Optimizing the Energy Efficiency of Electric Vehicles in Urban and Metropolitan Environments According to Various Driving Cycles and Behavioral Conditions

Abstract

1. Introduction

- Reduced atmospheric pollution because electric vehicles do not generate polluting contaminants: carbon monoxide (CO), nitrogen oxides (NOx), particulate matter (PM), and greenhouse gases (GHGs);

- Noise pollution is reduced as a result of the quietness of electric motors and systems used in electric vehicles;

- Operating costs are reduced due to the excellent energy efficiency of the electric motors that equip electric vehicles and due to the low price of electricity (particularly energy from renewable sources) compared to the price of fossil fuels;

- Maintenance costs are lowered since the systems that equip electric vehicles are less complex;

- Access to restricted areas in historic urban centers, free parking, and public and/or private charging stations with preferential pricing for power;

- Reductions in taxes and assessments, as well as financial incentives to buy new electric vehicles.

- Infrastructural development in the majority of major cities and a reduced number of public and private charging stations that may be insufficient to serve all electric vehicles;

- Increase in electricity consumption in national grids (at certain times of the day) as the number of electric vehicles grows;

- In comparison to vehicles equipped with conventional propulsion systems (internal combustion engines and hybrid propulsion systems), autonomy is limited;

- In comparison to vehicles powered by conventional or hydrogen fuel where refueling takes only a few minutes, fast charging in a short period of time for electric vehicles may be more expensive than an extended charge overnight;

- The initial cost was higher than conventional vehicles in similar categories;

- Environmental issues arising from the recycling of batteries, as well as the management of waste batteries.

2. Materials and Methods

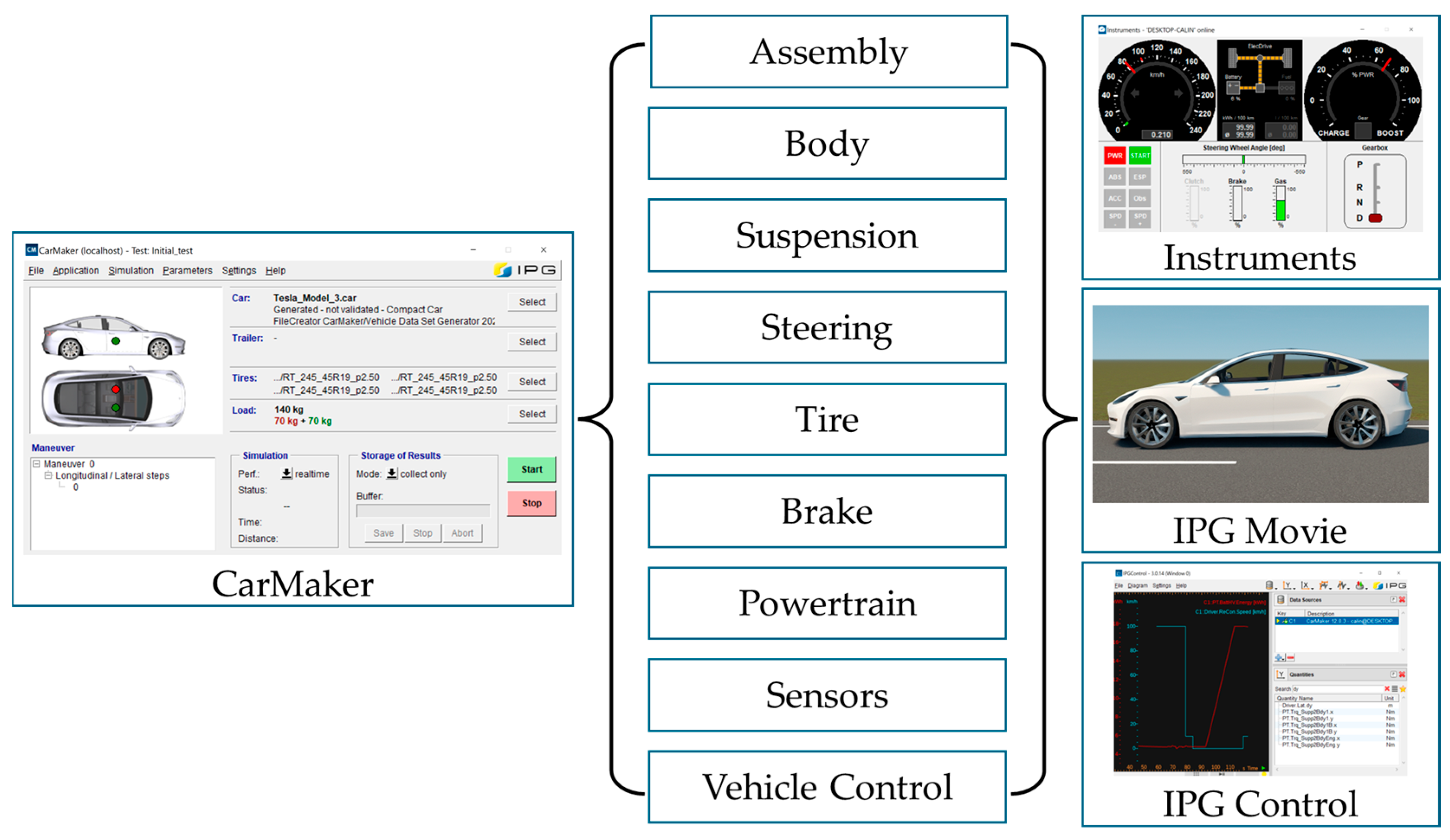

2.1. Simulation Platform

2.2. Selection of the Initial Data

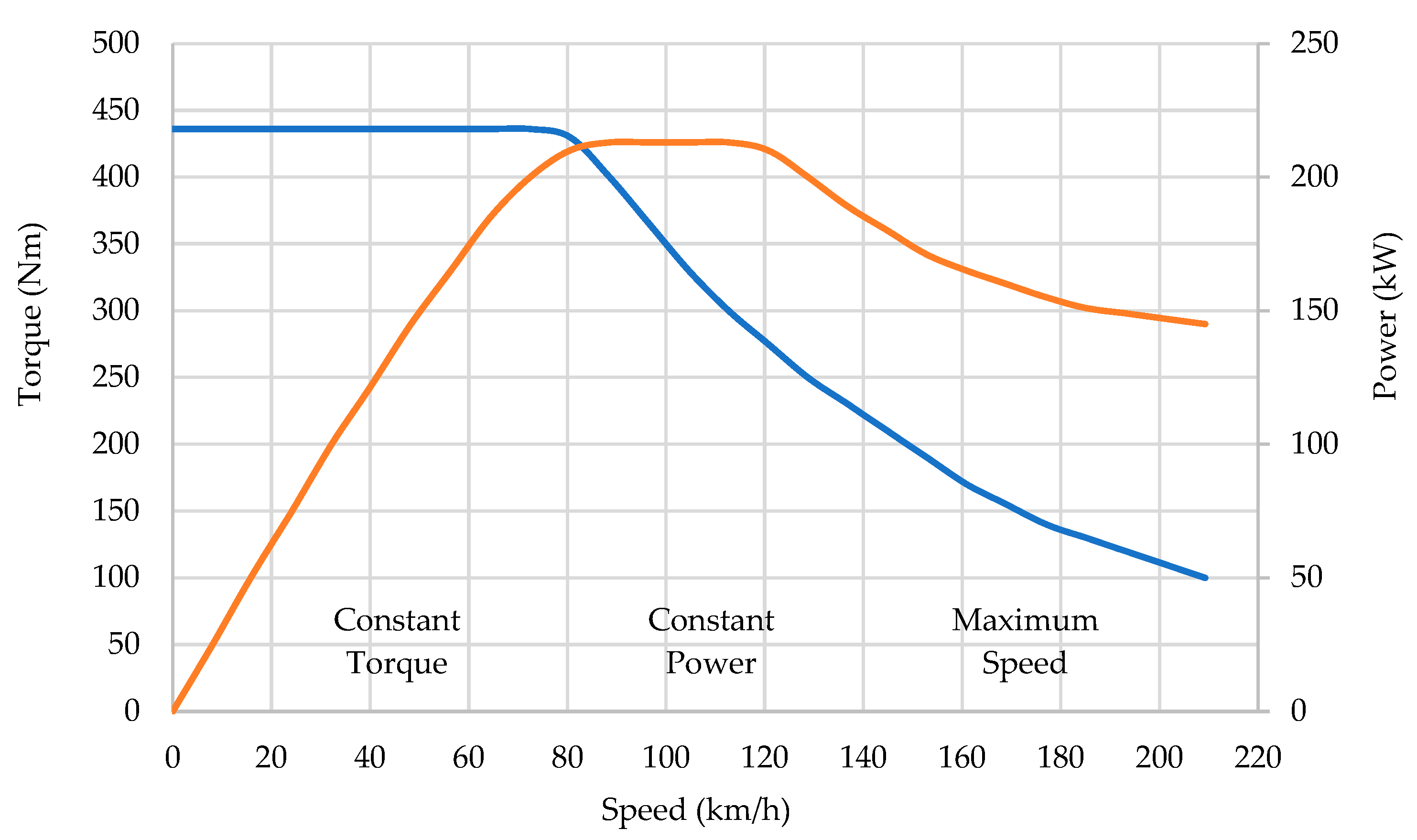

Electric Vehicle Characteristics and Performance

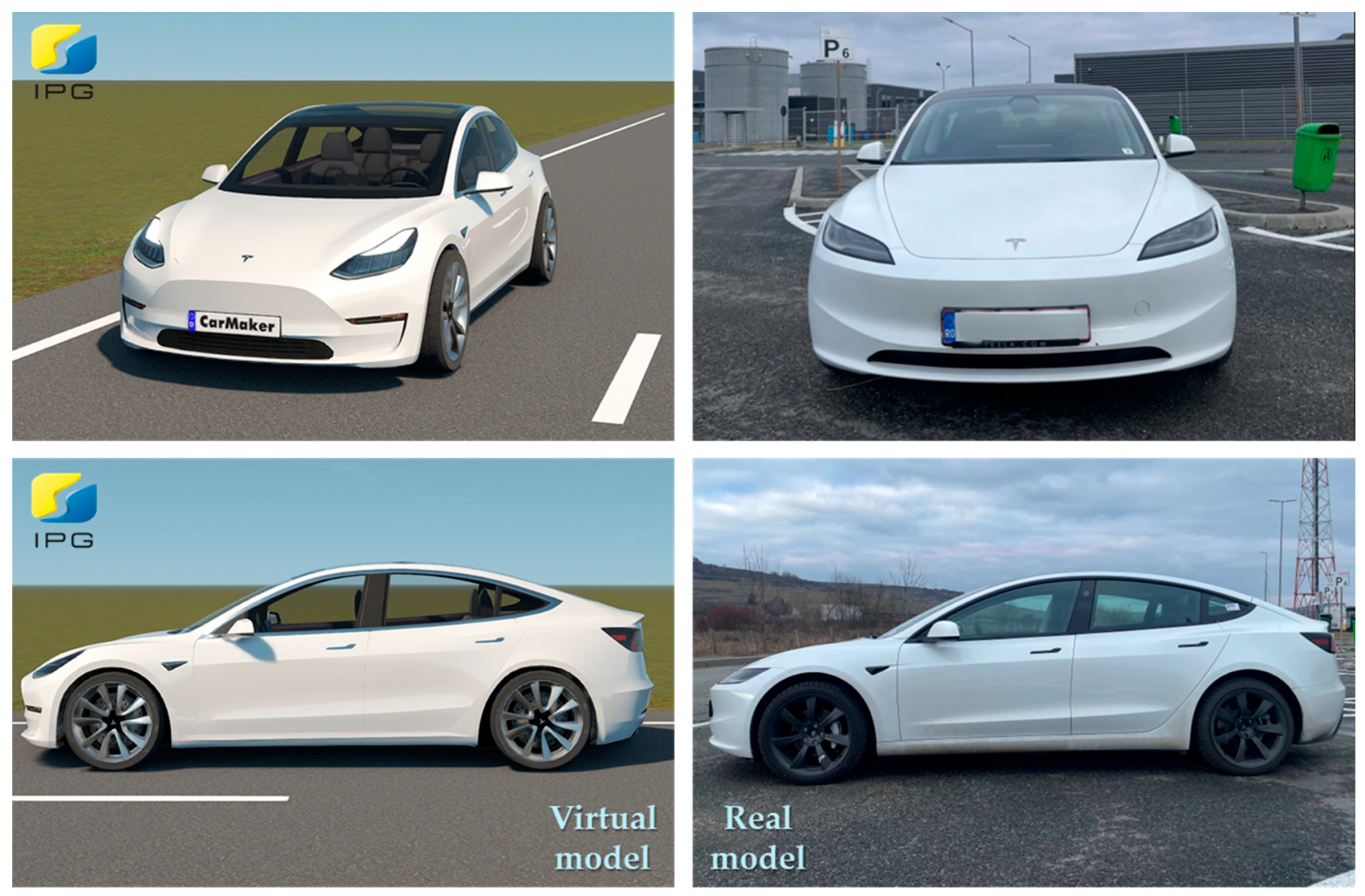

2.3. Virtual Model Development

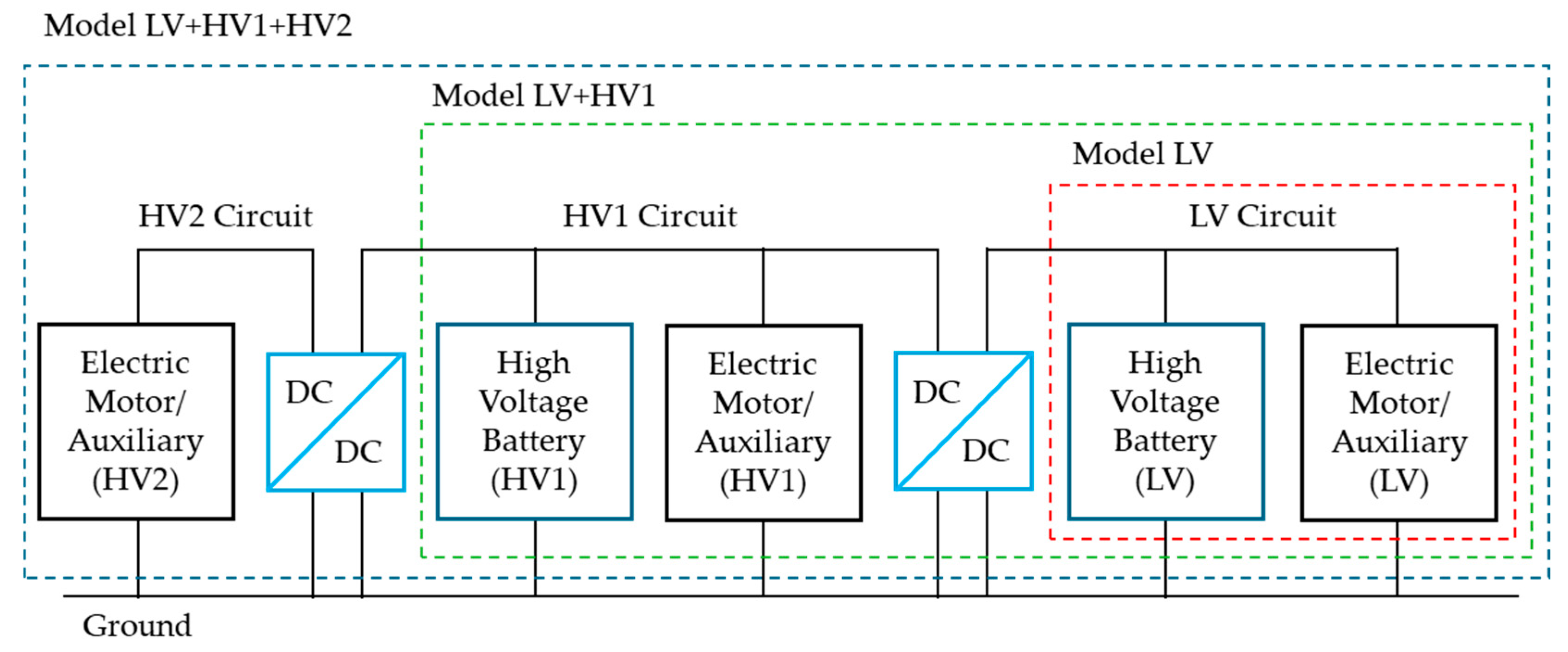

2.3.1. Virtual Model for Electric Vehicle

- Stabilizing the vehicle’s operational status by activating the start/stop button;

- Interpretation of load pedal position for determining desired torque for an electric motor;

- Mechanical energy management based on strategy mode selection;

- Electric energy management for controlling battery State-of-Charge (SoC) and Depth-of-Discharge (DoD);

- Estimate the maximum torque of the electric generator at each rotation;

- Calculate the maximum quantity of energy used to power HV electric motors and other LV electric consumers in the vehicle’s system.

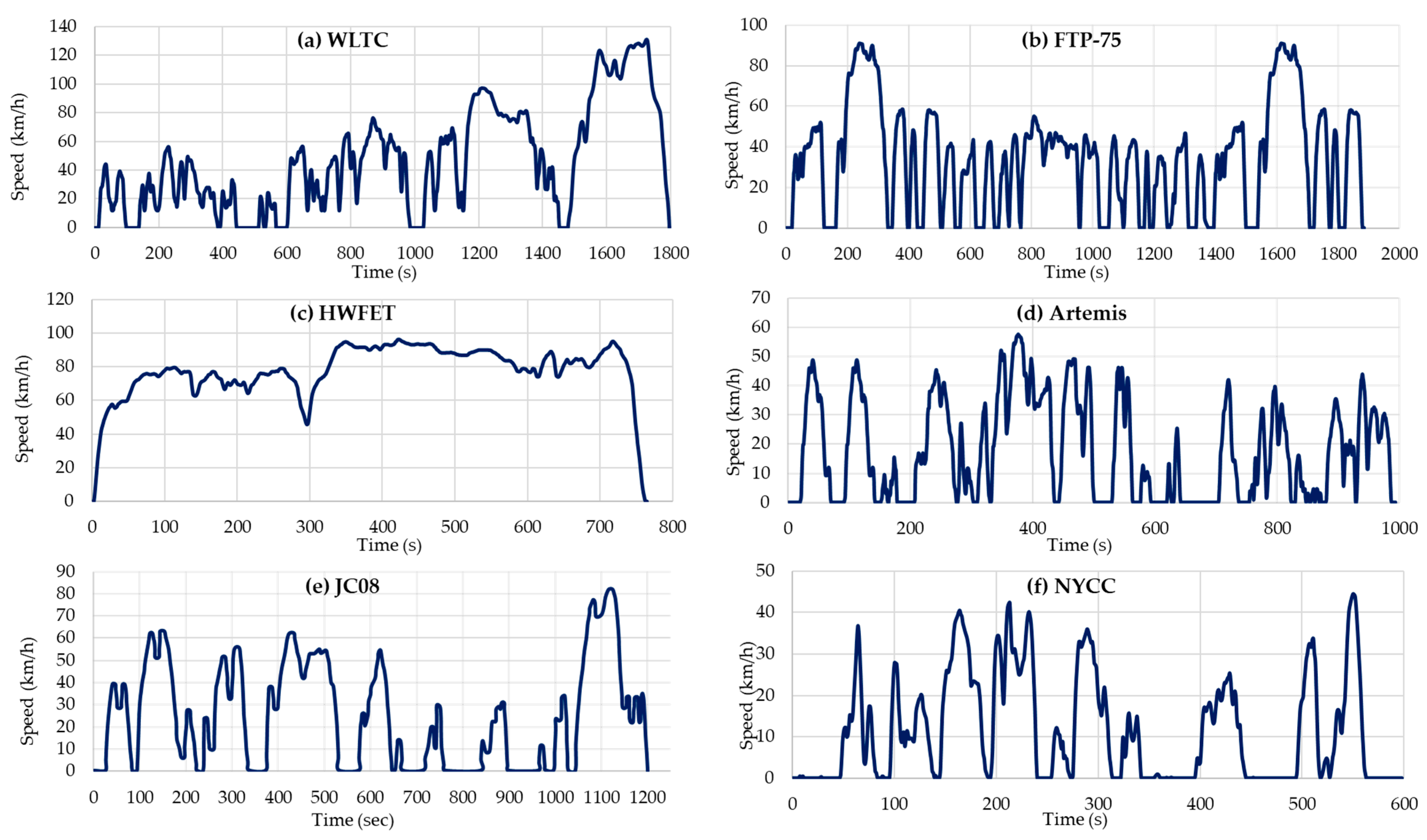

2.3.2. Virtual Model for Simulation Cycle

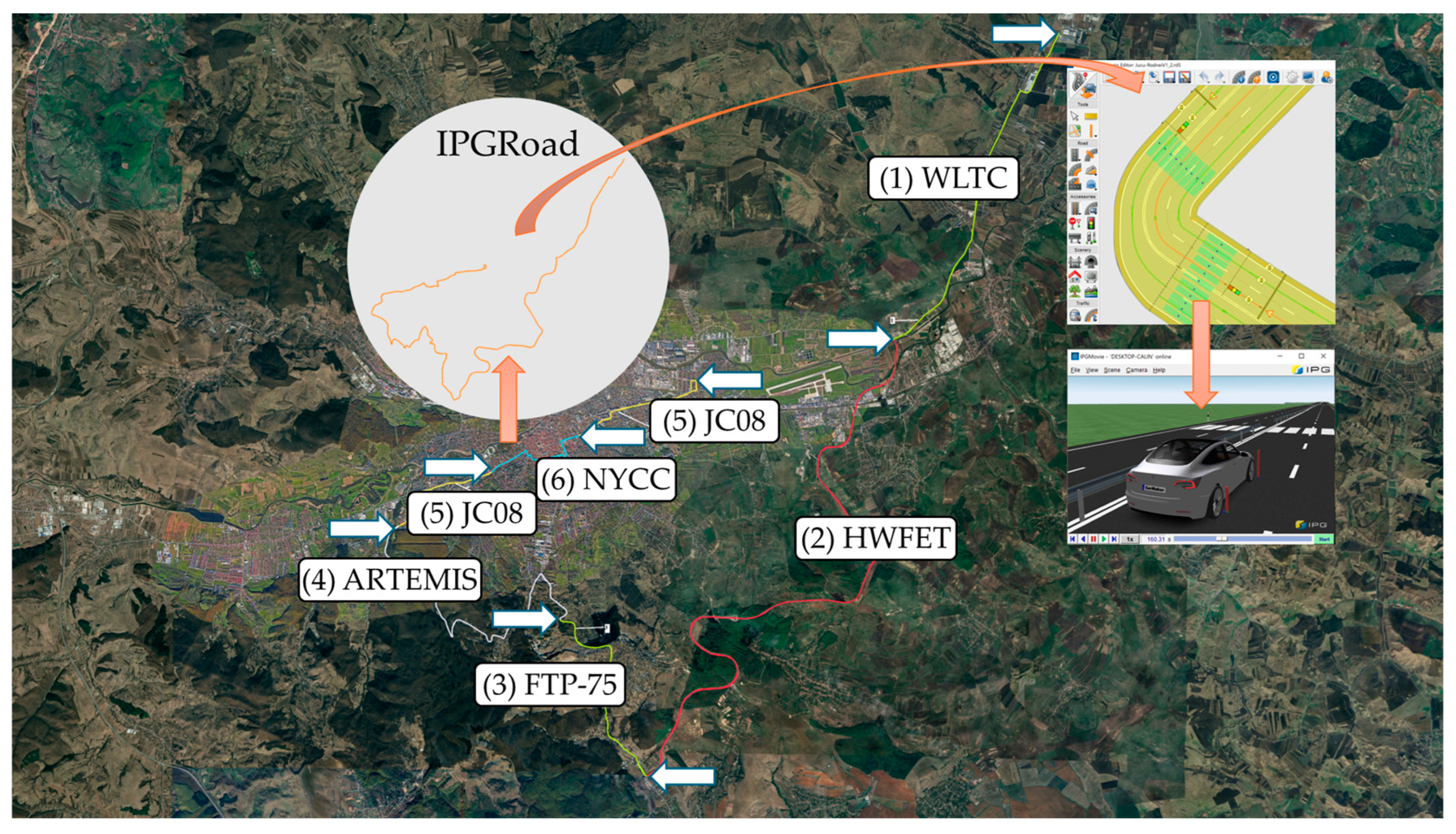

2.3.3. Virtual Road for Metropolitan Area

2.3.4. Virtual Environment

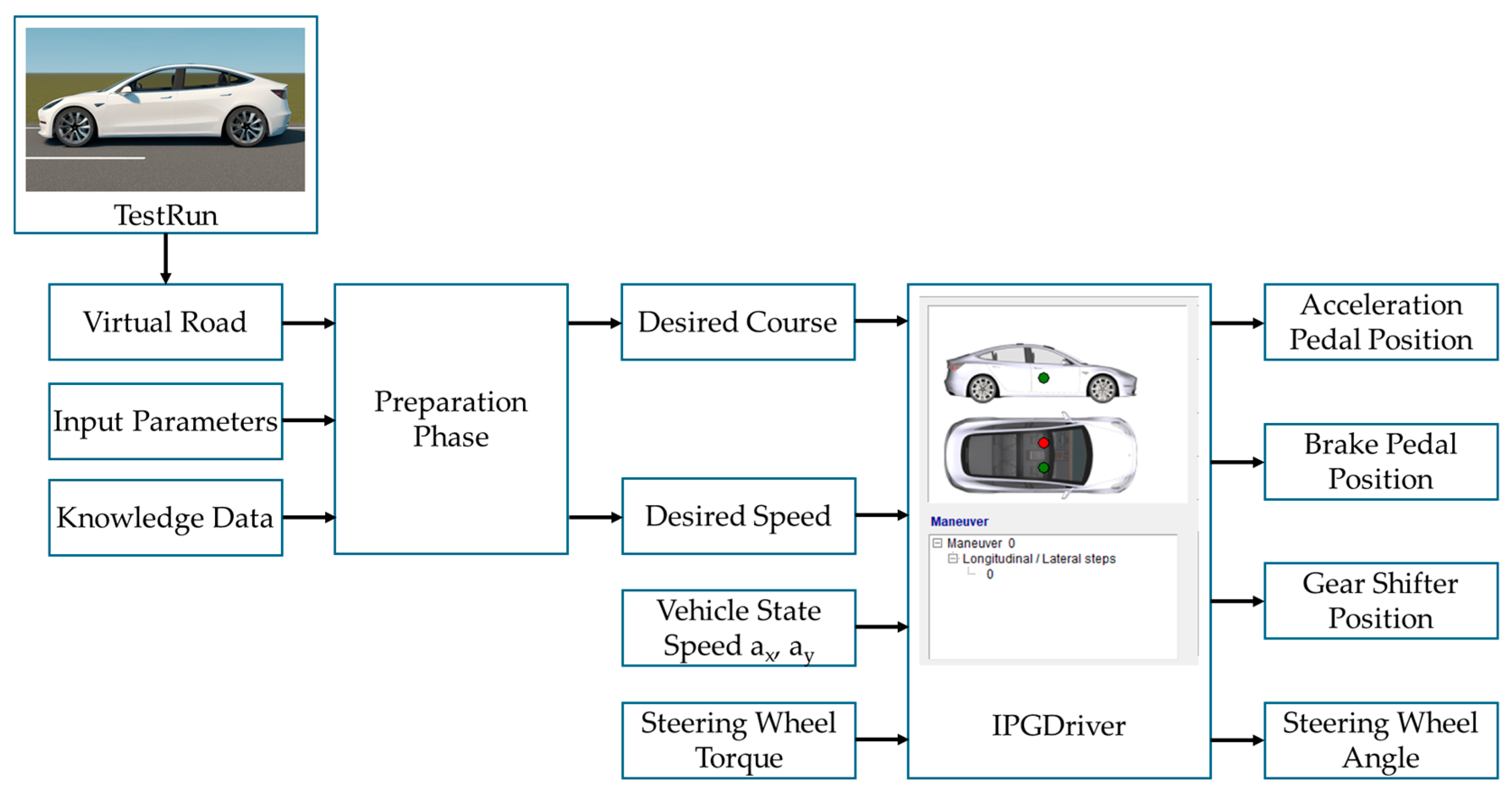

2.3.5. Virtual Driver Behavior

- Traffic-Aware Cruise Control is a function that allows for adaptive cruise control in response to vehicles in front of it;

- Autosteer is a function that allows for the maintaining of traffic lanes and the direction of movement while steering;

- Auto Lane Change—a function that allows for a vehicle to change lanes automatically using a direction indicator (on turn signal);

- Navigate on Autopilot—a feature that allows for the following of a predetermined route based on GPS coordinates;

- Autopark—a function that allows for parking parallel or perpendicular to the roadside;

- Actually Smart Summon is a function that allows the vehicle to be moved from its parking spot to the location where the driver has summoned it by a maximum of 6 m.

- (1)

- “Normal” driver characterized by moderate acceleration and braking typical of daily driving;

- (2)

- “Defensive” driver characterized by constant, anticipatory driving with lower peak loads and potentially better energetic efficiency;

- (3)

- “Aggressive” driver characterized by fast acceleration and late breaking, resulting in increased energy consumption and reduced regeneration rate.

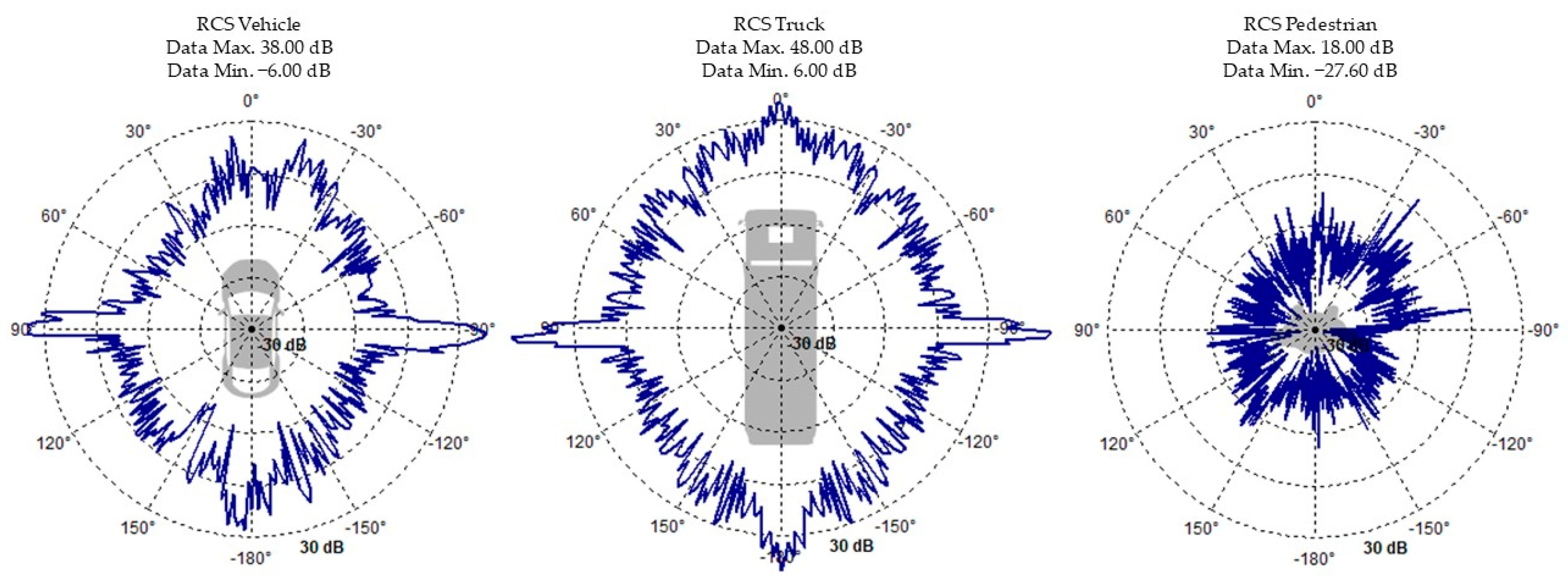

2.3.6. Virtual Traffic Model

2.4. Driver-in-the-Loop Simulator

2.4.1. Simulator Development

- Axis events indicate the evolution of movement on coordinate axis, which are analogic values generated by the steering wheel and/or pedal actions;

- Button events are actions that correspond to “true” or “false” values for certain predetermined selections, like light blocks, signalization, and sound alerts.

2.4.2. Simulation Task

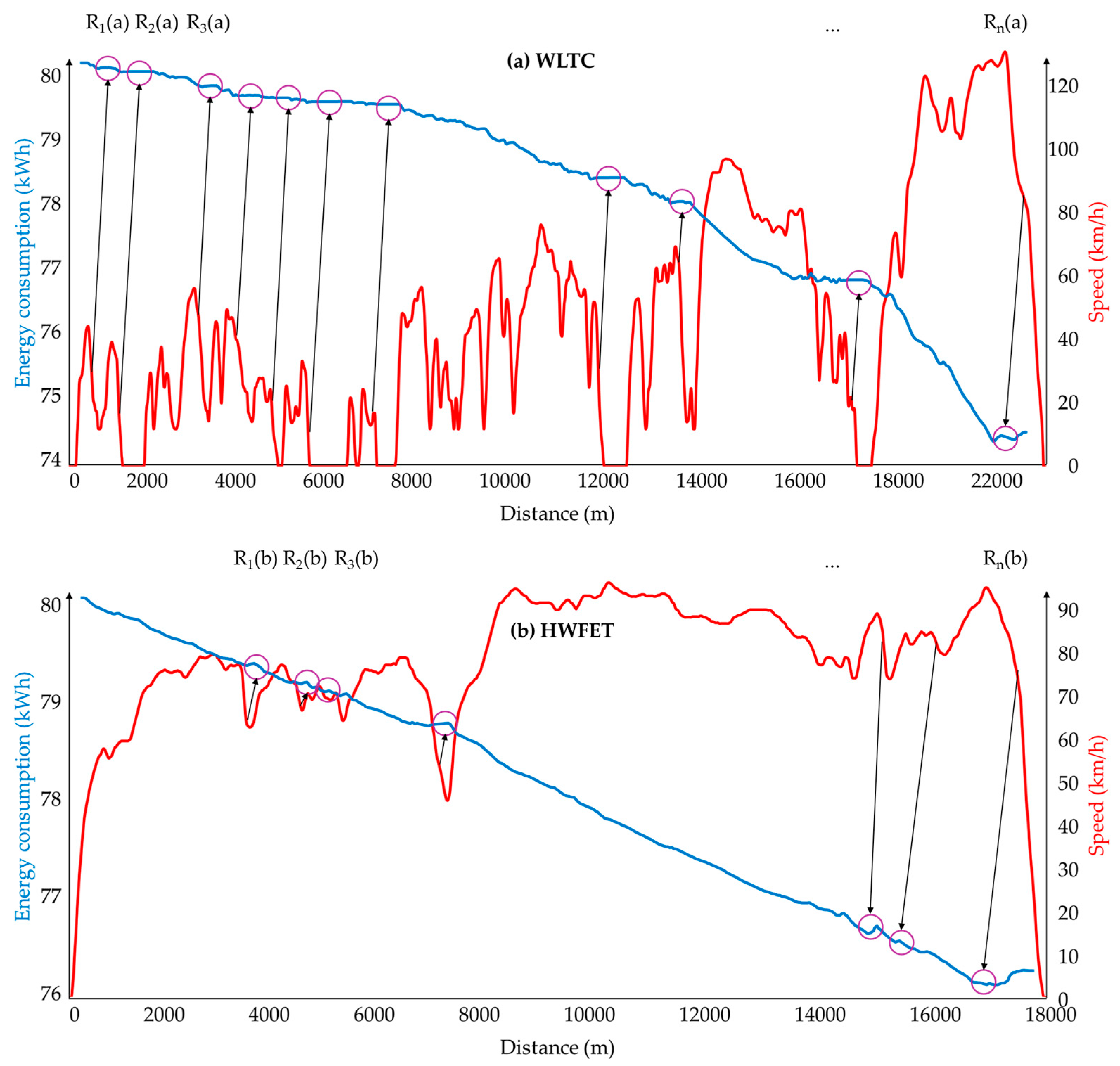

- In CarMaker with the plug-in Cockpit Package Standard, a human driver used a virtual Tesla Model 3 to simulate real-world driving conditions using a Driver-in-the-Loop simulator. The following parameters were monitored and recorded using CarMaker/IPGControl: Car.Distance (m), speed (km/h), consumption, respective recovery of electric energy PT.BattHV.Energy (kWh), and the key parameters of SoC battery charging PT.BCU.BattHV.SOC (%).

- ADAS functions (according to Level 2 SAE 3016TM) [51] ran computer simulations using a virtual Tesla Model 3 model similar to real driving conditions, ensuring movement control through the CarMaker/IPGDriver utility in standard driver mode in accordance with the values of the parameters corresponding to the behavioral profile of the virtual driver presented in Table 6 in extended driver mode in accordance with the values of the parameters corresponding to the behavioral profile of the virtual driver presented in Table 7. These profiles have been created to represent realistic behavioral differences and to evaluate fuel economy under a variety of scenarios. The “Normal” driver profile represents most drivers’ average daily driving and achieves a balance trade-off, with the maximum regeneration rates found during WLTC and FTP-75 driving cycles. The “Defensive” driver profile illustrates careful driving with smoother acceleration–braking transitions, which decreases energy consumption while simultaneously reducing regeneration events due to smoother deceleration. The “Aggressive” driver profile illustrates impulsive behavior with rapid acceleration and late braking, which repeatedly results in increased energy consumption and low regeneration caused by abrupt braking.

3. Results

3.1. Experimental Results

3.2. Simulation Results

4. Discussions

5. Conclusions

- (1)

- A validated simulation workflow with quantitative calibration metrics (RMSE, MAPE, confidence intervals) achieved an average MAPE of 4.52% compared to experimental data.

- (2)

- A detailed analysis of how driving behavior affects energy consumption and regenerative efficiency, revealing nonlinear and sometimes unexpected trends.

- (3)

- Integrating real-world environmental and behavioral characteristics into a controlled simulation environment to improve the virtual model’s realism and reproducibility.

- (1)

- The structural architecture of the virtual model and the electric battery model cannot be generalized and are difficult to modify for other vehicle models;

- (2)

- While various driving scenarios were modeled, completely stochastic traffic environments and random vehicle interactions were simplified in the simulation process or replaced with mobility scenarios controlled by driving cycles;

- (3)

- The analysis of energy regeneration following regenerative braking focused on deceleration dynamics; the simulation process did not take into account thermal effects, the battery degradation process, and long-term performance deviation.

- (1)

- Expanding the virtual modeling and simulation methods to include multiple electric vehicle platforms and enabling comparisons between them.

- (2)

- Using machine learning models to replicate real-time versatility and customization of driver behavior and vehicle settings.

- (3)

- Using simulation results to simulate the appropriate placement of urban charging stations using consumption–recovery models to achieve optimal Vehicle-to-Grid (V2G) interaction planning.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABC | Artificial Bee Colony |

| ACO | Ant Colony Optimization |

| ADAS | Advanced Driver-Assistance System |

| AFS | Adaptive Fuzzy System |

| AI | Artificial Intelligence |

| ANN | Artificial Neuronal Network |

| ARTEMIS | Assessment and Reliability of Transport Emission Models and Inventory Systems |

| AWD | All-Wheel Drive |

| CAN | Controller Area Network |

| DDT | Dynamic Driving Task |

| DoD | Depth-of-Discharge |

| ECU | Electronic Control Unit |

| EPA | Environmental Protection Agency |

| FFA | Fast Firefly Algorithm |

| FTP | Federal Test Procedure |

| GA | Genetic Algorithm |

| GHG | Greenhouse Gas |

| GLyC | Generic Lateral Control |

| GLxC | Generic Longitudinal Control |

| GPS | Global Positioning System |

| GWO | Grey Wolf Optimizer |

| Hi-Fi | High Fidelity |

| HiL | Hardware-in-the-Loop |

| HWFET | Highway Fuel Economy Test |

| HV | High Voltage |

| JC | Japanese Cycle |

| LV | Low Voltage |

| MAE | Mean Absolute Error |

| MAPE | Mean Absolute Percentage Error |

| ML | Machine Learning |

| NP | Nondeterministic Polynomial |

| NYCC | New York City Cycle |

| PS | Power Supply |

| RCS | Radar Cross-Section |

| RMSE | Root Mean Square Error |

| RSI | Raw Signal Interface |

| SDL2 | Simple Direct-media Layer |

| SNR | Signal-to-Noise Ratio |

| SoC | State-of-Charge |

| TP | Trajectory Planner |

| V2G | Vehicle-to-Grid |

| V2X | Vehicle-to-Everything |

| WLTCs | Worldwide harmonized Light vehicles Test Cycles |

| WLTP | Worldwide harmonized Light vehicles Test Procedure |

| ZLE | Zero Local Emissions |

References

- Alanazi, F. Electric Vehicles: Benefits, Challenges, and Potential Solutions for Widespread Adaptation. Appl. Sci. 2023, 13, 6016. [Google Scholar] [CrossRef]

- Tsoi, K.H.; Loo, B.P.; Li, X.; Zhang, K. The co-benefits of electric mobility in reducing traffic noise and chemical air pollution: Insights from a transit-oriented city. Environ. Int. 2023, 178, 108–116. [Google Scholar] [CrossRef] [PubMed]

- The Role of Electric Mobility for Low Carbon and Sustainable Cities. Available online: https://unhabitat.org/sites/default/files/2022/05/the_role_of_electric_mobility_for_low-carbon_and_sustainable_cities_1.pdf (accessed on 11 December 2024).

- García-Vázquez, C.; Llorens-Iborra, F.; Fernández-Ramírez, L.; Sánchez-Sainz, H.; Jurado, F. Comparative study of dynamic wireless charging of electric vehicles in motorway, highway and urban stretches. Energy 2017, 137, 42–57. [Google Scholar] [CrossRef]

- Muñoz-Villamizar, A.; Montoya-Torres, J.R.; Faulin, J. Impact of the use of electric vehicles in collaborative urban transport networks: A case study. Transp. Res. Part D Transp. Environ. 2017, 50, 40–54. [Google Scholar] [CrossRef]

- Liang, J.; Feng, J.; Fang, Z.; Lu, Y.; Yin, G.; Mao, X. An Energy-Oriented Torque-Vector Control Framework for Distributed Drive Electric Vehicles. IEEE Trans. Transp. Electrif. J. 2023, 9, 4014–4031. [Google Scholar] [CrossRef]

- Cavus, M.; Dissanayake, D.; Bell, M. Next Generation of Electric Vehicles: AI-Driven Approaches for Predictive Maintenance and Battery Management. Energies 2025, 18, 1041. [Google Scholar] [CrossRef]

- Daouda, A.S.M.; Atila, Ü. A Hybrid Particle Swarm Optimization with Tabu Search for Optimizing Aid Distribution Route. Artif. Intell. Stud. (AIS) 2024, 7, 10–27. [Google Scholar] [CrossRef]

- Aldossary, M. Enhancing Urban Electric Vehicle (EV) Fleet Management Efficiency in Smart Cities: A Predictive Hybrid Deep Learning Framework. Smart Cities 2024, 7, 3678–3704. [Google Scholar] [CrossRef]

- Ran, X.; Suyaroj, N.; Tepsan, W.; Ma, J.; Zhou, X.; Deng, W. A hybrid genetic-fuzzy ant colony optimization algorithm for automatic K-means clustering in urban global positioning system. Eng. Appl. Artif. Intell. 2024, 137, 109237. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Jung, J.J. Ant colony optimization-based traffic routing with intersection negotiation for connected vehicles. Appl. Soft Comput. 2021, 112, 107828. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Astarita, V.; Haghshenas, S.S.; Guido, G.; Vitale, A. Developing new hybrid grey wolf optimization-based artificial neural network for predicting road crash severity. Transp. Eng. 2023, 12, 100164. [Google Scholar] [CrossRef]

- Nadimi-Shahraki, M.H.; Taghian, S.; Mirjalili, S. An improved grey wolf optimizer for solving engineering problems. Expert Syst. Appl. 2021, 166, 113917. [Google Scholar] [CrossRef]

- Kar, A.K. Bio inspired computing—A review of algorithms and scope of applications. Expert Syst. Appl. 2024, 59, 20–32. [Google Scholar] [CrossRef]

- Bazi, S.; Benzid, R.; Bazi, Y.; Al Rahhal, M.M. A Fast Firefly Algorithm for Function Optimization: Application to the Control of BLDC Motor. Sensors 2021, 21, 5267. [Google Scholar] [CrossRef]

- Alshammari, N.F.; Samy, M.M.; Barakat, S. Comprehensive Analysis of Multi-Objective Optimization Algorithms for Sustainable Hybrid Electric Vehicle Charging Systems. Mathematics 2023, 11, 1741. [Google Scholar] [CrossRef]

- Forcael, E.; Carriel, I.; Opazo-Vega, A.; Moreno, F.; Orozco, F.; Romo, R.; Agdas, D. Artificial Bee Colony Algorithm to Optimize the Safety Distance of Workers in Construction Projects. Mathematics 2024, 12, 2087. [Google Scholar] [CrossRef]

- Iclodean, C.; Varga, B.O.; Cordos, N. Virtual Model. In Autonomous Vehicles for Public Transportation; Springer: Cham, Switzerland, 2022; pp. 195–335. [Google Scholar]

- Release 14.0 CarMaker Product Family. Feature Highlights. Available online: https://www.ipg-automotive.com/en/products-solutions/software/highlights-carmaker-product-family (accessed on 17 December 2024).

- Ricciardi, V.; Ivanov, V.; Dhaens, M.; Vandersmissen, V.; Geraerts, M.; Savitski, D.; Augsburg, K. Ride Blending Control for Electric Vehicles. World Electr. Veh. J. 2019, 10, 36. [Google Scholar] [CrossRef]

- IPG Automotive. User’s Guide Version 12.0.3 CarMaker. In Solutions for Virtual Test Driving; IPG Automotive Group: Karlsruhe, Germany, 2024. [Google Scholar]

- IPG Automotive. InfoFile Description Version 12.0.3 IPGRoad. In Solutions for Virtual Test Driving; IPG Automotive Group: Karlsruhe, Germany, 2024. [Google Scholar]

- Toth, B.; Szalay, Z. Development and Functional Validation Method of the Scenario-in-the-Loop Simulation Control Model Using Co-Simulation Techniques. Machines 2023, 11, 1028. [Google Scholar] [CrossRef]

- Jiang, B.; Sharma, N.; Liu, Y.; Li, C.; Huang, X. Real-Time FPGA/CPU-Based Simulation of a Full-Electric Vehicle Integrated with a High-Fidelity Electric Drive Model. Energies 2022, 15, 1824. [Google Scholar] [CrossRef]

- ISO 26262 Tool Certification for CarMaker. Available online: https://www.ipg-automotive.com/en/press/iso-26262-tool-certification-for-carmaker/ (accessed on 19 December 2024).

- Tesla Model S Owner’s Manual 2021+. Software Version 2024.38. Available online: https://www.tesla.com/ownersmanual/models/en_cn/ (accessed on 19 December 2024).

- Electric Vehicle Database—All Vehicles—Tesla Model 3 Long Range RWD (2024–2025). Available online: https://ev-database.org/car/3034/Tesla-Model-3-Long-Range-RWD (accessed on 18 March 2025).

- U.S. EPA EV Range Testing. Available online: https://www.epa.gov/greenvehicles/fuel-economy-and-ev-range-testing (accessed on 19 December 2024).

- Tesla Model 3 (Electricity) WLTP Fuel Consumption and Noise Level Guide. Available online: https://www.wltpinfo.com/model/tesla/model_3/Electricity.html (accessed on 18 March 2025).

- Iclodean, C. Introducere în Sistemele Autovehiculelor; Editura Risoprint, Colecția Scientia: Cluj-Napoca, Romania, 2023. [Google Scholar]

- Iqbal, M.; Han, J.C.; Zhou, Z.Q.; Towey, D.; Chen, T.Y. Metamorphic testing of Advanced Driver-Assistance System (ADAS) simulation platforms: Lane Keeping Assist System (LKAS) case studies. Inf. Softw. Technol. 2023, 155, 107104. [Google Scholar] [CrossRef]

- Indu, K.; Kumar, M.A. Design and performance analysis of braking system in an electric vehicle using adaptive neural networks. Sustain. Energy 2023, 36, 101215. [Google Scholar] [CrossRef]

- Šabanovic, E.; Kojis, P.; Šukevicius, Š.; Shyrokau, B.; Ivanov, V.; Dhaens, M.; Skrickij, V. Feasibility of a Neural Network-Based Virtual Sensor for Vehicle Unsprung Mass Relative Velocity Estimation. Sensors 2021, 21, 7139. [Google Scholar] [CrossRef] [PubMed]

- Sieklucki, G. Optimization of Powertrain in EV. Energies 2021, 14, 725. [Google Scholar] [CrossRef]

- de Carvalho Pinheiro, H. PerfECT Design Tool: Electric Vehicle Modelling and Experimental Validation. World Electr. Veh. J. 2023, 14, 337. [Google Scholar] [CrossRef]

- IPG Automotive. Reference Manual Version 12.0.3 CarMaker. In Solutions for Virtual Test Driving; IPG Automotive Group: Karlsruhe, Germany, 2024. [Google Scholar]

- IPG Automotive. User Manual Version 12.0.3 IPGDriver. In Solutions for Virtual Test Driving; IPG Automotive Group: Karlsruhe, Germany, 2024. [Google Scholar]

- Worldwide Harmonized Light Vehicles Test Cycle (WLTC). Available online: https://dieselnet.com/standards/cycles/wltp.php (accessed on 1 April 2025).

- FTP-75. Available online: https://dieselnet.com/standards/cycles/ftp75.php (accessed on 1 April 2025).

- EPA Highway Fuel Economy Test Cycle (HWFET). Available online: https://dieselnet.com/standards/cycles/hwfet.php (accessed on 1 April 2025).

- Common Artemis Driving Cycles (CADC). Available online: https://dieselnet.com/standards/cycles/artemis.php (accessed on 1 April 2025).

- Japanese JC08 Cycle. Available online: https://dieselnet.com/standards/cycles/jp_jc08.php (accessed on 1 April 2025).

- EPA New York City Cycle (NYCC). Available online: https://dieselnet.com/standards/cycles/nycc.php (accessed on 1 April 2025).

- Cimerdean, D.; Burnete, N.; Iclodean, C. Assessment of Life Cycle Cost for a Plug-in Hybrid Electric Vehicle. In Proceedings of the 4th International Congress of Automotive and Transport Engineering (AMMA 2018), Cluj-Napoca, Romania, 17–19 October 2018. [Google Scholar]

- Intercommunity Development Association Cluj Metropolitan Area. Available online: https://www.clujmet.ro/about-cluj-metropolitan-area-association (accessed on 20 December 2024).

- Magosi, Z.F.; Wellershaus, C.; Tihanyi, V.R.; Luley, P.; Eichberger, A. Evaluation Methodology for Physical Radar Perception Sensor Models Based on On-Road Measurements for the Testing and Validation of Automated Driving. Energies 2022, 15, 2545. [Google Scholar] [CrossRef]

- Thorat, S.; Pawase, R.; Agarkar, B. Modelling and Simulation-based Design Approach to Assisted and Automated Driving Systems Development. In Proceedings of the International Conference on Emerging Smart Computing and Informatics (ESCI), Pune, India, 5–7 March 2024. [Google Scholar]

- Movie NX. Real Physics. Strong Graphics. IPG Automotive GmbH. Available online: https://www.ipg-automotive.com/en/products-solutions/software/movienx (accessed on 26 December 2024).

- Reliable Prognosis Weather for 241 Countries of the World. Available online: https://rp5.ru/Weather_in_Cluj-Napoca (accessed on 20 December 2024).

- Taxonomy and Definitions for Terms Related to Driving Automation Systems for On-Road Motor Vehicles. SAE International. Available online: https://www.sae.org/standards/content/j3016_202104/ (accessed on 28 December 2024).

- Uluğhan, E. One of the First Fatalities of a Self-Driving Car: Root Cause Analysis of the 2016 Tesla Model S 70D Crash. J. Traffic Transp. Res. 2022, 5, 83–97. [Google Scholar]

- Iclodean, C.; Varga, B.O.; Cordos, N. Autonomous Driving Technical Characteristics. In Autonomous Vehicles for Public Transportation; Springer: Cham, Switzerland, 2022; pp. 15–68. [Google Scholar]

- Endsley, M.R. Autonomous Driving Systems: A Preliminary Naturalistic Study of the Tesla Model S. J. Cogn. Eng. Decis. Mak. 2017, 11, 225–238. [Google Scholar] [CrossRef]

- Rudigier, M.; Nestlinger, G.; Tong, K.; Solmaz, S. Development and Verification of Infrastructure-Assisted Automated Driving Functions. Electronics 2021, 10, 2161. [Google Scholar] [CrossRef]

- Noei, S.; Parvizimosaed, M.; Noei, M. Longitudinal Control for Connected and Automated Vehicles in Contested Environments. Electronics 2021, 10, 1994. [Google Scholar] [CrossRef]

- Kwon, S.K.; Seo, J.H.; Yun, J.Y.; Kim, K.D. Driving Behavior Classification and Sharing System Using CNN-LSTM Approaches and V2X Communication. Appl. Sci. 2021, 11, 10420. [Google Scholar] [CrossRef]

- Aparow, V.R.; Hong, C.J.; Onn, L.K.; Jawi, Z.M.; Jamaluddin, H. Scenario-Based Simulation Testing of Autonomous Vehicle using Driver-in-the-loop Simulation: Verification and Validation Framework. In Proceedings of the International Conference on Vehicular Technology and Transportation Systems (ICVTTS), Singapore, 27–28 September 2024. [Google Scholar]

- Driver-in-the-Loop. IPG Automotive. Available online: https://www.ipg-automotive.com/en/products-solutions/test-systems/driver-in-the-loop/ (accessed on 30 March 2025).

- Covaci, C. SiL/HiL Testbed for Electric Vehicles. Dissertation Thesis, Technical University of Cluj-Napoca, Cluj-Napoca, Romania, 2023. [Google Scholar]

- Hong, C.J.; Aparow, V.R. System configuration of Human-in-the-loop Simulation for Level 3 Autonomous Vehicle using IPG CarMaker. In Proceedings of the IEEE International Conference on Internet of Things and Intelligence Systems (IoTaIS), Virtually, 23–24 November 2021. [Google Scholar]

- Lee, S.; Eom, I.; Lee, B.; Won, J. Driving Characteristics Analysis Method Based on Real-World Driving Data. Energies 2024, 17, 185. [Google Scholar] [CrossRef]

- Cheng, R.; Zhang, W.; Yang, J.; Wang, S.; Li, L. Analysis of the Effects of Different Driving Cycles on the Driving Range and Energy Consumption of BEVs. World Electr. Veh. J. 2025, 16, 124. [Google Scholar] [CrossRef]

| Parameters | Unit | Value |

|---|---|---|

| Maximum motor power (6000–9500 1/min) | kW | 213 |

| Maximum motor torque (0–5800 1/min) | Nm | 436 |

| Battery energy storage | kWh | 78 |

| Battery nominal voltage | VDC | 357 |

| Battery number of cells [28] | - | 4416 |

| Battery pack configuration (serial/parallel) [28] | - | 96s46p |

| Rapid charging (supercharger V3 up to 282 km) | min | 15 |

| Energy consumption | kWh/km | 0.14 |

| Estimate range (EPA-FTP-75 range test [29]) | km/kWh/km | 488/0.16 |

| Estimate range (WLTP range test [30]) | km/kWh/km | 528/0.15 |

| Certified range (0 to 100 km/h) | s | 5.2 |

| Maximum speed | km/h | 201 |

| Parameters | Unit | Value |

|---|---|---|

| Overall length | mm | 4720 |

| Overall width (including mirrors) | mm | 2089 |

| Overall height | mm | 1442 |

| Wheelbase | mm | 2875 |

| Overhang front/rear | mm | 868/977 |

| Ground clearance | mm | 138 |

| Track wheels front/rear | mm | 1584/1584 |

| Curb mass (no occupants and no cargo) | kg | 1823 |

| Technically permissible maximum laden mass | kg | 2255 |

| Maximum payload | kg | 432 |

| Parameters | WLTC | FTP-75 | HWFET | ARTEMIS | JC08 | NYCC |

|---|---|---|---|---|---|---|

| Distance (m) | 23,266 | 17,769 | 16,503 | 4874 | 8159 | 1902 |

| Duration (s) | 1800 | 1877 | 765 | 993 | 1204 | 598 |

| Maximum speed (km/h) | 131.30 | 91.25 | 96.32 | 57.32 | 81.60 | 44.45 |

| Average cycle speed (km/h) | 46.53 | 34.08 | 77.70 | 17.70 | 24.40 | 11.50 |

| Average driving speed (km/h) | 53.21 | 41.57 | 77.76 | 22.29 | 34.24 | 16.63 |

| Driving time (s) | 1574 | 1539 | 759 | 787 | 858 | 412 |

| Maximum acceleration (m/s2) | 1.67 | 1.48 | 1.43 | 2.86 | 1.69 | 2.68 |

| Average acceleration (m/s2) | 0.41 | 0.51 | 0.20 | 0.53 | 0.43 | 0.00 |

| Minimum deceleration (m/s2) | −1.50 | −1.48 | −1.48 | −1.48 | −1.22 | −1.50 |

| Average deceleration (m/s2) | −0.45 | −0.58 | −0.22 | −0.57 | −0.46 | −0.48 |

| Standing time (s) | 226 | 338 | 1 | 206 | 346 | 186 |

| Number of stops (-) | 8 | 19 | 1 | 14 | 11 | 7 |

| Parameters | Unit | Value |

|---|---|---|

| Autonomous emergency braking | ||

| Referenced object sensor | - | Front radar |

| Maximal deceleration | m/s2 | 6.0 |

| Acceleration controller factor P (proportional) | - | 0.001 |

| Acceleration controller factor I (integral) | - | 3.0 |

| Minimal distance | m | 5.0 |

| Time braking after standstill | s | 5.0 |

| Time brake reacts | s | 0.2 |

| Forward collision warming | ||

| Time first warming level | s | 2.0 |

| Time second warming level | s | 1.0 |

| Parameters | Unit | Value |

|---|---|---|

| Initial line detection mode | - | Line sensor |

| Line keeping assist system | ||

| Maximal velocity | km/h | 55.0 |

| Maximal assist torque | Nm | 2.0 |

| Time constant PT (powertrain) filter | s | 0.003 |

| Maximal lane width | m | 7.0 |

| Minimal line width | m | 1.8 |

| Curvature controller factor P (proportional) | - | 2.0 |

| Curvature controller factor I (integral) | - | 0.2 |

| Curvature controller factor D (derivative) | - | 0.0 |

| Maximal deviation distance | m | 10.0 |

| Assist torque coefficient | Ns2 | 2.0 |

| Lane departure warning | ||

| Maximal velocity | km/h | 55.0 |

| Distance departure warning | m | 0.2 |

| Standard Driving Mode | Longitudinal Acceleration (m/s2) | Longitudinal Deceleration (m/s2) | Lateral Acceleration (m/s2) |

|---|---|---|---|

| Driver presets standard “Normal” | 3.00 | −4.00 | 4.00 |

| Driver presets standard “Defensive” | 2.00 | −2.00 | 3.00 |

| Driver presets standard “Aggressive” | 4.00 | −6.00 | 5.00 |

| Extended Driver Driving Mode | Dynamics | Energy Efficiency | Nervousness |

|---|---|---|---|

| Energy-efficient driver | 0.20 | 0.10 | 0.00 |

| Stressed driver | 0.70 | 0.00 | 0.50 |

| Area | Length (m) | Average Speed (km/h) | Energy Consumption (kWh/km) | Recovered Energy (kWh/km) | Total Energy (kWh/km) |

|---|---|---|---|---|---|

| Extra-urban metropolitan 1 | 10,030 | 54.99 | 0.177 | 0.031 | 0.146 |

| Metropolitan ring | 20,020 | 81.30 | 0.269 | 0.023 | 0.269 |

| Extra-urban metropolitan 2 | 5970 | 54.40 | 0.187 | 0.009 | 0.178 |

| Urban metropolitan | 10,240 | 42.00 | 0.172 | 0.029 | 0.143 |

| Urban peripheral 1 | 3330 | 17.48 | 0.130 | 0.011 | 0.119 |

| Urban central | 3290 | 15.70 | 0.173 | 0.010 | 0.163 |

| Urban peripheral 2 | 4460 | 21.00 | 0.179 | 0.016 | 0.163 |

| Area | Length (m) | Average Speed (km/h) | Energy Consumption (kWh/km) | Recovered Energy (kWh/km) | Total Energy (kWh/km) |

|---|---|---|---|---|---|

| Extra-urban metropolitan 1 | 10,035 | 54.99 | 0.170 | 0.020 | 0.150 |

| Metropolitan ring | 20,020 | 81.30 | 0.220 | 0.025 | 0.195 |

| Extra-urban metropolitan 2 | 5970 | 54.40 | 0.180 | 0.010 | 0.170 |

| Urban metropolitan | 10,240 | 42.00 | 0.165 | 0.030 | 0.135 |

| Urban peripheral 1 | 3330 | 17.48 | 0.125 | 0.015 | 0.110 |

| Urban central | 3290 | 15.70 | 0.160 | 0.010 | 0.150 |

| Urban peripheral 2 | 4460 | 21.00 | 0.170 | 0.020 | 0.150 |

| Driving Cycle | Cycle Length (m) | “Normal” Driving Behavior | “Aggressive” Driving Behavior | “Defensive” Driving Behavior | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Average Speed (km/h) | Energy Consumption (kWh/km) | Energy Recovered (kWh/km) | Average Speed (km/h) | Energy Consumption (kWh/km) | Energy Recovered (kWh/km) | Average Speed (km/h) | Energy Consumption (kWh/km) | Energy Recovered (kWh/km) | ||

| (1) WLTC | 23,266 | 46.13 | 0.188 | 0.040 | 46.07 | 0.201 | 0.000 | 40.32 | 0.173 | 0.005 |

| (2) HWFET | 16,503 | 77.67 | 0.166 | 0.023 | 77.54 | 0.173 | 0.000 | 72.38 | 0.155 | 0.018 |

| (3) FTP-75 | 17,769 | 34.11 | 0.162 | 0.014 | 34.07 | 0.169 | 0.000 | 30.99 | 0.150 | 0.006 |

| (4) ARTEMIS | 51,687 | 17.63 | 0.183 | 0.003 | 17.60 | 0.256 | 0.000 | 15.66 | 0.163 | 0.002 |

| (5) JC08 | 8159 | 24.42 | 0.174 | 0.003 | 24.39 | 0.194 | 0.000 | 21.93 | 0.145 | 0.002 |

| (6) NYCC | 1902 | 11.38 | 0.216 | 0.002 | 11.34 | 0.235 | 0.000 | 9.57 | 0.198 | 0.002 |

| Area | RMSE (kWh/km) | MAPE (%) | Confidence Interval (kWh/km) |

|---|---|---|---|

| Extra-urban metropolitan 1 | 0.019 | 3.45 | 0.130–0.150 |

| Extra-urban metropolitan 2 | |||

| Metropolitan ring | 0.015 | 3.87 | 0.138–0.155 |

| Urban metropolitan | 0.017 | 4.21 | 0.149–0.167 |

| Urban central | 0.013 | 7.98 | 0.140–0.160 |

| Urban peripheral 1 | 0.011 | 4.61 | 0.124–0.140 |

| Urban peripheral 2 | |||

| Average for all sectors | 0.016 | 4.52 | - |

| Area | Total Energy Consumed | Total Energy Recovered | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kWh/km) | (%) of Total | (kWh/km) | (%) of Total | |||||||||

| N | D | A | N | D | A | N | D | A | N | D | A | |

| Extra-urban metropolitan 1, 2 (WLTC) | 3.008 | 2.768 | 3.216 | 32.27 | 30.47 | 29.50 | 0.640 | 0.080 | 0.000 | 50.29 | 15.26 | 0.00 |

| Metropolitan ring (HWFET) | 3.320 | 3.100 | 3.460 | 35.62 | 34.16 | 31.77 | 0.460 | 0.360 | 0.000 | 36.18 | 68.77 | 0.00 |

| Urban metropolitan (FTP-75) | 1.650 | 1.530 | 1.730 | 17.79 | 16.90 | 15.87 | 0.143 | 0.060 | 0.000 | 11.28 | 11.72 | 0.00 |

| Urban peripheral 1 (ARTEMIS) | 0.400 | 0.540 | 0.850 | 4.39 | 5.97 | 7.82 | 0.009 | 0.006 | 0.000 | 0.78 | 1.27 | 0.00 |

| Urban central (NYCC) | 0.140 | 0.480 | 0.780 | 1.55 | 5.36 | 7.09 | 0.009 | 0.006 | 0.000 | 0.77 | 1.25 | 0.00 |

| Urban peripheral 2 (JC08) | 0.770 | 0.640 | 0.860 | 8.32 | 7.14 | 7.95 | 0.008 | 0.008 | 0.000 | 0.70 | 1.73 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iclodean, C.-D.; Jurchis, B.-M.; Macavei, C.-M.; Volosciuc, E.-R.; Iclodean, A.-G. Optimizing the Energy Efficiency of Electric Vehicles in Urban and Metropolitan Environments According to Various Driving Cycles and Behavioral Conditions. Electronics 2025, 14, 2224. https://doi.org/10.3390/electronics14112224

Iclodean C-D, Jurchis B-M, Macavei C-M, Volosciuc E-R, Iclodean A-G. Optimizing the Energy Efficiency of Electric Vehicles in Urban and Metropolitan Environments According to Various Driving Cycles and Behavioral Conditions. Electronics. 2025; 14(11):2224. https://doi.org/10.3390/electronics14112224

Chicago/Turabian StyleIclodean, Călin-Doru, Bogdan-Manolin Jurchis, Cristian-Marius Macavei, Edmond-Roland Volosciuc, and Andrei-George Iclodean. 2025. "Optimizing the Energy Efficiency of Electric Vehicles in Urban and Metropolitan Environments According to Various Driving Cycles and Behavioral Conditions" Electronics 14, no. 11: 2224. https://doi.org/10.3390/electronics14112224

APA StyleIclodean, C.-D., Jurchis, B.-M., Macavei, C.-M., Volosciuc, E.-R., & Iclodean, A.-G. (2025). Optimizing the Energy Efficiency of Electric Vehicles in Urban and Metropolitan Environments According to Various Driving Cycles and Behavioral Conditions. Electronics, 14(11), 2224. https://doi.org/10.3390/electronics14112224