1. Introduction

In modern electronic devices, high clock speeds, densely packed PCB layouts, and the proximity of high-speed circuits exacerbate electromagnetic interference (EMI) issues. Furthermore, the extensive use of wireless communication and sophisticated power management systems adds to the challenge. As concerns about EMI grow, the importance of effective shielding and noise suppression techniques is also increasing.

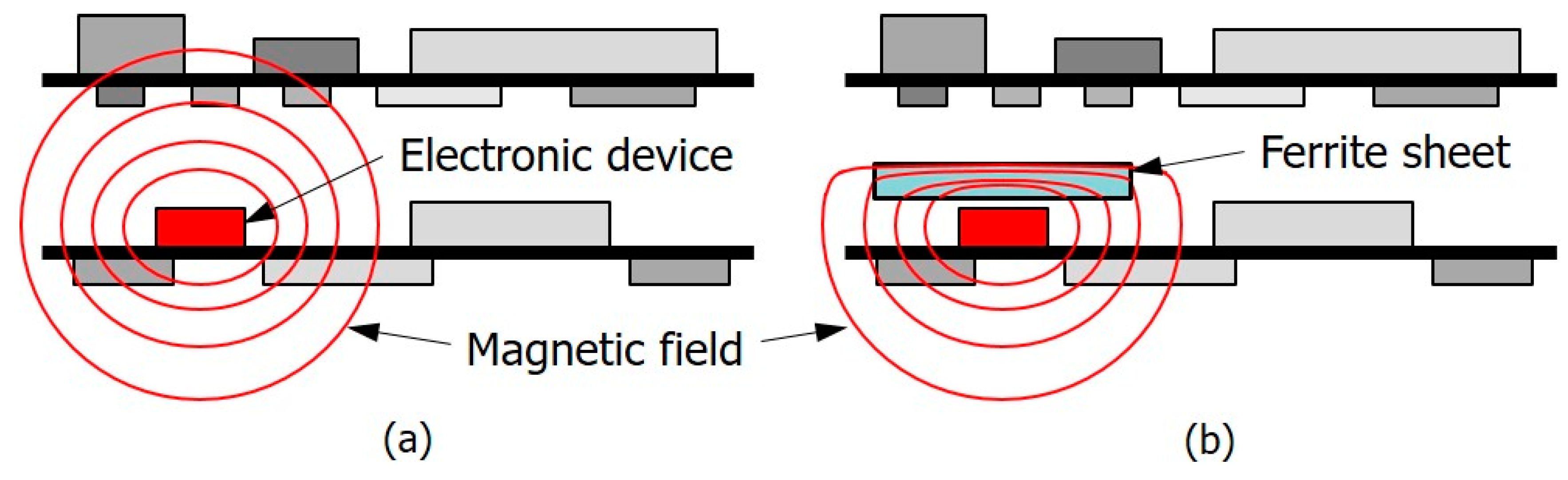

Magnetic sheets, typically made from flexible magnetic materials like ferrite or metal alloy composites, are designed to absorb and dissipate unwanted electromagnetic noise that can interfere with electronic circuits and components as shown in

Figure 1. Furthermore, when the coupling between noisy components and susceptible components increases due to the metallic boxes or enclosures that package them, attaching magnetic sheets to the metallic surfaces can help reduce noise coupling caused by the induced currents on the inner conducting plane, as depicted in

Figure 2. Therefore, in an increasingly noisy electromagnetic environment, magnetic sheets are indispensable for maintaining the performance and integrity of electronic devices.

In particular, noise suppression sheets (NSSs) are commonly employed for reducing and suppressing noise coupling and propagation at the GHz frequency range in modern electronic devices. Numerous studies have been conducted on NSSs [

1,

2,

3,

4,

5]. In addition to their use in the GHz high-frequency range, magnetic sheets are increasingly being employed to reduce low-frequency noise in electric vehicles [

6,

7]. The noise reduction mechanisms of magnetic sheets differ between high-frequency and low-frequency ranges. In high-frequency ranges, noise is absorbed due to the loss characteristics associated with the imaginary component of the permeability of the magnetic material. In contrast, in low-frequency ranges, the real component of the permeability causes the magnetic field to concentrate within the magnetic material, thereby converting or guiding the magnetic field path to reduce noise coupling between the noise source and victim circuits.

During the design phase of electronic devices, accurately predicting the near-field magnetic shielding properties of magnetic sheets is essential for selecting the most suitable materials to mitigate noise coupling. However, conventional approaches that rely on numerical simulations, such as finite element analysis (FEA) or other complex computational methods, have several limitations. These simulations often demand computational time and resources due to the complexity of the magnetic materials and the need to model intricate device geometries accurately. Additionally, they require specialized expertise to set up and interpret the results effectively, making the process labor-intensive and potentially impractical for quick design iterations. As a result, there is a need for more efficient prediction methods that can provide reliable results with less effort and time investment.

In this paper, we propose a method to predict the near-field magnetic shielding effectiveness (NSE) of the ferrite-based magnetic materials up to 100 MHz by measuring their real permeability using regression analysis. To extract the eight regression models, complex relative permeability and NSE were measured using commercial ferrite sheets. Additionally, the differences or errors between the predicted NSE from the extracted regression models and the measured NSE were analyzed using an error assessment indicator: mean square error (MSE). The results confirmed that the proposed regression models provide sufficiently accurate predictions of NSE in the low-frequency range up to 100 MHz. The proposed method achieves comparable accuracy with negligible computational time when compared to numerical simulations.

2. Methodology

The procedure of regression analysis consists of three phases for predicting the NSE of ferrite sheets and for verifying the accuracy of the predicted results, as illustrated in

Figure 3. In phase 1, regression models were developed using the measured permeability and NSE data of five commercial ferrite sheets (Group #1). The regression analysis was performed using Minitab [

8]. In phase 2, the NSE was predicted using the measured permeability data of another two commercial ferrite sheets (Group #2) as input for the extracted regression models. In phase 3, the NSE of the ferrite sheets in Group #2 was measured, and the accuracy was verified by comparing them with the predicted NSE. The predicted NSE of the ferrite sheets in Group #1 used for extracting the regression models was also compared with the measured NSE.

The prediction of NSE is made by the regression models, which were extracted through the measured frequency-dependent permeabilities and the NSE of five commercial ferrite sheets (Group #1). For NSE prediction, the measured permeability is required not only for the ferrite sheet in Group #1 but also for the ferrite sheets in Group #2. The complex relative permeability of the ferrite sheets was measured from 1 kHz to 100 MHz using the 16454A magnetic material test fixture provided by Keysight [

9]. A material under test (MUT) with a toroidal core shape and a thickness below 3 mm was coiled with a wire. Its relative permeability was calculated by measuring the impedance of the MUT based on the relationship between inductance and permeability.

Table 1 lists the measured real relative permeability at 1 MHz and the thickness of the commercial ferrite sheets used in the analysis.

The NSE was measured using a microstrip line and loop probe [

10,

11,

12].

Figure 4 shows a fabricated test fixture for magnetic shielding measurement of a thin magnetic sheet, which consists of a test board with a 50

microstrip line and a loop probe. The size of the test board is 140 mm

140 mm and the thickness is 2.0 mm with FR4 substrate (

= 4.3). The length and width of the microstrip line are 60 mm and 3.78 mm, respectively. To capture the leakage near-field passing through a magnetic sheet, a magnetic loop probe (RF-R 400-1 [

13]) with a diameter is 24 mm is employed. The distance (

h) between the loop probe and microstrip line is set to be 1 mm. The size of ferrite sheets is 140

140 mm, which is the same as that of the test board and is sufficiently larger than that of the loop probe. The ferrite sheets are mounted at the center of the test board. One port of the vector network analyzer (VNA) is connected to the microstrip line, and the other port is connected to the loop probe. The other end of the microstrip line is terminated by 50

. The NSE is defined by a ratio of two-port S-parameters between the microstrip line and loop probe as NSE

, where

are transmission coefficients of S-parameters in the absence (reference) and presence (load) of the magnetic sheet, respectively. The measured permeabilities and NSE were used as input data for Minitab’s regression analysis to obtain the regression models.

Figure 5 shows the complex relative permeability and near-field magnetic SE (NSE) of the R2 ferrite sheet with 0.4 mm thickness measured up to 100 MHz. The real part of the relative permeability remains nearly constant up to 10 MHz, peaks at 20 MHz, and then decreases linearly at higher frequencies. The imaginary part of the permeability is close to zero up to 10 MHz, increases up to approximately 30 MHz, and then decreases. The measured NSE closely follows the changes in the real permeability of the MUT as a function of frequency. This indicates that the NSE is determined by the value of the real permeability and can be predicted using the real permeability value.

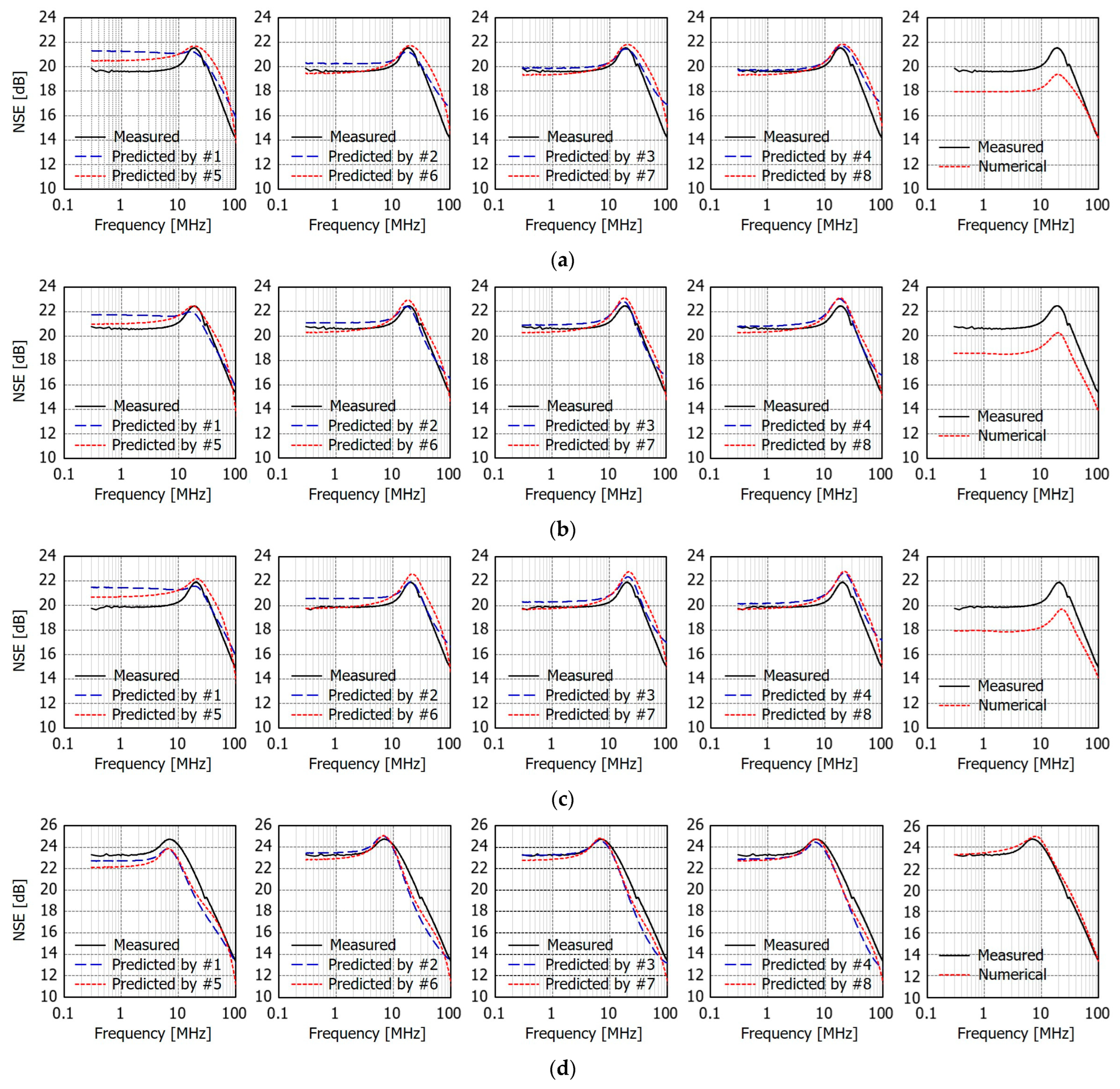

Eight regression models were derived using the measured real relative permeability and NSE of five ferrite sheets in Group #1. Model #1 is a linear combination of frequency and real permeability. Model #2 adds a square term of the permeability to this linear combination and Model #3 includes up to a cubic term of the permeability. Model #4 includes the fourth-order term of permeability. Model #5 incorporates a square term of the frequency into the linear combination of frequency and real permeability, and Model #6 includes both the square terms of frequency and permeability. Model #7 includes the third-order term of permeability from Model #6, while Model #8 includes the fourth-order term of permeability from Model #7. All models contain a linear term of thickness. As a result, these models demonstrate the impact of higher-order terms of permeability and frequency on the prediction accuracy of NSE. These models are determined by the coefficients in front of each term, which are derived through Minitab’s regression analysis, and the results are listed in

Table 2.

When performing regression analysis, we should check two output results as criteria that determine the reliability of the analysis:

p-value and adjusted coefficient of determination (R-Sq(adj)). The

p-value measures the probability of obtaining the observed results, assuming that the null hypothesis is true. The lower the

p-value, the greater the statistical significance of the observed difference. If insignificant independent variables are included in the regression equation, the R-Sq(adj) decreases and is often used as a criterion for selecting the optimal model. If the

p-value is smaller than 0.05 and R-Sq(adj) is large, it means that the regression equation is statistically significant and accurate.

Table 2 also lists the R-Sq(adj) and

p-value for each model. It can be seen that the

p-value for all models is 0.00, and the R-Sq(adj) for all models, except for Model #1, is above 90%, with R-Sq(adj) increasing to 95.4% in Models #7 and #8. This indicates that the extracted regression models are statistically significant and accurate. As higher-order terms of the permeability are included, the R-Sq(adj) increases, but models with the fourth-order term in permeability show similar R-Sq(adj) values to those with the third-order term. Therefore, it means that the fourth-order term of permeability is not necessary. Additionally, models that include the squared frequency term have a higher R-Sq(adj) compared to those that do not.

Figure 6 shows the regression analysis results for Model #6 and the residual plots for the predicted NSE. A normal probability plot of the residuals is used to check whether the residuals follow a normal distribution. The residuals histogram helps identify whether the data are skewed in a specific direction or if there are any outliers. The residuals versus fits plot is used to verify if the residuals are randomly distributed. If the plot shows a random distribution without any consistent pattern, it suggests that the assumptions of linearity and homoscedasticity are met. The residuals versus order plot checks whether the residuals are independent over time; if a specific pattern appears over time, it may indicate the presence of autocorrelation, suggesting that time-dependent factors are not accounted for in the regression model. Consequently, the residuals for the NSE in Model #6 are randomly distributed, follow a normal distribution, have no outliers, and are independent over time.

4. Conclusions

In this paper, we presented a method to predict the near-field magnetic shielding effectiveness (NSE) of ferrite sheets using the prediction models obtained through regression analysis. The commercial ferrite sheets used in the analysis were divided into Group #1 and Group #2. Eight regression models were developed using the measured relative permeability and NSE of the sheets in Group #1. The predicted NSE of the sheets in both Group #1 and Group #2 were then calculated and compared with the measured NSE. To verify the accuracy of the proposed regression models, an analysis of mean square errors (MSEs) was employed. The regression models with second-order frequency terms exhibited lower MSE compared to those with only first-order frequency terms. Additionally, while the inclusion of higher-order permeability terms further reduced MSE, the improvement was not significant beyond quadratic terms. Among the eight regression models, Model #6, which includes quadratic terms for both frequency and permeability, achieved the smallest MSE of 0.46. This is less than one-tenth of the MSE from numerical simulations. In terms of computation time, numerical simulations require over 4 h, whereas the proposed regression models can predict NSE in real time. Therefore, the regression models provide a highly effective method for NSE prediction compared to numerical simulations. As a result, if the real permeability and thickness information of ferrite sheets are known, the NSE can be predicted using regression models without the need for NSE measurements.

Finally, we would like to point out the limitations of the NSE prediction method proposed in this paper using regression analysis. First, since regression analysis is a statistical technique, the accuracy of the predictive model improves as the amount of data increases. Therefore, it is crucial to secure a sufficient number of MUTs. Second, the accuracy of the data used to extract the regression models is essential. If the data contains outliers, the prediction accuracy of the extracted model will decrease. Thus, for accurate NSE prediction, the precise measurement of the permeability of magnetic sheets is paramount. Not only the accurate measurement of the NSE of magnetic sheets but also the reproducibility and repeatability of the measurement methods for precise permeability measurements must be secured first.