Demagnetization Fault Diagnosis of a PMSM for Electric Drilling Tools Using GAF and CNN

Abstract

1. Introduction

2. Demagnetization Mechanism and Fault Simulation of PMSM

2.1. Demagnetization Mechanism

2.2. Modeling of the Thermal Demagnetization of a PM

2.3. Demagnetization Fault Simulation of the PMSM

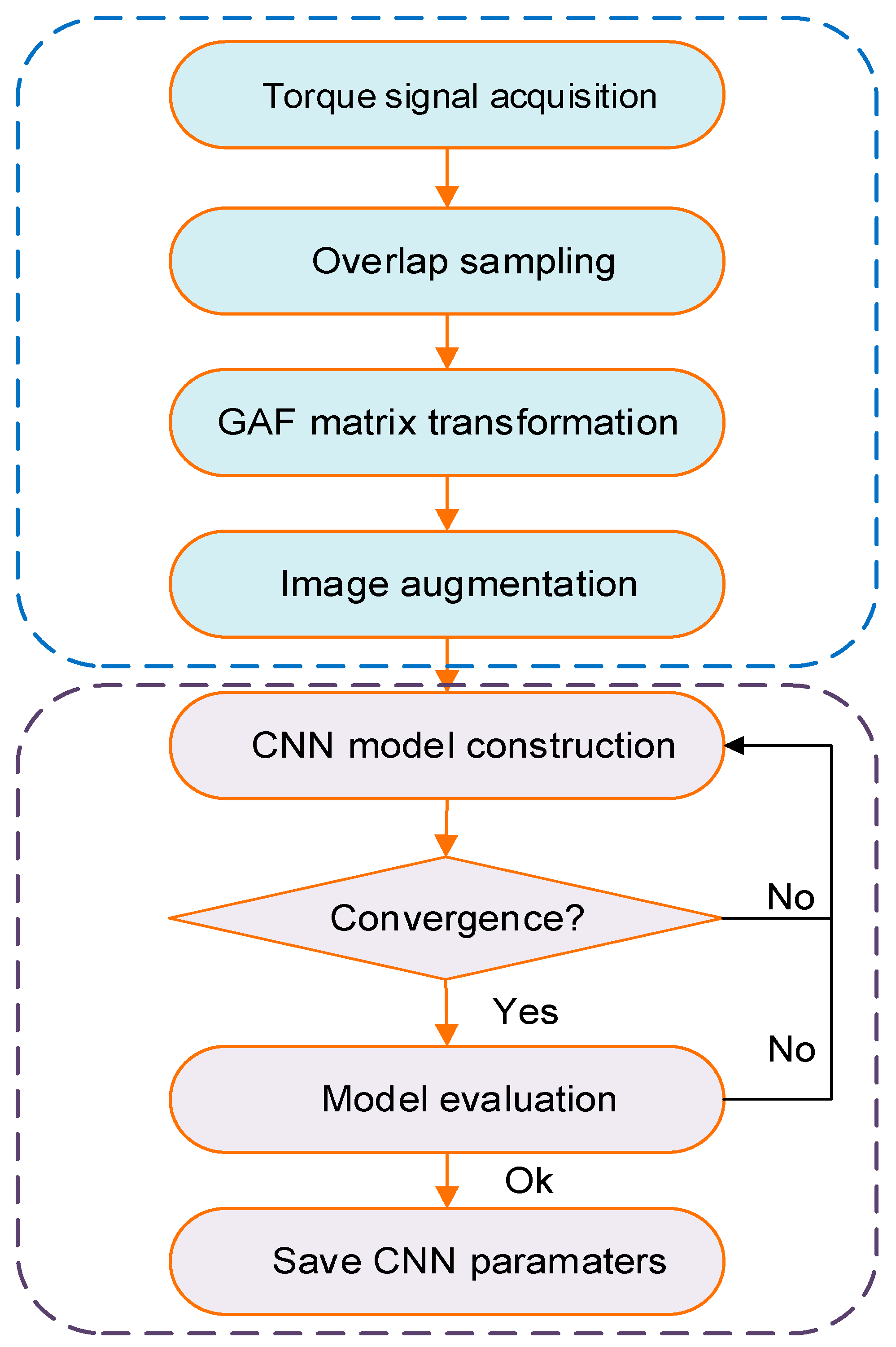

3. Image Transformation and Augmentation

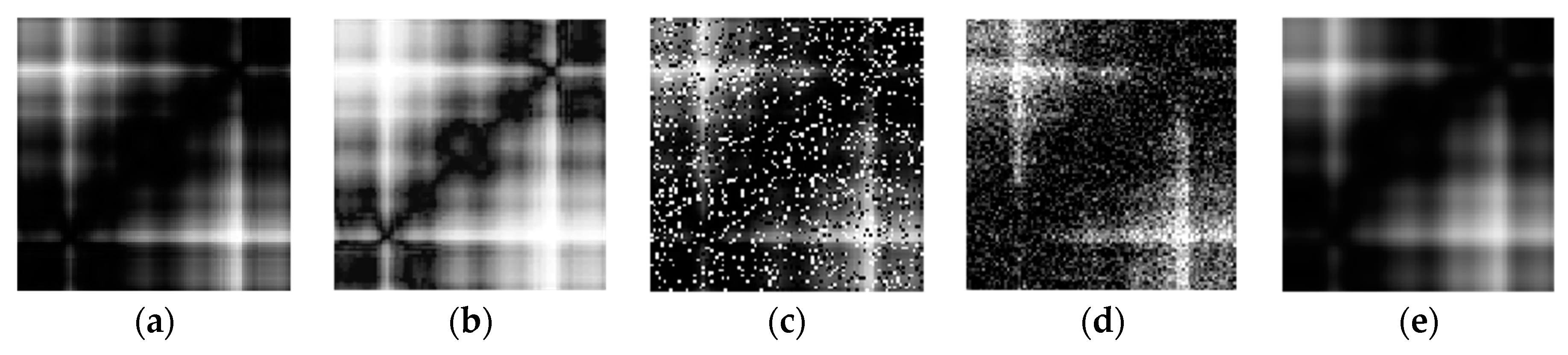

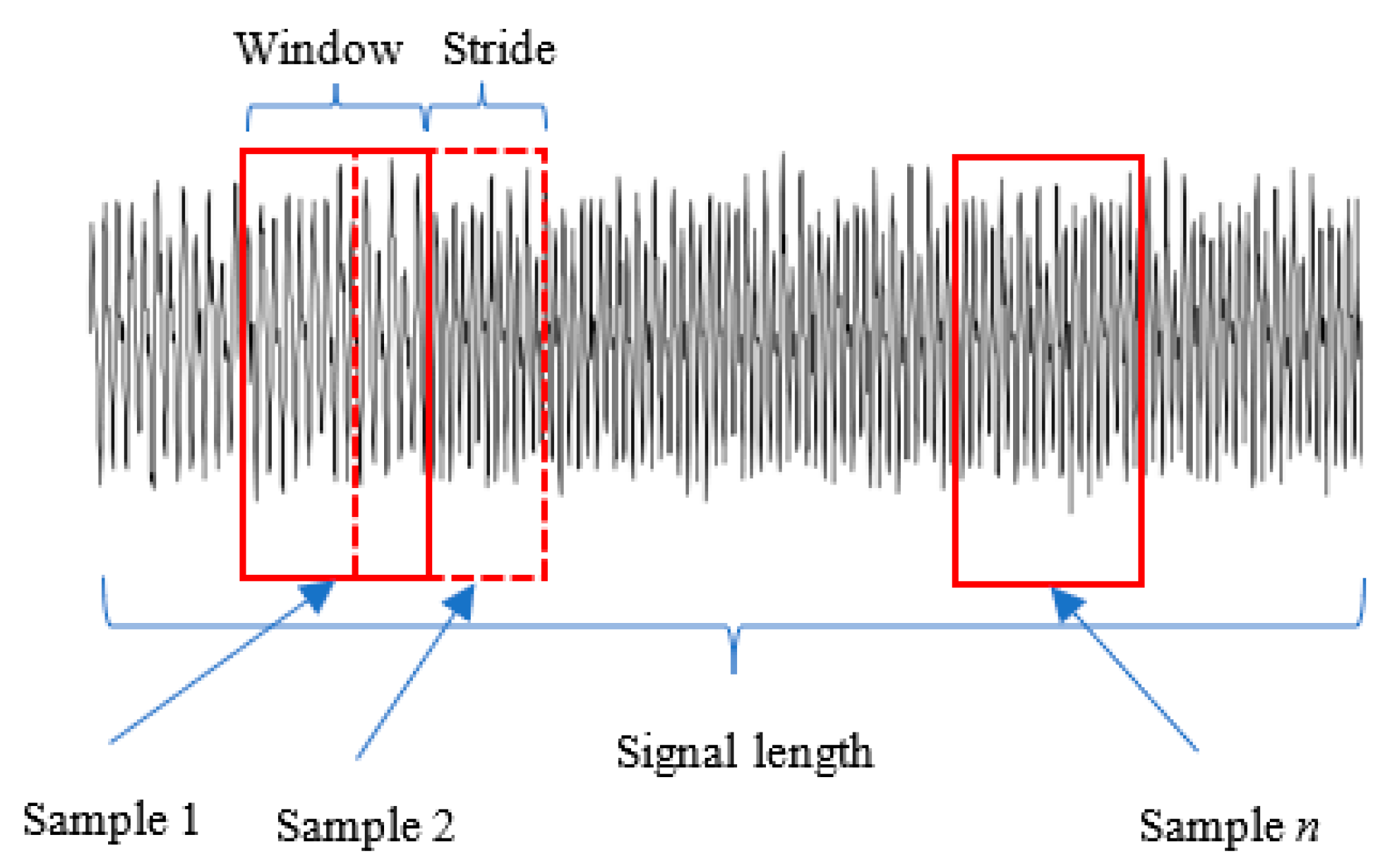

3.1. Image Transformation of the Torque Signal based on GAF

3.2. Image Augmentation

3.2.1. Image Contrast Increasing

3.2.2. Noise Increasing

3.2.3. Noise Blurring

4. Demagnetization Fault Recognition Based on CNN

4.1. Dataset Establishment

4.2. Structure of the Designed CNN

4.3. Analysis of the Classification Results and Visualization of Features

5. Experimental Verification

5.1. Experimental Platform Establishment

5.2. Model Evaluation with the Experimental Data

6. Discussion and Conclusions

- (1)

- The output torque signal of a PMSM can be used as an effective means of gaining information on a demagnetization fault. The GASF matrix transformation makes fault feature extraction easier.

- (2)

- Transforming the one-dimensional torque signal into gray images for demagnetization fault diagnosis requires less data than processing data directly, reduces the computer storage space, and improves the calculation rate effectively at the same time.

- (3)

- Compared with PD and MD, the proposed method has higher diagnostic accuracy for UD with torque signal.

- (4)

- The proposed demagnetization recognition method is immune to the loads, which makes full use of the advantages of CNN image recognition, and the designed deep network model has good stability and robustness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Du, Y.; Wu, L.; Zhan, H.; Ruan, G.; Fang, Y. Investigation of post demagnetization unbalanced magnetic force in PM machines considering short circuit faults. IEEE Trans. Transp. Electrif. 2021, 7, 2728–2742. [Google Scholar] [CrossRef]

- Prieto, M.D.; Espinosa, A.G.; Ruiz, J.R.R.; Urresty, J.C.; Ortega, J.A. Feature extraction of demagnetization faults in permanent-magnet synchronous motors based on box-counting fractal dimension. IEEE Trans. Ind. Electron. 2011, 58, 1594–1605. [Google Scholar] [CrossRef]

- Liu, Z.; Xiao, W.; Cui, J.; Mei, L. Application of an information fusion method to the incipient fault diagnosis of the drilling permanent magnet synchronous motor. J. Pet. Sci. Eng. 2022, 219, 111124. [Google Scholar] [CrossRef]

- Zhu, M.; Yang, B.; Hu, W.; Feng, G.; Kar, N.C. Vold-Kalman filtering order tracking based rotor demagnetization detection in PMSM. IEEE Trans. Ind. Appl. 2020, 55, 5768–5778. [Google Scholar] [CrossRef]

- Song, J.; Zhao, J.; Dong, F.; Zhao, J.; Song, X. Demagnetization fault detection for double-sided permanent magnet linear motor based on three-line magnetic signal signature analysis. IEEE/ASME Trans. Mechatron. 2020, 25, 2815–2827. [Google Scholar] [CrossRef]

- Zhu, M.; Hu, W.; Kar, N.C. Acoustic noise-based uniform permanent-magnet demagnetization detection in SPMSM for high-performance PMSM drive. IEEE Trans. Transp. Electrif. 2018, 4, 303–313. [Google Scholar] [CrossRef]

- Gritli, Y.; Rossi, C.; Casadei, D.; Zarri, L.; Filippetti, F. Demagnetizations diagnosis for permanent magnet synchronous motors based on advanced wavelet analysis. In Proceedings of the 20th International Conference on Electrical Machines (ICEM), Marseille, France, 2–5 September 2012. [Google Scholar]

- Moosavi, S.S.; Djerdir, A.; Amirat, Y.A.; Khaburi, D.A. Demagnetization fault diagnosis in permanent magnet synchronous motors:A review of the state-of-the-art. J. Magn. Magn. Mater. 2015, 391, 203–212. [Google Scholar] [CrossRef]

- Faiz, J.; Mazaheri-Tehrani, E. Demagnetization modeling and fault diagnosing techniques in permanent magnet machines under stationary and nonstationary conditions: An overview. IEEE Trans. Ind. Appl. 2017, 53, 2772–2785. [Google Scholar] [CrossRef]

- Candelo-Zuluaga, C.; Riba, J.R.; Thangamuthu, D.V.; Garcia, A. Detection of partial demagnetization faults in five-phase permanent magnet assisted synchronous reluctance machines. Energies 2020, 13, 3496. [Google Scholar] [CrossRef]

- Huang, F.; Zhang, X.; Qin, G.; Xie, J.; Peng, J.; Huang, S.; Long, Z.; Tang, Y. Demagnetization Fault Diagnosis of Permanent Magnet Synchronous Motors Using Magnetic Leakage Signals. IEEE Trans. Ind. Inf. 2023, 19, 6105–6116. [Google Scholar] [CrossRef]

- Ruiz, J.R.R.; Rosero, J.A.; Espinosa, A.G.; Romeral, L. Detection of demagnetization faults in permanent-magnet synchronous motors under nonstationary conditions. IEEE Trans. Magn. 2009, 45, 2961–2969. [Google Scholar] [CrossRef]

- Guo, X.; Chen, L.; Shen, C. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement 2016, 93, 490–502. [Google Scholar] [CrossRef]

- Park, Y.; Fernandez, D.; Lee, S.B.; Hyun, D.; Jeong, M.; Kommuri, S.K.; Cho, C.; Reigosa, D.D.; Briz, F. Online detection of rotor eccentricity and demagnetization faults in PMSMs based on Hall-effect field sensor measurements. IEEE Trans. Ind. Appl. 2019, 55, 2499–2509. [Google Scholar] [CrossRef]

- Song, J.; Zhao, J.; Dong, F.; Zhao, J.; Xu, L.; Yao, Z. A new demagnetization fault recognition and classification method for DPMSLM. IEEE Trans. Ind. Inf. 2020, 16, 1559–1570. [Google Scholar] [CrossRef]

- Xia, M.; Li, T.; Xu, L.; Liu, L.; de Silva, C.W. Fault diagnosis for rotating machinery using multiple sensors and convolutional neural networks. IEEE/ASME Trans Mechatron. 2018, 23, 101–110. [Google Scholar] [CrossRef]

- Jiang, G.; He, H.; Yan, J.; Xie, P. Multiscale convolutional neural networks for fault diagnosis of wind turbine gearbox. IEEE Trans. Ind. Electron. 2019, 66, 3196–3207. [Google Scholar] [CrossRef]

- Liu, W.; Ma, T.; Xie, Q.; Tao, D.; Cheng, J. LMAE: A large margin auto-encoders for classification. signal processing. Signal Process 2017, 141, 137–143. [Google Scholar] [CrossRef]

- Tran, V.T.; Althobiani, F.; Ball, A. An approach to fault diagnosis of reciprocating compressor valves using Teager-Kaiser energy operator and deep belief net-works. Expert Syst. Appl. 2014, 41, 4113–4122. [Google Scholar] [CrossRef]

- Mandal, S.; Santhi, B.; Sridha, S.; Vinolia, K.; Swaminathan, P. Nuclear power plant thermocouple sensor-Fault detection and classification using deep learning and generalized likelihood ratio test. IEEE Trans. Nucl. Sci. 2017, 64, 1526–1534. [Google Scholar] [CrossRef]

- Cho, H.C.; Knowles, J.; Fadali, M.S.; Lee, K.S. Fault detection and isolation of induction motors using recurrent neural networks and dynamic bayesian. IEEE Trans. Control Syst. Technol. 2010, 18, 430–437. [Google Scholar] [CrossRef]

- Sun, W.; Zhao, R.; Yan, R.; Shao, S.; Chen, X. Convolutional discriminative feature learning for induction motor fault diagnosis. IEEE Trans. Ind. Inf. 2017, 13, 1350–1359. [Google Scholar] [CrossRef]

- Skowron, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Detection of Permanent Magnet Damage of PMSM Drive Based on Direct Analysis of the Stator Phase Currents Using Convolutional Neural Network. IEEE Trans. Ind. Electron. 2022, 69, 13665–13675. [Google Scholar] [CrossRef]

- Faiz, J.; Nejadi-Koti, H. Demagnetization fault indexes in permanent magnet synchronous motors-an overview. IEEE Trans. Magn. 2016, 52, 8201511. [Google Scholar] [CrossRef]

- Kao, I.H.; Wang, W.J.; Lai, Y.H.; Perng, J.W. Analysis of permanent magnet synchronous motor fault diagnosis based on learning. IEEE Trans. Instrum. Meas. 2019, 68, 310–324. [Google Scholar] [CrossRef]

- Van, T.D.; Ui-Pil, C. Signal model-based fault detection and diagnosis for induction motors using features of vibration signal in two-dimension domain. J. Mech. Eng. 2011, 57, 655–666. [Google Scholar]

- Uddin, J.; Islam, M.R.; Kim, J.M.; Kim, C.H. A two-dimensional fault diagnosis model of induction motors using a Gabor filter on segmented images. Int. J. Control Autom. 2016, 9, 11–22. [Google Scholar] [CrossRef]

- Borecki, M.; Rychlik, A.; Vrublevskyi, O.; Olejnik, A.; Korwin-Pawlowski, M.L. Method of Non-Invasive determination of wheel rim technical condition using vibration measurement and artificial neural network. Measurement 2021, 185, 110050. [Google Scholar] [CrossRef]

- Sun, Z.; Machlev, R.; Wang, Q.; Belikov, J.; Levron, Y.; Baimel, D. A public data-set for synchronous motor electrical faults diagnosis with CNN and LSTM reference classifiers. Energy AI 2023, 14, 100274. [Google Scholar] [CrossRef]

- Kaya, Y.; Kuncan, M.; Kaplan, K.; Minaz, M.R.; Ertunc, H.M. A new feature extraction approach based on one dimensional gray level co-occurrence matrices for bearing fault classification. J. Exp. Theor. Artif. Intell. 2021, 33, 161–178. [Google Scholar] [CrossRef]

- Li, Z.; Wu, Q.; Yang, S.; Chen, X. Diagnosis of rotor demagnetization and eccentricity faults for IPMSM based on deep CNN and image recognition. Complex Intell. Syst. 2022, 8, 5469–5488. [Google Scholar] [CrossRef]

- Lin, L.; Wang, D.; Zhao, S.; Chen, L.; Huang, N. Power quality disturbance feature selection and pattern recognition based on image enhancement techniques. IEEE Access 2019, 7, 67889–67904. [Google Scholar] [CrossRef]

- Liang, H.; Cao, J.; Zhao, X. Average descent rate singular value decomposition and two-dimensional residual neural network for fault diagnosis of rotating machinery. IEEE Trans. Instrum. Meas. 2022, 71, 3512616. [Google Scholar] [CrossRef]

- Gritli, Y.; Tani, A.; Rossi, C.; Casadei, D. Assessment of current and voltage signature analysis for the diagnosis of rotor magnet demagnetization in five-phase AC permanent magnet generator drives. Math. Comput. Simul. 2019, 158, 91–106. [Google Scholar] [CrossRef]

- Chakraborty, S.; Keller, E.; Ray, A.; Mayer, J. Detection and estimation of demagnetization faults in permanent magnet synchronous motors. Electr. Power Syst. Res. 2013, 96, 225–236. [Google Scholar] [CrossRef]

- Huang, G.; Li, J.; Fukushima, E.F.; Zhang, C.; He, J.; Zhao, K. An improved equivalent-input-disturbance approach for PMSM drive with demagnetization fault. ISA Trans. 2020, 105, 120–128. [Google Scholar] [CrossRef]

- Gao, W.; Jin, H.; Yang, G. Series arc fault diagnosis method of photovoltaic arrays based on GASF and improved DCGAN. Adv. Eng. Inf. 2022, 54, 101809. [Google Scholar] [CrossRef]

- Shorten, C.; Khoshgoftaar, T.M. A survey on image data augmentation for deep learning. J. Big Data 2019, 6, 60. [Google Scholar] [CrossRef]

- Gu, J.; Wang, Z.; Kuen, J.; Ma, L.; Shahroudy, A.; Shuai, B. Recent advances in convolutional neural networks. Pattern Recognit. 2018, 77, 354–377. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Rated power (kW) | 95 |

| Rated speed (rpm) | 300 |

| Rated voltage (V) | 1140 |

| Rated current (A) | 71.4 |

| Magnet material | NdFeB |

| Number of pole pairs | 7 |

| Length (mm) | 7450 |

| Winding connection | 2Y |

| The thickness of the magnet (mm) | 6.8 |

| Number of slots | 12 |

| Demagnetization Type and Degree | Number of Samples | Fault Label | Operating State |

|---|---|---|---|

| Healthy | 9500 | 0 | Speed: 300 rpm; Loads: 0, 1/4 TN, 1/2TN, 3/4TN, and TN. |

| UD (10%) | 9500 | 1 | |

| PD (N1:30%) | 9500 | 2 | |

| MD (N1:30% remaining PMs:10%) | 9500 | 3 |

| Name of the Parameter | Value |

|---|---|

| Number of convolution layers | 3 |

| Convolution kernel size for each layer | 3 × 3 |

| Number of convolution kernels per layer | 20-40-40 |

| Activation function | ReLU |

| Pooling method | Max |

| Pooling size | 2 × 2 |

| Probability of dropout layer | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Cui, J.; Xiao, W.; Mei, L.; Yu, X. Demagnetization Fault Diagnosis of a PMSM for Electric Drilling Tools Using GAF and CNN. Electronics 2024, 13, 189. https://doi.org/10.3390/electronics13010189

Zhang Q, Cui J, Xiao W, Mei L, Yu X. Demagnetization Fault Diagnosis of a PMSM for Electric Drilling Tools Using GAF and CNN. Electronics. 2024; 13(1):189. https://doi.org/10.3390/electronics13010189

Chicago/Turabian StyleZhang, Qingxue, Junguo Cui, Wensheng Xiao, Lianpeng Mei, and Xiaolong Yu. 2024. "Demagnetization Fault Diagnosis of a PMSM for Electric Drilling Tools Using GAF and CNN" Electronics 13, no. 1: 189. https://doi.org/10.3390/electronics13010189

APA StyleZhang, Q., Cui, J., Xiao, W., Mei, L., & Yu, X. (2024). Demagnetization Fault Diagnosis of a PMSM for Electric Drilling Tools Using GAF and CNN. Electronics, 13(1), 189. https://doi.org/10.3390/electronics13010189