S-SP Inductive Power Transfer System with High Misalignment Tolerance Based on a Switch-Controlled Capacitor

Abstract

1. Introduction

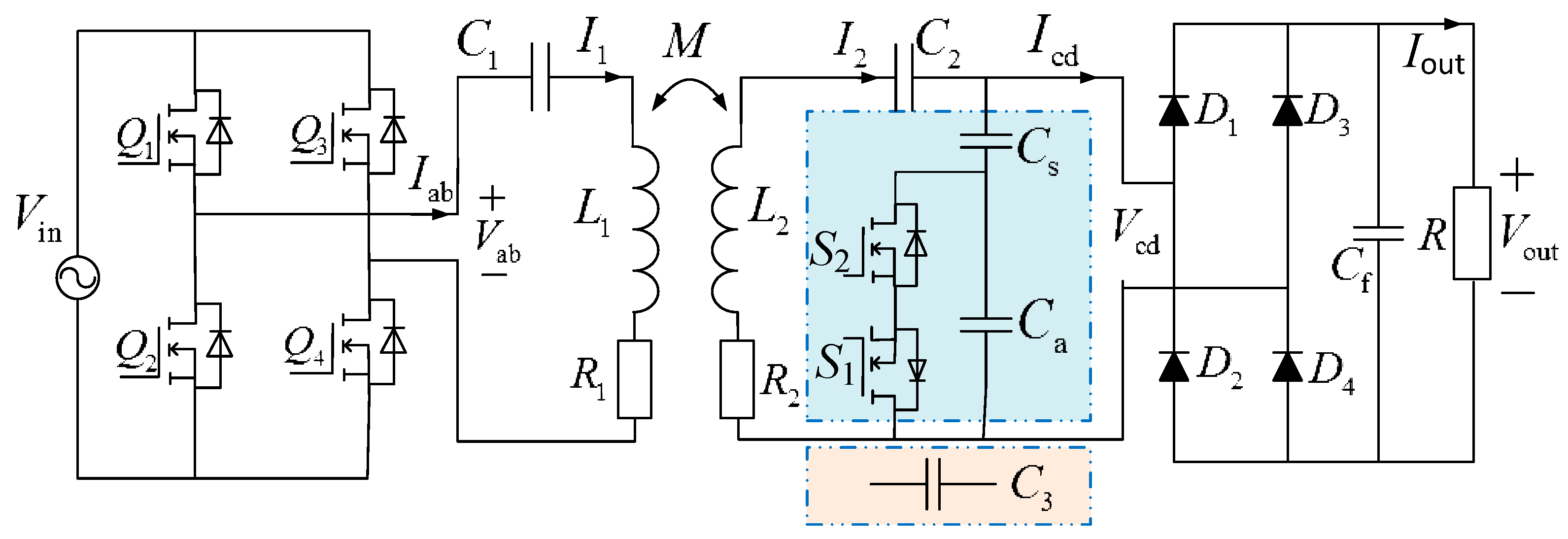

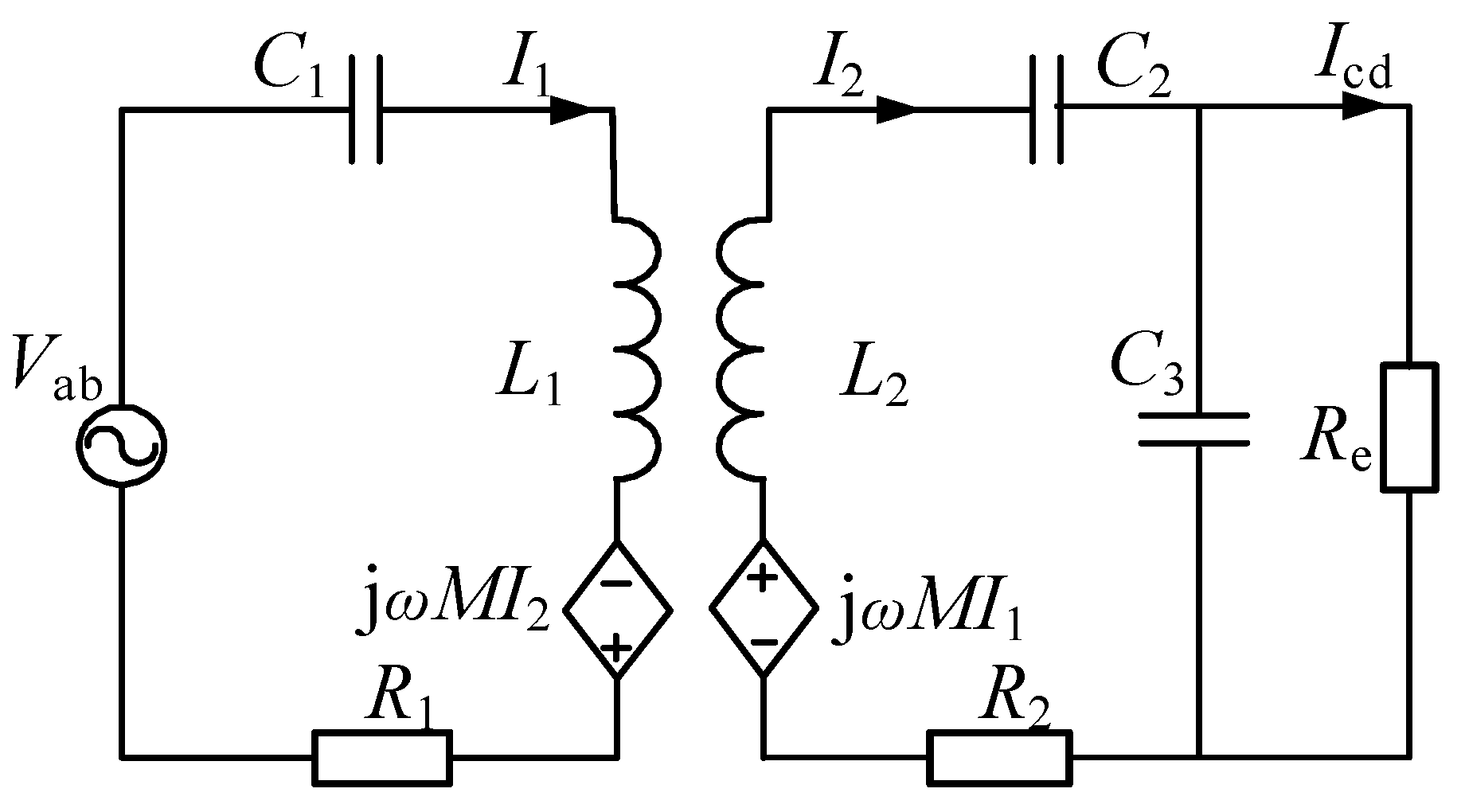

2. S-SP Compensation Topology Theoretical Analysis

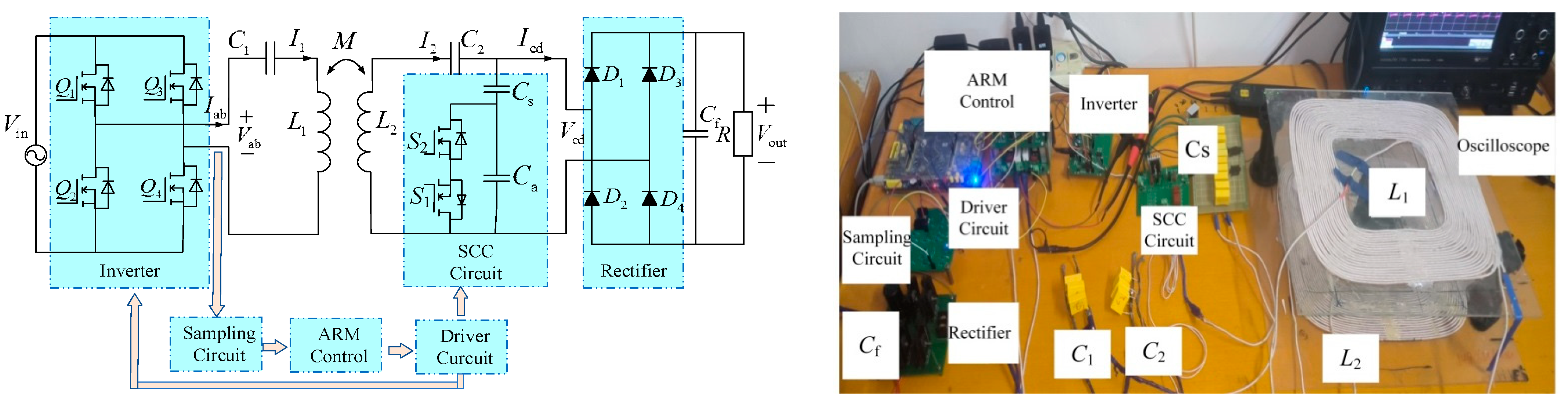

2.1. S-SP’s Fully Tuned State

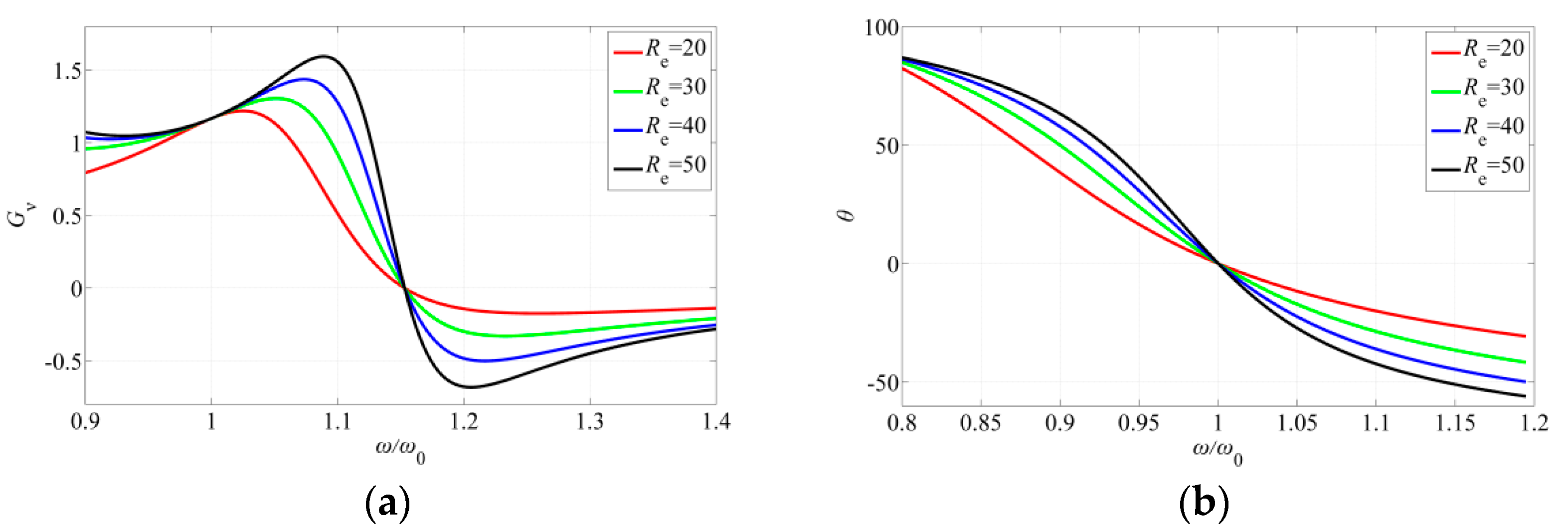

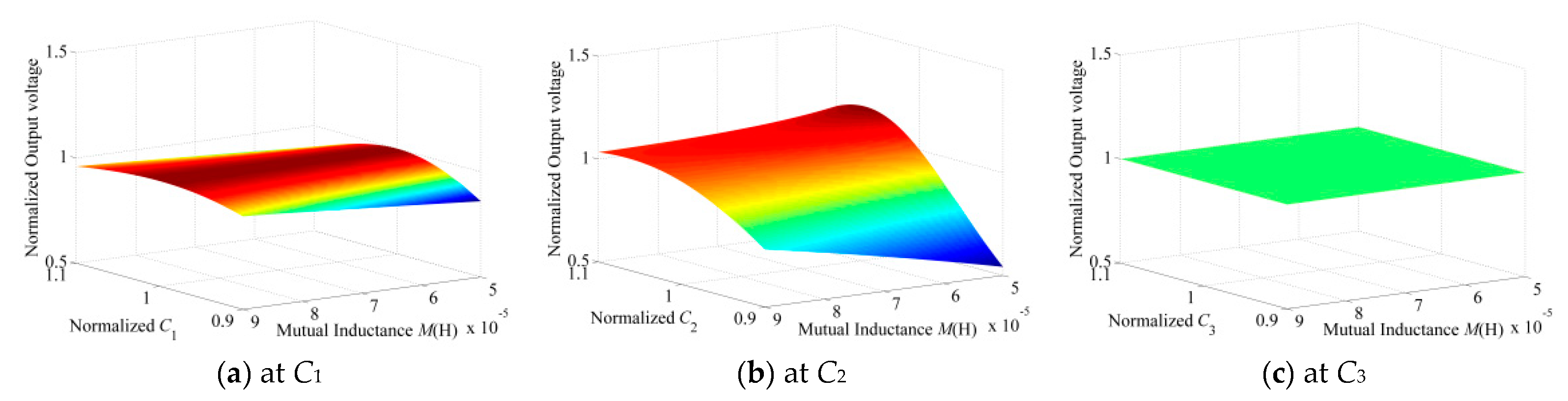

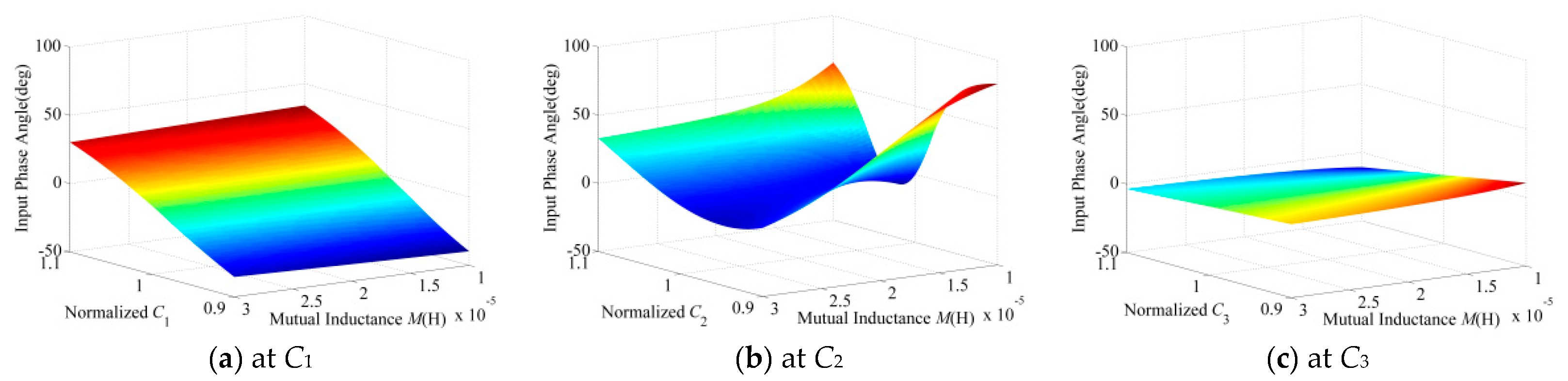

2.2. S-SP Parameter Sensitivity Analysis

2.3. S-SP Detuned State

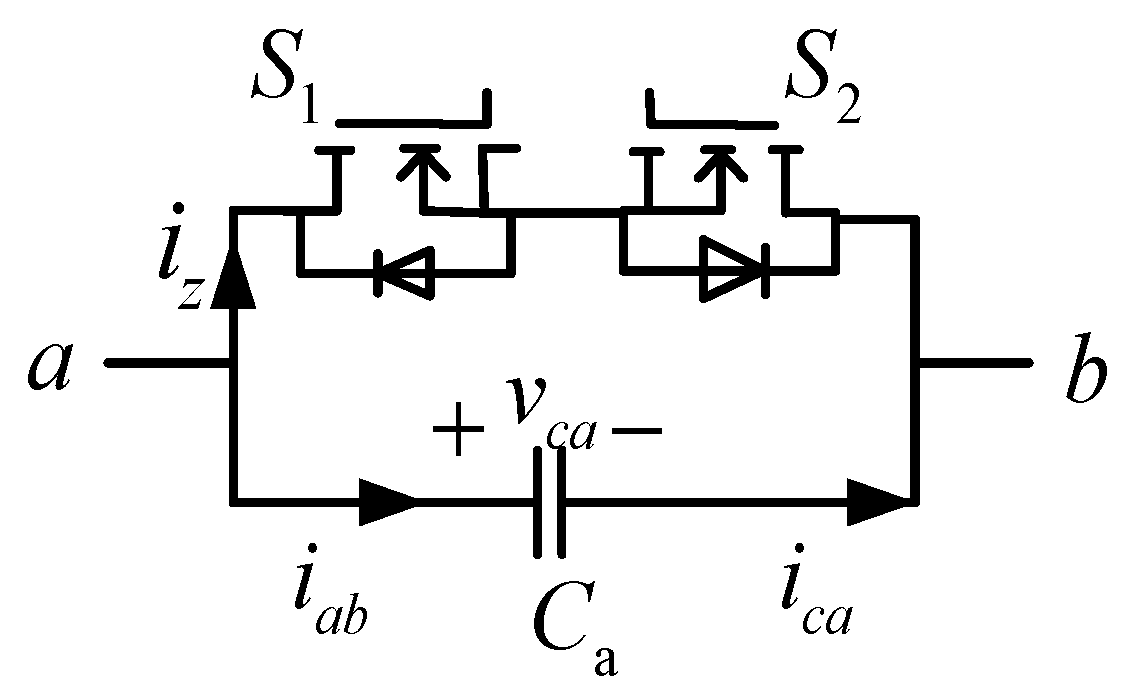

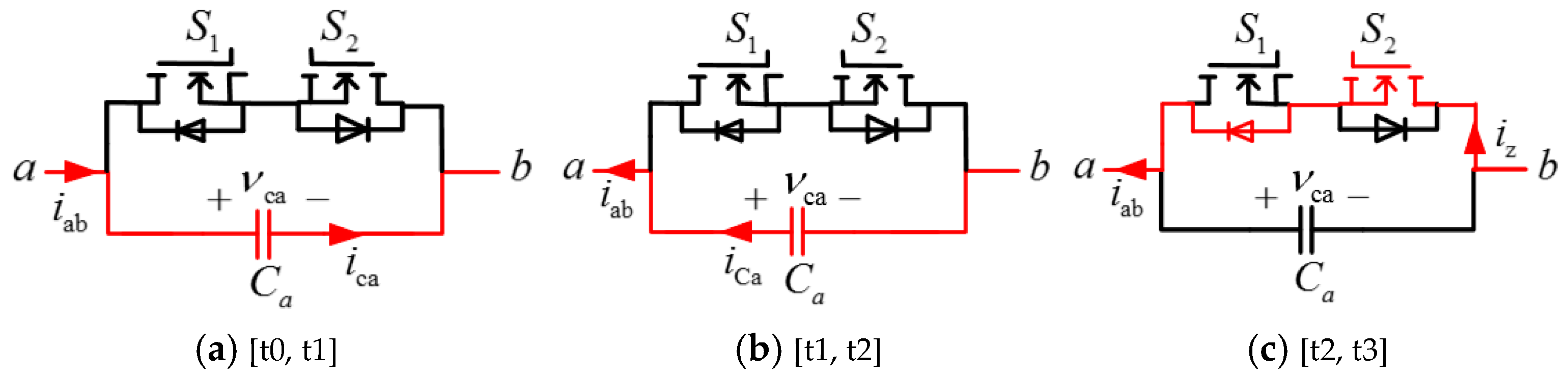

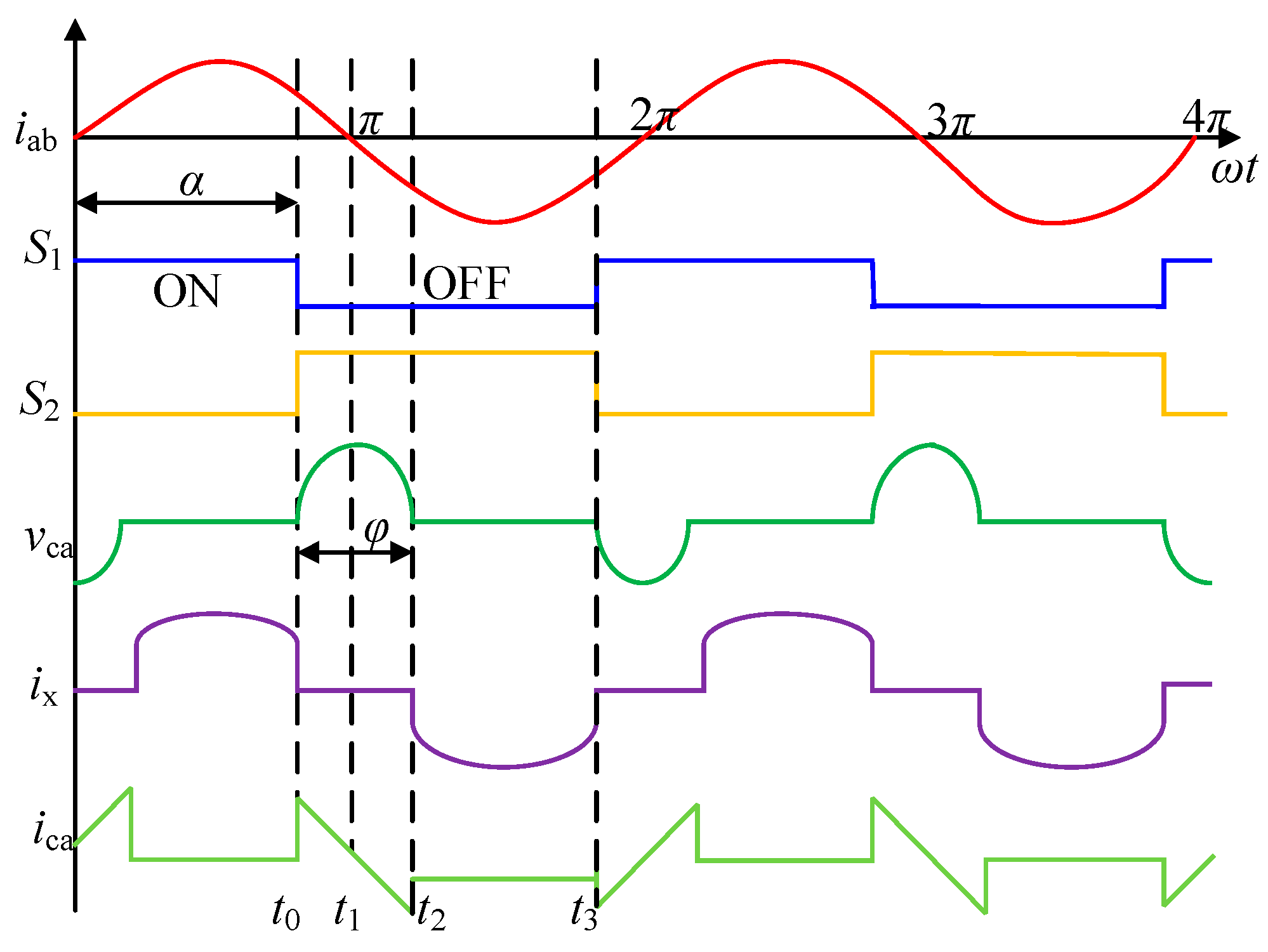

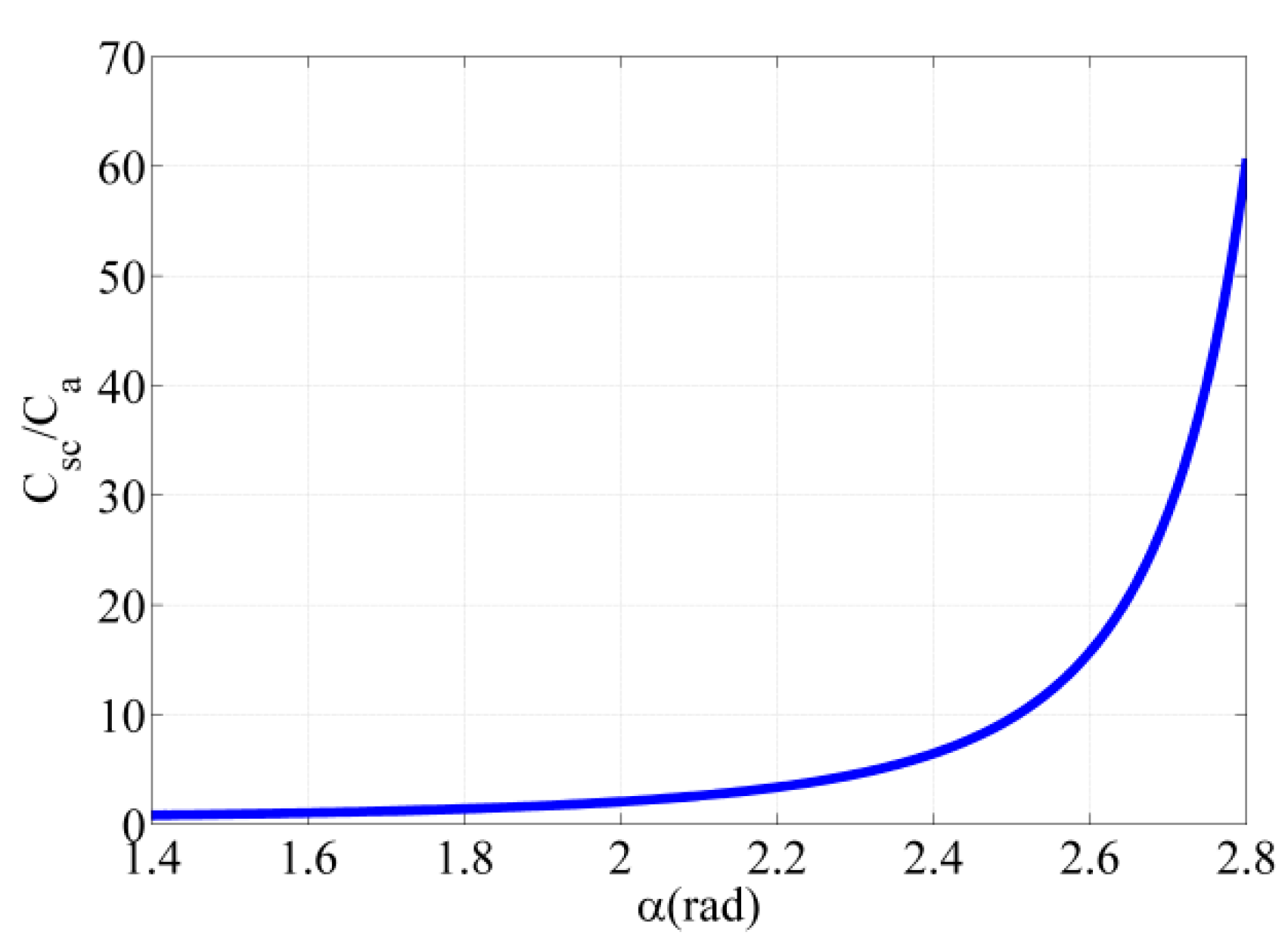

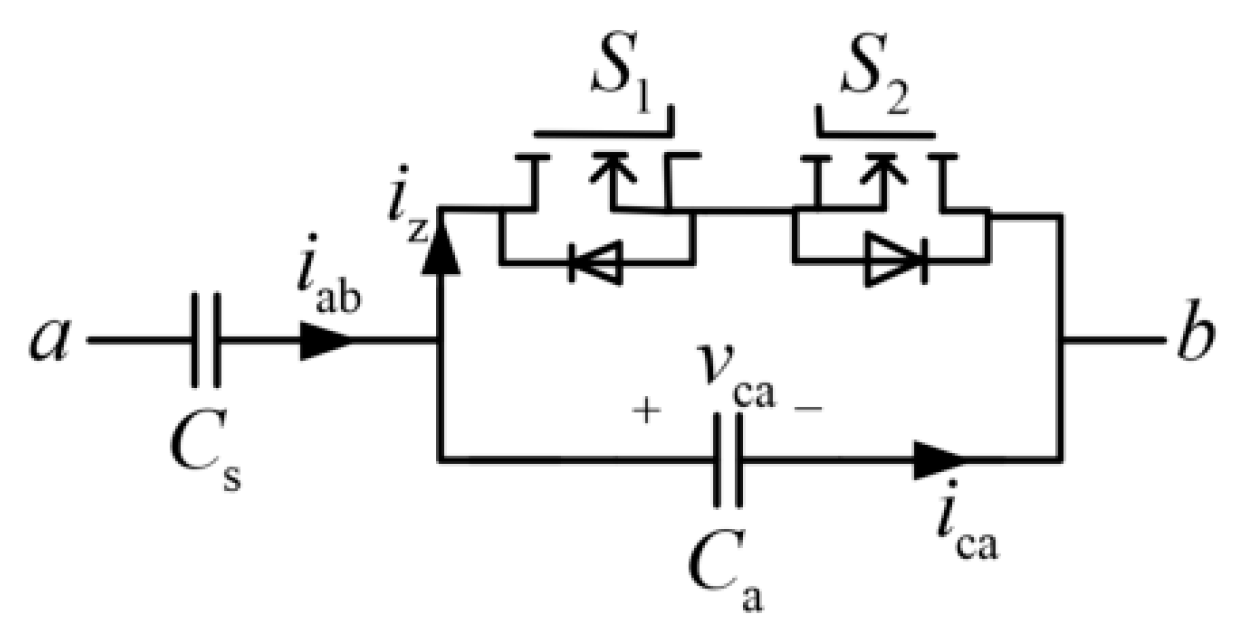

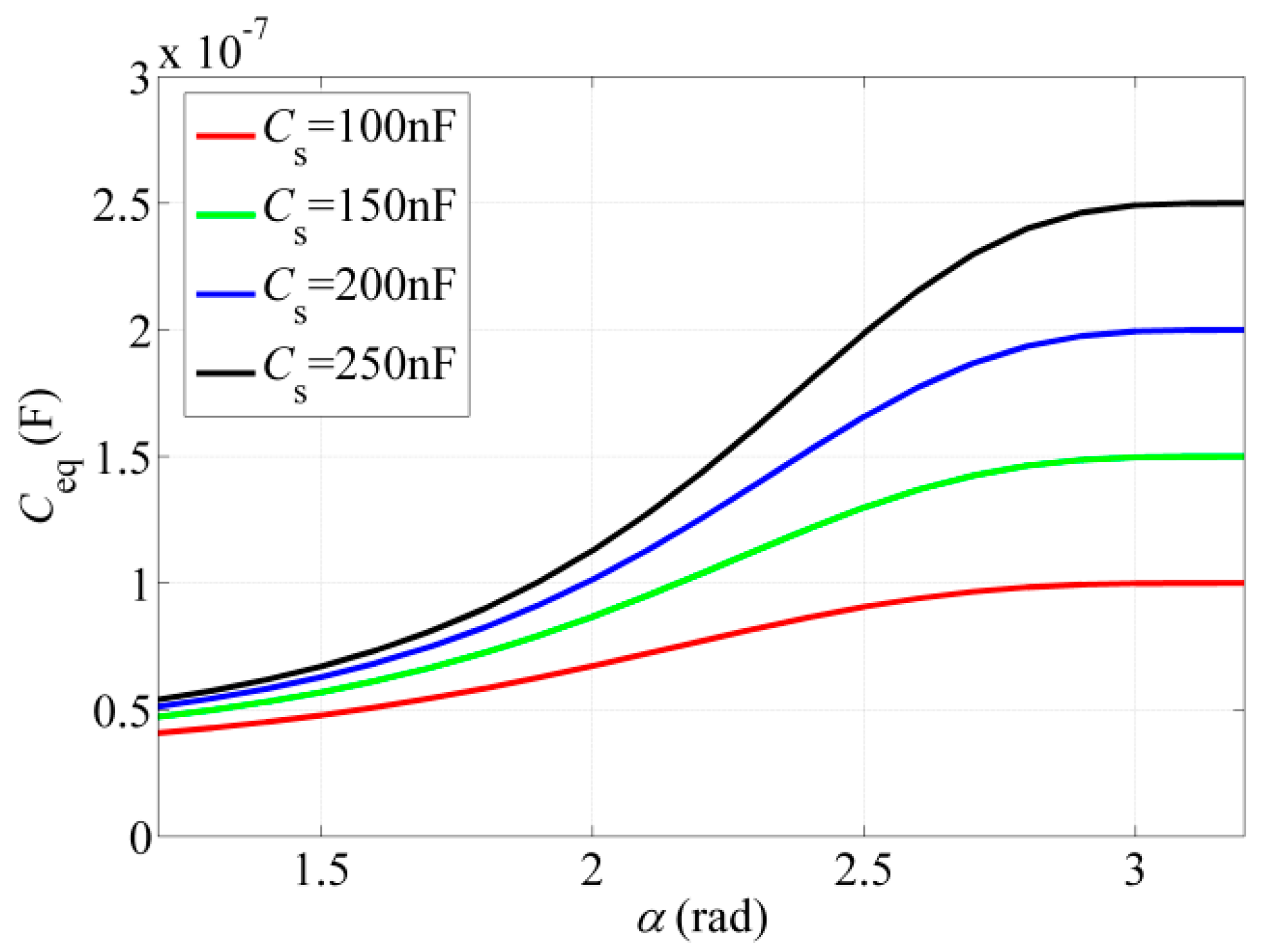

3. Principle Analysis of SCC Strategy

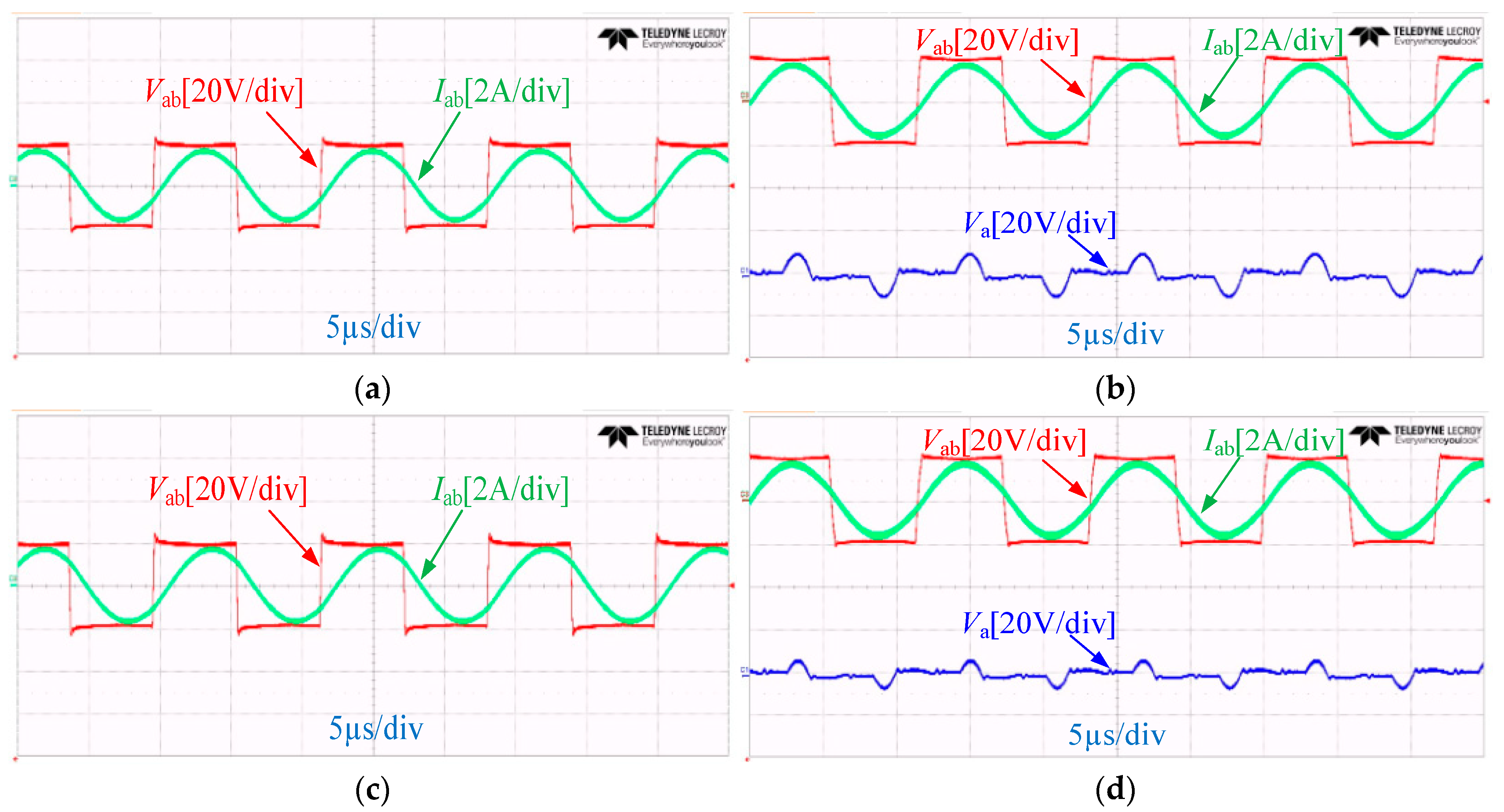

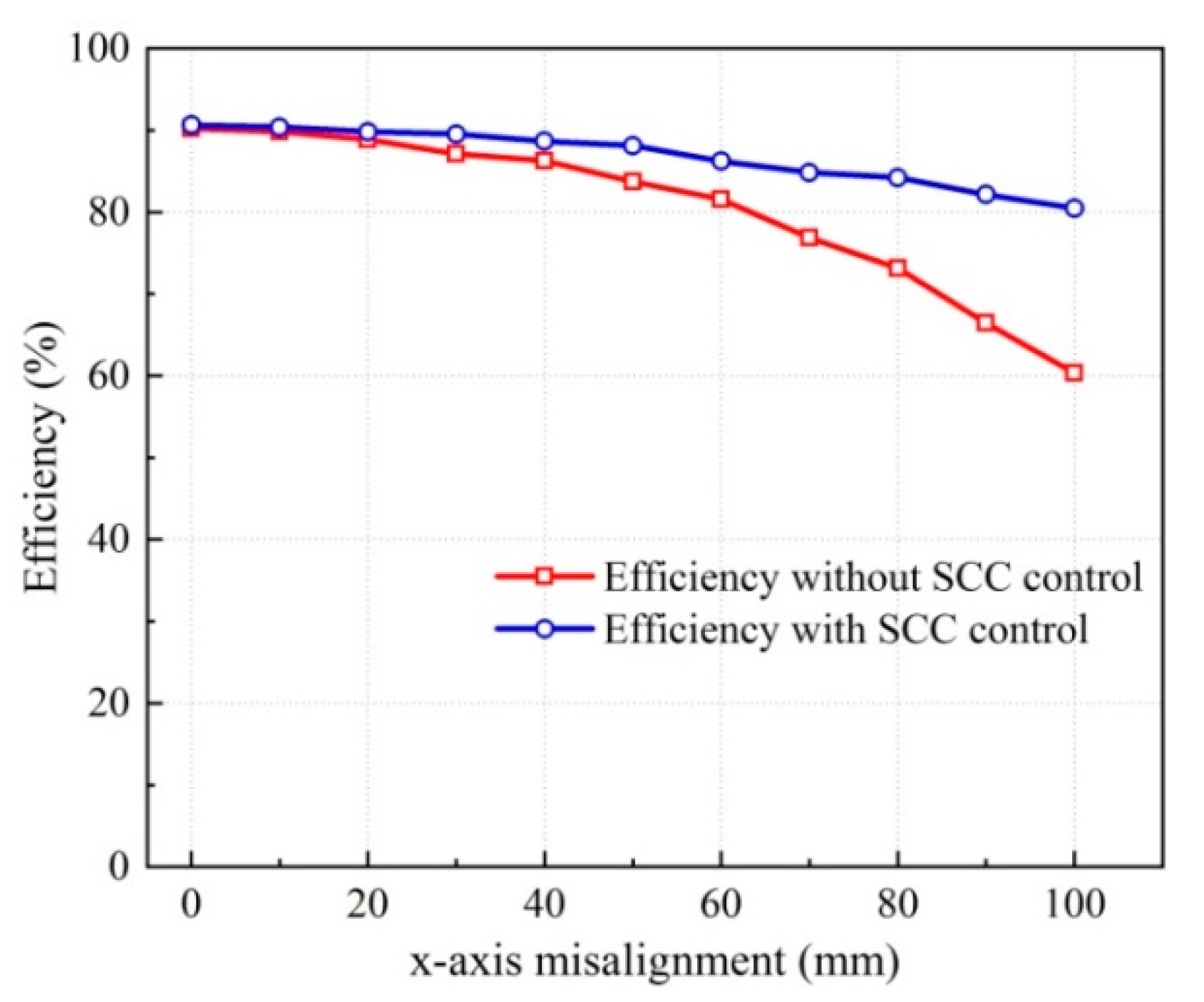

4. Experimental Verification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, J.; Wei, G.; Wang, Y. A Novel Impedance Compensation Method for IPT System Applying Inverse Coupled Current Doubler Rectifier. IEEE Trans. Power Electron. 2024, 71, 15235–15238. [Google Scholar] [CrossRef]

- Tao, C.; Liu, Z.; Li, S.; Guo, Y.; Wang, L. A High-efficiency Wireless Power Transfer System Using Quasi-Z-Source Inverter and Current-Double Synchronous Rectifier for Low-Voltage and High-Current Applications. IEEE Trans. Transp. Electrif. 2022, 8, 2758–2769. [Google Scholar] [CrossRef]

- Jeong, M.S.; Jang, J.H.; Lee, E.S. Optimal IPT Core Design for Wireless Electric Vehicles by Reinforcement Learning. IEEE Trans. Power Electron. 2023, 38, 13262–13272. [Google Scholar] [CrossRef]

- Zhang, X.; Xue, R.; Wang, F.; Xu, F.; Chen, T.; Chen, Z. Capacitor Tuning of LCC-LCC Compensated IPT System with Constant-Power Output and Large Misalignments Tolerance for Electric Vehicles. IEEE Trans. Power Electron. 2023, 38, 11928–11939. [Google Scholar] [CrossRef]

- Feng, H.; Dayerizadeh, A.; Lukic, S. A Coupling-Insensitive X-Type IPT System for High Position Tolerance. IEEE Trans. Ind. Electron. 2021, 68, 6917–6926. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Zhou, K.; He, Z.; Li, W.; Mai, R. Uniform Power IPT System with Three-Phase Transmitter and Bipolar Receiver for Dynamic Charging. IEEE Trans. Power Electron. 2019, 34, 2013–2017. [Google Scholar] [CrossRef]

- Lu, J.; Zhu, G.; Lin, D. Load-Independent Voltage and Current Transfer Characteristics of High-Order Resonant Network in IPT System. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 7, 422–436. [Google Scholar] [CrossRef]

- Dai, X.; Li, X.; Li, Y.; Hu, A.P. Maximum Efficiency Tracking for Wireless Power Transfer Systems with Dynamic Coupling Coefficient Estimation. IEEE Trans. Power Electron. 2018, 33, 5005–5015. [Google Scholar] [CrossRef]

- Yang, L.; Shi, Y.; Wang, M.; Ren, L. Constant Voltage Charging and Maximum Efficiency Tracking for WPT Systems Employing Dual-Side Control Scheme. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 945–955. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, Y.; Liu, X. Analysis, Design, and Optimization of LC/S Compensation Topology with Excellent Load-Independent Voltage Output for Inductive Power Transfer. IEEE Trans. Transp. Electrif. 2018, 4, 767–777. [Google Scholar] [CrossRef]

- Wang, C.; Covic, G.; Stielau, O. Power transfer capability and bifurcation phenomena of loosely coupled inductive power transfer systems. IEEE Trans. Ind. Electron. 2004, 51, 148–157. [Google Scholar] [CrossRef]

- Li, Z.; Song, K.; Jiang, J.; Zhu, C. Constant Current Charging and Maximum Efficiency Tracking Control Scheme for Supercapacitor. IEEE Trans. Power Electron. 2022, 33, 9088–9100. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, F.; Mei, T. Multifrequency Phase-Shifted Control for Multiphase Multiload MCR WPT System to Achieve Targeted Power Distribution and High Misalignment Tolerance. IEEE Trans. Power Electron. 2021, 36, 991–1003. [Google Scholar] [CrossRef]

- Miller, J.; Onar, O.; Chinthavali, M. Primary-side power flow control of wireless power transfer for electric vehicle charging. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 147–162. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, B. Angular-Misalignment Insensitive Omnidirectional Wireless Power Transfer. IEEE Trans. Ind. Electron. 2020, 67, 2755–2764. [Google Scholar] [CrossRef]

- Kim, S.; Covic, G.; Boys, J. Tripolar Pad for Inductive Power Transfer Systems for EV Charging. IEEE Trans. Power Electron. 2017, 32, 5045–5057. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, B.; Zhou, X.; Li, Q.; He, Z.; Mai, R.; Lai, J.S. A Hybrid Inductive Power Transfer System with Misalignment Tolerance Using Quadruple-D Quadrature Pads. IEEE Trans. Ind. Electron. 2020, 35, 6039–6049. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, Y.; Liu, X.; Pei, Y. A Novel Unsymmetrical Coupling Structure Based on Concentrated Magnetic Flux for High-Misalignment IPT Applications. IEEE Trans. Power Electron. 2019, 34, 3110–3123. [Google Scholar] [CrossRef]

- Ahmad, A.; Alam, M.S.; Mohamed, A.A.S. Design and Interoperability Analysis of Quadruple Pad Structure for Electric Vehicle Wireless Charging Application. IEEE Trans. Transp. Electrif. 2019, 5, 934–945. [Google Scholar] [CrossRef]

- Zhao, L.; Thrimawithana, D.; Madawala, U. Hybrid Bidirectional Wireless EV Charging System Tolerant to Pad Misalignment. IEEE Trans. Ind. Electron. 2017, 64, 7079–7086. [Google Scholar] [CrossRef]

- Zhao, L.; Thrimawithana, D.J.; Madawala, U.K.; Hu, A.P.; Mi, C.C. A Misalignment-Tolerant Series-Hybrid Wireless EV Charging System with Integrated Magnetics. IEEE Trans. Power Electron. 2019, 34, 1276–1285. [Google Scholar] [CrossRef]

- Qu, X.; Yao, Y.; Wang, D.; Wong, S.C.; Chi, K.T. A Family of Hybrid IPT Topologies with Near Load-Independent Output and High Tolerance to Pad Misalignment. IEEE Trans. Ind. Electron. 2020, 35, 6867–6877. [Google Scholar] [CrossRef]

- Mai, J.; Wang, Y.; Yao, Y.; Xu, D. Analysis and Design of High-Misalignment-Tolerant Compensation Topologies with Constant-Current or Constant-Voltage Output for IPT Systems. IEEE Trans. Power Electron. 2021, 36, 2685–2695. [Google Scholar] [CrossRef]

- Yang, B.; Li, Y.; Zhang, Z.; He, S.; Peng, Y.; Chen, Y.; He, Z.; Mai, R. A Detuned S-S Compensated IPT System with Two Discrete Frequencies for Maintaining Stable Power Transfer Versus Wide Coupling Variation. IEEE Trans. Transp. Electrif. 2023, 9, 3836–3848. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, Y.; Liu, X.; Pei, Y.; Xu, D.; Liu, X. Particle Swarm Optimization-Based Parameter Design Method for S/CLC-Compensated IPT Systems Featuring High Tolerance to Misalignment and Load Variation. IEEE Trans. Power Electron. 2019, 34, 5268–5282. [Google Scholar] [CrossRef]

- Feng, H.; Cai, T.; Duan, S.; Zhang, X.; Hu, H.; Niu, J. A Dual-Side-Detuned Series–Series Compensated Resonant Converter for Wide Charging Region in a Wireless Power Transfer System. IEEE Trans. Ind. Electron. 2018, 65, 2177–2188. [Google Scholar] [CrossRef]

- Wang, Y.; Mai, J.; Yao, Y.; Xu, D. Analysis and Design of an IPT System Based on S/SP Compensation with Improved Output Voltage Regulation. IEEE Trans. Ind. Inform. 2020, 16, 3256–3266. [Google Scholar] [CrossRef]

- Zhou, L.; Mai, R.; Liu, S.; Yu, J.; Li, Y.; Fu, L. Minimizing Input Current of the Rectifier of LCC–LCC Compensated IPT Systems by Switch-Controlled Capacitor for Improving Efficiency. IEEE Trans. Ind. Appl. 2022, 58, 1010–1021. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Uin | 20/V | f | 85/kHz |

| L1 | 149.56/μH | Cs | 250/nF |

| L2 | 149.2/μH | Ca | 50/nF |

| Lf | 470/μH | Cf | 50/nF |

| C1 | 30/nF | M | 34.5/uH |

| C2 | 30/nF | R | 20/30/Ω |

| Proposed in | [25] | [26] | [27] | [28] | This Work |

|---|---|---|---|---|---|

| Compensation topology | S-CLC | SS | S-SP | LCC-LCC | S-SP |

| Number of components | 4 | 2 | 3 | 6 | 3 |

| Coupling coefficient | 0.2–0.4 | 0.08–0.2 | 0.14–0.285 | 0.128–0.173 | 0.14–0.2 |

| Output characteristic | Constant Voltage | Constant Power | Constant Voltage | Constant Current | Constant Voltage |

| Misalignment tolerance | Yes | Yes | Yes | No | Yes |

| Input phase angle | ZVS | ZVS | ZVS | ZPA | ZPA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, M.; Zhang, H.; Yang, Y.; Wang, H.; Zhang, N.; Gong, Z. S-SP Inductive Power Transfer System with High Misalignment Tolerance Based on a Switch-Controlled Capacitor. Electronics 2025, 14, 188. https://doi.org/10.3390/electronics14010188

Xie M, Zhang H, Yang Y, Wang H, Zhang N, Gong Z. S-SP Inductive Power Transfer System with High Misalignment Tolerance Based on a Switch-Controlled Capacitor. Electronics. 2025; 14(1):188. https://doi.org/10.3390/electronics14010188

Chicago/Turabian StyleXie, Mengqi, Heng Zhang, Yajing Yang, Hao Wang, Ningchao Zhang, and Zhaowei Gong. 2025. "S-SP Inductive Power Transfer System with High Misalignment Tolerance Based on a Switch-Controlled Capacitor" Electronics 14, no. 1: 188. https://doi.org/10.3390/electronics14010188

APA StyleXie, M., Zhang, H., Yang, Y., Wang, H., Zhang, N., & Gong, Z. (2025). S-SP Inductive Power Transfer System with High Misalignment Tolerance Based on a Switch-Controlled Capacitor. Electronics, 14(1), 188. https://doi.org/10.3390/electronics14010188