3D-Printed Circular Horn Antenna with Dielectric Lens for Focused RF Energy Delivery

Abstract

1. Introduction

2. Theoretical Framework and Design Methodology

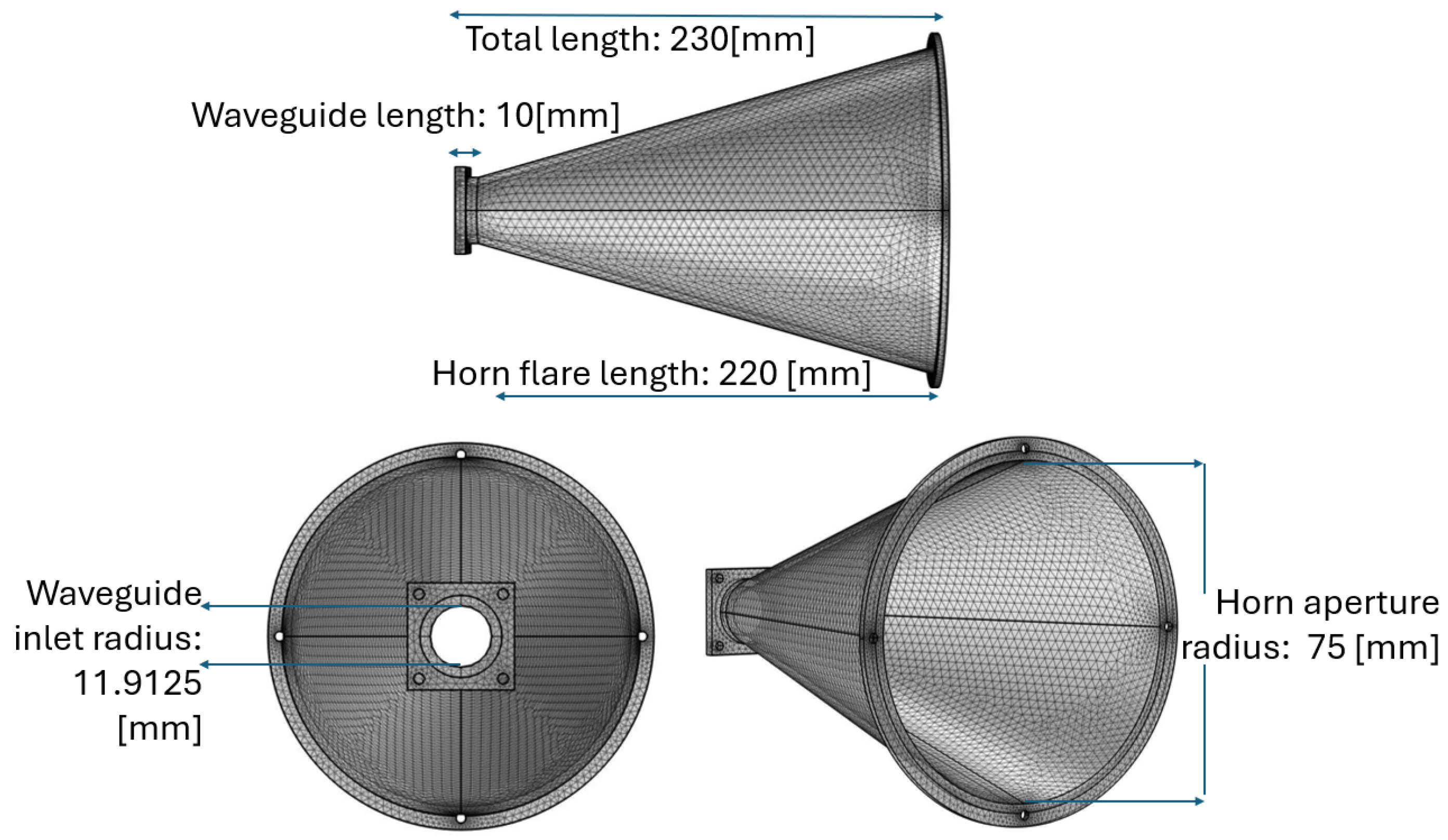

2.1. Circular Horn Antenna Design

- Waveguide inlet radius: mm.

- Circular waveguide length: mm.

- Horn flare length: mm.

- Horn aperture radius: mm (aperture diameter mm, i.e., ).

- Total antenna length: mm.

- Operating frequency: GHz.

- Antenna material: metallized 3D-printed structure (modeled as perfect electric conductor).

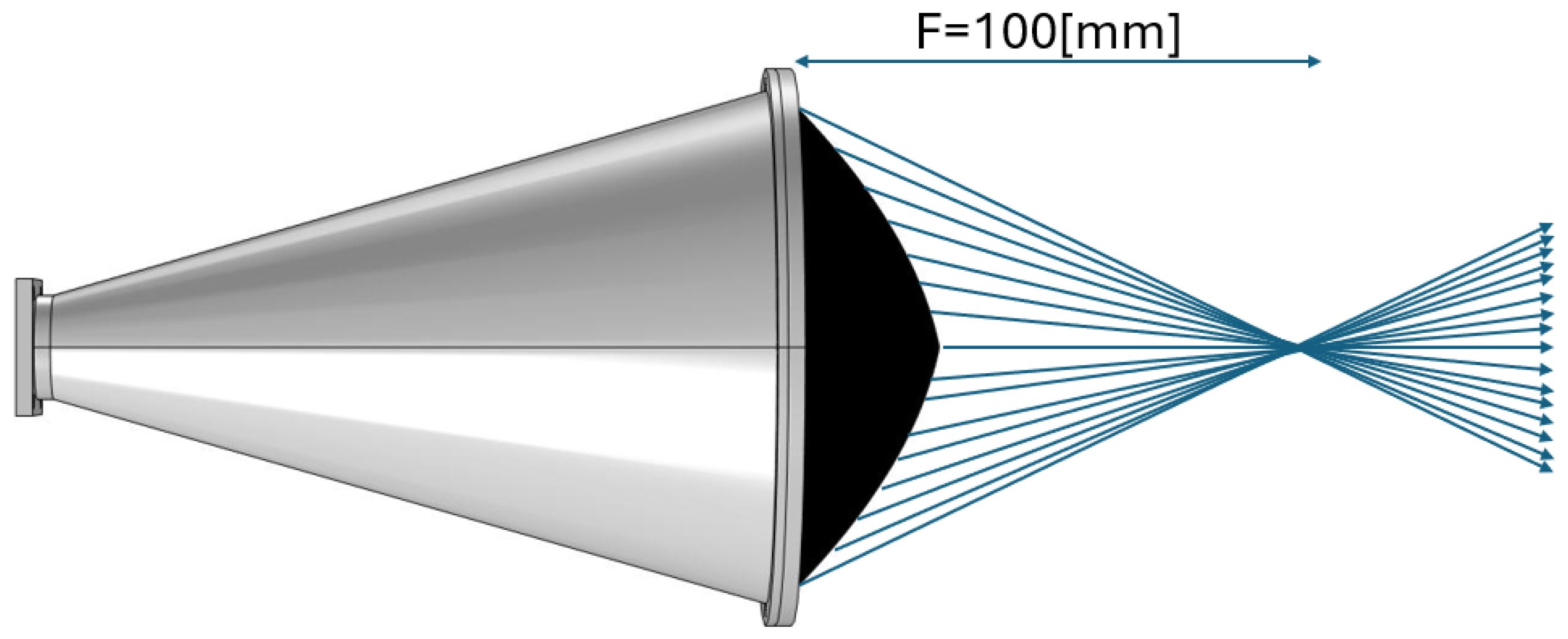

2.2. Dielectric Lens Design

- Desired focal length: mm.

- Configuration: symmetrical biconvex lens with 5 mm central gap.

2.3. Surface Roughness Considerations

3. Simulation Methodology and Results

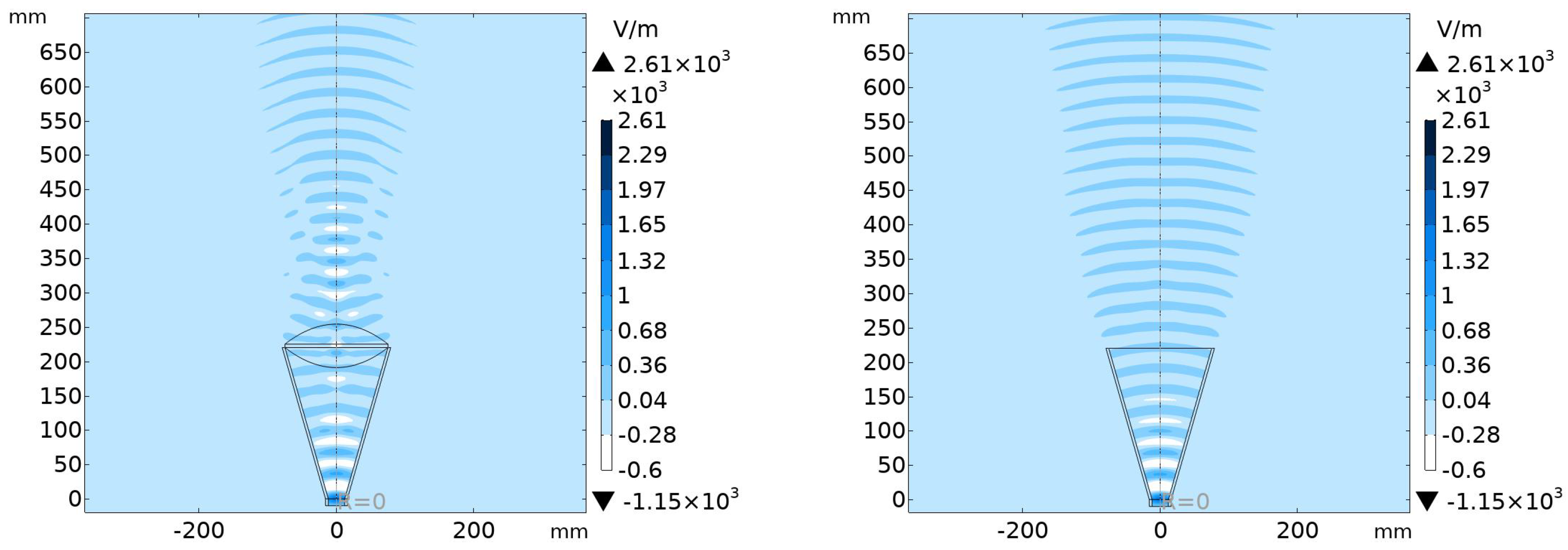

3.1. Simulation Setup

- Excitation: mode at waveguide input port.

- Boundary conditions: Perfect Electric Conductor (PEC) for antenna surfaces.

- External boundaries: Perfectly Matched Layers (PML) to eliminate reflections.

- Mesh resolution: minimum element size in critical regions.

- Dielectric properties: PTFE with and loss tangent .

3.2. Electric Field Distribution

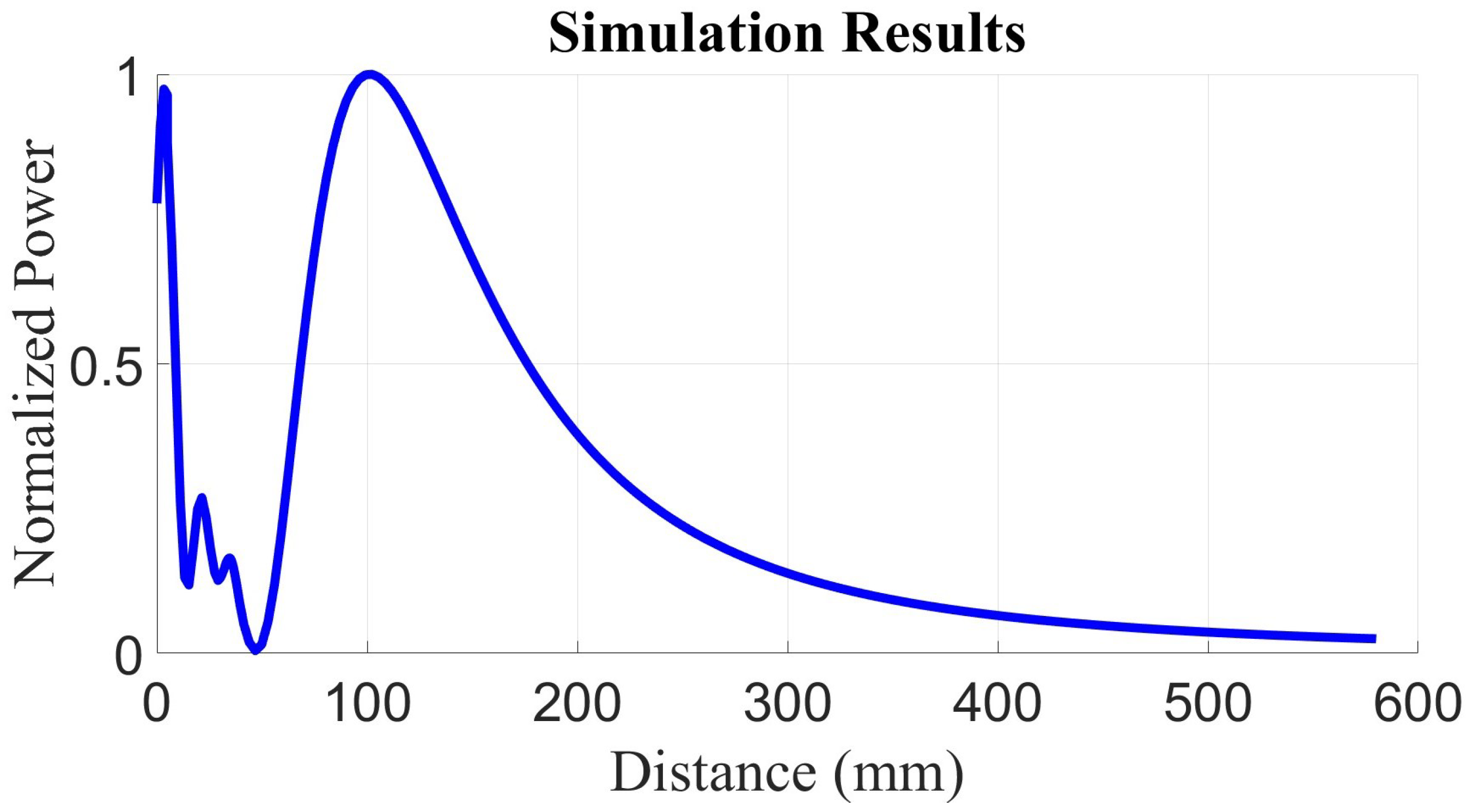

3.3. Power Density Distribution

3.4. Focal Performance Validation

4. Fabrication Process

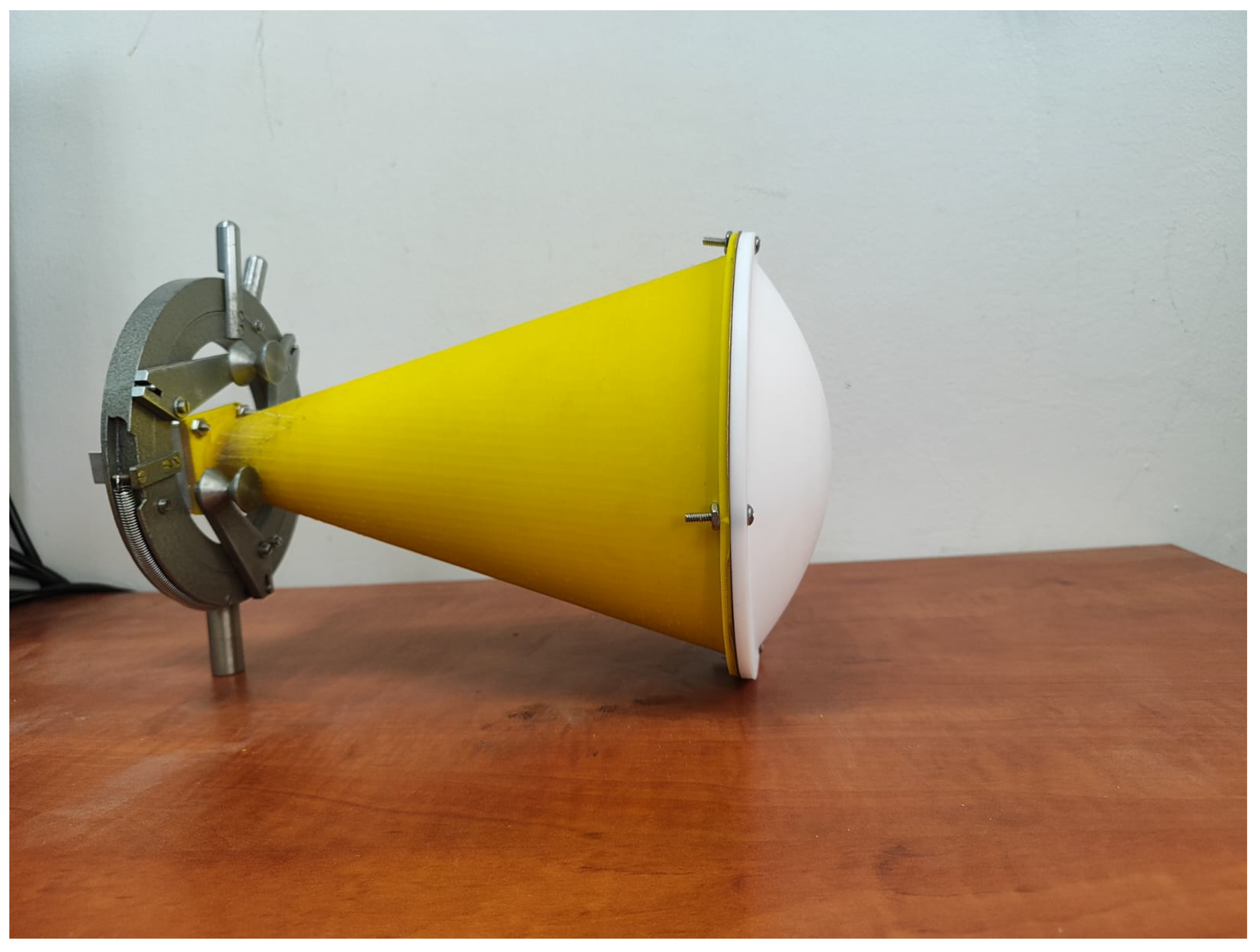

4.1. Antenna Fabrication

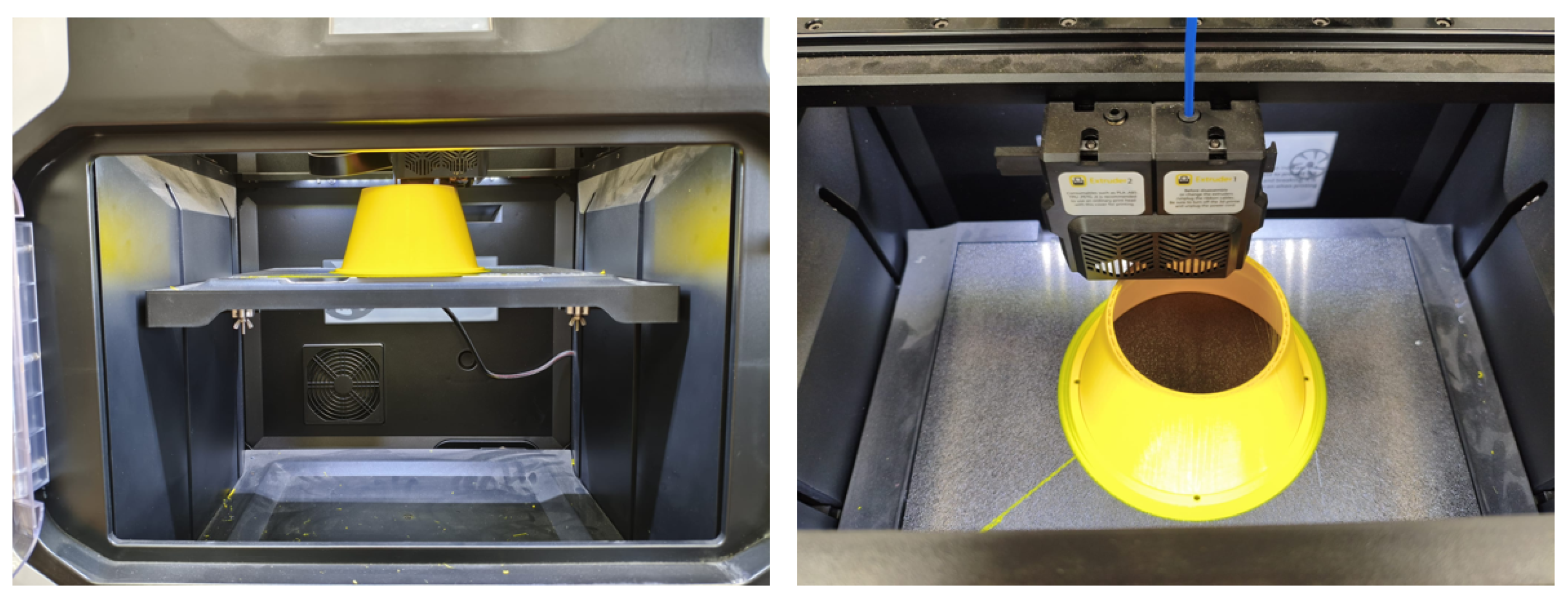

4.2. Dielectric Lens Fabrication

4.3. Assembly

4.4. Quality Control

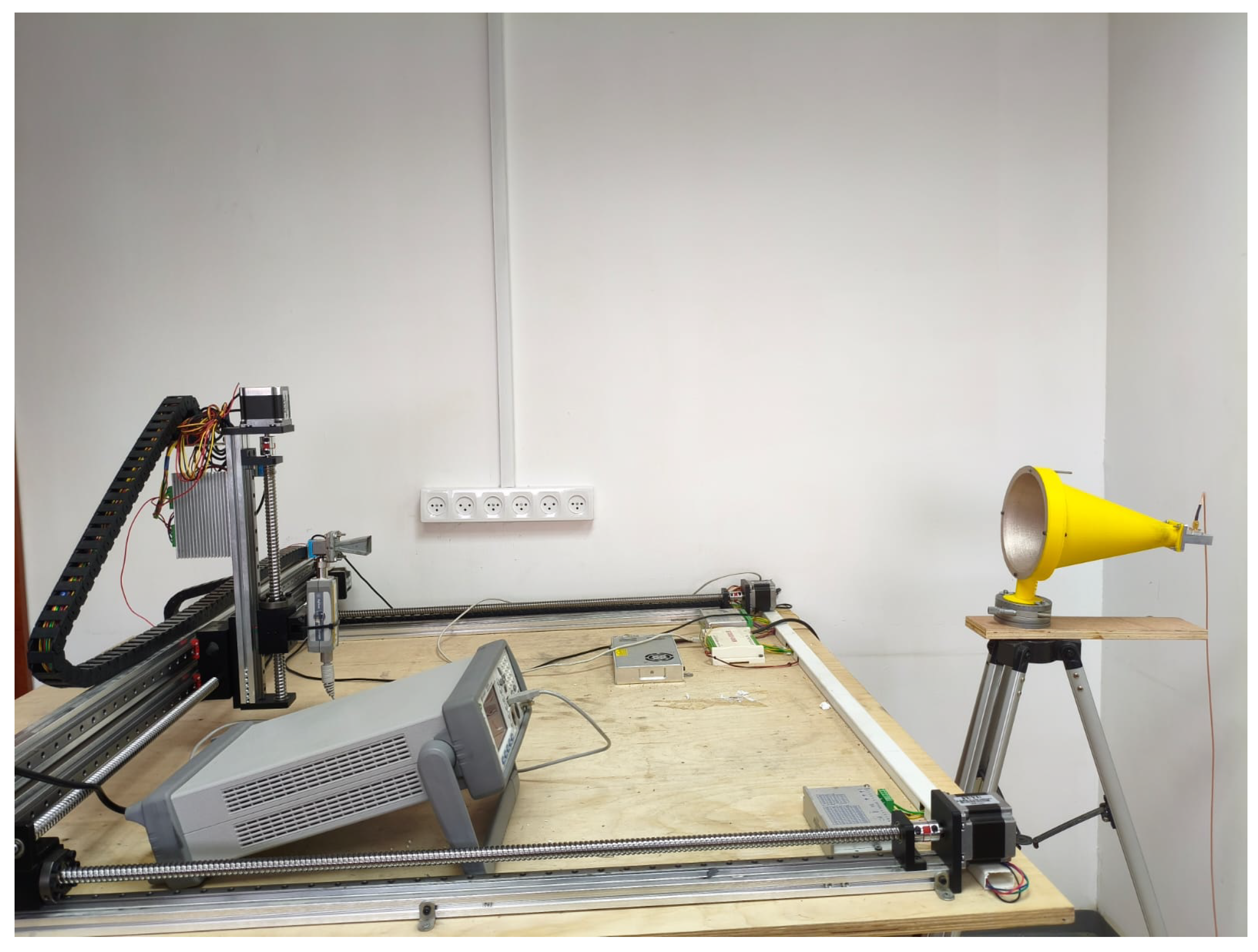

5. Experimental Validation

5.1. Power Density Measurement as a Function of Distance

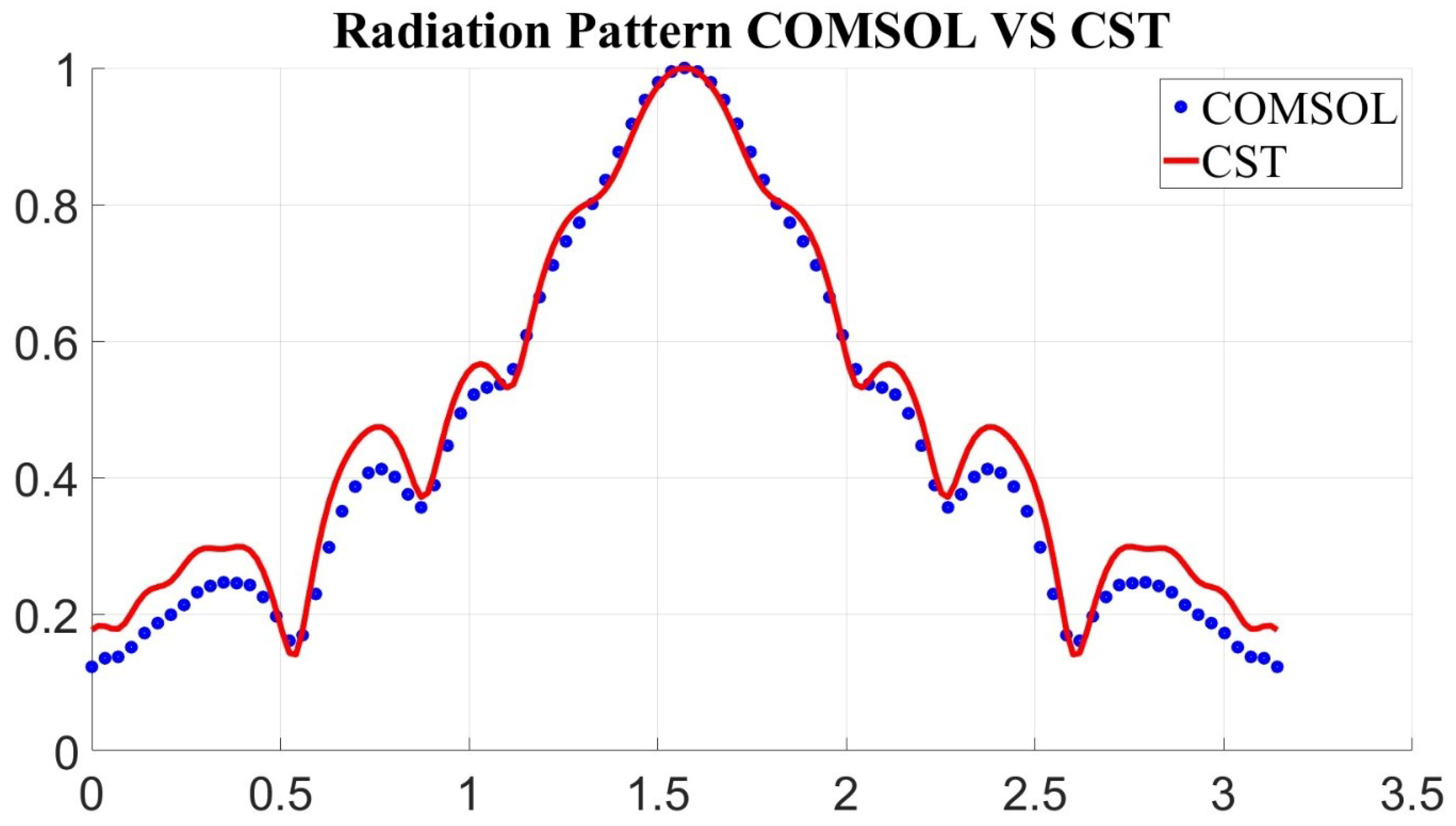

5.2. Radiation Pattern Measurement

6. Experimental Results

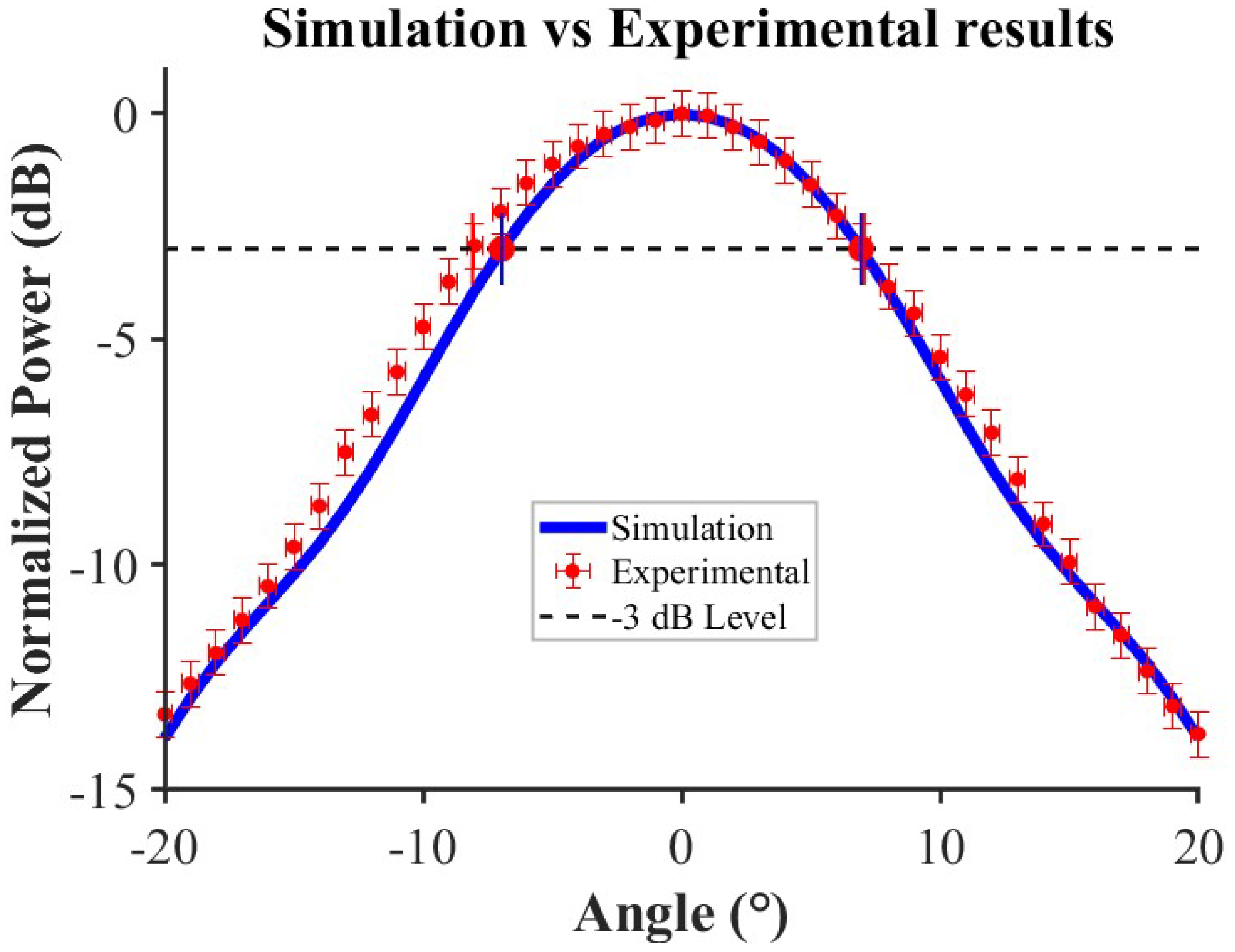

6.1. Radiation Pattern Measurement Results

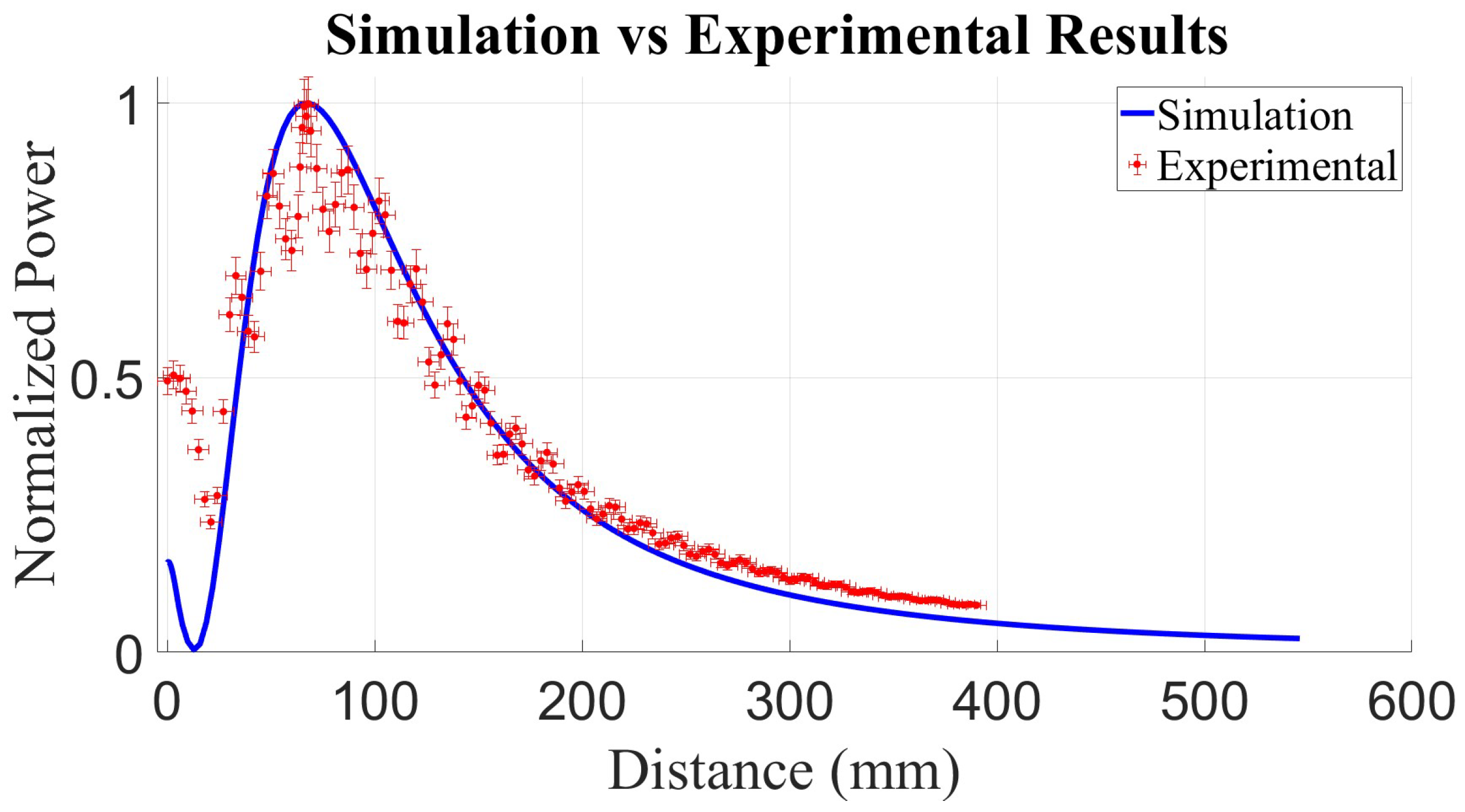

6.2. Axial Power Density Measurement Results

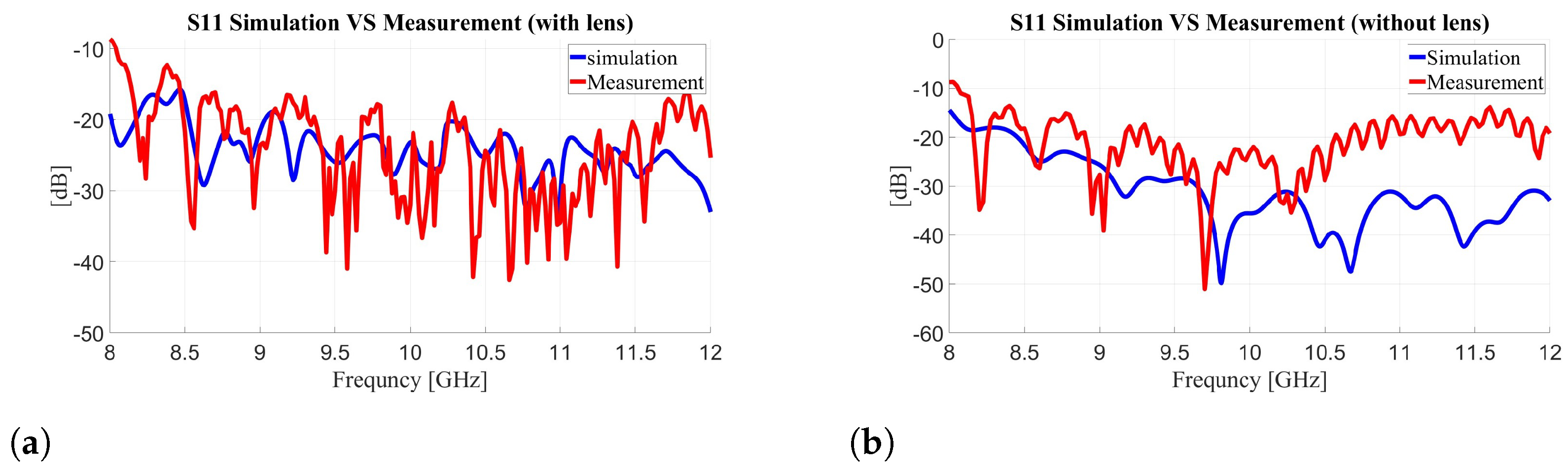

6.3. Input Impedance Performance (S11)

7. Discussion

7.1. Validation of Baseline Horn Antenna

7.2. Focusing Performance with Dielectric Lens

7.3. Manufacturing and Cost Considerations

7.4. Limitations and Future Work

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Y.; Liu, C.; Huang, Y. Wireless power transfer for implanted medical application: A review. Energies 2020, 13, 2837. [Google Scholar] [CrossRef]

- Khan, A.N.; Cha, Y.O.; Giddens, H.; Hao, Y. Recent advances in organ specific wireless bioelectronic devices: Perspective on biotelemetry and power transfer using antenna systems. Engineering 2022, 11, 50–63. [Google Scholar] [CrossRef]

- Nisamol, T.A.; Ansha, K.K.; Abdulla, P. Design of Sub-THz beam scanning antenna using Luneburg lens for 5G communications OR beyond. Prog. Electromagn. Res. C 2020, 99, 179–191. [Google Scholar] [CrossRef][Green Version]

- Bor, J.; Lafond, O.; Merlet, H.; Le Bars, P.; Himdi, M. Foam based Luneburg lens antenna at 60 GHz. Prog. Electromagn. Res. Lett. 2014, 44, 1–7. [Google Scholar] [CrossRef][Green Version]

- Khan, A.N.; Ermakov, A.; Sukhorukov, G. Radio frequency controlled wireless drug delivery devices. Appl. Phys. Rev. 2019, 6, 041301. [Google Scholar] [CrossRef]

- Balanis, C.A. Antenna Theory: Analysis and Design, 4th ed.; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar]

- Wang, C.; Wu, J.; Guo, Y.-X. A 3-D-printed wideband circularly polarized parallel-plate Luneburg lens antenna. IEEE Trans. Antennas Propag. 2020, 68, 4944–4949. [Google Scholar] [CrossRef]

- Rodríguez Pino, M.; González Ayestarán, R.; Nepa, P.; Manara, G. An overview on synthesis techniques for near-field focused antennas. In Wireless Power Transfer Technologies and Applications; IntechOpen: London, UK, 2019. [Google Scholar]

- Sivakumar, R.; Azemi, S.N.; Lee, Y.S.; Kok, Y.Y.; Soh, P.J. 3-D Printed Antennas with Dielectric Lens for Free-Space Constitutive Parameters Measurement. Semarak Int. J. Electron. Syst. Eng. 2024, 1, 1–25. [Google Scholar] [CrossRef]

- Goulas, A.; Zhang, S.; McGhee, J.R.; Cadman, D.A. Fused filament fabrication of functionally graded polymer composites with variable relative permittivity for microwave devices. Mater. Des. 2020, 191, 108635. [Google Scholar] [CrossRef]

- Helena, D.; Ramos, A.; Varum, T.; Matos, J.N. Antenna design using modern additive manufacturing technology: A review. IEEE Access 2020, 8, 177064–177083. [Google Scholar] [CrossRef]

- Riddle, B.; Baker-Jarvis, J.; Krupka, J. Complex Permittivity Measurements of Common Plastics over Variable Temperatures. IEEE Trans. Microw. Theory Techn. 2003, 51, 727–733. [Google Scholar] [CrossRef]

- Salski, B.; Cuper, J.; Karpisz, T.; Kopyt, P.; Krupka, J. Complex Permittivity of Common Dielectrics in 20–110 GHz Frequency Range Measured with a Fabry–Pérot Open Resonator. Appl. Phys. Lett. 2021, 119, 052902. [Google Scholar] [CrossRef]

- Alhassoon, K.; Malallah, Y.; Daryoush, A.S. RF Characterization of 3-D-Printed Material for Antenna Applications. IEEE Trans. Antennas Propag. 2023, 71, 7073–7080. [Google Scholar] [CrossRef]

- Shi, C.; Zhao, W.; Chen, S.; Li, W. Multilevel diffractive lenses: Recent advances and applications. Symmetry 2024, 16, 1377. [Google Scholar] [CrossRef]

- Lobascio, F.; Di Modugno, R.; Fiore, M.; Clemente, S. Microwave and radiofrequency ablation: A comparative study between technologies in ex vivo tissues. Drugs Drug Candidates 2024, 3, 32. [Google Scholar] [CrossRef]

- Adibzadeh, F.; Sumser, K.; Curto, S.; Yeo, D.T.B. Systematic review of pre-clinical and clinical devices for magnetic resonance-guided radiofrequency hyperthermia. Int. J. Hyperth. 2020, 37, 151–172. [Google Scholar] [CrossRef]

- Molaei, A.; Bisulco, A.; Tirado, L.; Zhu, A.; Cachay, D.; Dagheyan, A.G.; Martinez-Lorenzo, J. 3D-printed E-band compressive horn antenna for high-sensing-capacity imaging applications. IEEE Antennas Wireless Propag. Lett. 2018, 17, 1639–1642. [Google Scholar] [CrossRef]

- Kosamiya, V.; Wang, J. High-k, low-loss ceramic-thermoplastic composite feedstock filaments for fused deposition modeling of microwave and mm-wave devices. In Fused Deposition Modeling; IntechOpen: London, UK, 2024. [Google Scholar]

- Maulana, M.F.; Darwis, F.; Desvasari, W. On the use of 3D printing technique for 5G mmWave antenna development. In Proceedings of the 2024 15th Global Symposium on Millimeter-Waves (GSMM), Crete, Greece, 22–24 May 2024; pp. 1–3. [Google Scholar]

- Poyanco, J.M.; Baños, G.V.; Rajo-Iglesias, E. Beam steering 3D printed dielectric lens antennas for millimeter-wave and 5G applications. Sensors 2023, 23, 6961. [Google Scholar] [CrossRef]

- Atak, A.C.; Frölich, A.; Quint, A.; Zwick, T. AD–band horn antenna made by a proprietary metallization process of photopolymer 3D–prints. In Proceedings of the 2024 54th European Microwave Conference (EuMC), Paris, France, 24–26 September 2024; pp. 1159–1162. [Google Scholar]

- Pfeiffer, C.; Massman, J.; Steffen, T. 3-D Printed Metallic Dual-Polarized Vivaldi Arrays on Square and Triangular Lattices. IEEE Trans. Antennas Propag. 2021, 69, 8483–8495. [Google Scholar] [CrossRef]

- Chieh, J.C.S.; Dick, B.; Loui, S.; Rockway, J.D. Development of a Ku-band corrugated conical horn using 3-D print technology. IEEE Antennas Wireless Propag. Lett. 2014, 13, 201–204. [Google Scholar] [CrossRef]

- Cheng, Y.; Dong, Y. High-Gain All-Metal 3-D Printed Lens-Horn Antenna for Millimeter-Wave Applications. IEEE Antennas Wireless Propag. Lett. 2022, 21, 308–312. [Google Scholar] [CrossRef]

- Anwar, M.S.; Abufanas, H.; Bangert, A. 3D printed dielectric lens for the gain enhancement of a broadband antenna. Int. J. RF Microw. Comput.-Aided Eng. 2020, 30, e22115. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michael, A.; Balal, N. 3D-Printed Circular Horn Antenna with Dielectric Lens for Focused RF Energy Delivery. Electronics 2025, 14, 3191. https://doi.org/10.3390/electronics14163191

Michael A, Balal N. 3D-Printed Circular Horn Antenna with Dielectric Lens for Focused RF Energy Delivery. Electronics. 2025; 14(16):3191. https://doi.org/10.3390/electronics14163191

Chicago/Turabian StyleMichael, Aviad, and Nezah Balal. 2025. "3D-Printed Circular Horn Antenna with Dielectric Lens for Focused RF Energy Delivery" Electronics 14, no. 16: 3191. https://doi.org/10.3390/electronics14163191

APA StyleMichael, A., & Balal, N. (2025). 3D-Printed Circular Horn Antenna with Dielectric Lens for Focused RF Energy Delivery. Electronics, 14(16), 3191. https://doi.org/10.3390/electronics14163191