Investigation into Applicability of 3D-Printed Composite Polymers with Enhanced Mechanical Properties in the Development of Microwave Components

Abstract

1. Introduction

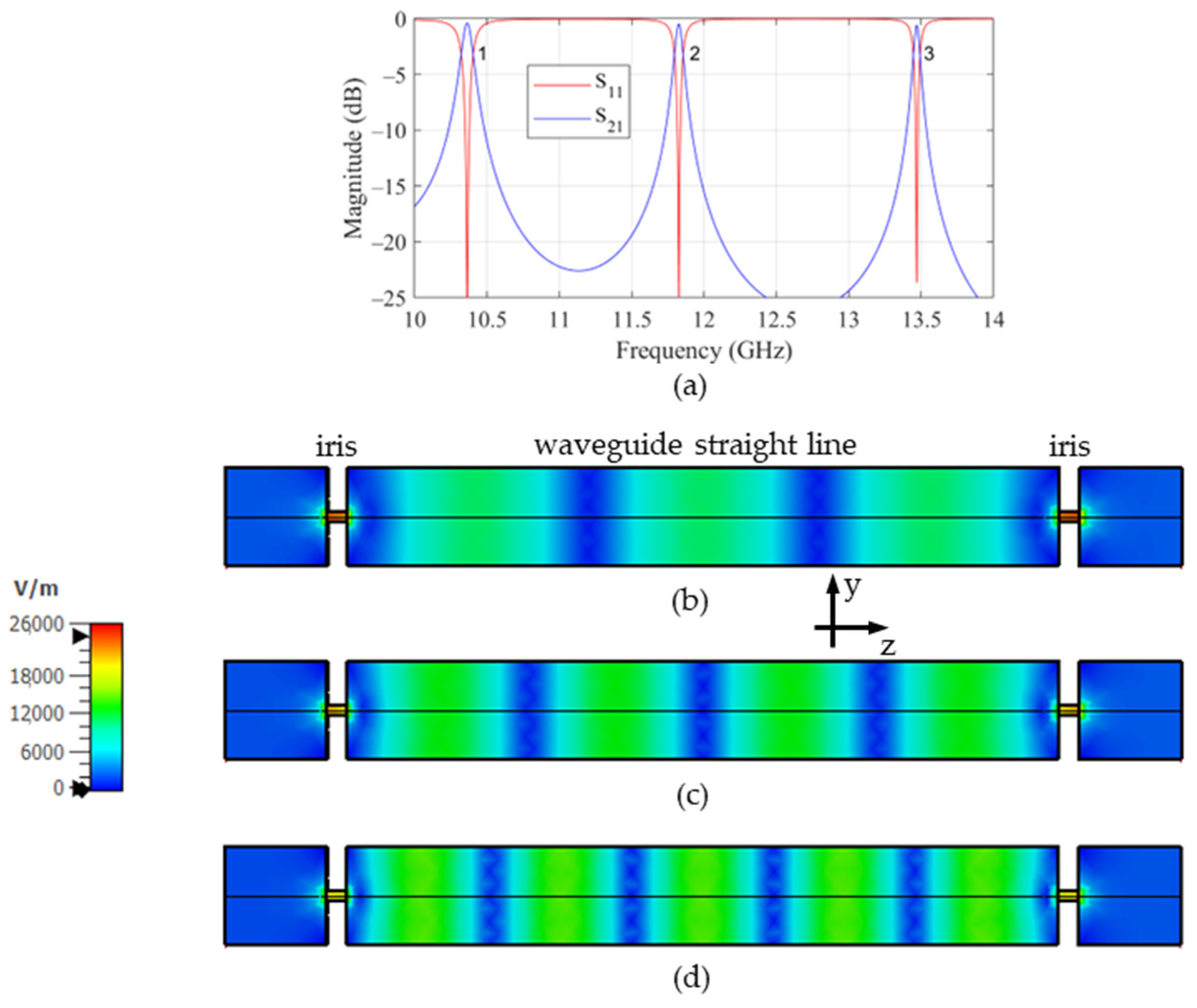

2. Manufacturing Routes

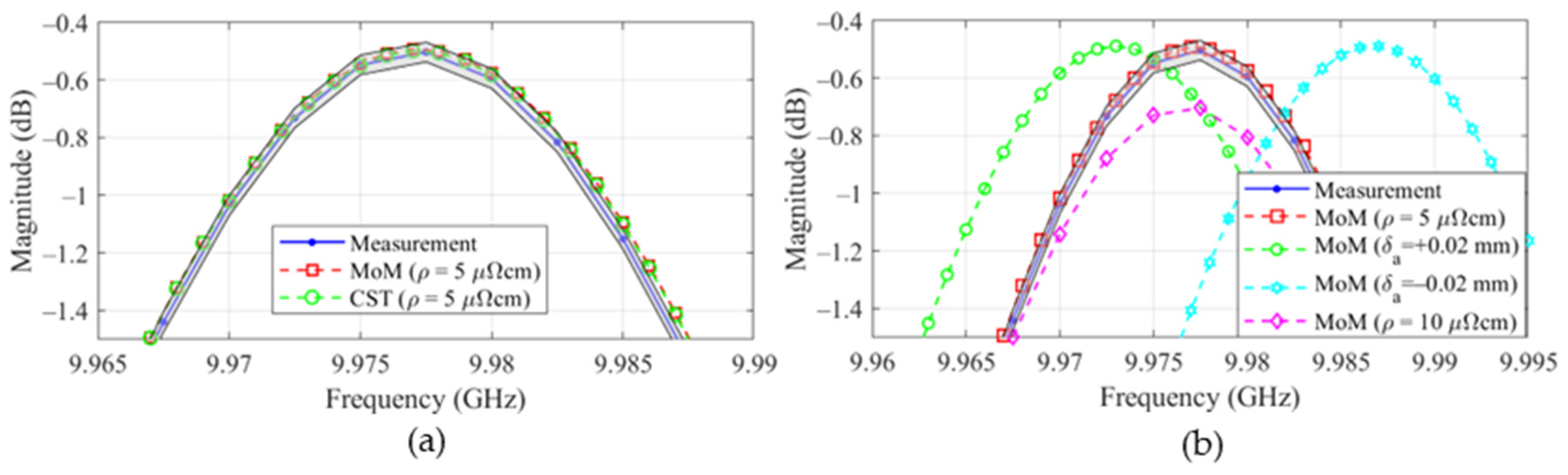

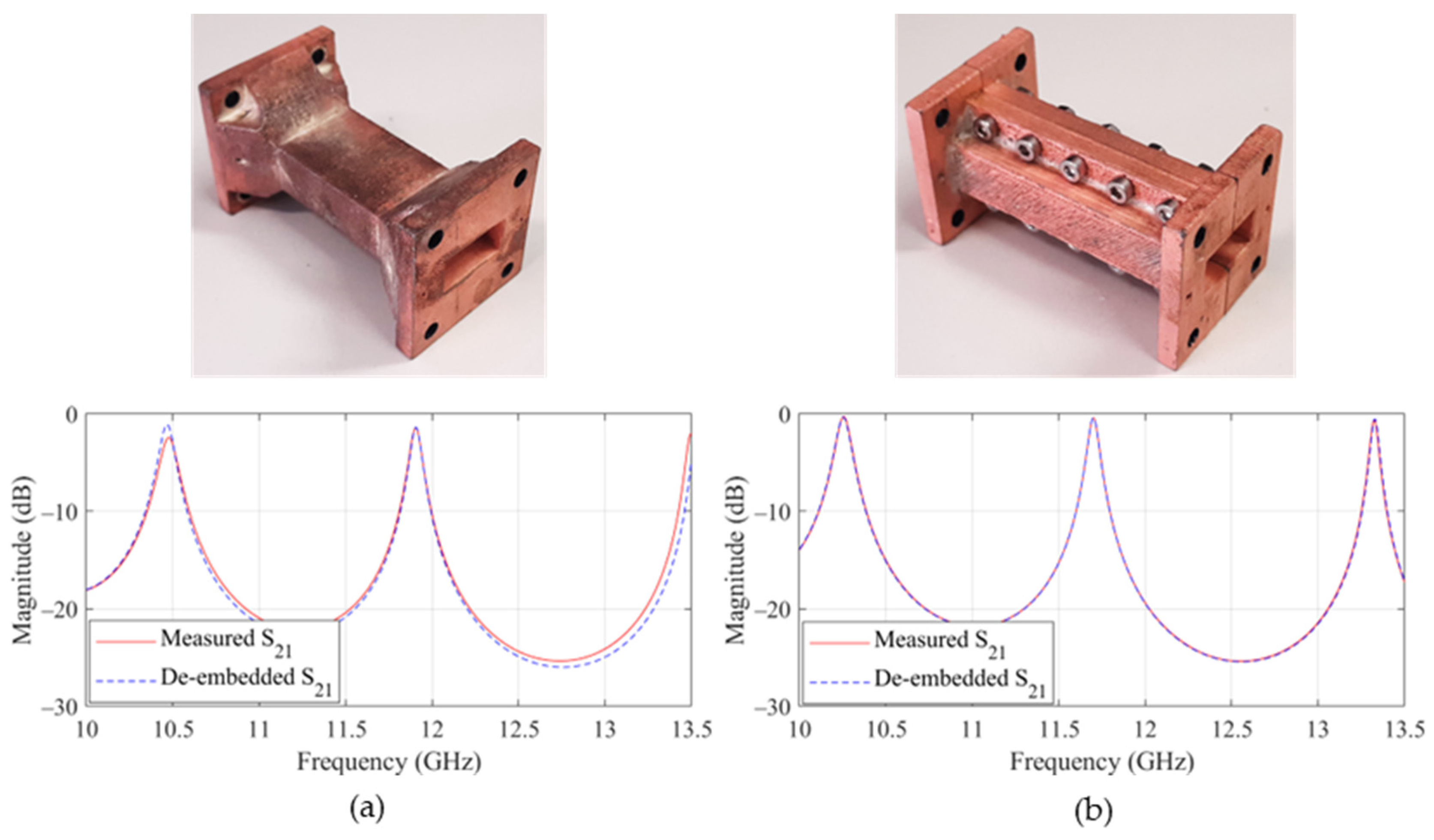

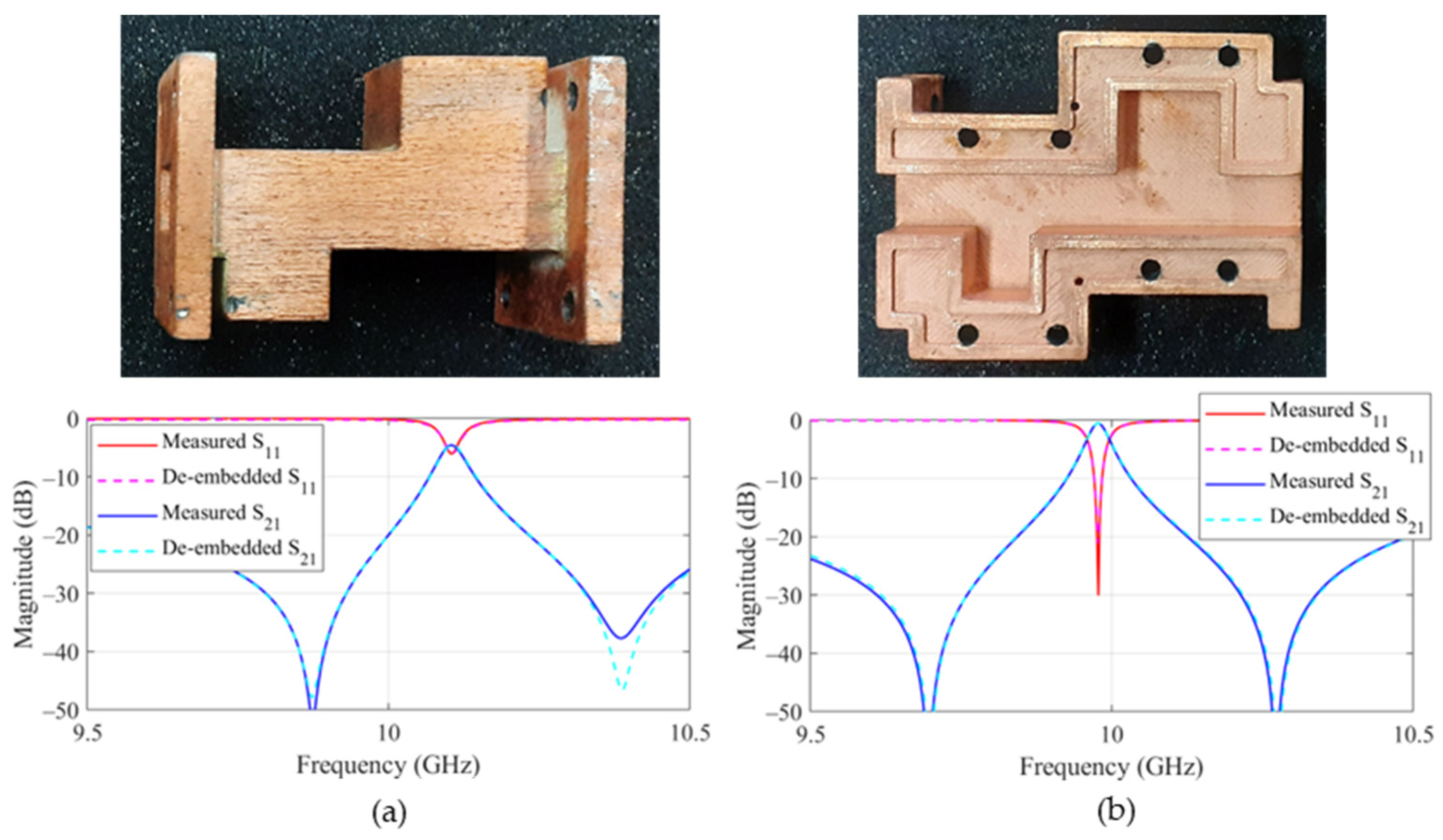

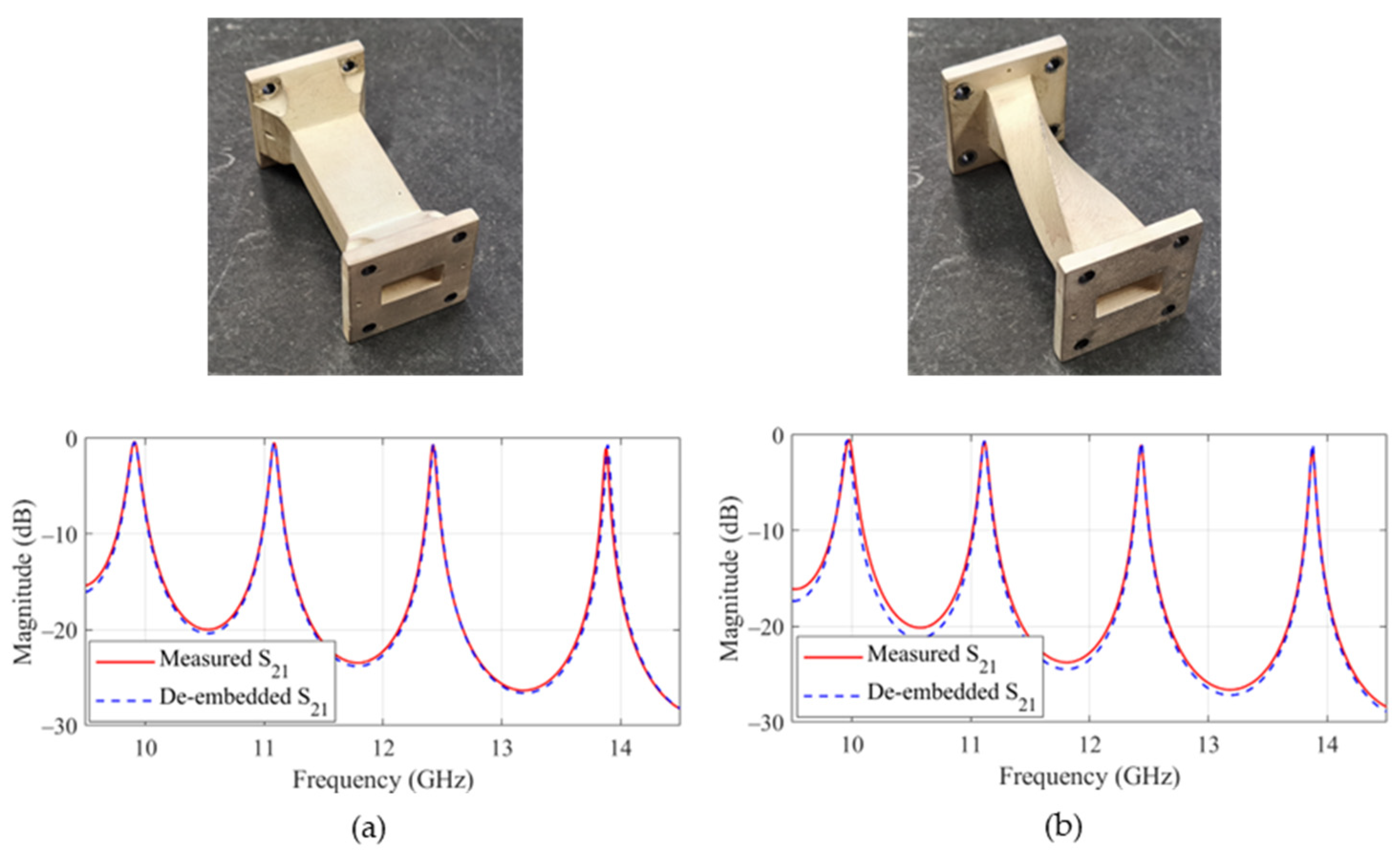

2.1. Materials

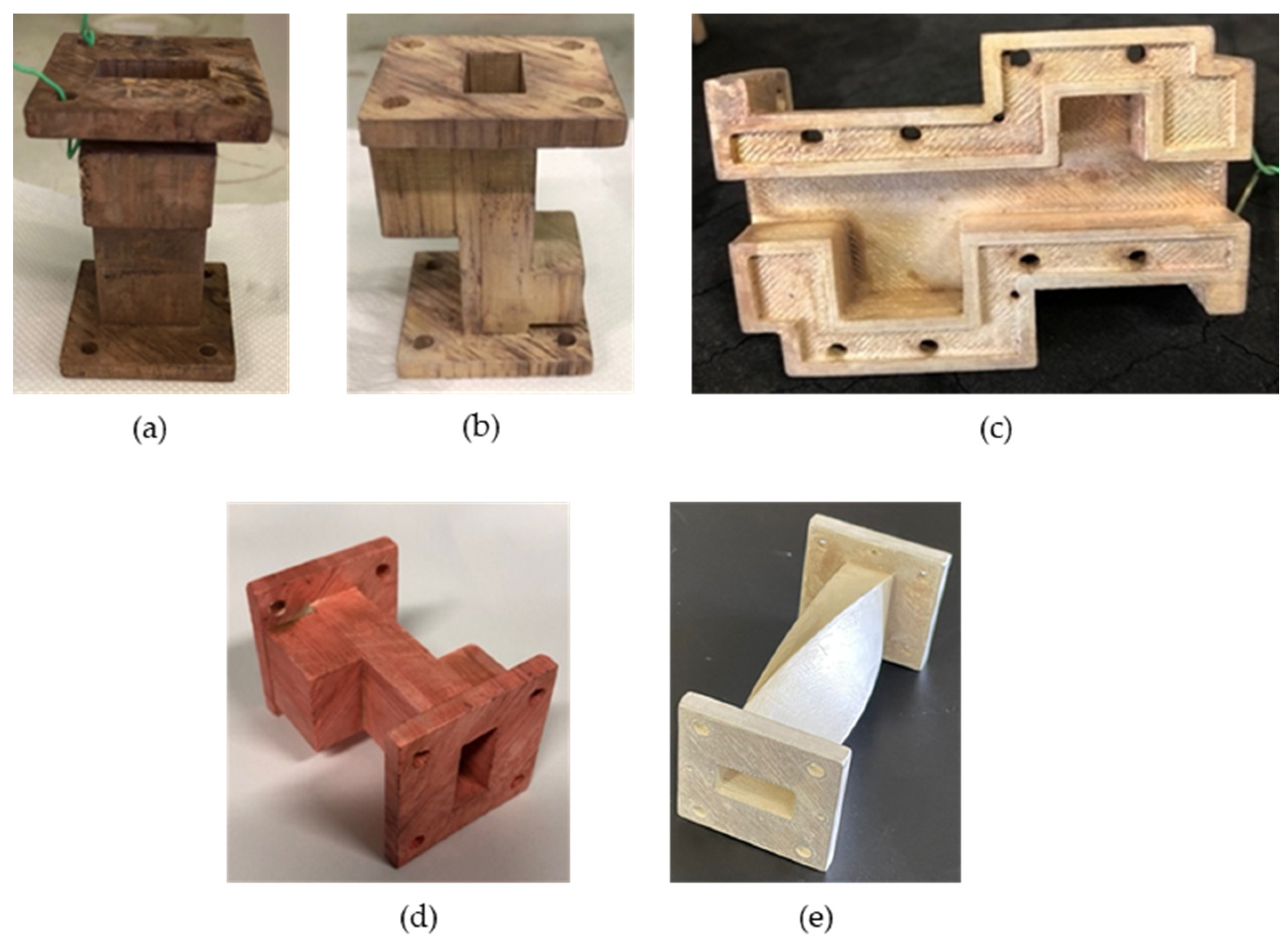

2.2. Manufacturing Processes

2.2.1. Polymer Powder-Bed Fusion Laser-Based Process

2.2.2. Material Extrusion Process

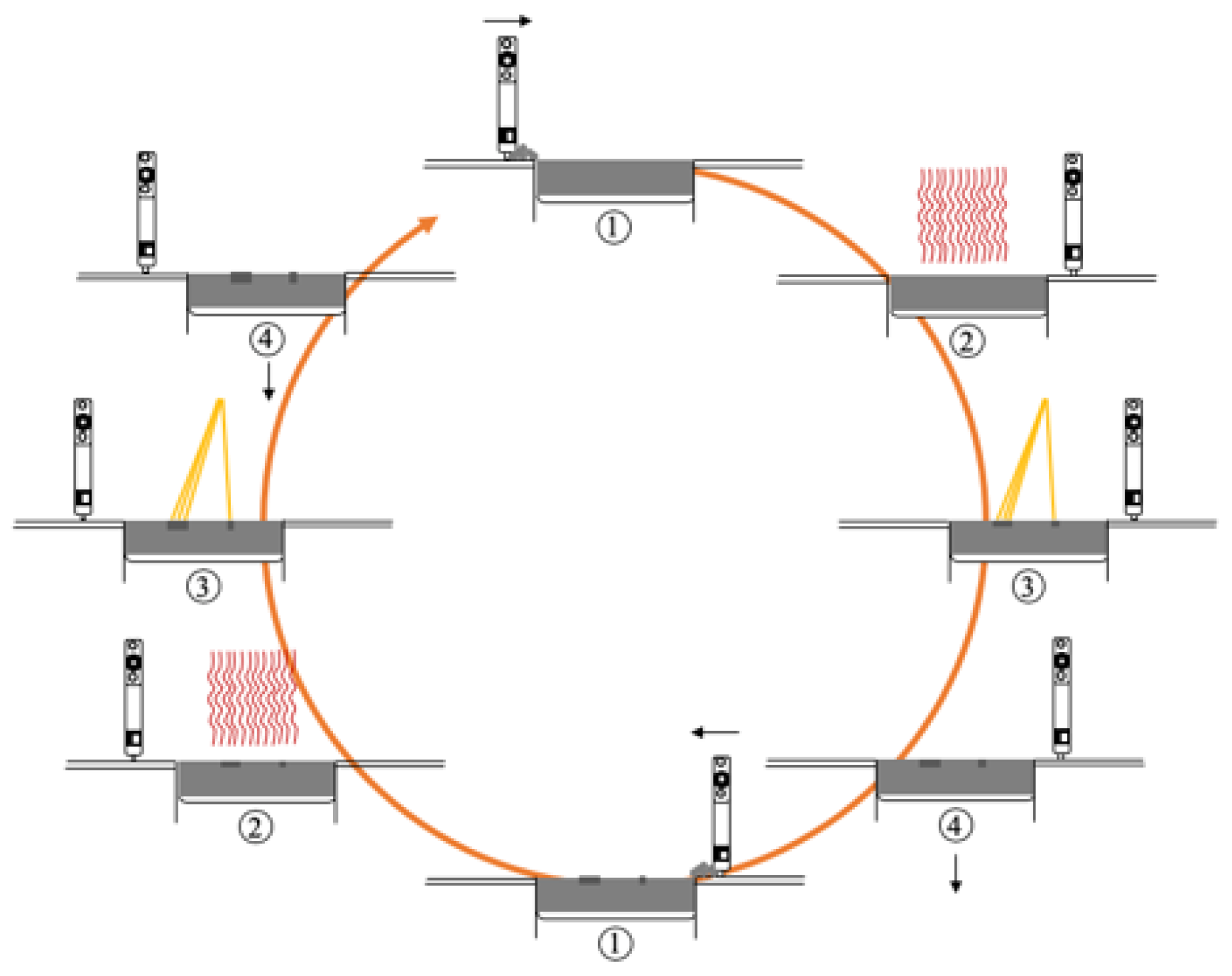

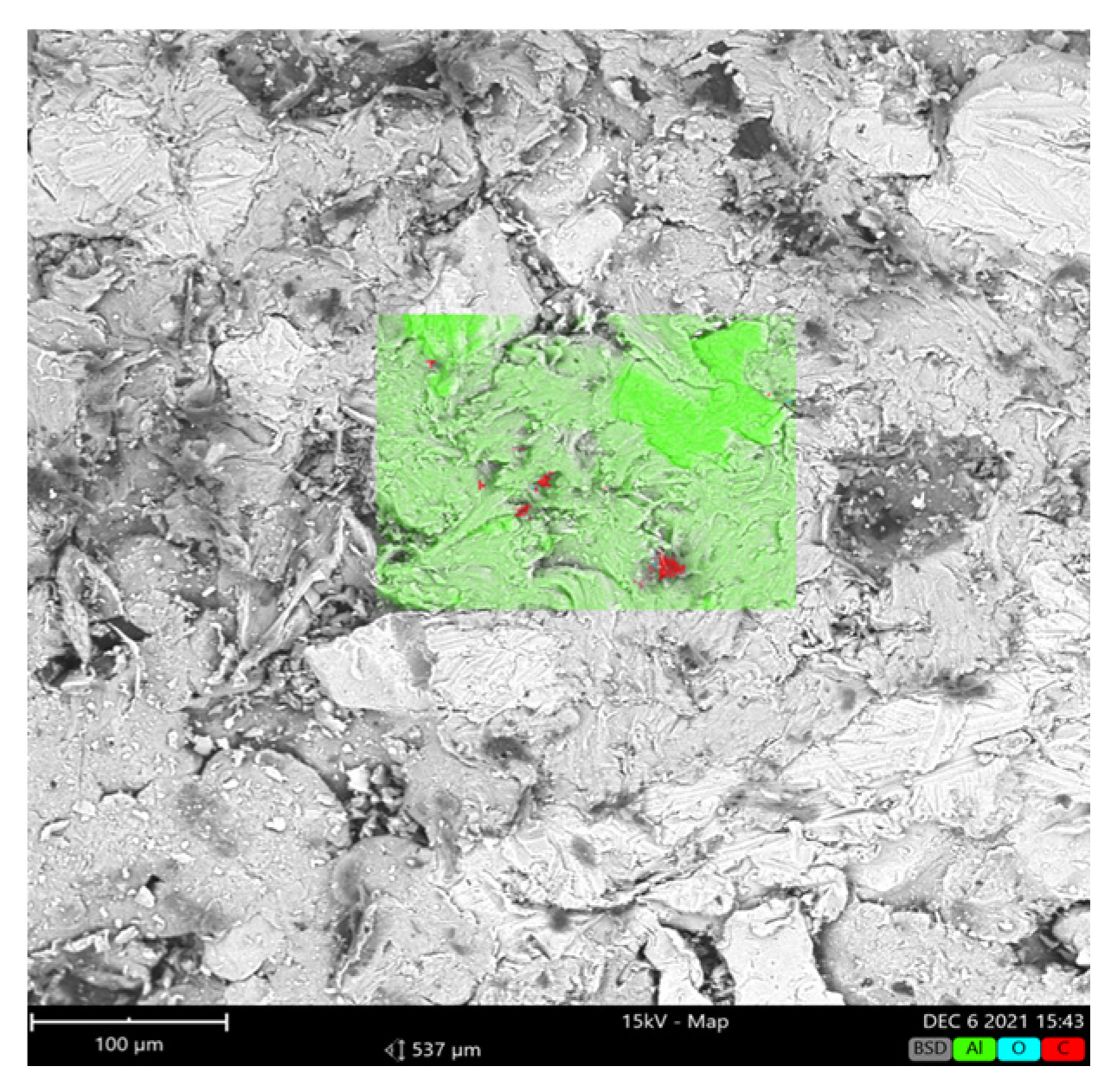

2.3. Metal Plating Processes

- Distilled water (H2O), Ammonia solution (NH3 Carlo Erba Reagents) Silver nitrate (Sigma Aldrich > 99.0%) ammonium sulfate (Sigma Aldrich > 99.0%) were mixed together in the H2O:NH3:((NH4)2SO4):(AgNO3) in the molar ratio 14:2:0.1:0.002.

- Mixing was performed in a Pyrex glass beaker at RT under constant magnetic stirring.

- Samples were dipped in the activation solution for 1 min and dried for 24 h at RT.

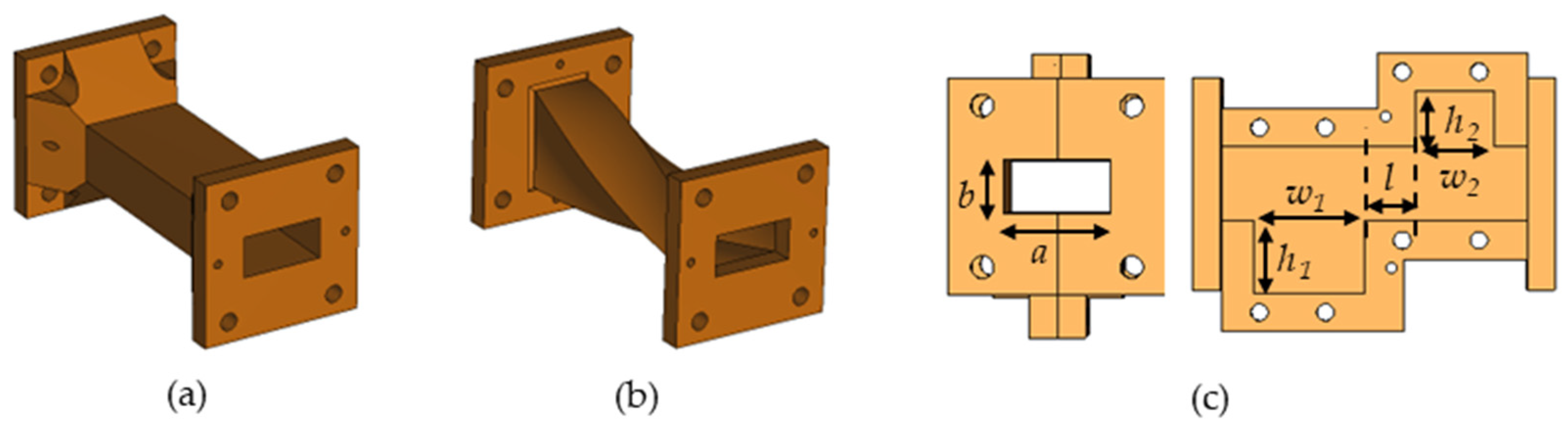

3. Definition of Microwave Test Vehicles and Measurement Setups

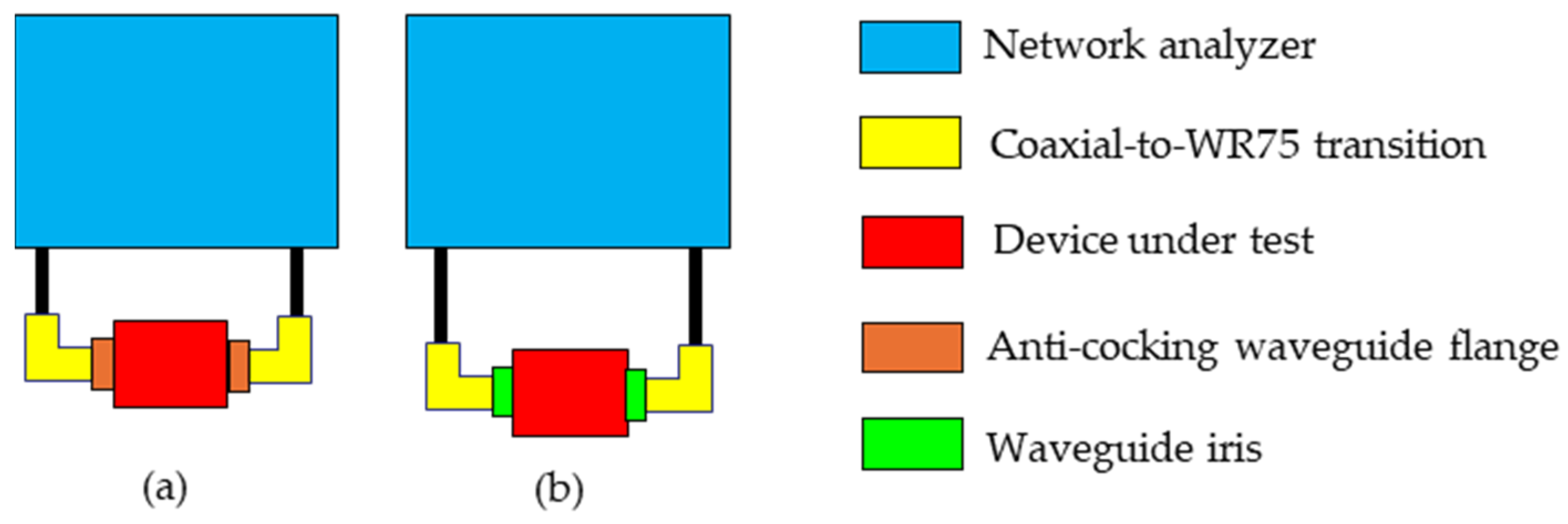

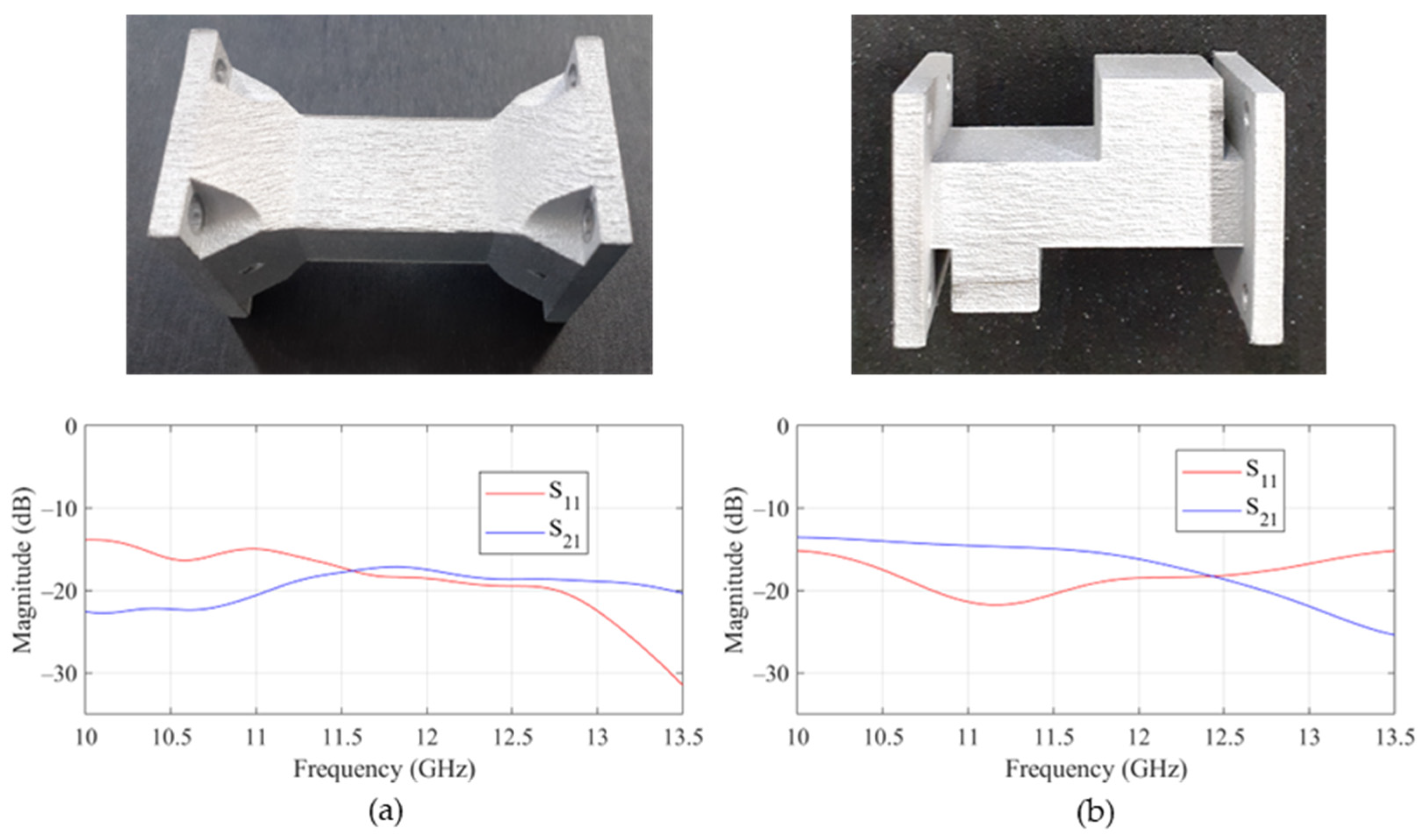

4. Breadboarding and Experimental Results

5. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wohlers, T.T.; Campbell, R.I.; Diegel, O.; Kowen, J.; Mostow, N.; Fidan, I. Wohlers Report 2022: 3D Printing and Additive Manufacturing Global State of the Industry; Wohlers Associates Inc.: Fort Collins, CO, USA, 2022. [Google Scholar]

- Peverini, O.A.; Lumia, M.; Addamo, G.; Virone, G.; Fonseca, N.J.G. How 3D-printing is changing RF front-end design for Space applications. IEEE J. Microw. 2023, 3, 800–814. [Google Scholar] [CrossRef]

- Gomez-Torrent, A.; Teberio, F.; Martinez, A.; Percaz, J.M.; Arnedo, I.; Maestrojuan, I.; Arregui, I.; Crespo, G.; Lopetegi, T.; Laso, M.A.G.; et al. A study of the additive manufacturing technology for RF/microwave components. In Proceedings of the 11th European Conference on Antennas and Propagation (EUCAP), Paris, France, 19–24 March 2017. [Google Scholar]

- Miek, D.; Simmich, S.; Kamrath, F.; Höft, M. Additive manufacturing of E-plane cut dual-mode X-band waveguide filters with mixed topologies. IEEE Trans. Microw. Theory Tech. 2020, 68, 2097–2107. [Google Scholar] [CrossRef]

- Fujiwara, K.; Kobayashi, R.; Kuwahara, S.; Takemura, S.; Takizawa, K.; Watanabe, Y. 3-D printed iris waveguide filter in W-band. In Proceedings of the 23rd International Microwave and Radar Conference (MIKON), Warsaw, Poland, 5–8 October 2020. [Google Scholar]

- Li, N.; Link, G.; Jelonnek, J. Electroplating of 3D printed plastic component for the application of microwave filter. In Proceedings of the 2022 IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications (IMWS-AMP), Guangzhou, China, 27–29 November 2022. [Google Scholar]

- Laplanche, E.; Tantot, O.; Delhote, N.; Périgaud, A.; Verdeyme, S.; Bila, S.; Baillargeat, D.; Carpentier, L. A Ku-band diplexer based on 3dB directional couplers made by plastic additive manufacturing. In Proceedings of the 47th European Microwave Conference (EuMC), Nuremberg, Germany, 10–12 October 2017. [Google Scholar]

- Saeidi-Manesh, H.; Saeedi, S.; Mirmozafari, M.; Zhang, G.; Sigmarsson, H.H. Design and fabrication of orthogonal-mode transducer using 3-D printing technology. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2013–2016. [Google Scholar] [CrossRef]

- Zhang, S.; Cadman, D.; Vardaxoglou, J.Y.C. Additively manufactured profiled conical horn antenna with dielectric loading. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2128–2132. [Google Scholar] [CrossRef]

- Sharma, A.; Owenby, D.N.; Valenti, J. 3D printed circular polarized millimeter wave slotted waveguide antenna for 5G and 6G systems. In Proceedings of the 2023 International Conference on Electromagnetics in Advanced Applications (ICEAA), Venice, Italy, 9–13 October 2023. [Google Scholar]

- Silva, J.S.; García-Vigueras, M.; Debogović, T.; Costa, J.R.; Fernandes, C.A.; Mosig, J.R. Stereolithography-based antennas for satellite communications in Ka-Band. Proc. IEEE 2017, 105, 655–667. [Google Scholar] [CrossRef]

- Paek, S.W.; Balasubramanian, S.; Stupples, D. Composites Additive Manufacturing for Space Applications: A Review. Materials 2022, 15, 4709. [Google Scholar] [CrossRef]

- Tamayo-Domínguez, A.; Fernández-González, J.-M.; Sierra-Pérez, M. Metal-coated 3D-printed waveguide devices for mm-wave applications. IEEE Microw. Mag. 2019, 20, 18–31. [Google Scholar] [CrossRef]

- Dionigi, M.; Tomassoni, C.; Venanzoni, G.; Sorrentino, R. Simple high-performance metal-plating procedure for stereolithographically 3-D-printed waveguide components. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 953–955. [Google Scholar] [CrossRef]

- Calignano, F.; Bove, A.; Mercurio, V.; Marchiandi, G. Effect of recycled powder and gear profile into the functionality of additive manufacturing polymer gears. Rapid Prototyp. J. 2023, 30, 16–31. [Google Scholar] [CrossRef]

- Yuan, M.; Bourell, D.; Diller, T. Thermal conductivity measurements of polyamide 12. In Proceedings of the 22nd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF, Austin, TX, USA, 8–10 August 2011. [Google Scholar]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Bragaglia, M.; Pascale, V.; Rinaldi, M.; Nanni, F. Silver electroless plating on 3D printed resins via stereolithography: A sustainable solution. Thin Solid Films 2022, 757, 139417. [Google Scholar] [CrossRef]

- Mallory, G.O.; Hajdu, J.B. Electroless Plating: Fundamentals and Applications; William Andrew: New York, NY, USA, 1990. [Google Scholar]

- Equbal, A.; Dixit, N.K.; Sood, A.K. Electroless plating on plastic. Int. J. Sci. Eng. Res. 2013, 8, 12–18. [Google Scholar]

- Dechasit, P.; Treakarnpruk, W. Ni electroless plating of ABS polymer by palladium and tin-free process. J. Met. Mater. Miner. 2011, 21, 19–27. [Google Scholar]

- Jagannathan, R.; Krishnan, M. Electroless plating of copper at a low pH level. IBM J. Res. Dev. 1993, 37, 117–124. [Google Scholar] [CrossRef]

- Zhang, M.C.; Kang, E.T.; Neoh, K.G.; Tan, K.L. Electroless plating of copper and nickel on surface-modified poly(tetrafluoroethylene) films. J. Electrochem. Soc. 2001, 148, 71–80. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, J. Fabrication of Nickel coating on polyethylene terephthalate substrate modified with primer: Effect of surface roughness on structural properties of plated coating. J. Electron. Mater. 2019, 48, 6298–6305. [Google Scholar] [CrossRef]

- Uzunlar, E.; Wilson, Z.; Kohl, P.A. Electroless copper deposition using Sn/Ag catalyst on epoxy laminates. J. Electrochem. Soc. 2013, 160, 3237–3246. [Google Scholar] [CrossRef]

- Han, X.; Wang, G.; He, Y.; Wang, Y.; Qiao, Y.; Zang, L. Surface modification of ABS with Cr6+ free etching process in the electroless plating. J. Adhes. Sci. Technol. 2018, 32, 2481–2493. [Google Scholar] [CrossRef]

- Lee, C.; Syu, C. Ag nanoparticle as a new activator for catalyzing electroless copper bath with 2,2′-bipyridyl. Electrochim. Acta 2011, 56, 8880–8883. [Google Scholar] [CrossRef]

- Fujiwara, Y.; Kobayashi, Y.; Kita, K.; Kakehashi, R.; Noro, M.; Katayama, J.-I.; Otsuka, K. Ag nanoparticle catalyst for electroless Cu deposition and promotion of its adsorption onto epoxy substrate. J. Electrochem. Soc. 2008, 155, 377–382. [Google Scholar] [CrossRef]

- Bragaglia, M.; Paleari, L.; Mariani, M.; Nanni, F. Sustainable formaldehyde-free copper electroless plating on carbon-epoxy substrates. J. Mater. Sci. Mater. Electron. 2024, 35, 707. [Google Scholar] [CrossRef]

- Schaefers, S.; Rast, L.; Stanishevsky, A. Electroless silver plating on spin-coated silver nanoparticle seed layers. Mater. Lett. 2006, 60, 706–709. [Google Scholar] [CrossRef]

- Fritz, N.; Koo, H.-C.; Wilson, Z.; Uzunlar, E.; Wen, Z.; Yeow, X.; Ann, S.; Allen, B.; Kohl, P.A. Electroless deposition of copper on organic and inorganic substrates using a Sn/Ag catalyst. J. Electrochem. Soc. 2012, 159, 386–392. [Google Scholar] [CrossRef]

- Blackham, D. Trends for computing VNA uncertainties. In Proceedings of the 89th Microwave Measurement Conference (ARFTG), Honololu, HI, USA, 9 June 2017. [Google Scholar]

- Rival, G.; Dantras, É.; Paulmier, T. Ageing of PEEK/Carbon Fibre composite under electronic irradiations: Influence on mechanical behaviour and charge transport. Compos. Part A: Appl. Sci. Manuf. 2022, 154, 106769. [Google Scholar] [CrossRef]

- Kalra, S.; Munjal, B.S.; Singh, V.R.; Mahajan, M.; Bhattacharya, B. Investigations on the suitability of PEEK material under space environment conditions and its application in a parabolic space antenna. Adv. Space Res. 2019, 63, 4039–4045. [Google Scholar] [CrossRef]

- Abdullah, F.; Okuyama, K.; Fajardo, I.; Urakami, N. In situ measurement of carbon fibre/polyether ether ketone thermal expansion in low Earth orbit. Aerospace 2020, 7, 35. [Google Scholar] [CrossRef]

- Enginser. Available online: https://www.ensingerplastics.com/en/ (accessed on 20 March 2025).

- Simplify3D. Available online: https://www.simplify3d.com/r (accessed on 20 March 2025).

- Gold, G.; Helmreich, K. A physical model for skin effect in rough surfaces. In Proceedings of the 7th European Microwave Integrated Circuit Conference, Amsterdam, The Netherlands, 29–30 October 2012. [Google Scholar]

| Material | AM Technology | Density (g/cm3) | Tensile Strength (MPa) | Tensile Modulus (MPa) | Heat Deflection Temperature at 1.8 MPa (°C) |

|---|---|---|---|---|---|

| ABS | MEX | 1.06 | 22 | 1627 | 76 |

| ABS | SLA | 1.21 | 42 | 1950 | 39 |

| Accura Xtreme | SLA | 1.19 | 40 | 1900 | 54 |

| Alumide | PBF-LB/P | 1.36 | 48 | 3800 | 144 |

| CF-PEEK | MEX | 1.34 | 87 | 3900 | 315 |

| New White | SLA | 1.23 | 55 | 2600 | 60 |

| Nylon 12 | MEX | 1.01 | 48 | 1310 | 82 |

| PA 12 | PBF-LB/P | 0.95 | 46 | 1700 | 86 |

| PA 12 CF | PBF-LB/P | 1.07 | 60 | 3654 | 172 |

| PEEK | MEX | 1.32 | 100 | 3792 | 160 |

| PEEK | PBF-LB/P | 1.31 | 90 | 4250 | 165 |

| PerForm | SLA | 1.61 | 68 | 10,500 | 82 |

| Stonelike | SLA | 1.3 | 52 | 4500 | 187 |

| Ultem 9085 | MEX | 1.34 | 72 | 2220 | 153 |

| Parameters | Ultem | CF-PEEK |

|---|---|---|

| Retraction distance (mm) | 0.5 | 1.0 |

| Retraction speed (mm/s) | 36.7 | 36.7 |

| First layer height (mm) | 0.1 | 0.2 |

| Upper solid layers | 5 | 5 |

| Lower solid layers | 5 | 5 |

| Contour/perimeter enclosures | 2 | 2 |

| Infill (%) | 20% | 40% |

| Offset | +45/−45 | +45/−45 |

| Support infill (%) | 20% | 30% |

| Separation offset (mm) | 0.7 | 0.7 |

| Bed Temperature (°C) | 150.0 | 150.0 |

| Extruder Temperature (°C) | 380.0 | 430.0 |

| Speed (mm/s) | 36.7 | 36.7 |

| Material | Configuration | Δa (mm) | Δl (mm) | ρ (μΩcm) |

|---|---|---|---|---|

| Ultem | monolithic | −0.18 | +0.02 | 1000 |

| Ultem | split-block | +0.25 | −0.30 | 310 |

| CK-PEEK | monolithic | −0.40 | −0.05 | 130 |

| CK-PEEK | split-block | +0.25 | +0.35 | 8 |

| Material | Configuration | Δa (mm) | Δl (mm) | Δh1 (mm) | Δh1 (mm) | ρ (μΩcm) |

|---|---|---|---|---|---|---|

| Ultem | monolithic | −0.04 | +0.02 | −0.07 | 0.06 | 42 |

| Ultem | split-block | Not de-embedded | ||||

| CK-PEEK | monolithic | −0.30 | +0.06 | −0.12 | −0.15 | 440 |

| CK-PEEK | split-block | +0.03 | +0.10 | +0.18 | −0.10 | 5 |

| Component | Prototype Number | Δa (mm) | Δl (mm) | ρ (μΩcm) |

|---|---|---|---|---|

| Line | 1 | −0.17 | +0.15 | 50 |

| Line | 2 | −0.21 | +0.02 | 10 |

| Line | 3 | −0.17 | −0.3 | 12 |

| Twist | 1 | −0.34 | −0.15 | 150 |

| Twist | 2 | −0.36 | −0.05 | 20 |

| Twist | 3 | −0.33 | −0.05 | 16 |

| Machining | Electro-Forming | PBF-LB/M | PBF-LB/P | MEX | SLA | |

|---|---|---|---|---|---|---|

| Material | Al 6061 | Cu | Al alloys | Alumide | CF-PEEK, Ultem | Stonelike |

| Dimensional accuracy (μm) | 5–20 | 1–5 | 40–80 | 40–80 | 100–200 | 40–80 |

| Surface roughness Ra (μm) | 0.4–1.5 | 0.4–1 | 3–6 | 3–6 | 10–30 | 1–3 |

| Electrical resistivity (μΩcm) | 4–6 | 3–5 | 6–12 | metal plating is mandatory | ||

| Melting point (metals) Glass transition temperature (polymers) (°C) | 650 | 1083 | 570 | 144 | 145–186 | T.B.D. |

| Density g/cm3 | 2.7 | 8.9 | 2.7 | 1.3 | 1.2–1.3 | 1.3 |

| Tensile strength (MPa) | 260–310 | 200–360 | 440–480 | 48 | 72–87 | 52 |

| Near-net shapes | No | yes | yes | yes | yes | yes |

| Mechanical layouts | Split-block Multi-layer | Monolithic | Monolithic | Spilt block layouts may be required for metal plating | ||

| Lead time/cost | Medium | High | Low | Low | Low | Low |

| TRL | 9 | 8–9 | 8–9 | 3 | 3 | 2 |

| Surface Roughness Rq (μm) | Equivalent Surface Electrical Resistivity ρ (μΩcm) | Attenuation (dB/m) |

|---|---|---|

| 0.5 | 4 | 0.25 |

| 1 | 8 | 0.36 |

| 2 | 17 | 0.52 |

| 3 | 25 | 0.63 |

| 4 | 31 | 0.71 |

| 5 | 37 | 0.77 |

| 6 | 42 | 0.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lumia, M.; Bragaglia, M.; Nanni, F.; Valeri, M.; Bouzekri, O.; Calignano, F.; Manfredi, D.; Addamo, G.; Paonessa, F.; Peverini, O.A. Investigation into Applicability of 3D-Printed Composite Polymers with Enhanced Mechanical Properties in the Development of Microwave Components. Electronics 2025, 14, 1865. https://doi.org/10.3390/electronics14091865

Lumia M, Bragaglia M, Nanni F, Valeri M, Bouzekri O, Calignano F, Manfredi D, Addamo G, Paonessa F, Peverini OA. Investigation into Applicability of 3D-Printed Composite Polymers with Enhanced Mechanical Properties in the Development of Microwave Components. Electronics. 2025; 14(9):1865. https://doi.org/10.3390/electronics14091865

Chicago/Turabian StyleLumia, Mauro, Mario Bragaglia, Francesca Nanni, Matteo Valeri, Oilid Bouzekri, Flaviana Calignano, Diego Manfredi, Giuseppe Addamo, Fabio Paonessa, and Oscar Antonio Peverini. 2025. "Investigation into Applicability of 3D-Printed Composite Polymers with Enhanced Mechanical Properties in the Development of Microwave Components" Electronics 14, no. 9: 1865. https://doi.org/10.3390/electronics14091865

APA StyleLumia, M., Bragaglia, M., Nanni, F., Valeri, M., Bouzekri, O., Calignano, F., Manfredi, D., Addamo, G., Paonessa, F., & Peverini, O. A. (2025). Investigation into Applicability of 3D-Printed Composite Polymers with Enhanced Mechanical Properties in the Development of Microwave Components. Electronics, 14(9), 1865. https://doi.org/10.3390/electronics14091865