Modelling of the Power Interface of the Digital-Physical Hybrid Simulation System of a VSC-HVDC Based on Virtual Resistance Compensation

Abstract

:1. Introduction

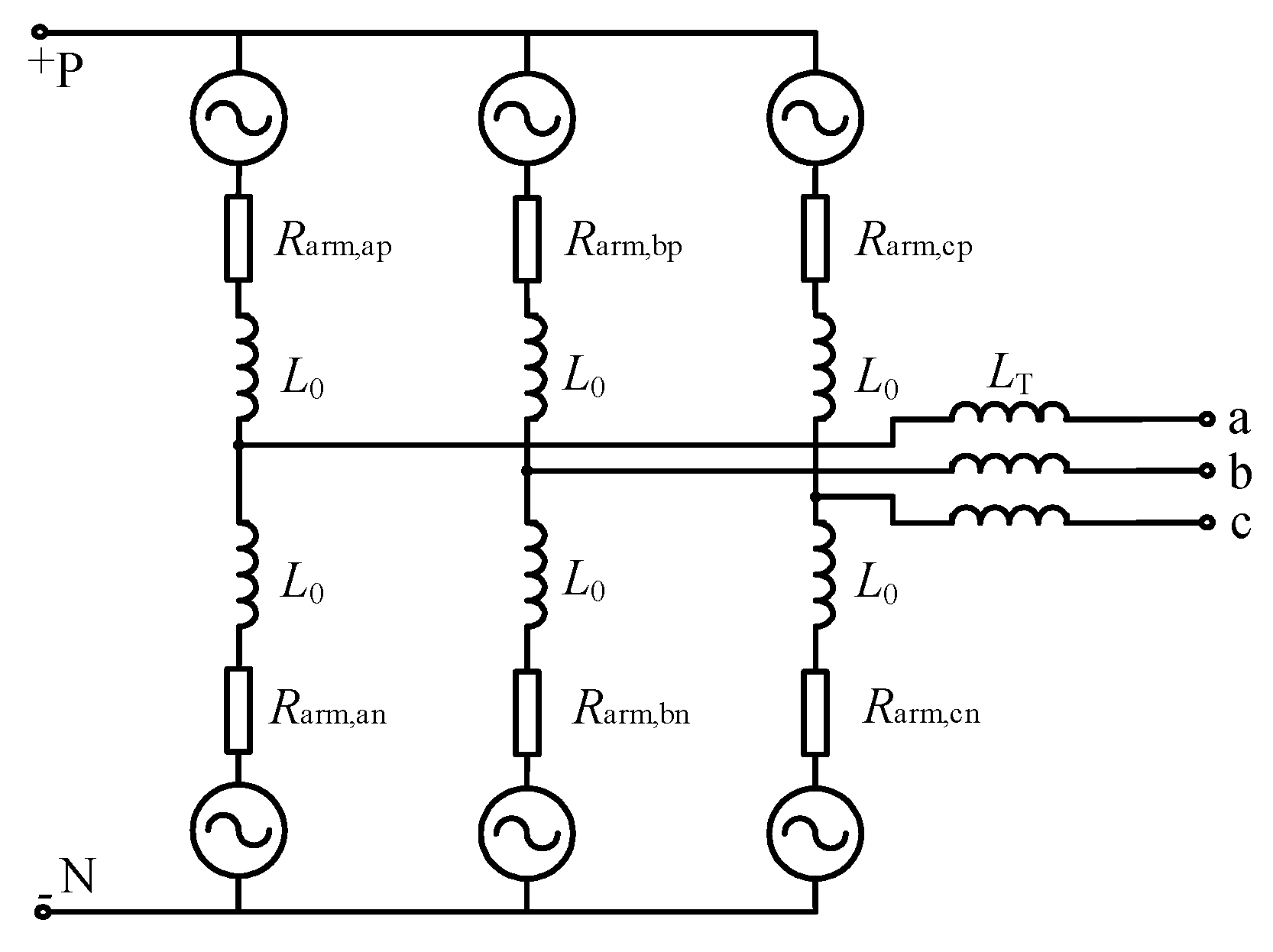

2. Operation Principle of the Power Interface of a DPHS System

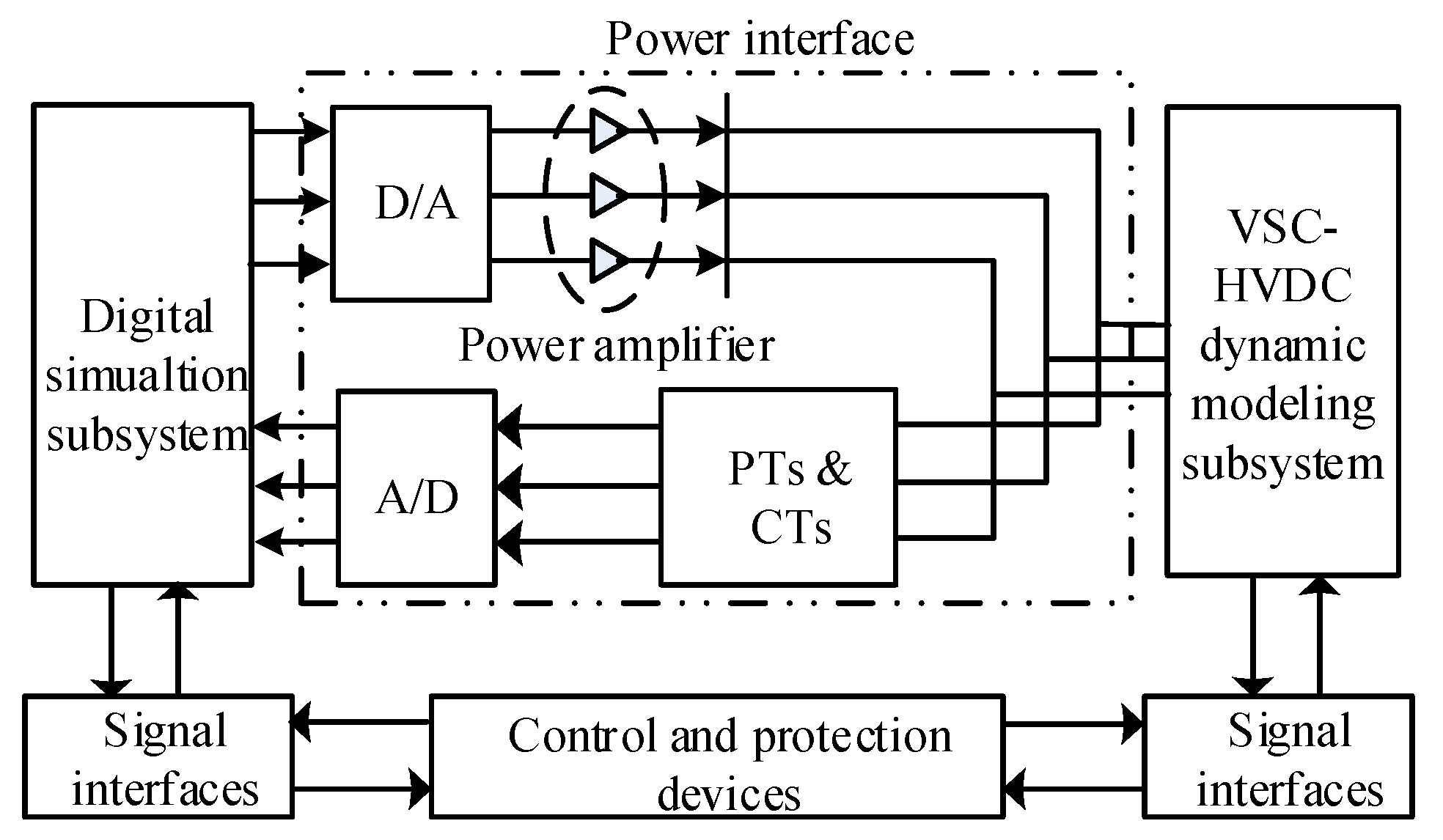

2.1. General Structure of the DPHS System

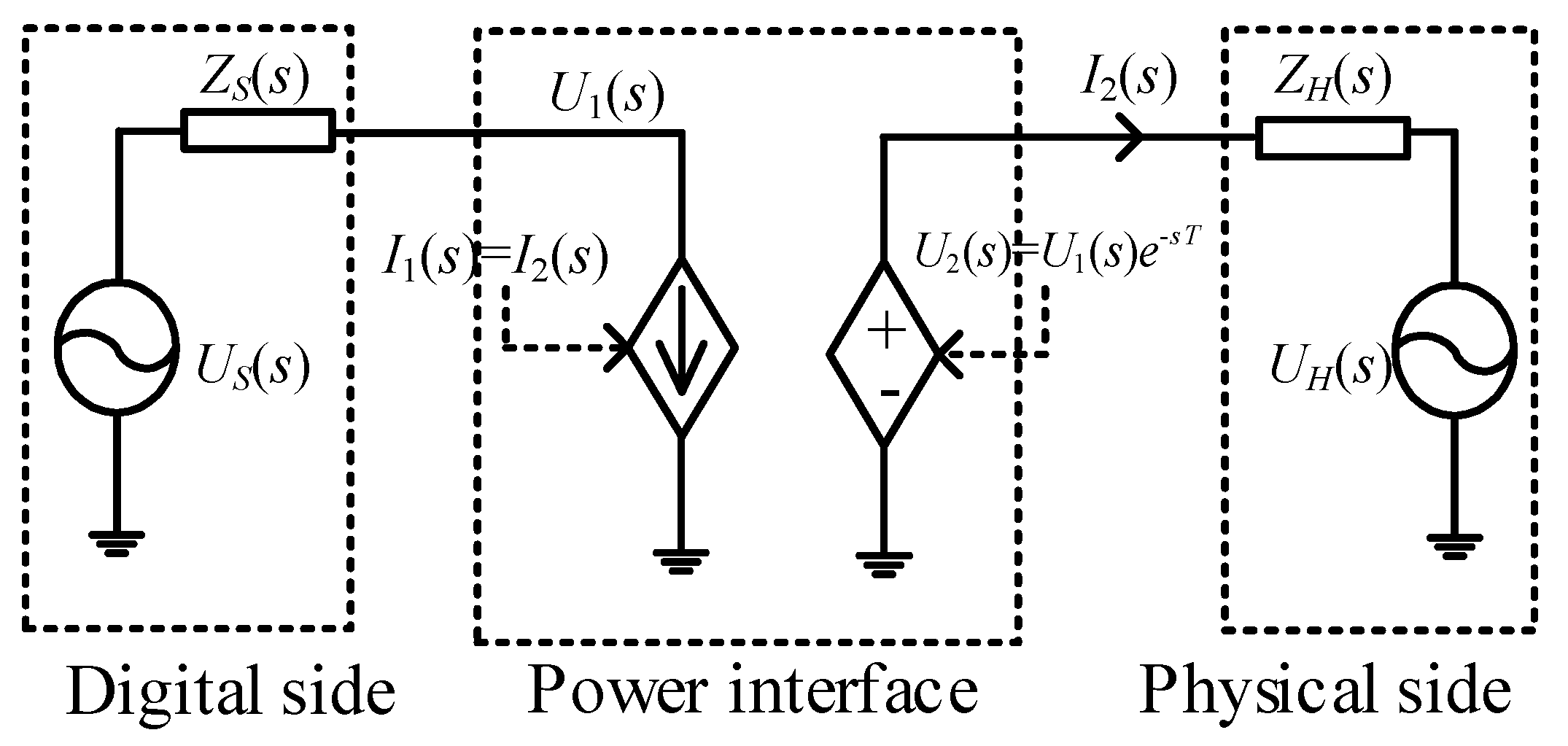

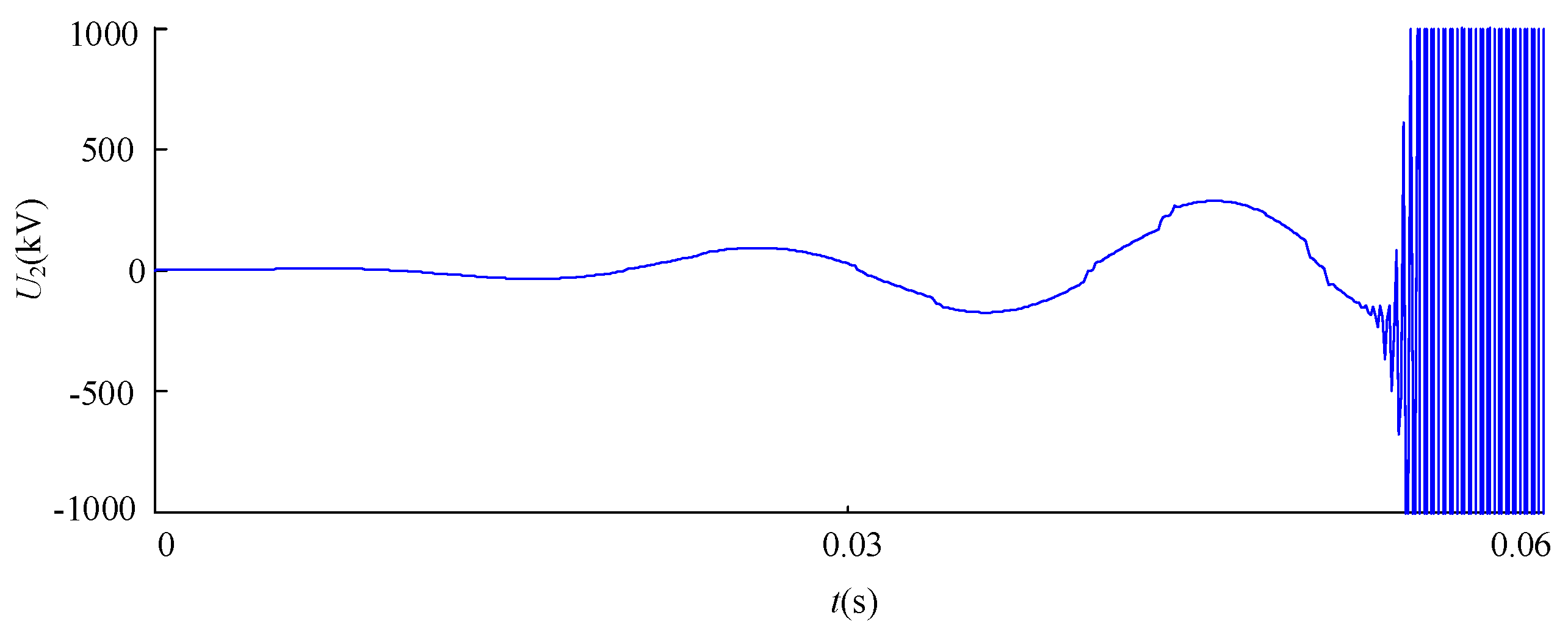

2.2. Current Modeling Method Based on ITM

2.3. System Stability Analysis of the Current ITM-Based Modeling Method

3. Power Interface Modeling Method Based on Virtual Resistance Compensation

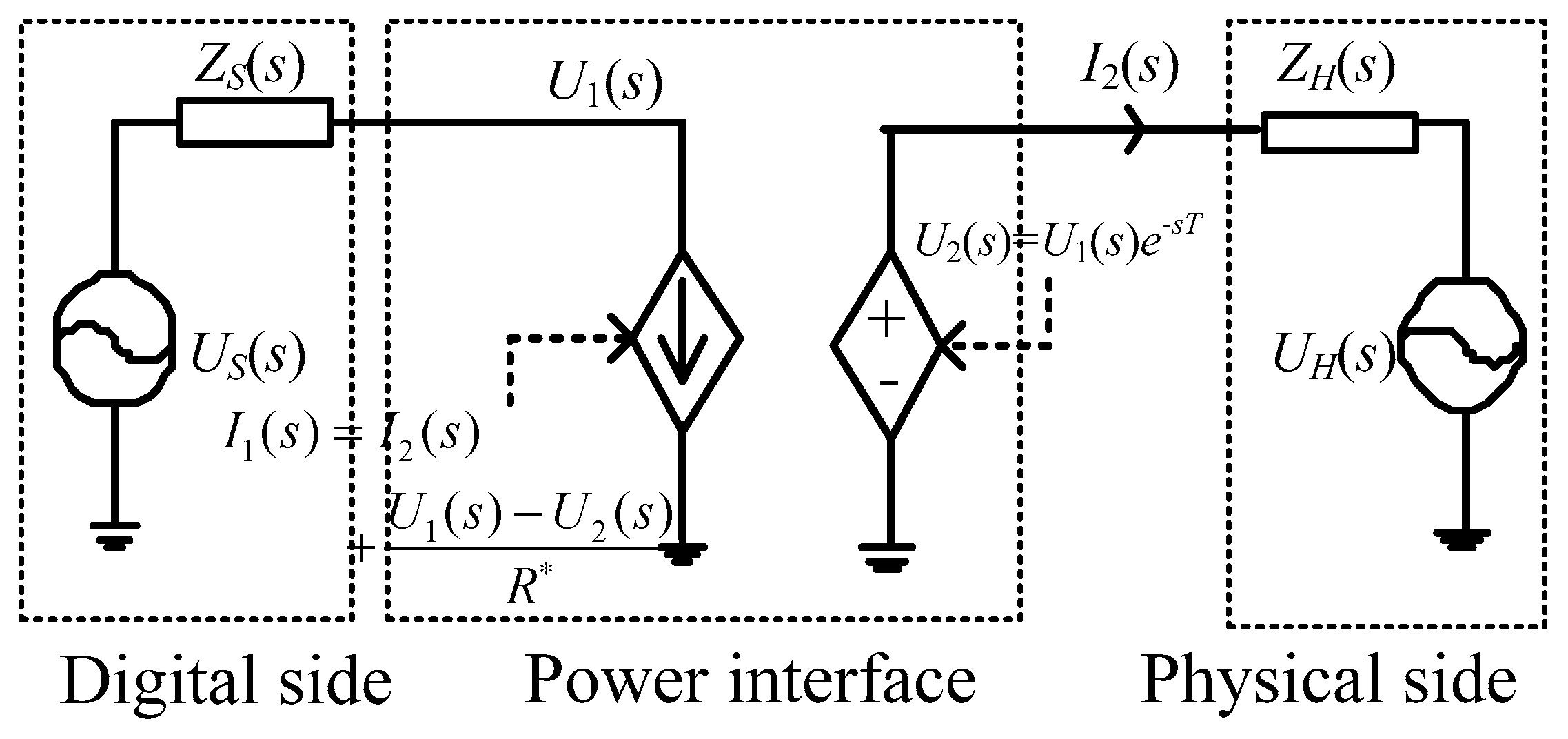

3.1. Principle of the Improved Modeling Method

3.2. System Stability Analysis

- (1)

- When |ZS(s)| < |ZH(s)|, we can know from Formulas (5) and (12) that both the DPHS systems adopting the voltage-source-type ITM method and our virtual resistance compensation modeling algorithm with R* > 0 are stable. Therefore, we can conclude that the system stability will not be degraded by the introduction of the virtual resistor with any positive value at least.

- (2)

- When |ZS(s)| > |ZH(s)|, the voltage-source-type ITM method fails to guarantee the stability of the DPHS system. While Formula (12) definitely informs us that the system stability can be recovered by just adding a virtual resistor into the power interface model, provided that the resistance satisfies:

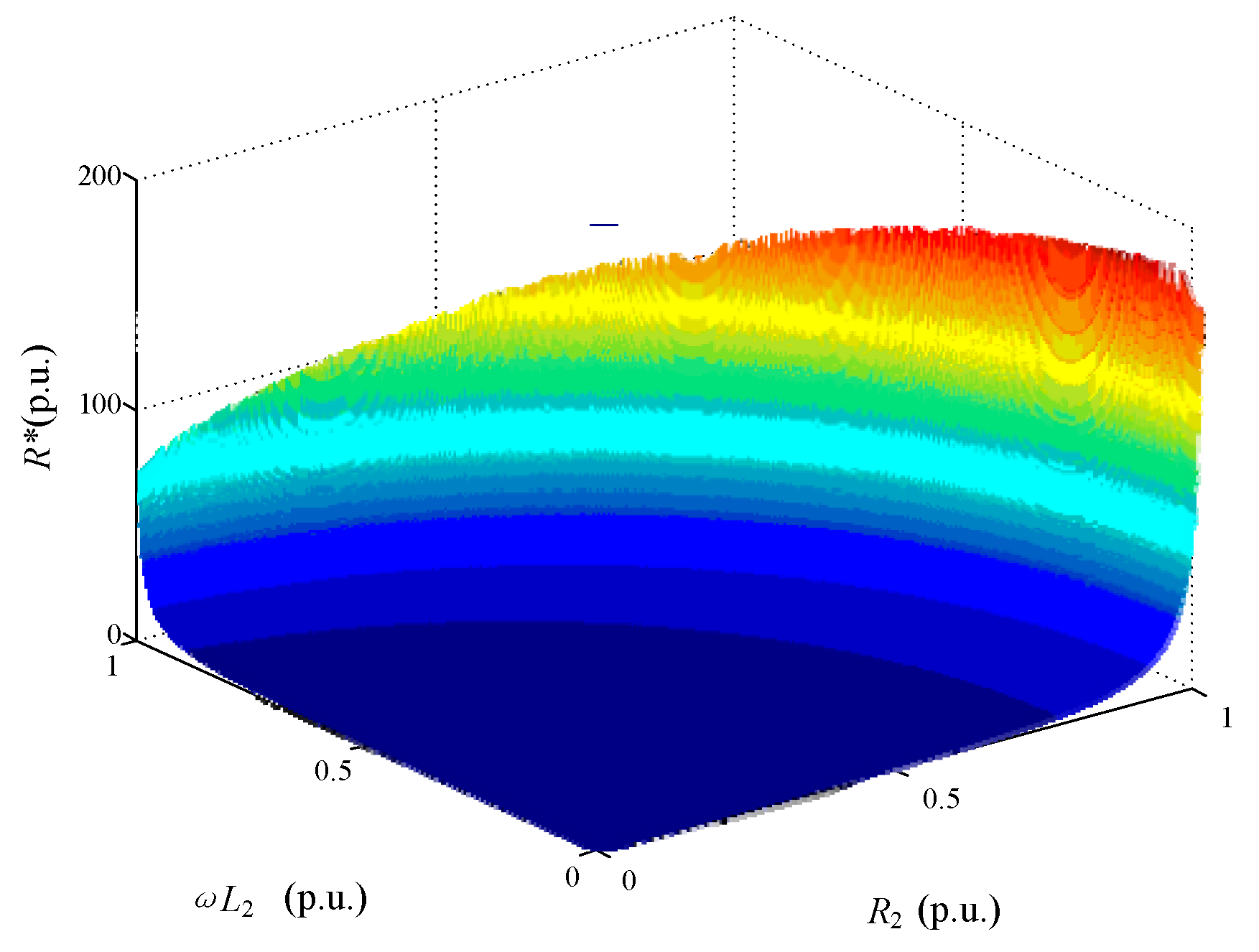

3.3. Tuning Method for the Virtual Resistance

4. Simulation Verification

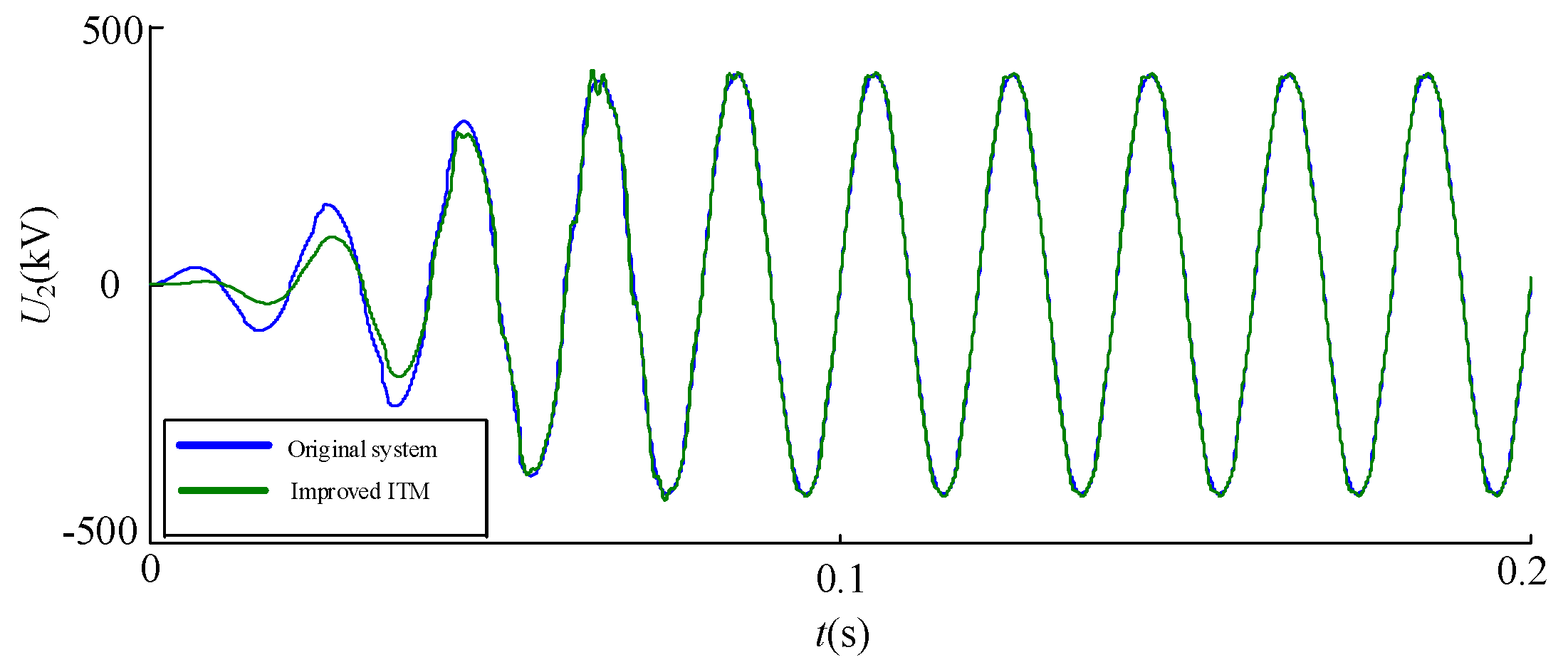

4.1. Verification of the Virtual Resistance modeling Algorithm

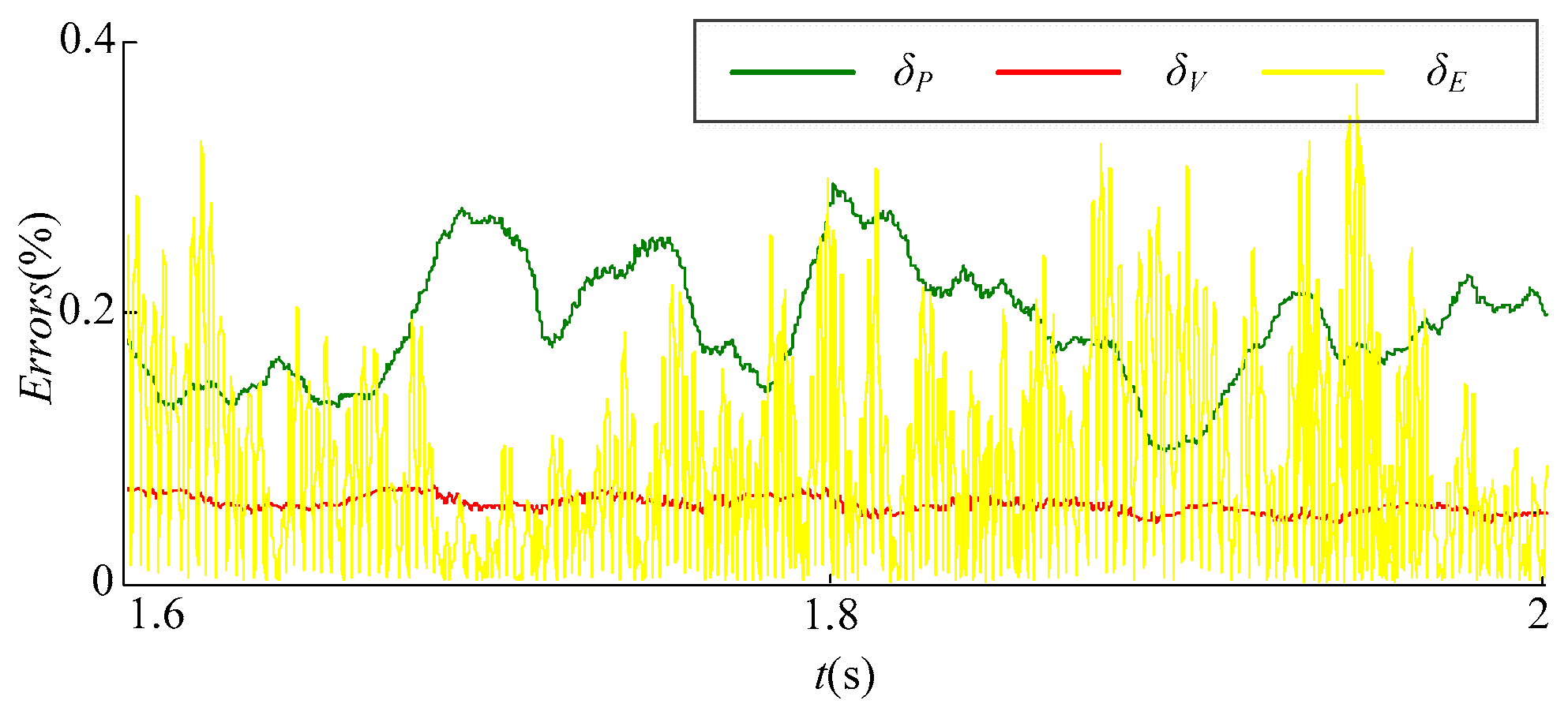

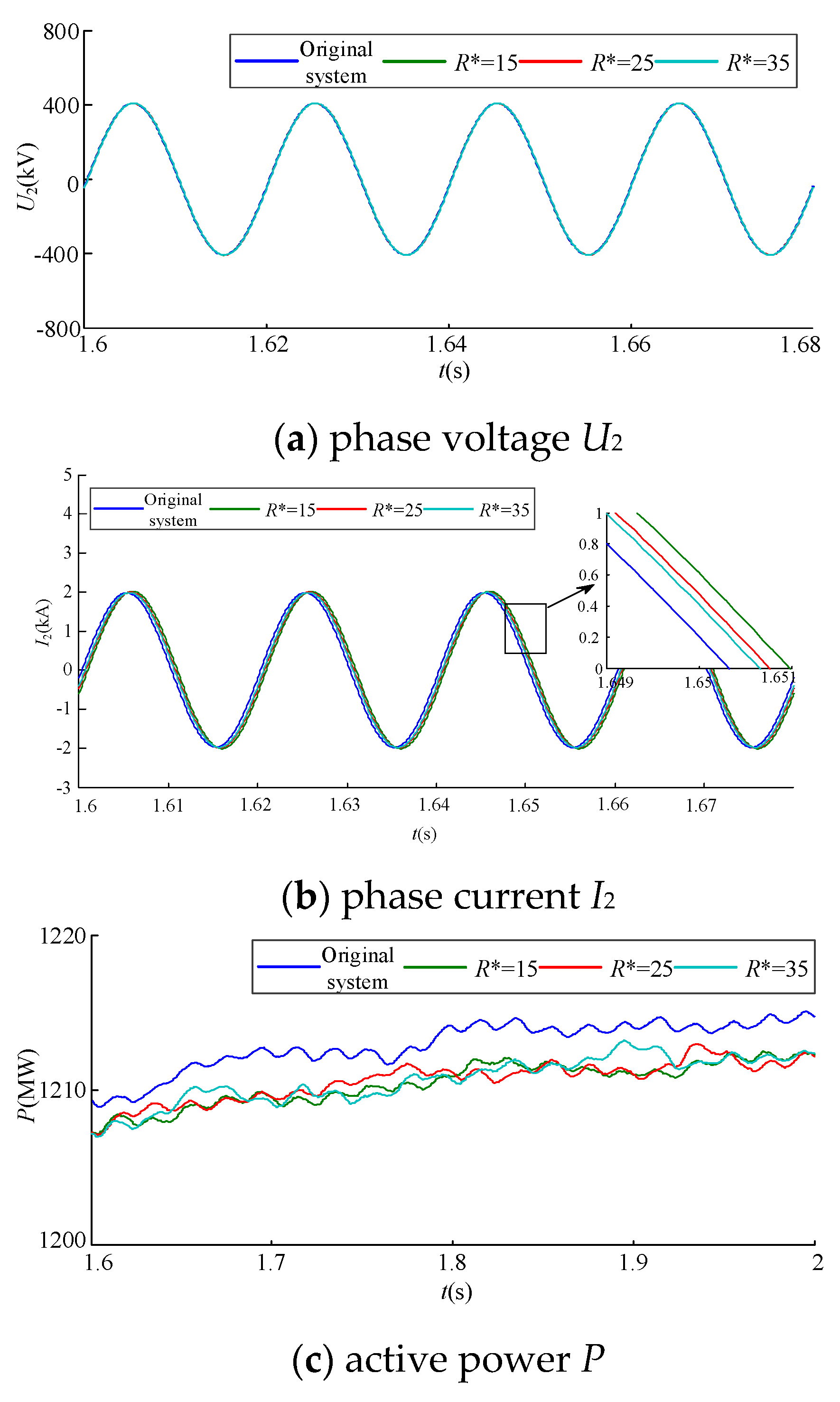

4.2. Simulation Accuracy of the Virtual Resistance Modeling Algorithm

4.3. Simulation Accuracy for Different Values of the Virtual Impedance

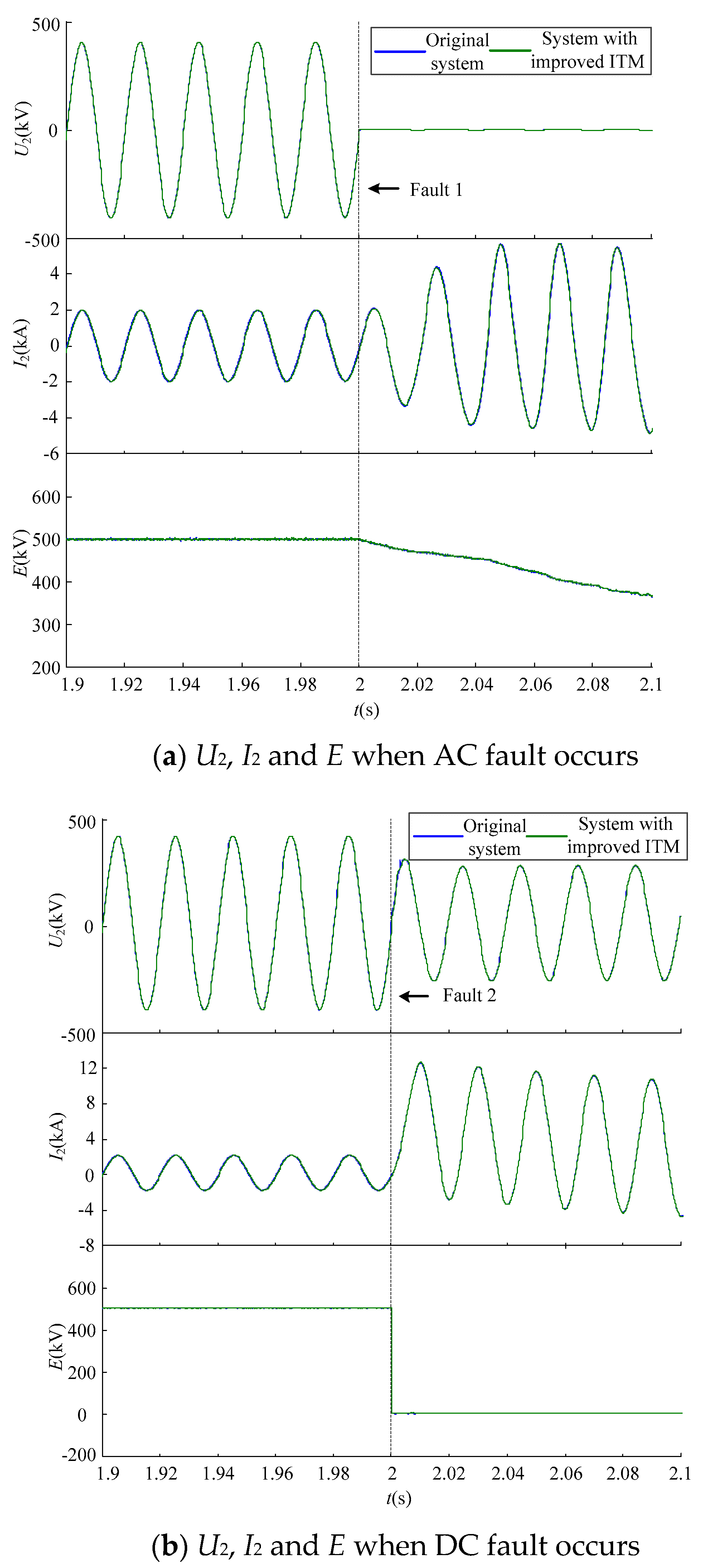

4.4. Verification of the Virtual Resistance Modeling Algorithm in the Transient Process

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xiang, W.; Lin, W.; Xu, L.; Wen, J. Enhanced independent pole control of hybrid MMC-HVDC system. IEEE Trans. Power Deliv. 2018, 33, 861–872. [Google Scholar] [CrossRef]

- Guo, Y.F.; Gao, H.L.; Wu, Q.W.; Zhao, H.; Østergaard, J.; Shahidehpour, M. Enhanced voltage control of VSC-HVDC-connected offshore wind farms based on model predictive control. IEEE Trans. Sustain. Energy 2018, 9, 474–487. [Google Scholar] [CrossRef]

- Sanz, I.M.; Judge, P.D.; Spallarossa, C.E.; Chaudhuri, B.; Green, T.C. Dynamic overload capability of VSC HVDC interconnections for frequency support. IEEE Trans. Energy Convers. 2017, 32, 1544–1553. [Google Scholar] [CrossRef]

- Papaspiliotopoulos, V.A.; Korres, G.N.; Kleftakis, V.A.; Hatziargyriou, N.D. Hardware-In-the-Loop design and optimal setting of adaptive protection schemes for distribution systems with distributed generation. IEEE Trans. Power Deliv. 2015, 32, 393–400. [Google Scholar] [CrossRef]

- Kotsampopoulos, P.C.; Lehfuss, F.; Lauss, G.F.; Bletterie, B.; Hatziargyriou, N.D. The limitations of digital simulation and the advantages of PHIL testing in studying distributed generation provision of ancillary services. IEEE Trans. Ind. Electron. 2015, 62, 5502–5515. [Google Scholar] [CrossRef]

- Ren, W.; Sloderbeck, M.; Steurer, M.; Dinavahi, V.; Noda, T.; Filizadeh, S. Interfacing issues in real-time digital simulators. IEEE Trans. Power Deliv. 2011, 26, 1221–1230. [Google Scholar] [CrossRef]

- Kuffel, R.; Wierckx, R.P.; Duchen, H.; Lagerkvist, M.; Wang, X.; Forsyth, P.; Holmberg, P.; Chevrefils, A.R.; Matar, M.; Iravani, R.; et al. Expanding an analogue HVDC simulator’s modelling capability using a real-time digital simulator (RTDS). In Proceedings of the First International Conference on Digital Power System Simulators (ICDS’95), College Station, TX, USA, 5–7 April 1995; IEEE: New York, NY, USA, 1995; pp. 199–204. [Google Scholar]

- Hu, Y.; Zhang, P.; Fang, C.; Bao, H. Power hardware-in-the-loop simulation system: Part one characteristics of interface algorithms. Autom. Electr. Power Syst. 2013, 37, 36–41. [Google Scholar]

- Hong, M.; Horie, S.; Miura, Y.; Ise, T.; Dufour, C. A method to stabilize a power hardware-in-the-loop simulation of inductor coupled system. In Proceedings of the International Conference on Power System Transients, Seoul, Korea, 27–29 December 2009; pp. 1–7. [Google Scholar]

- Lauss, G.; Lehfuß, F.; Viehweider, A.; Strasser, T. Power hardware in the loop simulation with feedback current filtering for electric systems. In Proceedings of the Conference on IEEE Industrial Electronics Society (IECON 2011), Melbourne, Australia, 7–10 November 2011; IEEE: New York, NY, USA, 2011; pp. 3725–3730. [Google Scholar]

- Yoo, I.D.; Gole, A.M. Compensating for interface equipment limitations to improve simulation accuracy of real-time Power Hardware in Loop simulation. IEEE Trans. Power Deliv. 2012, 27, 1284–1291. [Google Scholar] [CrossRef]

- Xin, Y.; Jiang, S.; Li, G.; Wang, L. Review on interface algorithms of power hardware-in-the-loop simulation for power systems. Autom. Electr. Power Syst. 2016, 40, 159–167. [Google Scholar]

- Paran, S.; Edrington, C.S.; Vural, B. Investigation of HIL interfaces in nonlinear load studies. In Proceedings of the North American Power Symposium, Champaign, IL, USA, 9–11 September 2012; IEEE: New York, NY, USA, 2012; pp. 1–6. [Google Scholar]

- Paran, S.; Edrington, C.S. Improved power hardware in the loop interface methods via impedance matching. In Proceedings of the Electric Ship Technologies Symposium, Arlington, VA, USA, 22–24 April 2013; IEEE: New York, NY, USA, 2013; pp. 342–346. [Google Scholar]

- Paran, S.; Fleming, F.; Li, D.; Edrington, C.S. Utilization of adaptive PHIL interfaces for harmonic load cases. In Proceedings of the IEEE Conference of the Industrial Electronics Society (IECON 2014), Dallas, TX, USA, 30 October–1 November 2014; IEEE: New York, NY, USA, 2015; pp. 3803–3808. [Google Scholar]

- Lin, C.Q.; Jiang, S.Q.; Chen, H.H. An improved interface algorithm of power hardware-in-the-loop simulation for MMC-HVDC. J. Northeast Dianli Univ. 2016, 36, 1–6. [Google Scholar]

| Parameter | Value | |

|---|---|---|

| AC systems | Rated line-to-line voltage | 500 kV |

| Rs1 and Rs1 | 1.2 Ω | |

| Ls1 and Ls1 | 0.06 H | |

| Converter transformers | Rated capacity | 1500 MVA |

| Transformation ratio | 500/270 | |

| LT | 0.1 p.u. | |

| Converters | L0 | 0.1 H |

| N | 90 | |

| RON | 0.005 Ω | |

| DC system | Rated DC voltage | ±500 kV |

| Rated transmission capacity | 1200 MVA | |

| Power interface | T | 50 μs |

| Time delay of A/D and CTs | 0 μs | |

| Simulation model | Simulation step size | 10 μs |

| Simulation time | 3 s |

| δP (%) | δV (%) | δE (%) | |

|---|---|---|---|

| Normal | 0.30 | 0.07 | 0.40 |

| Fault 1 | 0.28 | 0 | 0.53 |

| Fault 2 | 0.44 | 0.23 | 0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, J.; Zhang, H.; Wang, C.; Li, X.; Zhu, J. Modelling of the Power Interface of the Digital-Physical Hybrid Simulation System of a VSC-HVDC Based on Virtual Resistance Compensation. Electronics 2018, 7, 333. https://doi.org/10.3390/electronics7110333

Le J, Zhang H, Wang C, Li X, Zhu J. Modelling of the Power Interface of the Digital-Physical Hybrid Simulation System of a VSC-HVDC Based on Virtual Resistance Compensation. Electronics. 2018; 7(11):333. https://doi.org/10.3390/electronics7110333

Chicago/Turabian StyleLe, Jian, Hao Zhang, Cao Wang, Xingrui Li, and Jiangfeng Zhu. 2018. "Modelling of the Power Interface of the Digital-Physical Hybrid Simulation System of a VSC-HVDC Based on Virtual Resistance Compensation" Electronics 7, no. 11: 333. https://doi.org/10.3390/electronics7110333

APA StyleLe, J., Zhang, H., Wang, C., Li, X., & Zhu, J. (2018). Modelling of the Power Interface of the Digital-Physical Hybrid Simulation System of a VSC-HVDC Based on Virtual Resistance Compensation. Electronics, 7(11), 333. https://doi.org/10.3390/electronics7110333