A Novel Impedance Matching of Class DE Inverter for High Efficiency, Wide Impedance WPT System

Abstract

1. Introduction

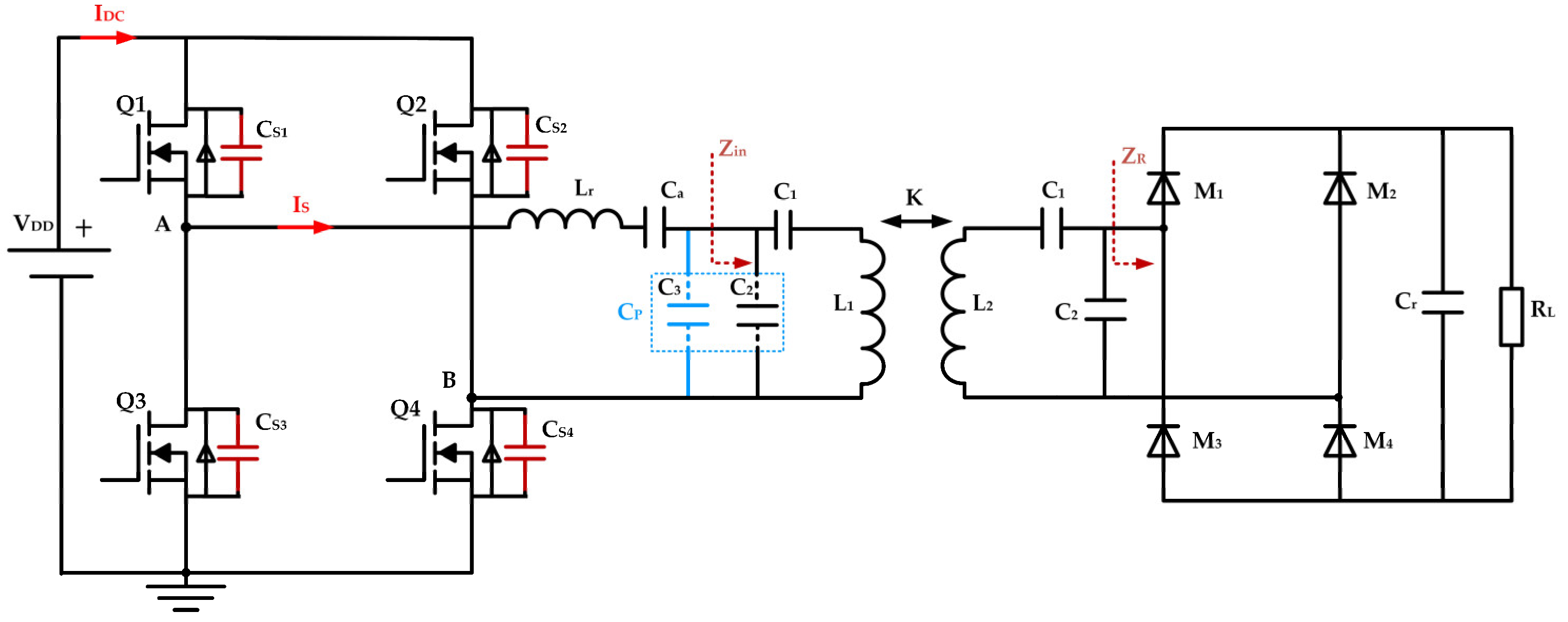

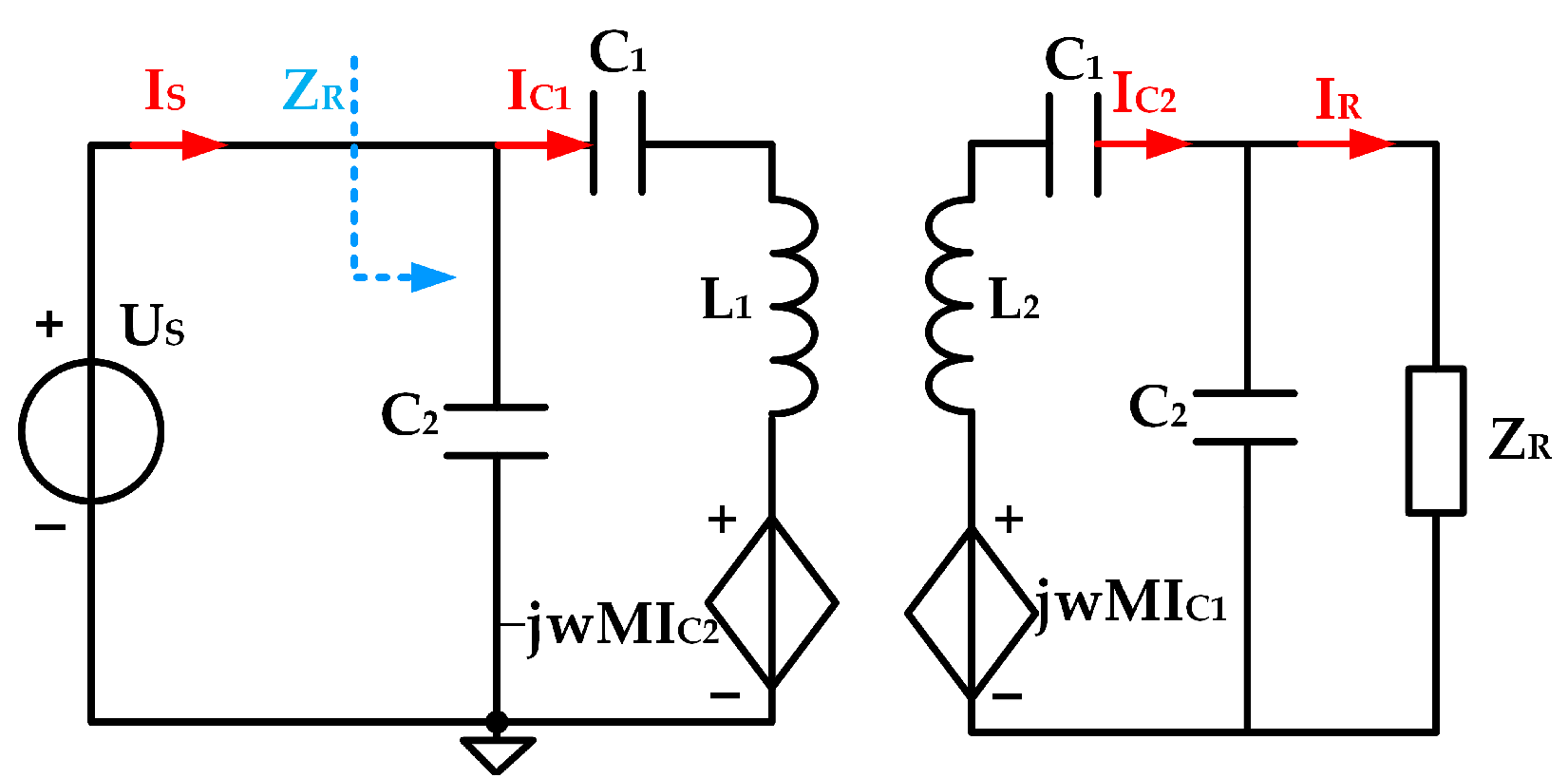

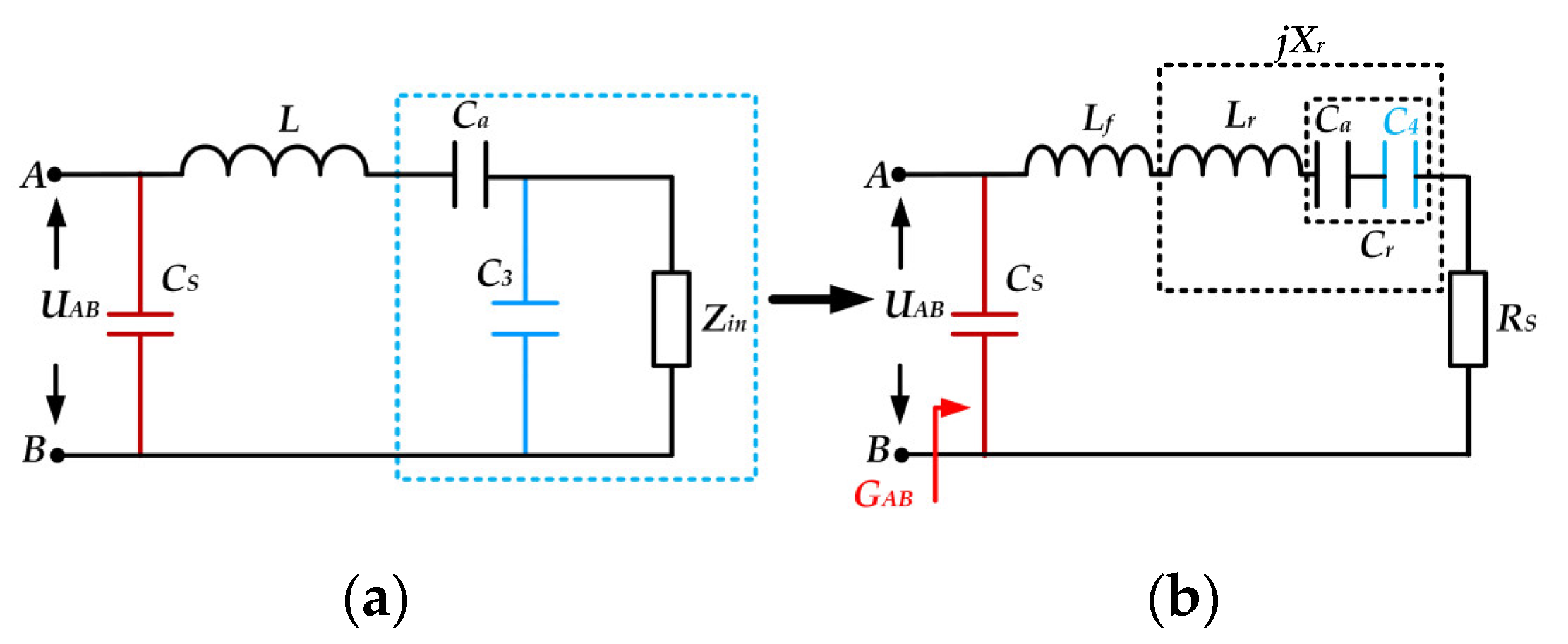

2. Characterization of Coupling Coils for PS/PS Impedance Matching Compensation

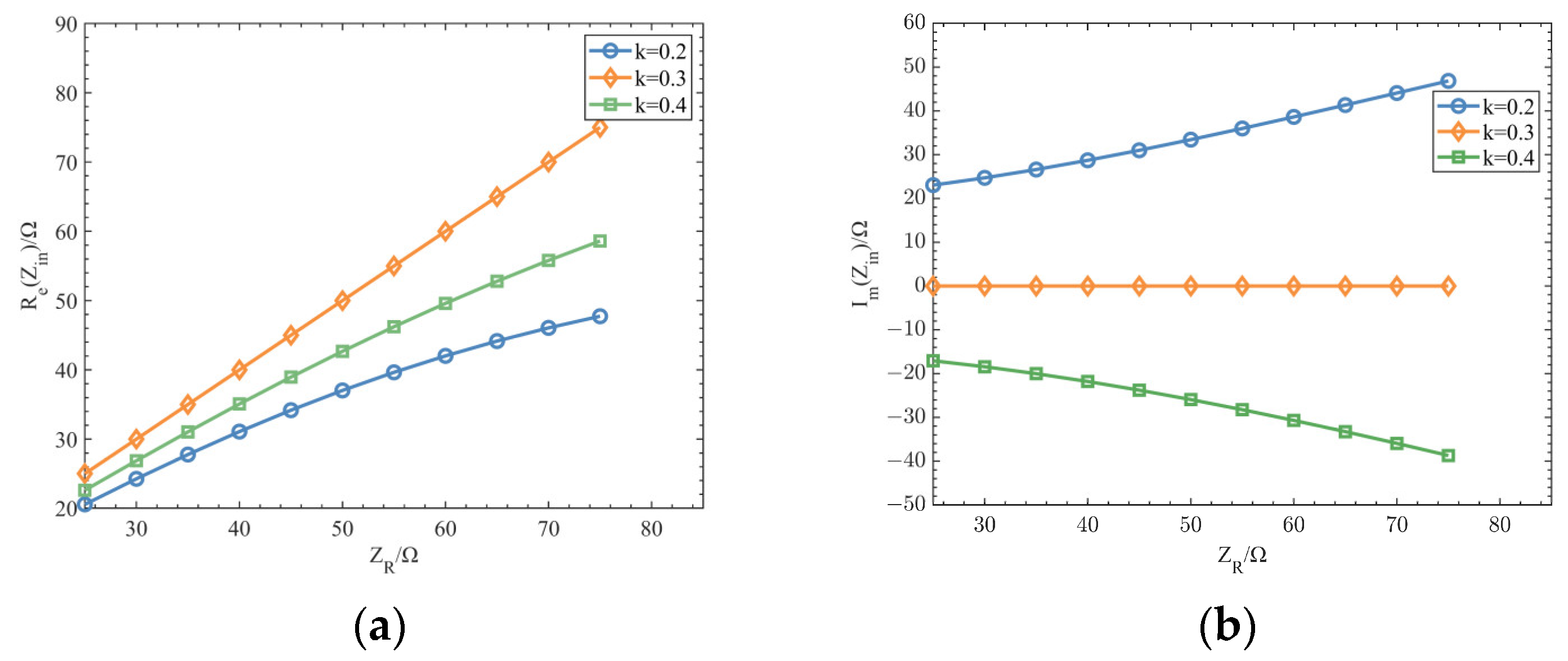

2.1. Coils PS/PS Impedance Matching Compensation

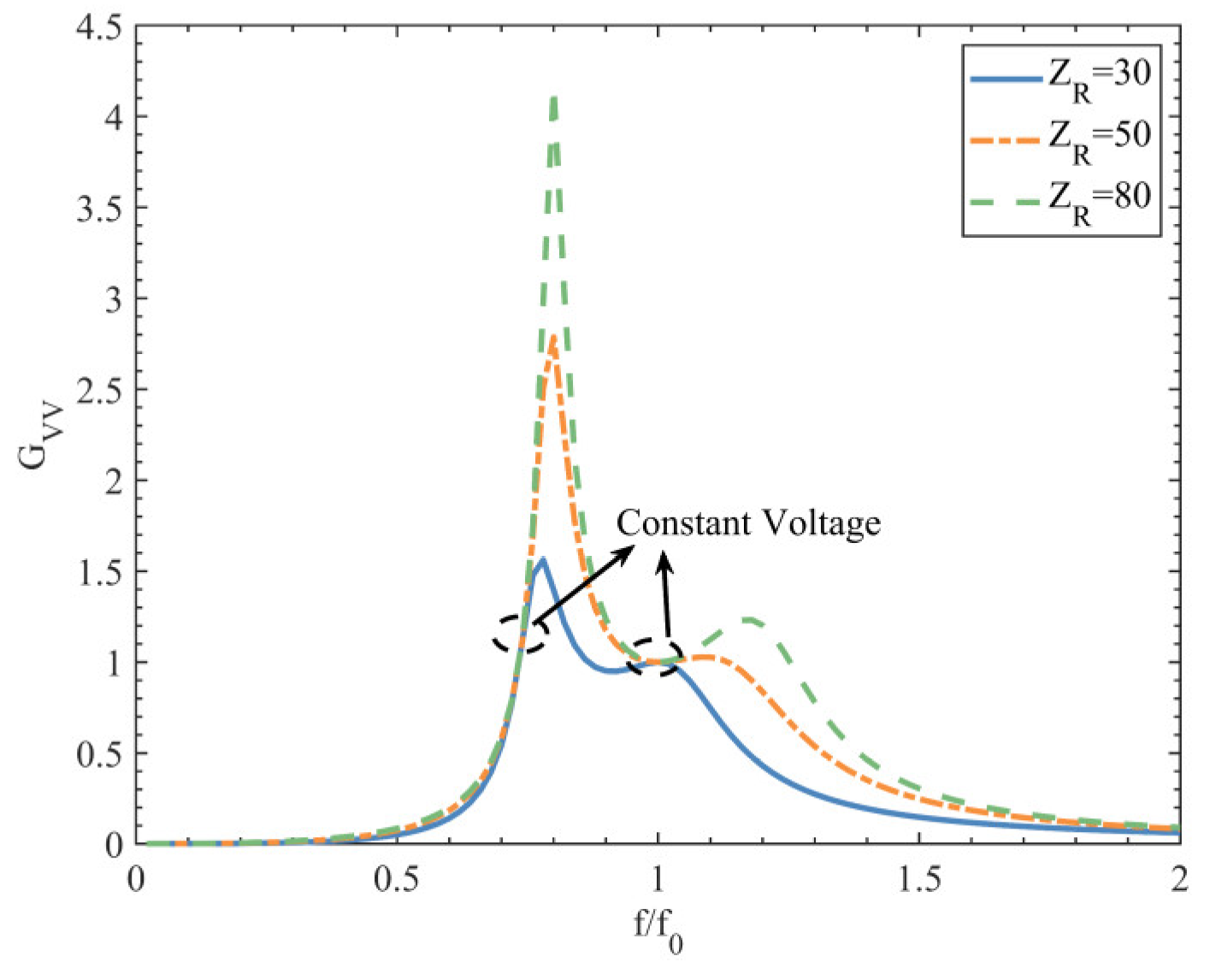

2.2. Voltage Gain and Constant Voltage Characteristics

3. Theoretical Analysis and Design of Class DE Inverters

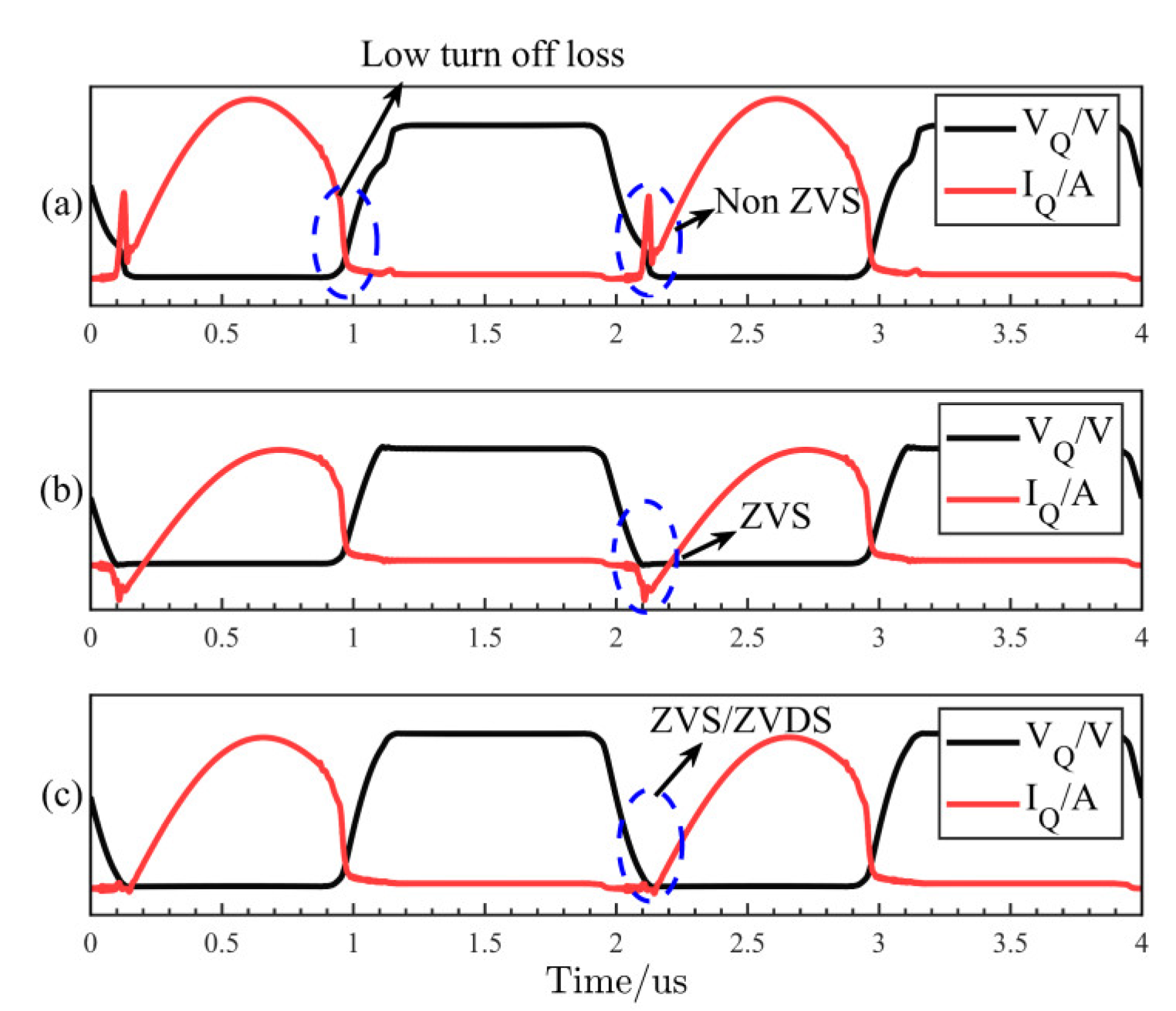

3.1. Theoretical Description of Class DE Inverter

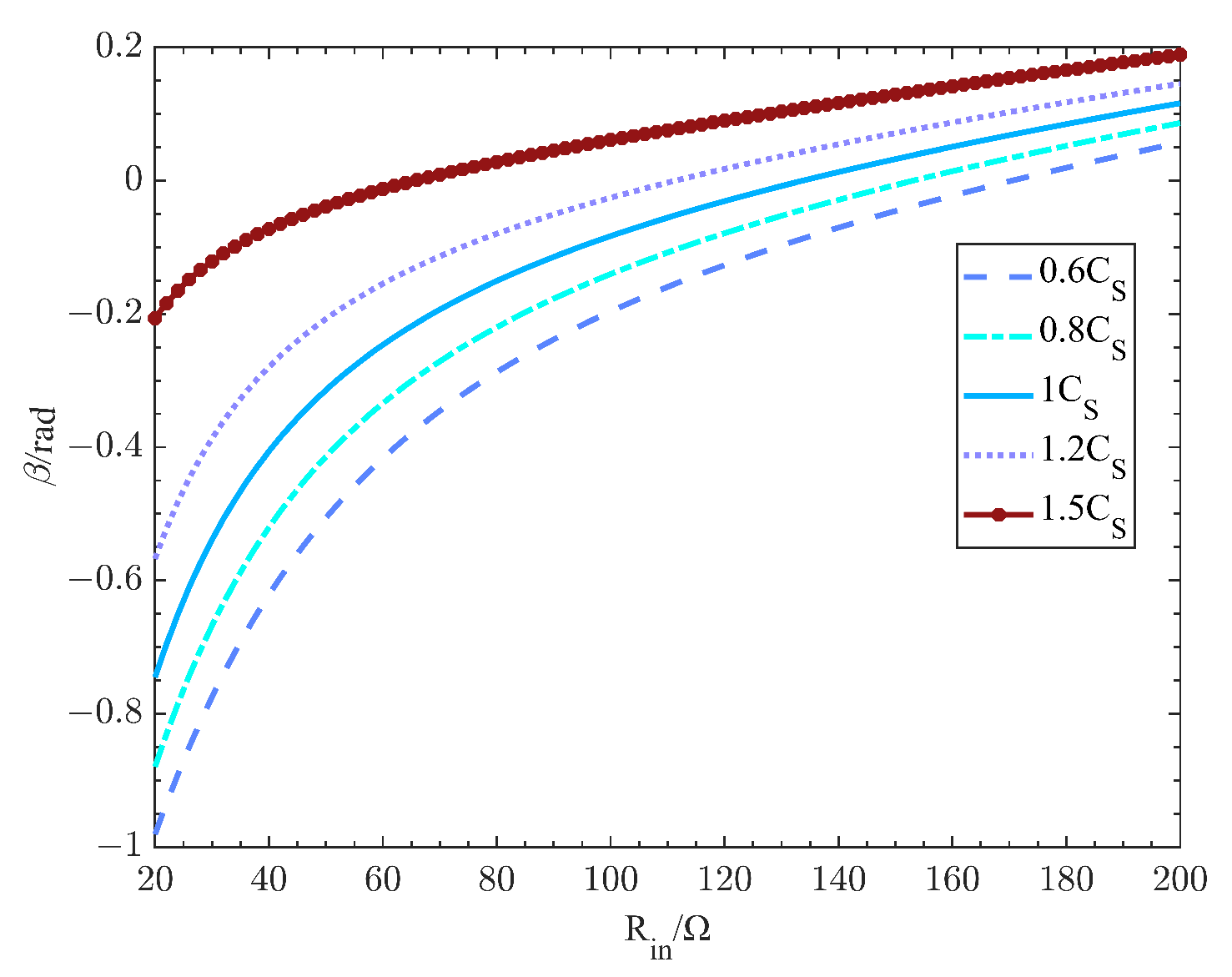

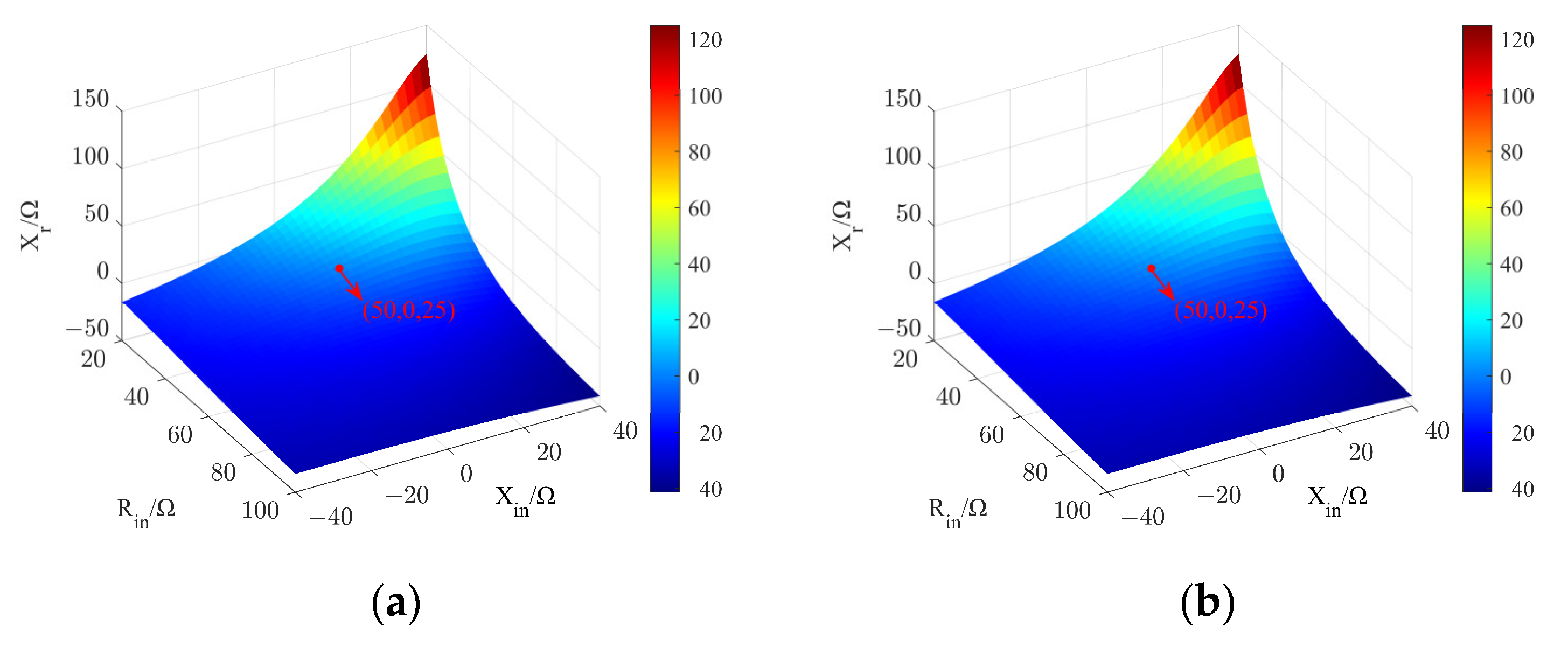

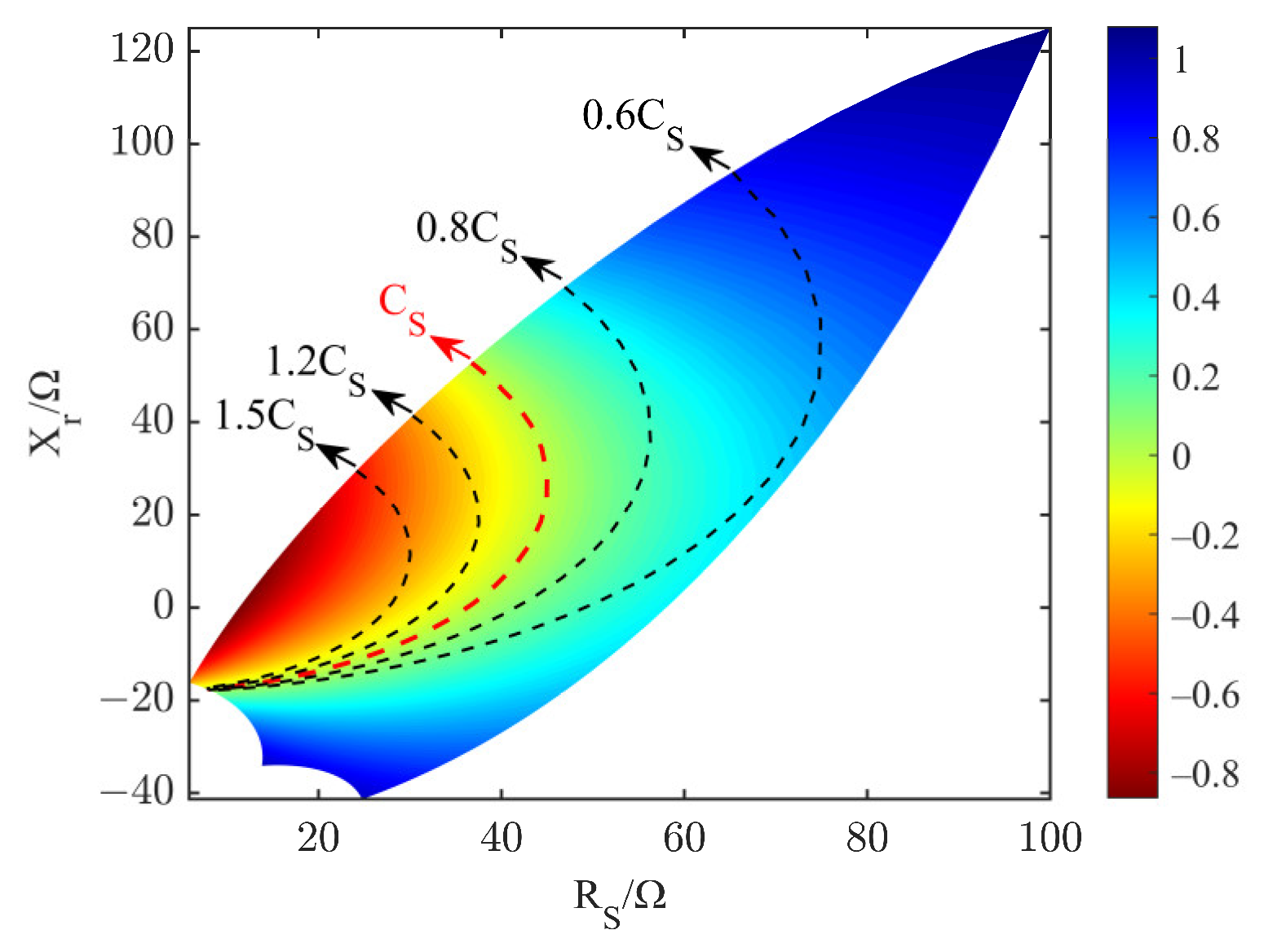

3.2. Analysis of Wide Load ZVS Conditions

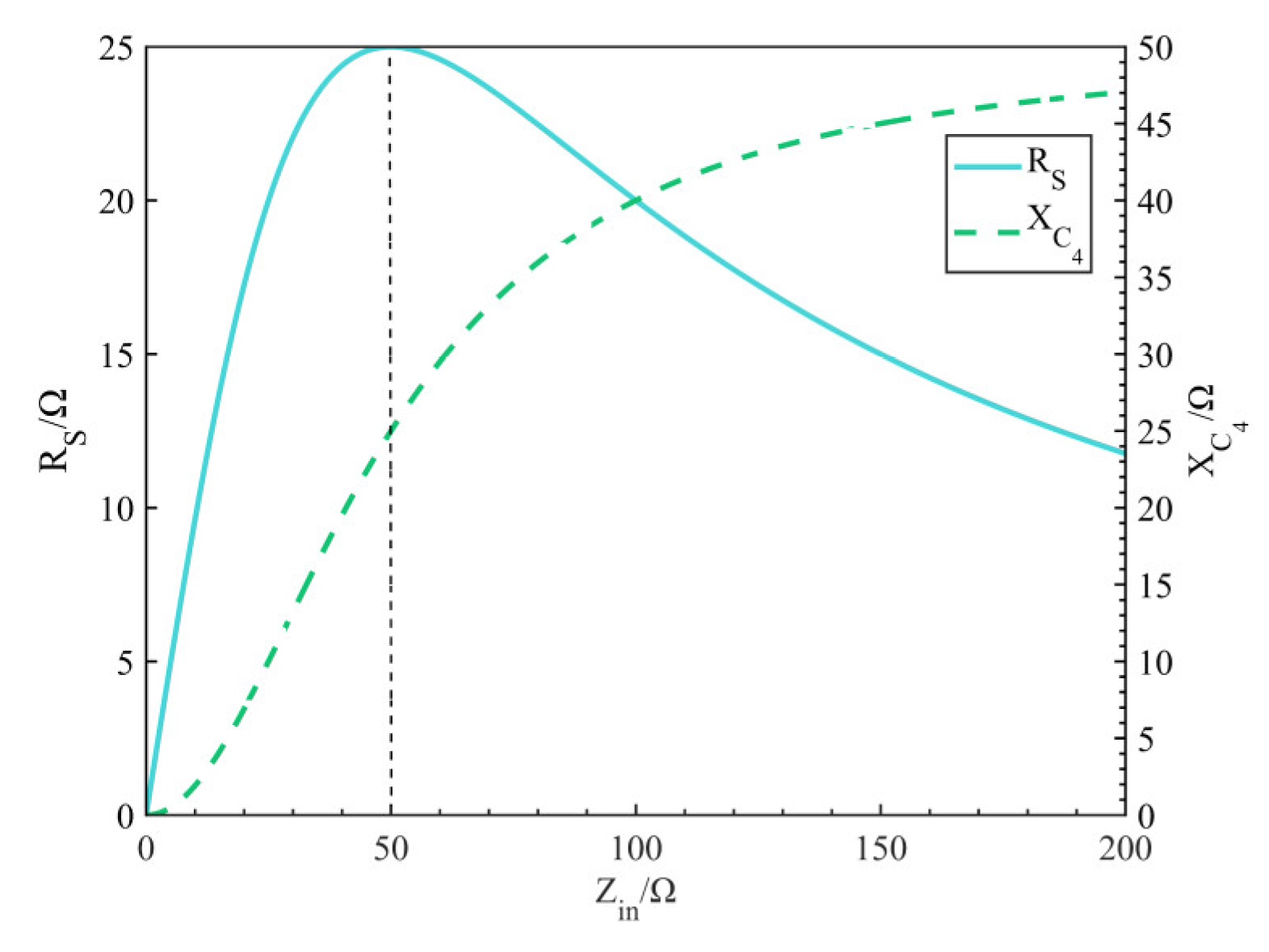

3.3. Wide Load ZVS Matched Resonant Network Design

3.4. Analysis of the Effect of Parameter Variations on the Wide Load ZVS

4. System Validation and Loss Analysis

4.1. System Loss Analysis

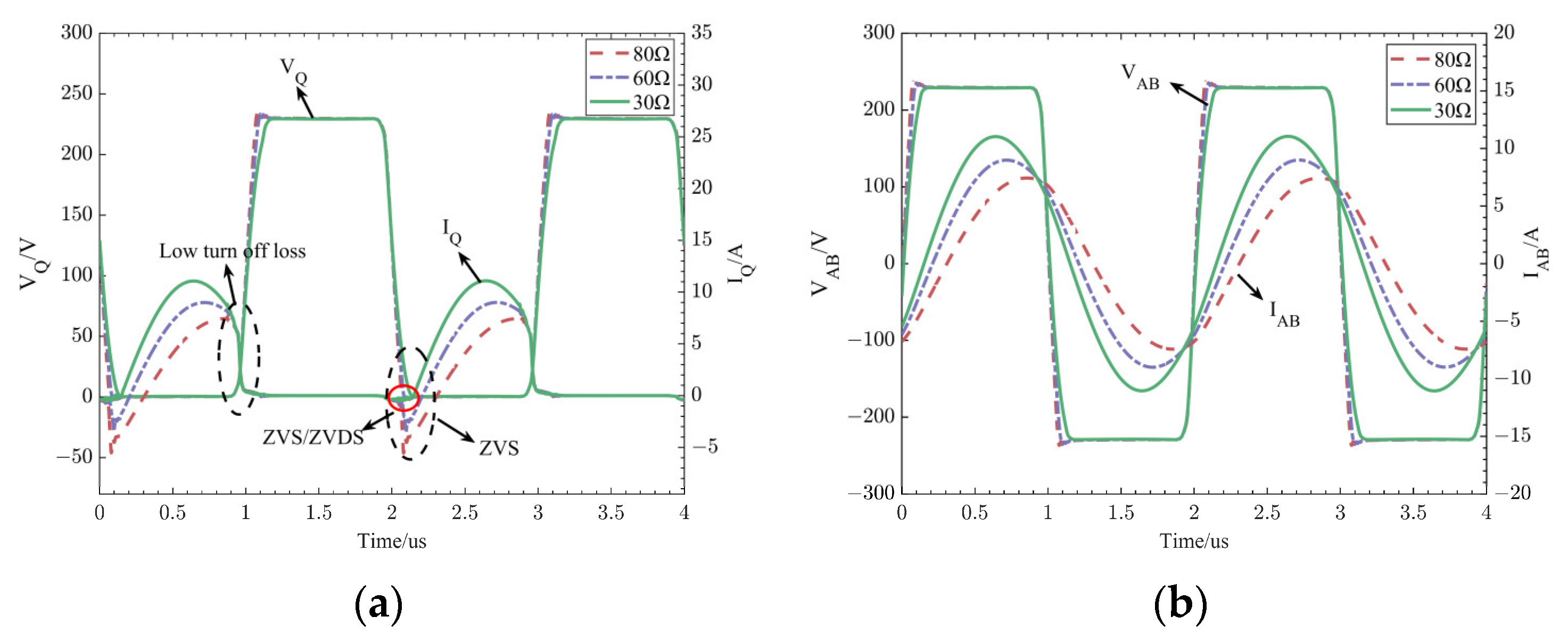

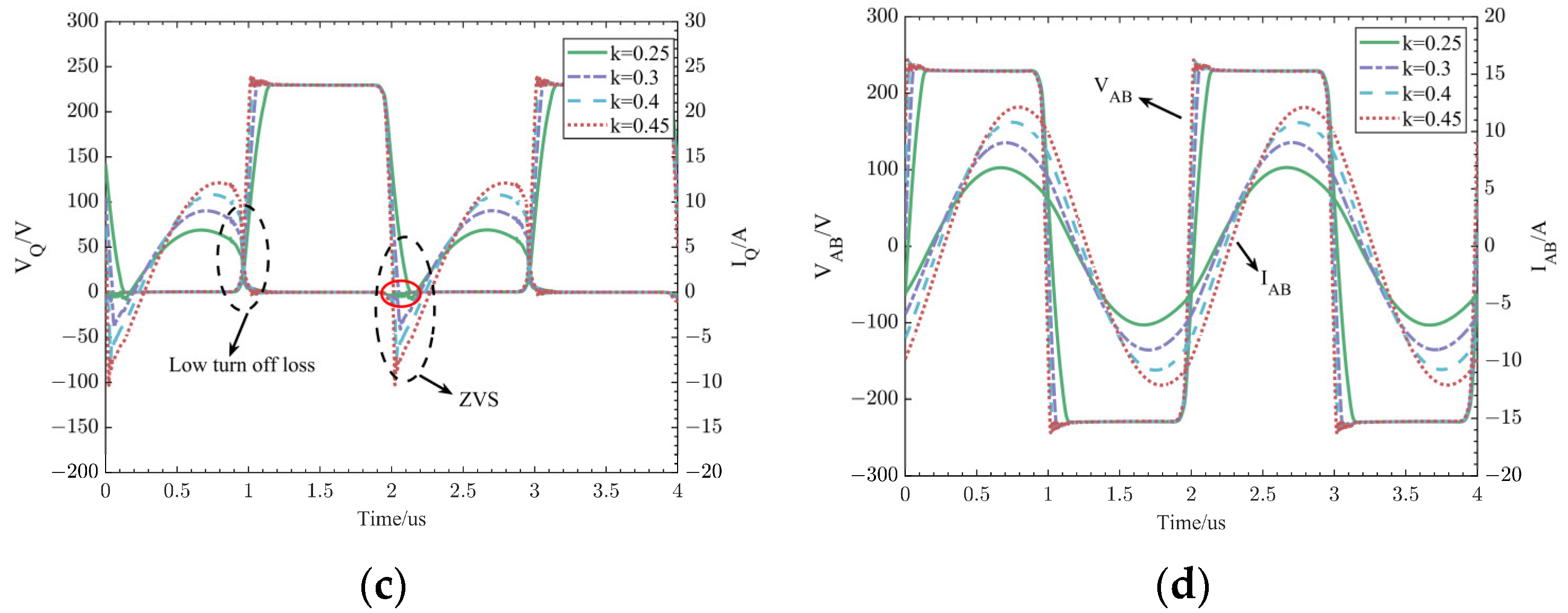

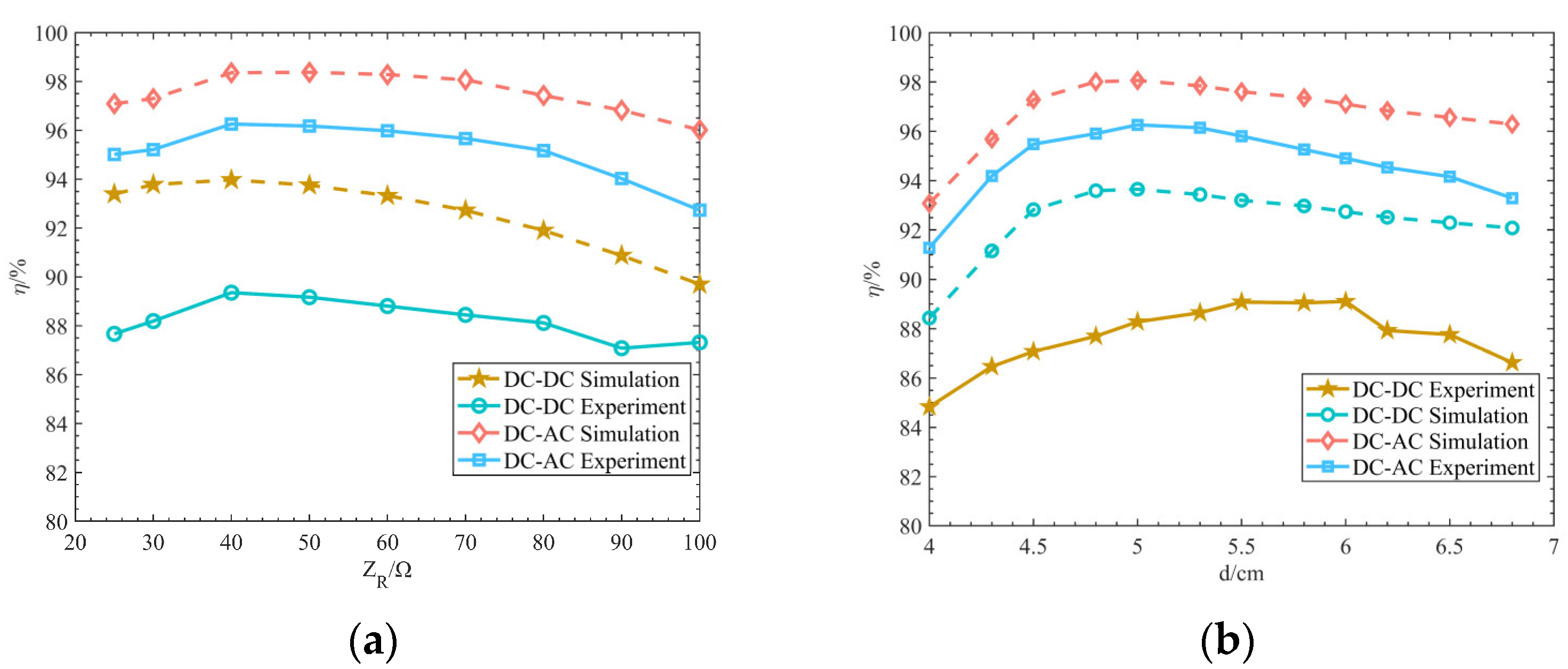

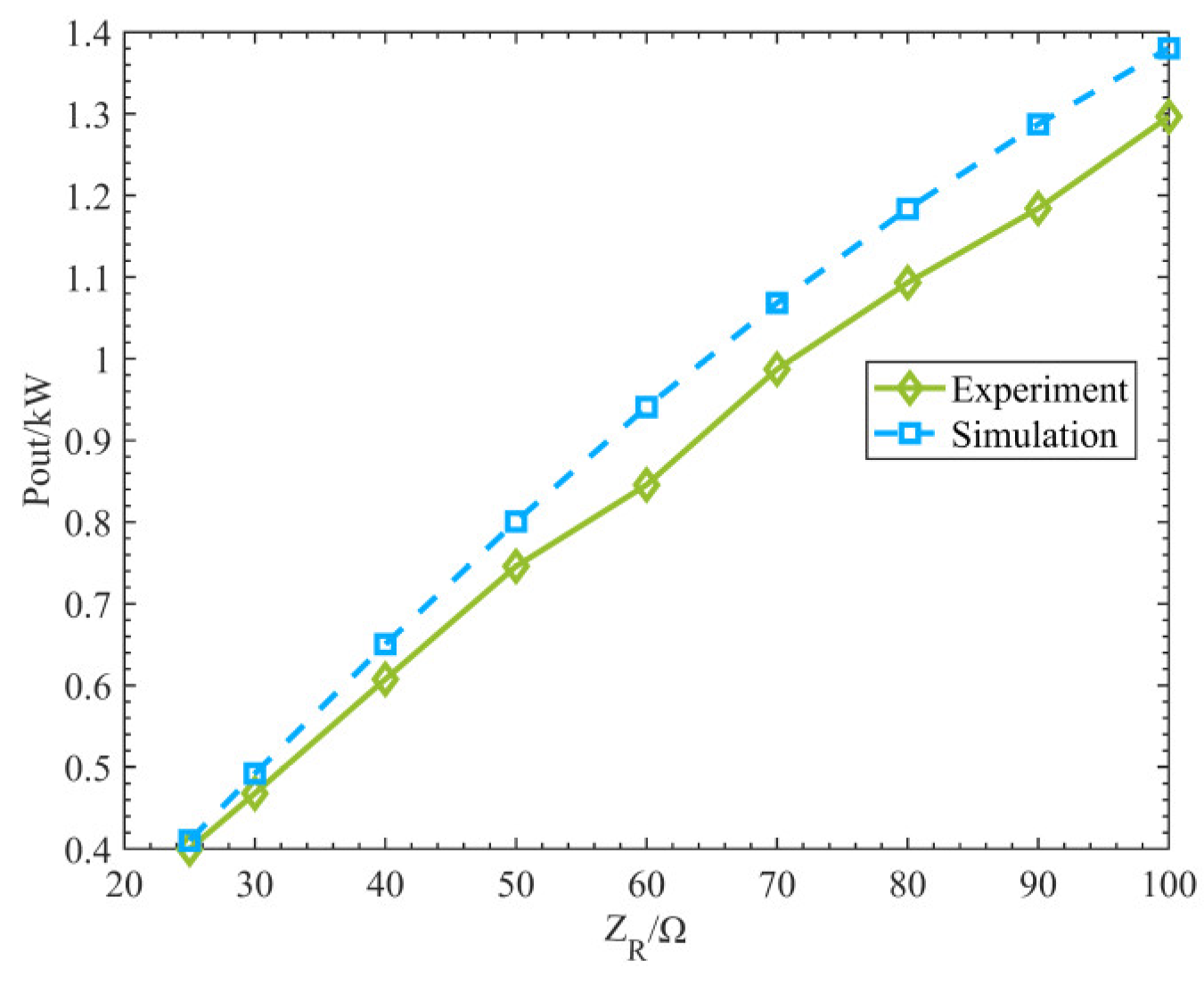

4.2. Simulation Verification

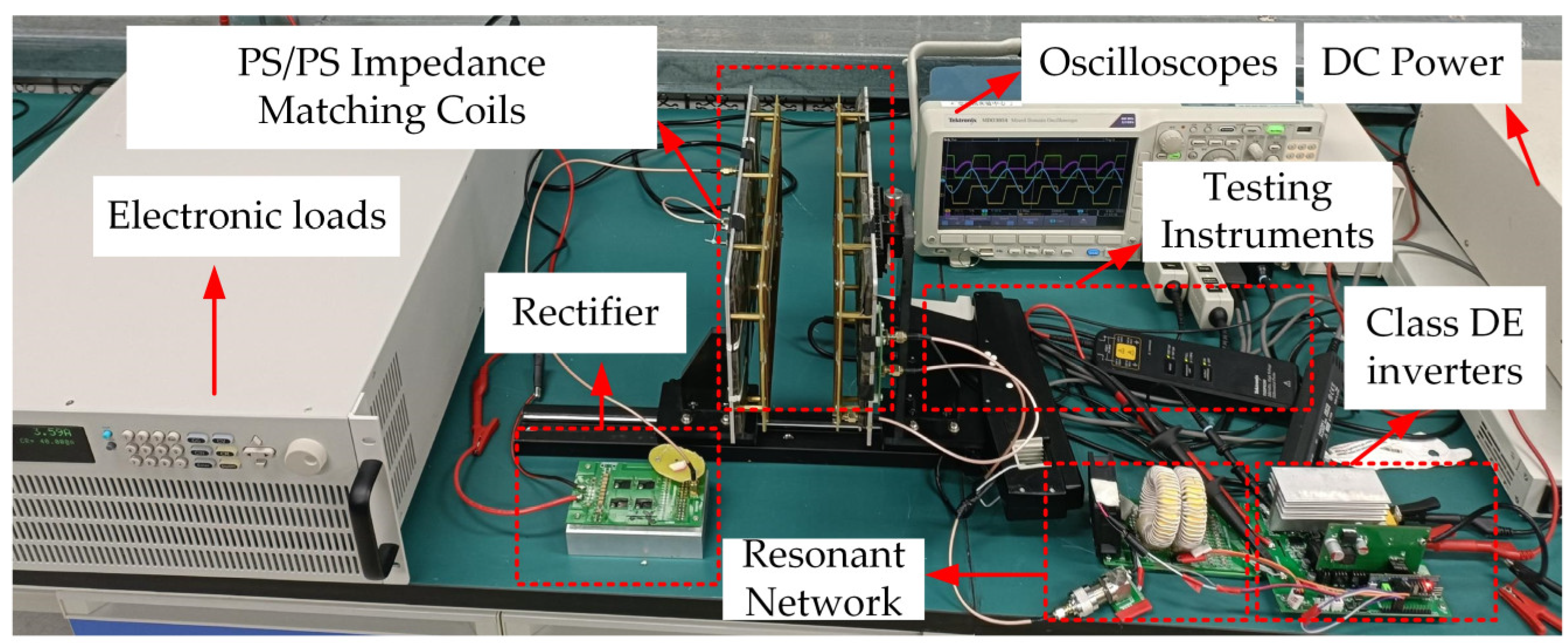

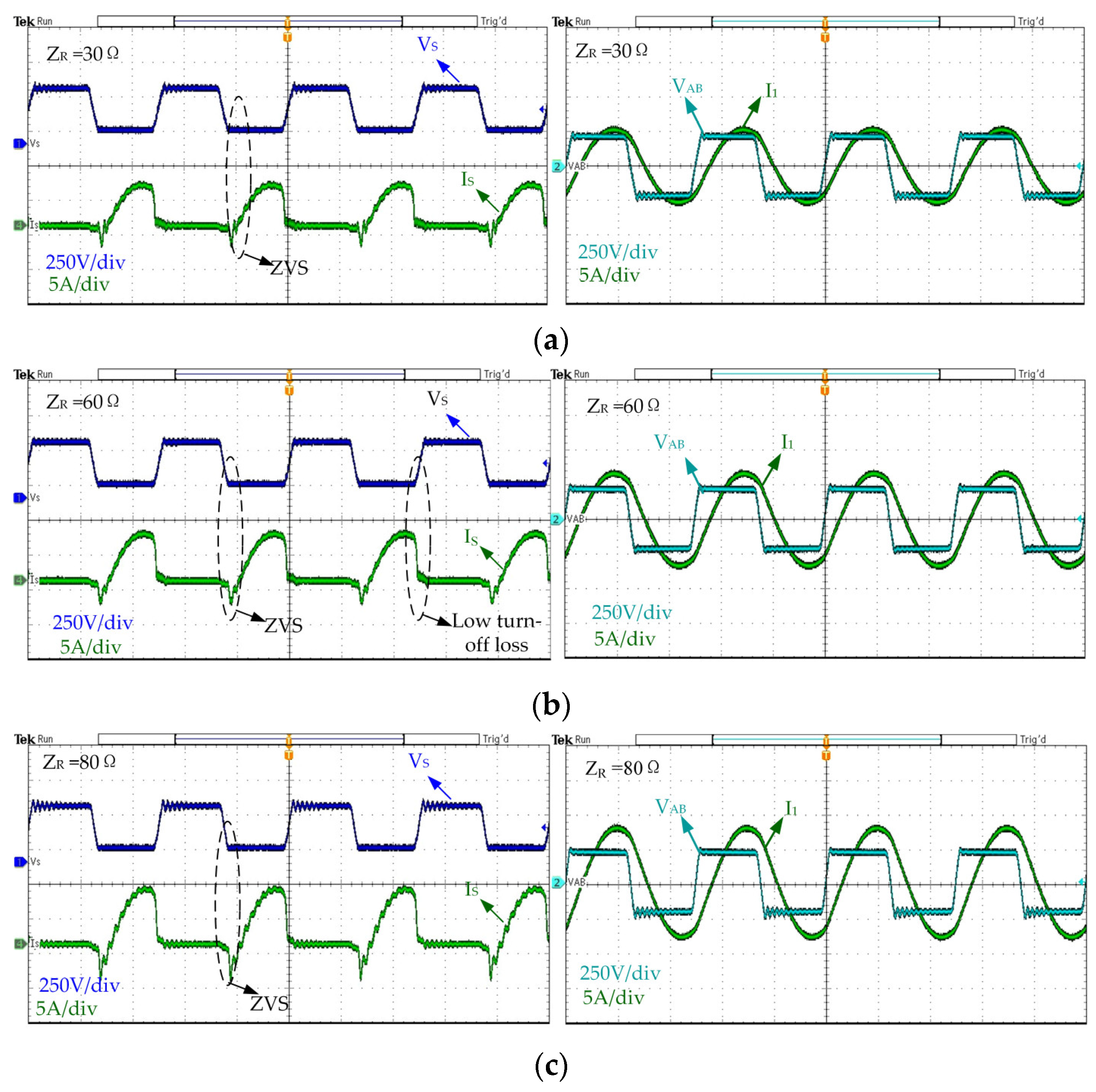

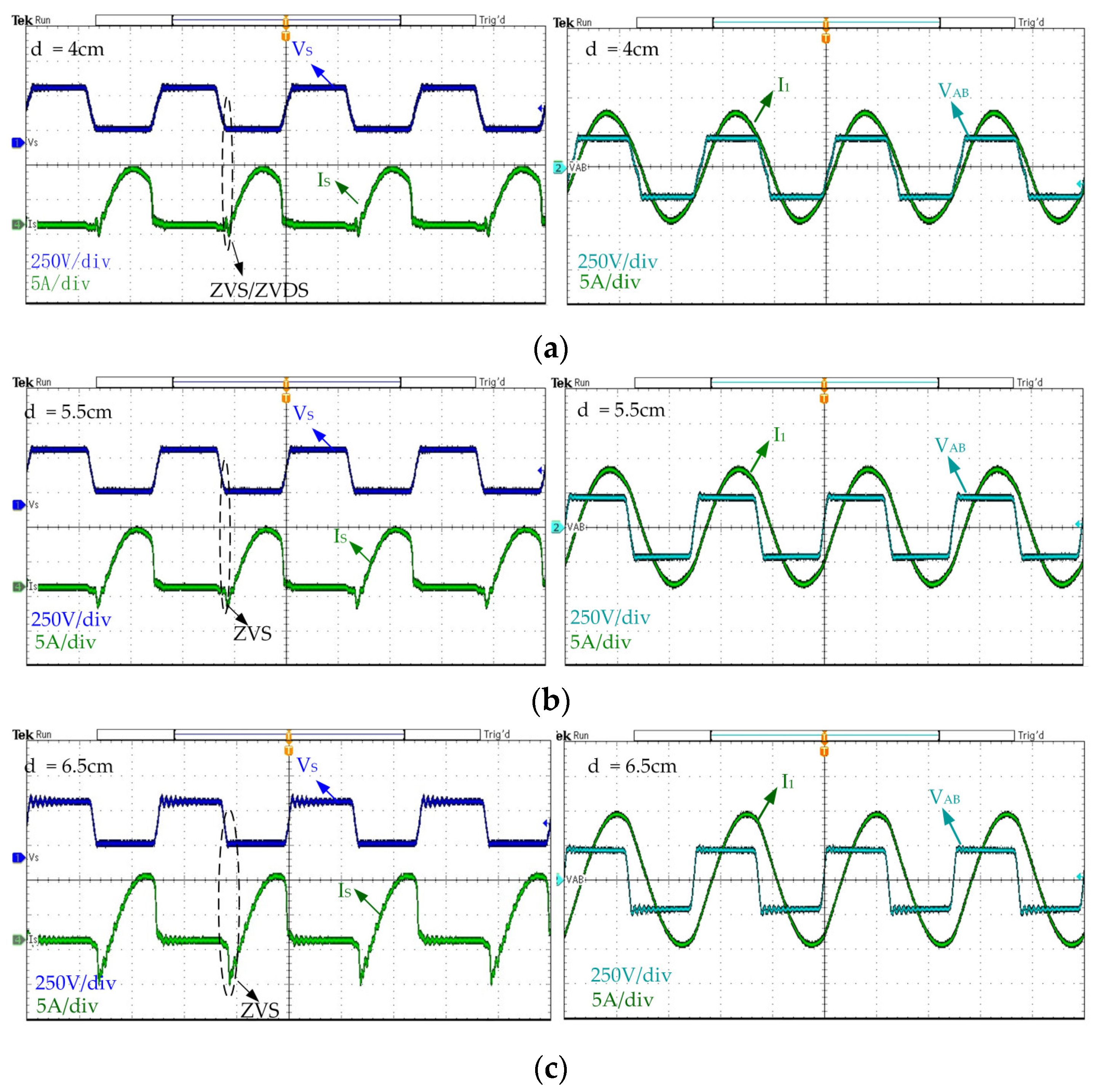

4.3. Experimental Verification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Qin, R.; Sun, J.; Costinett, D. Systematic Design of a 100-W 6.78-MHz Wireless Charging Station Covering Multiple Devices and a Large Charging Area. IEEE Trans. Power Electron. 2022, 37, 4877–4889. [Google Scholar] [CrossRef]

- Cai, C.; Liu, X.; Wu, S.; Chen, X.; Chai, W.; Yang, S. A Misalignment Tolerance and Lightweight Wireless Charging System via Reconfigurable Capacitive Coupling for Unmanned Aerial Vehicle Applications. IEEE Trans. Power Electron. 2023, 38, 22–26. [Google Scholar] [CrossRef]

- Zhu, Q.; Wang, L.; Guo, Y.; Liao, C.; Li, F. Applying LCC Compensation Network to Dynamic Wireless EV Charging System. IEEE Trans. Ind. Electron. 2016, 63, 6557–6567. [Google Scholar] [CrossRef]

- Inoue, K.; Kusaka, K.; Itoh, J.-I. Reduction in Radiation Noise Level for Inductive Power Transfer Systems Using Spread Spectrum Techniques. IEEE Trans. Power Electron. 2018, 33, 3076–3085. [Google Scholar] [CrossRef]

- Luo, Z.; Wei, X. Analysis of Square and Circular Planar Spiral Coils in Wireless Power Transfer System for Electric Vehicles. IEEE Trans. Ind. Electron. 2018, 65, 331–341. [Google Scholar] [CrossRef]

- Ukita, K.; Kashiwagi, T.; Sakamoto, Y.; Sasakawa, T. Evaluation of a Non-Contact Power Supply System with a Figure-of-Eight Coil for Railway Vehicles. In Proceedings of the 2015 IEEE PELS Workshop on Emerging Technologies: Wireless Power (2015 WoW), Daejeon, Republic of Korea, 5–6 June 2015; pp. 1–6. [Google Scholar]

- Waters, B.H.; Sample, A.P.; Bonde, P.; Smith, J.R. Powering a Ventricular Assist Device (VAD) With the Free-Range Resonant Electrical Energy Delivery (FREE-D) System. Proc. IEEE 2012, 100, 138–149. [Google Scholar] [CrossRef]

- Tang, S.C.; Lun, T.L.T.; Guo, Z.; Kwok, K.-W.; McDannold, N.J. Intermediate Range Wireless Power Transfer With Segmented Coil Transmitters for Implantable Heart Pumps. IEEE Trans. Power Electron. 2017, 32, 3844–3857. [Google Scholar] [CrossRef]

- Wang, W.; Hemour, S.; Wu, K. Coupled Resonance Energy Transfer Over Gigahertz Frequency Range Using Ceramic Filled Cavity for Medical Implanted Sensors. IEEE Trans. Microw. Theory Techn. 2014, 62, 956–964. [Google Scholar] [CrossRef]

- Yang, L.; Ju, M.; Zhang, B. Bidirectional Undersea Capacitive Wireless Power Transfer System. IEEE Access 2019, 7, 121046–121054. [Google Scholar] [CrossRef]

- Mai, R.; Yan, Z.; Chen, Y.; Liu, S.; He, Z. A Hybrid Transmitter-Based Efficiency Improvement Controller with Full-Bridge Dual Resonant Tank for Misalignment Condition. IEEE Trans. Power Electron. 2020, 35, 1124–1135. [Google Scholar] [CrossRef]

- Li, H.; Li, J.; Wang, K.; Chen, W.; Yang, X. A Maximum Efficiency Point Tracking Control Scheme for Wireless Power Transfer Systems Using Magnetic Resonant Coupling. IEEE Trans. Power Electron. 2014, 30, 3998–4008. [Google Scholar] [CrossRef]

- Li, H.; Wang, K.; Fang, J.; Tang, Y. Pulse Density Modulated ZVS Full-Bridge Converters for Wireless Power Transfer Systems. IEEE Trans. Power Electron. 2018, 34, 369–377. [Google Scholar] [CrossRef]

- Stankiewicz, J.M. Estimation of the Influence of the Coil Resistance on the Power and Efficiency of the WPT System. Energies 2023, 16, 6210. [Google Scholar] [CrossRef]

- Prengel, S.; Helwig, M.; Modler, N. Lightweight Coil for Efficient Wireless Power Transfer: Optimization of Weight and Efficiency for WPT Coils. In Proceedings of the 2014 IEEE Wireless Power Transfer Conference (WPTC), Jeju, Republic of Korea, 8–9 May 2014. [Google Scholar]

- Sohn, Y.H.; Choi, B.H.; Lee, E.S.; Lim, G.C.; Cho, G.-H.; Rim, C.T. General Unified Analyses of Two-Capacitor Inductive Power Transfer Systems: Equivalence of Current-Source SS and SP Compensations. IEEE Trans. Power Electron. 2015, 30, 6030–6045. [Google Scholar] [CrossRef]

- Chowdary, K.V.V.S.R.; Kumar, K.; Banerjee, S.; Kumar, R.R. Comparative Analysis between High-Order Compensation and SS-Compensation for Dynamic Wireless Power Transfer System. In Proceedings of the 2020 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Jaipur, India, 16–19 December 2020; pp. 1–6. [Google Scholar]

- Zhang, W.; Tse, C.K.; Chen, Q. Load-Independent Duality of Current and Voltage Outputs of a Series- or Parallel-Compensated Inductive Power Transfer Converter With Optimized Efficiency. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 137–146. [Google Scholar] [CrossRef]

- Yang, L.; Jiang, S.; Wang, C.; Shi, Y.; Wang, M.; Cai, C.; Zhang, L. A High-Efficiency Integrated LCC/S WPT System with Constant Current Output. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 341–354. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, Y.; Liu, X.; Xu, D.; Cai, L. An LC/S Compensation Topology and Coil Design Technique for Wireless Power Transfer. IEEE Trans. Power Electron. 2018, 33, 2007–2025. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Deng, J.; Nguyen, T.D.; Mi, C.C. A Double-Sided LCC Compensation Network and Its Tuning Method for Wireless Power Transfer. IEEE Trans. Veh. Technol. 2015, 64, 2261–2273. [Google Scholar] [CrossRef]

- Chen, L.; Liu, S.; Zhou, Y.C.; Cui, T.J. An Optimizable Circuit Structure for High-Efficiency Wireless Power Transfer. IEEE Trans. Ind. Electron. 2013, 60, 339–349. [Google Scholar] [CrossRef]

- Fereshtian, A.; Ghalibafan, J.; Koohestani, M. A Comprehensive Design Analysis of a Cost-Effective WPT System with a Class-E Power Amplifier and a T-Matching Network. AEU–Int. J. Electron. Commun. 2021, 137, 153826. [Google Scholar] [CrossRef]

- Liu, S.; Liu, M.; Yang, S.; Ma, C.; Zhu, X. A Novel Design Methodology for High-Efficiency Current-Mode and Voltage-Mode Class-E Power Amplifiers in Wireless Power Transfer Systems. IEEE Trans. Power Electron. 2016, 32, 4514–4523. [Google Scholar] [CrossRef]

- Fu, M.; Yin, H.; Liu, M.; Ma, C. Loading and Power Control for a High-Efficiency Class E PA-Driven Megahertz WPT System. IEEE Trans. Ind. Electron. 2016, 63, 6867–6876. [Google Scholar] [CrossRef]

- Liang, J.; Liao, W.-H. Steady-State Simulation and Optimization of Class-E Power Amplifiers with Extended Impedance Method. IEEE Trans. Circuits Syst. I 2011, 58, 1433–1445. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Liu, Y.; Liang, J.; Wang, H.; Fu, M. Multiconstraint Design of Single-Switch Resonant Converters Based on Extended Impedance Method. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 1901–1912. [Google Scholar] [CrossRef]

- Abbasian, S.; Johnson, T. Power-Efficiency Characteristics of Class-F and Inverse Class-F Synchronous Rectifiers. IEEE Trans. Microw. Theory Techn. 2016, 64, 4740–4751. [Google Scholar] [CrossRef]

- Jedi, H.; Salvatierra, T.; Ayachit, A.; Kazimierczuk, M.K. High-Frequency Single-Switch ZVS Gate Driver Based on a Class ∅2 Resonant Inverter. IEEE Trans. Ind. Electron. 2020, 67, 4527–4535. [Google Scholar] [CrossRef]

- Kaczmarczyk, Z. High-Efficiency Class E, Class EF2, and Class E/F3 Inverters. IEEE Trans. Ind. Electron. 2006, 53, 1584–1593. [Google Scholar] [CrossRef]

- Samanta, S.; Rathore, A.K. Wireless Power Transfer Technology Using Full-bridge Current-fed Topology for Medium Power Applications. IET Power Electron. 2016, 9, 1903–1913. [Google Scholar] [CrossRef]

- Jiang, L.; Costinett, D. A High-Efficiency GaN-Based Single-Stage 6.78 MHz Transmitter for Wireless Power Transfer Applications. IEEE Trans. Power Electron. 2019, 34, 7677–7692. [Google Scholar] [CrossRef]

- Tebianian, H.; Salami, Y.; Jeyasurya, B.; Quaicoe, J.E. A 13.56-MHz Full-Bridge Class-D ZVS Inverter With Dynamic Dead-Time Control for Wireless Power Transfer Systems. IEEE Trans. Ind. Electron. 2020, 67, 1487–1497. [Google Scholar] [CrossRef]

- De Rooij, M. Performance Comparison for A4WP Class-3 Wireless Power Compliance between eGaN® FET and MOSFET in a ZVS Class D Amplifier. In Proceedings of the PCIM Europe 2015, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 19–20 May 2015; pp. 1–8. [Google Scholar]

- De Rooij, M.; Zhang, Y. eGaN® FET Based 6.78 MHz Differential-Mode ZVS Class D AirFuelTM Class 4 Wireless Power Amplifier. In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 9–11 September 2016; pp. 1–8. [Google Scholar]

- Chung, E.; Ha, J.I. Impedance Matching Network Design for 6.78-MHz Wireless Power Transfer System With Constant Power Characteristics Against Misalignment. IEEE Trans. Power Electron. 2023, 39, 1788–1801. [Google Scholar] [CrossRef]

- Han, Y.; Leitermann, O.; Jackson, D.A.; Rivas, J.M.; Perreault, D.J. Resistance Compression Networks for Radio-Frequency Power Conversion. IEEE Trans. Power Electron. 2007, 22, 41–53. [Google Scholar] [CrossRef]

- Issi, F.; Kaplan, O. Design and Application of Wireless Power Transfer Using Class-E Inverter Based on Adaptive Impedance-Matching Network. ISA Trans. 2022, 126, 415–427. [Google Scholar] [CrossRef] [PubMed]

- Owais, M. Deep Learning for Integrated Origin–Destination Estimation and Traffic Sensor Location Problems. IEEE Trans. Intell. Transp. Syst. 2024, 1–13. [Google Scholar] [CrossRef]

- Owais, M.; Alshehri, A.; Gyani, J.; Aljarbou, M.H.; Alsulamy, S. Prioritizing Rear-End Crash Explanatory Factors for Injury Severity Level Using Deep Learning and Global Sensitivity Analysis. Expert Syst. Appl. 2024, 245, 123114. [Google Scholar] [CrossRef]

- Koizumi, H.; Suetsugu, T.; Fujii, M.; Shinoda, K.; Mori, S.; Iked, K. Class DE High-Efficiency Tuned Power Amplifier. IEEE Trans. Circuits Syst. I 1996, 43, 51–60. [Google Scholar] [CrossRef]

- Wei, X.; Sekiya, H.; Nagashima, T.; Kazimierczuk, M.K.; Suetsugu, T. Steady-State Analysis and Design of Class-D ZVS Inverter at Any Duty Ratio. IEEE Trans. Power Electron. 2016, 31, 394–405. [Google Scholar] [CrossRef]

- Sarnago, H.; Lucía, Ó.; Mediano, A.; Burdío, J.M. Class-D/DE Dual-Mode-Operation Resonant Converter for Improved-Efficiency Domestic Induction Heating System. IEEE Trans. Power Electron. 2013, 28, 1274–1285. [Google Scholar] [CrossRef]

- Albertoni, L.; Grasso, F.; Matteucci, J.; Piccirilli, M.C.; Reatti, A.; Ayachit, A.; Kazimierczuk, M.K. Analysis and Design of Full-Bridge Class-DE Inverter at Fixed Duty Cycle. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 5609–5614. [Google Scholar]

- Inoue, K.; Nagashima, T.; Wei, X.; Sekiya, H. Design of High-Efficiency Inductive-Coupled Wireless Power Transfer System with Class-DE Transmitter and Class-E Rectifier. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 613–618. [Google Scholar]

- Krishna, A.V.; Rashmi, M.R. Wireless Power Transfer for LED Display System Using Class-DE Inverter. In Emerging Research in Electronics, Computer Science and Technology; Sridhar, V., Padma, M.C., Rao, K.A.R., Eds.; Springer: Singapore, 2019; pp. 1271–1282. [Google Scholar]

- Yusop, Y.; Saat, S.; Kamarudin, K.; Husin, H.; Nguang, S.K. Π1a and Π1b Impedance Matching for Capacitive Power Transfer System. In Embracing Industry 4.0; Lecture Notes in Electrical Engineering; Mohd Razman, M.A., Mat Jizat, J.A., Mat Yahya, N., Myung, H., Zainal Abidin, A.F., Abdul Karim, M.S., Eds.; Springer: Singapore, 2020; Volume 678, pp. 227–249. [Google Scholar]

- Pellitteri, F.; Boscaino, V.; Di Tommaso, A.O.; Miceli, R.; Capponi, G. Experimental Test on a Contactless Power Transfer System. In Proceedings of the 2014 Ninth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 25–27 March 2014; pp. 1–6. [Google Scholar]

- Huang, X.; Lu, C.; Liu, M. Calculation and Analysis of Near-Field Magnetic Spiral Metamaterials for MCR-WPT Application. Appl. Phys. A 2020, 126, 1–9. [Google Scholar] [CrossRef]

| Operation Modes | Switching Status | |||

|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | |

| ON | OFF | OFF | ON |

| OFF | OFF | OFF | OFF |

| OFF | ON | ON | OFF |

| OFF | OFF | OFF | OFF |

| Symbol | Parameter | Value |

|---|---|---|

| k | Coil coupling coefficient | 0.3 |

| α | Shunt capacitance factor | 0.85 |

| φ | Initial phase shift capacitance | 2.82 rad |

| C1 | compensation series capacitance | 5.36 nF |

| C2 | compensated shunt capacitance | 6.32 nF |

| CP | compensated shunt capacitance | 12.43 nF |

| L1/L2 | Primary and secondary inductance | 27.3 μH |

| RL | Load resistance | 35~110 Ω |

| L | Inverter resonant cavity inductance | 40.23 μH |

| D | Duty cycle | 0.423 |

| Q | Quality factor | 5.05 |

| CS | MOSFET parallel total capacitance | 1.2 nF |

| f0 | Operating frequency | 500 kHz |

| Ca | resonant compensation capacitance | 3.776 nF |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Li, Q.; Liu, Y.; Yuan, W.; Yan, K.; Pang, Z. A Novel Impedance Matching of Class DE Inverter for High Efficiency, Wide Impedance WPT System. Electronics 2024, 13, 959. https://doi.org/10.3390/electronics13050959

Wang P, Li Q, Liu Y, Yuan W, Yan K, Pang Z. A Novel Impedance Matching of Class DE Inverter for High Efficiency, Wide Impedance WPT System. Electronics. 2024; 13(5):959. https://doi.org/10.3390/electronics13050959

Chicago/Turabian StyleWang, Ping, Qian Li, Yanming Liu, Wei Yuan, Kui Yan, and Zixu Pang. 2024. "A Novel Impedance Matching of Class DE Inverter for High Efficiency, Wide Impedance WPT System" Electronics 13, no. 5: 959. https://doi.org/10.3390/electronics13050959

APA StyleWang, P., Li, Q., Liu, Y., Yuan, W., Yan, K., & Pang, Z. (2024). A Novel Impedance Matching of Class DE Inverter for High Efficiency, Wide Impedance WPT System. Electronics, 13(5), 959. https://doi.org/10.3390/electronics13050959