1. Introduction

In the process of underwater environment detection [

1], the complexity and high danger of the seabed environment make manual underwater operations challenging [

2]. The autonomous underwater vehicle-manipulator system used for assistance in underwater operations not only it improves efficiency but also ensures the safety of underwater workers [

3]. The underwater vehicle typically uses a manipulator to perform tasks such as opening and closing valves, underwater welding, and cutting underwater cables during underwater operations [

4]. Currently, the operation of the autonomous underwater vehicle-manipulator system faces various challenges [

5]. The widely applied approach is to utilize teleoperation technology to assist remotely in underwater tasks. An underwater teleoperation system generally consists of an operator, the master manipulator for operation, a communication channel, the remotely operated slave manipulator on the underwater side, and the underwater working environment [

6]. The operator generates and sends force or position commands to the master manipulator, and the master manipulator controller transmits the force and position information through the communication channel to the remotely operated slave manipulator. The remotely operated robotic arm completes underwater tasks by tracking the position information from the master manipulator [

7].

In order to improve the stability and transparency of the underwater teleoperation system, force feedback is introduced into the underwater teleoperation system [

8]. The force signal sensed by the end of the underwater manipulator is transmitted to the master manipulator through the force sensor at the end, so that the operator can perceive the interactive force of the underwater working environment, which improves the operator’s sense of presence during underwater operations, reduces work errors, and improves the efficiency of underwater operations. The application of force feedback in master–slave manipulators in underwater teleoperation systems is particularly significant in tasks such as underwater mine clearance, explosive ordnance disposal, and obstacle clearance. It eliminates the need for operators to be present in hazardous areas, thereby reducing the risk of personnel casualties. Additionally, it combines the advanced intelligence of humans and the scalability of robots, overcomes distance limitations, and improves operating efficiency and control performance.

The teleoperation of underwater manipulators faces a series of challenges and problems, including but not limited to dynamic uncertainty, external uncertain disturbance, and communication time delay [

9]. The complexity of the underwater environment causes the manipulator system to face a large number of uncertainties, including changes in water flow, seabed topography, and variations in material properties [

10]. These factors make it difficult for traditional control methods to deal with uncertainty. External disturbances that may exist in the underwater environment, such as changes in water flow and water pressure, may interfere with the movement and positioning of the manipulator and affect the accuracy and stability of remote teleoperation [

11]. There is the time-delay problem in underwater communications, which may cause control delays and reduce the responsiveness of the system for remote operations with high real-time requirements. The robot is a time-varying, strongly coupled multi-input multi-output nonlinear system, and uncertainty is inevitable in practical applications [

12]. Therefore, under the premise of ensuring the stability of the overall system, uncertainty teleoperation control improves transparency and robustness, and enables position and force signals to be reproduced synchronously on the slave manipulator and the master manipulator, which is still the overall control goal.

In the teleoperation system, the master manipulator can be regarded as a force feedback device that reproduces the standard force signals and provides position tracking signals to the slave manipulator. The slave manipulator can be regarded as a position tracking robot system that is in contact with the external environment and has limited movement constraints. Due to the requirement of underwater teleoperation systems, the master manipulator is typically installed within a surface vessel, while the underwater slave manipulator is commonly situated on a remotely operated vehicle (ROV) or an autonomous underwater vehicle (AUV). The data communication distance between the master and slave manipulators is relatively short. In addition, 5G communications can increase the communication rate and reduce the communication time delay. Therefore, the communication delay can be ignored. At this time, the decisive influence on the control law design of the underwater robot teleoperation system is the uncertainty of the manipulator model caused by external uncertain disturbance and joint friction.

In order to solve the problems of model uncertainty and external disturbance in teleoperation control, many scholars have proposed different control methods. Numerous effective control schemes, including the adaptive bilateral control method [

13,

14], predictive control [

15,

16], optimal control [

17], intelligent control based on fuzzy logic [

12,

18] or neural networks [

19,

20], prescribed-performance-based control [

21,

22], etc., have been developed for bilateral teleoperation systems in recent years. The adaptive neural network controller with an adaptive time-delay estimator and parameter adaptive method is designed for the precise position tracking in the teleoperation system under communication constraints [

14]. The adaptive dynamic surface control strategy with an observer-based adaptive fuzzy synchronization framework is proposed for teleoperation systems with the time-delay derivative in [

9]. In [

23], a dynamical force observer was introduced for teleoperations, based on the prescribed performance functions. Aiming at the problem of unmeasurable speed and uncertain dynamics, Yana Yang designed a robust sliding mode control based on a speed observer with neural network uncertainty compensation [

24], which realized the force position synchronization of master and slave. Majtaba proposed an adaptive bilateral control method for the manipulator dynamics uncertainty [

25], and applied it to the medical equipment teleoperation process [

26], but the uncertainty caused by external disturbance is not considered [

27]. What is more, Parham M proposed a robust adaptive scheme that effectively deals with time-varying delay and uncertainties in teleoperation systems. For the problem of position tracking in teleoperation systems subject to external forces, Bahareh Aboutalebian designed an adaptive control algorithm and adaptive laws based on a nonlinear disturbance observer in order to address the tracking error caused by external forces and dynamic uncertainty in the teleoperation systems [

28]. In paper [

29], two sliding-mode observers with a novel power-reaching law are proposed to deal with the uncertainties of teleoperation systems, and the finite time convergence of the tracking errors can be realized with the proposed observers. Longnan Li proposed an adaptive neural learning fixed-time control scheme incorporating an integral barrier Lyapunov function to achieve the master and slave position tracking, and the neural networks are utilized to reconstruct environmental forces and approximate the total uncertainty of the robot [

30]. Hang Li proposed an adaptive fuzzy neural network backstepping control scheme for bilateral teleoperation systems with asymmetric time delays to achieve consistent synchronization of master–slave manipulator positions [

11]. Parham proposed an adaptive interval type-2 fuzzy neural network control scheme for teleoperation systems with time-varying delays and uncertainties; the stability and performance of the proposed control was analyzed using the Lyapunov-Krasovskii method [

27].

Hongjiu Yang proposed a continuous terminal sliding mode control (CTSMC) strategy based on an extended state observer (ESO) and a time-delay part observer to achieve the master and slave position tracking performance in bilateral teleoperation systems [

31]. Yanna Yang proposed the synchronization control problem of an uncertain single-master multislave (SMMS) teleoperation system, in which every subsystem is connected with each other via a directed constrained communication network [

32]. In paper [

11], the synchronization tracking control issue is investigated for uncertain teleoperation systems with input saturation and output error constraints. Hang Li proposed an adaptive fuzzy neural network backstepping control scheme for bilateral teleoperation systems with asymmetric time delays induced by the communication links and various uncertainties [

11]. These control algorithms achieve the purpose of coordinated and consistent synchronization of bilateral force and position by overcoming external uncertain disturbance or mathematical model uncertainty caused by internal uncertainty [

33].

This paper presents an innovative adaptive bilateral control strategy to address the challenges posed by uncertainty in the motion model of master–slave manipulators and external disturbances during remote operations of underwater manipulators. To tackle uncertainties in both model parameters and motion characteristics of the master manipulator, we introduce a reference adaptive impedance control based on the nominal model. This approach employs adaptive control laws to compensate for model uncertainty, facilitating accurate force representation by the operator on the master manipulator and an interaction force between the slave manipulator and the environment. Addressing uncertainties in the slave manipulator, we utilize an RBF network to approximate the uncertain model components. The sliding mode variable structure controller and adaptive controller are then employed to eliminate approximation errors, ensuring a consistent, stable, and bounded position tracking error of the slave manipulator relative to the master manipulator. Furthermore, the control stability is rigorously proven through Lyapunov function analysis.

The remain of this paper is arranged as below. In

Section 2, both kinematic and dynamic models of the dual manipulators are introduced, and the corresponding manipulator properties are also introduced. In

Section 3, the overall structure design of the bilateral robust adaptive impedance controller is achieved, and the master adaptive impedance controller and slave adaptive neural network control are designed in detail using Lyapunov-based stability theory. The simulation verification of a two-degrees-of-freedom (DOF) teleoperation system is completed in

Section 4. In

Section 5, an experimental setup of a single-degree-of-freedom (DOF) teleoperation system is established to validate the force and position tracking performance of the dual manipulators with the designed controller. The experimental results provide evidence of the effectiveness of the proposed controller in achieving the desired force and position coordination during teleoperation. Finally, in

Section 6, the main conclusions of the study are presented, summarizing the findings and contributions of the research.

2. Mathematical Model and Basic Properties

The joint space nonlinear dynamic model of the

n-link master–slave manipulators can be described as [

34]:

where

;

represents the identification of the master and slave manipulators;

,

, and

represent the position, velocity, and acceleration of the joints in the master and slave manipulators; and

,

,

,

, and

are, respectively, denoted as the inertia, the sum of centrifugal force and Coriolis force, gravity term, friction torque and Jacobian matrix.

represents the force exerted by the operator on the master manipulator and

denotes the interaction force between the slave manipulator and the operating object. The disturbance torque of

indicates the bounded uncertainty of the external disturbance of the slave manipulator. It is assumed that

and

can be measurable with the tactile force sensor. It is supposed that

and

are generated from the internal joint friction, which can be formulated as

, where

and

represent the sticky coefficient and the Cullen coefficient, respectively. The sticky coefficient,

, denotes the viscous friction in the joints space, while the Cullen coefficient,

, denotes the Coulomb friction in the joint space.

To achieve force and position tracking in Cartesian coordinates, the dynamics of the dual manipulator in the joint space are transformed and expressed in the operation space:

where

is the position vector of master and slave manipulator end-effectors in the task space;

represent the mapping relationship between the joint space and task space of the dual manipulators; and the joint space velocity,

, is described as [

25]:

Assuming that the manipulator joint is non-redundant, the Jacobian matrix,

, can be expressed as:

According to Equation (

1), the relationship between joint acceleration and acceleration in task space is described by:

According to Equations (

4) and (

5),

and

can be concluded and combining with the joint dynamic model, Equation (

1), and the dynamic model based on task space can be obtained [

25]:

The relations of the dynamic matrices between the joint space and the task space with the non-singular Jacobian matrices,

, can be concluded as [

25]:

The master and slave manipulators possess the following properties [

35]:

- Property 1.

The inertia matrix and of the manipulator are positive definite;

- Property 2.

and are, respectively, skew-symmetric matrices.

- Property 3.

According to different unknown parameters, the manipulator dynamics can be linearized as:

where

;

represents the identification of the master and slave manipulators;

,

is any known vector; the regressor matrix

is a regression matrix function known for the parameters containing joint space information in terms of the arbitrary vectors

and

; and

is the unknown parameters of the manipulator.

The slave manipulator tracks the motion of the master manipulator, which can be divided into free space motion and motion with limited contact with the environment. Considering only the influence of the movement position on

, when the manipulator is in contact with the environment, the force on the environment can be regarded as a passive linear spring, and the contact force,

, can be expressed as [

36]:

where

represents the position of the slave manipulator and the contact environment, and

represents the stiffness coefficient of the grasping target. When

, the movement of the master hand and the slave hand is in a free space state; at

, the slave manipulator can be seen contacting the environment, generating a tactile force.

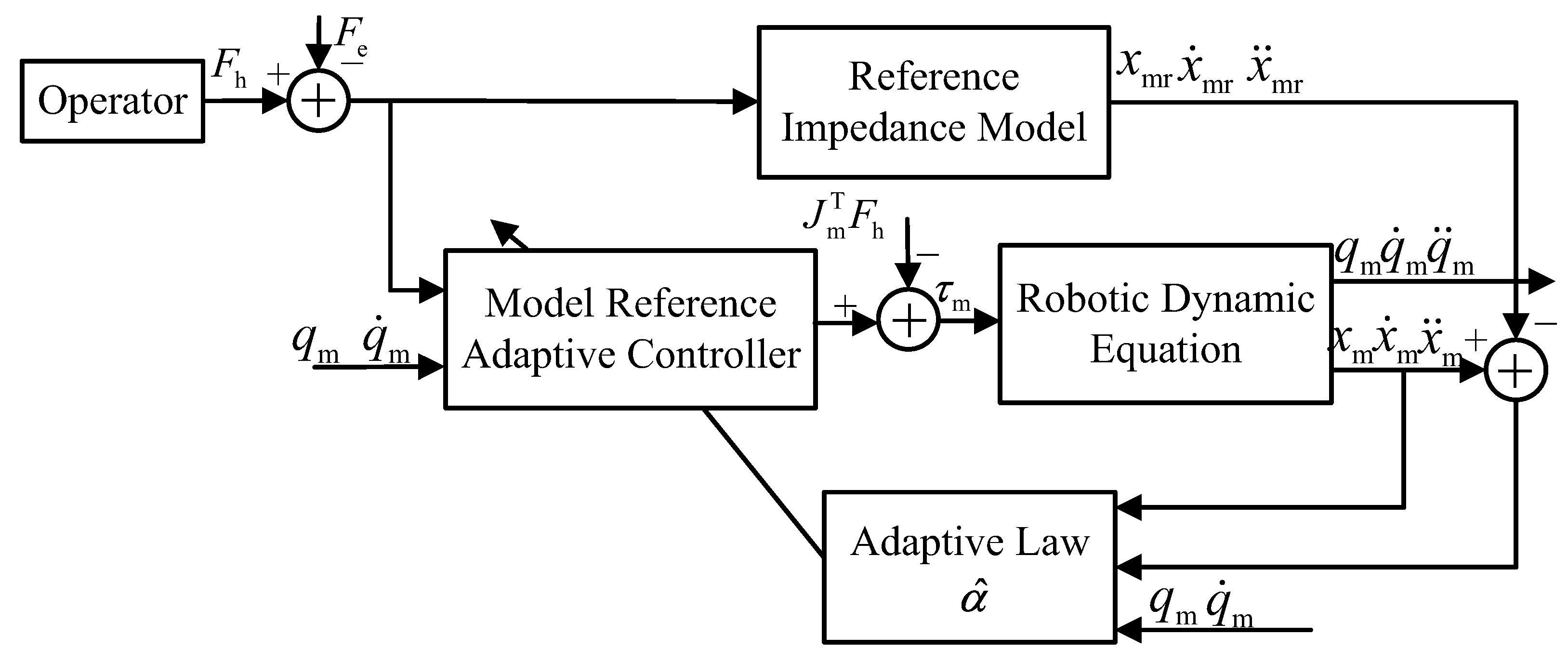

4. Adaptive Force Tracking Control of the Master Manipulator

The impedance control adjusts the target impedance model set by the user to achieve the goal of flexible motion for the manipulator’s terminal. By adding adaptive features to impedance control, the master manipulator’s tactile force tracking performance becomes robust under external uncertain conditions [

37]. A second-order mathematical model can be established between the operator’s master manipulator force, the slave manipulator force, the master terminal velocity, and acceleration. The designed model is considered as the target impedance model. In order to track the environmental contact force exerted by the operator, the impedance control model is expressed as [

38]:

where the matrices

and

are the target impedance parameters, which are the desired inertia and damping matrix of the manipulator, respectively;

is the contact force between the slave manipulator and the environment;

is the force exerted by the operator on the master manipulator; and

is the output reference position of the target impedance model in the Cartesian coordinate system. In the second-order model of the target impedance, the reference position,

, is obtained by the error between the master force,

, and the environment force,

, as the master manipulator position tracking target, and the matching of the manipulator position to achieve the matching of the grasp and environmental power. When the system is in a steady state,

can be obtained, and, at the same time,

and

are zero, which satisfies the impedance relation, Equation (

10), for balance. The master model refers to the adaptive impedance control structure diagram shown in

Figure 2.

Since the dynamic equation of the master manipulator is a nonlinear second-order system, in order to realize the location of the manipulator’s operating space,

is expected to reference position

tracking of the master manipulator, and the design is:

where

is a positive diagonal matrix, and define

,

is the difference between the end position,

, of the master manipulator and the expected reference position,

. Define the reference speed vector:

From Equations (

11) and (

12), it can be obtained:

. The control law for the master manipulator is designed as follows in the Cartesian coordinate system:

Because the real model parameters of the master manipulator cannot be obtained,

,

,

, and

are the corresponding estimates of the number of master manipulator parameters, respectively. The control law of the design angle coordinate system, then the control law of Equation (

13) in the joint coordinate system, correspond to:

Equation (

14) can be expressed as:

The joint angles and lengths of the manipulator are known, so the Jacobian matrix,

, is a known quantity.

and

in Equation (

15) are known vectors, which are as follows:

Referring to manipulator Property 3, the control law, Equation (

15), can be expressed as:

where

is the regression matrix derived from the linearization of the manipulator dynamic model, Equation (

1),

is the estimated value of the uncertain parameter, and the adaptive law is designed as:

where

is a positive definite diagonal matrix. Substituting the control law, Equation (

17), into the manipulator dynamics model, Equation (

1), and, according to manipulator model Property 3, the closed-loop control system with the master adaptive control law can be expressed as:

where

represents the error between the uncertainty estimation value and the real value.

is a constant vector, and

can be obtained. The master manipulator can be regarded as a force feedback device, and the stability of the master manipulator should be ensured with the adaptive controller. In order to prove that the stability of the master manipulator and the force tracking error tend to zero, the Lyapunov function,

, is designed as:

Due to the positiveness of and , can obviously be obtained.

Taking the first derivative of

with respect to time, and combining equations

, Equations (

18) and (

19), with Property 2, we can conclude:

According to Equation (

21), it is known that

. With the Lyapunov stability theorem, the controller ensures the global stability of the master manipulator system as

,

, thereby achieving

. Therefore, the master manipulator position,

, is gradually converged at the reference position,

, of the impedance model under the condition of the desired impedance model with Equation (

11).

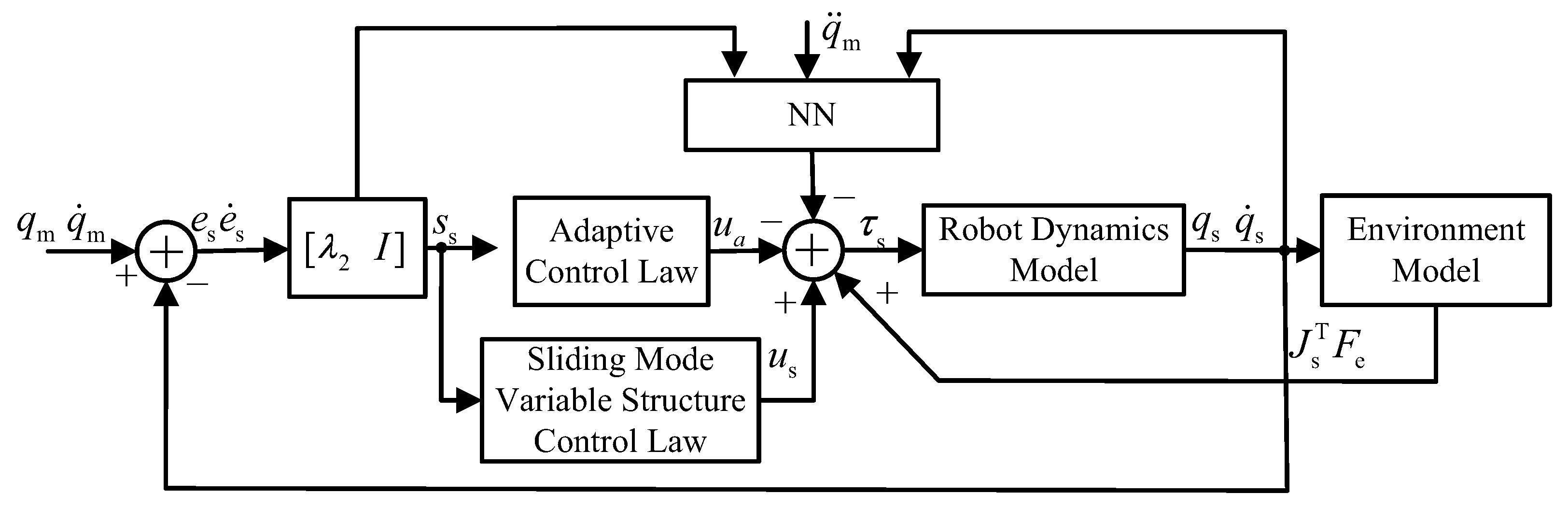

5. Slave Manipulator Adaptive Position Tracking Control

The master manipulator is generally located on a ship or in an underwater operating submersible, and the slave manipulator is generally fixed on an underwater vehicle such as a cabled underwater robot or an autonomous underwater robot. The distance between the master and the slave is relatively close, so the impact of the master–slave manipulator controller communication time delay on the system is ignored. The slave manipulator is equivalent to the position tracking of the tracking position standard signal, and transmits the force signal of the interaction between the slave manipulator and the environment to the master manipulator for force tracking. For external tracking under external uncertainty conditions of the slave hand, an adaptive slave hand controller is designed, including an RBF neural network compensator, sliding mode control, and adaptive control law. The utilization of the online learning algorithm for the RBF neural network, as detailed in [

39], demonstrates robust self-learning and self-organizing capabilities. This approach can effectively learn external disturbances in complex environments, accurately approximate intricate models, and mitigate the impact of disturbances on the motion of underwater manipulator systems.

The control objective for the slave manipulator is to achieve

as

using the adaptive controller. Assuming the tactile force of the slave manipulator is measurable, the controller is devised employing the calculated torque method. The position error between the slave manipulator and the master manipulator is denoted as

. Additionally,

, where

represents the reference variable for angular position tracking, and

is a positive definite diagonal matrix. The sliding mode variable is defined as follows:

Combining the dynamics of the slave manipulator given by Equations (

1) and (

22), we obtain:

where

, and

. Utilizing the RBF neural network to approximate the function

, we can express

as

. Here,

W is the neural network weight matrix,

represents the basis function, and

is the approximation error of the exact model. The estimated value of

is given by

. Equation (

23) can be written as follows:

Among them,

represents the weight error. According to Equation (

24),

denotes the torque exerted by the contact force between the slave manipulator and the environment on the slave manipulator.

is the sliding mode variable structure control law, and

, where

and

are positive definite diagonal moment arrays.

is the regulation law of neural network control,

, with the adaptive law of

given by

, where

Q is a positive definite matrix.

is a robust adaptive control law, used to overcome neural network approximation errors and system uncertainty, thereby improving robustness. Take

, and the adaptive law is as follows:

. The overall control is illustrated in

Figure 3.

By substituting the control law,

, into the dynamic of the slave manipulator, the closed-loop equation can be obtained, as shown in Equation (

25).

To establish the stability of the tracking of the slave manipulator in the presence of adaptive control law, we will utilize the Lyapunov function. Let us assume that the Lyapunov function,

, for the slave manipulator system is given by:

where

represents the trace of the matrix, and

is the upper boundary of

. Since

and

are positive definite matrices, it is straightforward to establish that

. Finding the derivative of

with respect to time, and considering Equation (

25) derived from the closed-loop system of the slave manipulator, we can obtain:

Equation (

27) is derived from the adaptive law of robotic Property 2, involving the variables

and

:

Points from 0 to

on both sides of Equation (

28) can be obtained:

Equation (

29) can be rewritten as:

Since

and

, there are:

From Equation (

31), it can be concluded that, as

,

, and the position tracking error,

, along with the error change rate,

, gradually converge to 0. The tracking error in the slave manipulator controller caused by parameter uncertainties and external disturbances is compensated using RBF neural networks. Furthermore, the controller achieves robustness through sliding mode control and adaptive laws.

6. Simulation and Verification

According to the system model of the master and slave manipulators and the control requirements, simulations were conducted on the Matlab Simulink platform. The simulations considered the uncertainty of the mechanical power model and external disturbance of the mechanical model of the manipulator, while neglecting the impact of the carrier in the underwater manipulator on the posture. The master manipulator was set up in the vertical plane. For the mathematical model, based on references [

40,

41,

42], the impedance model parameters are defined as follows:

,

,

, and

. The masses of the master manipulator are specified as

kg and

kg, and the lengths are

m and

m. The initial positions of the master manipulator are set as

rad and

rad.

In the slave manipulator system, the parameters of the RBF network are set as follows: Gaussian basis function center , width , sliding mode coefficient , and . The controller input gains are and , and the uncertain upper bound estimate for the initial value is .

For the slave manipulator, the masses are specified as kg and kg, and the lengths are m and m. The initial positions of the slave manipulator are set as rad and rad. The environmental stiffness coefficient is configured as , and the slave manipulator is in contact with the grasping target at a distance of m in the x-axis direction. Both master and slave manipulators have internal joint friction described by , with relevant parameters and . The uncertain disturbance inputs for the master manipulator and the slave manipulator are specified as and , respectively.

The simulation time is set to 30 s, with a 10 s application of 10 N force on the master manipulator, followed by 0 N force for the remaining 20 s. This setup allows observation of the force–displacement tracking status of the manipulator.

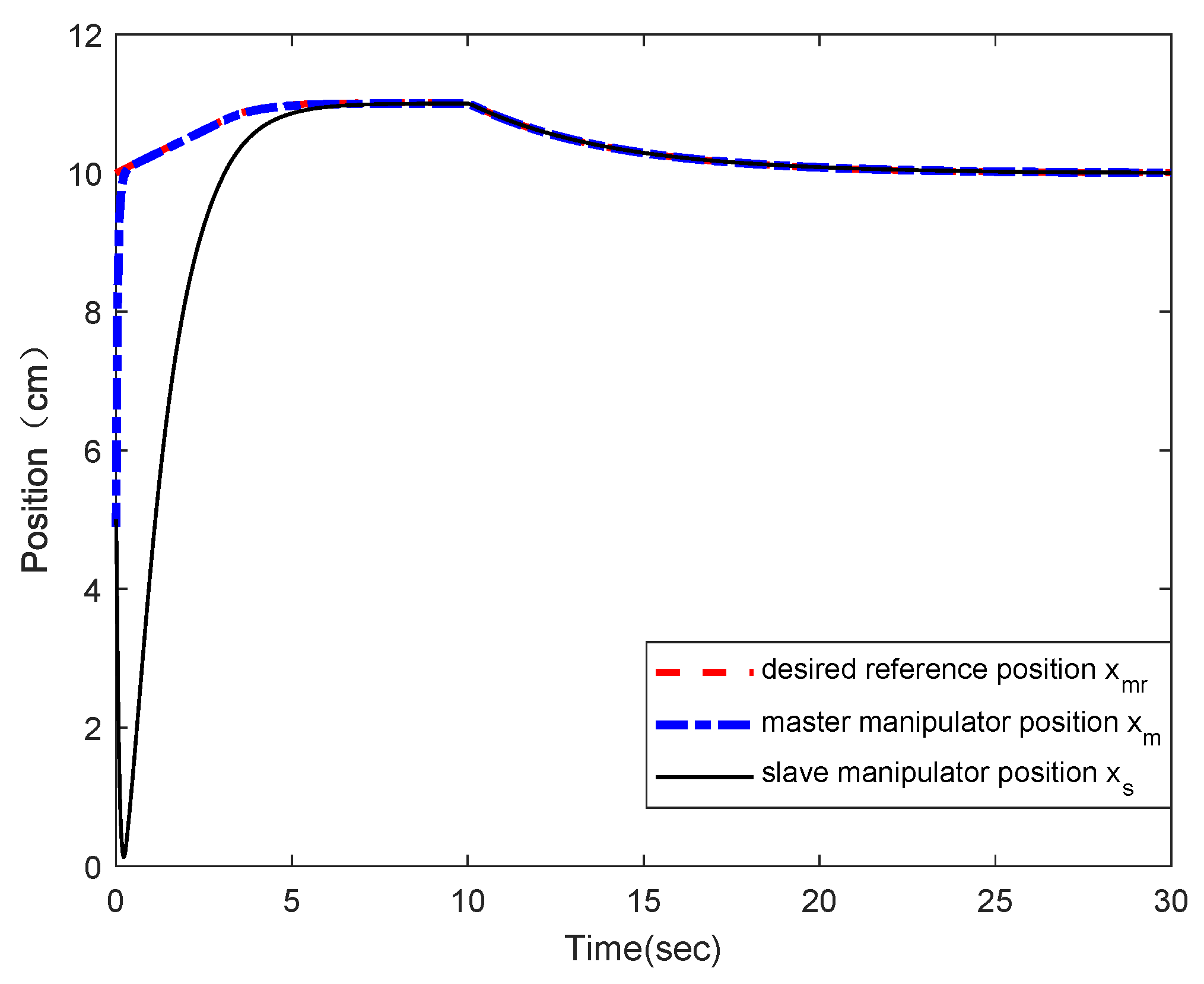

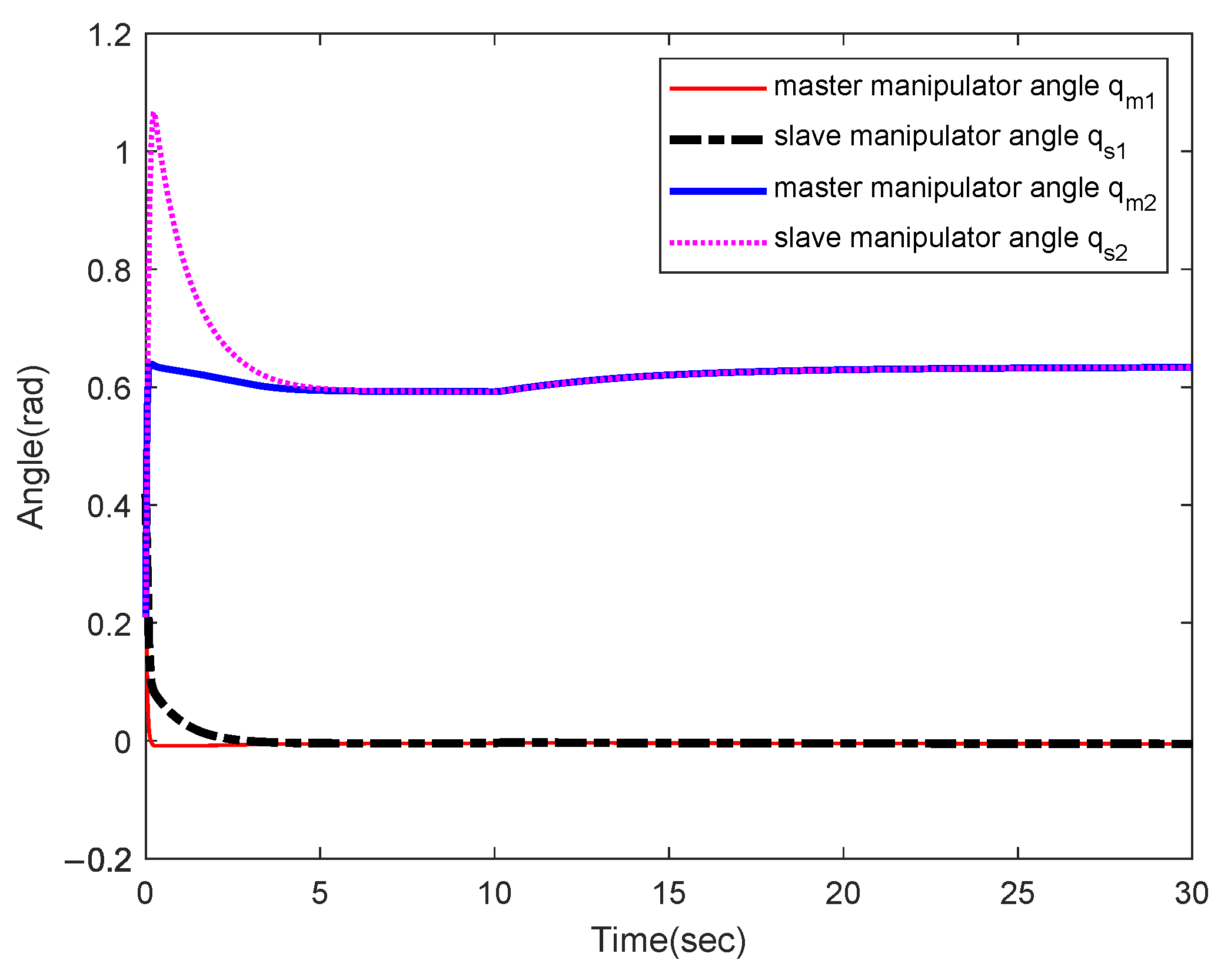

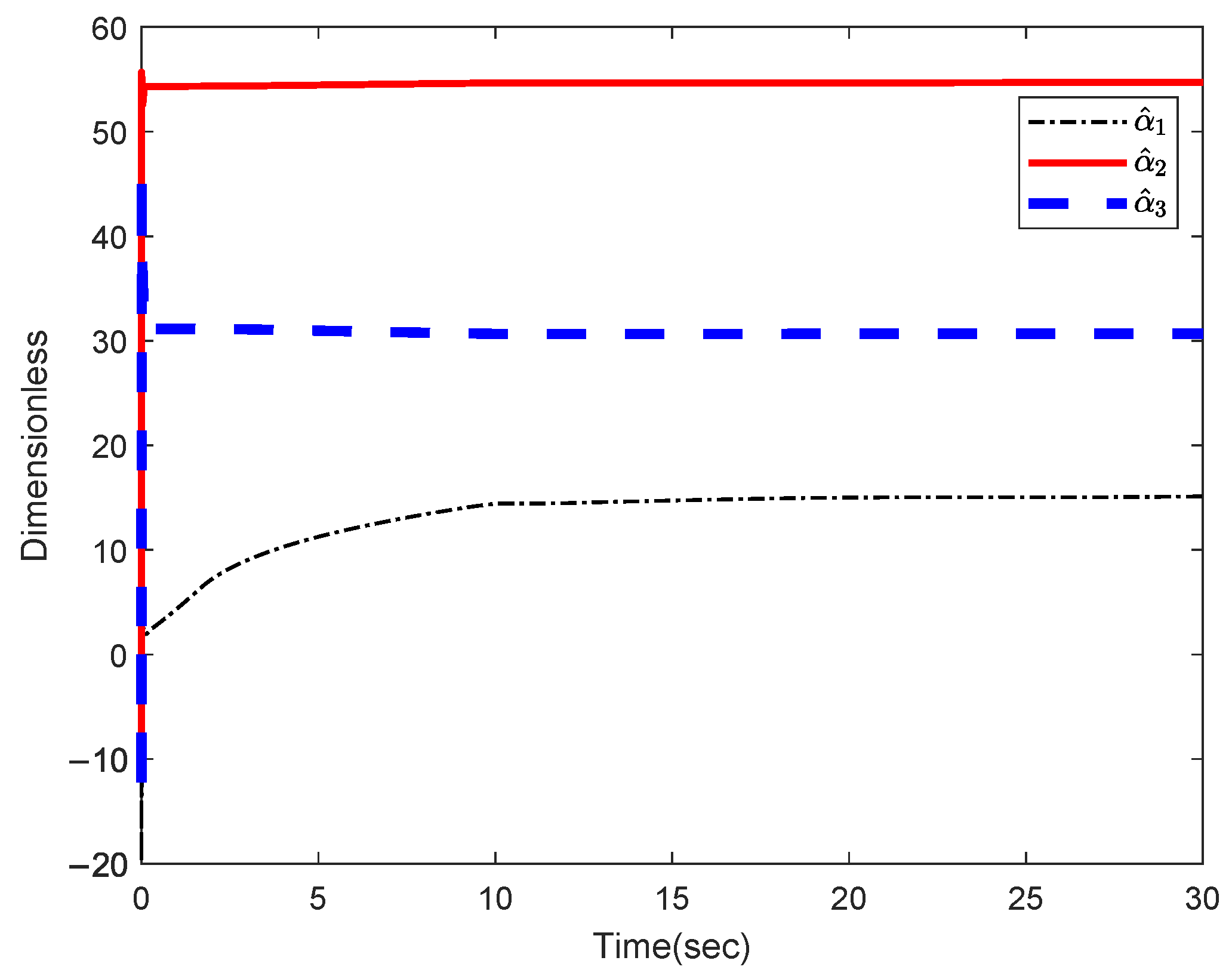

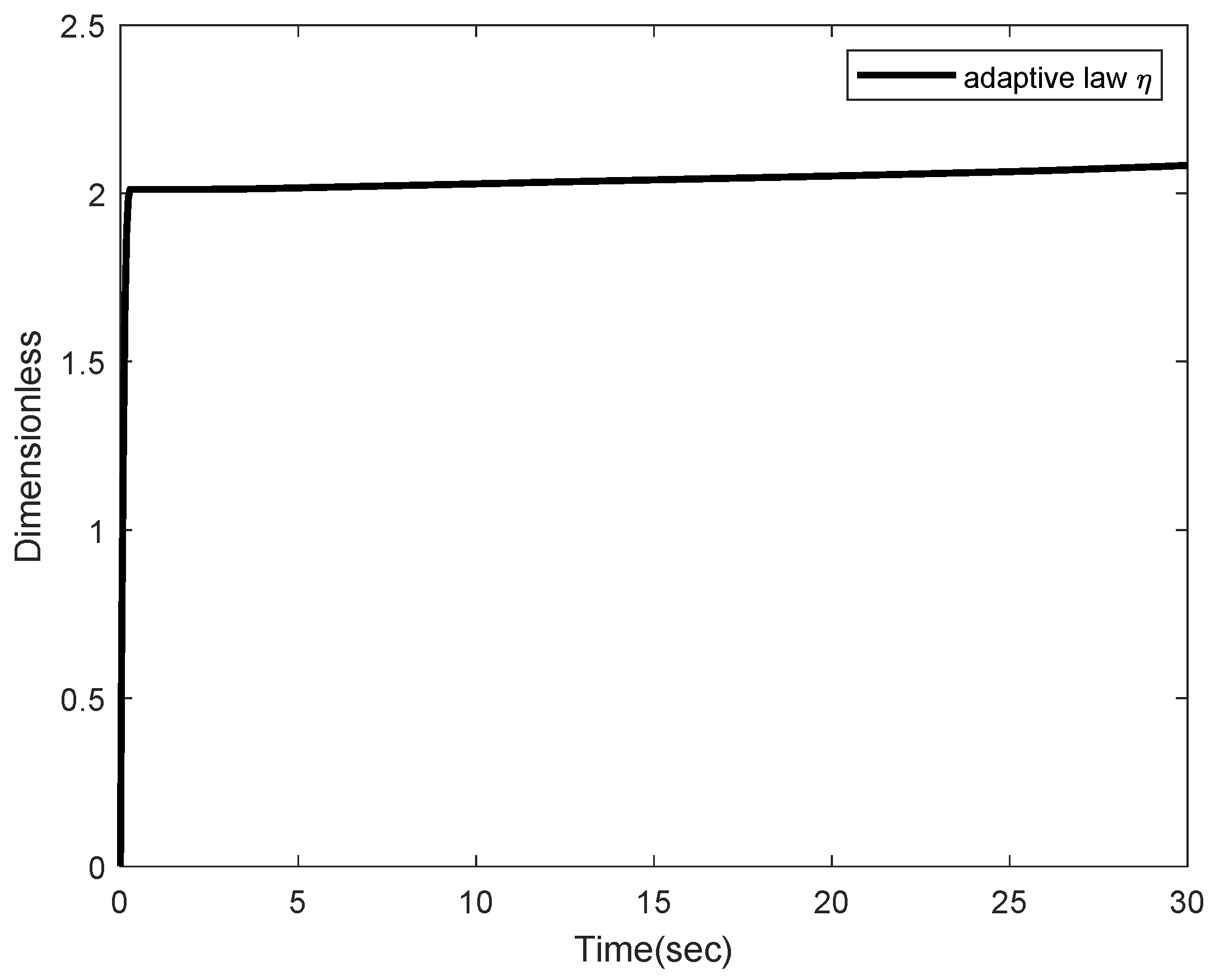

From

Figure 4,

Figure 5 and

Figure 6, it can be observed that the static tracking error of the slave manipulator’s position with respect to the master manipulator’s position is

, with no overshoot in overall tracking. After the force is released on the master manipulator, both the slave and master manipulators eventually come to a stop at a distance of 0.1m from the critical contact point with the environment. The slave manipulator still ensures position tracking of the master manipulator, while the master manipulator achieves force tracking of the slave manipulator. As shown in

Figure 7 and

Figure 8, the output parameters of the adaptive law for the master and slave manipulators are bounded, ensuring the effectiveness of the estimation values and achieving system control stability.

From

Figure 4,

Figure 5,

Figure 6 and

Figure 7, it can be observed that, under the system uncertain models and external disturbance conditions, the overall system still ensures force and position tracking of the slave manipulator with respect to the master manipulator. The adaptive control of the master manipulator and the radial basis function (RBF) network of the slave manipulator compensate for external disturbances and model uncertainties.

To verify the effectiveness and reliability of the newly designed approach, a comparison is made with the PD+like scheme, as proposed in reference [

43], and the model reference adaptive impedance control (MRAIC), as illustrated in reference [

44]. The manipulator dynamics are described by Equation (

1), and the two-link degree-of-freedom (DOF) serial teleoperation system shown in

Figure 1 is subjected to joint friction and external disturbances. A 10 N force is applied in the

x-axis direction on the master manipulator, and the force and position responses of the three controllers are recorded and depicted in

Figure 9 and

Figure 10.

From

Figure 9 and

Figure 10, we can conclude that the proposed adaptive control strategy exhibits superior force–position tracking convergence performance compared with the other two controllers, especially in the presence of system uncertainty and external disturbances. The response of the designed approach has the characteristics of little overshoot and no static errors, and the response shaking is suppressed with the new controller under external disturbances.

7. Experimental Verification

According to the simulation verification above, effective performance in force and position tracking ability is demonstrated with the proposed approach. For further research and verification, a single-degree-of-freedom (DOF) manipulator teleoperation experimental system is set up with the proposed controller. Similar to the simulation system, the complete structural diagram with the proposed controller is depicted in

Figure 11.

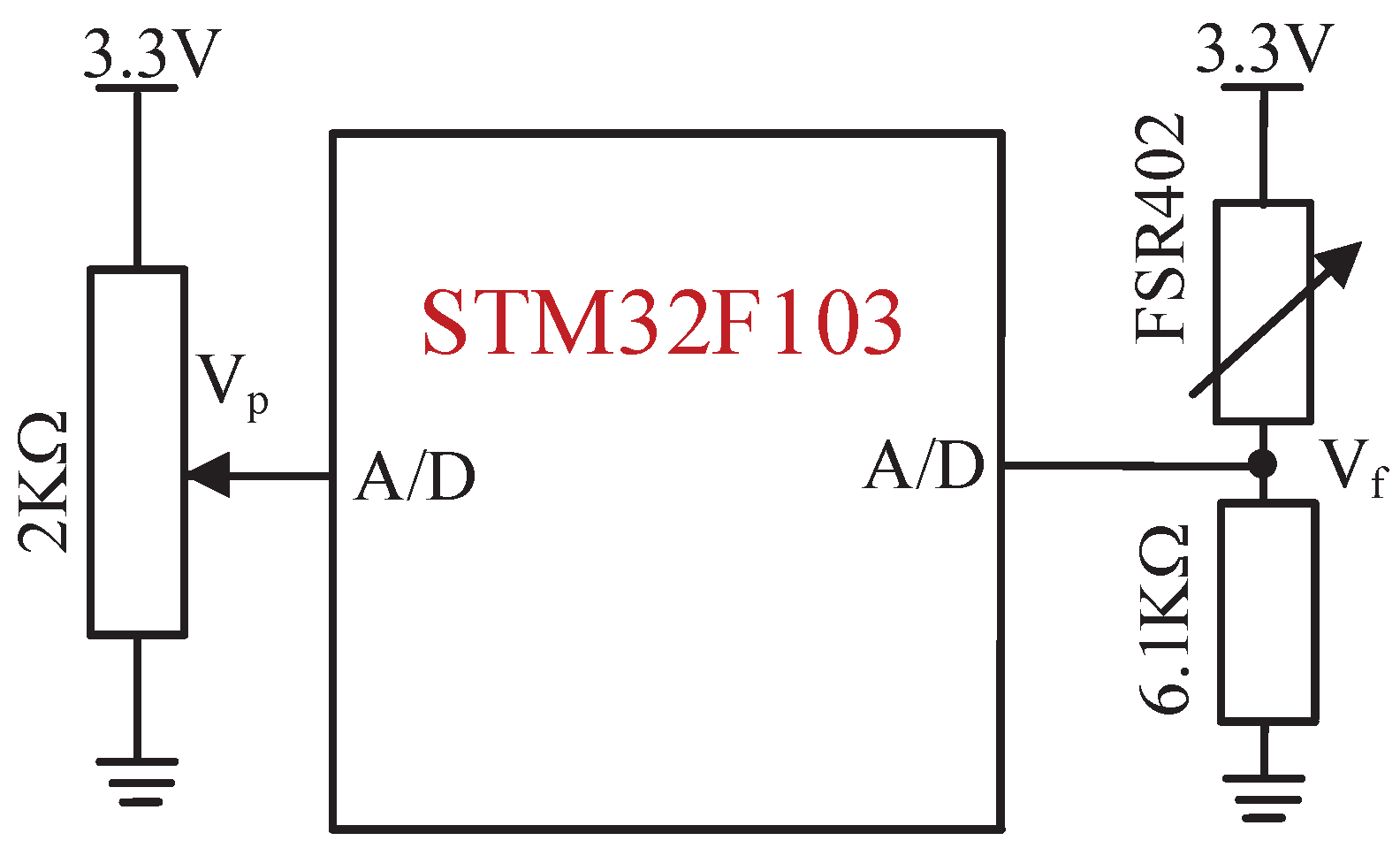

Both the master and slave manipulators are designed with the same structure, comprising a single-degree-of-freedom (DOF) manipulator driven by a stepper motor to achieve drive torque output. An angle sensor is coaxially connected with the linkage to measure the rotation joint position. Additionally, a piezoelectric film-type tactile force sensor is installed at the force sensing point of the linkage end to measure the force exerted by the master operator.

The master driver board is responsible for acquiring the angle and tactile force signals through A/D conversion. It also receives the control law for the master manipulator from the master controller through the serial bus, and sends the collected force and position information of the master manipulator back to the master controller through the same serial bus. The master controller is connected to the master host computer via the internet, transmitting the master force and position signals to the master computer. It also receives the control law from the master host computer, which is then converted into a PWM pulse performance and sent to the master driver board for execution. The master host computer primarily runs the Matlab/Simulink platform, supporting Peter Corke’s robot toolbox [

45] and the hardware board structure. The hardware support is realized by installing the driver package in the Matlab environment. The Matlab/Simulink platform obtains the master position and force information from the master controller, simultaneously obtaining the slave position and force information from the slave host computer through internet communication. The robot toolbox and the single DOF manipulator model are used to calculate the adaptive impedance control law, and the resulting control law is sent to the master controller.

Simultaneously, the Matlab/Simulink platform running on the master computer transmits the master position and force information to the slave host computer via internet communication. Similarly, the slave host computer runs mainly on the Matlab/Simulink platform. It receives the slave position and force information through internet communication from the slave controller. By combining this information with the master position and force information, the slave adaptive law is calculated and transmitted back to the slave controller. At the same time, the slave position and force information are also transmitted to the master host computer.

The slave controller obtains the control law from the slave host computer, converts it into a PWM pulse performance, and sends it to the slave driver board. At the same time, the slave controller obtains the slave force and position information from the driver board and transmits it to the slave host computer. The slave driver board is responsible for collecting the force and position signals through A/D conversion. It also controls the slave stepper motor using PWM pulse signals. The Matlab/Simulink platform supports the robot toolbox and hardware boards such as the Raspberry Pi. If the Raspberry Pi 4B, which is equivalent to a microcomputer, is chosen as the controller of the master and slave manipulators, it supports network communication and serial communication.

The A/D conversion process is used to obtain force and position signals, as shown in

Figure 12. We express the force unit in mV instead of N, as the true force value is not required for this experiment. It is important to emphasize that the accuracy and precision of the A/D conversion process are critical to the success of this experiment. Any errors or noise in the A/D conversion process can have a significant impact on the quality of the acquired signals. Therefore, it is imperative to ensure that the A/D converter is correctly calibrated and that the input signal is within the valid input range.

In conclusion, this experiment highlights the use of A/D conversion for force and position signal acquisition using a tactile force sensor and a precision conductive potentiometer. The accuracy and precision of the A/D conversion process are crucial factors for the experiment’s success, and care must be taken to calibrate the A/D converter correctly and ensure a valid input signal.

In order to display the effect of the experiment better, by sensing the stiffness of the operation object directly and avoiding blocking the stepper motor of the slave manipulator with an insufficient force contacting the force sensor, the virtual force,

, is formulated instead of the real slave operation force measurement. The slave feedback force is considered as the linear function of the slave rotation joint position, which is expressed as Equation (

32). The operation object is seen as a spring, and the greater the rotation angle is, the greater is the feedback force. The initial rotation position is

, and

is the virtual spring coefficient. As a result, the soft or hard degree can be acquired by the operator with a different

.

The uncertainty disturbance is added to the dynamic model in the linkage in the Matlab/Simulink environment. The direction of the master and slave force, denoted as

and

, changes from time to time with the different rotation angle, and, as a result,

and

in the master desired impedance model, Equation (

10), can, respectively, be described as

and

in the MATLAB/Simulink platform. The experimental process consists of exerting the force on the master force sensor on the master end-linkage, releasing the force and applying the force with several cycles, recording the force and position data, and plotting the diagram demonstrated in

Figure 13,

Figure 14 and

Figure 15. What is more, the virtual spring elasticity coefficient is set as

, 52, and 61 mV

, respectively.

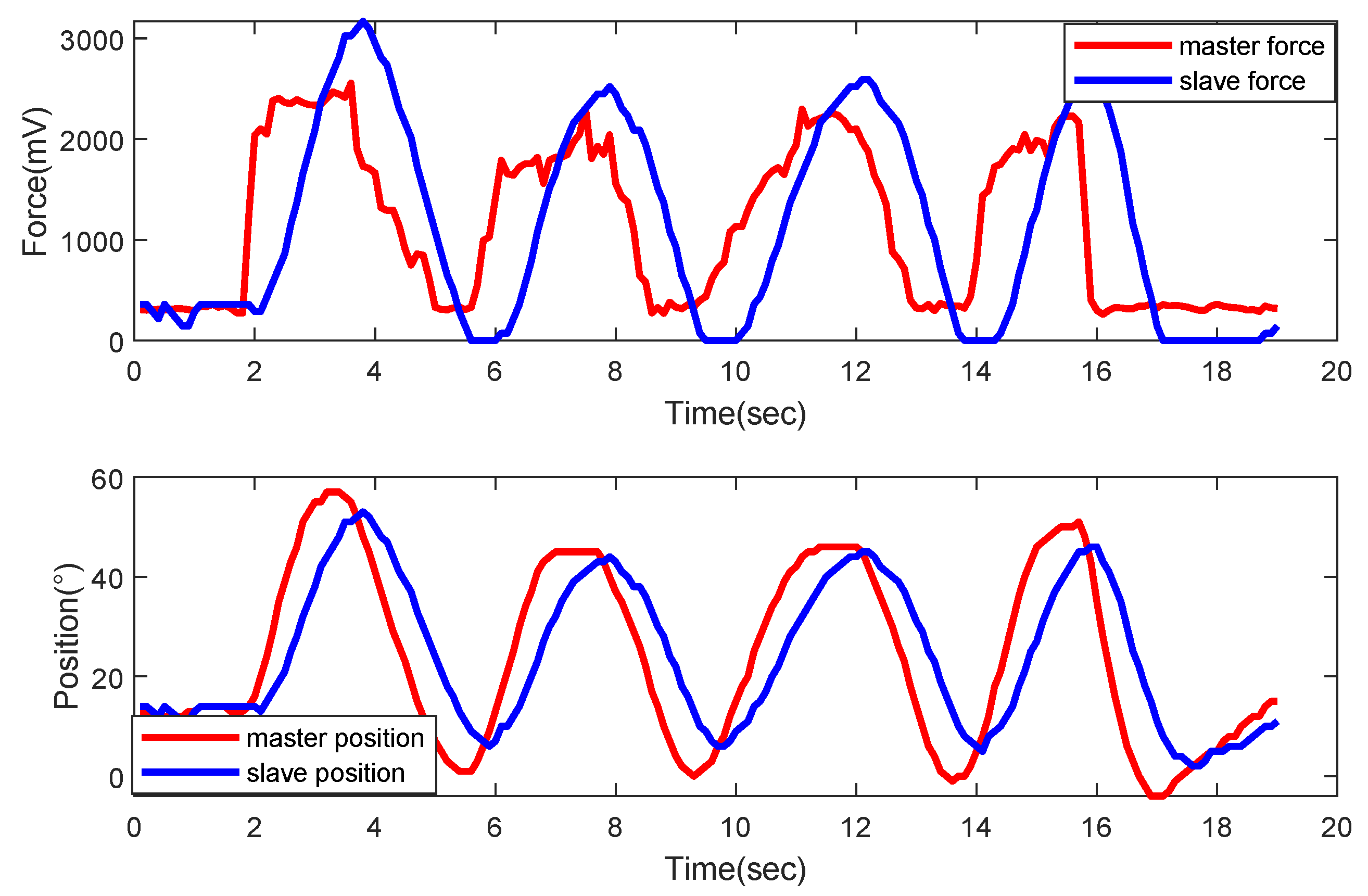

According to

Figure 13,

Figure 14 and

Figure 15, it can be concluded that the force and position asymptotic convergence of the dual manipulators is achieved with the controller under the periodically applied and released force on the master manipulator. The response characteristics of the master force tracking and slave position tracking are fast, following the response and small overshoot. The controller ensures that the operator applying force on the master manipulator can immediately sense the slave’s operation force. After the master force is released, the dual manipulators still guarantee force and position coordinated synchronization, and, finally, the dual manipulators stay at the critical position with the operation object.

It is evident from

Figure 13,

Figure 14 and

Figure 15 that, even with an uncertain system model and external disturbances, the overall system maintains the force tracking of the master to the slave manipulator and the position tracking of the slave to the master manipulator. This achievement is attributed to the implementation of the model uncertainty adaptive law and the adaptive law for estimating the upper bound of external disturbances, which effectively compensates for both external disturbances and model uncertainties, thus ensuring the robust stability characteristics of the system. The designed control law for the master–slave robotic manipulators ensures consistent synchronous performance in the teleoperation system, and guarantees the system stability and robustness.

According to

Figure 13,

Figure 14 and

Figure 15, the rotation angle range is

when

mV

, comparatively, the rotation angle range is

when

mV

with the same maximum tactile force of 2500 mV on the master manipulator. The larger the stiffness coefficient is, the smaller the rotation angle range is, which means the operator can sense the stiffness of the slave operation object with the same master force applying. As a result, the whole experiment verifies the effectiveness of the proposed controller, which satisfies the force–position coordinated synchronization of the dual manipulators and the immersion sensing for the slave environment.