Channel Temperature Measurement of GaN HEMT Used in Kilowatt-Level Power Amplifier

Abstract

1. Introduction

- (1)

- Optical temperature measurement techniques: such as infrared thermography, Raman spectroscopy, and thermoreflectance imaging, can directly acquire die-temperature data [6]. However, optical thermometers with microsecond-level temporal resolution and micrometer-level spatial resolution are extremely expensive and often require dedicated device samples and specialized equipment [7], which are generally inaccessible in many electronics laboratories.

- (2)

- Three-dimensional modeling and simulation: constructing a three-dimensional finite element model based on the HEMT’s structure and material parameters to simulate the temperature distribution [8,9]. The advantage of this approach is the rapid acquisition of temperature profiles with extremely high spatial resolution. Nevertheless, accurate simulation requires precise structural dimensions of the transistor, which are often not fully disclosed by manufacturers due to confidentiality issues. Moreover, most mainstream thermal simulation software relies on Fourier’s law, which has certain limitations at micrometer-scale dimensions, making it difficult to accurately predict heat transfer processes [10].

- (3)

- Electrical measurements: indirect identification procedures from electrical measurements [11,12], which indirectly measure the temperature based on the dependence of electrical parameters on temperature. It is usually measured through electrical parameters with higher temperature sensitivity, such as threshold voltage and drain current [13,14]. The advantage of the electrical measurement method is that it can be rapidly measured using standard equipment and does not require direct contact with the power amplifier. Nevertheless, there are multiple factors influencing kW-class GaN HEMTs, such as the relatively large gate leakage current affecting the gate voltage and the trap effect influencing the drain current [15,16]. As a result, temperature is no longer a single variable of the drain current, making it difficult to accurately reflect the temperature variation by measuring the drain current.

2. Detailed Analysis of the Proposed Method

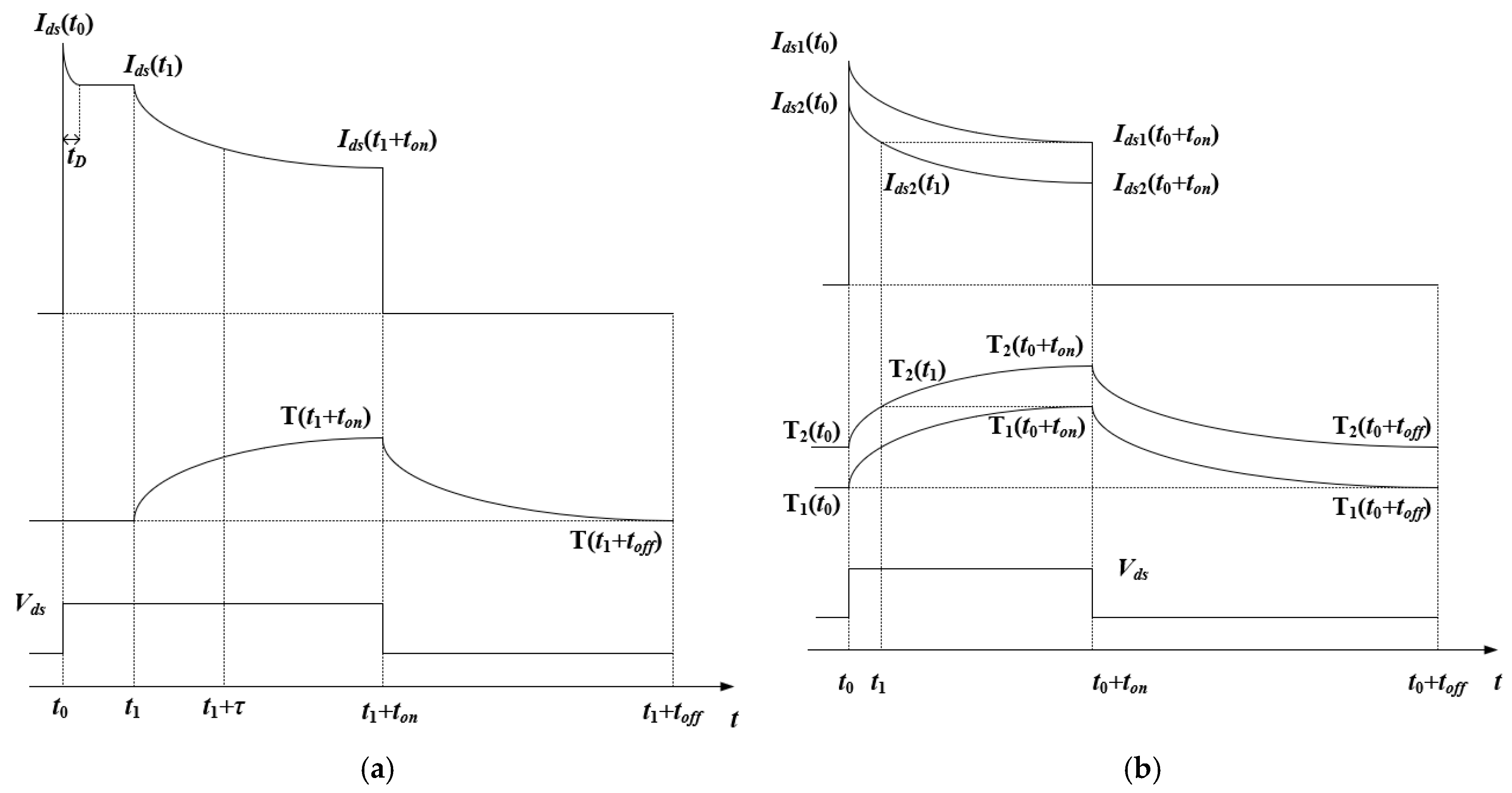

2.1. Derivation of Drain Current Equations

2.2. Key Factors Influencing Drain Current

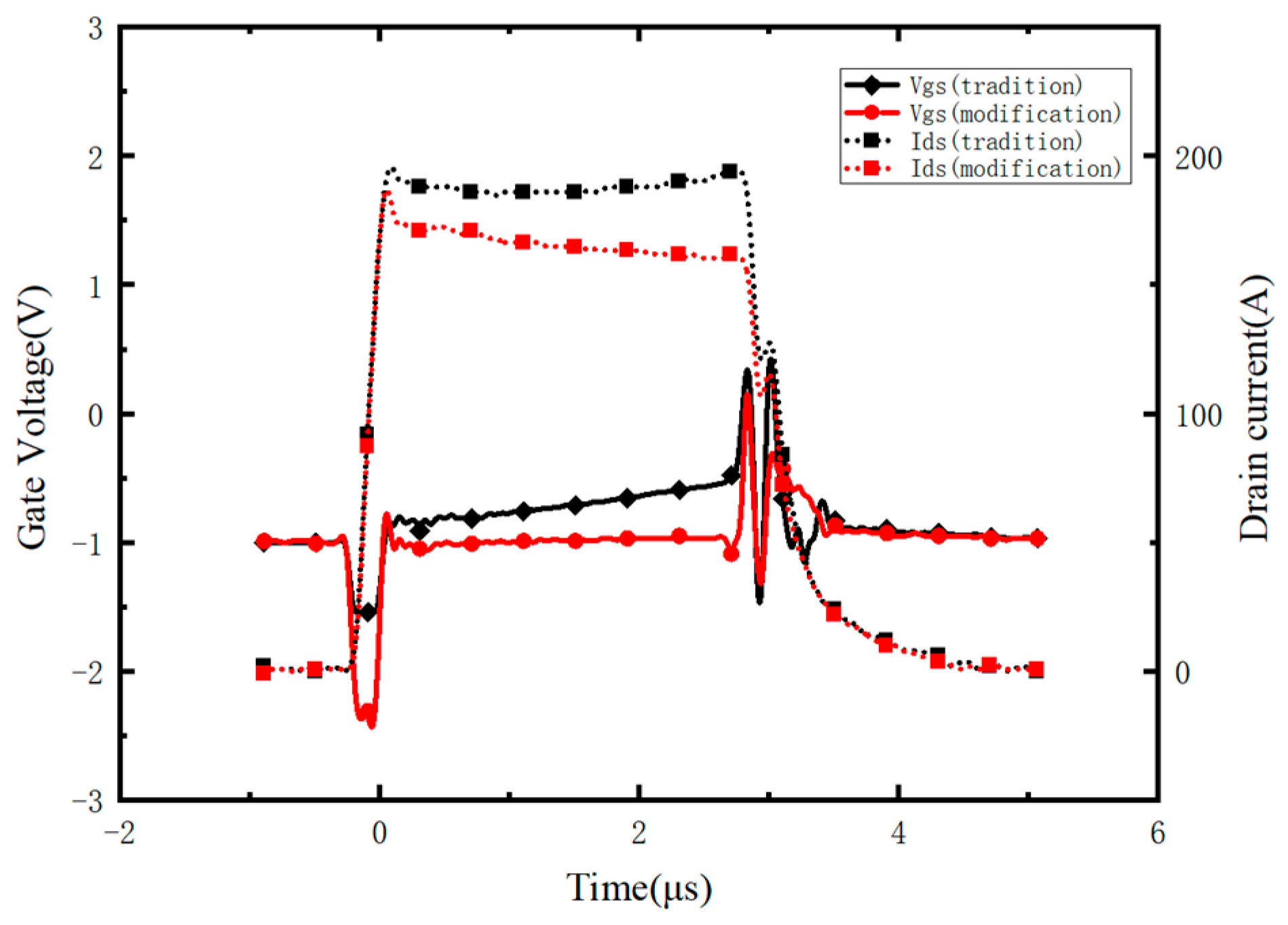

2.2.1. Gate Voltage

2.2.2. Trap Effect

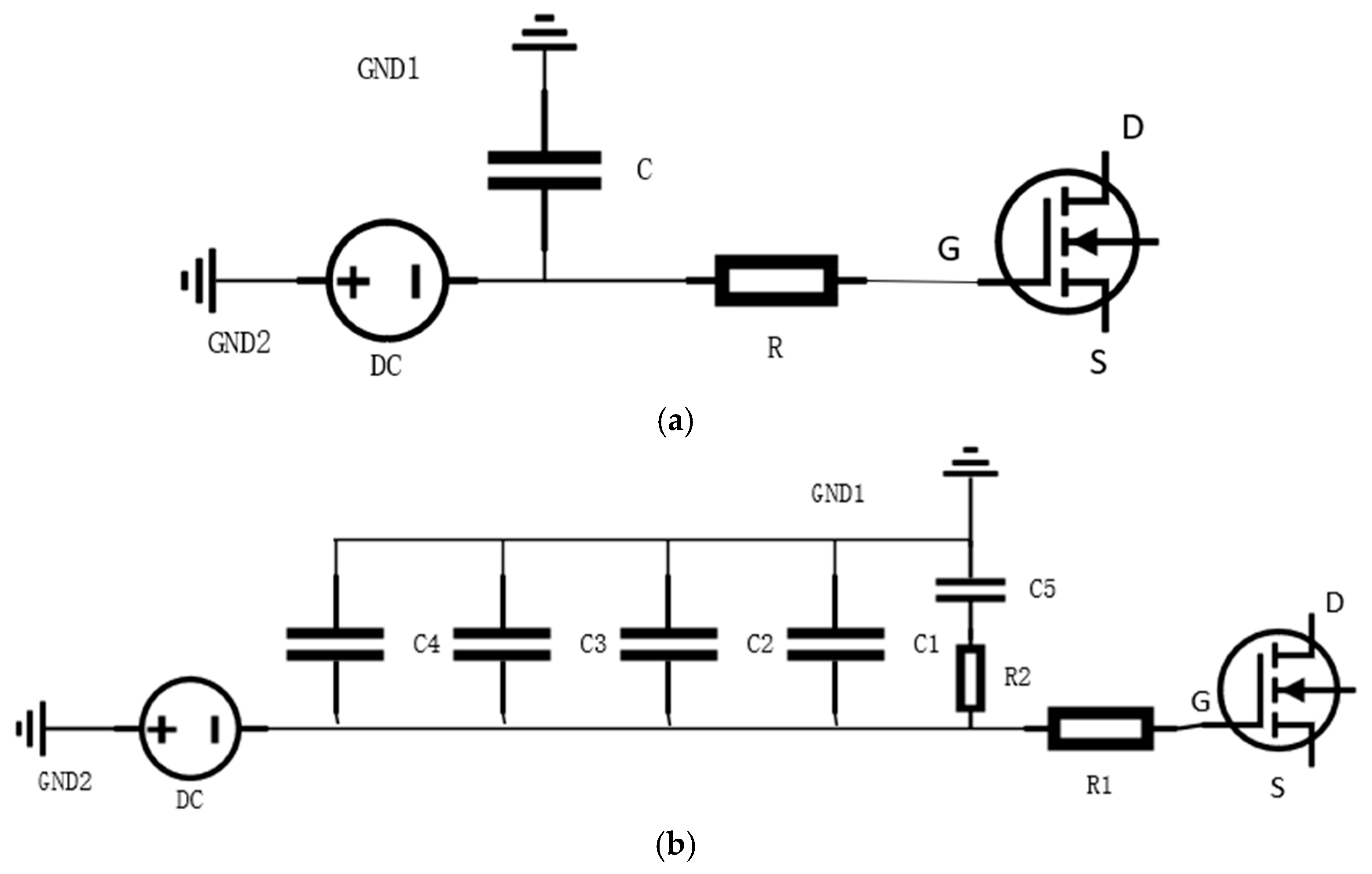

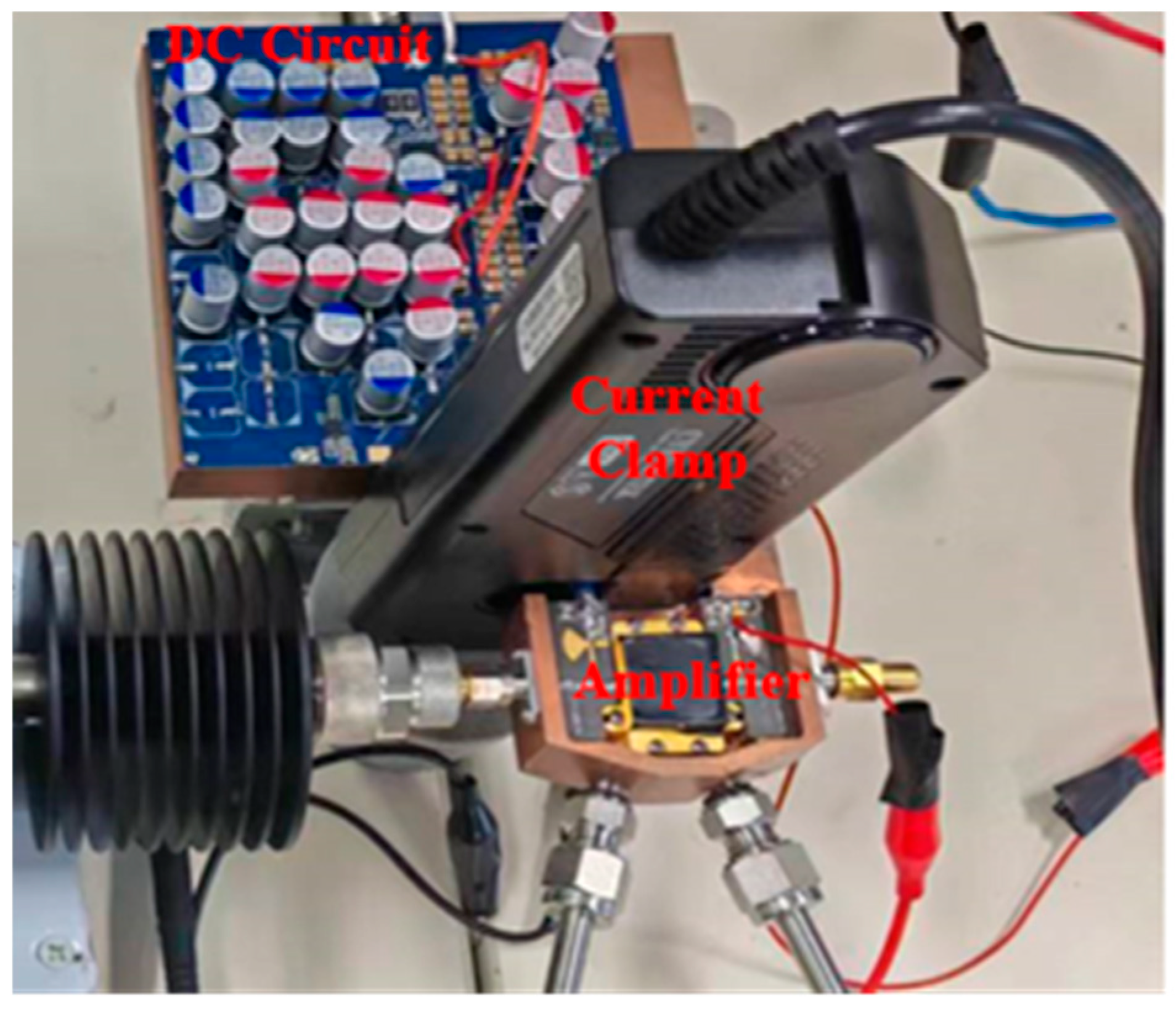

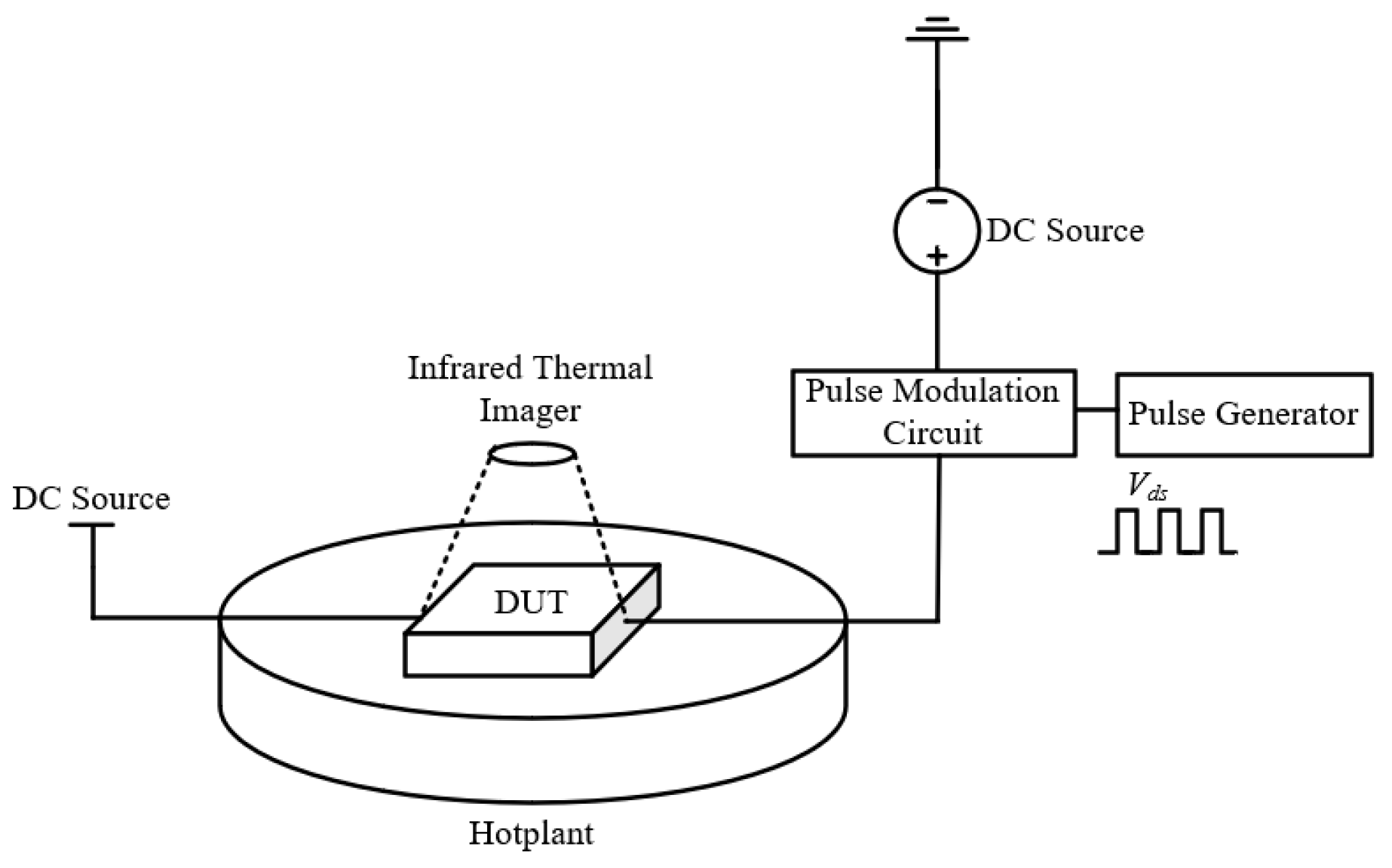

3. Measurement Setup of the Proposed Method

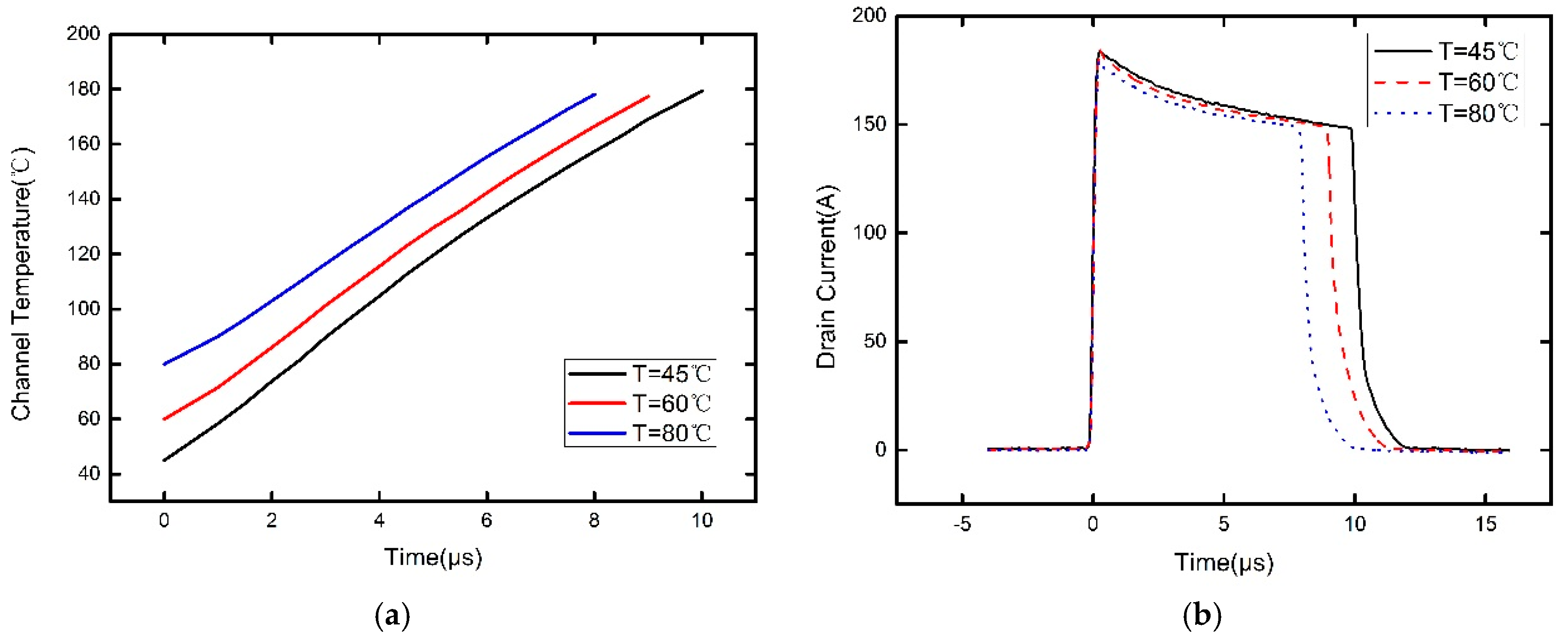

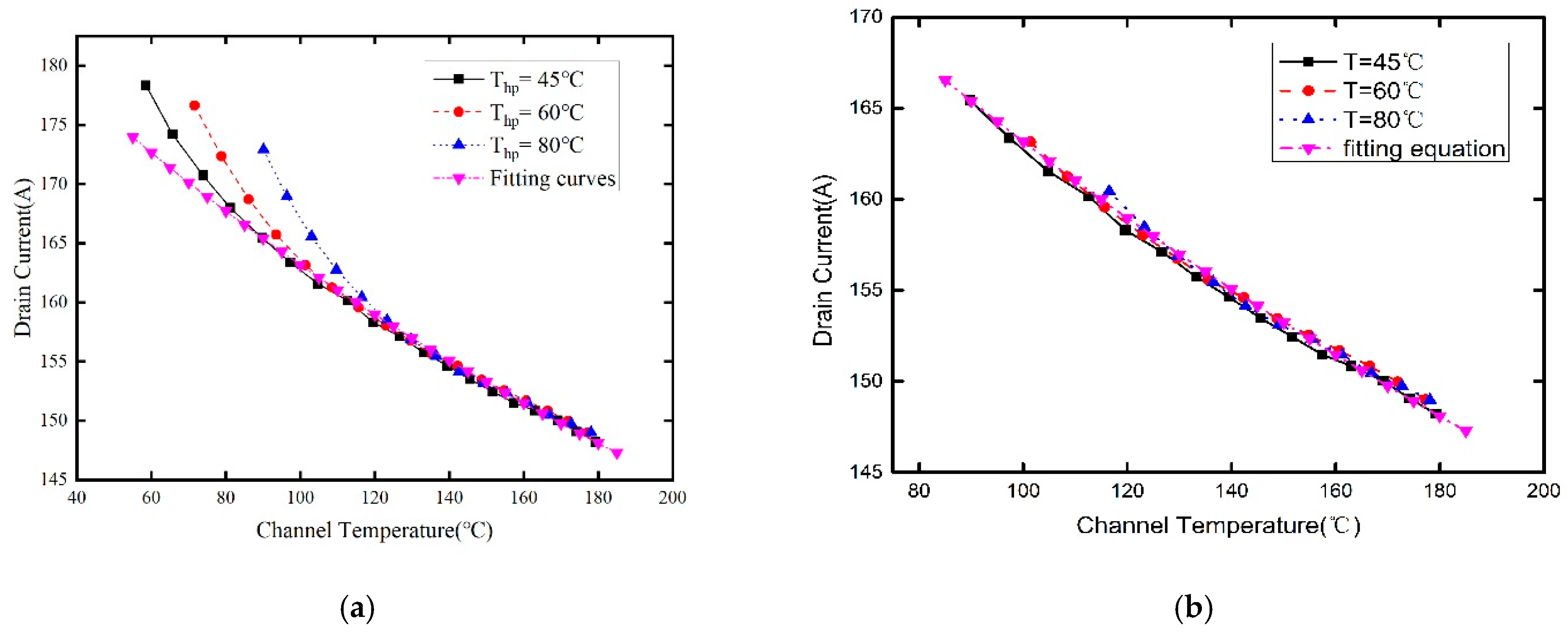

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mishra, U.K.; Shen, L.; Kazior, T.E.; Wu, Y.-F. GaN-Based RF Power Devices and Amplifiers. Proc. IEEE 2008, 96, 287–305. [Google Scholar] [CrossRef]

- Dunleavy, L.; Baylis, C.; Curtice, W.; Connick, R. Modeling GaN: Powerful but Challenging. IEEE Microw. Mag. 2010, 11, 82–96. [Google Scholar] [CrossRef]

- Komiak, J.J. GaN HEMT: Dominant Force in High-Frequency Solid-State Power Amplifiers. IEEE Microw. Mag. 2015, 16, 97–105. [Google Scholar] [CrossRef]

- Schwitter, B.K.; Parker, A.E.; Mahon, S.J.; Fattorini, A.P.; Heimlich, M.C. Heimlich Impact of Bias and Device Structure on Gate Junction Temperature in AlGaN/GaN-on-Si HEMTs. IEEE Trans. Electron Devices 2014, 61, 1327–1334. [Google Scholar] [CrossRef]

- Zeng, C.; Wang, Y.; Liao, X.; Li, R.; Chen, Y.; Lai, P.; Huang, Y.; En, Y. Reliability assessment of Algangan Hemts for high voltage applications based on high temperature reverse bias test. In Proceedings of the 2014 10th International Conference on Reliability, Maintainability and Safety (ICRMS), Guangzhou, China, 6–8 August 2014; pp. 298–301. [Google Scholar] [CrossRef]

- Park, J.; Shin, M.W.; Lee, C.C. Thermal modeling and measurement of AlGaN-GaN HFETs built on sapphire and SiC substrates. IEEE Trans. Electron Devices 2004, 51, 1753–1759. [Google Scholar] [CrossRef]

- Killat, N.; Montes, M.; Pomeroy, J.W.; Paskova, T.; Evans, K.R.; Leach, J.; Li, X.; Ozgur, U.; Morkoc, H.; Chabak, K.D.; et al. Thermal Properties of AlGaN/GaN HFETs on Bulk GaN Substrates. IEEE Electron Device Lett. 2012, 33, 366–368. [Google Scholar] [CrossRef]

- Prejs, A.; Wood, S.; Pengelly, R.; Pribble, W. Thermal analysis and its application to high power GaN HEMT amplifiers. In Proceedings of the 2009 IEEE MTT-S International Microwave Symposium Digest, Boston, MA, USA, 7–12 June 2009; pp. 917–920. [Google Scholar] [CrossRef]

- Harris, M.; Wagner, B.; Tong, W.; Menkara, H.; Halpern, S. Thermal analysis and validation of packaging for 100W and higher GaN MMIC power amplifiers. In Proceedings of the WAMICON 2011 Conference Proceedings, Clearwater Beach, FL, USA, 18–19 April 2011; pp. 1–5. [Google Scholar] [CrossRef]

- Shen, Y.; Chen, X.-S.; Hua, Y.-C.; Li, H.-L.; Wei, L.; Cao, B.-Y. Bias Dependence of Non-Fourier Heat Spreading in GaN HEMTs. IEEE Trans. Electron Devices 2023, 70, 409–417. [Google Scholar] [CrossRef]

- Hu, Z.; Gao, X.; Cai, S. Electro-thermal model extraction of power GaN HEMT using I–V pulsed and DC measurements. In Proceedings of the 2011 9th IEEE International Conference on ASIC, Xiamen, China, 25–28 October 2011; pp. 850–853. [Google Scholar] [CrossRef]

- McAlister, S.P.; Bardwell, J.A.; Haffouz, S.; Tang, H. Self-heating and the temperature dependence of the DC characteristics of GaN heterostructure field effect transistors. J. Vac. Sci. Technol. A 2006, 24, 624–628. [Google Scholar] [CrossRef]

- Simms, R.J.T.; Pomeroy, J.W.; Uren, M.J.; Martin, T.; Kuball, M. Channel Temperature Determination in High-Power AlGaN/GaN HFETs Using Electrical Methods and Raman Spectroscopy. IEEE Trans. Electron Devices 2008, 55, 478–482. [Google Scholar] [CrossRef]

- Kuzmik, J.; Javorka, R.; Alam, A.; Marso, M.; Heuken, M.; Kordos, P. Determination of channel temperature in AlGaN/GaN HEMTs grown on sapphire and silicon substrates using DC characterization method. IEEE Trans. Electron Devices 2002, 49, 1496–1498. [Google Scholar] [CrossRef]

- Santarelli, A.; Di Giacomo, V.; Cignani, R.; D’Angelo, S.; Niessen, D.; Filicori, F. Nonlinear thermal resistance characterization for compact electrothermal GaN HEMT modelling. In Proceedings of the 5th European Microwave Integrated Circuits Conference, Paris, France, 27–28 September 2010; pp. 82–85. [Google Scholar]

- Dahmani, S.; Mengistu, E.S.; Kompa, G. Thermal Model Extraction of GaN HEMTs for Large-Signal Modeling. In Proceedings of the 2008 European Microwave Integrated Circuit Conference, Amsterdam, The Netherlands, 27–28 October 2008; pp. 226–229. [Google Scholar] [CrossRef]

- Rashmi; Kranti, A.; Haldar, S.; Gupta, M.; Gupta, R.S. Comprehensive analysis of small-signal parameters of fully strained and partially relaxed high Al-content lattice mismatched Al/sub m/Ga/sub 1-m/N/GaN HEMTs. IEEE Trans. Microw. Theory Tech. 2003, 51, 607–617. [Google Scholar] [CrossRef]

- Rashmi; Kranti, A.; Haldar, S.; Gupta, R.S. An accurate charge control model for spontaneous and piezoelectric polarization dependent two-dimensional electron gas sheet charge density of lattice-mismatched AlGaN/GaN HEMTs. Solid-State Electron. 2002, 46, 621–630. [Google Scholar] [CrossRef]

- Wei, J.; Xu, H.; Xie, R.; Chen, K.J. Principles and impacts of dynamic threshold voltage in a p-GaN gate high-electron-mobility transistor. Semicond. Sci. Technol. 2018, 36, 024006. [Google Scholar] [CrossRef]

- Tsividis, Y.; McAndrew, C. Operation and Modeling of the MOS Transistor, 3rd ed.; Oxford University Press: New York, NY, USA, 2011; pp. 181–194. [Google Scholar]

- Anghel, C.; Gillon, R.; Ionescu, A.M. Self-heating characterization and extraction method for thermal resistance and capacitance in HV MOSFETs. IEEE Electron Device Lett. 2004, 25, 141–143. [Google Scholar] [CrossRef]

- Joh, J.; del Alamo, J.A.; Chowdhury, U.; Chou, T.-M.; Tserng, H.-Q.; Jimenez, J.L. Measurement of Channel Temperature in GaN High-Electron Mobility Transistors. IEEE Trans. Electron Devices 2009, 56, 2895–2901. [Google Scholar] [CrossRef]

- Florian, C.; Santarelli, A.; Cignani, R.; Filicori, F. Characterization of the Nonlinear Thermal Resistance and Pulsed Thermal Dynamic Behavior of AlGaN–GaN HEMTs on SiC. IEEE Trans. Microw. Theory Tech. 2013, 61, 1879–1891. [Google Scholar] [CrossRef]

- Kang, T.-S.; Ren, F.; Gila, B.P.; Pearton, S.J.; Patrick, E.; Cheney, D.J.; Law, M.; Zhang, M.-L. Investigation of traps in AlGaN/GaN high electron mobility transistors by sub-bandgap optical pumping. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. 2015, 33, 061202. [Google Scholar] [CrossRef]

- Ahmed, N.; Dutta, A.K. Analytical models for the 2DEG concentration and gate leakage current in AlGaN/GaN HEMTs. Solid-State Electron. 2017, 132, 64–72. [Google Scholar] [CrossRef]

- Gao, L.; Zhong, Z.; Zhang, Q.; Li, X.; Xiong, X.; Chen, S.; Chen, L.; Yan, H.; Zhang, A.; Han, J.; et al. Stability of GaN HEMT Device Under Static and Dynamic Gate Stress. IEEE J. Electron Devices Soc. 2024, 12, 165–169. [Google Scholar] [CrossRef]

- Santarelli, A.; Cignani, R.; Niessen, D.; Traverso, P.A.; Filicori, F. New pulsed measurement setup for GaN and GaAs FETs characteri zation. Int. J. Microw. Wirel. Technol. 2012, 4, 387–397. [Google Scholar] [CrossRef]

- Gomes, J.L.; Nunes, L.C.; Gonçalves, C.F.; Pedro, J.C. An Accurate Characterization of Capture Time Constants in GaN HEMTs. IEEE Trans. Microw. Theory Tech. 2019, 67, 2465–2474. [Google Scholar] [CrossRef]

- Stockman, A.; Masin, F.; Meneghini, M.; Zanoni, E.; Meneghesso, G.; Bakeroot, B.; Moens, P. Gate Conduction Mechanisms and Lifetime Modeling of p-Gate AlGaN/GaN High-Electron-Mobility Transistors. IEEE Trans. Electron Devices 2018, 65, 5365–5372. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, M.; Lei, W.; Han, C. Dynamic gate leakage current of p-GaN Gate AlGaN/GaN HEMT under positive bias Conditions. In Proceedings of the 2021 IEEE Workshop on Wide Bandgap Power Devices and Applications in Asia (WiPDA Asia), Wuhan, China, 25–27 August 2021; pp. 232–235. [Google Scholar] [CrossRef]

- Jardel, O.; De Groote, F.; Reveyrand, T.; Jacquet, J.-C.; Charbonniaud, C.; Teyssier, J.-P.; Floriot, D.; Quere, R. An Electrothermal Model for AlGaN/GaN Power HEMTs Including Trapping Effects to Improve Large-Signal Simulation Results on High VSWR. IEEE Trans. Microw. Theory Tech. 2007, 55, 2660–2669. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, S.; Fang, W.; Zhao, J.; Huang, W.; Fu, C.; Wang, L.; He, T. Channel Temperature Measurement of GaN HEMT Used in Kilowatt-Level Power Amplifier. Electronics 2025, 14, 3861. https://doi.org/10.3390/electronics14193861

Zhong S, Fang W, Zhao J, Huang W, Fu C, Wang L, He T. Channel Temperature Measurement of GaN HEMT Used in Kilowatt-Level Power Amplifier. Electronics. 2025; 14(19):3861. https://doi.org/10.3390/electronics14193861

Chicago/Turabian StyleZhong, Sheng, Wenrao Fang, Juan Zhao, Wenhua Huang, Chao Fu, Lulu Wang, and Tianwei He. 2025. "Channel Temperature Measurement of GaN HEMT Used in Kilowatt-Level Power Amplifier" Electronics 14, no. 19: 3861. https://doi.org/10.3390/electronics14193861

APA StyleZhong, S., Fang, W., Zhao, J., Huang, W., Fu, C., Wang, L., & He, T. (2025). Channel Temperature Measurement of GaN HEMT Used in Kilowatt-Level Power Amplifier. Electronics, 14(19), 3861. https://doi.org/10.3390/electronics14193861