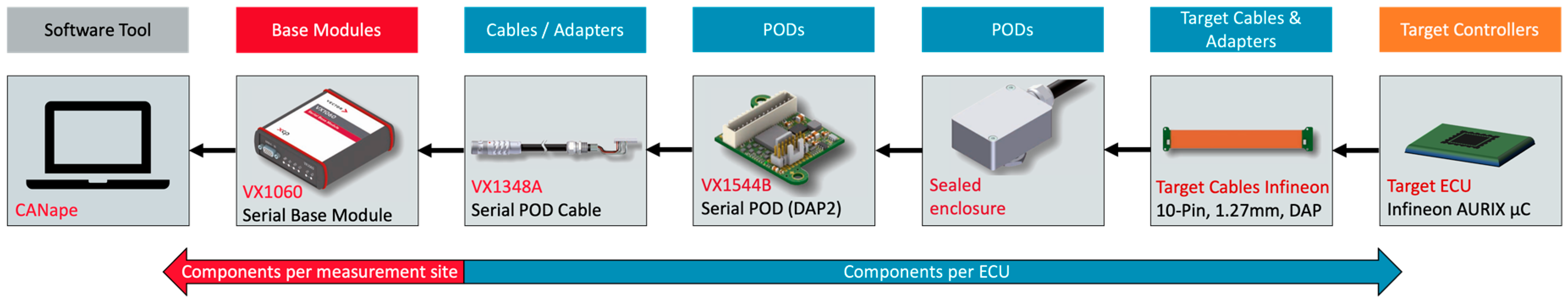

To acquire the raw rotor shaft position values (sine and cosine) as well as the estimated rotor position by the ECU for plausibility check, the parameters have to be determined in a way that avoids effects on the µC’s runtime and thus on the measurement process. Therefore, the considered approach is based on a direct polling of the acquired sensor data from the memory of the µC, in more detail the registers, to the test bench measurement equipment. The equipment used in the present work has been delivered by

Vector [

21]. The measurement chain is set up as a modular platform. The following components were used to realize the introduced method of characterization and benchmark automotive drive train sensor systems on the test bench. Starting with the head unit, the

Vector VX1060 Serial Base Module contains a FPGA that allows communication with the desired ECU. The base module itself is connected with the test bench computer by a variable and interchangeable transport layer, named universal measurement and calibration protocol (XCP) over Ethernet (ETH) that enables real-time data transmission. A separate piece of software,

CANape [

21], manages the measurement procedures and also enables

MATLAB™ [

22] data export, which is essential for evaluation of the system-under-test. Furthermore, the base module needs to be connected with the ECU itself to poll the data. To enable a flexible measurement on different µCs, an additional FPGA is necessary to convert the µC’s data to a bitstream that is readable for the base module. This essential additional FPGA is represented by a so-called serial

POD (Plug-On-Device) that is located between the base module and the specific ECU to be investigated. Using a standardized high-speed serial interface called

Debug Access Port (DAP) from

joint test action group (JTAG) [

23], between the µC and the

POD [

21,

24], the µC’s register can be read.

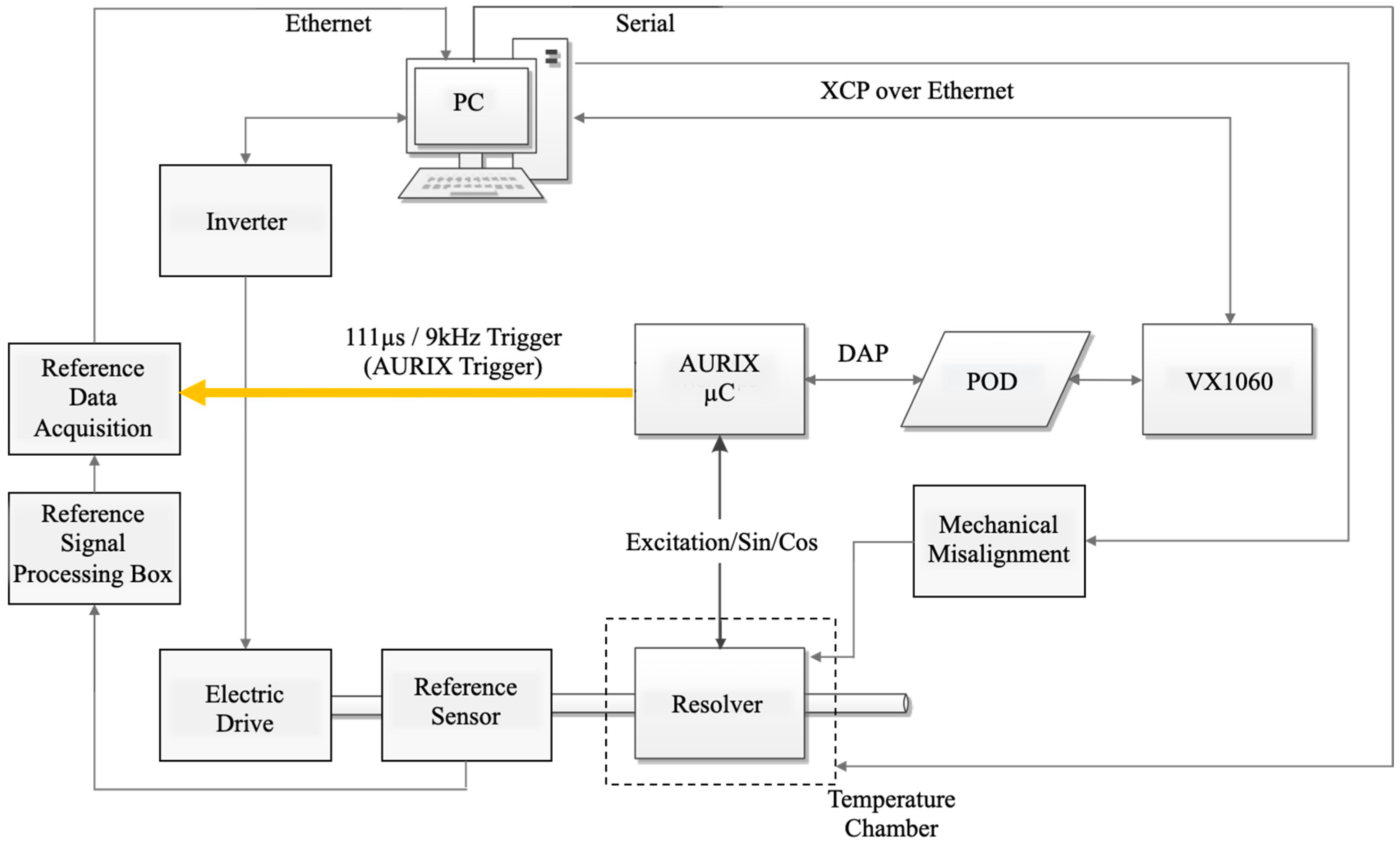

Figure 8 shows a scheme of the entire chain between the

VX1060 and the AURIX µC (target ECU). Depending on the ECU that is being investigated, the configuration between the target ECU and the base module changes (see

Figure 8: “Components per ECU”). Depending on the sort of measurement, the base module changes (see

Figure 8: “Components per measurement site”).

For reading data out of the registers and gathering the sensor information, two parts are essential. Firstly, the operating software on the µC has to provide programmed interrupts that rise every time a new sensor feedback value is read into the registers. Secondly, the base module (FPGA) needs to operate at the same clock frequency as the µC does (here: fApp Event = 9 kHz) to read in the data synchronously. When both systems have the same clock frequency, the base module can “listen” on the registers and wait for a memory interrupt to be raised. In such an event, the actual value is captured and sent (including the original µC timestamp) to the XCP over ETH connection to the PC. This enables a real time data acquisition of the µC’s memory. The separate software CANape is used to perform plots and further operations (e.g., calculations, manipulations) as well as to export the data sets to other file formats for further investigations.

After describing the hardware and software environment applied in this research work, the synchronization methodology of the new approach will be introduced in the following section. This approach enables a comparison of two independent measurement systems, namely the reference data acquisition [

25], and the ECU-based measurement system.

2.4. Synchronization Approach

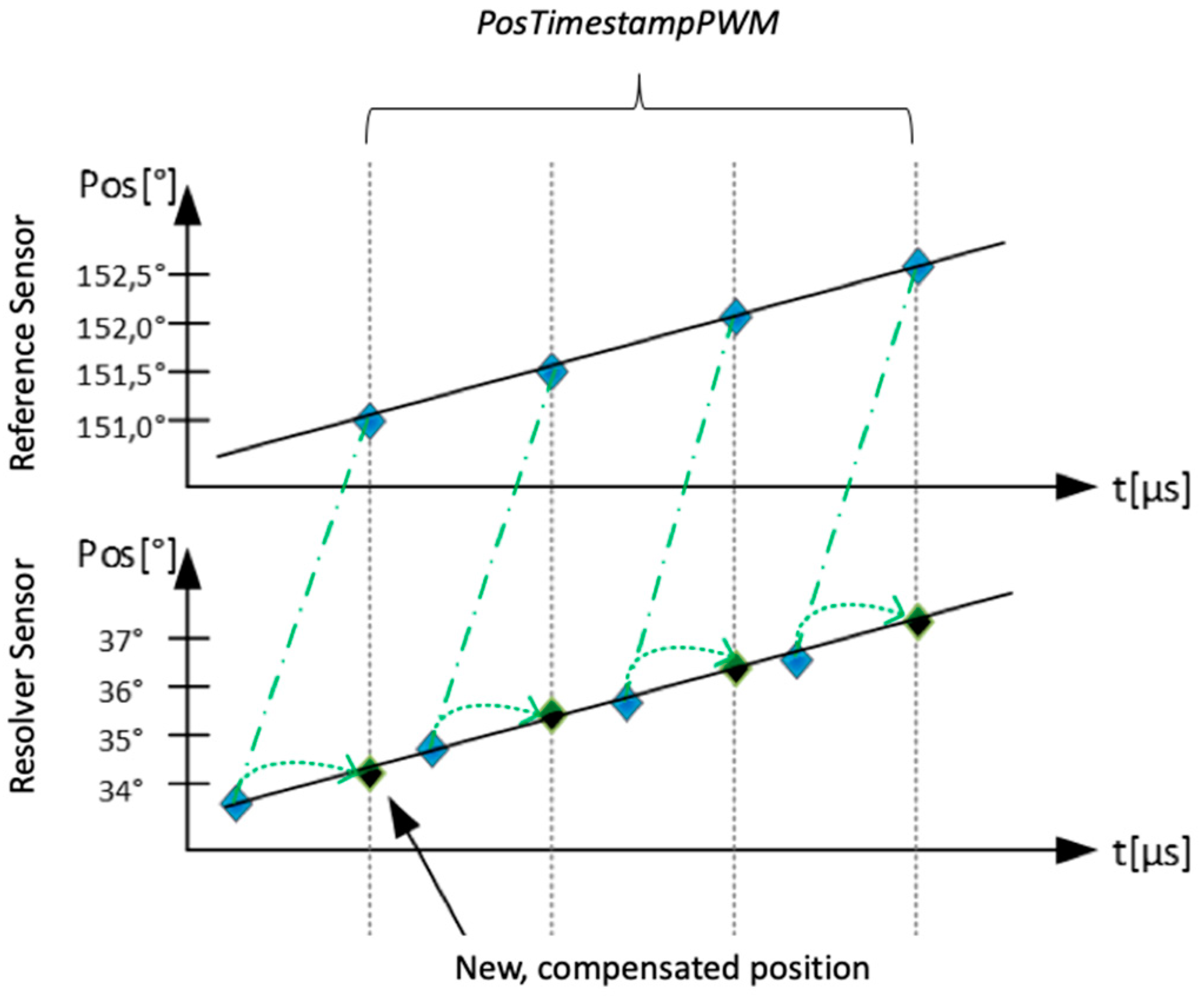

The introduced method enables a comparison of not only the DUT itself with a more accurate reference sensor, but also the consideration of the whole sensor system (ECU+DUT). This task challenges the applied data processing strategy because both systems work independently with a different, fixed sampling rate asynchronously. That is why the more flexible system, here the universal reference acquisition card, needs to be adapted in both ways regarding sampling frequency and capturing the actual sensor position data synchronously. To realize this concept, an electrical synchronization signal that acts as a trigger was introduced.

Figure 9 visualizes the synchronization approach at a glance: two sensors, here the resolver as DUT and the reference encoder, are measuring independently the same rotor shaft position on the sensor test bench under certain influence parameter variations. A discussion of the effects of these parameter variations on the investigated sensor systems is not a focus of this work but can be found in [

6]. The performed tests are run automatically by a sensor control algorithm (SCA) and are validated and characterized by a data acquisition (DA) unit on the test bench computer. The provided reference position is transferred directly to the DA, while the position of the DUT needs to be passed through a sensor interface to an input of the ECU, here an AURIX [

19] µC (AURIX Board). Within the AURIX Board, the signal is conditioned and processed before the angular information is read out. The Sync block in

Figure 9 represents the reference configuration as well as the mentioned electrical trigger signal, generated by the ECU, that releases the capturing of the reference position in the reference data acquisition unit.

When measuring the DUT by the ECU (AURIX µC), a software-based configured interrupt is raised every time a new value is captured. In case of the AURIX µC, this procedure has a frequency of

f = 9 kHz, which corresponds to a time step of

t = 111 µs due to the already explained software task timing issue, introduced in

Section 2.2.2. The interrupt inside the µC triggers both the

Vector base module for capturing the DUT values and an output stage providing a TTL level. This electrical signal level is triggering the reference acquisition card using a digital input. However, the sampling of the DUT by the ∆Σ-ADC happens at every

t = 102.4 µs (

f = 9.763 kHz), according to

Section 2.2.2 (

Figure 7). This means the DUT signals and DUT angle, provided by the software, are not up-to-date. For that reason, the ECU software needs to be adapted by introducing two internal counter variables (“

PosTimestampDSADC” and “

PosTimestampPWM”). Each of these variables is related to one event, either

DSADC Event or

App Event and contains the actual counter value in 10-ns ticks. By calculating the difference between those two values, the actual time stamp difference (see

Figure 7) can be investigated. Based on this difference, the actual, correct DUT angle can be found under consideration of the current, constant angle velocity, measured by the reference system.

Recapping, with this approach, the sensor system to be investigated (in more detail the µC) triggers the more flexible reference system so that the reference read out is done synchronously to the read out of the DUT angle. This enables a merge of two independent measurement systems providing two angular positions from two sensors at one timestamp t = n.

In addition, both systems must perform the data acquisition at the same time stamp in respect to a defined starting time t = 0 s. Therefore, both measurement system recordings start quasi-simultaneously controlled by each system’s software application program interface (API) within the test bench automatization. For first approximation, the starting time t = 0 s of each system is considered ideal (one starting time for both systems), although time jitter can occur when calling software commands in the test bench automatization.

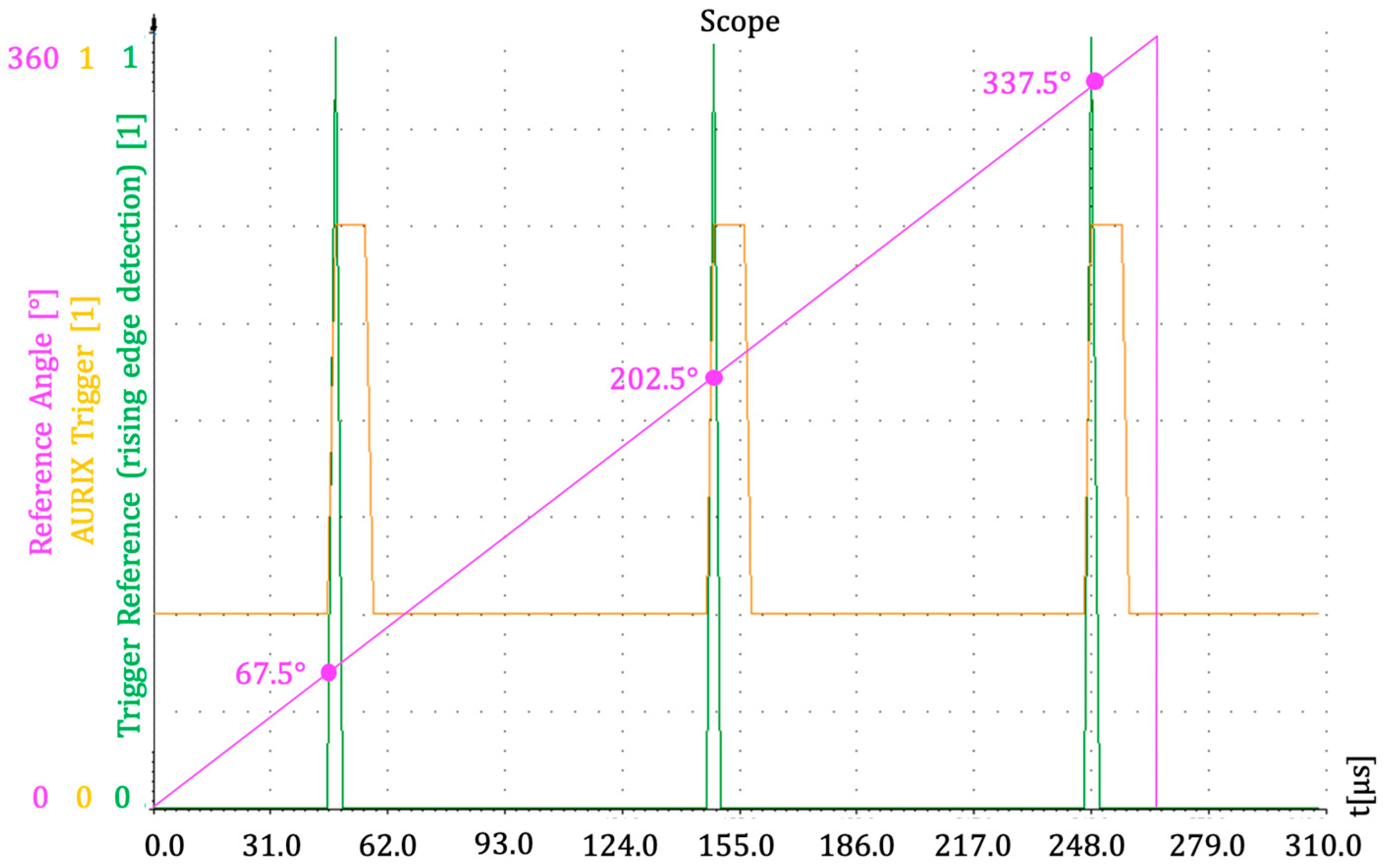

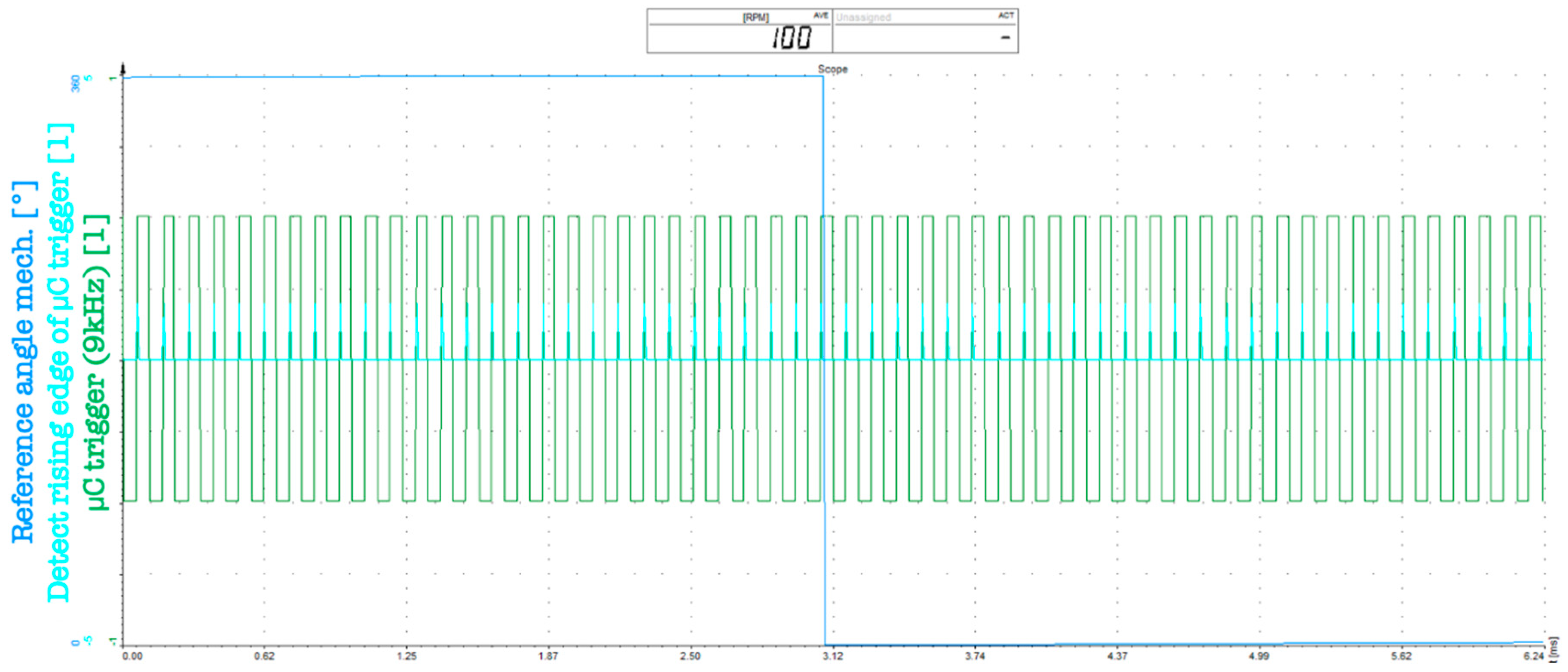

Considering those two essential parts for a proper synchronization,

Figure 10 gives an overview of the entire setup as well as the electrical synchronization trigger signal coherent with the sampling of the resolver’s raw sine and cosine signals.

Regarding the reference system’s

f = 9 kHz trigger synchronization,

Figure 11 demonstrates an exemplary display pattern, determining the synchronous position in the reference data acquisition software environment based on the method explained earlier. Obviously, the reference sensor delivers a higher resolution to enable a sufficient accurate comparison process between the reference sensor and the system-under-test. The reference data acquisition that is activated by the captured µC trigger needs to be configured properly, so that the reference sensor value can be read out when the rising edge of the trigger signal appears (see signal

Trigger Reference,

Figure 11). This can be done directly in online processing using dedicated software [

26] suitable for the reference data acquisition unit. The FPGA of this acquisition card is configured to detect the rising edge of the digital input trigger signal, delivered by the µC and as a result of the actual position capturing of the test bench reference sensor.

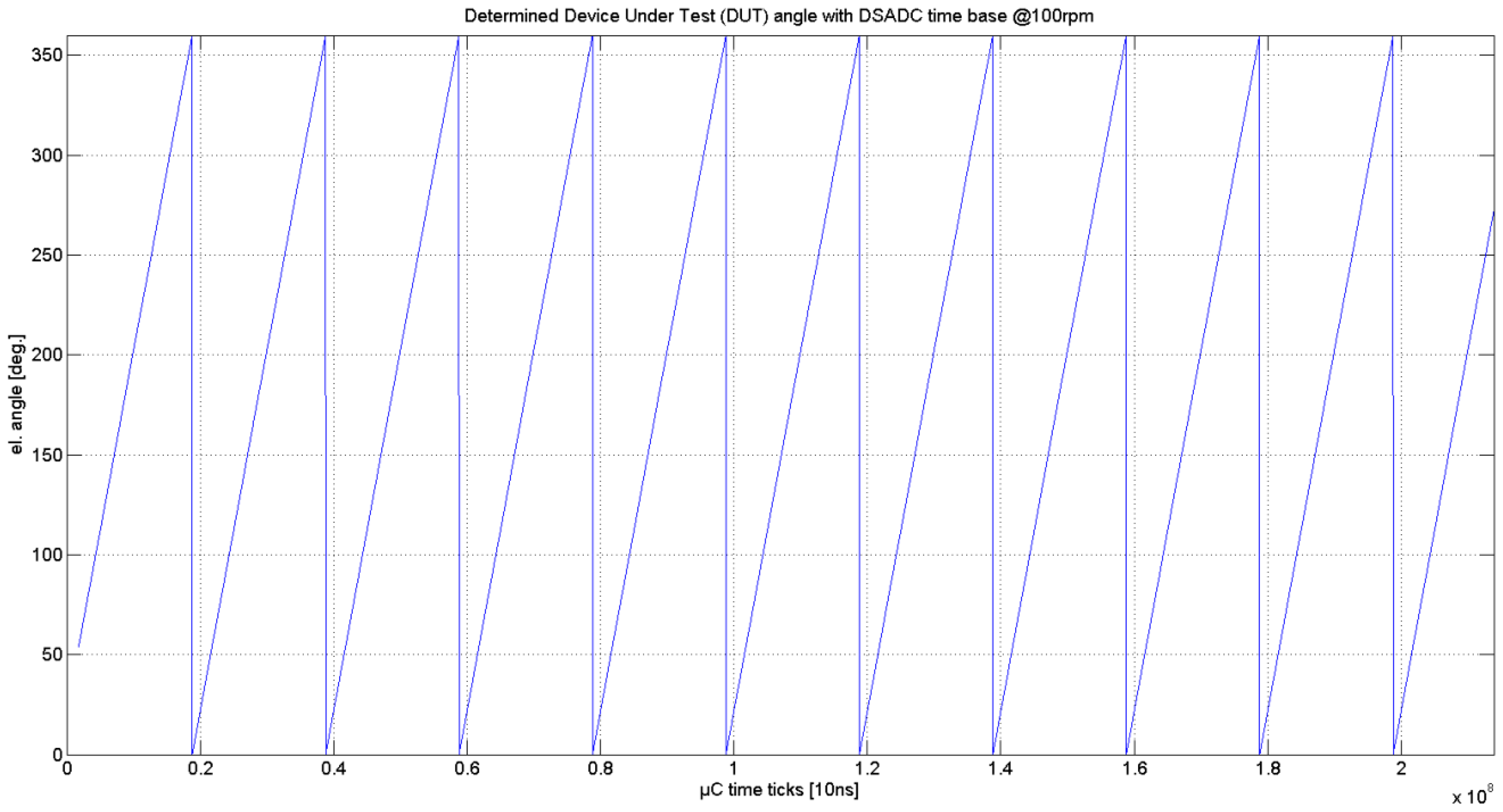

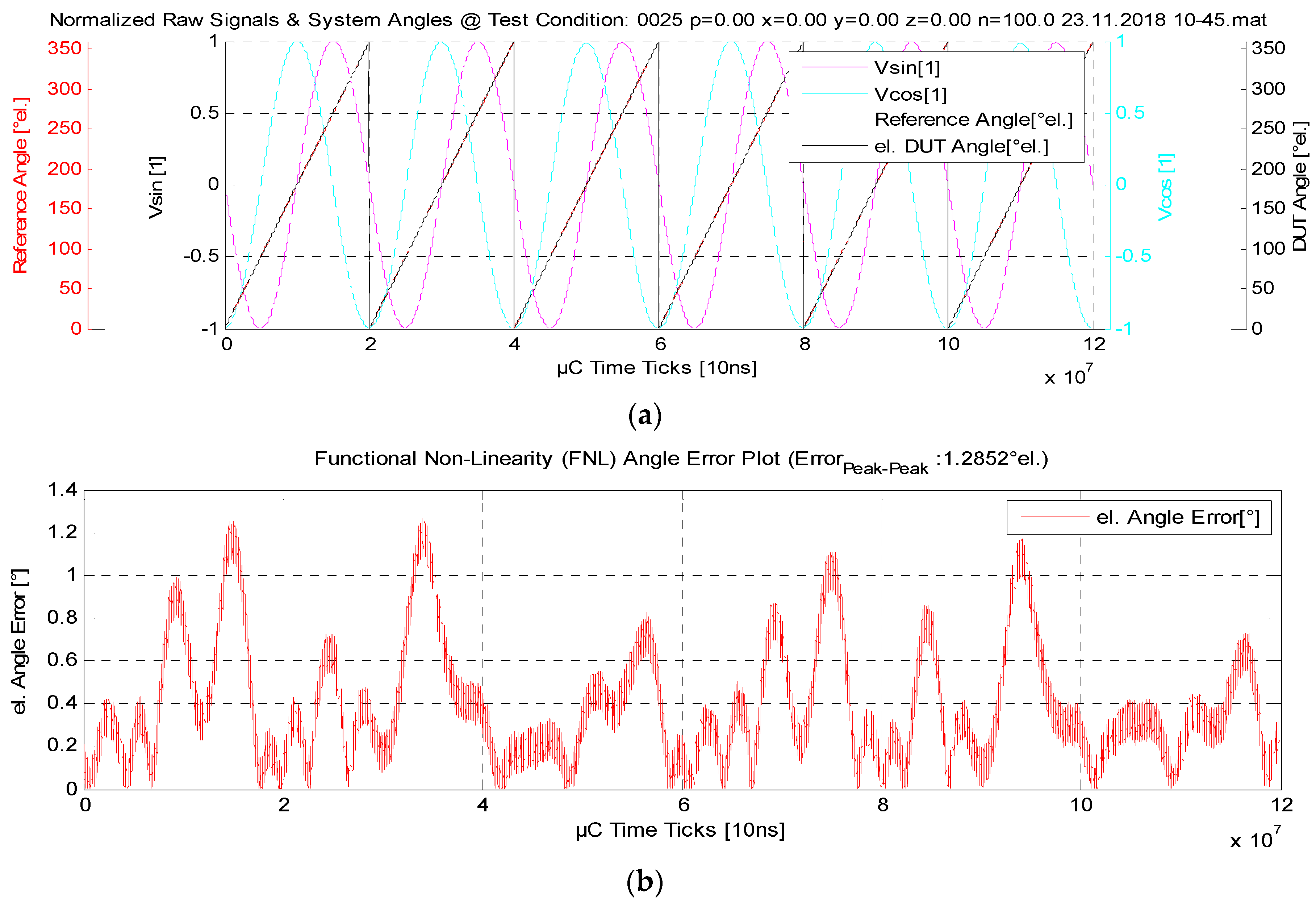

2.6. Merging of DUT and Reference Angle Plus Angle Error Determination (Characterization)

The DUT raw signals with the new time base are calculated by an

ATAN2-function to determine the DUT position. In the case of a multispeed resolver, the number of electrical revolutions is higher than those of the mechanical revolutions of the reference (see

Section 2.2.1). For that reason, the reference angle is manipulated by a Euclidean division operation times the number of poles regarding the DUT. After applying the angular compensation as stated in the previous section, both resulting electrical angles need to be synchronized to 0° to compensate the mechanical offset that stems from the mounting procedure at the test bench.

For the functional non-linearity (FNL) analysis, both angles are set to 0° only at the beginning of the investigated interval (e.g.,

t/

Ts periods). The developed algorithm described in Equations (5) and (6) iterates through all measurement points of each angle (reference and DUT), checking where both angle values are equal or similar at the same point. The difference (offset) is subtracted from the leading angle, shown in Equations (8)–(11). The resulting, merged angle signals used for further computation (e.g., in characterization computation,

Figure 13) are described in Equations (12) and (13) as a saw-tooth characteristic with the starting value

φref and

φDUT from Equations (10) and (11).

For the common error analysis, this compensation is done every period, see n ∈ M in Equation (6) and Equation (7) vs. n ∈ N in Equation (14) and Equation (15). The compensation is described by the Equations (12)–(19). The main benefit of the applied FNL analysis is that an error drift can be investigated if certain influences provoke a change of the DUT angle.

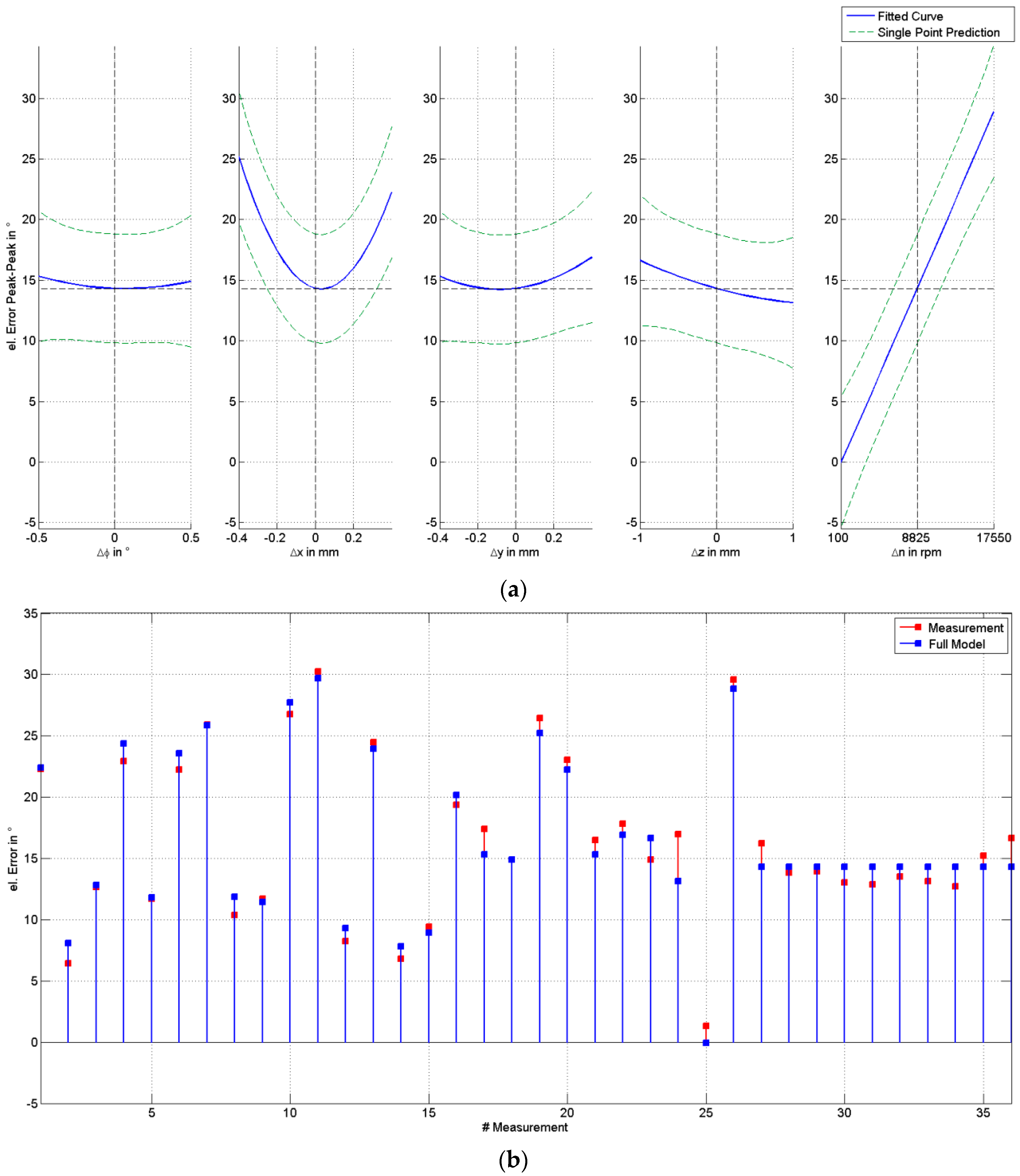

The results are then plotted (see

Section 3) to support graphical analysis and investigations (e.g., DUT angle error tolerances). Furthermore, the plotted results are converted into a

Microsoft PowerPoint [

27] file format automatically via a specific application program interface (API) to enable effective and automated figure results for further investigations and analysis. Besides the figures, all relevant results, e.g., electrical peak–peak error (°), electrical min. and max. error (°) in respect of the specific test condition, are entered automatically in a

Microsoft Excel [

28] sheet contributing to an intuitive overview of the system-under-test performance. These additional features enable an extended sensor-oriented characterization in addition to the sensor model-based characterization introduced in [

5]. Besides an evaluation and modelling of rotor position sensor characteristics [

5], the extended evaluation approach enables FNL angle error analysis, as well as standard error analysis over a desired number of electrical periods. This enables a more detailed statement of the actual measured rotor position error under certain mechanical and/or temperature and/or speed conditions.