A Universal I2C-to-RS-485 Module for Industrial Sensing

Abstract

1. Introduction

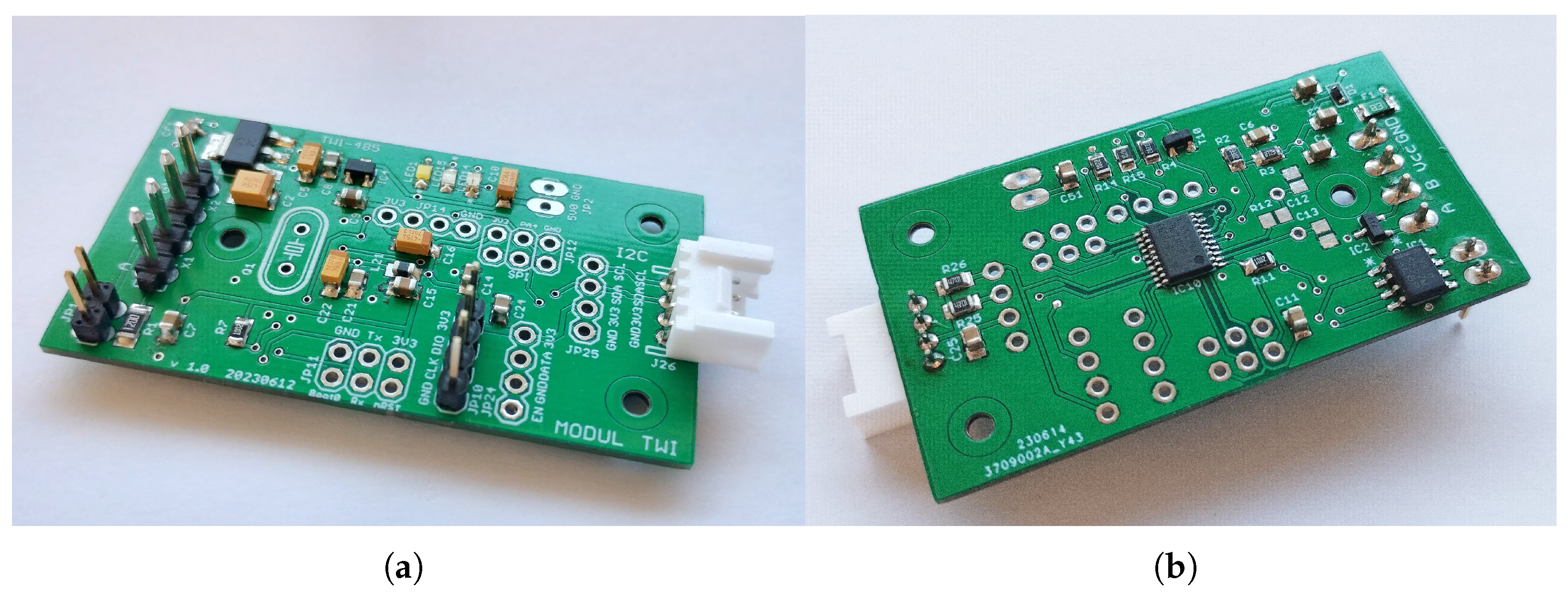

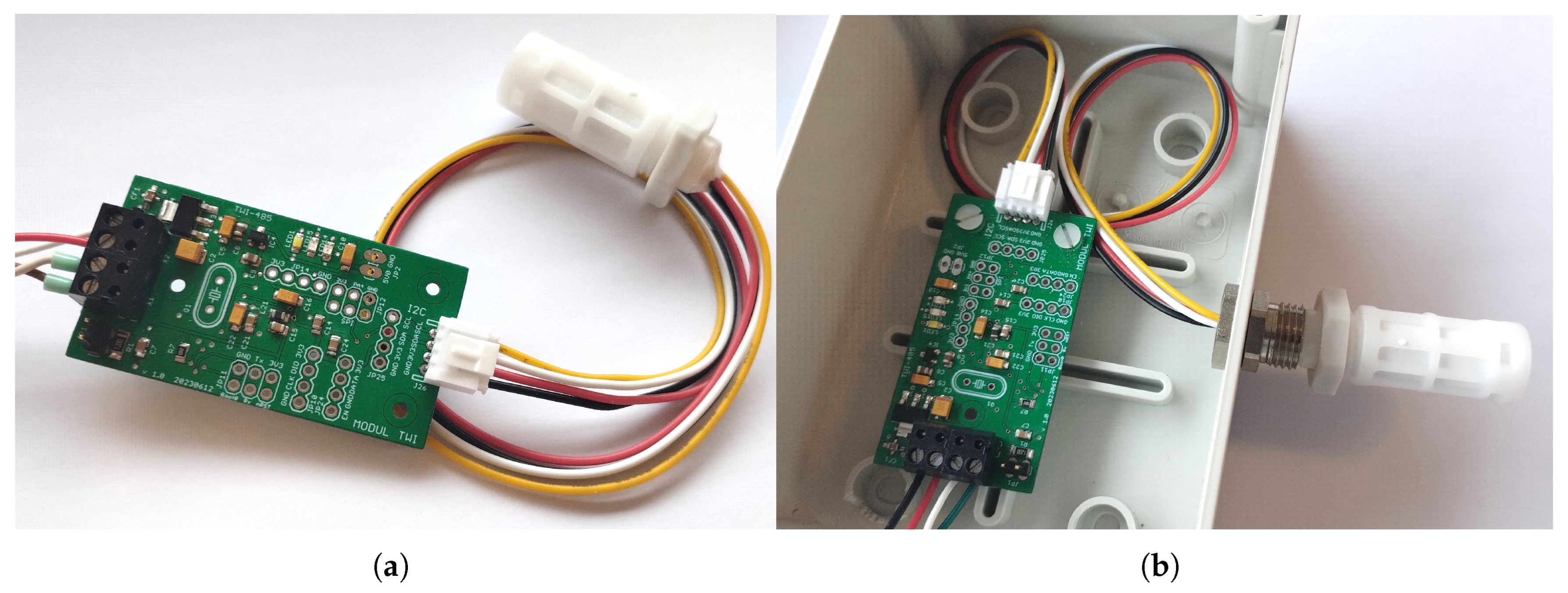

2. Materials and Methods

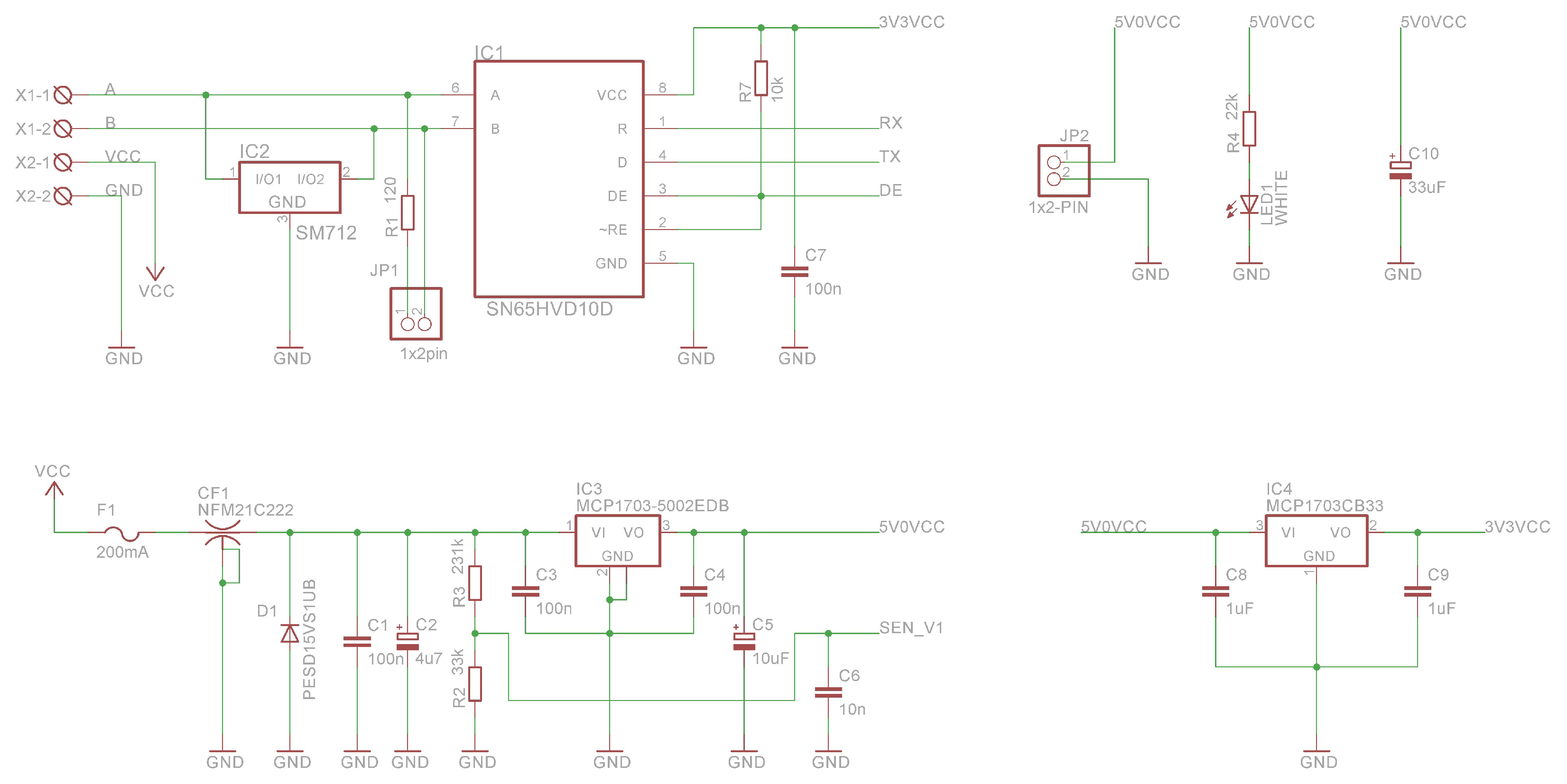

2.1. Power Unit

2.2. RS-485 to Serial Circuitry

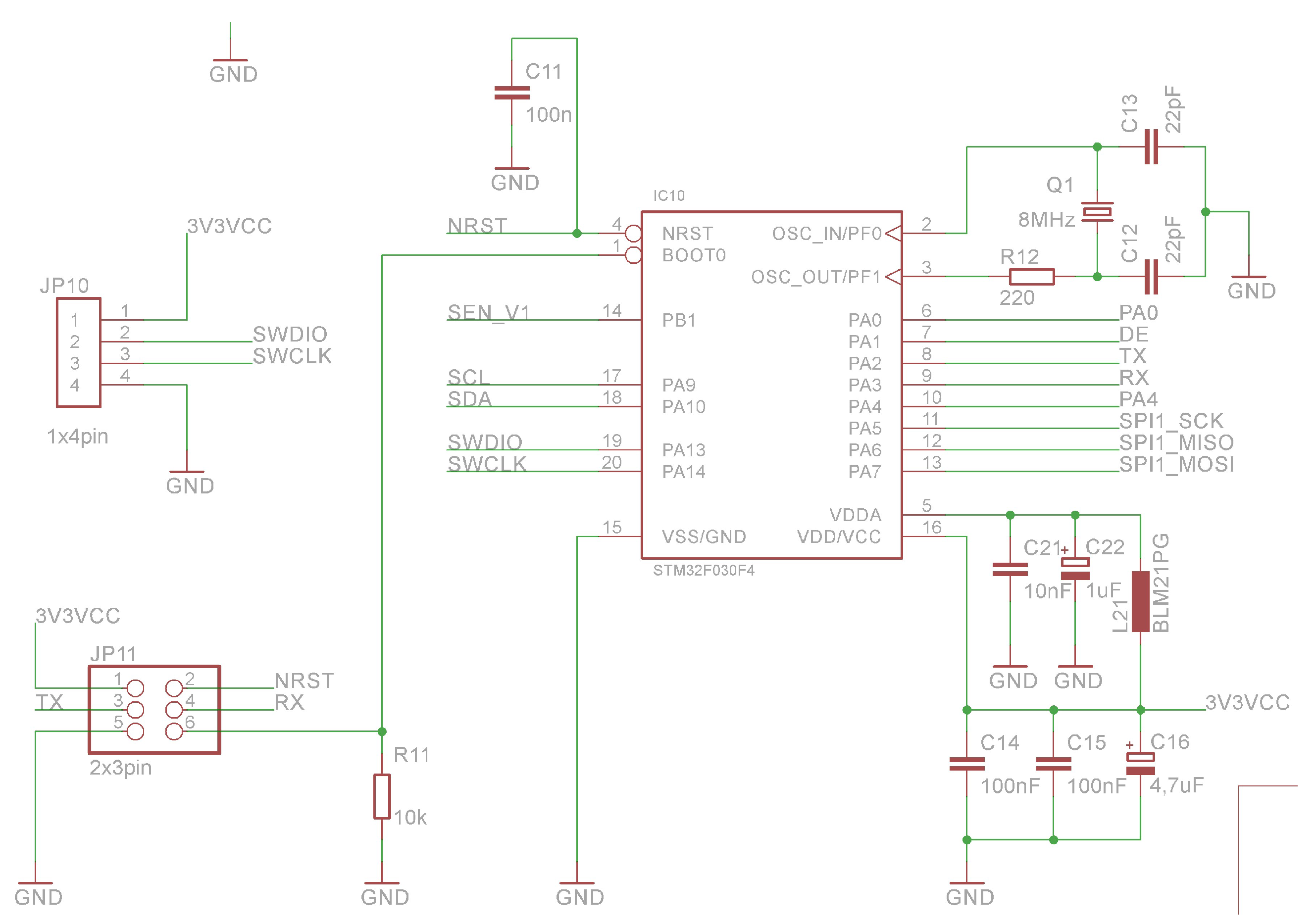

2.3. Microcontroller

2.4. LED Status Lights

- White LED indicates the presence of the supply voltage.

- Blue LED signals activity on the communication line.

- Orange LED is used to indicate fault conditions or specific operational states of the microcontroller, such as a firmware update (flashing) in progress.

2.5. I2C Interface

- A dedicated JST 2.0 connector, featuring compact dimensions, which is particularly suitable for permanent or production-level integrations.

- A standard 2.54 mm pitch pin header, which allows for flexible and rapid testing or swapping of sensors during development and debugging.

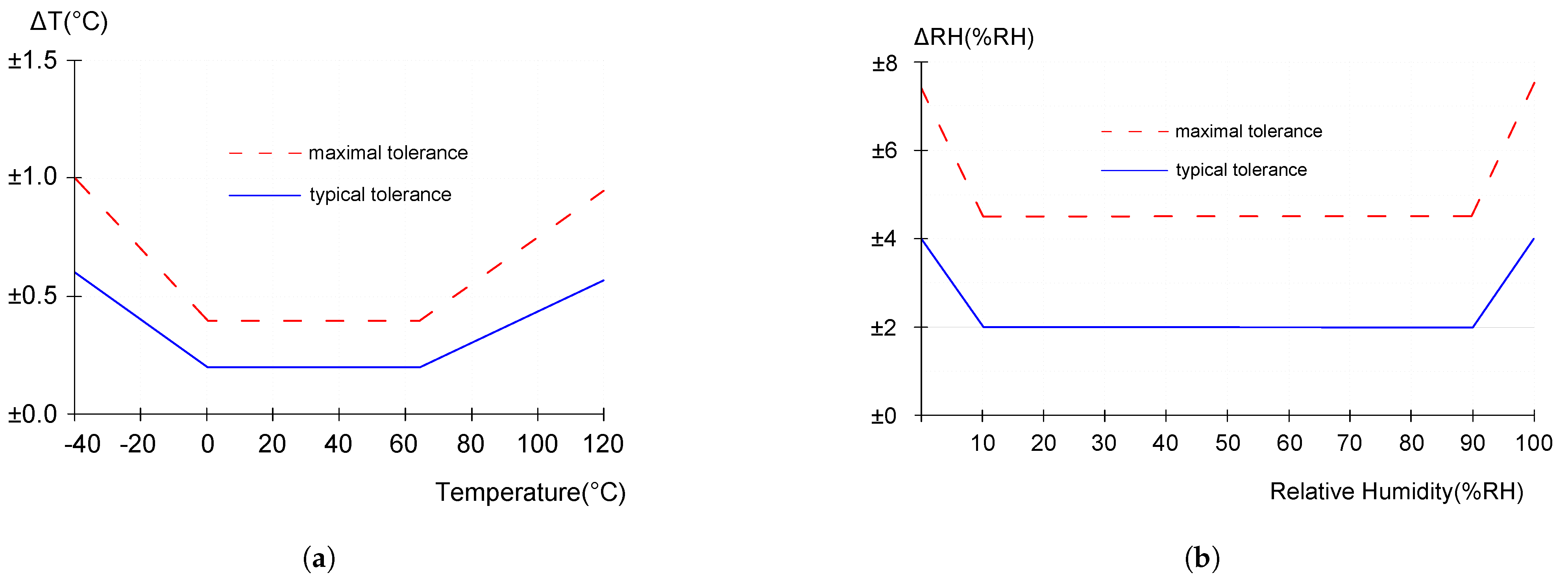

2.6. Sensor

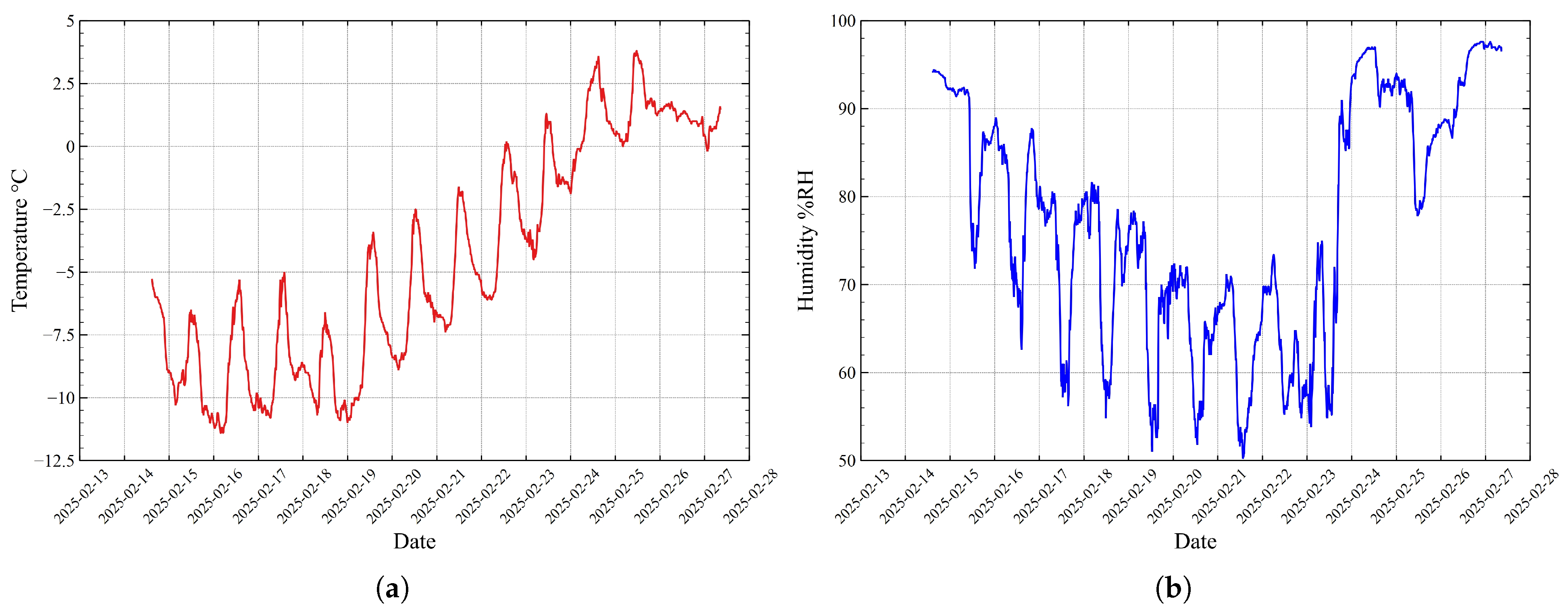

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Oladimeji, D.; Gupta, K.; Kose, N.A.; Gundogan, K.; Ge, L.; Liang, F. Smart Transportation: An Overview of Technologies and Applications. Sensors 2023, 23, 3880. [Google Scholar] [CrossRef]

- Musa, A.A.; Malami, S.I.; Alanazi, F.; Ounaies, W.; Alshammari, M.A.; Haruna, S.I. Sustainable Traffic Manage-ment for Smart Cities Using Internet-of-Things-Oriented Intelligent Transportation Systems (ITS): Challen-ges and Recommendations. Sustainability 2023, 15, 9859. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. AI-enhanced fault-tolerant control and security in transportation and logistics systems: Addressing physical and cyber threats. Complex Eng. Syst. 2024, 4, 17. [Google Scholar] [CrossRef]

- Roșca, C.M.; Stancu, A.; Gortoescu, I.A. Advanced Sensor Integration and AI Architectures for Next-Generation Traffic Navigation. Appl. Sci. 2025, 15, 4301. [Google Scholar] [CrossRef]

- Micko, K.; Papcun, P.; Zolotova, I. Review of IoT Sensor Systems Used for Monitoring the Road Infrastructure. Sensors 2023, 23, 4469. [Google Scholar] [CrossRef] [PubMed]

- Kubina, M.; Bubelíny, O. The Smart City Concept to Incentivize Public Transport in the v4 Countries in the Post-COVID-19 Period. Commun.-Sci. Lett. Univ. Zilina 2022, 24, 15–23. [Google Scholar] [CrossRef]

- Khanmohamadi, M.; Guerrieri, M. Advanced Sensor Technologies in CAVs for Traditional and Smart Road Condition Monitoring: A Review. Sustainability 2024, 16, 8336. [Google Scholar] [CrossRef]

- Hassan, M.U.; Steinnes, O.M.H.; Gustafsson, E.G.; Løken, S.; Hameed, I.A. Predictive Maintenance of Norwegian Road Network Using Deep Learning Models. Sensors 2023, 23, 2935. [Google Scholar] [CrossRef]

- Mohsen, B.M. AI-Driven Optimization of Urban Logistics in Smart Cities: Integrating Autonomous Vehicles and IoT for Efficient Delivery Systems. Sustainability 2024, 16, 11265. [Google Scholar] [CrossRef]

- Căpriță, H.V.; Selişteanu, D. Improvement of Automotive Sensors by Migrating AUTOSAR End-to-End Communication Protection Library into Hardware. Elektron. Ir Elektrotechnika 2022, 28, 34. [Google Scholar] [CrossRef]

- Xue, X.; Hui, J.; Chen, L.; Liang, M.; Yao, Z. Monitoring the Internal Conditions of Road Structures by Smart Sensing and In Situ Monitoring Technology: A Review. Appl. Sci. 2025, 15, 3945. [Google Scholar] [CrossRef]

- Fan, Z.; Pang, C.; Tang, H. Sensors on Internet of Things Systems for the Sustainable Development of Smart Cities: A Systematic Literature Review. Sensors 2024, 24, 2074. [Google Scholar] [CrossRef]

- Liu, L.; Guo, X.; Liu, W.; Lee, C. Recent Progress in the Energy Harvesting Technology—From Self-Powered Sensors to Self-Sustained IoT, and New Applications. Nanomaterials 2021, 11, 2975. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.; Ha, Q.P. Wireless Sensor Network Dependable Monitoring for Urban Air Quality. IEEE Access 2022, 10, 40051. [Google Scholar] [CrossRef]

- Šećerov, I.; Popov, S.; Sladojević, S.; Milin, D.; Lazić, L.; Milošević, D.; Arsenović, D.; Savić, S. Achieving High Reliability in Data Acquisition. Remote Sens. 2021, 13, 345. [Google Scholar] [CrossRef]

- Xu, K. Silicon electro-optic micro-modulator fabricated in standard CMOS technology as components for all silicon monolithic integrated optoelectronic systems. J. Micromech. Microeng. 2021, 31, 054001. [Google Scholar] [CrossRef]

- Sufyan, M. I2C vs SPI vs UART: A Comprehensive Comparison. 2025. Available online: https://www.wevolver.com/article/i2c-vs-uart (accessed on 11 September 2025).

- Chen, C.; Huang, S. Analysis and Comparison of UART, SPI and I2C. In Proceedings of the 2023 IEEE 2nd International Conference on Electrical Engineering, Big Data and Algorithms (EEBDA), Changchun, China, 24–26 February 2023; p. 272. [Google Scholar] [CrossRef]

- Ďuďák, J.; Gašpar, G. Design and Implementation of Sensory Solutions for Industrial Environment; Springer Nature: Berlin/Heidelberg, Germany, 2023. [Google Scholar] [CrossRef]

- Gaspar, G.; Dudak, J.; Mikolajcikova, M.; Gurin, D. Proposal of a Skin Temperature Measurement System Based on Digital Thermometers. IEEE Access 2023, 11, 25050–25062. [Google Scholar] [CrossRef]

- Gašpar, G.e.a. IoT-ready data logger with simple file system and data logging method, 2024. SK Utility model 10005.

- Kwon, S.W.; Jeong, S.G.; Lee, J.; Koo, Y.S. Design of Destruction Protection and Sustainability Low-Dropout Regulator Using an Electrostatic Discharge Protection Circuit. Sustainability 2023, 15, 10126. [Google Scholar] [CrossRef]

- Dey, S.; Mallik, A. A Comprehensive Review of EMI Filter Network Architectures: Synthesis, Optimization and Comparison. Electronics 2021, 10, 1919. [Google Scholar] [CrossRef]

- Chen, W.C.; Ker, M. Surge protection design with surge-to-digital converter for microelectronic circuits and systems. Microelectron. Reliab. 2018, 88, 2–5. [Google Scholar] [CrossRef]

- SENSIRION AG. Datasheet SHT3x-DIS. Ver. 7. 2022. Available online: https://sensirion.com/media/documents/213E6A3B/63A5A569/Datasheet_SHT3x_DIS.pdf (accessed on 11 September 2025).

- STM32F0x1—Arm Cortex-M0 Cost-Effective Microcontrollers (MCU)—STMicroelectronics. Available online: https://www.st.com/en/microcontrollers-microprocessors/stm32f0x1.html (accessed on 11 September 2025).

- COMMU Module Extend RS485/TTL CAN/I2C Port—shop.m5stack.com. Available online: https://shop.m5stack.com/products/commu-module (accessed on 5 August 2025).

- RS485 I2C Converter—I2C Master|Coptonix—coptonix.com. Available online: https://coptonix.com/en/products/rs485-i2c-adapter-master/ (accessed on 5 August 2025).

- TIDA-01281 Reference Design|TI.com—ti.com. Available online: https://www.ti.com/tool/TIDA-01281 (accessed on 5 August 2025).

| Parameter | I2C | RS485 |

|---|---|---|

| Communication type | Serial, synchronous, two-wire | Serial, asynchronous, differential (two wires) |

| Transfer rate | 100 kHz (standard), up to 5 MHz (ultra-fast mode) | Up to 10 Mbit/s (short bus) |

| Maximum distance | ∼1 m | Up to 1200 m (at 100 kbps) |

| Number of devices on the bus | Up to 127 devices (at 7-bit address) | Up to 32 (without repeater), more with repeaters |

| Network topology | Star or bus | Bus (multipoint) |

| Addressing | Yes, 7- or 10-bit addresses | Not native—depends on higher layer protocol (e.g., Modbus) |

| Interference immunity | Low (sensitivity to electromagnetic interference) | High (differential transmission reduces the impact of interference) |

| Shared wires | Yes (SDA and SCL) | No—separate bus, not dependent on shared clock signal |

| Cabling intensity | Low—only 2 wires to communicate | Higher—requires separate communication link |

| Power consumption with more devices | Higher—continuous monitoring of shared bus | Lower—devices can be addressed selectively |

| Address management and conflicts | Potential conflicts—each sensor must have a unique address | Address management depends on higher layer protocol (e.g., Modbus) |

| Robustness in case of device failure | Low—failure of one device can affect others | High—failure of one node does not affect the rest of the network |

| Suitability for islanded systems (e.g., IoT) | High—low power, simplicity | Limited—higher energy and communication interface requirements |

| Possibility to integrate with other protocols | Limited | High—often used with Modbus, BACnet, DMX, and others |

| Parameter | Value |

|---|---|

| Supply Voltage | 2.15 V to 5.5 V |

| Temperature Measurement Range | −40 °C to +125 °C |

| Relative Humidity Measurement Range | 0% to 100% RH V |

| Measurement Accuracy | ±2% RH over the 20% to 80% RH range ±0.2 °C over the 0 °C to 90 °C range |

| Measurement Resolution | 0.01% RH, 0.01 °C |

| Communication Interface | I2C, including support for CRC (Cyclic Redundancy Check) to ensure data transmission integrity |

| I2C Address Options | 0x44 or 0x45 (selectable) |

| Part | 5.5–12 VDC | 7.5–24 VDC |

|---|---|---|

| CF1 | NFM21PC104 | NFM21PC222 |

| F1 | SN020-30 | SN020-30 |

| D1 | PESD15VS1UB | PESD24VS1UB |

| IC1 | MCP1703-5002 | UA78M05DCY |

| Solution | Type/Usage | Interfaces | Adaptability | Key Features | Limitations |

|---|---|---|---|---|---|

| Proposed solution | Universal module | I2C, RS-485 | Very high (open firmware on STM32, open hardware) | Full control over firmware, hardware protections, optimization for specific applications, low component costs. | Requires development and testing, lacks industrial certification. |

| M5Stack COMMU [27] | Commercial module | I2C, CAN, RS-485, TTL | Low (module designed for the M5Stack ecosystem) | Simple integration, small size, multiple interfaces in one. | Limited customization options, more suited for prototyping than industrial deployment. |

| Coptonix RS485 I2C Adapter [28] | Industrial converter | I2C, RS-485 | Medium (configuration via ASCII commands) | Industrial standard, I2C level shifter, adjustable address via DIP switches. | Higher price, limited firmware flexibility, focused only on conversion. |

| TI TIDA-01281 [29] | Reference design | Isolated I2C, CAN, RS-485 | High (reference design for further development) | Fully isolated interfaces, complies with industry standards (IEC), robust solution for demanding environments. | Requires implementation and production, and has a higher design complexity. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sládek, I.; Skovajsa, M.; Kuchár, P.; Kafková, J.; Šedivý, Š.; Gašpar, G. A Universal I2C-to-RS-485 Module for Industrial Sensing. Electronics 2025, 14, 3675. https://doi.org/10.3390/electronics14183675

Sládek I, Skovajsa M, Kuchár P, Kafková J, Šedivý Š, Gašpar G. A Universal I2C-to-RS-485 Module for Industrial Sensing. Electronics. 2025; 14(18):3675. https://doi.org/10.3390/electronics14183675

Chicago/Turabian StyleSládek, Ivan, Martin Skovajsa, Pavol Kuchár, Júlia Kafková, Štefan Šedivý, and Gabriel Gašpar. 2025. "A Universal I2C-to-RS-485 Module for Industrial Sensing" Electronics 14, no. 18: 3675. https://doi.org/10.3390/electronics14183675

APA StyleSládek, I., Skovajsa, M., Kuchár, P., Kafková, J., Šedivý, Š., & Gašpar, G. (2025). A Universal I2C-to-RS-485 Module for Industrial Sensing. Electronics, 14(18), 3675. https://doi.org/10.3390/electronics14183675