Application of the STFT for Detection of the Rotor Unbalance of a Servo-Drive System with an Elastic Interconnection

Abstract

1. Introduction

2. Literature Overview

3. The Unbalance Model

4. Two-Mass System with Flexible Joint

5. STFT Transformation

6. Laboratory Bench and Research Methodology

6.1. Laboratory Stand Description

6.2. The Effect of the Laboratory Bench Frame Resonance—Frequency Analysis Limit

6.3. Laboratory Bench Identification—Comparative Analysis of Thin Shaft Influence on the Laboratory Stand Properties

6.4. The Influence of Additional Test Mas Mounting Angle on the Vibration Level

6.5. The Influence of Additional Test Mas on the Vibration Level

6.6. The Influence of the Shaft Diameter on the Vibration Level

6.7. The Issues Related to Two-Mass System

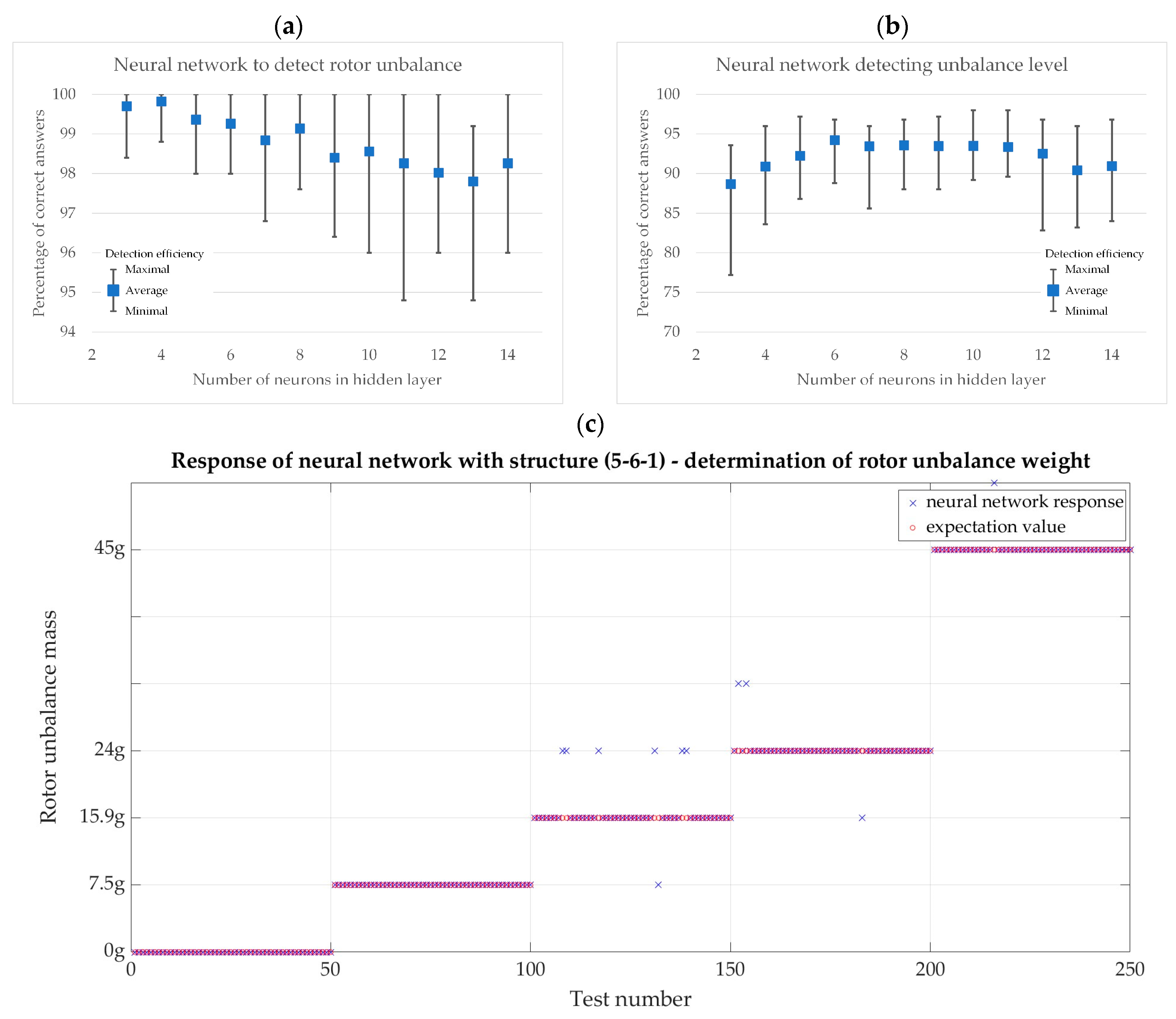

7. Neural Detector of Rotor Unbalance

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Yang, J.; Ye, H.; Zhou, W. A review of Permanent Magnet Synchronous Motor fault diagnosis. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August 2014–3 September 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Krichen, M.; Ben hadj, N.; Chaeib, M.; Neji, R. Fault Detection and Diagnosis Methods in Permanent Magnet Synchronous Machines: A Review. In Proceedings of the International Conference on Recent Advances in Electrical Systems, Hammamet, Tunisia, 22–24 December 2017; pp. 229–237. [Google Scholar]

- Chen, Y.; Liang, S.; Li, W.; Liang, H.; Wang, C. Faults and Diagnosis Methods of Permanent Magnet Synchronous Motors: A Review. Appl. Sci. 2019, 9, 2116. [Google Scholar] [CrossRef]

- Orlowska-Kowalska, T.; Wolkiewicz, M.; Pietrzak, P.; Skowron, M.; Ewert, P.; Tarchala, G.; Kowalski, C.T. Fault Diagnosis and Fault-Tolerant Control of PMSM Drives–State of the Art and Future Challenges. IEEE Access 2022, 10, 59979–60024. [Google Scholar] [CrossRef]

- Boudiaf, M.; Cherroun, L.; Benbrika, M. Real-time diagnosis of three-phase induction machine using Arduino-Uno card based on park’s circle method. Diagnostyka 2018, 19, 63–71. [Google Scholar] [CrossRef]

- Huang, S.-R.; Huang, K.-H.; Chao, K.-H.; Chiang, W.-T. Fault analysis and diagnosis system for induction motors. Comput. Electr. Eng. 2016, 54, 195–209. [Google Scholar] [CrossRef]

- Lee, J.-H.; Pack, J.-H.; Lee, I.-S. Fault Diagnosis of Induction Motor Using Convolutional Neural Network. Appl. Sci. 2019, 9, 2950. [Google Scholar] [CrossRef]

- Wolkiewicz, M.; Skowron, M. Diagnostic System for Induction Motor Stator Winding Faults Based on Axial Flux. Power Electron. Drives 2017, 2, 137–150. [Google Scholar] [CrossRef]

- Ewert, P.; Kowalski, C.T.; Orlowska-Kowalska, T. Low-Cost Monitoring and Diagnosis System for Rolling Bearing Faults of the Induction Motor Based on Neural Network Approach. Electronics 2020, 9, 1334. [Google Scholar] [CrossRef]

- ISO 20816-3:2022; Measurement and Evaluation of Machine Vibration—Part 3: Industrial Machinery with a Power Rating above 15 kW and Operating Speeds between 120 r/min and 30 000 r/min. Measurement and Evaluation of Mechanical Vibration and Shock as Applied to Machines, Vehicles and Structures. OCT: Geneva, Switzerland, 2022.

- Faiz, J.; Takbash, A.M.; Mazaheri-Tehrani, E. A Review of Application of Signal Processing Techniques for Fault Diagnosis of Induction Motors—Part I. AUT J. Electr. Eng. 2017, 49, 109–122. [Google Scholar] [CrossRef]

- Ribeiro Junior, R.F.; De Almeida, F.A.; Gomes, G.F. Fault classification in three-phase motors based on vibration signal analysis and artificial neural networks. Neural Comput. Appl. 2020, 32, 15171–15189. [Google Scholar] [CrossRef]

- Liang, H.; Chen, Y.; Liang, S.; Wang, C. Fault Detection of Stator Inter-Turn Short-Circuit in PMSM on Stator Current and Vibration Signal. Appl. Sci. 2018, 8, 1677. [Google Scholar] [CrossRef]

- Lipus, J.; Jankovych, R.; Hammer, M.; Lipus, T. Vibration and related diagnostics of motors and generators. MM Sci. J. 2016, 2016, 1639–1642. [Google Scholar] [CrossRef]

- Pawlik, P.; Lepiarczyk, D.; Dudek, R.; Ottewill, J.R.; Rzeszuciński, P.; Wojcik, M.; Tkaczyk, A. Vibroacoustic study of powertrains operated in changing conditions by means of order tracking analysis. Eksploat. Niezawodn.—Maint. Reliab. 2016, 18, 606–612. [Google Scholar] [CrossRef]

- Ewert, P.; Kowalski, C.T.; Jaworski, M. Comparison of the Effectiveness of Selected Vibration Signal Analysis Methods in the Rotor Unbalance Detection of PMSM Drive System. Electronics 2022, 11, 1748. [Google Scholar] [CrossRef]

- Rafaq, M.S.; Lee, H.; Park, Y.; Lee, S.B.; Fernandez, D.; Diaz-Reigosa, D.; Briz, F. A Simple Method for Identifying Mass Unbalance Using Vibration Measurement in Permanent Magnet Synchronous Motors. IEEE Trans. Ind. Electron. 2022, 69, 6441–6444. [Google Scholar] [CrossRef]

- Ewert, P. The Application of the Bispectrum Analysis to Detect the Rotor Unbalance of the Induction Motor Supplied by the Mains and Frequency Converter. Energies 2020, 13, 3009. [Google Scholar] [CrossRef]

- Zhang, J.; Hang, J.; Cheng, M. Diagnosis of Mechanical Unbalance Fault in Permanent Magnet Synchronous Machine Drives. Electr. Power Compon. Syst. 2016, 44, 1408–1417. [Google Scholar] [CrossRef]

- Hang, J.; Zhang, J.; Cheng, M.; Wang, Z. Fault Diagnosis of Mechanical Unbalance for Permanent Magnet Synchronous motor Drive System under Nonstationary Condition. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 3556–3562. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, J.; Ahn, G.; Youn, M.; Youn, B.D. Fault Detection of PMSM under Non-Stationary Conditions Based on Wavelet Transformation Combined with Distance Approach. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019; pp. 88–93. [Google Scholar] [CrossRef]

- Xie, T.; Wang, T.; He, Q.; Diallo, D.; Claramunt, C. A review of current issues of marine current turbine blade fault detection. Ocean Eng. 2020, 218, 108194. [Google Scholar] [CrossRef]

- Rahman, M.M.; Uddin, M.N. Online Unbalanced Rotor Fault Detection of an IM Drive Based on Both Time and Frequency Domain Analyses. IEEE Trans. Ind. Appl. 2017, 53, 4087–4096. [Google Scholar] [CrossRef]

- Pietrzak, P.; Wolkiewicz, M. Stator Winding Fault Detection of Permanent Magnet Synchronous Motors Based on the Short-Time Fourier Transform. Power Electron. Drives 2022, 7, 112–133. [Google Scholar] [CrossRef]

- Bouras, A.; Bouras, S.; Kerfali, S. Prediction of the mass unbalance of a variable speed induction motor by stator current multiple approaches. Turk. J. Electr. Eng. Comput. Sci. 2018, 26, 1056–1068. [Google Scholar] [CrossRef]

- Al-Badour, F.; Cheded, L.; Sunar, M. Non-stationary vibration signal analysis of rotating machinery via time-frequency and wavelet techniques. In Proceedings of the 10th International Conference on Information Science, Signal Processing and Their Applications (ISSPA 2010), Kuala Lumpur, Malaysia, 10–13 May 2010; pp. 21–24. [Google Scholar] [CrossRef]

- Atmaja, B.T.; Arifianto, D. Machinery fault diagnosis using independent component analysis (ICA) and Instantaneous Frequency (IF). In Proceedings of the International Conference on Instrumentation, Communication, Information Technology, and Biomedical Engineering 2009, Bandung, Indonesia, 23–25 November 2009; pp. 1–5. [Google Scholar] [CrossRef]

- Mohammad-Alikhani, A.; Pradhan, S.; Dhale, S.; Mobarakeh, B.N. A Variable Speed Fault Detection Approach for Electric Motors in EV Applications based on STFT and RegNet. In Proceedings of the 2023 IEEE Transportation Electrification Conference & Expo (ITEC), Detroit, MI, USA, 21–23 June 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Chandra, N.H.; Sekhar, A.S. Fault detection in rotor bearing systems using time frequency techniques. Mech. Syst. Signal Process. 2016, 72–73, 105–133. [Google Scholar] [CrossRef]

- Delgado-Arredondo, P.A.; Garcia-Perez, A.; Morinigo-Sotelo, D.; Osornio-Rios, R.A.; Avina-Cervantes, J.G.; Rostro-Gonzalez, H.; Romero-Troncoso, R.d.J. Comparative Study of Time-Frequency Decomposition Techniques for Fault Detection in Induction Motors Using Vibration Analysis during Startup Transient. Shock Vib. 2015, 2015, 708034. [Google Scholar] [CrossRef]

- Wisal, M.; Oh, K.-Y. A New Deep Learning Framework for Imbalance Detection of a Rotating Shaft. Sensors 2023, 23, 7141. [Google Scholar] [CrossRef] [PubMed]

- Son, T.; Hong, D.; Kim, B. Multi–Output Classification Based on Convolutional Neural Network Model for Untrained Compound Fault Diagnosis of Rotor Systems with Non–Contact Sensors. Sensors 2023, 23, 3153. [Google Scholar] [CrossRef] [PubMed]

- Bera, B.; Lin, C.-L.; Huang, S.-C.; Liang, J.-W.; Lin, P.T. Establishing a Real-Time Multi-Step Ahead Forecasting Model of Unbalance Fault in a Rotor-Bearing System. Electronics 2023, 12, 312. [Google Scholar] [CrossRef]

- Glowacz, A. Recognition of Acoustic Signals of Commutator Motors. Appl. Sci. 2018, 8, 2630. [Google Scholar] [CrossRef]

- Li, L.; Cao, S.; Li, J.; Nie, R.; Hou, L. Review of Rotor Balancing Methods. Machines 2021, 9, 89. [Google Scholar] [CrossRef]

- Shibo, Z.; Xingmin, R.; Qingyang, Z.; Kuan, L.; Chao, F.; Yongfeng, Y. Transient dynamic balancing of the rotor system with uncertainty. Mech. Syst. Signal Process. 2022, 171, 108894. [Google Scholar] [CrossRef]

- MacCamhaoil, M. Static and Dynamic Balancing of Rigid Rotors; Application Note BO 0276-12; Bruel & Kjaer: Naerum, Denmark, 2016; pp. 1–20. Available online: https://www.yumpu.com/en/document/read/7936761/static-and-dynamicbalancing-of-rigid-rotors (accessed on 14 January 2024).

- AbdulBary, M.; Embaby, A.; Gomaa, F. Fault Diagnosis in Rotating System Based on Vibration Analysis. ERJ Eng. Res. J. 2021, 44, 285–294. [Google Scholar] [CrossRef]

- Yamamoto, G.K.; Da Costa, C.; Da Silva Sousa, J.S. A smart experimental setup for vibration measurement and imbalance fault detection in rotating machinery. Case Stud. Mech. Syst. Signal Process. 2016, 4, 8–18. [Google Scholar] [CrossRef]

- Mohammadi, E.; Fadaeinedjad, R.; Moschopoulos, G. Performance Investigation of a Stall-Regulated Wind Turbine Considering Rotor Imbalance Faults. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 2469–2474. [Google Scholar] [CrossRef]

- Korkua, S.; Jain, H.; Lee, W.-J.; Kwan, C. Wireless health monitoring system for vibration detection of induction motors. In Proceedings of the 2010 IEEE Industrial and Commercial Power Systems Technical Conference—Conference Record, Tallahassee, FL, USA, 9–13 May 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Luczak, D. Mathematical model of multi-mass electric drive system with flexible connection. In Proceedings of the 2014 19th International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 2–5 September 2014; pp. 590–595. [Google Scholar] [CrossRef]

- Brock, S.; Luczak, D. Speed control in direct drive with non-stiff load. In Proceedings of the 2011 IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011; pp. 1937–1942. [Google Scholar] [CrossRef]

- Janiszewski, D. Real-time control of drive with elestic coupling based on motor position measured only. In Proceedings of the 2011 IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011; pp. 1931–1936. [Google Scholar] [CrossRef]

- Szczepanski, R.; Kaminski, M.; Tarczewski, T. Auto-Tuning Process of State Feedback Speed Controller Applied for Two-Mass System. Energies 2020, 13, 3067. [Google Scholar] [CrossRef]

- Derugo, P.; Szabat, K. Damping of torsional vibrations of two-mass system using adaptive low computational cost fuzzy PID controller. In Proceedings of the 2015 IEEE 11th International Conference on Power Electronics and Drive Systems, Sydney, Australia, 9–12 June 2015; pp. 1162–1165. [Google Scholar] [CrossRef]

- Wicher, B.; Nowopolski, K. Model of ADRC speed control system for complex mechanical object with backlash. In Proceedings of the 2017 22nd International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzyzdroje, Poland, 28–31 August 2017; pp. 379–383. [Google Scholar] [CrossRef]

- Galardini, D.G.; Nordin, M.; Gutman, P.O. Robust PI tuning for an elastic two-mass system. In Proceedings of the 1997 European Control Conference (ECC), Brussels, Belgium, 1–7 July 1997; pp. 979–984. [Google Scholar] [CrossRef]

- Orlowska-Kowalska, T.; Szabat, K. Damping of Torsional Vibrations in Two-Mass System Using Adaptive Sliding Neuro-Fuzzy Approach. IEEE Trans. Ind. Inform. 2008, 4, 47–57. [Google Scholar] [CrossRef]

- Janiszewski, D. Extended Kalman Filter Based Speed Sensorless PMSM Control with Load Reconstruction. In Proceedings of the IECON 2006—32nd Annual Conference on IEEE Industrial Electronics, Paris, France, 6–10 November 2006; pp. 1465–1468. [Google Scholar] [CrossRef]

- Wicher, B. ADRC Load Position Controller for Two Mass System with Elastic Joint and Backlash. In Proceedings of the 2018 23rd International Conference on Methods & Models in Automation & Robotics (MMAR), Miedzyzdroje, Poland, 27–30 August 2018; pp. 333–338. [Google Scholar] [CrossRef]

- Deskur, J.; Pajchrowski, T.; Zawirski, K. Speed controller for a drive with complex mechanical structure and variable parameters. In Proceedings of the 2014 16th International Power Electronics and Motion Control Conference and Exposition, Antalya, Turkey, 21–24 September 2014; pp. 762–767. [Google Scholar] [CrossRef]

- Brock, S.; Deskur, J.; Janiszewski, D.; Muszyński, R. Active damping of torsional vibrations in servodrives. Power Electron. Electr. Driv.—Sel. Probl. 2007, 271–290. [Google Scholar] [CrossRef]

- Li, Q.; Wang, W.; Chen, L.; Sun, D. Rotor-System Log-Decrement Identification Using Short-Time Fourier-Transform Filter. Int. J. Rotating Mach. 2015, 2015, 809785. [Google Scholar] [CrossRef]

- Satpathi, K.; Yeap, Y.M.; Ukil, A.; Geddada, N. Short-Time Fourier Transform Based Transient Analysis of VSC Interfaced Point-to-Point DC System. IEEE Trans. Ind. Electron. 2018, 65, 4080–4091. [Google Scholar] [CrossRef]

- Deskur, J.; Muszynski, R. The problems of high dynamic drive control under circumstances of elastic transmission. In Proceedings of the 2008 13th International Power Electronics and Motion Control Conference, Poznan, Poland, 1–3 September 2008; pp. 2227–2234. [Google Scholar] [CrossRef]

- Bishop, C.M. Neural Networks for Pattern Recognition; Clarendon Press: New York, NY, USA; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Haykin, S.S. Neural Networks: A Comprehensive Foundation, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

| Parameter | Explanation | |

|---|---|---|

| Input data | Analyzed signal | Vibration acceleration in the Y axis |

| Input data | Amplitudes of: fr, 2fr, 3fr, 4fr and current angular velocity | |

| Calculation of kfr amplitude | An averaged value within +/−5% of the kfr frequency width calculated from the current speed value | |

| Normalization of input data | Yes, in the range <0, 1> | |

| The number of elements of the training vector | 250 | |

| The number of elements of the testing vector | 250 | |

| Neural network | Type of neural network | Feed-forward backpropagation network |

| Transfer function of hidden layers | Hyperbolic tangent sigmoid transfer function (tansig) | |

| Transfer function of output layer | Linear transfer function (purelin) | |

| Network training function | Levenberg-Marquardt backpropagation (trainlm) | |

| Weight/bias learning function | Gradient descent with momentum weight and bias learning function (learngdm) | |

| Performance function | Mean squared normalized error performance function (mse) | |

| Maximum number of epochs to train | 2000 | |

| Performance goal | 1 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ewert, P.; Wicher, B.; Pajchrowski, T. Application of the STFT for Detection of the Rotor Unbalance of a Servo-Drive System with an Elastic Interconnection. Electronics 2024, 13, 441. https://doi.org/10.3390/electronics13020441

Ewert P, Wicher B, Pajchrowski T. Application of the STFT for Detection of the Rotor Unbalance of a Servo-Drive System with an Elastic Interconnection. Electronics. 2024; 13(2):441. https://doi.org/10.3390/electronics13020441

Chicago/Turabian StyleEwert, Pawel, Bartłomiej Wicher, and Tomasz Pajchrowski. 2024. "Application of the STFT for Detection of the Rotor Unbalance of a Servo-Drive System with an Elastic Interconnection" Electronics 13, no. 2: 441. https://doi.org/10.3390/electronics13020441

APA StyleEwert, P., Wicher, B., & Pajchrowski, T. (2024). Application of the STFT for Detection of the Rotor Unbalance of a Servo-Drive System with an Elastic Interconnection. Electronics, 13(2), 441. https://doi.org/10.3390/electronics13020441