A Data-Centric Framework for Implementing Artificial Intelligence in Smart Manufacturing

Abstract

1. Introduction

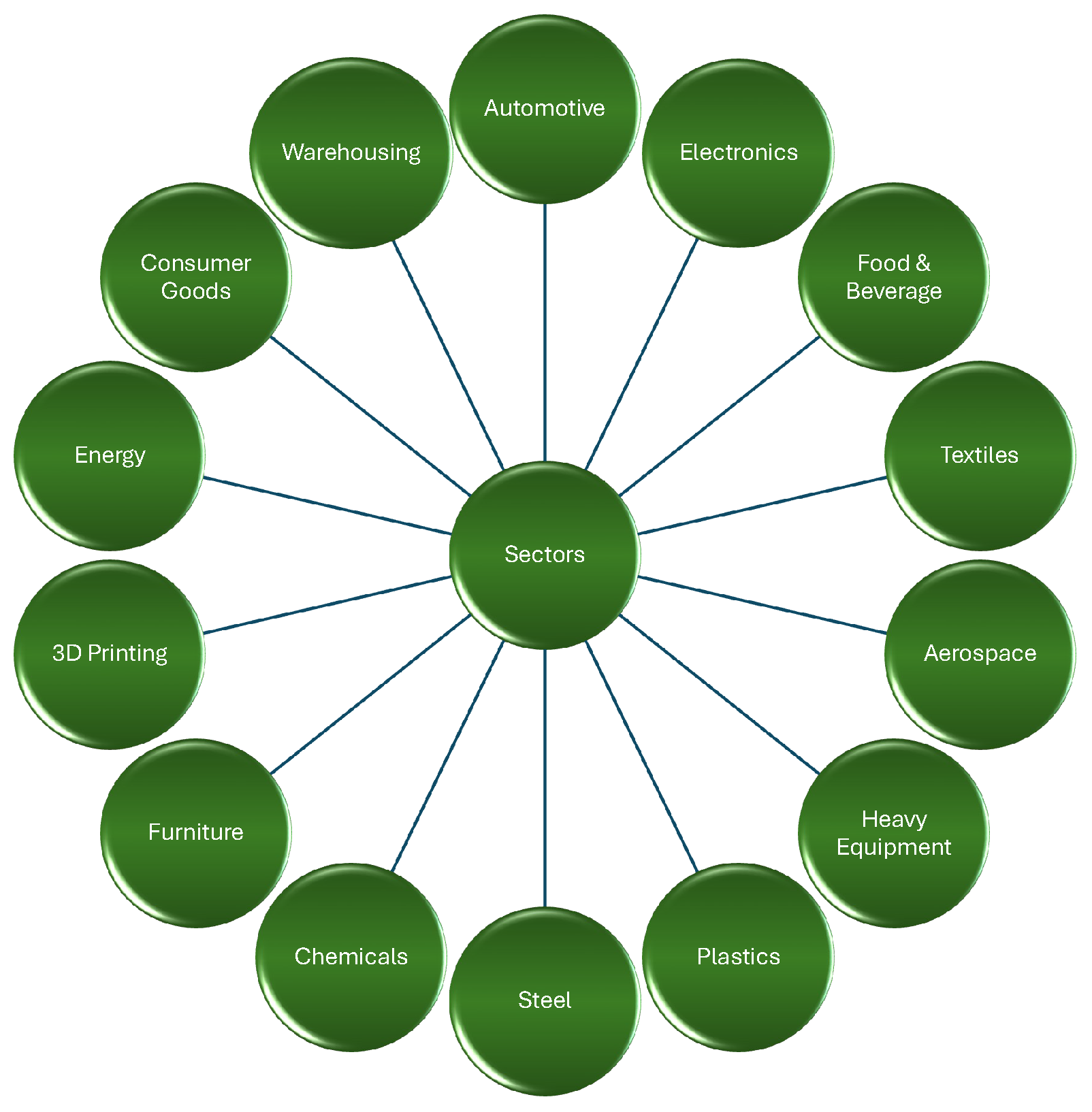

2. Sectors in Manufacturing

3. The Big Challenge of Massive Data in Manufacturing

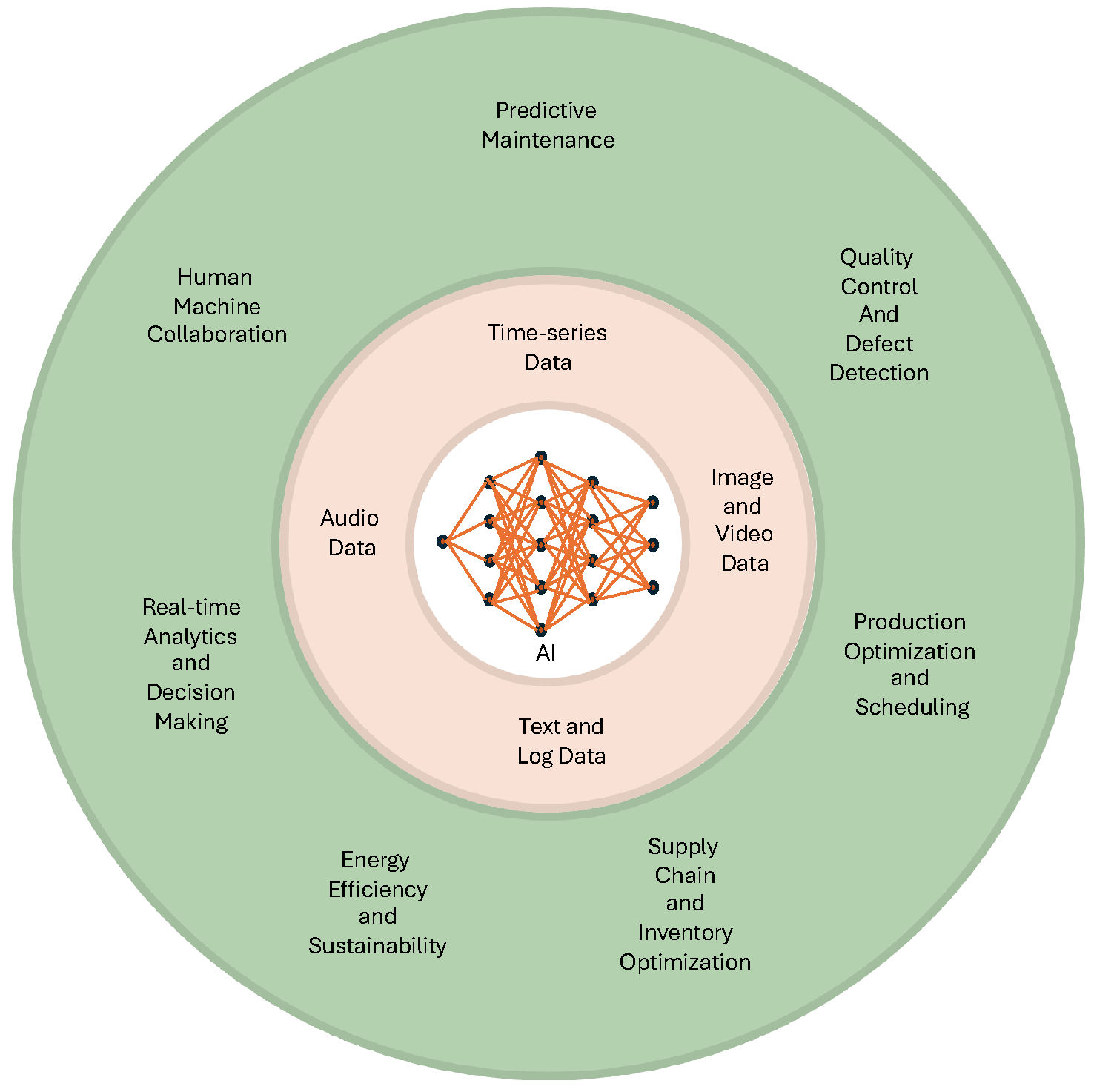

4. Data Modalities in Manufacturing

4.1. Sensor Data (Time-Series Data)

4.2. Image and Video Data (Vision Data)

4.3. Textual and Log Data

4.4. Audio Data

5. AI-Powered Use Cases for Smart Manufacturing

5.1. Predictive Maintenance and Equipment Health Monitoring

5.2. Quality Control and Defect Detection

5.3. Production Optimization and Scheduling

5.4. Supply Chain and Inventory Optimization

5.5. Energy Efficiency and Sustainability

5.6. Real-Time Analytics and Decision-Making

5.7. Human–Machine Collaboration

6. Data-Centric Framework for Intelligent AI Systems in Manufacturing

6.1. Data Acquisition Layer

6.2. Data Storage Layer

6.3. Data Processing Layer

6.4. AI Model Development, Training, and Deployment

6.5. Data Security and Privacy Layer

6.6. Data Visualization and Decision-Making Layer

6.7. Continuous Improvement and Feedback Loop

7. Discussion

8. Conclusions

Funding

Conflicts of Interest

References

- Kim, S.W.; Kong, J.H.; Lee, S.W.; Lee, S. Recent Advances of Artificial Intelligence in Manufacturing Industrial Sectors: A Review. Int. J. Precis. Eng. Manuf. 2022, 23, 111–129. [Google Scholar] [CrossRef]

- Arinez, J.F.; Chang, Q.; Gao, R.X.; Xu, C.; Zhang, J. Artificial intelligence in advanced manufacturing: Current status and future outlook. J. Manuf. Sci. Eng. 2020, 142, 110804. [Google Scholar] [CrossRef]

- Zeba, G.; Dabić, M.; Čičak, M.; Daim, T.; Yalcin, H. Technology mining: Artificial intelligence in manufacturing. Technol. Forecast. Soc. Change 2021, 171, 120971. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart Manufacturing and Intelligent Manufacturing: A Comparative Review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Chien, C.-F.; Dauzère-Pérès, S.; Huh, W.T.; Jang, Y.J.; Morrison, J.R. Artificial intelligence in manufacturing and logistics systems: Algorithms, applications, and case studies. Int. J. Prod. Res. 2020, 58, 2730–2731. [Google Scholar] [CrossRef]

- Buchmeister, B.; Palcic, I.; Ojstersek, R. Artificial intelligence in manufacturing companies and broader: An overview. In DAAAM International Scientific Book; DAAAM International: Vienna, Austria, 2019; pp. 81–98. [Google Scholar]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar] [CrossRef]

- Trakadas, P.; Simoens, P.; Gkonis, P.; Sarakis, L.; Angelopoulos, A.; Ramallo-González, A.P.; Skarmeta, A.; Trochoutsos, C.; Calvo, D.; Pariente, T.; et al. An Artificial Intelligence-Based Collaboration Approach in Industrial IoT Manufacturing: Key Concepts, Architectural Extensions and Potential Applications. Sensors 2020, 20, 19. [Google Scholar] [CrossRef]

- Plathottam, S.J.; Rzonca, A.; Lakhnori, R.; Iloeje, C.O. A review of artificial intelligence applications in manufacturing operations. J. Adv. Manuf. Process. 2023, 5, e10159. [Google Scholar] [CrossRef]

- Ding, H.; Gao, R.X.; Isaksson, A.J.; Landers, R.G.; Parisini, T.; Yuan, Y. State of AI-based monitoring in smart manufacturing and introduction to focused section. IEEE/ASME Trans. Mechatron. 2020, 25, 2143–2154. [Google Scholar] [CrossRef]

- AlMangour, B. (Ed.) Handbook of Smart Manufacturing: Forecasting the Future of Industry 4.0; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Chatterjee, S.; Rana, N.P.; Dwivedi, Y.K.; Baabdullah, A.M. Understanding AI adoption in manufacturing and production firms using an integrated TAM-TOE model. Technol. Forecast. Soc. Change 2021, 170, 120880. [Google Scholar] [CrossRef]

- Kumar, S.P. State of The Art-Intense Review on Artificial Intelligence Systems Application in Process Planning and Manufacturing. Eng. Appl. Artif. Intell. 2017, 65, 294–329. [Google Scholar] [CrossRef]

- Lu, Y.; Witherell, P.; Jones, A. Standard connections for IIoT empowered smart manufacturing. Manuf. Lett. 2020, 26, 17–20. [Google Scholar] [CrossRef] [PubMed]

- Boddapati, V.N. Optimizing Production Efficiency in Manufacturing Using Big Data and AI/ML. 2025. Available online: https://papers.ssrn.com/sol3/Delivery.cfm?abstractid=5101316 (accessed on 17 August 2025).

- Wang, J.; Gao, R.X. Innovative smart scheduling and predictive maintenance techniques. In Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology; Elsevier: Amsterdam, The Netherlands, 2022; pp. 181–207. [Google Scholar]

- Markatos, N.G.; Mousavi, A. Manufacturing quality assessment in the industry 4.0 era: A review. Total Qual. Manag. Bus. Excell. 2023, 34, 1655–1681. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Artificial intelligence applications for industry 4.0: A literature-based study. J. Ind. Integr. Manag. 2022, 7, 83–111. [Google Scholar] [CrossRef]

- Nasr, E.S.A.; Kamrani, A.K. Intelligent Design and Manufacturing. In Collaborative Engineering: Theory and Practice; Kamrani, A.K., Nasr, E.S.A., Eds.; Springer: Boston, MA, USA, 2008; pp. 103–125. [Google Scholar]

- Rao, M.; Wang, Q.; Cha, J. Integrated Distributed Intelligent Systems in Manufacturing, 1st ed.; Springer Publishing Company: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Katz, Y. Manufacturing an Artificial Intelligence Revolution. 2017. Available online: https://ssrn.com/abstract=3078224 (accessed on 17 August 2025).

- Simone, V.D.; Pasquale, V.D.; Miranda, S. An overview on the use of AI/ML in Manufacturing MSMEs: Solved issues, limits, and challenges. Procedia Comput. Sci. 2023, 217, 1820–1829. [Google Scholar] [CrossRef]

- Zdravković, M.; Panetto, H.; Weichhart, G. AI-enabled enterprise information systems for manufacturing. Enterp. Inf. Syst. 2022, 16, 668–720. [Google Scholar] [CrossRef]

- Li, B.-H.; Hou, B.-C.; Yu, W.-T.; Lu, X.-B.; Yang, C.-W. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Hrnjica, B.; Softic, S. Explainable AI in manufacturing: A predictive maintenance case study. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Novi Sad, Serbia, 30 August–3 September 2020; pp. 66–73. [Google Scholar]

- Xu, J.; Kovatsch, M.; Mattern, D.; Mazza, F.; Harasic, M.; Paschke, A.; Lucia, S. A review on AI for smart manufacturing: Deep learning challenges and solutions. Appl. Sci. 2022, 12, 8239. [Google Scholar] [CrossRef]

- Ullrich, K.; von Elling, M.; Gutzeit, K.; Dix, M.; Weigold, M.; Aurich, J.C.; Wertheim, R.; Jawahir, I.S.; Ghadbeigi, H. AI-based optimisation of total machining performance: A review. CIRP J. Manuf. Sci. Technol. 2024, 50, 40–54. [Google Scholar] [CrossRef]

- Wang, L.; Nee, A.Y.C.; Nee, A.Y.C.; Wang, L. Collaborative Design and Planning for Digital Manufacturing; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Schöggl, J.-P.; Rusch, M.; Stumpf, L.; Baumgartner, R.J. Implementation of digital technologies for a circular economy and sustainability management in the manufacturing sector. Sustain. Prod. Consum. 2023, 35, 401–420. [Google Scholar] [CrossRef]

- Sharma, P.; Shah, J.; Patel, R. Artificial intelligence framework for MSME sectors with focus on design and manufacturing industries. Mater. Today Proc. 2022, 62, 6962–6966. [Google Scholar] [CrossRef]

- Wan, J.; Li, X.; Dai, H.-N.; Kusiak, A.; Martinez-Garcia, M.; Li, D. Artificial-intelligence-driven customized manufacturing factory: Key technologies, applications, and challenges. Proc. IEEE 2020, 109, 377–398. [Google Scholar] [CrossRef]

- Kutz, J.; Neuhüttler, J.; Spilski, J.; Lachmann, T. Implementation of AI Technologies in manufacturing-success factors and challenges. In The Human Side of Service Engineerin, Proceedings of the 13th International Conference on Applied Human Factors and Ergonomics (AHFE 2022), New York, NY, USA, 24–28 July 2022; AHFE International: Orlando, FL, USA, 2022; pp. 24–28. [Google Scholar]

- Sahu, C.K.; Young, C.; Rai, R. Artificial intelligence (AI) in augmented reality (AR)-assisted manufacturing applications: A review. Int. J. Prod. Res. 2020, 59, 4903–4959. [Google Scholar] [CrossRef]

- Fahle, S.; Prinz, C.; Kuhlenkötter, B. Systematic review on machine learning (ML) methods for manufacturing processes–Identifying artificial intelligence (AI) methods for field application. Procedia CIRP 2020, 93, 413–418. [Google Scholar] [CrossRef]

- Rai, R.; Tiwari, M.K.; Ivanov, D.; Dolgui, A. Machine learning in manufacturing and industry 4.0 applications. Int. J. Prod. Res. 2021, 59, 4773–4778. [Google Scholar] [CrossRef]

- Rashid, A.; Rasheed, R. A Paradigm for Measuring Sustainable Performance Through Big Data Analytics–Artificial Intelligence in Manufacturing Firms. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Rizvi, A.T.; Haleem, A.; Bahl, S.; Javaid, M. Artificial intelligence (AI) and its applications in Indian manufacturing: A review. In Current Advances in Mechanical Engineering: Select Proceedings of ICRAMERD 2020; Springer: Berlin/Heidelberg, Germany, 2021; pp. 825–835. [Google Scholar]

- Sahoo, S.; Lo, C.-Y. Smart manufacturing powered by recent technological advancements: A review. J. Manuf. Syst. 2022, 64, 236–250. [Google Scholar] [CrossRef]

- Lazaroiu, G.; Androniceanu, A.; Grecu, I.; Grecu, G.; Negurita, O. Artificial intelligence-based decision-making algorithms, Internet of Things sensing networks, and sustainable cyber-physical management systems in big data-driven cognitive manufacturing. Oeconomia Copernic. 2022, 13, 1047–1080. [Google Scholar] [CrossRef]

- Akinsolu, M.O. Applied artificial intelligence in manufacturing and industrial production systems: PEST considerations for engineering managers. IEEE Eng. Manag. Rev. 2022, 51, 52–62. [Google Scholar] [CrossRef]

- Mao, S.; Wang, B.; Tang, Y.; Qian, F. Opportunities and challenges of artificial intelligence for green manufacturing in the process industry. Engineering 2019, 5, 995–1002. [Google Scholar] [CrossRef]

- Bukkapatnam, S.T.S.; Afrin, K.; Dave, D.; Kumara, S.R.T. Machine learning and AI for long-term fault prognosis in complex manufacturing systems. CIRP Ann. 2019, 68, 459–462. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Huang, W.; Li, Y. Survey on artificial intelligence for additive manufacturing. In Proceedings of the 2017 23rd International Conference on Automation and Computing (ICAC), Huddersfield, UK, 7–8 September 2017; pp. 1–6. [Google Scholar]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.D.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Xie, J.; Sun, L.; Zhao, Y.F. On the Data Quality and Imbalance in Machine Learning-based Design and Manufacturing‚ ÄîA Systematic Review. Engineering 2025, 45, 105–131. [Google Scholar] [CrossRef]

- Gmeiner, F.; Yang, H.; Yao, L.; Holstein, K.; Martelaro, N. Exploring Challenges and Opportunities to Support Designers in Learning to Co-create with AI-based Manufacturing Design Tools. In Proceedings of the 2023 CHI Conference on Human Factors in Computing Systems, Hamburg, Germany, 23–28 April 2023; pp. 1–20. [Google Scholar]

- Patel, D.; Sahu, C.K.; Rai, R. Security in modern manufacturing systems: Integrating blockchain in artificial intelligence-assisted manufacturing. Int. J. Prod. Res. 2024, 62, 1041–1071. [Google Scholar] [CrossRef]

- Aggour, K.S.; Gupta, V.K.; Ruscitto, D.; Ajdelsztajn, L.; Bian, X.; Brosnan, K.H.; Kumar, N.C.; Dheeradhada, V.; Hanlon, T.; Iyer, N.; et al. Artificial intelligence/machine learning in manufacturing and inspection: A GE perspective. MRS Bull. 2019, 44, 545–558. [Google Scholar] [CrossRef]

- Ciobota, N.D.; Gheorghe, G.I.; Despa, V. Additive Manufacturing as an Important Industry Player for the Next Decades. Sci. Bull. Valahia Univ.-Mater. Mech. 2019, 17, 68–71. [Google Scholar] [CrossRef]

- Luckow, A.; Kennedy, K.; Ziolkowski, M.; Djerekarov, E.; Cook, M.; Duffy, E.; Schleiss, M.; Vorster, B.; Weill, E.; Kulshrestha, A.; et al. Artificial intelligence and deep learning applications for automotive manufacturing. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 3144–3152. [Google Scholar]

- Demlehner, Q.; Schoemer, D.; Laumer, S. How can artificial intelligence enhance car manufacturing? A Delphi study-based identification and assessment of general use cases. Int. J. Inf. Manag. 2021, 58, 102317. [Google Scholar] [CrossRef]

- Syed, F.M.; Es, F.K. AI in Securing Pharma Manufacturing Systems Under GxP Compliance. Int. J. Mach. Learn. Res. Cybersecur. Artif. Intell. 2024, 15, 448–472. [Google Scholar]

- Rathore, A.S.; Nikita, S.; Thakur, G.; Mishra, S. Artificial intelligence and machine learning applications in biopharmaceutical manufacturing. Trends Biotechnol. 2023, 41, 497–510. [Google Scholar] [CrossRef]

- Chinnici, P.; Bacarella, S.; Chironi, S.; Naselli, V.; Ingrassia, M. How will artificial intelligence drive marketing in the beverage industry?—A bibliometric literature review. Future Foods 2025, 12, 100704. [Google Scholar] [CrossRef]

- Ding, H.; Tian, J.; Yu, W.; Wilson, D.I.; Young, B.R.; Cui, X.; Xin, X.; Wang, Z.; Li, W. The Application of Artificial Intelligence and Big Data in the Food Industry. Foods 2023, 12, 4511. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Jelil, R.A. Review of artificial intelligence applications in garment manufacturing. In Artificial Intelligence for Fashion Industry in the Big Data Era; Springer: Singapore, 2018; pp. 97–123. [Google Scholar]

- Li, C.; Li, J.; Li, Y.; He, L.; Fu, X.; Chen, J. Fabric defect detection in textile manufacturing: A survey of the state of the art. Secur. Commun. Netw. 2021, 2021, 9948808. [Google Scholar] [CrossRef]

- Gao, M.; Sun, T.; Li, Y.; Zhang, Z.; Lee, C.; Choi, J. AI-enabled metal-polymer plain bearing based on the triboelectric principle. Adv. Funct. Mater. 2023, 33, 2304070. [Google Scholar] [CrossRef]

- Ruiz-Gonzalez, A. AI-Driven Chemical Design: Transforming the Sustainability of the Pharmaceutical Industry. Future Pharmacol. 2025, 5, 24. [Google Scholar] [CrossRef]

- Brunello, A.; Fabris, G.; Gasparetto, A.; Montanari, A.; Saccomanno, N.; Scalera, L. A survey on recent trends in robotics and artificial intelligence in the furniture industry. Robot. Comput.-Integr. Manuf. 2025, 93, 102920. [Google Scholar] [CrossRef]

- Hassan, M.; Misra, M.; Taylor, G.W.; Mohanty, A.K. A review of AI for optimization of 3D printing of sustainable polymers and composites. Compos. Part C Open Access 2024, 15, 100513. [Google Scholar] [CrossRef]

- Chen, M.; Liu, Q.; Huang, S.; Dang, C. Environmental cost control system of manufacturing enterprises using artificial intelligence based on value chain of circular economy. Enterp. Inf. Syst. 2020, 16, 1856422. [Google Scholar] [CrossRef]

- Munguía, J.; Lloveras, J.; Llorens, S.; Laoui, T. Development of an AI-based Rapid Manufacturing Advice System. Int. J. Prod. Res. 2010, 48, 2261–2278. [Google Scholar] [CrossRef]

- Matin, A.; Islam, M.R.; Wang, X.; Huo, H.; Xu, G. AIoT for sustainable manufacturing: Overview, challenges, and opportunities. Internet Things 2023, 24, 100901. [Google Scholar] [CrossRef]

- Kehayov, M.; Holder, L.; Koch, V. Application of artificial intelligence technology in the manufacturing process and purchasing and supply management. Procedia Comput. Sci. 2022, 200, 1209–1217. [Google Scholar] [CrossRef]

- Wuest, T.; Kusiak, A.; Dai, T.; Tayur, S. Impact of COVID-19 on Manufacturing and Supply Networks—The Case for AI-Inspired Digital Transformation. SSRN Electron. J. 2020. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Bryde, D.J.; Giannakis, M.; Foropon, C.; Roubaud, D.; Hazen, B.T. Big data analytics and artificial intelligence pathway to operational performance under the effects of entrepreneurial orientation and environmental dynamism: A study of manufacturing organisations. Int. J. Prod. Econ. 2020, 226, 107599. [Google Scholar] [CrossRef]

- Kasie, F.M.; Bright, G.; Walker, A. Decision support systems in manufacturing: A survey and future trends. J. Model. Manag. 2017, 12, 432–454. [Google Scholar] [CrossRef]

- Cochran, D.S.; Smith, J.; Mark, B.G.; Rauch, E. Information Model to Advance Explainable AI-Based Decision Support Systems in Manufacturing System Design. In Managing and Implementing the Digital Transformation; Springer: Berlin/Heidelberg, Germany, 2022; pp. 49–60. [Google Scholar]

- Hossain, M.A.; Agnihotri, R.; Rushan, M.R.I.; Rahman, M.S.; Sumi, S.F. Marketing analytics capability, artificial intelligence adoption, and firms’ competitive advantage: Evidence from the manufacturing industry. Ind. Mark. Manag. 2022, 106, 240–255. [Google Scholar] [CrossRef]

- Wang, K.-L.; Sun, T.-T.; Xu, R.-Y. The impact of artificial intelligence on total factor productivity: Empirical evidence from China’s manufacturing enterprises. Econ. Change Restruct. 2023, 56, 1113–1146. [Google Scholar] [CrossRef]

- Mudgal, P.; Wouhaybi, R.H. Edge AI in Manufacturing—A Data Centric Approach. Available online: https://www.researchgate.net/profile/Priyanka-Mudgal/publication/393146007_Edge_AI_in_Manufacturing_-_A_Data_Centric_Approach/links/6861b7ee07b3253fd1ca7e7a/Edge-AI-in-Manufacturing-A-Data-Centric-Approach.pdf (accessed on 17 August 2025).

- Pellegrinelli, S.; Pedrocchi, N.; Tosatti, L.M.; Fischer, A.; Tolio, T. Multi-robot spot-welding cells for car-body assembly: Design and motion planning. Robot. Comput.-Integr. Manuf. 2017, 44, 97–116. [Google Scholar] [CrossRef]

- Ojha, V.K.; Goyal, S.; Ch, M.; Kumar, A. A framework for data-driven decision making in advanced manufacturing systems: Development and implementation. Concurr. Eng. 2024, 32, 58–77. [Google Scholar] [CrossRef]

- Papulov, Z.; Gazova, A.; Sufliarsky, L. Implementation of Automation Technologies of Industry 4.0 in Automotive Manufacturing Companies. Procedia Comput. Sci. 2022, 200, 1488–1497. [Google Scholar] [CrossRef]

- Mueller, C.; Mezhuyev, V. AI models and methods in automotive manufacturing: A systematic literature review. In Recent Innovations in Artificial Intelligence and Smart Applications; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–25. [Google Scholar]

- Demlehner, Q.; Laumer, S. Shall We Use It or Not? Explaining the Adoption of Artificial Intelligence for Car Manufacturing Purposes. In Proceedings of the European Conference on Information Systems, Marrakech, Morocco, 15–17 June 2020. [Google Scholar]

- KPMG 2023 KPMG US Technology Survey Report. Available online: https://kpmg.com/us/en/articles/2023/us-tech-survey-2023.html (accessed on 6 August 2025).

- Li, W.; Kara, S. Methodology for Monitoring Manufacturing Environment by Using Wireless Sensor Networks (WSN) and the Internet of Things (IoT). Procedia CIRP 2017, 61, 323–328. [Google Scholar] [CrossRef]

- Gao, R.X.; Kruger, J.; Merklein, M.; Mohring, H.-C.; Vancza, J. Artificial Intelligence in manufacturing: State of the art, perspectives, and future directions. CIRP Ann. 2024, 73, 723–749. [Google Scholar] [CrossRef]

- de Soto, B.G.; Gonzalez-Moret, V.; Brilakis, I. Front matter and table of contents. In Proceedings of the 40th International Symposium on Automation and Robotics in Construction, Chennai, India, 5–7 July 2023. [Google Scholar]

- Zhao, S.; Liu, S.; Jiang, Y.; Zhao, B.; Lv, Y.; Zhang, J.; Wang, L.; Zhong, R.Y. Industrial Foundation Models (IFMs) for intelligent manufacturing: A systematic review. J. Manuf. Syst. 2025, 82, 420–448. [Google Scholar] [CrossRef]

- Park, K.S.; Kim, S.H. Artificial intelligence approaches to determination of CNC machining parameters in manufacturing: A review. Artif. Intell. Eng. 1998, 12, 127–134. [Google Scholar] [CrossRef]

- Kfner, T.; Uhlemann, T.H.-J.; Ziegler, B. Lean Data in Manufacturing Systems: Using Artificial Intelligence for Decentralized Data Reduction and Information Extraction. Procedia CIRP 2018, 72, 219–224. [Google Scholar] [CrossRef]

- He, F.; Yuan, L.; Mu, H.; Ros, M.; Ding, D.; Pan, Z.; Li, H. Research and application of artificial intelligence techniques for wire arc additive manufacturing: A state-of-the-art review. Robot. Comput.-Integr. Manuf. 2023, 82, 102525. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Su, X. Driving factors of digital transformation for manufacturing enterprises: A multi-case study from China. Int. J. Technol. Manag. 2021, 87, 229. [Google Scholar] [CrossRef]

- Gungor, O.; Rios, A.; Mudgal, P.; Ahuja, N.; Rosing, T. A Robust Framework for Evaluation of Unsupervised Time-Series Anomaly Detection. In International Conference on Pattern Recognition; Springer Nature: Cham, Switzerland, 2025; pp. 48–64. [Google Scholar]

- Liu, Y.; Yu, W.; Dillon, T.; Rahayu, W.; Li, M. Empowering IoT Predictive Maintenance Solutions with AI: A Distributed System for Manufacturing Plant-Wide Monitoring. IEEE Trans. Ind. Inform. 2022, 18, 1345–1354. [Google Scholar] [CrossRef]

- Mudgal, P.; Wouhaybi, R.H. Ensemble Method for System Failure Detection Using Large-Scale Telemetry Data. In Proceedings of the 2024 IEEE International Conference on Industry 4.0, Artificial Intelligence, and Communications Technology (IAICT), Bali, Indonesia, 4–6 July 2024; pp. 212–216. [Google Scholar]

- Alam, M.; Islam, R. AI-Based Predictive Maintenance for U.S. Manufacturing: Reducing Downtime and Increasing Productivity. Int. J. Adv. Eng. Technol. Innov. 2023, 1, 541–567. [Google Scholar]

- Papadimitriou, I.; Gialampoukidis, I.; Vrochidis, S.; Kompatsiaris, I. AI methods in materials design, discovery and manufacturing: A review. Comput. Mater. Sci. 2024, 235, 112793. [Google Scholar] [CrossRef]

- Bhavanasi, G.; Neven, D.; Arteaga, M.; Ditzel, S.; Dehaeck, S.; Bey-Temsamani, A. Enhanced Vision-Based Quality Inspection: A Multiview Artificial Intelligence Framework for Defect Detection. Sensors 2025, 25, 1703. [Google Scholar] [CrossRef]

- Fu, Y.; Xu, J. LogTransformer: Transforming IT System Logs Into Events Using Tree-Based Approach. IEEE Trans. Netw. Serv. Manag. 2024, 21, 3904–3918. [Google Scholar] [CrossRef]

- Huang, S.; Liu, Y.; Qi, J.; Shang, J.; Xiao, Z.; Fung, C.; Wu, Z.; Yang, H.; Luan, Z.; Qian, D. Gloss: Guiding Large Language Models to Answer Questions from System Logs. In Proceedings of the 2024 IEEE International Conference on Software Analysis, Evolution and Reengineering (SANER), Rovaniemi, Finland, 12–15 March 2024; pp. 91–101. [Google Scholar]

- Pan, J.; Wong, S.L.; Chia, X.W.; Yuan, Y. Enhancing Reasoning Capacity of SLM using Cognitive Enhancement. In Proceedings of the 2025 International Conference on Artificial Intelligence in Information and Communication (ICAIIC), Fukuoka, Japan, 18–21 February 2025; pp. 0366–0371. [Google Scholar]

- Zhong, A.; Mo, D.; Liu, G.; Liu, J.; Lu, Q.; Zhou, Q.; Wu, J.; Li, Q.; Wen, Q. Logparser-llm: Advancing efficient log parsing with large language models. In Proceedings of the 30th ACM SIGKDD Conference on Knowledge Discovery and Data Mining, Barcelona, Spain, 25–29 August 2024; pp. 4559–4570. [Google Scholar]

- Pan, J.; Liang, W.S.; Yidi, Y. Raglog: Log anomaly detection using retrieval augmented generation. In Proceedings of the 2024 IEEE World Forum on Public Safety Technology (WFPST), Herndon, VA, USA, 14–15 May 2024; pp. 169–174. [Google Scholar]

- Jiang, Z.; Liu, J.; Chen, Z.; Li, Y.; Huang, J.; Huo, Y.; He, P.; Gu, J.; Lyu, M.R. Lilac: Log parsing using llms with adaptive parsing cache. Proc. ACM Softw. Eng. 2024, 1, 137–160. [Google Scholar] [CrossRef]

- Mudgal, P.; Wouhaybi, R. An Assessment of ChatGPT on Log Data. In AI-Generated Content; Springer Nature: Singapore, 2024; pp. 148–169. [Google Scholar]

- Mudgal, P.; Arbab, B.; Kumar, S.S. CrashEventLLM: Predicting System Crashes with Large Language Models. In Proceedings of the 2024 International Conference on Information Technology and Computing (ICITCOM), Yogyakarta, Indonesia, 7–8 August 2024; pp. 72–76. [Google Scholar] [CrossRef]

- Ramachandran, S.; Agrahari, R.; Mudgal, P.; Bhilwaria, H.; Long, G.; Kumar, A. Automated log classification using deep learning. Procedia Comput. Sci. 2023, 218, 1722–1732. [Google Scholar] [CrossRef]

- Astekin, M.; Hort, M.; Moonen, L. An exploratory study on how non-determinism in large language models affects log parsing. In Proceedings of the ACM/IEEE 2nd International Workshop on Interpretability, Robustness, and Benchmarking in Neural Software Engineering, Lisbon, Portugal, 15 April 2024; pp. 13–18. [Google Scholar]

- Ye, T.; Peng, T.; Yang, L. Review on Sound-Based Industrial Predictive Maintenance: From Feature Engineering to Deep Learning. Mathematics 2025, 13, 1724. [Google Scholar] [CrossRef]

- Li, Z.; Liu, R.; Wu, D. Data-driven smart manufacturing: Tool wear monitoring with audio signals and machine learning. J. Manuf. Processes 2019, 48, 66–76. [Google Scholar] [CrossRef]

- Han, S.; Mannan, N.; Stein, D.C.; Pattipati, K.R.; Bollas, G.M. Classification and regression models of audio and vibration signals for machine state monitoring in precision machining systems. J. Manuf. Syst. 2021, 61, 45–53. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward new-generation intelligent manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, Y.; Wang, B.; Zang, J. Human–cyber–physical systems (HCPSs) in the context of new-generation intelligent manufacturing. Engineering 2019, 5, 624–636. [Google Scholar] [CrossRef]

- Teti, R.; Kumara, S.R.T. Intelligent computing methods for manufacturing systems. Cirp Ann. 1997, 46, 629–652. [Google Scholar] [CrossRef]

- Huang, S.H.; Zhang, H.-C. Neural-expert hybrid approach for intelligent manufacturing: A survey. Comput. Ind. 1995, 26, 107–126. [Google Scholar] [CrossRef]

- Escobar, C.A.; McGovern, M.E.; Morales-Menendez, R. Quality 4.0: A review of big data challenges in manufacturing. J. Intell. Manuf. 2021, 32, 2319–2334. [Google Scholar] [CrossRef]

- Meziane, F.; Vadera, S.; Kobbacy, K.; Proudlove, N. Intelligent systems in manufacturing: Current developments and future prospects. Integr. Manuf. Syst. 2000, 11, 218–238. [Google Scholar] [CrossRef]

- Wang, L. From intelligence science to intelligent manufacturing. Engineering 2019, 5, 615–618. [Google Scholar] [CrossRef]

- Tran, K.P. Artificial intelligence for smart manufacturing: Methods and applications. Sensors 2021, 21, 5584. [Google Scholar] [CrossRef] [PubMed]

- Zeid, A.; Sundaram, S.; Moghaddam, M.; Kamarthi, S.; Marion, T. Interoperability in smart manufacturing: Research challenges. Machines 2019, 7, 21. [Google Scholar] [CrossRef]

- Panigrahi, R.R.; Shrivastava, A.K.; Qureshi, K.M.; Mewada, B.G.; Alghamdi, S.Y.; Almakayeel, N.; Almuflih, A.S.; Qureshi, M.R.N. AI Chatbot Adoption in SMEs for Sustainable Manufacturing Supply Chain Performance: A Mediational Research in an Emerging Country. Sustainability 2023, 15, 13743. [Google Scholar] [CrossRef]

- Ayvaz, S.; Alpay, K. Predictive maintenance system for production lines in manufacturing: A machine learning approach using IoT data in real-time. Expert Syst. Appl. 2021, 173, 114598. [Google Scholar] [CrossRef]

- Bonada, F.; Echeverria, L.; Albin, X.D.; Varas, G.A. AI for Improving the Overall Equipment Efficiency in Manufacturing Industry. In New Trends in the Use of Artificial Intelligence for the Industry 4.0; IntechOpen: London, UK, 2020. [Google Scholar]

- Cohen, J.; Huan, X.; Ni, J. Shapley-based explainable AI for clustering applications in fault diagnosis and prognosis. J. Intell. Manuf. 2024, 35, 4071–4086. [Google Scholar] [CrossRef]

- Okpala, C.; Igbokwe, N.; Nwankwo, C.O. Revolutionizing Manufacturing: Harnessing the Power of Artificial Intelligence for Enhanced Efficiency and Innovation. Int. J. Eng. Res. Dev. 2023, 19, 18–25. [Google Scholar]

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial intelligence applications for increasing resource efficiency in manufacturing companies—A comprehensive review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- Kiangala, S.K.; Wang, Z. An effective adaptive customization framework for small manufacturing plants using extreme gradient boosting-XGBoost and random forest ensemble learning algorithms in an Industry 4.0 environment. Mach. Learn. Appl. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Nikita, S.; Thakur, G.; Jesubalan, N.G.; Kulkarni, A.; Yezhuvath, V.B.; Rathore, A.S. AI-ML applications in bioprocessing: ML as an enabler of real time quality prediction in continuous manufacturing of mAbs. Comput. Chem. Eng. 2022, 164, 107896. [Google Scholar] [CrossRef]

- Goldman, C.V.; Baltaxe, M.; Chakraborty, D.; Arinez, J. Explaining learning models in manufacturing processes. Procedia Comput. Sci. 2021, 180, 259–268. [Google Scholar] [CrossRef]

- Jin, Z.; Zhang, Z.; Gu, G.X. Automated real-time detection and prediction of interlayer imperfections in additive manufacturing processes using artificial intelligence. Adv. Intell. Syst. 2020, 2, 1900130. [Google Scholar] [CrossRef]

- Han, F.; Liu, S.; Zou, J.; Ai, Y.; Xu, C. Defect detection: Defect classification and localization for additive manufacturing using deep learning method. In Proceedings of the 2020 21st International Conference on Electronic Packaging Technology (ICEPT), Guangzhou, China, 12–15 August 2020; pp. 1–4. [Google Scholar]

- Mattera, G.; Nele, L.; Paolella, D.A. Monitoring and control the Wire Arc Additive Manufacturing process using artificial intelligence techniques: A review. J. Intell. Manuf. 2023, 35, 467–497. [Google Scholar] [CrossRef]

- Priore, P. Dynamic scheduling of manufacturing systems using machine learning: An updated review. Ai Edam 2014, 28, 83–97. [Google Scholar] [CrossRef]

- Renzi, C.; Leali, F.; Cavazzuti, M.; Andrisano, A.O. A review on artificial intelligence applications to the optimal design of dedicated and reconfigurable manufacturing systems. Int. J. Adv. Manuf. Technol. 2014, 72, 403–418. [Google Scholar] [CrossRef]

- Wong, W.; Chan, C. An Artificial Intelligence Method for Planning the Clothing Manufacturing Process. J. Text. Inst. 2001, 92, 168–178. [Google Scholar] [CrossRef]

- Subramaniyan, M.; Skoogh, A.; Bokrantz, J.; Sheikh, M.A.; Thürer, M.; Chang, Q. Artificial intelligence for throughput bottleneck analysis–State-of-the-art and future directions. J. Manuf. Syst. 2021, 60, 734–751. [Google Scholar] [CrossRef]

- Chen, C.-T.; Chen, S.-C.; Khan, A.; Lim, M.K.; Tseng, M.-L. Big data analytics-artificial intelligence and supply chain ambidexterity impacts on corporate image and green communication. Ind. Manag. Data Syst. 2024, 124, 2899–2918. [Google Scholar] [CrossRef]

- Hayhoe, T.; Podhorska, I.; Siekelova, A.; STEHEL, V. Sustainable manufacturing in industry 4.0: Cross-sector networks of multiple supply chains, cyber-physical production systems, and AI-driven decision-making. J. Self-Gov. Manag. Econ. 2019, 7, 31. [Google Scholar]

- Wang, X.; Kumar, V.; Kumari, A.; Kuzmin, E. Impact of digital technology on supply chain efficiency in manufacturing industry. In Digital Transformation in Industry: Digital Twins and New Business Models; Springer: Berlin/Heidelberg, Germany, 2022; pp. 347–371. [Google Scholar]

- Tian, H.; Zhao, L.; Yunfang, L.; Wang, W. Can enterprise green technology innovation performance achieve “corner overtaking” by using artificial intelligence?—Evidence from Chinese manufacturing enterprises. Technol. Forecast. Soc. Change 2023, 194, 122732. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Machine learning and artificial intelligence in CNC machine tools, a review. Sustain. Manuf. Serv. Econ. 2023, 2, 100009. [Google Scholar] [CrossRef]

- Jeong, H.; Fekete, T.; Bashyal, A.; Wicaksono, H. From Theory to Practice: Implementing Causal AI in Manufacturing for Sustainability. Procedia Comput. Sci. 2025, 253, 1495–1504. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Mroziński, A.; Macko, M. Green Energy Management in Manufacturing Based on Demand Prediction by Artificial Intelligence—A Review. Electronics 2024, 13, 3338. [Google Scholar] [CrossRef]

- Liu, J.; Qian, Y.; Yang, Y.; Yang, Z. Can Artificial Intelligence Improve the Energy Efficiency of Manufacturing Companies? Evidence from China. Int. J. Environ. Res. Public Health 2022, 19, 2091. [Google Scholar] [CrossRef]

- Liang, S.; Yang, J.; Ding, T. Performance evaluation of AI driven low carbon manufacturing industry in China: An interactive network DEA approach. Comput. Ind. Eng. 2022, 170, 108248. [Google Scholar] [CrossRef]

- Kerr, R.M. Knowledge-Based Manufacturing Management: Applications of Artificial Intelligence to the Effective Management of Manufacturing Companies, 1st ed.; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 1990. [Google Scholar]

- Chien, C.-F.; Hsu, C.-Y.; Hsiao, C.-W. Manufacturing intelligence to forecast and reduce semiconductor cycle time. J. Intell. Manuf. 2012, 23, 2281–2294. [Google Scholar] [CrossRef]

- Abdel-Latif, K.; Bateni, F.; Crouse, S.; Abolhasani, M. Flow Synthesis of Metal Halide Perovskite Quantum Dots: From Rapid Parameter Space Mapping to AI-Guided Modular Manufacturing. Matter 2020, 3, 1053–1086. [Google Scholar] [CrossRef]

- Rožanec, J.M.; Zajec, P.; Kenda, K.; Novalija, I.; Fortuna, B.; Mladenić, D. XAI-KG: Knowledge Graph to Support XAI and Decision-Making in Manufacturing. In Advanced Information Systems Engineering Workshops; Springer: Berlin/Heidelberg, Germany, 2021; pp. 167–172. [Google Scholar]

- Paturi, U.M.R.; Cheruku, S. Application and performance of machine learning techniques in manufacturing sector from the past two decades: A review. Mater. Today Proc. 2021, 38, 2392–2401. [Google Scholar] [CrossRef]

- Bu, L.; Zhang, Y.; Liu, H.; Yuan, X.; Guo, J.; Han, S. An IIoT-driven and AI-enabled framework for smart manufacturing system based on three-terminal collaborative platform. Adv. Eng. Inform. 2021, 50, 101370. [Google Scholar] [CrossRef]

- Othman, U.; Yang, E. Human–robot collaborations in smart manufacturing environments: Review and outlook. Sensors 2023, 23, 5663. [Google Scholar] [CrossRef] [PubMed]

- Jwo, J.-S.; Lin, C.-S.; Lee, C.-H. Smart technology–driven aspects for human-in-the-loop smart manufacturing. Int. J. Adv. Manuf. Technol. 2021, 114, 1741–1752. [Google Scholar] [CrossRef]

- Baicun, W.A.N.G.; Yuan, X.U.E.; Jianlin, Y.A.N.; Xiaoying, Y.; Yuan, Z. Human-centered intelligent manufacturing: Overview and perspectives. Strateg. Study CAE 2020, 22, 139. [Google Scholar]

- Bousdekis, A.; Apostolou, D.; Mentzas, G. A human cyber physical system framework for operator 4.0–artificial intelligence symbiosis. Manuf. Lett. 2020, 25, 10–15. [Google Scholar] [CrossRef]

- Chen, X.; Zeng, Y.; Kang, S.; Jin, R. Inn: An interpretable neural network for ai incubation in manufacturing. ACM Trans. Intell. Syst. Technol. (TIST) 2022, 13, 1–23. [Google Scholar] [CrossRef]

- Nau, D.S.; Gupta, S.K.; Regli, W.C. AI Planning Versus Manufacturing-Operation Planning: A Case Study. Int. Jt. Conf. Artif. Intell. 1995, 2, 1670–1676. [Google Scholar]

- Bag, S.; Pretorius, J.H.C.; Gupta, S.; Dwivedi, Y.K. Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities. Technol. Forecast. Soc. Change 2020, 163, 120420. [Google Scholar] [CrossRef]

- Garrel, J.; Jahn, C. Design Framework for the Implementation of AI-based (Service) Business Models for Small and Medium-sized Manufacturing Enterprises. J. Knowl. Econ. 2022, 14, 3551–3569. [Google Scholar]

- Zhou, M.; Greenwell, R.; Tannock, J. Object-oriented methods for manufacturing information systems. Comput. Integr. Manuf. Syst. 1994, 7, 113–121. [Google Scholar] [CrossRef]

- Xiong, Y.; Tang, Y.; Zhou, Q.; Ma, Y.; Rosen, D.W. Intelligent additive manufacturing and design: State of the art and future perspectives. Addit. Manuf. 2022, 59, 103139. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Operator 5.0: A Survey on Enabling Technologies and a Framework for Digital Manufacturing Based on Extended Reality. J. Mach. Eng. 2022, 22, 43–69. [Google Scholar] [CrossRef]

- Patel, P.; Ali, M.I.; Sheth, A. From Raw Data to Smart Manufacturing: AI and Semantic Web of Things for Industry 4.0. IEEE Intell. Syst. 2018, 33, 79–86. [Google Scholar] [CrossRef]

- Yao, X.; Jin, H.; Zhang, J. Towards a wisdom manufacturing vision. Int. J. Comput. Integr. Manuf. 2015, 28, 1291–1312. [Google Scholar] [CrossRef]

- Huo, X.; Wang, X. Internet of things for smart manufacturing based on advanced encryption standard (AES) algorithm with chaotic system. Results Eng. 2023, 20, 101589. [Google Scholar] [CrossRef]

- Sackett, P.J.; Williams, D.K. Data visualization in manufacturing decision making. J. Adv. Manuf. Syst. 2003, 2, 163–185. [Google Scholar] [CrossRef]

- Silva, M.; Vieira, E.; Signoretti, G.; Silva, I.; Silva, D.; Ferrari, P. A Customer Feedback Platform for Vehicle Manufacturing Compliant with Industry 4.0 Vision. Sensors 2018, 18, 3298. [Google Scholar] [CrossRef]

- Ahmad, M.M.; Dhafr, N. Establishing and improving manufacturing performance measures. Robot. Comput.-Integr. Manuf. 2002, 18, 171–176. [Google Scholar] [CrossRef]

- Merayo, D.; Rodriguez-Prieto, A.; Camacho, A.M. Comparative analysis of artificial intelligence techniques for material selection applied to manufacturing in Industry 4.0. Procedia Manuf. 2019, 41, 42–49. [Google Scholar] [CrossRef]

- Wieder, P.; Nolte, H. Toward data lakes as central building blocks for data management and analysis. Front. Big Data 2022, 5, 945720. [Google Scholar] [CrossRef]

- Giebler, C.; Gröger, C.; Hoos, E.; Schwarz, H.; Mitschang, B. Modeling data lakes with data vault: Practical experiences, assessment, and lessons learned. In Proceedings of the Conceptual Modeling: 38th International Conference, ER 2019, Salvador, Brazil, 4–7 November 2019; pp. 63–77. [Google Scholar]

- Bao, Y.; Ren, L.; Zhang, L.; Zhang, X.; Luo, Y. Massive sensor data management framework in cloud manufacturing based on Hadoop. In Proceedings of the IEEE 10th International Conference on Industrial Informatics, Beijing, China, 25–27 July 2012; pp. 397–401. [Google Scholar]

- Petrasch, R.; Hentschke, R. Cloud storage hub: Data management for IoT and industry 4.0 applications: Towards a consistent enterprise information management system. In Proceedings of the 2016 Management and Innovation Technology International Conference (MITicon), Bang-Saen, Chonburi, Thailand, 12–14 October 2016; p. MIT-108. [Google Scholar]

- Hao, Y.; Shamsuzzoha, A.; Helo, P. Cloud-based data storage for data management in the virtual factory. In Cloud Systems in Supply Chains; Springer: Berlin/Heidelberg, Germany, 2015; pp. 280–299. [Google Scholar]

- Lujic, I.; Maio, V.D.; Brandic, I. Resilient edge data management framework. IEEE Trans. Serv. Comput. 2019, 13, 663–674. [Google Scholar] [CrossRef]

- Yang, C.; Lan, S.; Wang, L.; Shen, W.; Huang, G.G.Q. Big data driven edge-cloud collaboration architecture for cloud manufacturing: A software defined perspective. IEEE Access 2020, 8, 45938–45950. [Google Scholar] [CrossRef]

- Sundaram, S.; Zeid, A. Artificial intelligence-based smart quality inspection for manufacturing. Micromachines 2023, 14, 570. [Google Scholar] [CrossRef]

- Ren, Y.; Leng, Y.; Cheng, Y.; Wang, J. Secure data storage based on blockchain and coding in edge computing. Math. Biosci. Eng. 2019, 16, 1874–1892. [Google Scholar] [CrossRef]

- Xu, S.; Lu, B.; Baldea, M.; Edgar, T.F.; Wojsznis, W.; Blevins, T.; Nixon, M. Data cleaning in the process industries. Rev. Chem. Eng. 2015, 31, 453–490. [Google Scholar] [CrossRef]

- Ilyas, I.F.; Chu, X. Data Cleaning. Morgan & Claypool; Association for Computing Machinery: New York, NY, USA, 2019. [Google Scholar]

- Saez, M.; Lengieza, S.; Maturana, F.; Barton, K.; Tilbury, D. A data transformation adapter for smart manufacturing systems with edge and cloud computing capabilities. In Proceedings of the 2018 IEEE International Conference on Electro/Information Technology (EIT), Rochester, MI, USA, 3–5 May 2018; pp. 0519–0524. [Google Scholar]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H.-A. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Shah, D.; Wang, J.; He, Q.P. Feature engineering in big data analytics for IoT-enabled smart manufacturing–Comparison between deep learning and statistical learning. Comput. Chem. Eng. 2020, 141, 106970. [Google Scholar] [CrossRef]

- Allada, V.; Anand, S.A.M. Feature-based modelling approaches for integrated manufacturing: State-of-the-art survey and future research directions. Int. J. Comput. Integr. Manuf. 1995, 8, 411–440. [Google Scholar] [CrossRef]

- Shyalika, C.; Wickramarachchi, R.; Kalach, F.E.; Harik, R.; Sheth, A. Evaluating the role of data enrichment approaches towards rare event analysis in manufacturing. Sensors 2024, 24, 5009. [Google Scholar] [CrossRef]

- Helena, S.T.; Camargo, V.R.S.; Amaral, T.V.B.; Szejka, A.L.; Leite, A.F.C.S.d.; Canciglieri, M.B. Interoperable data extraction and information enrichment system to support smart manufacturing: An experimental application on CNC machining lines of a healthcare product. Production 2022, 32, e20210058. [Google Scholar] [CrossRef]

- Syberg, M.; West, N.; Lenze, D.; Deuse, J. Framework for predictive sales and demand planning in customer-oriented manufacturing systems using data enrichment and machine learning. Procedia CIRP 2023, 120, 1107–1112. [Google Scholar] [CrossRef]

- Mozaffar, M.; Liao, S.; Xie, X.; Saha, S.; Park, C.; Cao, J.; Gan, Z. Mechanistic artificial intelligence (mechanistic-AI) for modeling, design, and control of advanced manufacturing processes: Current state and perspectives. J. Mater. Process. Technol. 2022, 302, 117485. [Google Scholar] [CrossRef]

- Zonta, T.; Costa, C.A.D.; Righi, R.d.; de Lima, M.J.; Trindade, E.S.D.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Ghelani, H. AI-Driven Quality Control in PCB Manufacturing: Enhancing Production Efficiency and Precision. Val. Int. J. Digit. Libr. 2024, 12, 1549–1564. [Google Scholar] [CrossRef]

- Liu, C.; Tian, W.; Kan, C. When AI meets additive manufacturing: Challenges and emerging opportunities for human-centered products development. J. Manuf. Syst. 2022, 64, 648–656. [Google Scholar] [CrossRef]

- Meister, S.; Möller, N.; Stüve, J.; Groves, R.M. Synthetic image data augmentation for fibre layup inspection processes: Techniques to enhance the data set. J. Intell. Manuf. 2021, 32, 1767–1789. [Google Scholar] [CrossRef]

- Jain, S.; Seth, G.; Paruthi, A.; Soni, U.; Kumar, G. Synthetic data augmentation for surface defect detection and classification using deep learning. J. Intell. Manuf. 2022, 33, 1007–1020. [Google Scholar] [CrossRef]

- Ortego, P.; Diez-Olivan, A.; Ser, J.D.; Sierra, B. Data augmentation for industrial prognosis using generative adversarial networks. In Proceedings of the Intelligent Data Engineering and Automated Learning–IDEAL 2020: 21st International Conference, Guimaraes, Portugal, 4–6 November 2020; Proceedings, Part II 21. pp. 113–122. [Google Scholar]

- Lee, Y.-T.T.; Riddick, F.H.; Johansson, B.J.I. Core Manufacturing Simulation Data—A manufacturing simulation integration standard: Overview and case studies. Int. J. Comput. Integr. Manuf. 2011, 24, 689–709. [Google Scholar] [CrossRef]

- Shao, G.; Shin, S.-J.; Jain, S. Data analytics using simulation for smart manufacturing. In Proceedings of the Winter Simulation Conference 2014, Savannah, GA, USA, 7–10 December 2014; pp. 2192–2203. [Google Scholar]

- Zhang, L.; Zhou, L.; Ren, L.; Laili, Y. Modeling and simulation in intelligent manufacturing. Comput. Ind. 2019, 112, 103123. [Google Scholar] [CrossRef]

- Mirkouei, A.; Bhinge, R.; McCoy, C.; Haapala, K.R.; Dornfeld, D.A. A pedagogical module framework to improve scaffolded active learning in manufacturing engineering education. Procedia Manuf. 2016, 5, 1128–1142. [Google Scholar] [CrossRef]

- van Houtum, G.J.J.; Vlasea, M.L. Active learning via adaptive weighted uncertainty sampling applied to additive manufacturing. Addit. Manuf. 2021, 48, 102411. [Google Scholar] [CrossRef]

- Rožanec, J.M.; Bizjak, L.; Trajkova, E.; Zajec, P.; Keizer, J.; Fortuna, B.; Mladenić, D. Active learning and novel model calibration measurements for automated visual inspection in manufacturing. J. Intell. Manuf. 2024, 35, 1963–1984. [Google Scholar] [CrossRef]

- Dasari, S.K.; Cheddad, A.; Lundberg, L.; Palmquist, J. Active learning to support in-situ process monitoring in additive manufacturing. In Proceedings of the in 2021 20th IEEE International Conference on Machine Learning and Applications (ICMLA), Pasadena, CA, USA, 13–16 December 2021; pp. 1168–1173. [Google Scholar]

- Zajec, P.; Rožanec, J.M.; Trajkova, E.; Novalija, I.; Kenda, K.; Fortuna, B.; Mladenić, D. Help me learn! Architecture and strategies to combine recommendations and active learning in manufacturing. Information 2021, 12, 473. [Google Scholar] [CrossRef]

- Sofianidis, G.; Rožanec, J.M.; Mladenic, D.; Kyriazis, D. A review of explainable artificial intelligence in manufacturing. Trust. Artif. Int. Manuf. 2021, 24, 93–113. [Google Scholar]

- Yoo, S.; Kang, N. Explainable artificial intelligence for manufacturing cost estimation and machining feature visualization. Expert Syst. Appl. 2021, 183, 115430. [Google Scholar] [CrossRef]

- Pinto, R.; Gonçalves, G. Application of artificial immune systems in advanced manufacturing. Array 2022, 15, 100238. [Google Scholar] [CrossRef]

- Wallis, K.; Schillinger, F.; Reich, C.; Schindelhauer, C. Safeguarding data integrity by cluster-based data validation network. In Proceedings of the 2019 Third World Conference on Smart Trends in Systems Security and Sustainablity (WorldS4), London, UK, 30–31 July 2019; pp. 78–86. [Google Scholar]

- Mullet, V.; Sondi, P.; Ramat, E. A review of cybersecurity guidelines for manufacturing factories in industry 4.0. IEEE Access 2021, 9, 23235–23263. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Wan, J.; Chen, X. An access control model for resource sharing based on the role-based access control intended for multi-domain manufacturing internet of things. IEEE Access 2017, 5, 7001–7011. [Google Scholar] [CrossRef]

- Ferraiolo, D.F.; Sandhu, R.; Gavrila, S.; Kuhn, D.R.; Chandramouli, R. Proposed NIST standard for role-based access control. ACM Trans. Inf. Syst. Secur. (TISSEC) 2001, 4, 224–274. [Google Scholar] [CrossRef]

- Sandhu, R.S. Role-based access control. In Advances in Computers; Elsevier: Amsterdam, The Netherlands, 1998; Volume 46, pp. 237–286. [Google Scholar]

- Hashem, F.; Alqatamin, R. Role of Artificial Intelligence in Enhancing Efficiency of Accounting Information System and Non-Financial Performance of the Manufacturing Companies. Int. Bus. Res. 2024, 14, 1–65. [Google Scholar]

- Banyal, R.K.; Jain, P.; Jain, V.K. Multi-factor authentication framework for cloud computing. In Proceedings of the 2013 Fifth International Conference on Computational Intelligence, Modelling and Simulation, Seoul, Rerpublic of Korea, 24–25 September 2013; pp. 105–110. [Google Scholar]

- Kim, J.-J.; Hong, S.-P. A method of risk assessment for multi-factor authentication. J. Inf. Process. Syst. 2011, 7, 187–198. [Google Scholar] [CrossRef]

- Vinoth, R.; Deborah, L.J.; Vijayakumar, P.; Kumar, N. Secure multifactor authenticated key agreement scheme for industrial IoT. IEEE Internet Things J. 2020, 8, 3801–3811. [Google Scholar] [CrossRef]

- Rodrguez-Espndola, O.; Chowdhury, S.; Dey, P.K.; Albores, P.; Emrouznejad, A. Analysis of the adoption of emergent technologies for risk management in the era of digital manufacturing. Technol. Forecast. Soc. Change 2022, 178, 121562. [Google Scholar] [CrossRef]

- Bender, W.; Gruhl, D.; Morimoto, N.; Lu, A. Techniques for data hiding. IBM Syst. J. 1996, 35, 313–336. [Google Scholar] [CrossRef]

- Wu, M.; Moon, Y. DACDI (Define, Audit, Correlate, Disclose, and Improve) framework to address cyber-manufacturing attacks and intrusions. Manuf. Lett. 2018, 15, 155–159. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. IEC 62443 Series—Industrial Communication Networks—Network and System Security. Available online: https://www.iec.ch/62443 (accessed on 17 August 2025).

- Prinsloo, J.; Sinha, S.; Solms, B.V. A review of industry 4.0 manufacturing process security risks. Appl. Sci. 2019, 9, 5105. [Google Scholar] [CrossRef]

- Wang, F.-Y.; Zhang, J.J.; Wang, X. Parallel intelligence: Toward lifelong and eternal developmental AI and learning in cyber-physical-social spaces. Front. Comput. Sci. 2018, 12, 401–405. [Google Scholar] [CrossRef]

- Sackett, P.J.; Al-Gaylani, M.F.; Tiwari, A.; Williams, D. A review of data visualization: Opportunities in manufacturing sequence management. Int. J. Comput. Integr. Manuf. 2006, 19, 689–704. [Google Scholar] [CrossRef]

- Zhou, F.; Lin, X.; Liu, C.; Zhao, Y.; Xu, P.; Ren, L.; Xue, T.; Ren, L. A survey of visualization for smart manufacturing. J. Vis. 2019, 22, 419–435. [Google Scholar] [CrossRef]

- Psarommatis, F.; Kiritsis, D. A hybrid Decision Support System for automating decision making in the event of defects in the era of Zero Defect Manufacturing. J. Ind. Inf. Integr. 2022, 26, 100263. [Google Scholar] [CrossRef]

- Liu, C.; Roux, L.L.; Ji, Z.; Kerfriden, P.; Lacan, F.; Bigot, S. Machine Learning-enabled feedback loops for metal powder bed fusion additive manufacturing. Procedia Comput. Sci. 2020, 176, 2586–2595. [Google Scholar] [CrossRef]

- Rani, S.; Jining, D.; Shoukat, K.; Shoukat, M.U.; Nawaz, S.A. A Human Machine Interaction Mechanism: Additive Manufacturing for Industry 5.0 Design and Management. Sustainability 2024, 16, 4158. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, P.; Peng, T.; Yang, H.; Zou, J. Smart additive manufacturing: Current artificial intelligence-enabled methods and future perspectives. Sci. China Technol. Sci. 2020, 63, 1600–1611. [Google Scholar] [CrossRef]

- Yang, J.; Ying, L.; Gao, M. The influence of intelligent manufacturing on financial performance and innovation performance: The case of China. Enterp. Inf. Syst. 2020, 14, 812–832. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mudgal, P. A Data-Centric Framework for Implementing Artificial Intelligence in Smart Manufacturing. Electronics 2025, 14, 3304. https://doi.org/10.3390/electronics14163304

Mudgal P. A Data-Centric Framework for Implementing Artificial Intelligence in Smart Manufacturing. Electronics. 2025; 14(16):3304. https://doi.org/10.3390/electronics14163304

Chicago/Turabian StyleMudgal, Priyanka. 2025. "A Data-Centric Framework for Implementing Artificial Intelligence in Smart Manufacturing" Electronics 14, no. 16: 3304. https://doi.org/10.3390/electronics14163304

APA StyleMudgal, P. (2025). A Data-Centric Framework for Implementing Artificial Intelligence in Smart Manufacturing. Electronics, 14(16), 3304. https://doi.org/10.3390/electronics14163304