1. Introduction

Robot manipulators have been widely used in industrial processes for a variety of high-precision and complex work scenarios, such as industrial production lines, machine tool loading and unloading, palletizing, machining, and welding [

1]. In order to cope with the requirements of different types of tasks, the tracking capabilities of robotic manipulators have to be more precise and faster. Although there have been some studies on the control functions of robotic arms, some problems may arise when designing the control algorithms, such as errors and parameter uncertainties [

2] between the nonlinear system and the modeled system, some parameters of the system itself which may require some a priori knowledge [

3] to determine their ranges, or some external factors, for example, noise, friction and collision may occur, which can create a time-varying perturbations [

4]. These factors may make the robotic arm movement inaccurate or even cause instability of the overall system.

Commonly used control methods for robotic arms include sliding mode control [

5], PID control [

6], and neural network control [

7]. Sliding mode control (SMC) has the advantage of being insensitive to system uncertainty and parameter changes, which can somewhat solve the instability factors that may occur in the robotic arm system. By using Matlab, we can simulate the movement path of the robotic arm more easily [

8]. Among them, Ilgenl et al. [

9] optimized the SMC controller by using the Simple Shape Search (SS) method and used it in controlling the trajectory tracking of a two-link planar robot manipulator arm, which has been shown experimentally to exhibit effective control performance in terms of trajectory, stabilization time, and end position required by the system. Ahmed et al. [

10] applied a new sliding mode control with PD and fuzzy control in the antishudder control of robot manipulator. The effectiveness and efficiency of the proposed control method is experimentally verified. Ji et al. [

11] proposed an improved exponential convergence law and nonlinear sliding mode surface for the problems of convergence speed and shuddering in the sliding mode variable structure control of manipulators. Experiments showed that it can improve the tracking accuracy and convergence speed to some extent while reducing system chattering. Sliding mode control applied to robotic arm control can improve its control accuracy, but due to the characteristics of its own algorithm, it is prone to high-frequency chattering, which in turn will produce noise, wear and tear, and other problems. At the same time, some parameters of the control algorithm need certain a priori knowledge to be defined, so it is necessary to make certain improvements to the sliding mode control algorithm.

There are many ways to improve the sliding mode control algorithm, such as neural network methods [

12], data-driven MPC algorithms [

13], and adaptive methods [

14], among which the adaptive method is also one of the improvement methods. It has the advantages of high adaptability to parameter changes and high fault tolerance. It is usually divided into ascending–descending ASMC [

15] and equivalent ASMC control [

16]. For example, Zhao et al. [

17] used the adaptive sliding film method to control the Dobot magician robotic arm and found that it has better self-tuning and trajectory tracking capabilities. Zaare et al. [

18] presented a high-speed and low power consumption adaptive fuzzy global coupled nonsingular fast terminal sliding mode control to the position tracking control of the n-rigid-link elastic-joint robot manipulators in the presence of the uncertainties. Seung-Hun et al. [

19] suggested an adaptive sliding mode control by using Nussbaum functions for the n-degree-of-freedom robotic arm tracking control problem. The experiment proved that the method can reduce the possibility of damage to the robotic arm when the control direction is uncertain. The adaptive method has, to some extent, enhanced the sensitivity of the sliding mode control to external disturbances, yet its capability to counteract time-varying external disturbances remains suboptimal. This indicates that the adaptive control approach requires further refinement. Recently, other researchers have also been making continuous improvements to adaptive control methods. For instance, Jerbi et al. [

20] have developed an adaptive robust controller based on Radial Basis Function (RBF) neural network (NN) systems and the Hamilton–Jacobi–Isaacs (HJI) approach, which exhibits a commendable disturbance rejection performance in Wearable Robotic Knees (WRKs).

In response to the above problems, perturbation observers can significantly ameliorate the effects of complex external disturbances. For example, Yin et al. [

21] used an adopted sliding film control based on a nonlinear disturbance observer for the tracking accuracy and disturbance immunity requirements of the trajectory tracking control of machining robot manipulators. Shi et al. [

22] applied a fixed-time sliding mode control strategy based on an adaptive disturbance observer to the trajectory tracking control of a nonlinear robotic arm system and proved to be able to overcome the problem well. It was verified that it can well overcome the problems of modeling error, unknown perturbation, and friction in practical control. Juan Xian et al. [

23] proposed a continuous sliding mode control scheme based on time-varying perturbation estimation and compensation in the study of high-precision trajectory tracking problem of uncertain robot manipulator arm, which has found that the scheme not only alleviates the jittery vibration but also makes the whole system’s antidisturbance performance significantly improved. In addition, Alshammari et al. [

24] used fuzzy theory to establish two fuzzy switching manifolds on disturbance and slip film observer systems to improve the synthesis effect of the controller. Kchaou et al. [

25] designed a set of slip film observer strategies based on fault-tolerant control with Takagi–Sugeno (T-S) fuzzy, which can be well-suited for nonlinear descriptor systems with actuator faults. Compared with the traditional sliding mode control, the adaptive sliding mode control with disturbance observer has a better control effect in terms of parameter uncertainty and complex disturbance.

In this paper, a terminal adaptive sliding mode control algorithm based on a disturbance observer is used to control a robotic arm. Firstly, the sliding mode control is utilized to cope with some error situations and parameter uncertainty that may be brought by the nonlinear model of the system. Secondly, an adaptive algorithm optimization is incorporated to cover all the boundary conditions by relying on the state of the model to be able to determine the corresponding, non-pre-fixed upper and lower bounds without the need for a priori knowledge. Finally, in order to cope with external interference, an interference observer is added, which can monitor and compensate for system interference in real time to ensure the stability and reliability of the overall system. Through the above algorithm design, the problems that may occur during the control of the seven-axis redundant robotic arm mentioned in the previous section can be better solved.

The rest of the paper is organized as follows.

Section 2 describes the dynamics modeling of the robotic manipulator.

Section 3 gives the design steps for the perturbation observer to be used.

Section 4 designs the terminal adaptive sliding mode controller and performs stability analysis. Simulation and experimental results are given in

Section 5 and

Section 6. Finally,

Section 7 gives the conclusions and outlook.

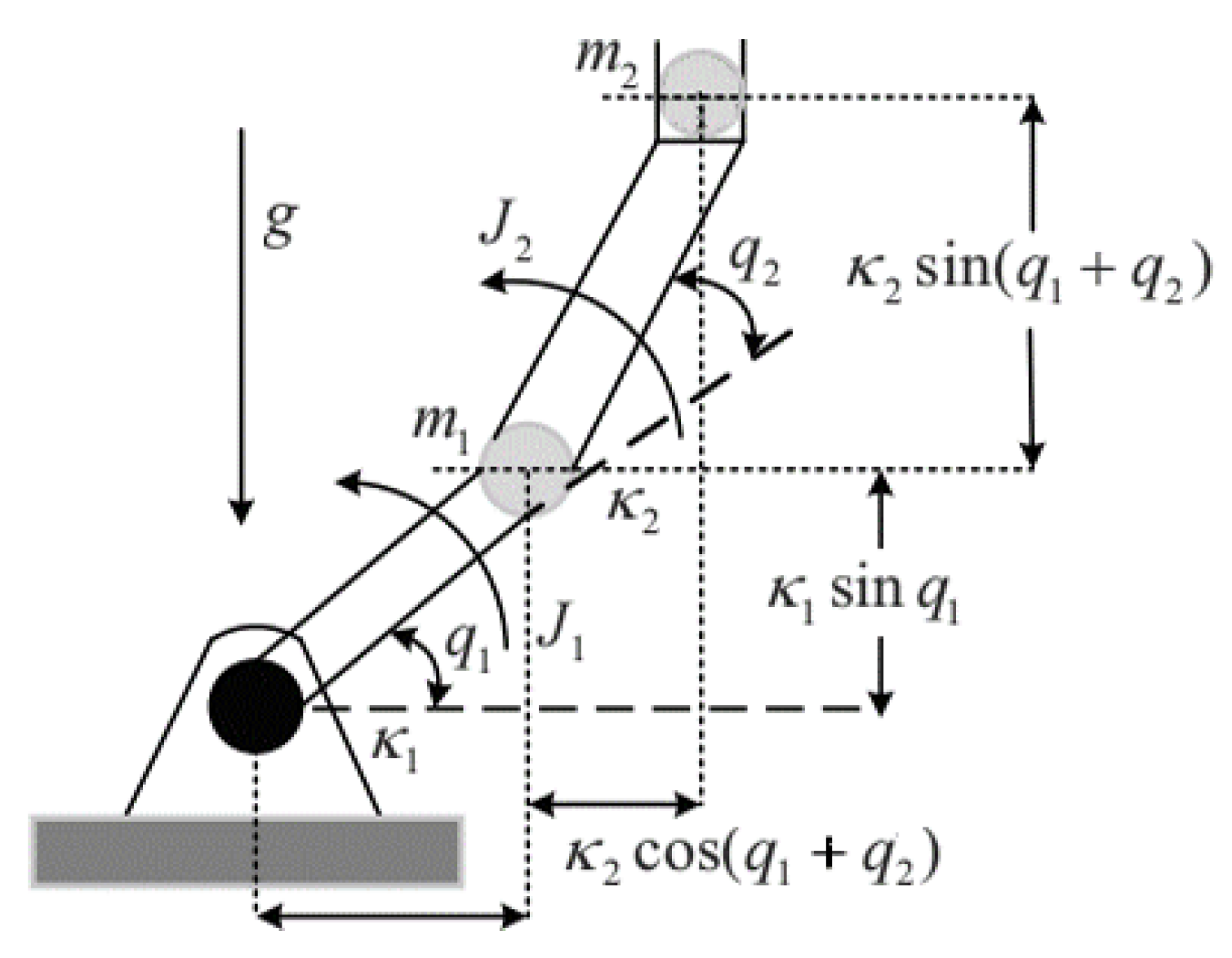

2. Dynamic Modeling

The dynamics of an n-link robot manipulator can be encapsulated by the following equation:

where

,

, and

are the vectors denoting the joint positions, velocities, and accelerations, respectively. The term

signifies the control input torques. The matrix

is the inertia matrix, portraying the mass properties of the manipulator.

represents the Coriolis and centrifugal forces matrix, and

corresponds to the gravitational force matrix. Here,

, and their corresponding boundaries

are all considered unknown. The vector

encompasses the total unknown disturbances in the system, including external disturbances and modeling errors.

A few assumptions are made here:

Assumption 1. The robotic arm system expects the joint angular positions and angular velocities to be known, and the actual positions and velocity trajectories of the system and the first-order derivatives to be measurable and continuously bounded.

Assumption 2. The total unknown disturbance ξ is assumed to be continuously differentiable and bounded, specifically , where represents the upper bound of its first derivative.

The dynamic model adheres to several key properties:

Property 1. The matrix is a symmetric positive definite matrix and such that .

Property 2. such that .

Property 3. is skew-symmetric. For brevity, q and are often omitted in , , and . And it is satisfied with for any nonzero vector z.

To further elucidate the dynamics of the robotic manipulator, the state–space representation of the dynamic equation is presented as follows:

The goal of the control method proposed in this study is to establish a control law in the form of actuator torque in the presence of disturbances and uncertainties that ensures that the joint output angle q accurately follows the desired joint trajectory .

3. Disturbance Observer Design

As the manipulator arm has external disturbances and its own modeling uncertainty in the actual control process, this will reduce the control accuracy of the manipulator arm. In order to reduce the influence of external disturbances on the robotic arm system, a disturbance observer is designed in this section in conjunction with the robotic arm dynamics model, which is used to approximate the system disturbance and differentiate them from the actual disturbances, and the disturbance error is converged to zero by correcting the disturbance estimate.

Based on the Equation (

2), the perturbation observer of the manipulator arm is designed as:

where

is the nonlinear gain matrix and

is the observed estimate of

.

Since the above equation needs to realize the angular acceleration of the state, using the velocity signal differentiation to obtain the acceleration signal will introduce noise leading to system instability. So, to solve the above problem, the interference observer can be designed as follows. Construct the following auxiliary function:

where

.

is the internal state vector of the observer,

is the vector of the function yet to be designed, and in order to avoid the introduction of acceleration signals, the perturbation of observer gain matrix

and

exists in the following relationship:

Based on Equations (

3)–(

5), the structure of the interference observer can be designed as:

Since a perturbed observer without acceleration is required, a modification of the above equation can be obtained:

After obtaining the non-accelerated perturbation observer, the observation error of the perturbation observer is defined as follows:

From Equations (

4) to (

8), the dynamic equation of the observer error is

The above equation requires a priori knowledge of interference differentiation, but this part of the actual conditions is unknown. Here, it is assumed that

changes slowly with respect to the characteristics of the interference observer, so Equation (

9) becomes as follows:

In the equation, take the nonlinear gain matrix

as an invertible matrix, and bring it into the integral of Equation (

5) to obtain:

In order to realize the accurate estimation of

by adjusting

so that the disturbance observation

approximates the total unknown disturbance

so that the observer error

z can converge to zero exponentially. To ensure the stability of the observer, the following Lyapunov function is constructed:

Then, the derivation and simplification of

is obtained:

Assume that there exists a symmetric positive definite matrix

such that

in Equation (

14) satisfies:

By multiplying both sides of the Equation (

15) with

and

, respectively, we obtain

According to the Assumption 1, there exists a

such that

, where

is the identity matrix. Consequently, the Equation (

16) becomes

Finally, by applying the Schur complement theorem, Equation (

17) is converted to the following matrix:

Use the Linear Matrix Inequality (LMI) toolbox to solve Equation (

18), thus ensuring that

is negatively definite.

4. Controller Design

In this section, a set of adaptive-based terminal sliding mode controllers will be designed in order to satisfy its need for no a priori knowledge and no prefixed upper and lower bounds.

Before proceeding with the design of the sliding mold surface, it needs to specify the inputs to the system. The inputs to the system are the deviation values of the manipulator arm joint angles and angular velocities of the robotic arm, which can be expressed as

To better represent the error vector, define

. And

.

Accordingly, the nonlinear fast terminal sliding mode surface function can be written as

where

and

are positive odd numbers satisfying

;

is defined as

and

.

Derivation of the Equation (

20) gives

To facilitate the next computational derivation process, multiplying

M to the left of Equation (

21) gives

where

.

Defined

,

. From Properties 1 and 2, the range of

in Equation (

22) can be determined:

Substituting Equation (

19) into Equation (

23) yields

where

,

,

as the unknown boundary range.

According to the previous analysis and calculation, the control rate of fast terminal sliding mode control based on adaptive law can be obtained as

where

, and the adaptive law

is defined as follows:

where

,

,

. The control rate of the manipulator is as follows:

The two control rates are, respectively,

where, to further attenuate the jitter, the power function

is used instead of the

function:

where

is a constant that affects the tracking speed;

is a constant that affects the filtering effect. The overall schematic diagram of the ADBSMC is depicted in

Figure 1. The stability analysis is demonstrated in

Appendix A.

6. Experiment

In order to verify the effectiveness of the proposed adaptive dynamic boundary sliding mode control based on the disturbance observer method in actual conditions, a comparative experimental study on the related tank is carried out in this section. As shown in

Figure 9, the validation of the ADBSMC is demonstrated using a 7-DOF Franka–Emika–Panda robot equipped with high-precision torque sensors. Control of the robot is achieved through the Franka Control Interface (FCI), and real-time control values are transmitted at a frequency of 1 kHz [

28]. The FCI provides a framework that enables the robot to receive real-time feedback from external sensors. The interface allows additional sensory information to be integrated into the robot’s control loop. The low-level control of the Franka is typically processed using C++. This involves direct communication with the robot’s hardware, real-time control loops, and handling low-level commands such as joint position control, torque control, and sensor data acquisition. We use Franka Matlab to create higher-level control logic. The FCI Simulink blocks send high-level commands to the robot, and then Simulink blocks translates into the appropriate low-level control signals that the robot recognises.

The experimental control parameters were consistent with the simulated control parameters in the previous section. In the mutation disturbance experiments, we also applied an external disturbance of 2 Nm at the joint positions of the robot arm at 3.1 s. The results from the first and second joints of the Franka–Emika–Panda robot were selected for the experimental analysis.

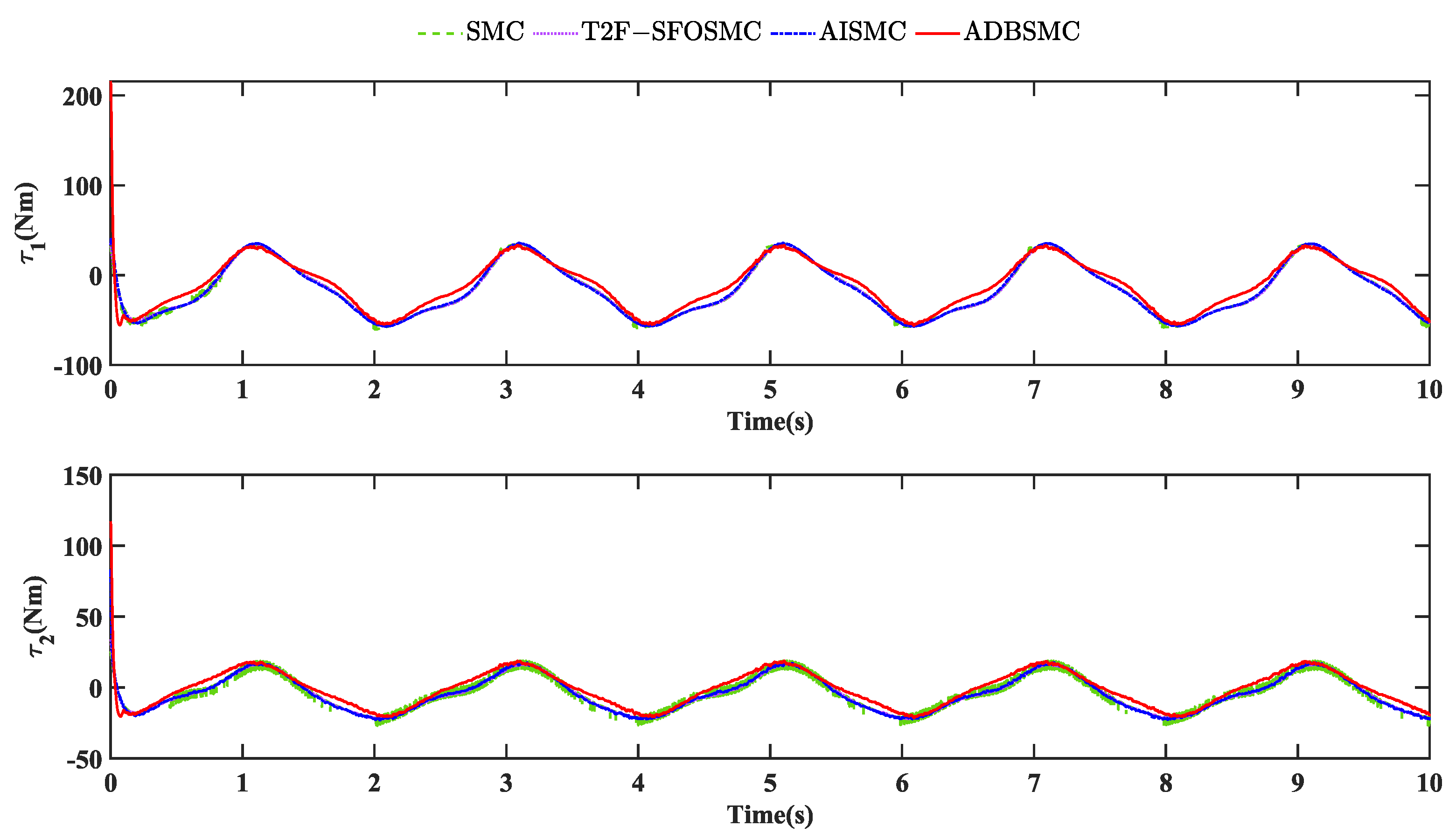

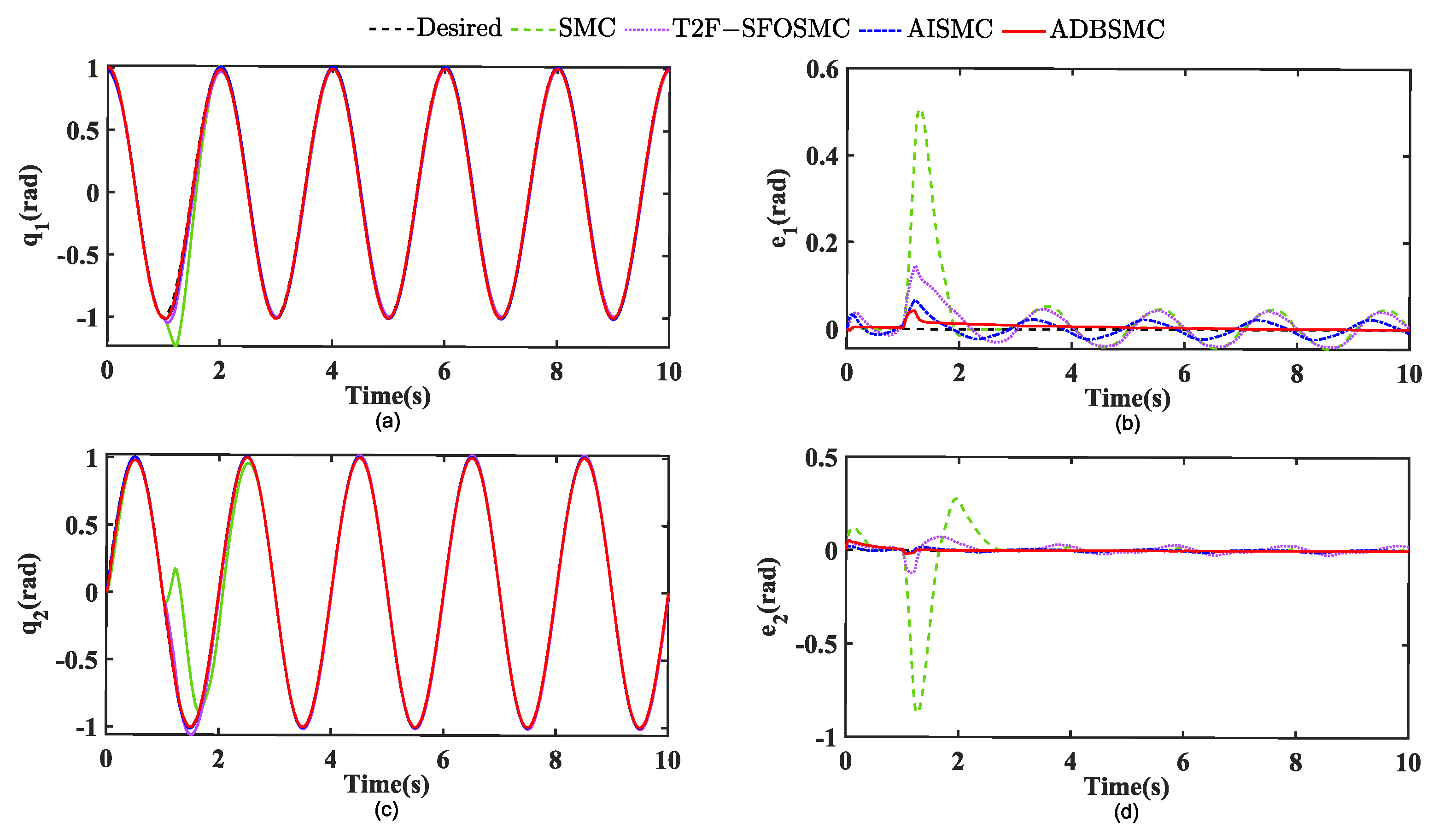

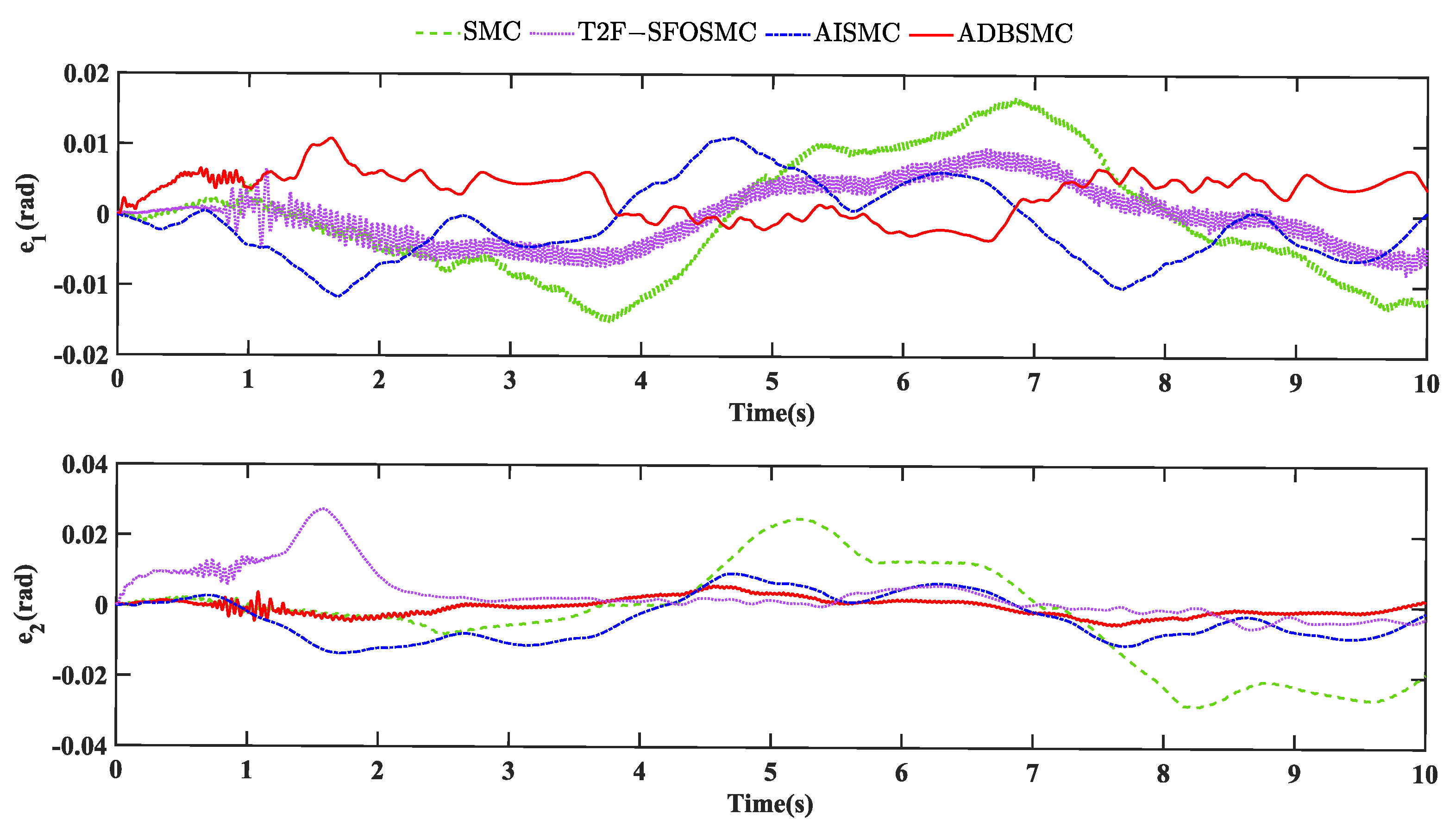

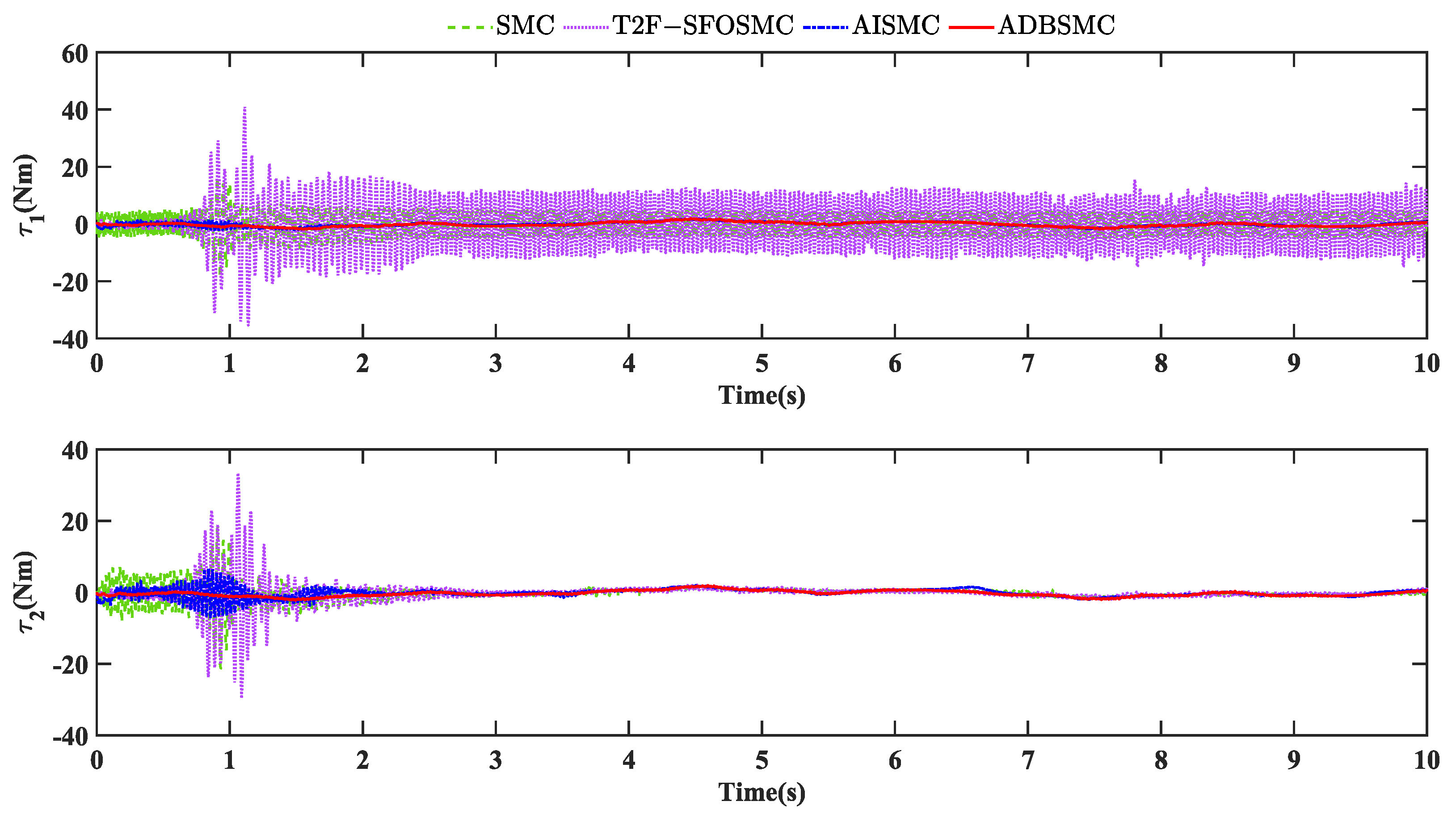

Figure 10 displays that in the presence of disturbances, the error remains minimal for all control methods, with the ADBSMC method exhibiting the most negligible deviation, suggesting its superior disturbance rejection capability. The control input torque, as shown in

Figure 11, reveals more about the control strategies’ robustness. While all methods experience initial spikes, indicative of a response to the disturbance, the ADBSMC method demonstrates a more damped torque output over time, pointing to its effectiveness in disturbance compensation and its potential in maintaining system stability under erratic conditions.

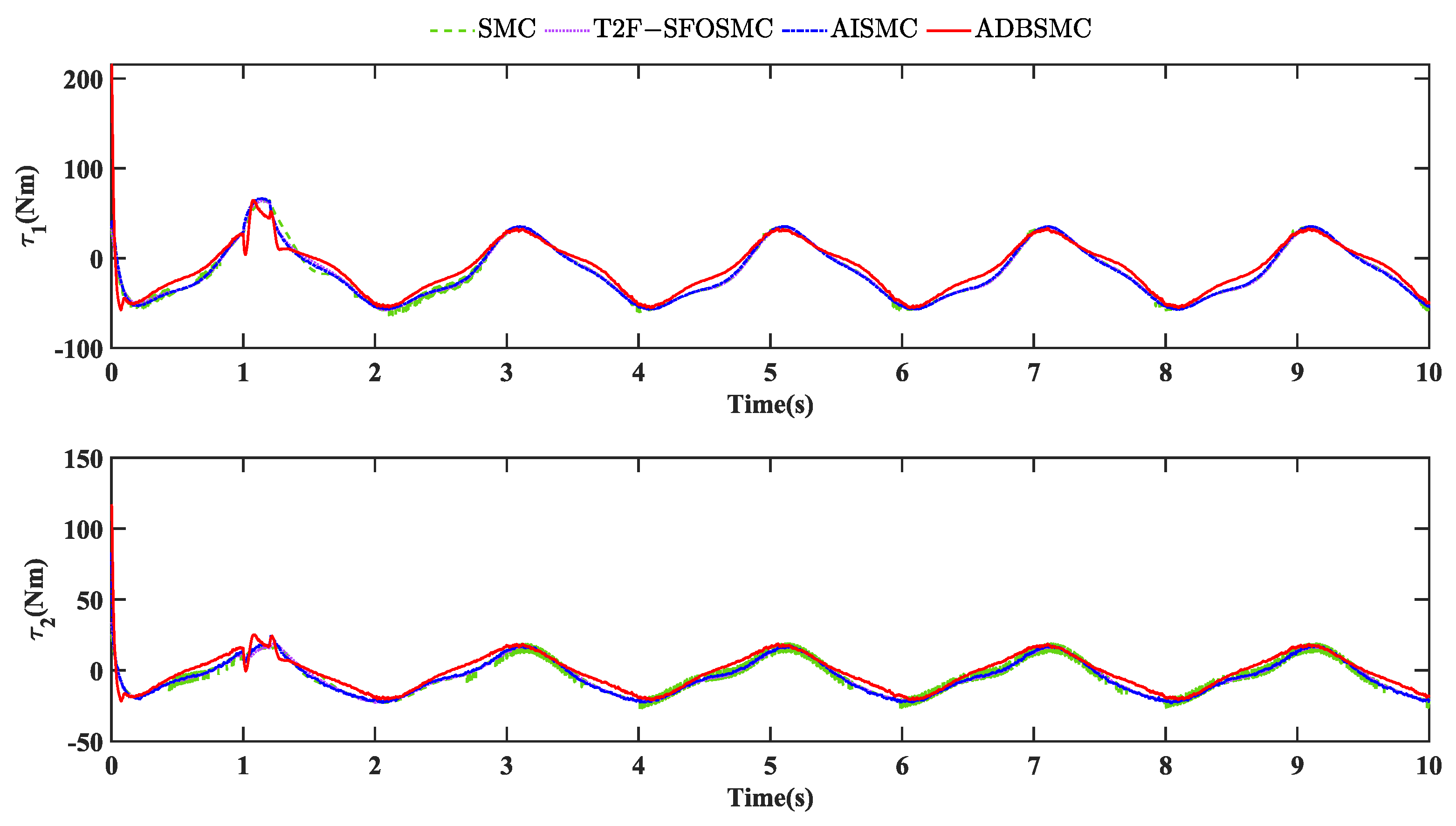

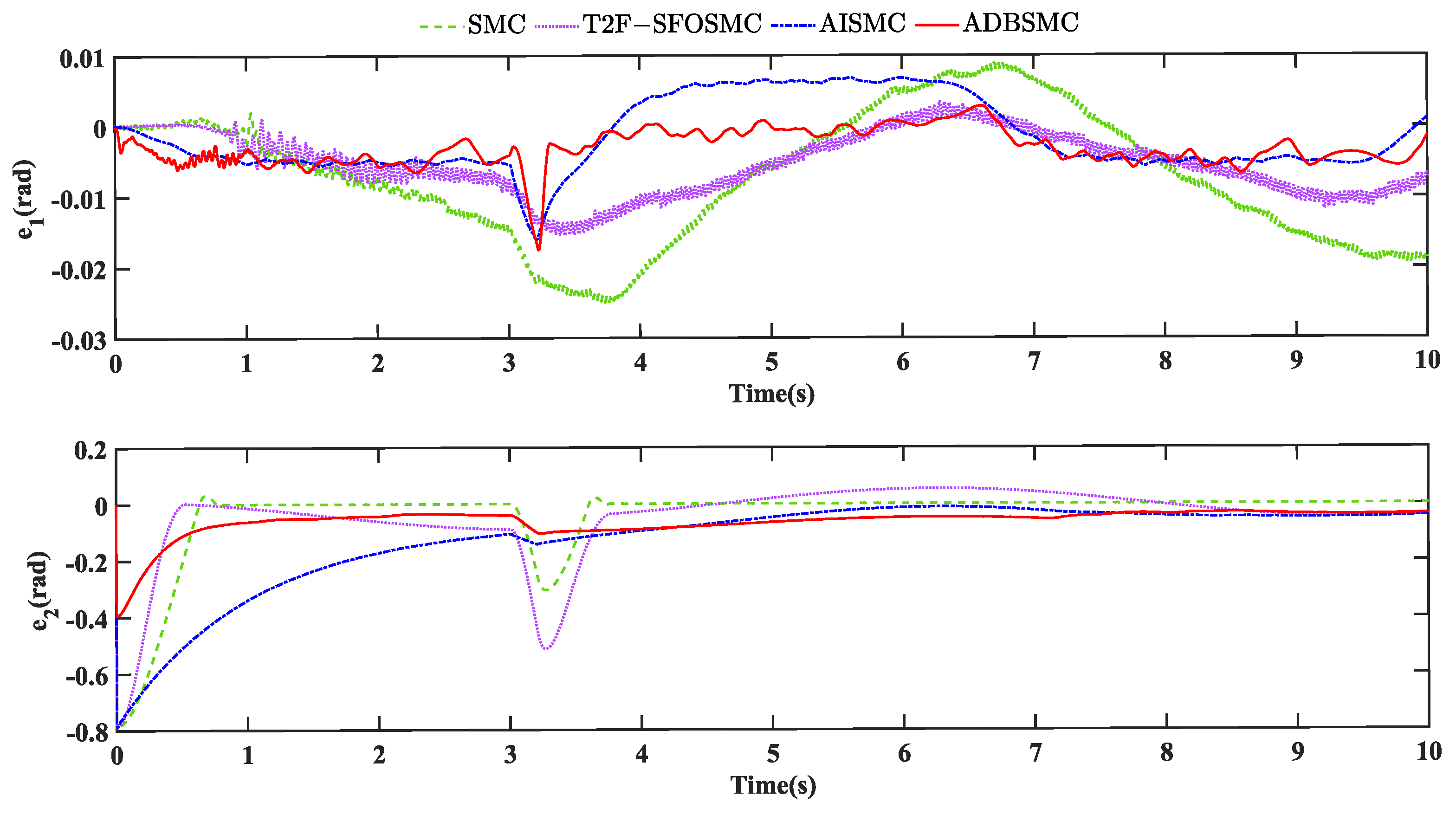

Figure 12 and

Figure 13 illustrate the system’s response to a sudden impulse disturbance applied at 3.1 s, represented by a 10 N impact.

Figure 12 shows a sharp response to the disturbance, with all control methods rapidly compensating for the error introduced. Notably, the ADBSMC maintains the error within the narrowest bounds, suggesting an effective handling of the abrupt change. Similarly,

Figure 13 displays an immediate spike at the moment of impact, reflecting the controllers’ action to counteract the disturbance. The ADBSMC method shows a more composed response post impact, with a smoother return to the baseline torque level, indicating a robust disturbance rejection and a quicker stabilization compared with the other methods. These results underscore the ADBSMC’s potential for high-precision control in dynamic environments, where coping with sudden disturbances is critical for maintaining system performance and stability. Moreover, the margin of error is acceptable.

For better analysis, we calculated the root mean square error (RMSE) and maximum absolute error (MAE) for each case based on the experimental data, which are detailed in

Table 3.

Table 3 shows that, as with the simulation results, our proposed controller maintains small RMSE and MAE values even under the influence of external disturbances compared with the SMC, T2F−SFOSMC, and AISMC controllers. This again demonstrates the robustness of our controllers in achieving excellent tracking performance under challenging conditions.