Insulator Defect Detection Based on Improved YOLO11n Algorithm Under Complex Environmental Conditions

Abstract

1. Introduction

2. Methods

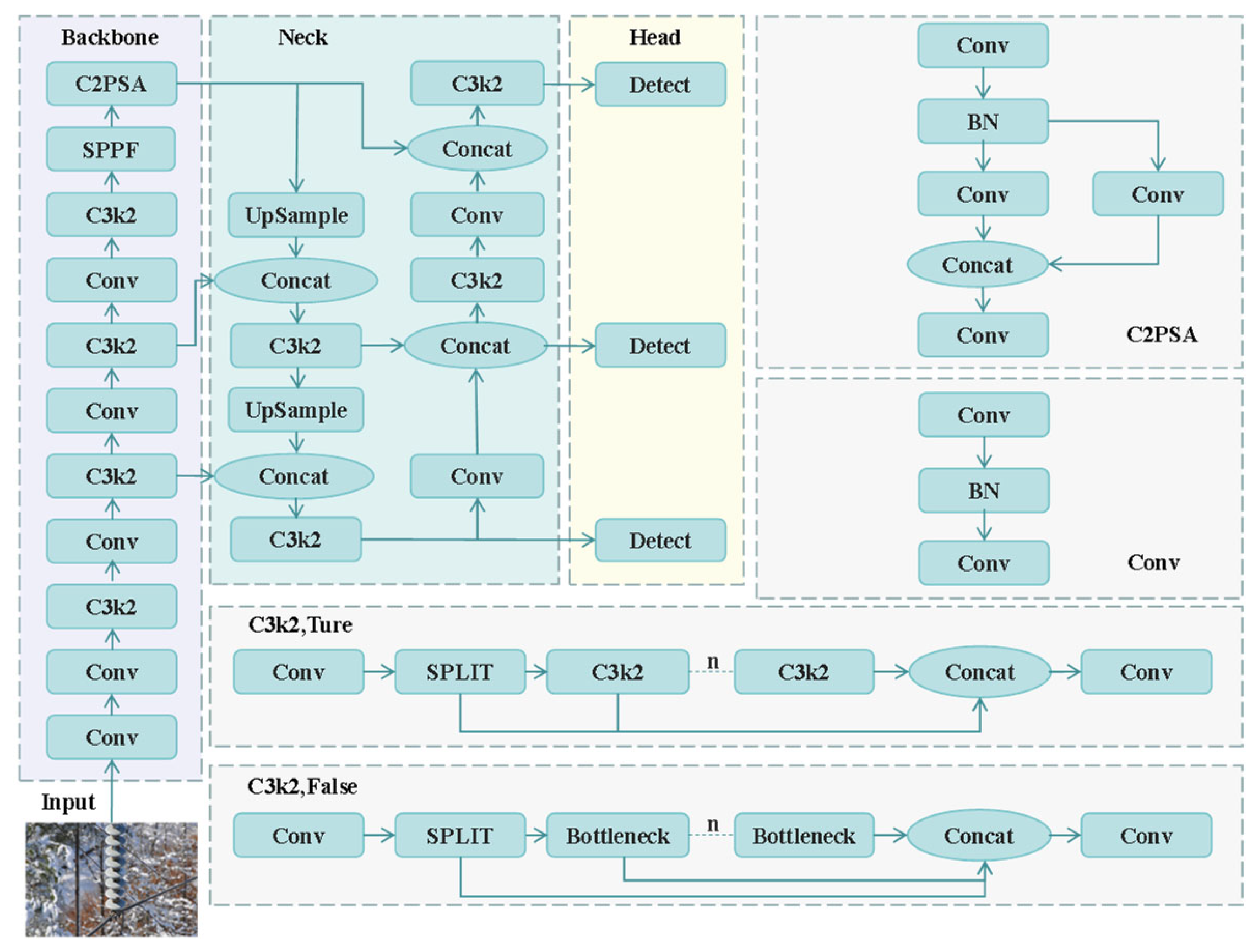

2.1. YOLO11n Object Detection Algorithm

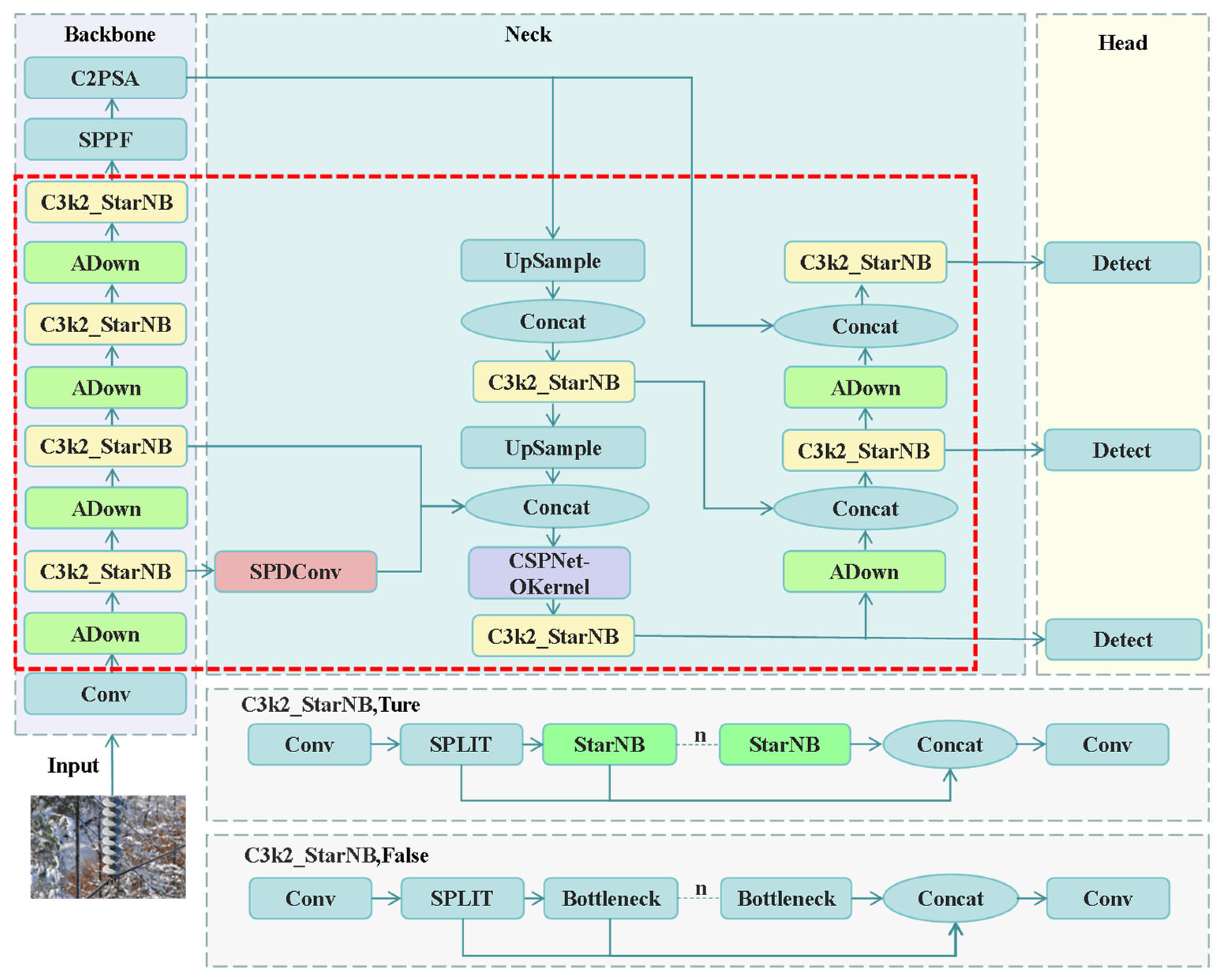

2.2. Improved YOLO11n Method: YOLO11n-SSA

- 1.

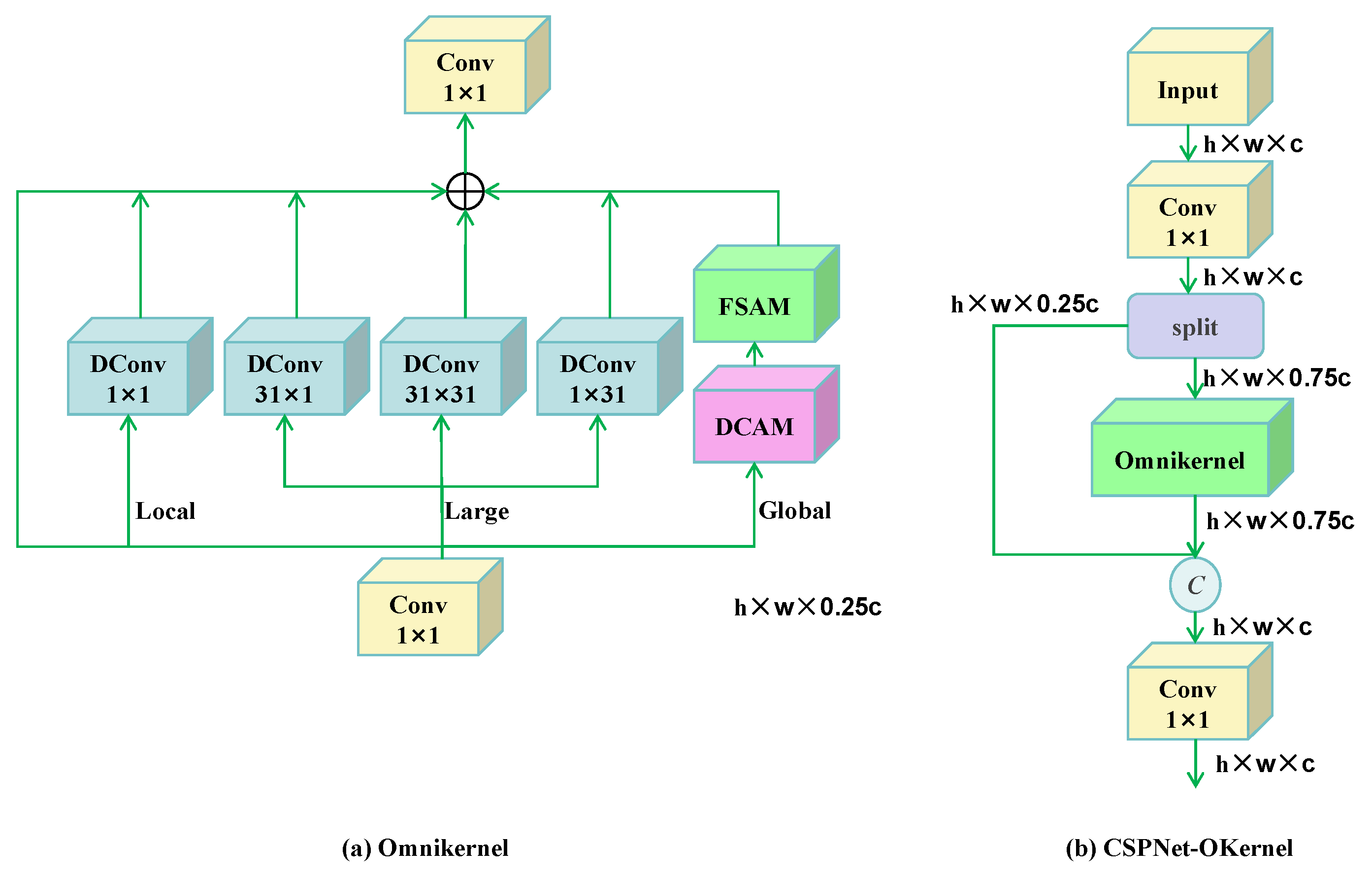

- StarNet Network Structure

- 2.

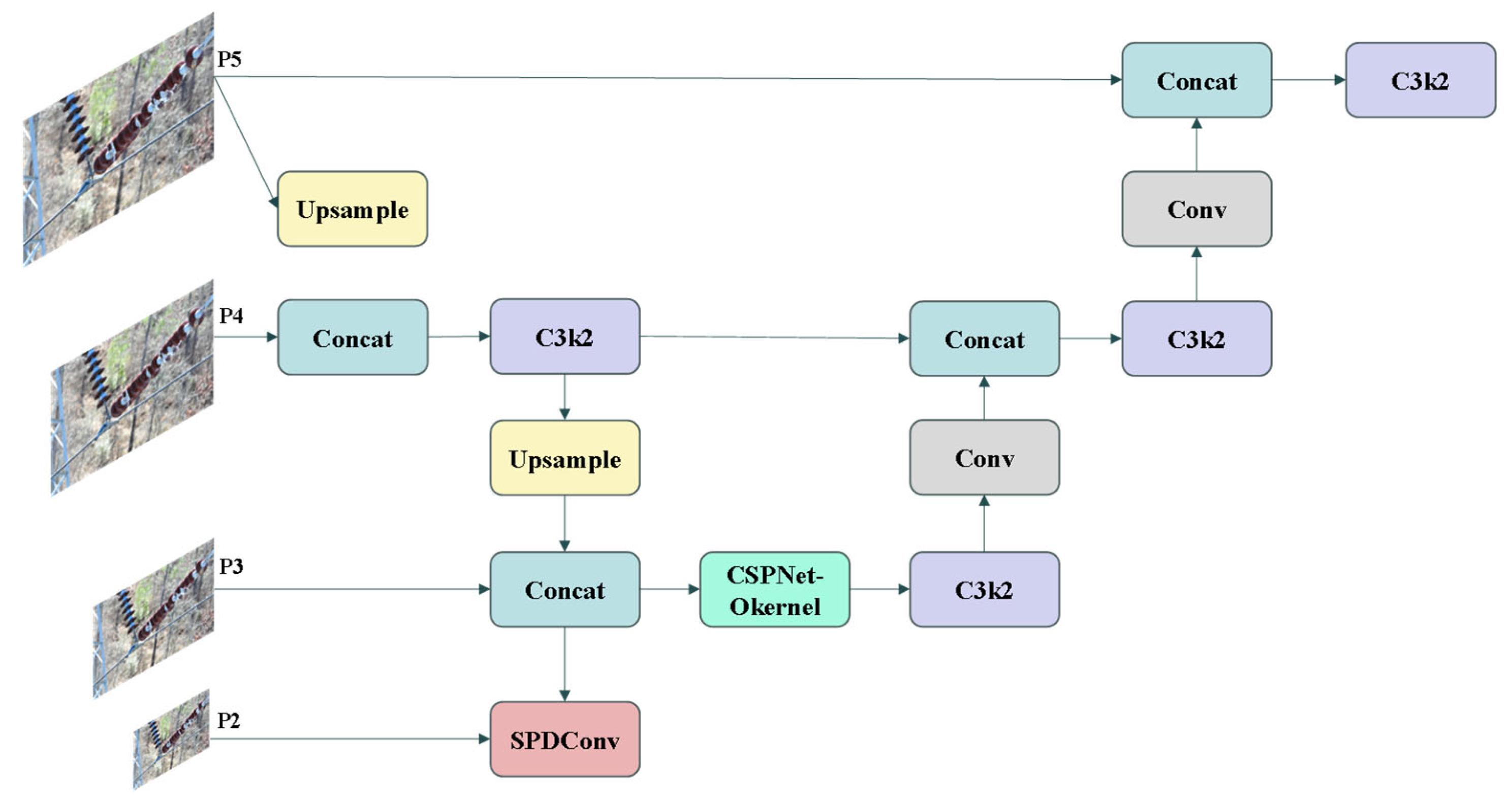

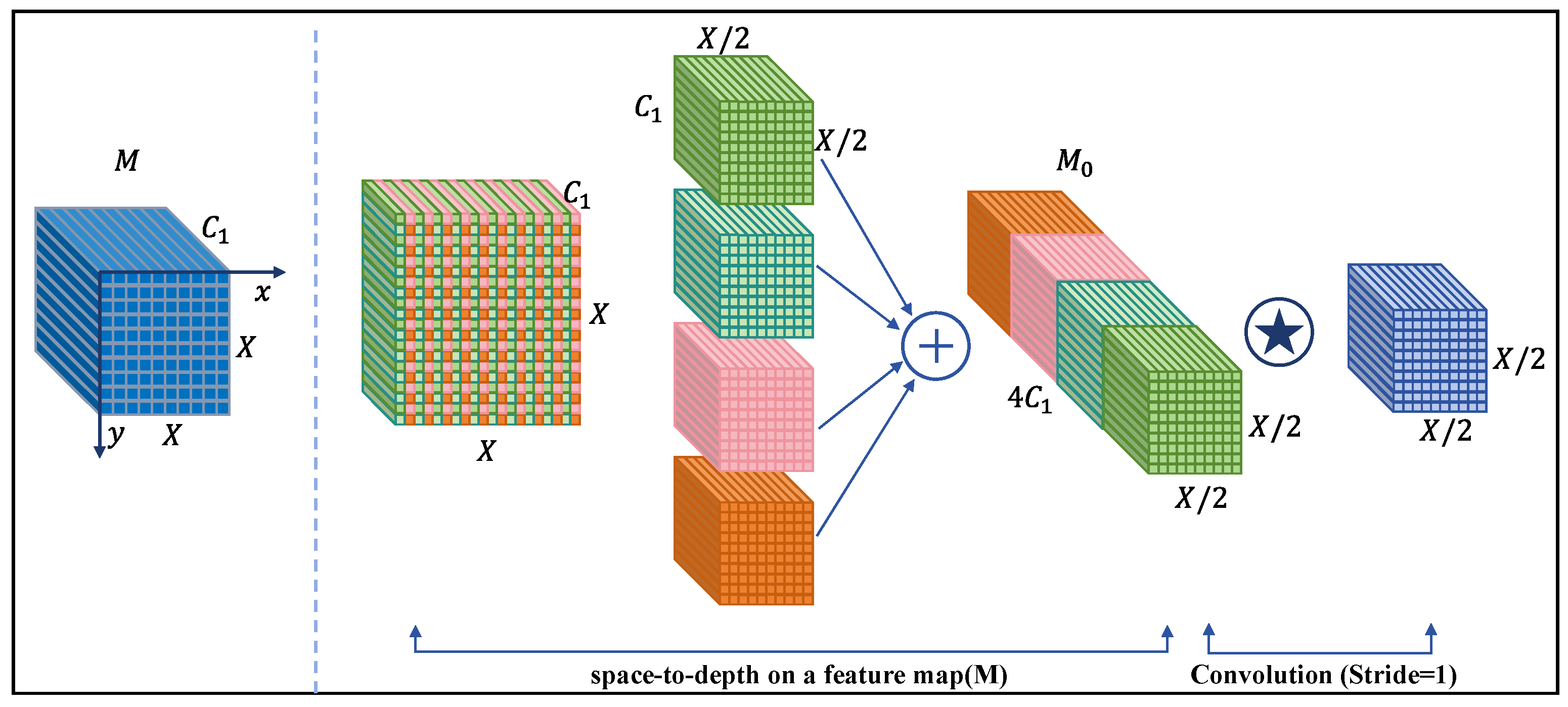

- Feature Pyramid Network of SOPN

- 3.

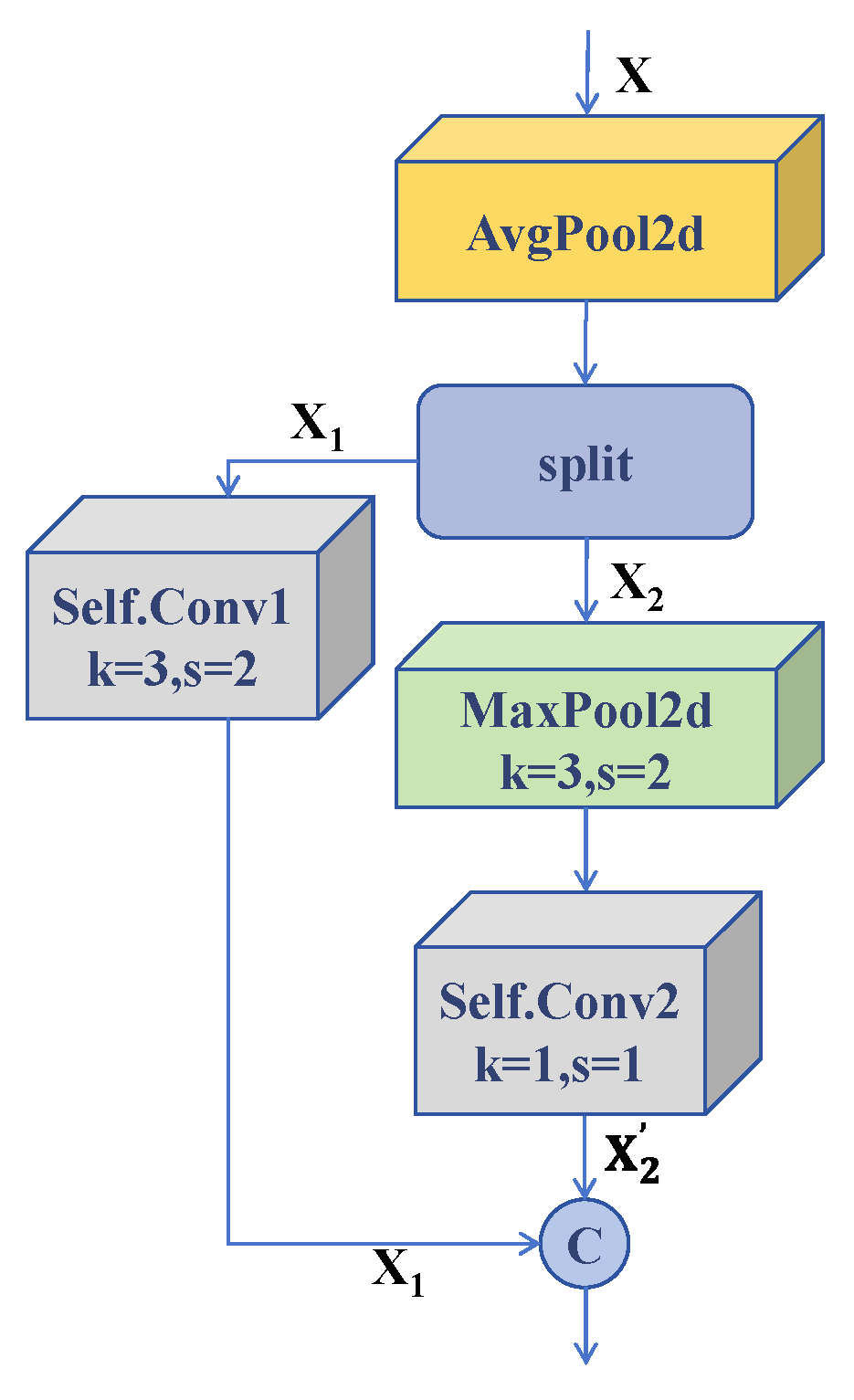

- ADown Module

- 4.

- Improvement in NWD Loss Function

3. Results

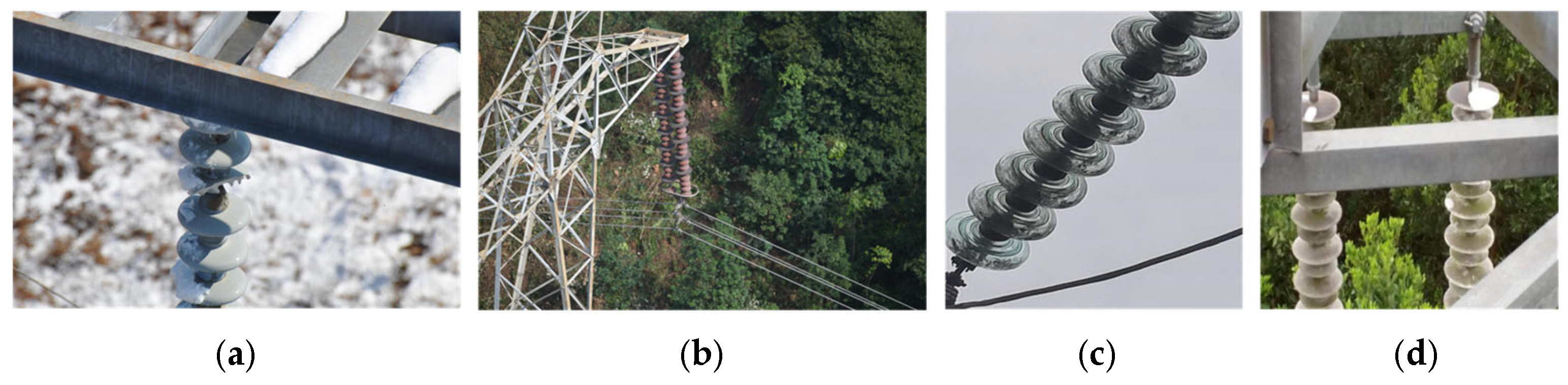

3.1. Dataset Preparation

3.2. Experimental Environment

3.3. Evaluation Metrics

3.4. Experimental Results and Analysis

- 1.

- Comparative Experiments

- 2.

- Ablation Experiments

- 3.

- Presentation of Detection Results

- (1)

- The YOLO11n-SSA algorithm significantly enhances the detection performance of small objects in complex backgrounds.

- (2)

- The YOLO11n-SSA algorithm improves the detection of small objects at long distances.

- 4.

- Visualization of Prediction Results: Heat Map Comparison Chart

4. Conclusions

- (1)

- The StarNet network structure is integrated into the model, which not only accelerates the model’s inference speed but also reduces both model size and parameter quantity. Additionally, the SOPN is incorporated in the model’s neck structure to strengthen multi-scale feature extraction for small objects, achieving enhanced detection performance through optimized feature fusion mechanisms. Furthermore, the ADown module is introduced to enhance the model’s capability of capturing image features while reducing its parameter quantity and size, thus enhancing the adaptability of the model for real-time object detection tasks. Ultimately, through the integration of the Normalized Wasserstein Distance (NWD), the loss function is reformulated by replacing conventional IoU metrics, achieving consistent accuracy improvements in small-object detection across multi-scale scenarios.

- (2)

- The proposed algorithm is tested and validated in this paper using the dataset. The experimental results demonstrate that the mAP@0.5 is effectively increased from 0.879 to 0.919, the mAP@0.5:0.95 from 0.652 to 0.707, the accuracy rate from 0.93 to 0.95, and the recall rate from 0.818 to 0.875. Moreover, it maintains a high detection speed, low parameter count, and low model size, reaching 13.4 ms, 2,438,620, and 4.94 MB, respectively. The experimental results confirm that the improved algorithm still has effective performance in detecting insulator defects under complex environmental conditions.

- (3)

- Although the YOLO11n-SSA algorithm has achieved accurate detection of insulator defects, opportunities for refinement persist in computational efficiency and parameter optimization. Future research will focus on optimizing the algorithm’s structure to achieve higher detection efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Hu, M.; Dong, J.; Lu, X. Summary of insulator defect detection based on deep learning. Electr. Power Syst. Res. 2023, 224, 109688. [Google Scholar] [CrossRef]

- Deng, L.; Wang, Z.; Liu, Q. AH-YOLO: An Improved YOLOv8-Based Lightweight Model for Fire Detection in Aircraft Hangars. Fire 2025, 8, 199. [Google Scholar] [CrossRef]

- Liu, F.; Mo, Q.; Zhao, X. Two-level optimal scheduling method for a renewable microgrid considering charging performances of heat pump with thermal storages. Renew. Energy 2023, 203, 102–112. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Z.; Nunez, A.; Han, Z. Unified deep learning architecture for the detection of all catenary support components. IEEE Access 2020, 8, 17049–17059. [Google Scholar] [CrossRef]

- Song, B.; Li, X. Power line detection from optical images. Neurocomputing 2014, 129, 350–361. [Google Scholar] [CrossRef]

- Yi, W.; Ma, S.; Li, R. Insulator and Defect Detection Model Based on Improved Yolo-S. IEEE Access 2023, 11, 93215–93226. [Google Scholar] [CrossRef]

- Jenssen, R.; Roverso, D. Intelligent monitoring and inspection of power line components powered by UAVs and deep learning. IEEE Power Energy Technol. Syst. J. 2019, 6, 11–21. [Google Scholar] [CrossRef]

- Wang, D.; Yao, Y.; Zhang, S.; Zhu, R.; Zhao, W. Deep Learning Method for Detecting Heat Spots of Photovoltaic Modules Based on Infrared Thermal Images. Proc. CSEE 2023, 43, 9608–9616. [Google Scholar]

- Li, J.; Li, H.; Hu, X.; Li, S.; Qiao, J. Research progress of surface defect detection technology based on deep learning. Comput. Integr. Manuf. Syst. 2024, 30, 774–790. [Google Scholar]

- Hu, S. Development Direction and Application of Smart Grid Digital Twin Technology. Acta Energiae Solaris Sin. 2023, 44, 576. [Google Scholar]

- Wang, S.; Liu, Y.; Qing, Y.; Wang, C.; Lan, T.; Yao, R. Detection of insulator defects with improved ResNeSt and region proposal network. IEEE Access 2020, 8, 184841–184850. [Google Scholar] [CrossRef]

- Ma, B.; Fu, Y.; Wang, C.; Li, J.; Wang, Y. A high-performance insulators location scheme based on YOLOv4 deep learning network with GDIoU loss function. IET Image Process. 2022, 16, 1124–1134. [Google Scholar] [CrossRef]

- Cheng, H.; Zhai, Y.; Chen, R. Faster R-CNN based recognition of insulators in aerial images. Mod. Electron. Tech. 2019, 42, 98–102. [Google Scholar]

- Yaseen, M. What is yolov9: An in-depth exploration of the internal features of the next-generation object detector. arXiv 2024, arXiv:2409.07813. [Google Scholar]

- Ma, N.; Sun, Y.; Li, C.; Liu, Z.; Song, H. AHG-YOLO: Multi-category detection for occluded pear fruits in complex orchard scenes. Front. Plant Sci. 2025, 16, 1580325. [Google Scholar] [CrossRef]

- Hui, Z.; Fang, T. Optimization of YOLOv11 for Fire Hazard Detection in Ultra-Small Targets. Res. Sq. 2025. [Google Scholar] [CrossRef]

- Kang, J.; Wang, Q.; Liu, W.; Xia, Y. Detection Model of Multi-Defect of Aerial Photo Insulator by Integrating CAT-BiFPN and Attention Mechanism. High Volt. Eng. 2023, 49, 3361–3372. [Google Scholar]

- Wang, L.; Qin, J.; Yan, K.; Sun, H.; Sun, S.; Geng, Y. A Lightweight Insulator Defect Detection Model Based on YOLOv8. In Proceedings of the 2024 5th International Seminar on Artificial Intelligence, Networking and Information Technology, Nanjing, China, 22–24 March 2024; pp. 2349–2353. [Google Scholar]

- Dong, L.; Zhu, H.; Ren, H.; Lin, T.-Y.; Lin, K.-P. A novel lightweight MT-YOLO detection model for identifying defects in permanent magnet tiles of electric vehicle motors. Expert Syst. Appl. 2025, 288, 128247. [Google Scholar] [CrossRef]

- Jocher, G.; Chaurasia, A.; Qiu, J. YOLO by Ultralytics. Available online: https://github.com/ultralytics/ultralytics (accessed on 5 June 2024).

- Wang, C.-Y.; Yeh, I.-H.; Mark Liao, H.-Y. Yolov9: Learning what you want to learn using programmable gradient information. In Proceedings of the European Conference on Computer Vision, Milan, Italy, 29 September–4 October 2024; pp. 1–21. [Google Scholar]

- Wang, A.; Chen, H.; Liu, L.; Chen, K.; Lin, Z.; Han, J. Yolov10: Real-time end-to-end object detection. Adv. Neural Inf. Process. Syst. 2024, 37, 107984–108011. [Google Scholar]

- Tian, Y.; Ye, Q.; Doermann, D. Yolov12: Attention-centric real-time object detectors. arXiv 2025, arXiv:2502.12524. [Google Scholar]

- Li, M.; Li, S.; Wu, Y.; Hu, H.; Zhou, Y.; Zheng, X.; Ding, G.; Du, S.; Wu, Z.; Gao, Y. YOLOv13: Real-Time Object Detection with Hypergraph-Enhanced Adaptive Visual Perception. arXiv 2025, arXiv:2506.17733. [Google Scholar]

- Fu, J.; Tan, J.; Zhou, L.; Cai, H.; Chen, B. Analysis of Intelligent Defect Recognition Method in UAV Inspection Images of Transmission Lines. High Volt. Technol. 2023, 49, 103–110. [Google Scholar]

- Liu, Y.; Huang, X.; Liu, D. Weather-domain transfer-based attention YOLO for multi-domain insulator defect detection and classification in UAV images. Entropy 2024, 26, 136. [Google Scholar] [CrossRef] [PubMed]

- Jocher, G.; Qiu, J. Ultralytics YOLO11. Available online: https://docs.ultralytics.com/zh/ (accessed on 30 September 2024).

- Liu, C.; Wu, Y.; Liu, J. Research Progress of Deep Learning Methods for Insulator Defect Detection in UAV Aerial Images. J. Electrotech. 2024, 40, 2897–2916. [Google Scholar]

- Pei, S.; Wang, W.; Wu, P.; Hu, C.; Sun, H.; Li, K.; Wu, M.; Lan, B. Detection of hydrophobicity grade of insulators based on AHC-YOLO algorithm. Sci. Rep. 2025, 15, 9673. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Ren, J.; Li, S. PHL-YOLO: A real-time lightweight yarn inspection method. J Real-Time Image Process. 2025, 22, 20. [Google Scholar] [CrossRef]

- Ma, X.; Dai, X.; Bai, Y.; Wang, Y.; Fu, Y. Rewrite the stars. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 17–21 June 2024; pp. 5694–5703. [Google Scholar]

- Cao, Q.; Chen, H.; Wang, S.; Wang, Y.; Fu, H.; Chen, Z.; Liang, F. LH-YOLO: A Lightweight and High-Precision SAR Ship Detection Model Based on the Improved YOLOv8n. Remote Sens. 2024, 16, 4340. [Google Scholar] [CrossRef]

- Sunkara, R.; Luo, T. No more strided convolutions or pooling: A new CNN building block for low-resolution images and small objects. In Proceedings of the Joint European Conference on Machine Learning and Knowledge Discovery in Databases, Grenoble, France, 19–23 September 2022; pp. 443–459. [Google Scholar]

- Xu, G.; Liao, W.; Zhang, X.; Li, C.; He, X.; Wu, X. Haar wavelet downsampling: A simple but effective downsampling module for semantic segmentation. Pattern Recognit. 2023, 143, 109819. [Google Scholar] [CrossRef]

- Wang, J.; Xu, C.; Yang, W.; Yu, L. A normalized Gaussian Wasserstein distance for tiny object detection. arXiv 2021, arXiv:2110.13389. [Google Scholar]

| Model | Precision | Recall | mAP@0.5 | mAP@0.5:0.95 | Size (MB) | Parameters | Speed (ms) |

|---|---|---|---|---|---|---|---|

| Faster R-CNN | 0.852 | 0.757 | 0.895 | 0.578 | 317 | 413,640,000 | 60.6 |

| SSD | 0.805 | 0.773 | 0.827 | 0.477 | 181 | 238,800,000 | 40.7 |

| YOLOv7-t | 0.934 | 0.832 | 0.891 | 0.625 | 11.7 | 6,705,169 | 10 |

| YOLOv8n | 0.926 | 0.816 | 0.876 | 0.647 | 5.98 | 3,006,428 | 6 |

| YOLOv9-t | 0.915 | 0.796 | 0.856 | 0.627 | 5.82 | 2,618,120 | 18 |

| YOLOv10n | 0.917 | 0.812 | 0.872 | 0.640 | 5.51 | 2,707,430 | 7.5 |

| YOLO11n | 0.93 | 0.818 | 0.88 | 0.652 | 5.23 | 2,582,932 | 8 |

| YOLOv12n | 0.924 | 0.800 | 0.866 | 0.645 | 5.2 | 2,520,428 | 7.9 |

| YOLOv13n | 0.941 | 0.822 | 0.889 | 0.669 | 5.4 | 2,460,675 | 16 |

| YOLO11n-SSA (Ours) | 0.95 | 0.875 | 0.919 | 0.707 | 4.94 | 2,444,828 | 9.7 |

| StarNB | SOPN | ADown | NWD | Precision | Recall | mAP@0.5 | mAP@0.5:0.95 | Parameters | Size (MB) |

|---|---|---|---|---|---|---|---|---|---|

| 0.93 | 0.818 | 0.88 | 0.652 | 2,582,932 | 5.23 | ||||

| √ | 0.909 | 0.775 | 0.851 | 0.618 | 2,440,572 | 4.91 | |||

| √ | 0.95 | 0.866 | 0.919 | 0.705 | 3,062,868 | 6.17 | |||

| √ | 0.939 | 0.825 | 0.885 | 0.658 | 2,100,372 | 4.32 | |||

| √ | 0.931 | 0.828 | 0.888 | 0.656 | 2,582,932 | 5.23 | |||

| √ | √ | 0.946 | 0.872 | 0.92 | 0.7 | 2,920,508 | 5.85 | ||

| √ | √ | √ | 0.943 | 0.876 | 0.919 | 0.699 | 2,438,620 | 4.94 | |

| √ | √ | √ | √ | 0.95 | 0.875 | 0.919 | 0.707 | 2,438,620 | 4.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, S.; Qin, Y.; Li, B.; Zhang, Q.; Zhao, Y. Insulator Defect Detection Based on Improved YOLO11n Algorithm Under Complex Environmental Conditions. Electronics 2025, 14, 2898. https://doi.org/10.3390/electronics14142898

Dong S, Qin Y, Li B, Zhang Q, Zhao Y. Insulator Defect Detection Based on Improved YOLO11n Algorithm Under Complex Environmental Conditions. Electronics. 2025; 14(14):2898. https://doi.org/10.3390/electronics14142898

Chicago/Turabian StyleDong, Shoutian, Yiqi Qin, Benrui Li, Qi Zhang, and Yu Zhao. 2025. "Insulator Defect Detection Based on Improved YOLO11n Algorithm Under Complex Environmental Conditions" Electronics 14, no. 14: 2898. https://doi.org/10.3390/electronics14142898

APA StyleDong, S., Qin, Y., Li, B., Zhang, Q., & Zhao, Y. (2025). Insulator Defect Detection Based on Improved YOLO11n Algorithm Under Complex Environmental Conditions. Electronics, 14(14), 2898. https://doi.org/10.3390/electronics14142898