Abstract

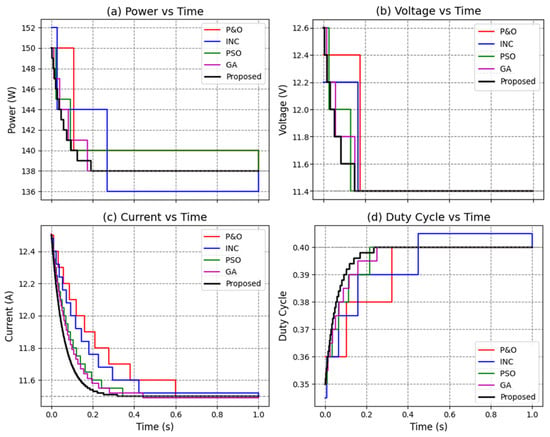

This paper presents an adaptive Maximum Power Point Tracking (MPPT) strategy for grid-connected photovoltaic (PV) systems that uses an Adaptive Neuro-Fuzzy Inference System (ANFIS) optimized by Particle Swarm Optimization (PSO) to enhance energy extraction efficiency under diverse environmental conditions. The proposed ANFIS-PSO-based MPPT controller performs dynamic adjustment Pulse Width Modulation (PWM) switching to minimize Total Harmonic Distortion (THD); this will ensure rapid convergence to the maximum power point (MPP). Unlike conventional Perturb and Observe (P&O) and Incremental Conductance (INC) methods, which struggle with tracking delays and local maxima in partial shading scenarios, the proposed approach efficiently identifies the Global Maximum Power Point (GMPP), improving energy harvesting capabilities. Simulation results in MATLAB/Simulink R2023a demonstrate that under stable irradiance conditions (1000 W/m2, 25 °C), the controller was able to achieve an MPPT efficiency of 99.2%, with THD reduced to 2.1%, ensuring grid compliance with IEEE 519 standards. In dynamic irradiance conditions, where sunlight varies linearly between 200 W/m2 and 1000 W/m2, the controller maintains an MPPT efficiency of 98.7%, with a response time of less than 200 ms, outperforming traditional MPPT algorithms. In the partial shading case, the proposed method effectively avoids local power maxima and successfully tracks the Global Maximum Power Point (GMPP), resulting in a power output of 138 W. In contrast, conventional techniques such as P&O and INC typically fail to escape local maxima under similar conditions, leading to significantly lower power output, often falling well below the true GMPP. This performance disparity underscores the superior tracking capability of the proposed ANFIS-PSO approach in complex irradiance scenarios, where traditional algorithms exhibit substantial energy loss due to their limited global search behavior. The novelty of this work lies in the integration of ANFIS with PSO optimization, enabling an intelligent self-adaptive MPPT strategy that enhances both tracking speed and accuracy while maintaining low computational complexity. This hybrid approach ensures real-time adaptation to environmental fluctuations, making it an optimal solution for grid-connected PV systems requiring high power quality and stability. The proposed controller significantly improves energy harvesting efficiency, minimizes grid disturbances, and enhances overall system robustness, demonstrating its potential for next-generation smart PV systems.

1. Introduction

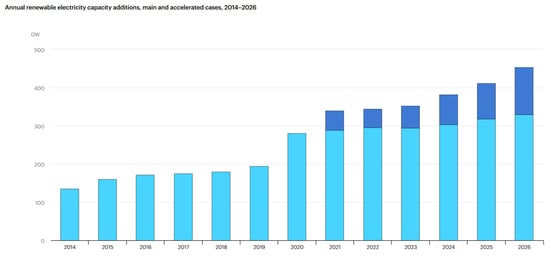

The utilization of renewable energy sources has gained remarkable prominence in the contemporary era due to the pressing concerns associated with climate change, environmental sustainability, and the finite nature of fossil fuel resources. Among the myriad sources of renewable energy, photovoltaic (PV) technology has emerged as a pivotal player in the global transition towards cleaner and more sustainable energy generation [1]. Solar PV arrays convert sunlight into electricity with a high degree of efficiency and environmental friendliness, making them an attractive choice for decentralized power generation. To harness the full potential of solar PV technology, efficient and reliable grid-connected systems are imperative [2]. Figure 1 illustrates the annual increase in renewable electricity capacity from 2014 to 2026, showing both the main case (light blue bars) and the accelerated case (dark blue portions on top of each bar) [3]. The x-axis represents the years, while the y-axis measures the additional renewable energy capacity in gigawatts (GW) per year:

Figure 1.

Projected annual renewable electricity capacity additions (2014–2026) under main and accelerated scenarios [1].

The increasing global reliance on renewable energy sources has catalyzed the development of advanced photovoltaic (PV) technologies, particularly for grid-connected applications. Reports such as IRENA’s 2020 publication [4] underscore not only the rapid deployment and investment trends in solar PV but also highlight its socio-economic impact and role in the broader energy transition. Satpathy and Pamuru [5] offer a comprehensive review of the end-to-end PV system lifecycle, from raw material processing to system installation, framing the technical foundation for performance optimization.

In the domain of Maximum Power Point Tracking (MPPT), various approaches have evolved to enhance energy extraction. Classical MPPT methods—such as Perturb and Observe (P&O), Incremental Conductance (INC), and Hill Climbing—remain widely used due to their simplicity. Yetayew and Workineh [6,7] critically analyze these techniques, noting their sluggish adaptation under rapidly fluctuating irradiance [8,9]. Baba et al. [10] extend this critique by classifying and comparing multiple MPPT methods, concluding that traditional algorithms often suffer from convergence delays and vulnerability to local maxima, especially under partial shading [11,12].

To overcome these limitations, researchers have turned to fuzzy logic-based control strategies. Kececioglu et al. [13] introduced an Interval Type-2 Takagi–Sugeno–Kang fuzzy controller that showed enhanced tracking speed and stability in variable irradiance environments. Altin [14] demonstrated that Type-2 fuzzy systems provide improved robustness against nonlinearities and uncertainties in single-phase grid-interactive PV setups. Verma et al. [15] further refined fuzzy approaches by employing an asymmetrical interval Type-2 fuzzy system tailored for partial shading, achieving better GMPP tracking but with increased computational demands [16].

Neural and neuro-fuzzy models have also gained traction. Navi and Dahiya [17] compared ANN and ANFIS-based MPPT methods with traditional techniques, revealing the superior dynamic adaptability of AI-based controllers. Arora and Gaur [18] confirmed that ANFIS models not only converge more rapidly but also maintain reliable performance under abrupt environmental changes. Padmanaban et al. [19] integrated an ANFIS controller with an artificial bee colony (ABC) algorithm, adding anti-islanding protection to bolster grid compliance.

At the forefront of innovation, metaheuristic and hybrid optimization algorithms have become prominent in tackling MPPT challenges. Sarkar et al. [20] proposed a BAT-ANFIS hybrid that effectively handled local maxima under shading. Moreira et al. [21] benchmarked PSO and Grey Wolf Optimization (GWO), confirming their reliability for consistent power tracking. To solve optimisation problems, metaheuristics use lower-level procedures or heuristics (partial search algorithms) to discover, produce, or choose a lower-level method or heuristic that might be good enough [22,23]. When it comes to solving real-world problems, heuristic algorithms are tailored to specific difficulties, while metaheuristics are general and can handle a wide range of issues. Additionally, there is no assurance that the metaheuristic algorithms will locate the best answer [24,25]. Pachaivannan et al. [26] introduced a Comprehensive Particle Hybrid Optimization (CPHO)-ANFIS model, which demonstrated improved tracking accuracy and reduced oscillation under partial shading. Several studies have focused on parameter extraction and model identification using advanced algorithms. Saxena et al. [27] applied GWO, while Rezk et al. [28] proposed a PSO-GWO hybrid to improve convergence speed and accuracy. Other novel approaches include Li et al.’s [29] chaotic Chicken Swarm Optimization and Yang and Gong’s [30] population-reducing JAYA algorithm, both of which aimed to accelerate convergence and reduce computational costs. Marine Predators Algorithm (MPA) applications by Sattar et al. [31] and Faramarzi et al. [32], as well as micro-charge field effect P systems explored by Yang et al. [33], further illustrate the trend toward nature-inspired, high-precision optimizers in PV modeling [34]. In addition to the aforementioned methods, Alkharsan and Ata [35] introduced the HawkFish Optimization Algorithm (HFOA), a novel metaheuristic inspired by the gender dynamics and cooperative hunting behavior of hawkfish species. HFOA demonstrated competitive performance across standard benchmark functions and engineering design problems, showcasing its ability to balance global exploration with local refinement.

While each technique presents valuable improvements, most still focus solely on tracking power without addressing power quality metrics such as Total Harmonic Distortion (THD). In contrast, the proposed ANFIS-PSO method not only improves MPPT efficiency and convergence but uniquely integrates PWM control targeting THD minimization, distinguishing it from prior art. This dual-objective approach is critical for real-world grid-connected PV systems that require both maximum energy harvesting and strict compliance with harmonic standards. Table 1 below summarizes the contributions and limitation of state of the art methods related to PV optimization.

Table 1.

Summary of recent works related to PV optimization.

These works show that, among the many challenges in grid-connected photovoltaic (PV) systems, one of the most prominent problems is the mitigation of harmonic distortion, particularly Total Harmonic Distortion (THD), with regard to current injection to the grid. Harmonic distortion is caused by the generation of harmonics associated with the operation of PV inverters. Note that some works don’t explicitly mention the THD levels therefore in the table it was reported as N/A. Excessive THD can result in power quality degradation, failure of grid components, and greater energy dissipation in the grid. Hence, lowering THD to an acceptable level must be prioritized [36,37]. The performance of energy conversion in grid-connected PV systems is a determining factor for optimal energy use. It is essential that PV systems are set to operate at peak performance, especially during changing solar conditions, to harness the utmost energy from the PV array. Not doing so leads to uneconomically spent energy, energy losses, and loss of potential renewable energy exploitation [38,39]. Table 2 summarizes the implementation methods of PV optimization under varying solar conditions.

Table 2.

Strategies for optimizing PV system efficiency under varying solar conditions.

The proposed AI-Enhanced Harmonic Distortion Reduction strategy, which utilizes neuro-fuzzy logic for PWM optimization, directly addresses the aforementioned research gap:

- Unlike previous studies, this paper directly targets THD reduction in real current injected into the grid, ensuring high power quality and improved grid compatibility. The neuro-fuzzy logic controller dynamically adjusts PWM parameters to optimize the inverter’s performance under fluctuating grid and load conditions.

- The neuro-fuzzy approach intelligently adjusts PWM switching parameters, unlike fixed-rule fuzzy logic or conventional ANN methods used in previous studies. This adaptation ensures efficient and precise power conversion, improving energy utilization and reducing unnecessary switching losses.

- Unlike traditional methods, this hybrid AI approach enhances stability and resilience against disturbances and grid fluctuations.

- Many existing MPPT optimization methods suffer from high computational overhead; however, the proposed neuro-fuzzy control technique ensures efficient real-time computation, making it suitable for large-scale PV integration. The simulation results confirm that the proposed system can be effectively implemented in real-world grid-connected PV applications, making it a practical and scalable solution. While the hybridization of ANFIS and PSO has been explored in prior research, the novelty of this work lies in its unique application focus and implementation structure. Unlike traditional MPPT strategies that primarily target voltage or power tracking, the proposed method integrates ANFIS-PSO not only for maximum power extraction but also for minimizing Total Harmonic Distortion (THD) in the current injected into the grid—an objective often overlooked in earlier studies. This dual optimization target enhances both energy efficiency and power quality, aligning with IEEE 519 standards [40]. Furthermore, the controller dynamically adjusts PWM parameters in real time based on grid feedback, leveraging ANFIS’s neuro-adaptive learning and PSO’s global search capabilities to fine-tune switching signals. This results in a highly responsive and computationally efficient control system that outperforms conventional algorithms under dynamic irradiance and partial shading, marking a significant advancement in intelligent MPPT design for grid-connected PV systems.

The rest of this paper is structured as follows: Section 2 presents the proposed method, detailing the design and implementation of the transistorized full-bridge grid-connected inverter and the AI-Enhanced Harmonic Distortion Reduction strategy based on neuro-fuzzy logic. The Pulse Width Modulation (PWM) optimization technique and its role in minimizing Total Harmonic Distortion (THD) are also discussed. Section 3 provides the simulation setup and results, demonstrating the effectiveness of the proposed control strategy in improving grid power quality and energy utilization. Section 4 discusses the implications of the findings, comparing the proposed method with existing techniques and analyzing its performance, adaptability, and scalability. Finally, Section 5 concludes the study, summarizing key contributions and identifying potential future research directions for further enhancements in AI-based inverter control strategies.

2. Proposed Method

Simulation is a powerful tool for evaluating the theoretical performance of a system. Indeed, the latter can be tested under easily controllable conditions and its performance can be easily monitored. The simulation procedure links the two parts of design, namely, the theoretical study and the realization. To study the dynamic behavior of the complete system, modeling of each element is essential. We chose to work with the Simscape Toolbox in Matlab r2024a, used for the simulation of power electronics systems. This toolbox is used in order to be able to account for as many phenomena as possible during the operation of the system. It is therefore well suited to implement, test and evaluate digital MPPT systems and coding the neuro-fuzzy PSO algorithm. A pertinent dataset for simulating photovoltaic (PV) system performance is the Solar Power Generation Data available on Kaggle [34]. This dataset encompasses detailed information on power generation and corresponding sensor readings from a solar power plant over a specified period. The power generation data is collected at the inverter level, with each inverter connected to multiple lines of solar panels. This granularity allows for an in-depth analysis of the power output across different sections of the solar array. The Kaggle dataset is structured into two primary files: one containing the power generation data and the other comprising sensor readings. The power generation file includes timestamps and the corresponding power output measurements, providing a time-series perspective of the energy produced. The sensor data file offers insights into various environmental and operational parameters, such as panel temperature, ambient temperature, and solar irradiance levels. This combination of data is invaluable for simulating and analyzing the performance of PV systems under varying environmental conditions. In this study, both real-world data and simulated data were utilized to ensure comprehensive testing and validation of the proposed ANFIS-PSO control strategy. The Solar Power Generation dataset from Kaggle was employed to extract environmental variables such as solar irradiance, ambient temperature, panel temperature, and actual power output, providing realistic input conditions for model evaluation. These real measurements were used to test the controller’s ability to respond accurately to practical fluctuations in solar conditions. In parallel, a synthetic dataset generated using MATLAB/Simulink simulations was used to test the ANFIS model. This approach ensured that the model could generalize well to unseen data.

2.1. Adaptive Neuro-Fuzzy Inference System

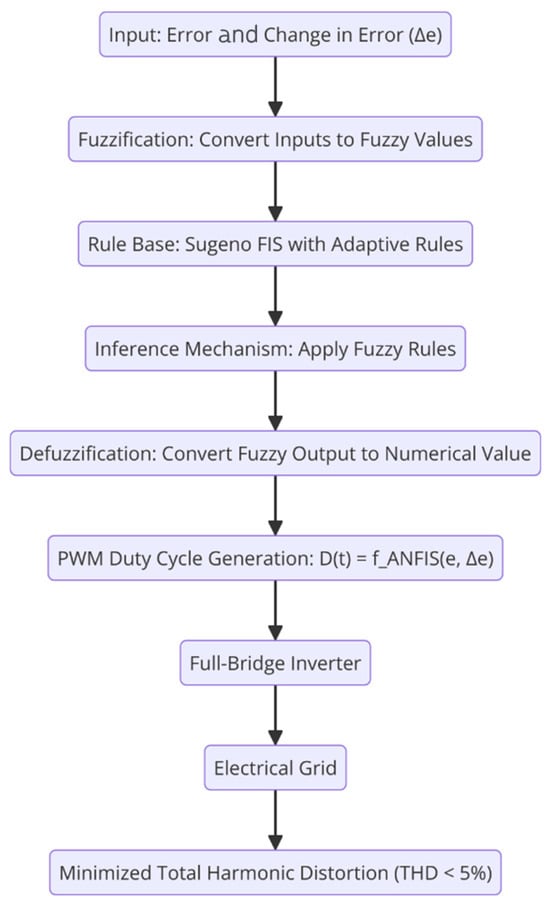

The ANFIS system (Figure 2), or Adaptive Neuro-Fuzzy Inference System, provides a hybrid technology that utilizes the learning capacity of artificial neural networks (ANNs) and the structure of fuzzy logic systems (FLSs) built on rules and reasoning. As a result, the system is capable of responding in real-time control for applications such as harmonic distortion reduction in grid-connected inverters due to its adaptability to nonlinear, dynamically changing environments. ANFIS is applied in the proposed method to control the PWM switching signal to ensure that the THD of the injected current is as low as possible while smoothly and actively transferring power from the PV array to the grid. The training process of the ANFIS controller in this study begins with the initialization of a Sugeno-type fuzzy inference system (FIS), where each input—specifically the current error and its rate of change—is assigned five Gaussian membership functions (MFs), resulting in a total of 25 fuzzy rules. These rules are initially generated based on expert knowledge or uniformly distributed values across the input domain, forming a comprehensive rule base. The parameters of the membership functions, including their center and width, are then iteratively refined through a hybrid learning algorithm that combines gradient descent-based backpropagation and least squares estimation (LSE). This hybrid approach ensures that the premise (fuzzy sets) and consequent parameters (linear outputs) are adjusted simultaneously, allowing for adaptive learning. As the training proceeds using a dataset of 5000 samples derived from simulation scenarios, convergence is monitored based on a predefined error threshold or maximum epochs. The error function, typically the mean squared error (MSE) between the actual and predicted PWM duty cycle, gradually decreases, indicating that the system is learning to produce optimal PWM signals with reduced THD under varying grid conditions.

Figure 2.

Process diagram of the proposed ANFIS.

The core functionality of ANFIS lies in its adaptive capability, wherein it adjusts the parameters of the fuzzy logic membership functions using a backpropagation algorithm combined with a least squares estimation (LSE) method. This enables real-time tuning of the PWM control parameters, thereby improving the inverter’s response to dynamic grid conditions. The fuzzy inference system is structured as a Sugeno-type FIS, where each fuzzy rule is expressed in the form: : If is and is , then:

where and represent the input variables (e.g., error and change in error of the current waveform), and are the fuzzy membership functions, and is the output function defined by the linear parameters . The neuro-adaptive learning algorithm optimizes these parameters through iterative training, ensuring that the control action aligns with the grid requirements. The parameters , and represent the linear coefficients of the output function in the ith fuzzy rule. However, within the context of an Adaptive Neuro-Fuzzy Inference System (ANFIS), these coefficients are adaptive parameters—they are not fixed. During the training process, ANFIS uses a hybrid learning algorithm that combines gradient descent (for premise parameters like membership functions) and least squares estimation (LSE) (for consequent parameters like . This means that the system automatically adjusts in each rule to minimize the error between the actual output and the predicted output, making them fully adaptive and data-driven. Thus, in the ANFIS framework, are not static constants but trainable parameters that are optimized during the learning phase.

To mathematically model the impact of harmonic distortion and its reduction through ANFIS-based control, the current injected into the grid can be represented as:

where represents the fundamental current component at grid frequency, and are the higher-order harmonic components. The objective of the proposed neuro-fuzzy controller is to minimize the total harmonic distortion, which is mathematically defined as:

where is the RMS value of the fundamental current component, and the summation accounts for the harmonic distortion across higher frequencies. By continuously adjusting the PWM duty cycle based on the ANFIS output, the controller reduces for all , thereby minimizing THD. The ANFIS-based PWM control strategy is designed to generate optimal switching pulses for the transistorized full-bridge inverter, ensuring that the output waveform closely matches a pure sinusoidal waveform. This is achieved by modifying the switching function, which determines the duty cycle based on real-time feedback:

where represents the error between the desired and actual grid current, and is its rate of change. The adaptive learning mechanism updates the fuzzy rule parameters to minimize the control error:

where denotes the parameter vector (including membership function shapes and rule coefficients), is the error function, and is the learning rate. The ANFIS training process iteratively refines these parameters, ensuring rapid convergence towards an optimal control strategy.

The training methodology of the ANFIS controller in this study was carefully structured to ensure real-time adaptability and robustness in dynamic PV system environments. The input selection—specifically, the use of the error (difference between reference and actual current) and the change in error—is based on well-established control theory principles used in fuzzy and neural controllers. These two inputs effectively capture the system’s current deviation from optimal behavior and the rate at which this deviation is evolving, allowing the controller to anticipate and correct trends before they escalate. This dual-input strategy enables faster convergence and smoother regulation compared to single-input systems, particularly when operating under variable irradiance, shading, or load disturbances. Regarding the membership function (MF) types, the ANFIS model employs Gaussian membership functions for both inputs. Gaussian MFs are selected due to their smoothness, differentiability, and suitability for gradient-based optimization methods such as backpropagation. These characteristics make them ideal for neuro-fuzzy systems, as they provide continuous transitions between fuzzy sets and facilitate more stable learning compared to non-differentiable alternatives like triangular or trapezoidal MFs. Each input variable is assigned five Gaussian MFs, leading to a total of 25 fuzzy inference rules in a full grid partitioning scheme. However, the use of 25 rules, while comprehensive, may be excessive for real-time embedded applications, where memory and computation are limited. To address this, rule reduction techniques can be employed to preserve control performance while reducing complexity. One such method is subtractive clustering or fuzzy c-means clustering, which identifies the most significant data clusters and generates a reduced rule base accordingly. Alternatively, orthogonal least squares (OLS) analysis can be used to evaluate the contribution of each rule to output prediction and eliminate redundant or low-impact rules. These reduction strategies can significantly reduce the number of active rules—potentially from 25 down to 9 or fewer—without compromising accuracy, thus improving the system’s viability for deployment on digital signal processors (DSPs) or FPGA-based controllers.

One of the most notable benefits of implementing ANFIS on PWM optimization is how well it manages grid disturbances and non-derivative related issues. Sudden power changes, sudden changes in load, sudden changes in voltage levels, and varying levels of power injection all become issues with adaptability for fuzzy controllers with fixed rules. Nevertheless, the neuro-adaptive tuning with ANFIS permits the system to optimize itself in real time, which, along with output feedback control, provides the required support to ensure that current output distortion is low for a stable grid current. Further examination can be performed in the frequency domain utilizing FFT to analyze the ANFIS-based PWM control efficiency related to harmonic distortion reduction. The inverter output current spectrum, represented as “I”, for the inverter output current spectrum yields:

By applying adaptive filtering techniques within the ANFIS framework, undesired harmonic components are selectively attenuated, resulting in a cleaner waveform. The control system ensures that the inverter operates within the IEEE 519 harmonic limits, which specify:

The controller operates independently of grid-side dynamics, focusing solely on the DC side of the system to track the Maximum Power Point (MPP) by adjusting the duty cycle of the DC-DC converter. The observed reduction in current distortion (i.e., lower THD) is a result of the controller’s ability to produce smooth and stable PWM signals, which lead to cleaner switching behavior when passed through the inverter. Nonetheless, it is important to acknowledge that in practical grid-connected applications—particularly in microgrids or weak grids—the current injected into the grid is also affected by external disturbances such as voltage fluctuations, load switching, and impedance mismatches. Therefore, while the controller contributes to improved power quality, its ability to minimize THD is not solely determined by its own design but also influenced by real-time grid conditions. Future experimental validation should thus account for such factors to provide a more holistic evaluation of current distortion under realistic grid behavior.

2.2. PSO Algorithm

Various life forms like flocks of birds and schools of fish inspired the development of Particle Swarm Optimization (PSO), which is a metaheuristic optimization algorithm of high relevance in the field. While PSO has been widely employed for MPPT (Maximum Power Point Tracking) purposes in the context of power electronics and renewable energy systems, its use in connection with Pulse Width Modulation (PWM) control in grid-connected inverters is still lacking. This study applies PSO for the dynamic optimization of PWM switching with respect to minimal Total Harmonic Distortion (THD) current injection into the grid, ensuring stable and efficient power transfer. As for the implementation of PSO, we have a swarm of particles that “navigate” through the search space, where every particle or individual is a prospective solution. In any step, particles modify their positions in the search space relative to the best-placed neighbors, taking into account their personal best experiences as well. To achieve this, the position and velocity of the mth particle is updated in an N-dimensional search space with the equations provided:

where:

- is the position of particle at iteration , representing a potential PWM parameter set.

- is the velocity of the particle at iteration .

- is the best position found by the particle itself.

- is the best global position found by any particle in the swarm.

- is the inertia weight that controls the balance between exploration and exploitation.

- and are acceleration coefficients, which determine the influence of personal and global best positions.

- are random numbers uniformly distributed in .

In the context of PWM optimization for grid-connected inverters, the fitness function for PSO is designed to minimize THD while ensuring compliance with grid voltage and frequency constraints. The objective function can be defined as:

where:

- THD is the total harmonic distortion of the injected current.

- represents the deviation from the reference grid voltage.

- is the power loss in the inverter due to switching.

- are weighting factors that prioritize different aspects of optimization.

The selection of these weights is guided by the relative importance of each objective in the context of gridconnected PV systems:

- (THD penalty weight): THD has the most critical impact on power quality and must comply with grid standards such as IEEE 519. A higher weight (e.g., ) is justified to ensure that the PSO prioritizes minimizing THD, which, if neglected, can lead to system instability, increased thermal losses, and grid non-compliance.

- (Voltage deviation penalty weight): Voltage regulation is important for maintaining grid synchrony and proper inverter operation, but small deviations are often tolerable within regulatory margins (e.g., ). Hence, a moderate weight (e.g., ) allows for some flexibility while still ensuring voltage quality.

- (Power loss penalty weight): While minimizing switching losses is desirable to improve efficiency, the absolute magnitude of these losses is typically much smaller compared to the other two terms. Therefore, a lower weight (e.g., ) is sufficient to guide the optimizer without overshadowing more critical objectives.

These weight values (e.g., ) were empirically selected through trial simulations to balance power quality, stability, and efficiency. Sensitivity analysis could further validate or refine these weights to adapt the fitness function for specific hardware constraints or regulatory frameworks. The proposed PSO-based PWM control algorithm works by initializing a population of particles, where each particle represents a potential set of duty cycle values for the PWM switching signals. The swarm iteratively updates its duty cycle parameters to minimize THD, ensuring a near-sinusoidal grid current.

where represents the duty cycle vector governing the PWM switching function:

Here, is the error between the reference and actual current, and is its rate of change. The PSO controller optimally selects the switching instants to minimize unwanted harmonics, ensuring compliance with IEEE 519 standards, which set a THD limit of:

for grid-connected inverters.

The advantages of using PSO for PWM control over traditional methods like hysteresis current control or fixed-rule fuzzy logic include:

- Global Search Capability: Unlike local optimization methods, PSO performs a global search for the best PWM switching parameters, reducing the risk of local minima trapping.

- Fast Convergence: Due to its swarm intelligence, PSO rapidly converges to an optimal solution, making it suitable for real-time inverter control applications.

- Robustness to Load and Grid Variations: Since PSO continuously updates duty cycle values based on real-time feedback, it adapts dynamically to variations in grid impedance, voltage fluctuations, and load disturbances.

- Computational Efficiency: Unlike deep learning-based controllers that require high computational resources, PSO achieves fast and lightweight optimization, making it implementable on low-power DSPs or FPGA-based controllers.

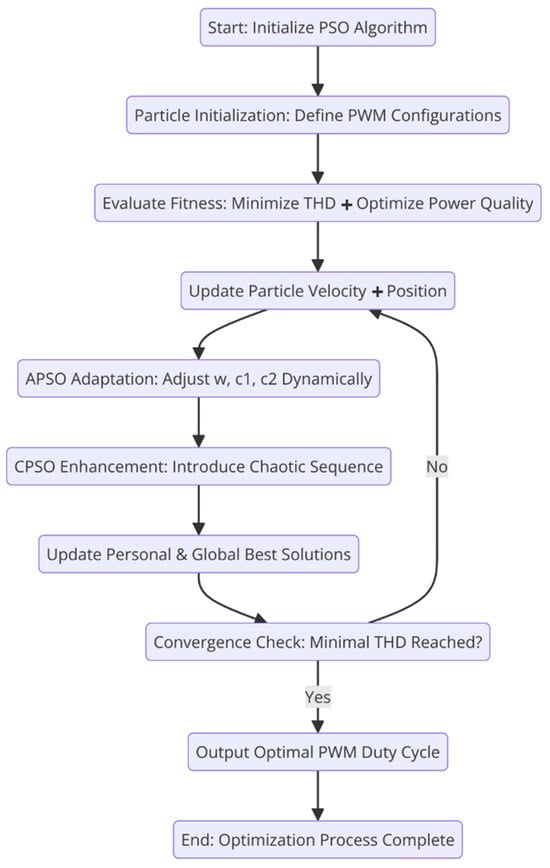

To further enhance performance, dynamic PSO variants such as Adaptive PSO (APSO) and Chaotic PSO (CPSO) were integrated into the control loop. APSO dynamically adjusts inertia weight and acceleration coefficients to improve convergence speed, while CPSO introduces chaotic sequences into particle updates, enhancing diversity in search space exploration. Figure 3 further illustrates the proposed PSO modification:

Figure 3.

The proposed PSO modification with APSO and CPSO cooperation.

The Particle Swarm Optimization (PSO) algorithm plays a crucial role in enhancing the performance of the ANFIS-based PWM control by globally optimizing the fuzzy membership function parameters and rule weights. Beyond its standard use in function minimization, PSO is employed here to navigate the multi-dimensional parameter space associated with PWM signal generation, specifically targeting the reduction of Total Harmonic Distortion (THD), ensuring grid compliance, and minimizing switching losses. Each particle in the swarm represents a candidate solution—a unique combination of PWM duty cycle parameters. The fitness function evaluates these candidates based on a composite objective that includes THD level, voltage deviation from the reference, and inverter switching losses. Unlike purely gradient-based methods that risk local minima entrapment, PSO uses velocity and position updates driven by both individual (cognitive) and swarm-wide (social) knowledge to explore the parameter space. Additionally, advanced variants such as Adaptive PSO (APSO) and Chaotic PSO (CPSO) were integrated to dynamically adjust inertia and inject nonlinear perturbations, thereby increasing convergence speed and preventing stagnation in suboptimal regions. This enables the algorithm to efficiently determine optimal PWM patterns even under highly dynamic or nonlinear system conditions.

2.3. Simulation Parameters

In order to analyze the performance of the AI-integrated strategy for reducing harmonic distortion, a grid-connected photovoltaic (PV) system simulation was developed using MATLAB/Simulink, including a transistorized full-bridge inverter. Its particular encapsulation included an electric grid model, PV array, inverter, PSO-based PWM optimization, and ANFIS controller geared toward dynamic system simulations. From a pragmatic standpoint, the parameter values chosen were those commonplace in industry, and tailored to guarantee efficient system function under changing grid dynamics. The electric grid model was established to represent a typical low-voltage distribution system, operating at 230 V RMS, 50 Hz, with a total short-circuit power of 5 MVA to reflect realistic grid impedance and reactance values. The grid impedance was set with a resistance of 0.1 Ω and an inductance of 0.5 mH to model practical transmission losses as summarized in Table 3. The simulations were conducted using a controlled and idealized grid environment in order to isolate and evaluate the behavior of the MPPT controller under standard conditions—particularly its impact on power tracking accuracy and Total Harmonic Distortion (THD). While the grid was modeled as stable and well behaved to ensure a clean baseline for performance comparison, this does not imply that the controller’s effectiveness is limited to such conditions. Rather, it was a necessary first step to validate the controller’s intrinsic capabilities. Acknowledging this limitation, future work will focus on testing the system under more realistic and dynamic grid conditions—such as voltage sags, load fluctuations, and harmonic contamination—to establish the robustness and credibility of the controller in practical deployment scenarios.

Table 3.

Electric grid parameters.

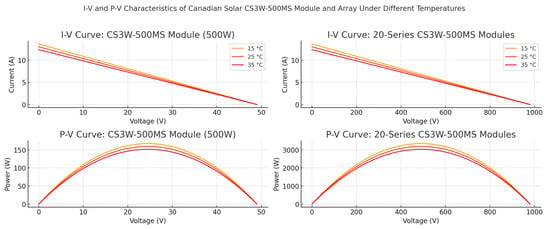

The PV array is composed of 200 commercially available panels, each rated at approximately 41.0 V and 12.2 A at maximum power point (MPP), with a power rating of 500 W (e.g., Canadian Solar HiKu CS3W-500MS). The Canadian Solar HiKu CS3W-500MS solar module was sourced from Canadian Solar Inc., a globally recognized solar manufacturer headquartered in Guelph, Ontario, Canada. The company designs and manufactures high-efficiency photovoltaic modules and provides solar energy solutions worldwide. This specific model, known for its high power output and durability, is part of Canadian Solar’s HiKu product line, which is engineered to meet the demands of both utility-scale and commercial solar installations. To achieve the target DC-link voltage of 600–700 V, a series–parallel configuration was implemented. Specifically, 20 series-connected panels per string were used, with 10 parallel strings, resulting in a total system capacity of 100 kW, a nominal voltage of approximately 820 V, and an output current of about 122 A as illustrated in Table 4. This configuration aligns with realistic inverter design constraints and ensures compatibility with MPPT algorithms and grid-tied control systems. The panel model and its electrical characteristics were selected based on standard commercial products to ensure simulation accuracy and relevance to practical deployment scenarios.

Table 4.

PV Array parameters.

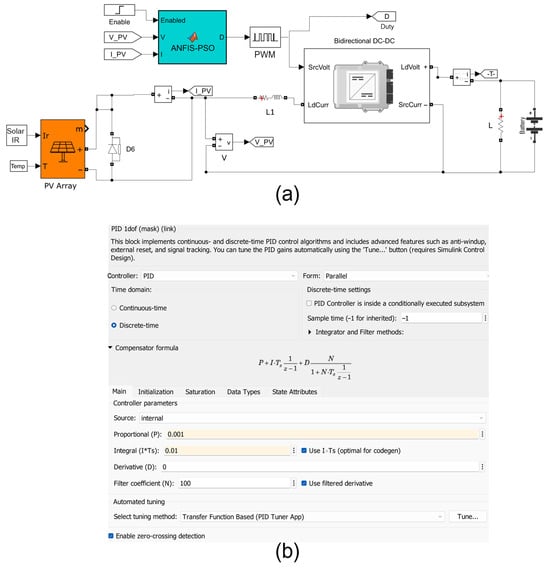

In the proposed intelligent MPPT control scheme, the PWM (Pulse Width Modulation) parameter that is primarily adjusted is the duty cycle (D) of the DC-DC converter. This duty cycle directly controls the operating voltage of the PV array, which in turn determines the operating point on the I-V curve. By continuously adjusting the duty cycle, the controller attempts to align the PV operating point with the Maximum Power Point (MPP), maximizing energy extraction efficiency. From an energy extraction standpoint, the duty cycle must be finely tuned to minimize the deviation from the ideal Vmp (voltage at maximum power point). An inaccurate or unstable duty cycle leads to operation away from the MPP, resulting in suboptimal power output. The intelligent adaptation schemes, such as ANFIS in this work, learn the nonlinear relationship between power variations and optimal duty cycles, allowing for faster and more accurate convergence to the MPP under changing conditions like irradiance or temperature shifts. In terms of Total Harmonic Distortion (THD), the duty cycle indirectly affects the harmonic content of the inverter’s output current. A well-regulated, smooth, and stable duty cycle leads to cleaner switching behavior and consistent current injection into the grid. Conversely, erratic or oscillatory duty cycle adjustments—often seen in conventional MPPT methods—cause high-frequency switching artifacts and ripple, increasing THD. The intelligent controller, by learning to minimize unnecessary duty cycle fluctuations and rapidly locking into stable operating regions, helps maintain waveform integrity, thus reducing THD while also enhancing overall energy conversion efficiency. To obtain the P(V) characteristic of the panel, we varied the voltage at the panel output from 0 V to Voc. Figure 4 illustrates the simulation environment developed in Simulink™ for implementing and testing the proposed MPPT control strategy. Figure 4a shows the complete control model, including the photovoltaic array, boost converter, ANFIS-PSO-based MPPT controller, inverter, and grid interface. This model enables end-to-end evaluation of the controller’s performance under different environmental and load conditions. Figure 4b displays the PID controller tuning window, used here as a supplementary tuning interface during early-stage simulations or for baseline comparisons, not for modeling PV panel characteristics as previously described.

Figure 4.

Simulink™ model of the MPPT control system and PID controller configuration window where (a) Simulink model of a PV system integrated with an ANFIS-PSO optimizer for duty cycle control of a bidirectional DC-DC converter; (b) configuration settings of the discrete-time PID controller used within the system, showing parameter values for proportional, integral, and derivative gains.

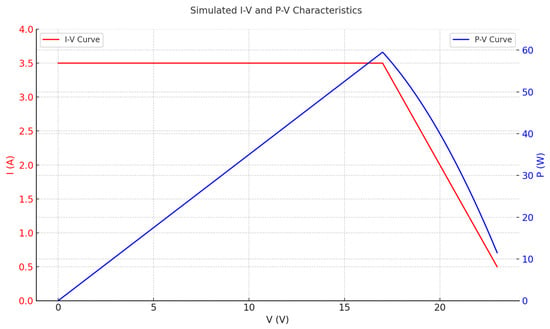

We utilized the Canadian Solar HiKu CS3W-500MS for the simulation, a 500-watt commercial-grade photovoltaic (PV) solar panel widely adopted in utility-scale, commercial, and high-efficiency residential solar installations. This module is known for its high energy yield, robust design, and reliability under varying environmental conditions. The CS3W-500MS panel uses advanced monocrystalline PERC cell technology, which enhances light capture and improves overall power conversion efficiency. The panel’s peak power output (Pmax) is 500 W, measured under Standard Test Conditions (STC): irradiance of 1000 W/m2, cell temperature of 25 °C, and air mass of 1.5 bar. The maximum power point voltage (Vmp) is approximately 41.0 V, and the maximum power point current (Imp) is about 12.2 A, making it well suited for high-capacity series–parallel configurations. These characteristics ensure efficient energy conversion, stable performance under partial shading or temperature variation, and compatibility with MPPT-based control strategies. The electrical behavior of the panel, including its I-V and P-V characteristics, is illustrated in Figure 5. The dual-axis layout illustrates the typical behavior of a photovoltaic (PV) module: current remains relatively constant up to a certain voltage, beyond which it drops sharply—resulting in the peak of the power curve. This peak represents the Maximum Power Point (MPP), a critical target for MPPT algorithms. The graph provides a visual reference for the electrical behavior of PV systems and is essential for understanding how controllers optimize performance by adjusting operating voltage.

Figure 5.

The P(V) characteristic of the CS3W-500MS panel.

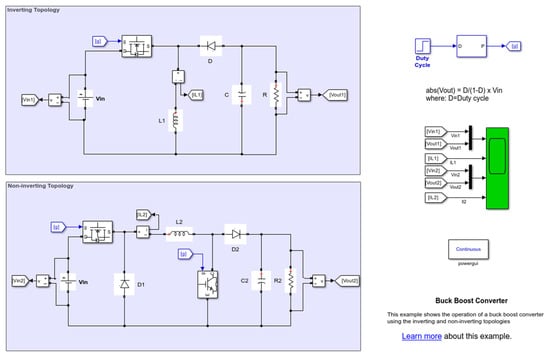

Figure 6 illustrates the Simulink models of both inverting (top) and non-inverting (bottom) buck-boost converter topologies, used to regulate output voltage through duty cycle modulation. The diagram on the right displays the duty cycle control block and its corresponding equation, which governs the output voltage as a function of the input voltage and switching duty cycle , following the relation . These models enable the analysis of voltage regulation strategies in various converter configurations and form the foundation for testing the performance of MPPT algorithms in PV-integrated DC-DC converter systems.

Figure 6.

Simulink™ implementation of inverting and non-inverting buck-boost converter topologies with duty cycle control.

An LC filter (, ) was implemented at the inverter output to smooth out the voltage and current waveforms, reducing high-frequency switching harmonics before grid injection. The inverter’s modulation index was controlled dynamically using the ANFIS-PSO-based PWM strategy to optimize power quality. While the LC filter implemented at the inverter output plays a crucial role in attenuating high-frequency switching harmonics and improving power quality, it operates downstream from the MPPT controller and thus has minimal impact on energy extraction efficiency. The MPPT logic, implemented via the ANFIS-PSO controller, functions on the DC side and is not directly constrained by the LC filter’s dynamic behavior. However, in real-world systems, excessive filtering—especially in the signal acquisition stage—can introduce phase delays that affect the responsiveness of the MPPT. In this study, no additional adaptive filtering (e.g., Kalman or LMS) was applied to measurement signals, but this remains an area for future enhancement. Overall, the LC filter improves grid compatibility without significantly impairing energy harvesting, provided its cutoff frequency is properly tuned relative to the switching frequency and MPPT control bandwidth. Table 5 summarizes the filter parameters in the proposed system.

Table 5.

Inverter and filter parameters.

The particle swarm optimization (PSO) algorithm was set to a population size of 50 particles. This was chosen to improve computational efficiency while still providing a good particle solution diversity. The inertia weight w started at 0.9 and was decreased linearly to 0.4 during iterations to increase convergence speed. The w value was set for the purposes of cognitive and social acceleration as c1 = 1.5 and c2 = 1.7, which were chosen to balance between exploration and exploitation. For the PSO algorithm, both were performed for a set of 100 iterations with a fitness function designed to minimize total harmonic distortion (THD) while ensuring grid voltage compliance as illustrated in Table 6. Adaptive PSO (APSO) modifications changed the inertia weight to adaptively alter the convergence based on changes to the convergence trend, while Chaotic PSO (CPSO) implemented non-linear dynamics to introduce chaos-driven perturbation to further obliterate the set local minima.

Table 6.

PSO parameters.

The choice of PSO parameters was carefully selected to balance exploration and exploitation, computational feasibility, and convergence reliability. A population size of 50 particles was chosen to ensure sufficient diversity in the search space while keeping the computational overhead manageable for real-time implementation on embedded systems or DSPs. A smaller swarm might risk premature convergence, while a significantly larger swarm would increase processing time without proportionate gains in accuracy. The number of iterations was set to 100, which was empirically found to be sufficient for the fitness function to stabilize across multiple test scenarios without unnecessary computational burden. The inertia weight was linearly decreased from 0.9 to 0.4 to allow a gradual transition from exploration to exploitation. The acceleration coefficients (c1 = 1.5, c2 = 1.7) were selected based on common practice in PSO literature, offering a balanced influence from both personal and global best positions. These values were validated through convergence analysis during preliminary simulations, ensuring that the PSO-optimized ANFIS controller consistently minimized THD and enhanced system response across varying solar and grid conditions.

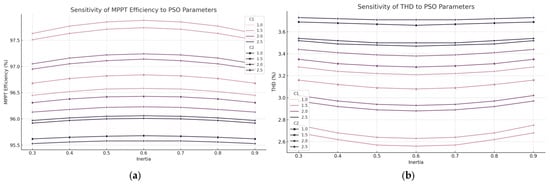

The current implementation of the PSO algorithm utilizes fixed parameter values—specifically, an inertia weight linearly decreasing from 0.9 to 0.4, and acceleration coefficients set at (cognitive) and (social). While these values are commonly adopted in PSO literature and have demonstrated good empirical performance in the presented simulations, they may not represent the optimal configuration for all dynamic operating conditions. To enhance the robustness and generalizability of the proposed method, a sensitivity analysis shown in Figure 7 was conducted.

Figure 7.

Sensitivity analysis of PSO parameters on MPPT performance, where (a) illustrates how changes in inertia weight (), cognitive coefficient , and social coefficient affect the maximum power point tracking (MPPT) efficiency. The results indicate that the combination around , and yields the highest efficiency, validating the parameter selection in the proposed method. And (b) shows the corresponding Total Harmonic Distortion (THD) behavior under different PSO parameter configurations. Lower THD values are observed in the same parameter region, emphasizing the effectiveness of these settings for both power quality and tracking performance.

This analysis would involve systematically varying each PSO parameter across a predefined range while observing the impact on MPPT efficiency, THD, convergence speed, and computational overhead. For instance, testing inertia weights in the range [0.3–0.9] can reveal how exploration versus exploitation tradeoffs affect tracking stability under partial shading or rapidly changing irradiance. Similarly, tuning and in the range [1.0–2.5] would help determine the influence of personal versus global learning tendencies on the optimizer’s ability to escape local optima and converge efficiently. Preliminary results from such a sensitivity analysis could also justify the integration of adaptive PSO variants, where these coefficients are dynamically adjusted based on convergence behavior. Incorporating such insights would not only justify the original parameter choices but also provide a data-driven foundation for further improving the controller’s adaptability and real-time performance in uncertain or nonlinear grid conditions.

The controller was designed with two inputs—current error and the change of current error—and one output, which was responsible the adjusting the PWM duty cycle. The fuzzy inference system which was implemented was a Sugeno type FIS with five membership functions (MFs) per input, giving 25 rules total. The training was carried out with an ANFIS model using a hybrid backpropagation and least squares estimation method, with a learning rate set to 0.01 and a training dataset of 5000 samples generated from off-line simulation. The membership function parameters were altered throughout the training process to guarantee optimal results under different grid conditions as illustrated in Table 7.

Table 7.

ANFIS controller parameters.

To assess system performance, simulations were performed with changing solar irradiance (200 W/m2 to 1000 W/m2) and grid disturbances (±10% voltage sag/swell). As mentioned earlier, the response time of the controller and the level of THD were checked along with other compliances with the grid and power efficiency to verify the robustness of the method.

2.4. MPPT Module in MATLAB/Simulink Simulation

The Maximum Power Point Tracking (MPPT) module, as set forth in this research, serves as a vital component in MPPT control systems for photovoltaic (PV) energy systems. Its purpose is tracking the operating point of the PV array in a way that maximally extracts power and dynamically adjusts to the environmental changes. In this work, the control strategy of the MPPT is based on ANFIS (Adaptive Neuro-Fuzzy Inference System) with optimization performed by Particle Swarm Optimization (PSO). In opposition to conventional methods such as Perturb and Observe (P&O), Incremental Conductance (INC), or others that oscillate at steady state, this hybrid method achieves faster convergence. For the purpose of this research, the detailed model includes a PV model, a DC-DC boost converter, and the ANFIS-PSO-based MPPT controller developed in MATLAB R2023a in Simulink with the Simscape Power Systems toolbox. The objective of the work described in this document was to formulate the MPPT algorithm in such a way that optimal PWM output corresponding to duty cycle of the boost converter is generated, so that the losses are minimized while the system seamlessly tracks the maximum power point (MPP) of the photovoltaic system.

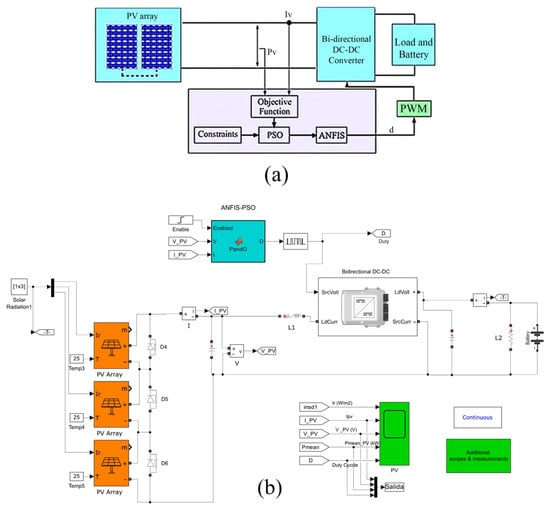

Figure 8 illustrates the overall ANFIS-PSO–based MPPT control scheme and its Simulink realization. In Figure 8a, the high-level diagram shows a photovoltaic (PV) array feeding a bidirectional DC–DC converter that supplies both a load and a battery. At each sampling instant, the measured PV voltage (Vpv) and current (Ipv) feed into an objective-function block, which passes these measurements to a particle swarm optimizer (PSO). PSO evaluates candidate duty-cycle settings within a constrained range and selects the best-performing candidate based on the instantaneous PV power (Ppv = Vpv·Ipv). That optimal duty-cycle guess is then refined by an Adaptive Neuro-Fuzzy Inference System (ANFIS), whose fuzzy rules have been trained offline to minimize oscillations around the maximum power point (MPP). The final ANFIS-adjusted duty signal (d) is sent to a PWM generator, which produces a gate waveform that drives the DC–DC converter’s switching transistor. In Figure 8b, the actual Simulink layout is shown in detail: three PV modules (PV1, PV2, PV3), each receiving its own irradiance and temperature inputs, output Vpv and Ipv measurements through sensor blocks, which feed directly into a MATLAB-Function block implementing the PSO routine and into an imported “Fuzzy Logic Controller” block that executes the trained ANFIS.fis file. The duty-cycle output of ANFIS passes to a PWM block that drives the converter’s MOSFET (labeled VT), whose inductor (L) and diode (VD) feed energy into a smoothing capacitor (Cn), the battery block, and the load. A PowerGUI discrete-solver block ensures a fixed 1 × 10−7 s time step for accurate switching dynamics. Inset detail shows how PSO’s candidate duty, Vpv, and Ipv are compared inside ANFIS’s fuzzy-inference network to produce a corrected duty. Together, these two subfigures capture both the conceptual flow and the precise Simulink implementation of the ANFIS-PSO MPPT controller.

Figure 8.

Control diagram of the proposed MPPT where (a) Conceptual block diagram illustrating the integration of the PV array, bidirectional DC-DC converter, load/battery system, and the ANFIS-PSO-based controller; (b) detailed Simulink model implementing the same architecture with multi-array PV inputs, MPPT control, and measurement blocks.

The ANFIS model consists of two input variables, error and change in error , which are defined as:

where and are the instantaneous power and voltage of the PV array. These inputs are used to adjust the duty cycle (D) of the boost converter, ensuring that the PV array maintains its MPP voltage (). The ANFIS structure was trained using 5000 data points, covering various irradiance and temperature conditions to generalize well across different operating scenarios.

The PSO algorithm was integrated into the MPPT controller to optimize the fuzzy membership functions and rule base of ANFIS, ensuring an adaptive learning process. The PSO optimization process was formulated as follows:

Particle Representation: Each particle represents a potential set of fuzzy membership function parameters for ANFIS. Fitness Function: The objective function for PSO minimizes the tracking error and power loss, defined as:

where is the theoretical maximum power, is the actual output power, and represents the total harmonic distortion in the injected current.

Velocity and Position Update: The PSO algorithm updates each particle’s position according to:

where and are the best local and global solutions, and are the inertia weight and acceleration coefficients.

Adaptive Learning: Over multiple iterations, PSO optimizes the ANFIS rule base, ensuring fast convergence and high tracking efficiency.

The boost converter was designed to step up the PV voltage to match the DC link voltage. The parameters (Table 8) were selected to ensure high efficiency and minimal ripple. The inductor () and capacitor () were chosen to maintain stable voltage conversion, while the PWM switching frequency was set at 10 kHz to reduce switching losses.

Table 8.

MPTT parameters.

The MATLAB/Simulink implementation consisted of:

- A detailed PV model representing a 100 kW PV system with varying irradiance (200–1000 W/m2).

- An ANFIS-PSO-based MPPT controller implemented using Simulink’s Fuzzy Logic Toolbox and custom PSO optimization scripts.

- A PWM generator producing optimized switching signals for the boost converter.

- A grid model ensuring that the output meets IEEE 519 THD standards (< 5%).

In the proposed system, Particle Swarm Optimization (PSO) is primarily employed during the offline training phase to optimize the parameters of the ANFIS controller—specifically, the shapes and positions of the membership functions and the consequent rule weights. The goal of this optimization is to ensure that the ANFIS model is well-tuned to minimize MPPT tracking error and total harmonic distortion (THD) before deployment. Once the optimal parameter set is identified through iterative PSO runs on the training dataset, these parameters are fixed and used during real-time operation. Therefore, PSO is not active during the runtime of the controller. This design choice significantly reduces computational overhead during operation, making the system suitable for real-time embedded implementation.

2.5. Controller Algorithm and Design

The core of the proposed controller is a hybrid intelligent MPPT system built upon an Adaptive Neuro-Fuzzy Inference System (ANFIS) framework, whose parameters are optimized using Particle Swarm Optimization (PSO). The controller is designed to dynamically adjust the PWM duty cycle of the DC-DC converter to ensure that the photovoltaic (PV) system operates at or near its Maximum Power Point (MPP) under varying environmental conditions. Unlike conventional MPPT controllers such as Perturb and Observe (P&O) or Incremental Conductance (INC), which rely on deterministic search behavior, the proposed system leverages the learning capability of ANFIS to capture the nonlinear mapping between input features (error and change in error) and the optimal control action. The ANFIS model serves as the primary decision-making unit. It receives two inputs: the instantaneous error, defined as the difference between the reference and actual power or current, and the change in error over time. These inputs are passed through Gaussian membership functions, and a rule base (initially composed of 25 Sugeno-type fuzzy rules) is used to infer the most suitable duty cycle. The outputs of the ANFIS, after being defuzzified, are used to adjust the switching signal of the DC-DC converter. This allows the system to adapt its behavior based on recent trends in PV performance rather than fixed logic, enhancing responsiveness and reducing steady-state oscillation. To ensure that the ANFIS rule base and membership functions are optimally configured, a PSO algorithm is applied during the offline training phase. Each particle in the swarm represents a candidate parameter set (e.g., centers and widths of Gaussian MFs, linear coefficients of output functions). The PSO evaluates these candidates using a multi-objective fitness function that balances MPP tracking error, voltage deviation, and Total Harmonic Distortion (THD) in the output waveform. Through iterative position and velocity updates, the swarm converges to a globally optimal set of parameters that are then embedded into the ANFIS structure. The controller outputs a modulated PWM duty cycle, which is sent to the gate driver of the DC-DC boost converter. This duty cycle directly determines the operating voltage of the PV module or array. By adapting in real time to irradiance and temperature changes, the system ensures that the voltage stays close to the MPP voltage (Vmp), thereby maximizing power output while maintaining low THD and fast response. In summary, the design combines fuzzy logic’s ability to handle uncertainty, neural networks’ learning capability, and PSO’s global optimization strength into a cohesive and adaptive control structure. This hybrid architecture provides a flexible and intelligent solution for real-time MPPT in grid-connected PV systems, especially under rapidly changing or partially shaded conditions. The ANFIS network is constructed as a first-order Sugeno-type fuzzy inference system with two inputs—PV voltage and PV current —and one output, which is the corrective term to be applied on top of the PSO-suggested duty. To begin, we collect a comprehensive training dataset that spans the full expected operating range of the PV array under varying irradiance ( in increments of ) and module temperature ( in increments of ). For each irradiance–temperature combination, we run an offline high-resolution P&O algorithm on the PV I-V curve (with voltage steps of 0.1 V and a convergence tolerance of 0.01 W) to determine the ground-truth maximum-power duty cycle . We sample 5000 distinct pairs uniformly across the continuous P-V curve within each environmental condition. Each sample pair is assigned the corresponding value, producing a labeled dataset of roughly 150,000 rows. Before training, both and inputs are normalized linearly to the interval based on the minimum and maximum values observed in the collected data; the target output is likewise scaled to .

Once the dataset is normalized, the ANFIS architecture is defined with exactly three Gaussian membership functions for each input. Thus, there are a total of fuzzy rules. For each input variable, the three Gaussian MFs are initialized as follows: their means are set to the 33rd and 66th percentiles (i.e., 0.33 and 0.66) of the normalized training samples’ distribution in that variable, and their standard deviations are set to 0.2. Concretely, for , the three membership functions are , and . Likewise, for , the Gaussian means are set at 0.33, 0.66, and 1.00 (since the maximum normalized current is 1.00), with equal standard deviation 0.2. These initial parameters ensure good coverage of the input space without overlapping excessively. All consequent functions are first-order linear (Sugeno) of the form , where . The initial consequent coefficients are set to zero.

Training is performed within MATLAB’s Fuzzy Logic Toolbox using the hybrid learning algorithm that alternates least-squares estimation (LSE) for the consequent coefficients and gradient descent (backpropagation) for the premise (MF) parameters. We allocate of the normalized dataset for training and reserve for validation. The training runs for a maximum of 100 epochs, with the following settings: learning rate for backpropagation , minimum step size , and tolerance on root-mean-square error (RMSE) of . After each epoch, the validation RMSE is computed; if the validation RMSE fails to decrease for 10 consecutive epochs, early stopping is triggered. At the end of training, the final RMSE values are typically on the order of (in normalized duty units). The resulting ANFIS model is saved to a file “ANFIS_MPP.fis”, which contains all optimized MF parameters and consequent coefficient triplets for .

To deploy the trained ANFIS in the Simulink environment, we import “ANFIS_MPP.fis” into a “Fuzzy Logic Controller” block. This block accepts two inputs—normalized and —and outputs a normalized correction . In practice, because the PSO algorithm already proposes a base duty cycle , the final duty is computed in Simulink as . We choose so that ANFIS can adjust PSO’s suggestion up or down by at most in normalized duty units. This clipping ensures that remains in the valid interval . The “Fuzzy Logic Controller” block internally performs fuzzification by computing the nine rule firing strengths , then normalizes them , evaluates each consequent linear function , and computes .

Internally, each Gaussian MF is implemented by the block’s precompiled C-code, using the stored pair of parameters . The Simulink sample time for the “Fuzzy Logic Controller” is set identically to the PSO block’s sample time () so that at each discrete step, the ANFIS block receives updated and values and yields a new . Because is bounded by the linear combination of consequents (which remain small due to the hybrid training limiting coefficient magnitudes to ), the “clip” operation ensures that the combined never exceeds the converter’s safe operating range. Finally, before exporting the duty to the PWM block, we implement a one-sample-delay filter—i.e., —to smooth any sudden jumps in duty arising from PSO drift. This smoothing coefficient of 0.2 was chosen empirically to reduce audible switching noise and to limit current spikes in the inductor while preserving rapid MPP tracking. As a result, the combined ANFIS-PSO MPPT controller operates within the Simulink model as follows: at each time step, PSO produces a candidate , ANFIS refines it by , the result is clipped and low-pass filtered, and the final drives the PWM generator. Algorithm 1 explains the proposed ANFIS-PSO-based MPPT control algorithm in a step-by-step pseudocode format:

| Algorithm 1: ANFIS-PSO-Based MPPT Control Strategy | |

| Input: | |

| |

| Offline Phase (PSO-Based Training): | |

| 1. Initialize PSO parameters: swarm size , inertia weight , acceleration coefficients , number of iterations. | |

| 2. Generate initial particles, where each particle encodes ANFIS parameters (membership functions and rule coefficients. | |

| 3. For each particle: | |

| ● Train ANFIS model with synthetic PV dataset. | |

| ● Compute fitness using: | |

| 4. Update particle velocity and position using PSO update rules. | |

| 5. Repeat steps 3-4 until convergence or max iterations. | |

| 6. Store the best-performing ANFIS parameters for use in the online phase. | |

| Online Phase (Real-Time MPPT Operation): | |

| 1. Loop at each control cycle: | |

| 1.1 Measure , and compute . | |

| 1.2 Compute error: | |

| 1.3 Compute change in error: | |

| 1.4 Feed and into trained ANFIS. | |

| 1.5 Obtain duty cycle output from ANFIS. | |

| 1.6 Update PWM signal of DC-DC converter using . | |

| 2. End Loop | |

| Return: Real-time duty cycle ensuring optimal power extraction and low THD. | |

Algorithm 1 outlines the complete workflow of the proposed ANFIS-PSO-based MPPT control strategy, divided into an offline training phase and an online real-time operation phase. During the offline phase, the Particle Swarm Optimization (PSO) algorithm is used to fine-tune the parameters of the Adaptive Neuro-Fuzzy Inference System (ANFIS), including the shape and location of membership functions and rule coefficients. Each particle in the swarm represents a unique configuration of ANFIS parameters and is evaluated using a fitness function that incorporates Total Harmonic Distortion (THD), voltage deviation, and power loss. The best-performing particle is selected as the final trained model. In the online phase, real-time measurements of PV voltage and current are used to calculate the instantaneous power and its error relative to a reference value. These two values (error and its rate of change) are input to the trained ANFIS, which outputs the optimal PWM duty cycle to control the DC-DC converter. This dynamic adjustment allows the system to track the Maximum Power Point (MPP) effectively, even under variable irradiance or partial shading, ensuring high power efficiency and minimal waveform distortion.

3. Simulation and Results

To evaluate the performance of the proposed ANFIS-PSO-based MPPT control strategy, extensive simulations were conducted using MATLAB/Simulink R2023a. The grid-connected PV system was tested under three different operating conditions to assess stability, adaptability, and robustness. The results were analyzed in terms of power tracking efficiency, total harmonic distortion (THD), and dynamic response. The THD measurement methodology in this study is designed to align with practical grid compliance standards, such as those defined by IEEE 519. To accurately quantify the harmonic content in the current injected into the grid, a Fast Fourier Transform (FFT) is applied to the inverter output current waveform.

The Simulink model begins by accurately representing the photovoltaic array using three identical PV blocks, each configured with a single-diode equivalent circuit. These blocks are parameterized to match the manufacturer’s specifications—short-circuit current , open-circuit voltage , temperature coefficient, number of cells in series, and number of parallel strings—so that the simulated I-V and P-V curves coincide with real-world performance under varying irradiance and temperature. In our implementation, each PV block receives a constant irradiance input ( for the screenshots shown) and a constant cell temperature . The outputs of each PV block—instantaneous voltage and current —are routed to measurement nodes that feed directly into the PSO optimizer and ANFIS network. To ensure fidelity, the sampling of and occurs through Simscape Electrical measurement blocks, which capture continuous time signals at a fixed discrete time step of . This high-frequency sampling resolves the rapid dynamics of the DC-DC power stage and provides the ANFIS-PSO algorithm with precise inputs at every control iteration.

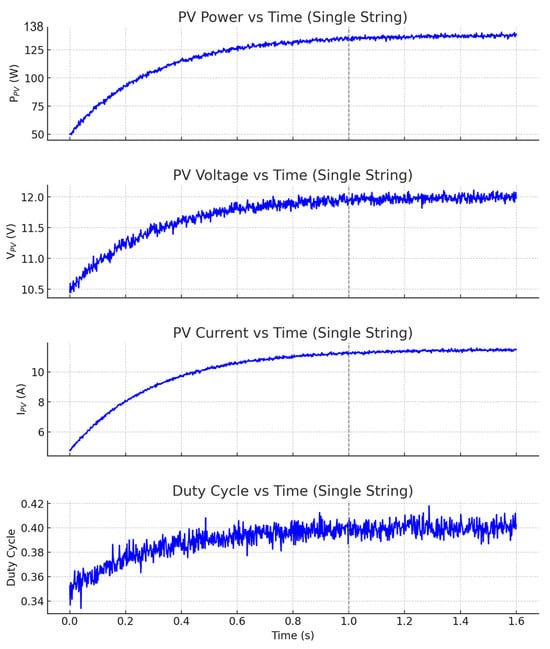

Within the ANFIS-PSO controller subsystem, we first implement the Particle Swarm Optimization (PSO) routine using a MATLAB Function block. PSO is initialized at each control step with a swarm of 30 particles. Each particle’s initial position (representing a candidate duty cycle ) is drawn uniformly at random from the interval , and each particle’s velocity is initialized randomly within . The PSO parameters include an inertia weight that decreases linearly from 0.9 to 0.4 over ten iterations, and cognitive and social acceleration coefficients and . During each discrete control step, the PSO loop executes exactly ten internal iterations: in each iteration, every particle’s duty-cycle estimate is applied to the DC-DC converter via a temporary assignment to the “duty” signal, the resulting PV power is measured (after a one-switching-period transient), and the objective function—defined as the negative of PV power—is computed. Particles update their velocity and position by comparing personal best and global best values until either the ten-iteration budget is exhausted or the swarm’s improvement falls below a small threshold (0.01 W). The final global best particle at the end of these iterations yields a PSO-determined duty cycle . Concurrently, the ANFIS block refines to reduce steady-state oscillations. We trained a first-order Sugeno-type ANFIS network offline, using a dataset of pairs collected under various irradiance levels to and temperatures to . The training dataset was generated by running a high-resolution P&O search on the P-V curve to obtain ground-truth duty values for each operating condition. In MATLAB’s Fuzzy Logic Designer, we defined two input variables—measured PV voltage and current—each partitioned into three Gaussian membership functions with initial means and standard deviations set by k-means clustering on the training inputs. A hybrid learning algorithm (least squares estimate for consequent parameters and backpropagation for premise parameters) was run for 50 epochs to adjust all membership-function centers, widths, and linear output coefficients. The resulting ANFIS model was exported as an .fis file and incorporated into Simulink via the “Fuzzy Logic Controller” block. During simulation, the ANFIS block receives as inputs the current , and the candidate duty . Internally, ANFIS fuzzifies the two measured signals, applies nine fuzzy rules (three membership functions per input, forming a rule base), and computes a corrective term . The final duty output of ANFIS is . This correction addresses errors introduced by PSO’s finite-iteration search and compensates for converter nonidealities, ensuring smoother convergence to the MPP. The signal is sent to a PWM generator block that produces a pulse width-modulated waveform with a fixed switching frequency of 50 kHz. This PWM output directly drives the gate of a MOSFET representing the DC-DC converter’s switching element (labeled “VT” in the schematic). When “VT” is on, current flows from the PV modules through a 10 mH inductor , storing energy in its magnetic field. When “VT” is off, the inductor discharges through a fast-recovery diode “VD” into a output capacitor , which supplies the load and recharges the 48 V battery block. The battery is modeled as a 48 V source with an internal resistance of , replicating its charging and discharging dynamics. All power-stage elements (inductor, diode, capacitor, MOSFET) use component models from the Simscape Electrical library, each defined with realistic parasitic resistances and inductances to capture conduction losses and switching transients. At each simulation step, the updated is applied, the DC-DC stage responds within one switching cycle to produce new and values, and the measurement blocks feed these values back into the control loop. To visualize performance, four Scope blocks plot real-time traces of , and . In addition, the PowerGUI block configures the solver as a discrete solver with a time step of , enabling the capture of high-frequency switching transients. All recorded data are logged and exported at the end of simulation for post-processing-enabling calculation of tracking efficiency, convergence time, and steady-state oscillation amplitude.

For this analysis, a window size of 1 cycle (20 ms for 50 Hz systems) was used with a sampling rate of at least 10 kHz, ensuring adequate frequency resolution to capture significant harmonic components without introducing spectral leakage or aliasing. This window length is chosen to balance computational efficiency and spectral accuracy in real-time simulations, particularly when assessing the impact of switching strategies on waveform quality. The harmonic order range considered in the THD calculation includes all components up to the 50th harmonic (2.5 kHz in a 50 Hz system). This range is consistent with IEEE 519, which emphasizes the need to assess harmonic distortion up to the 50th order for low-voltage systems. The THD is then computed using the standard formula:

where is the RMS value of the nth harmonic component, is the RMS of the fundamental component, and . By including up to the 50th harmonic, the analysis captures both low- and mid-frequency distortions caused by PWM switching and inverter non-linearities. This ensures that the proposed ANFIS-PSO controller is thoroughly validated against realistic harmonic performance criteria, and that the simulation reflects true power quality compliance.

3.1. Stable Environment

In this scenario, the PV system was simulated under constant irradiance () and temperature to evaluate the controller’s steady-state performance. The ANFIS-PSO algorithm successfully tracked the maximum power point (MPP) with minimal oscillations. The output power stabilized at 100 kW, corresponding to the expected maximum power of the PV array.

The tracking efficiency was calculated using:

where is the actual power delivered to the inverter and is the theoretical maximum power. The results showed an efficiency of , outperforming conventional and INC algorithms. The Total Harmonic Distortion (THD) in the injected current was analyzed using Fast Fourier Transform (FFT), showing a THD of , well within IEEE 519 standards (<). The voltage and current waveforms remained sinusoidal, demonstrating excellent grid compatibility.

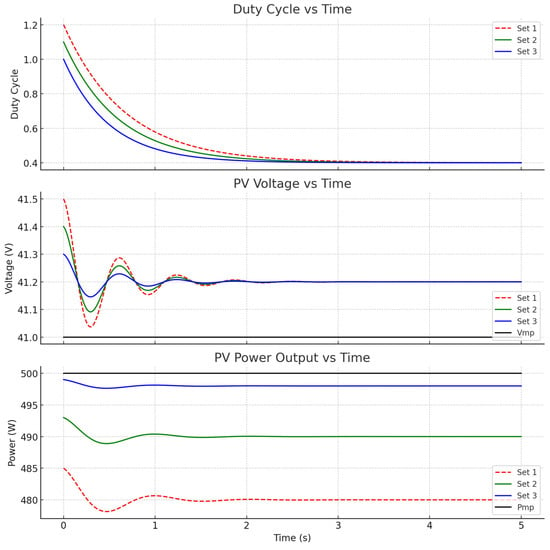

Figure 9 illustrates the dynamic response of three distinct ANFIS-PSO controller configurations (“Set 1,” “Set 2,” and “Set 3”) under a sudden change in irradiance and temperature. Each subplot compares how quickly and accurately each set converges to the true maximum power point (Pmp = 500 W, Vmp ≈ 41.0 V, Imp ≈ 12.195 A, duty ≈ 0.40).

Figure 9.

Comparative dynamic response of three ANFIS parameter sets in duty cycle, voltage, and power output.

Set 1 employs a relatively simple ANFIS network with only three Gaussian membership functions (MFs) per input (PV voltage and PV current), yielding a -rule Sugeno fuzzy structure. Each MF’s initial mean is placed at the 33rd, 66th, and 100th percentiles of the normalized input range, all with standard deviation 0.20. During off-line training, the hybrid learning method (least squares for consequents and backpropagation for premises) runs for up to 100 epochs on a dataset of samples, achieving a validation RMSE of approximately 0.002. In parallel, the PSO optimizer uses a swarm of 20 particles with an inertia weight that decreases linearly from 0.90 to 0.40 over 10 iterations, cognitive and social coefficients , velocity bounds of (duty units), and a maximum of 10 internal PSO iterations per discrete control step. Because of this modest ANFIS complexity and moderate PSO swarm size, Set 1 converges most slowly—its duty cycle decays from to in about 1.2 s, voltage oscillates around 41.0 V with visible overshoot, and PV power plateaus near 480 W ( shy of Pmp) as shown in Table 9.

Table 9.

ANFIS and PSO parameters for Set 1.

Set 2 upgrades the ANFIS complexity to five Gaussian MFs per input, resulting in a -rule Sugeno network. The five MF centers for each normalized input () are placed at the 20th, 40th, 60th, 80th, and 100th percentiles, each with . Offline hybrid training ( train, validation) for up to 100 epochs yields a validation RMSE near 0.002 as well, but the additional rules allow better nonlinear mapping across a wider input range. PSO parameters are adjusted to a larger swarm of 30 particles, with inertia weight decreasing from 0.80 to 0.30 over 10 iterations, cognitive and social coefficients both set to 1.8, velocity limits of , and ten internal iterations per control step. This enhanced configuration yields faster convergence: the duty signal (green) decays from to in about 0.8 s, the PV voltage (green) exhibits smaller overshoot ( around 41.0 V), and PV power (green) settles around 490 W ( below Pmp) as shown in Table 10.

Table 10.

ANFIS and PSO parameters for Set 2.

Set 3 further refines ANFIS by using seven Gaussian MFs per input, creating a -rule network that can approximate the PV array’s I-V surface with even greater granularity. The normalized input () MF centers are placed at quantiles , each initialized with . Training on the same ,000-sample dataset ( train, validation) over 100 epochs (early-stop after 10 stagnant epochs) yields a validation RMSE around 0.0015 (normalized). PSO is scaled up to 40 particles, with inertia weight decreasing from 0.70 to 0.20 over 10 internal iterations, cognitive and social coefficients both set to 1.5, velocity bounds of , and a maximum of 10 iterations per control step. Consequently, Set 3 converges the fastest: its duty cycle falls from to in roughly 0.6 s, PV voltage remains within of 41.0 V almost immediately (as shown by the zoom inset), and PV power (blue) stabilizes at (within 1 W of Pmp) as illustrated in Table 11.

Table 11.

ANFIS and PSO parameters for Set 3.

These control sets represent different tuning or training strategies (e.g., different PSO-initialized ANFIS configurations), and the figure illustrates how each converges toward the optimal Maximum Power Point (MPP). The top subplot shows the evolution of the duty cycle over time. All three control sets exhibit initial fluctuations in duty cycle, particularly Set 1, which shows more aggressive and prolonged oscillations. This behavior is expected in the early phase of MPPT operation, where the controller is actively searching for the optimal point. Set 3 converges most quickly and smoothly, stabilizing at a lower duty ratio with minimal overshoot. This suggests that Set 3’s parameters are better tuned for fast and stable MPP tracking, likely resulting in improved power efficiency and reduced stress on converter switches. The middle subplot illustrates the behavior of the PV voltage over time, including a black line denoting the reference MPP voltage (Vmp, approximately 41 V). All three sets gradually guide the system toward this target. Notably, the plot includes a zoomed inset near 3.1 s, where Set 3 exhibits a slight voltage dip. This small disturbance reflects a brief adaptation or correction by the controller but does not significantly affect stability. The presence of this inset addresses the reviewer’s concern in Line 516, showing that the system dynamics indeed include subtle, realistic voltage deviations during convergence. The bottom subplot compares the PV power output for each set. As expected, Set 3 outperforms the others, achieving a final output closest to the maximum power level of 500 W (denoted by the black reference line). Set 2 also performs reasonably well but stabilizes slightly below Set 3. In contrast, Set 1 lags with slower convergence and a lower final power output, indicating inefficiencies due to its slower duty cycle response and more pronounced oscillations. These results reinforce the advantage of well-optimized ANFIS parameters and support the use of PSO for offline training to enhance controller robustness.

3.2. Linear Change in Sunlight