Analysis of Voltage Control Strategies for DC Microgrid with Multiple Types of Energy Storage Systems

Abstract

1. Introduction

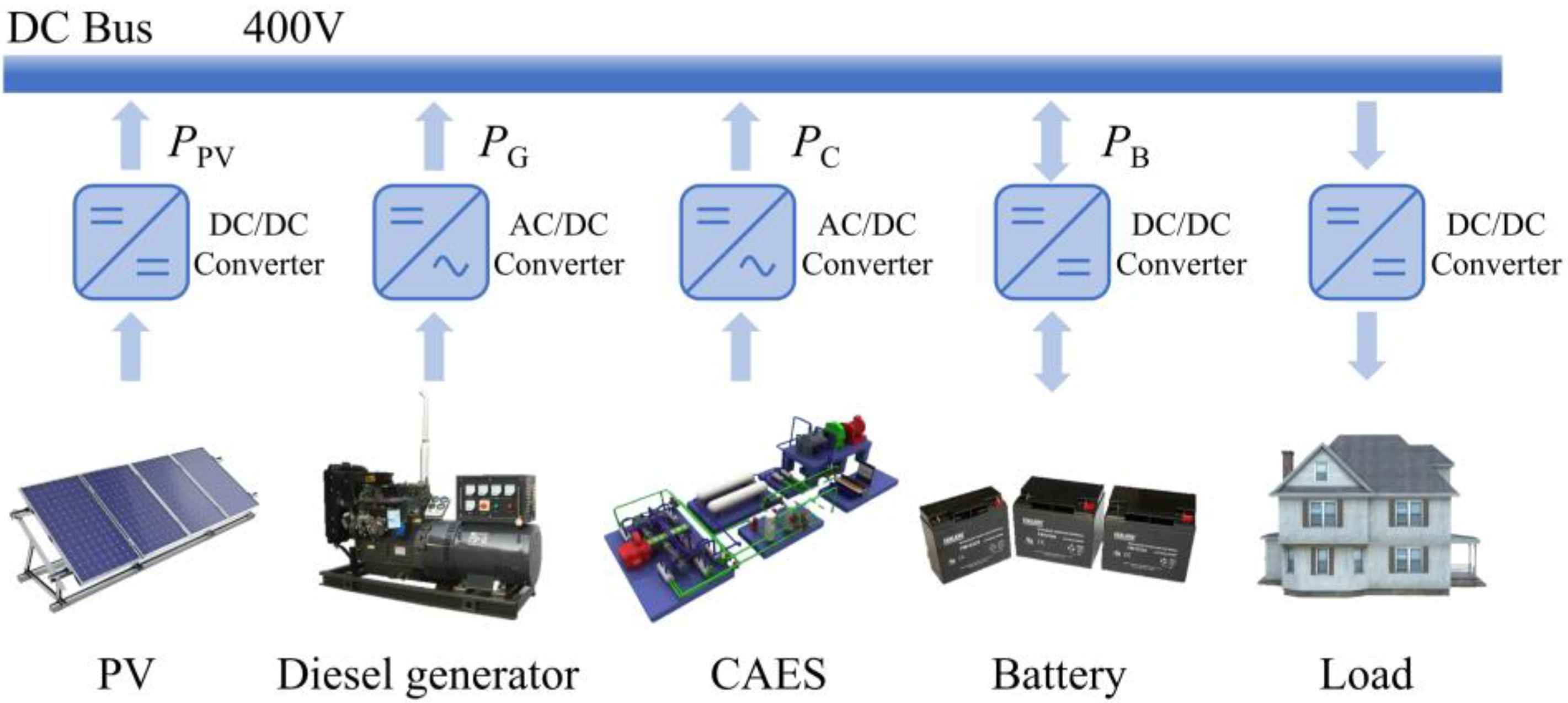

2. DC Microgrid System Structure and Dynamic Modeling of Its Constituent Units

2.1. DC Microgrid System Structure

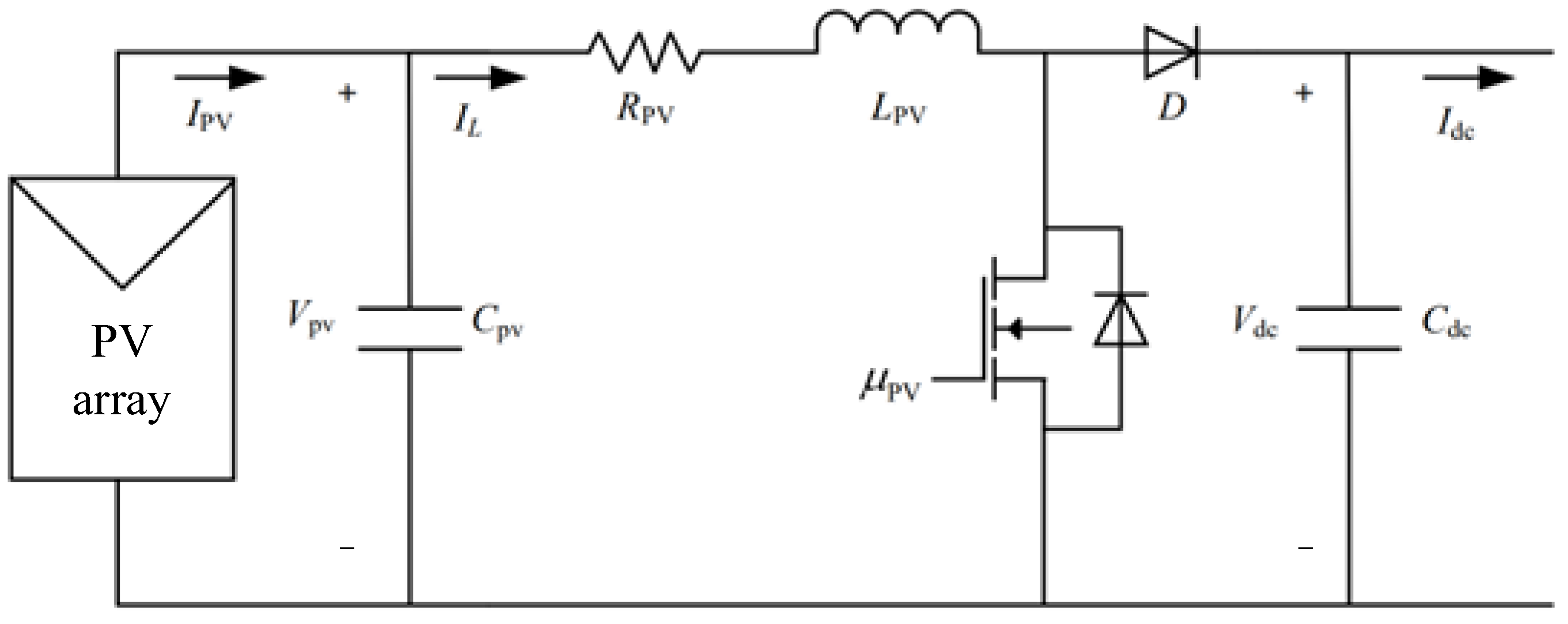

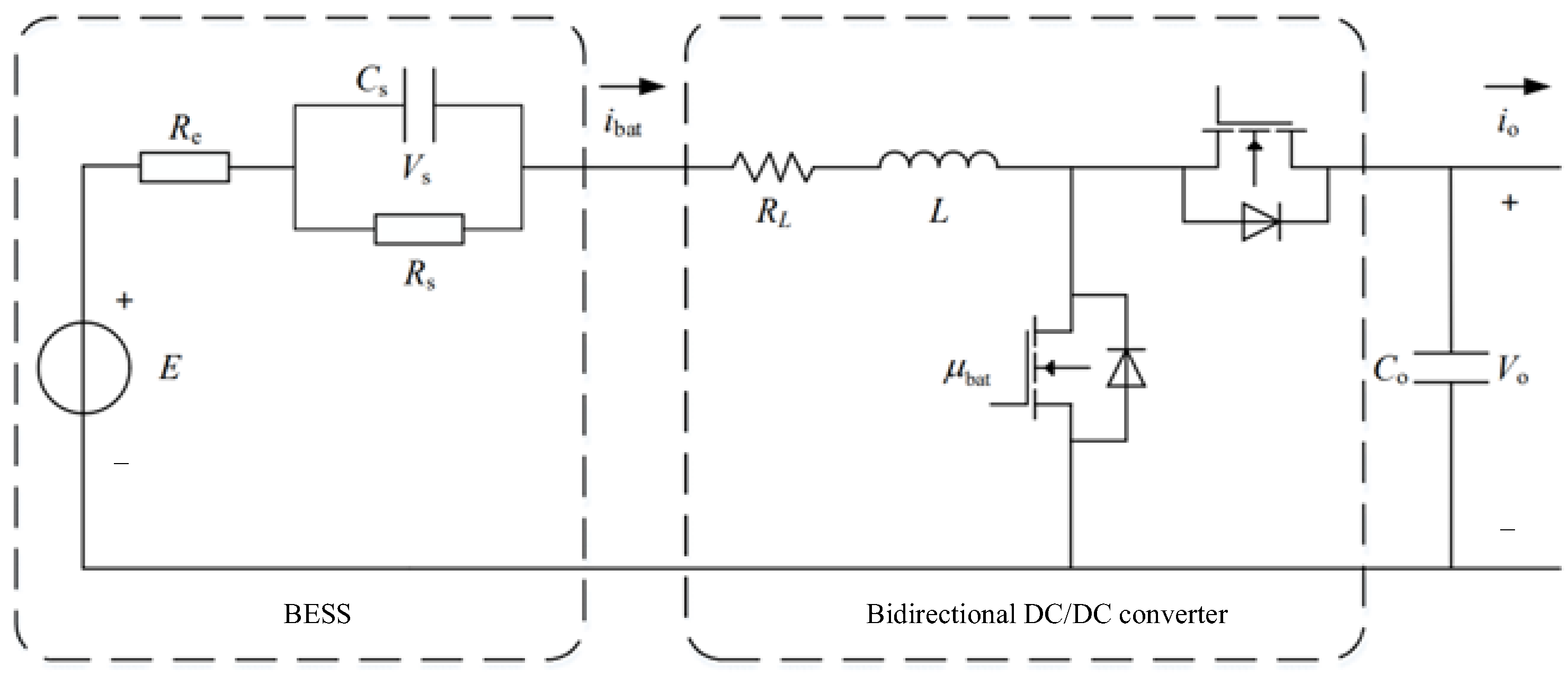

2.2. Dynamic Modeling and Characteristic Analysis of Each Unit in DC Microgrid

2.2.1. Modeling of Photovoltaic Power Generation Unit

2.2.2. Modeling of Diesel Generator

2.2.3. Modeling of Battery Energy Storage

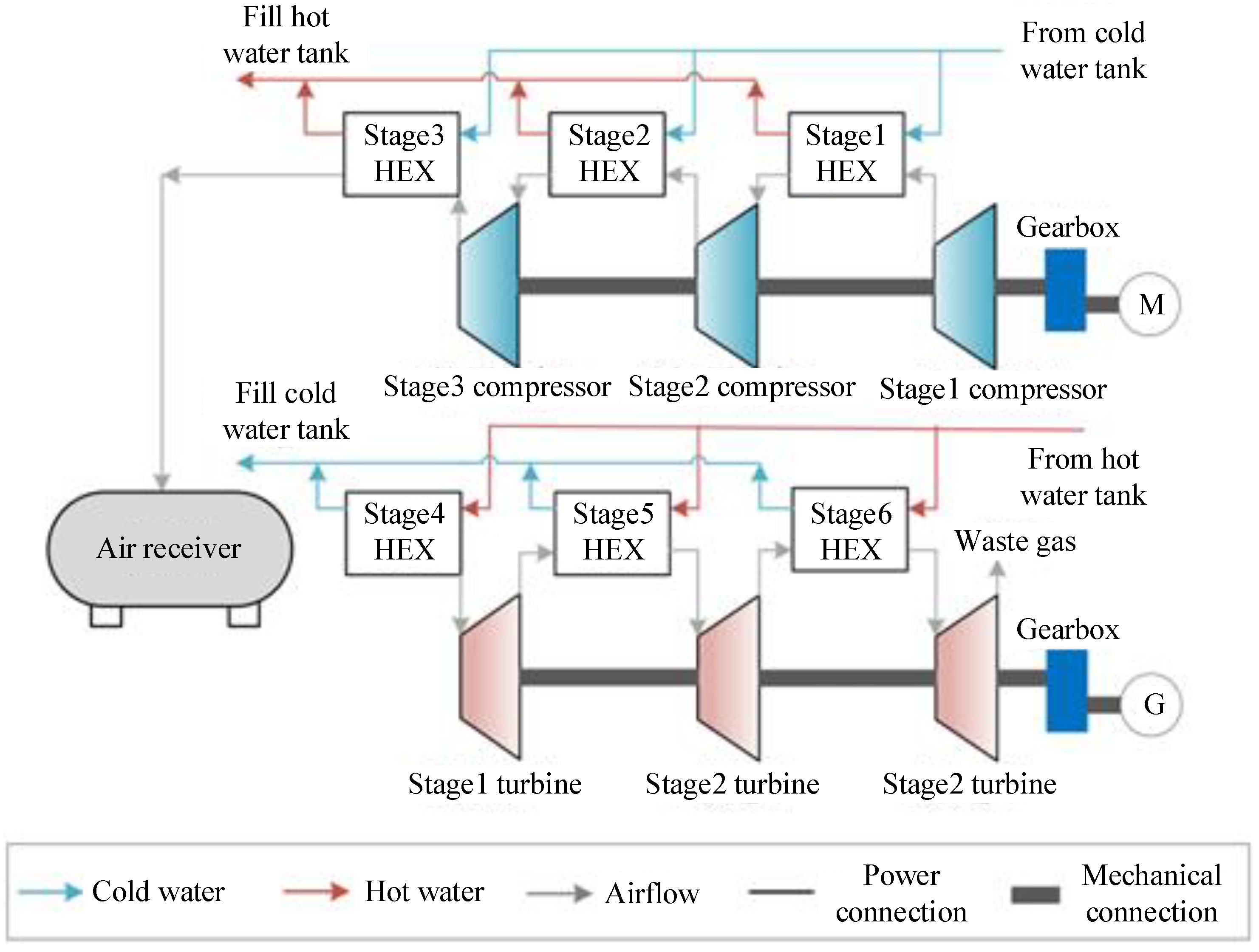

2.2.4. AA-CAES System Modeling

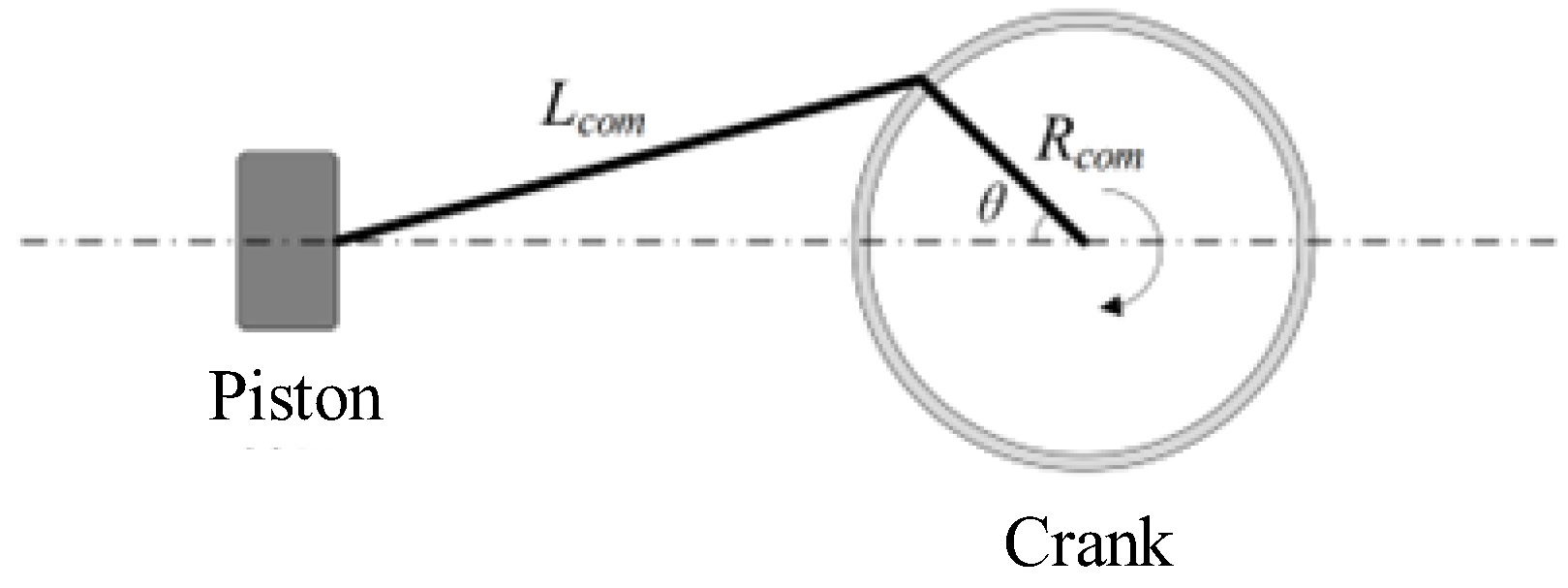

- 1.

- Piston compressor model

- 2.

- Radial turbine model

- 3.

- Air chamber model

- 4.

- Shell and tube heat exchanger model

3. Control Strategy of Independent DC Microgrid with Composite Energy Storage

3.1. Control Strategy of DC Microgrid System

3.1.1. MPPT Control of Photovoltaic Power Generation Unit

3.1.2. Droop Control of Diesel Generator and Energy Storage Unit

3.2. PI parameter Tuning of System Controller

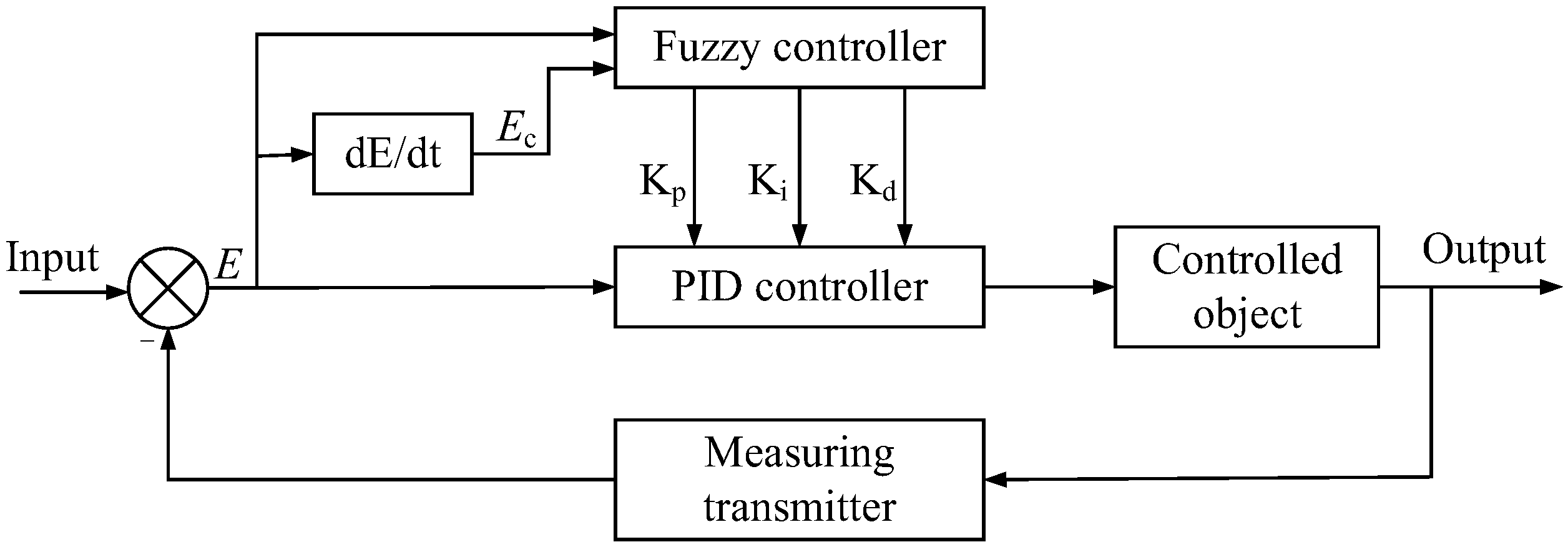

3.2.1. Fuzzy PI Control

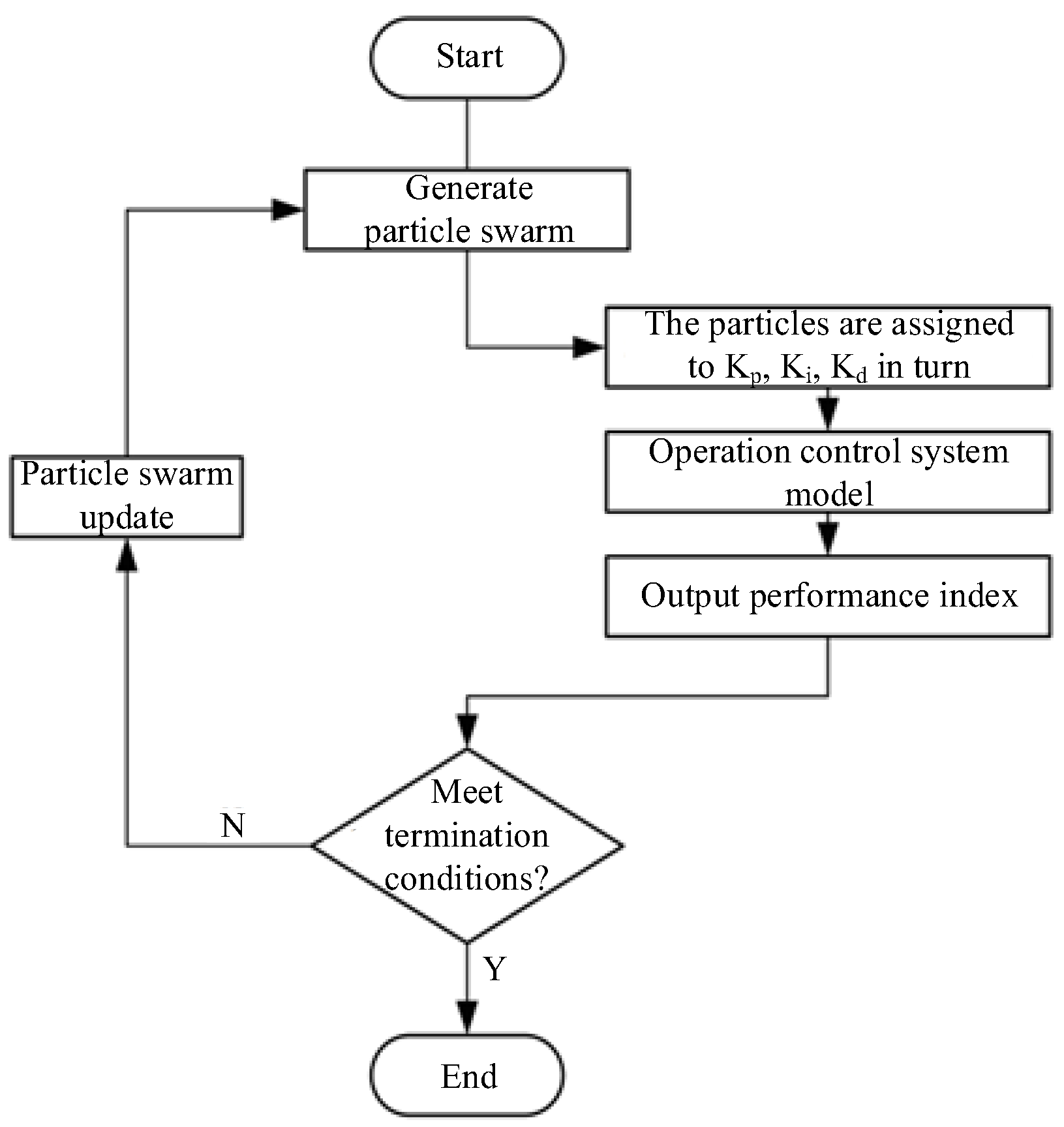

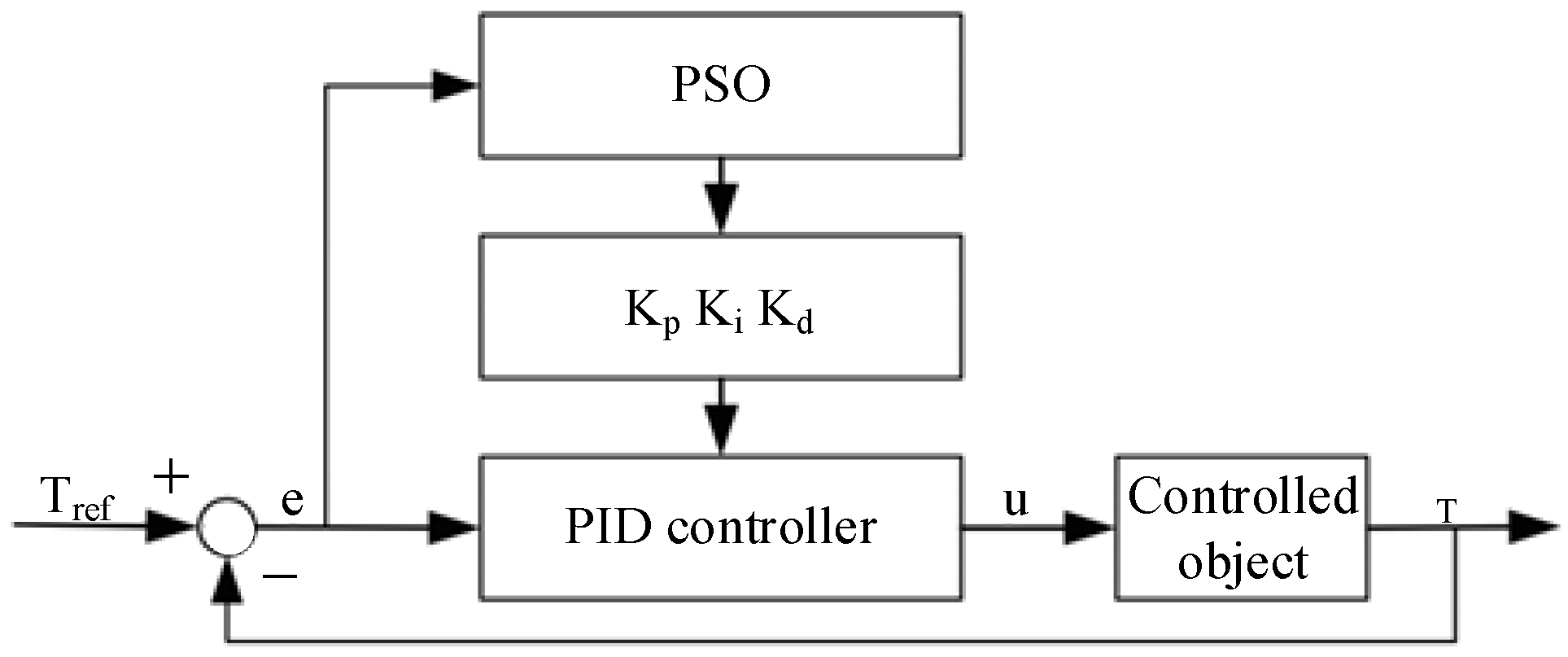

3.2.2. PSO PI Control

- (1)

- Initialize. Set parameters such as population size, iteration times and boundary conditions, and initialize the position, speed and fitness of particles.

- (2)

- Assignment. The generated population particles are assigned to the proportional and integral variables of the PI controller of each generation unit in turn, and the model output error performance index is run.

- (3)

- Judgment. Judge whether the algorithm reaches the set number of iterations or whether the ITAE value of the simulation model output is less than the set minimum fitness value. If the number of algorithm iterations is greater than the set number or the ITAE value is less than the set minimum fitness value, the algorithm is terminated. If the end condition of the algorithm is not met, each particle in the particle population will return to (2) after updating its position and speed and will exit the cycle until the exit condition of the algorithm is met.

4. Simulation Test

4.1. Simulation System and Parameters

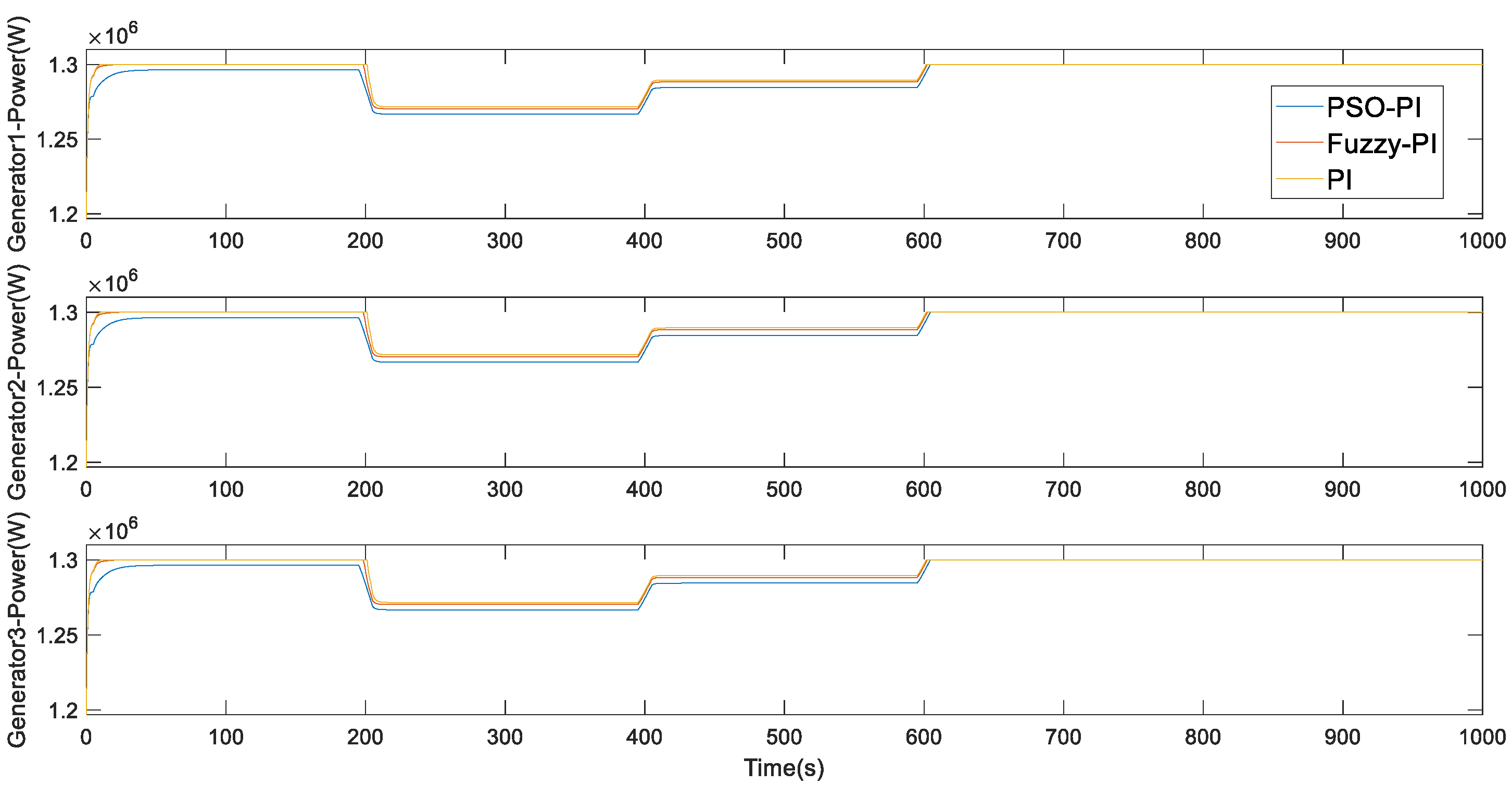

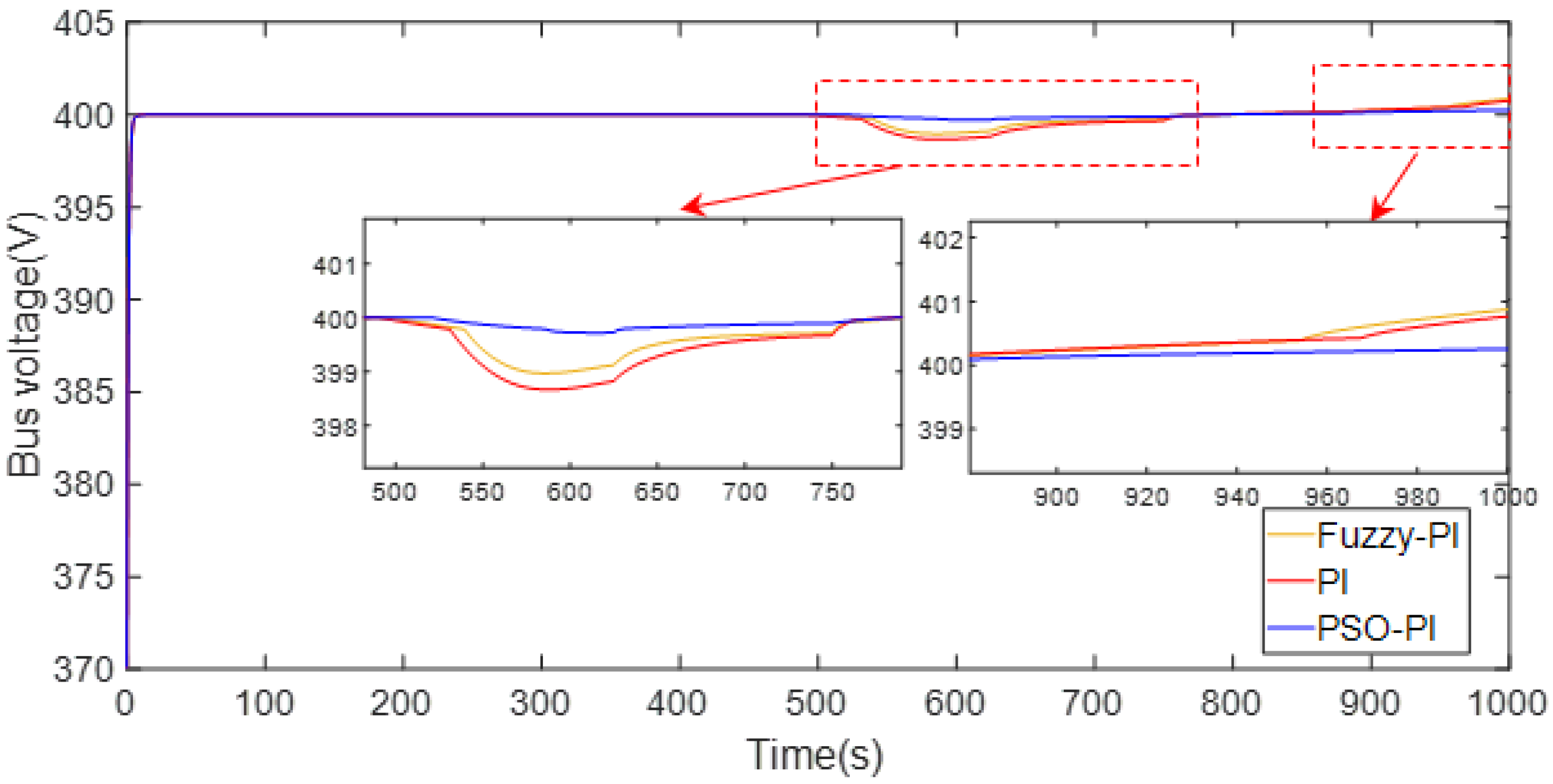

4.2. Example Analysis of the Effect of Composite Energy Storage on DC Microgrid Voltage Stabilization

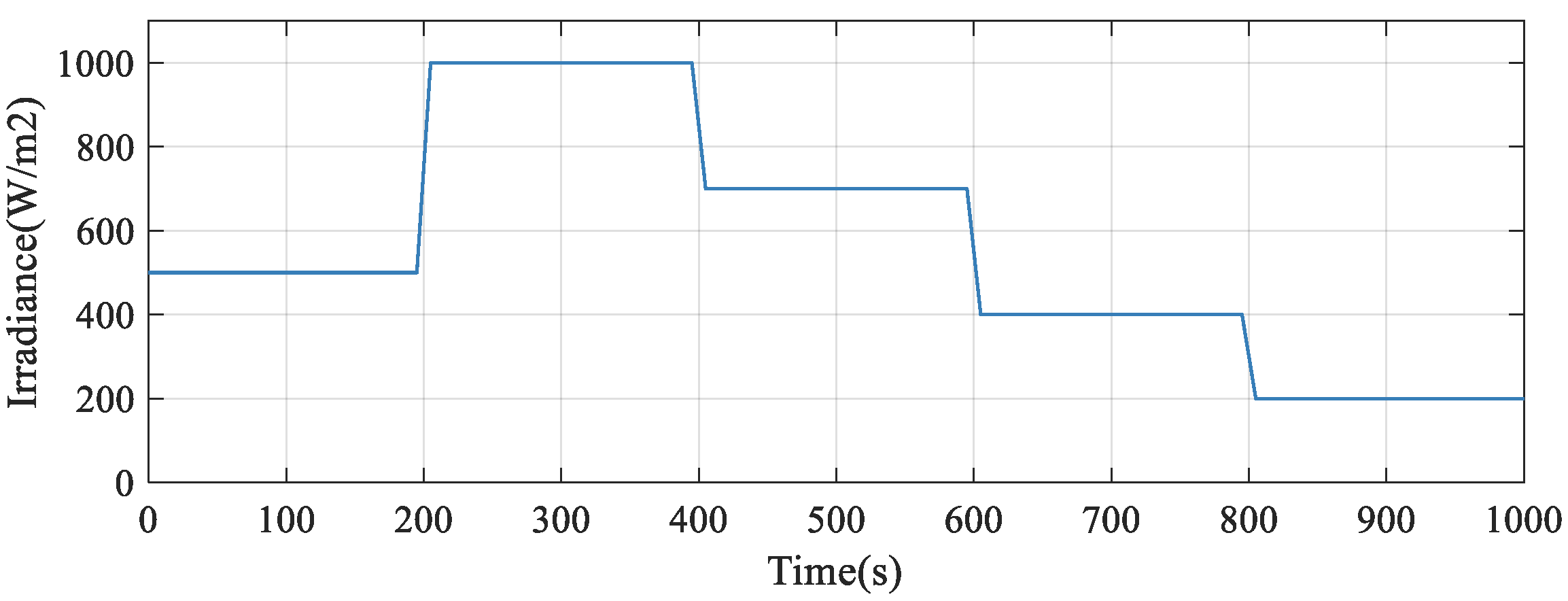

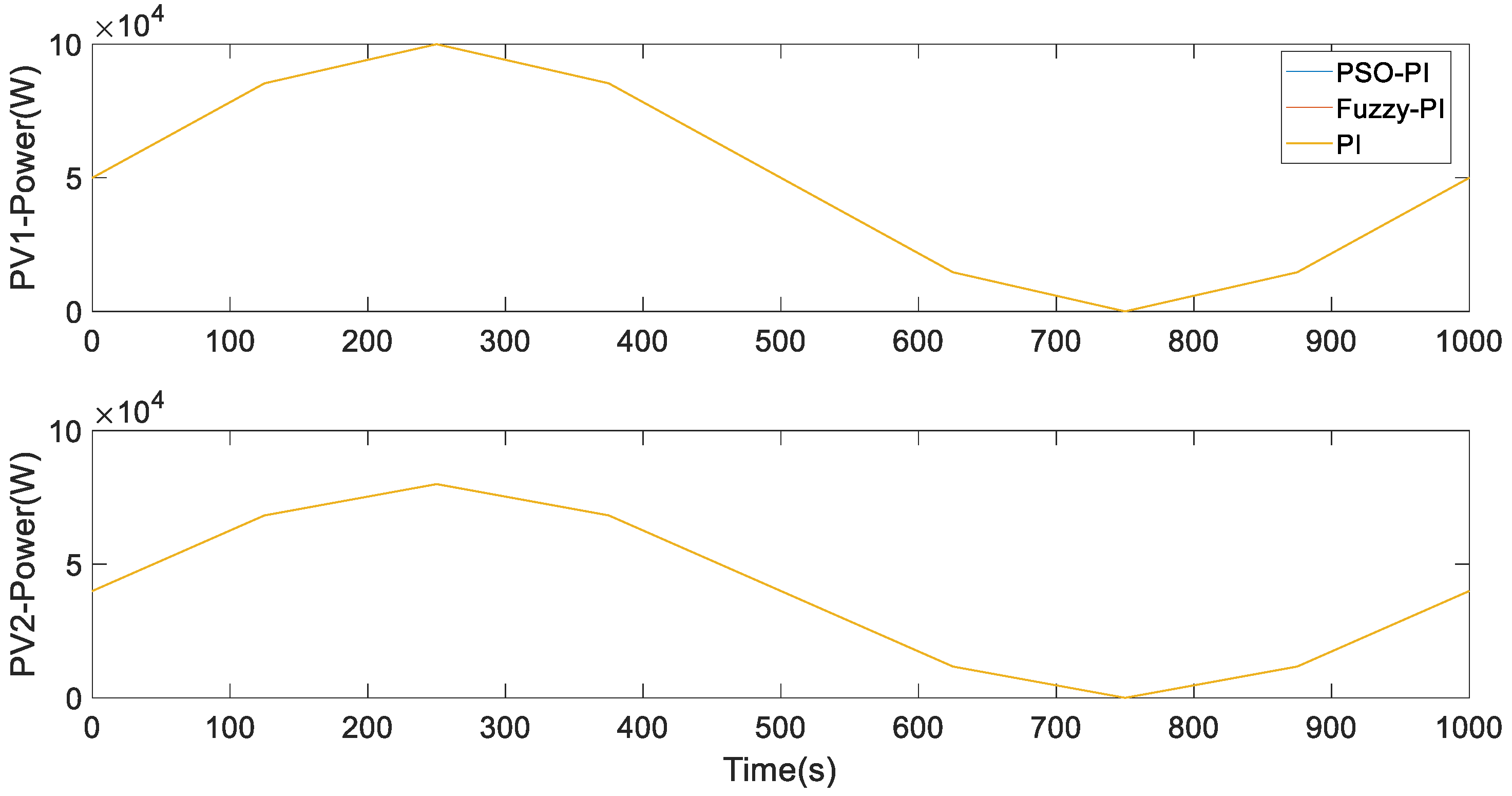

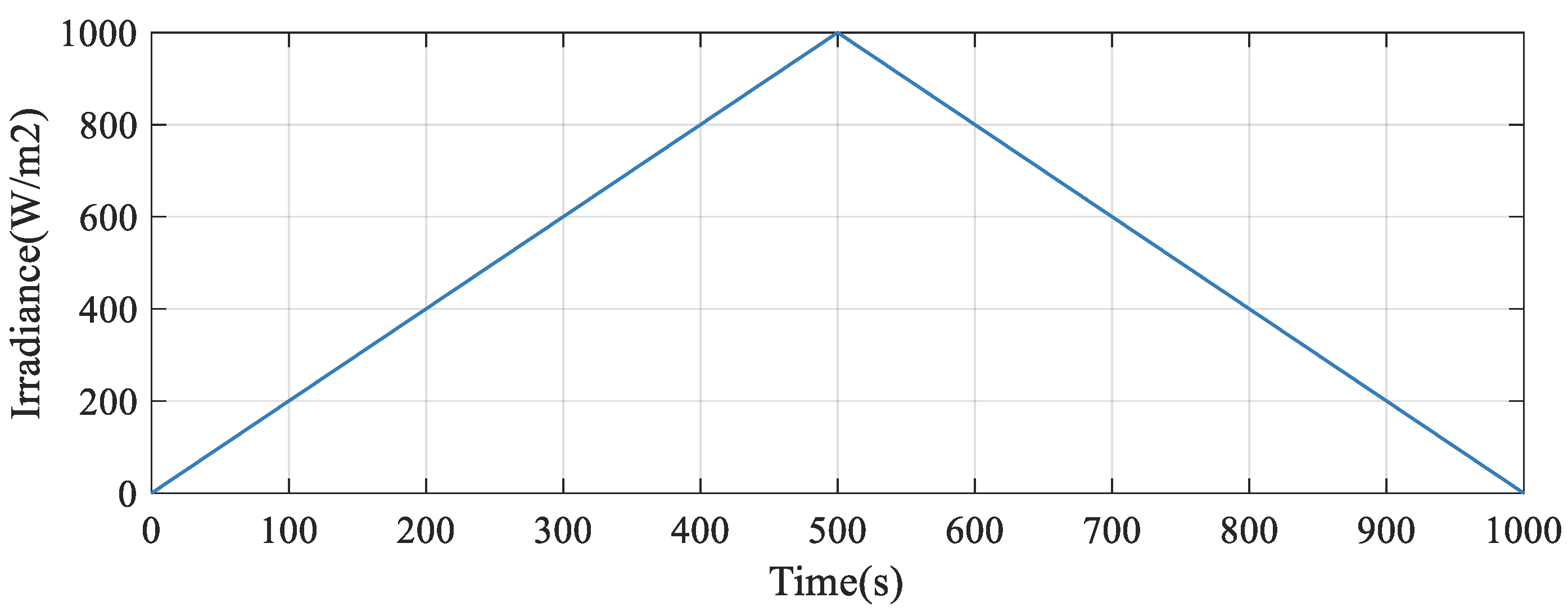

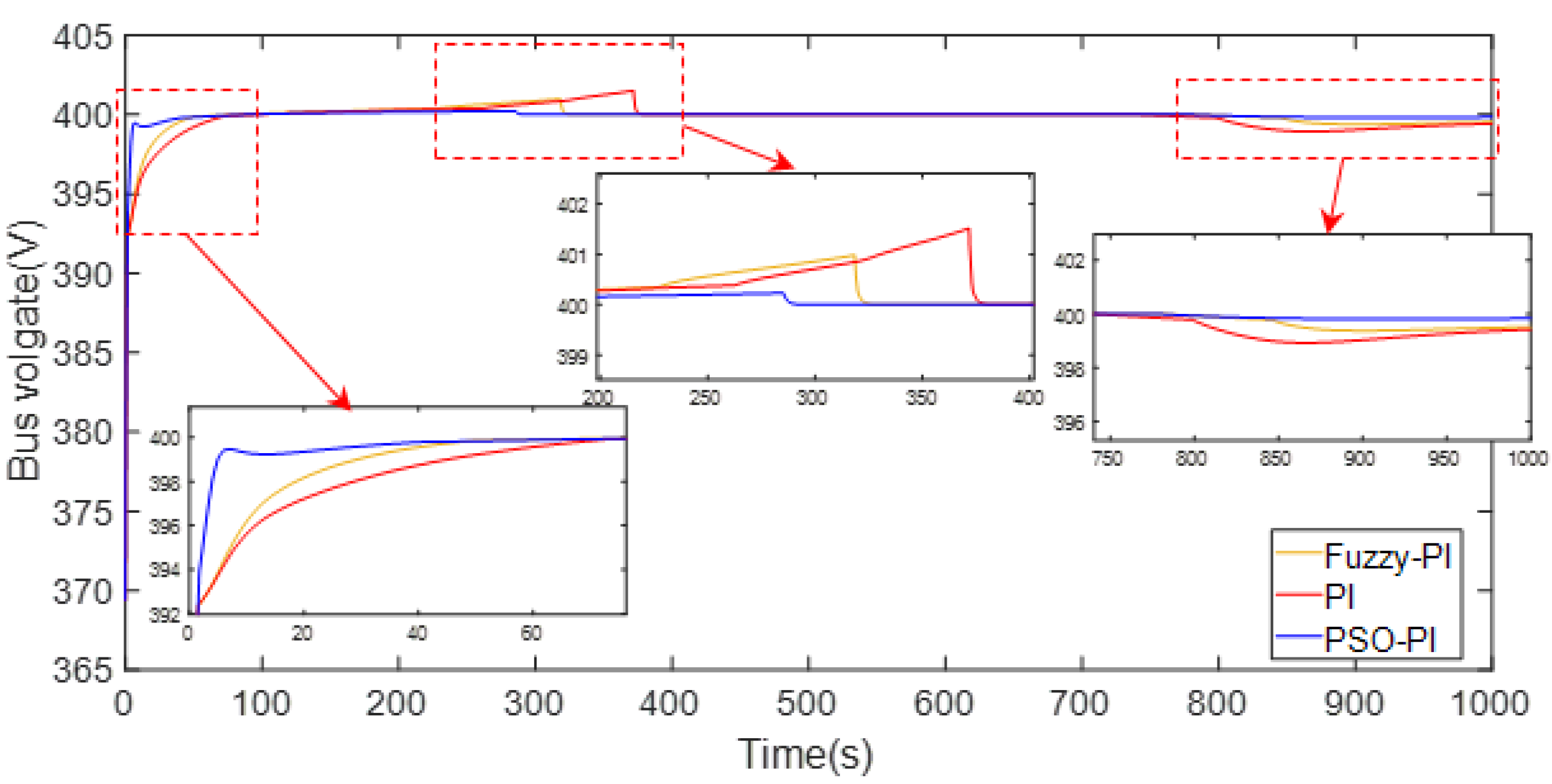

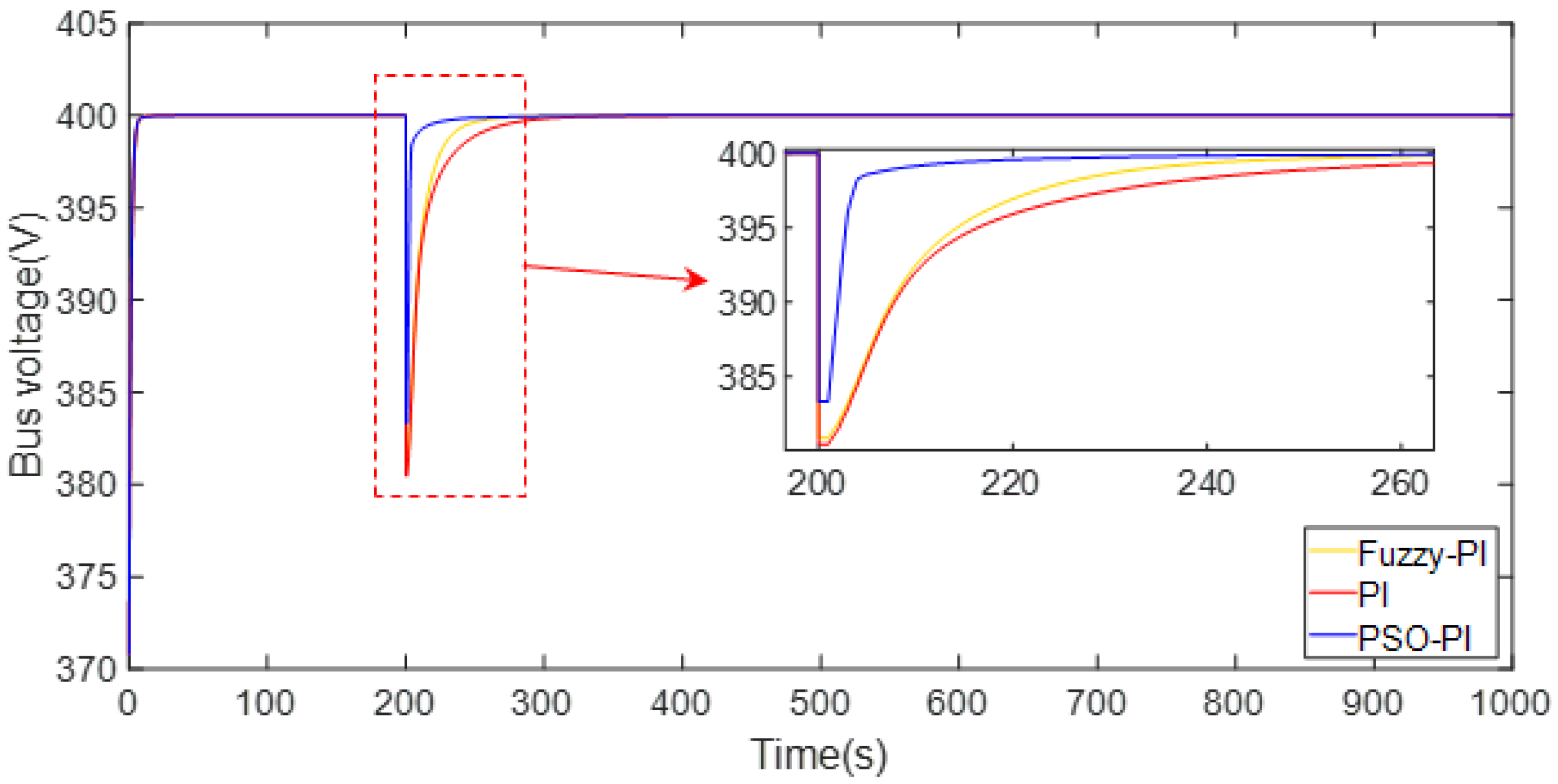

4.2.1. Light Intensity Fluctuation

- (1)

- Example 1

- (2)

- Example 2

- (3)

- Example 3

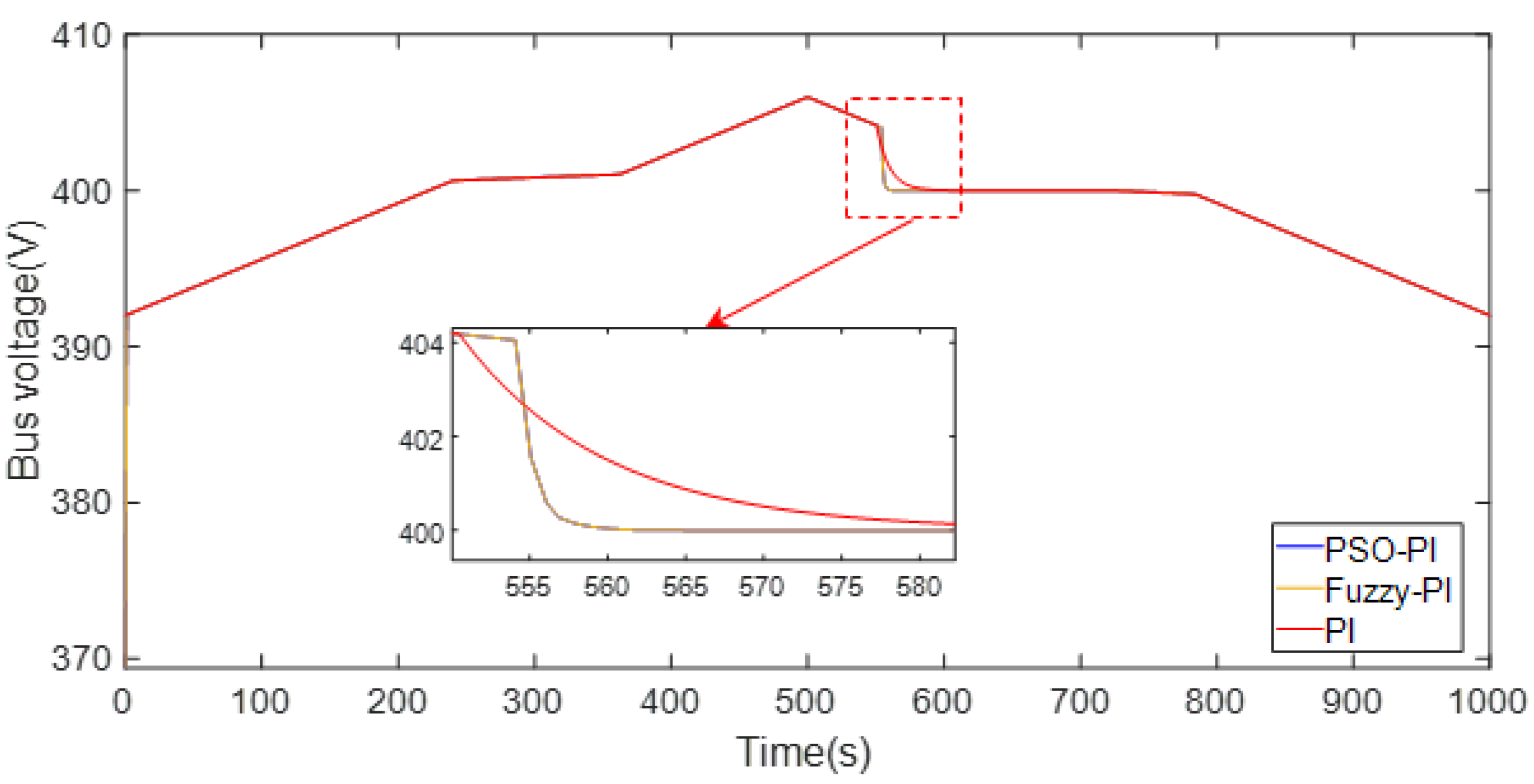

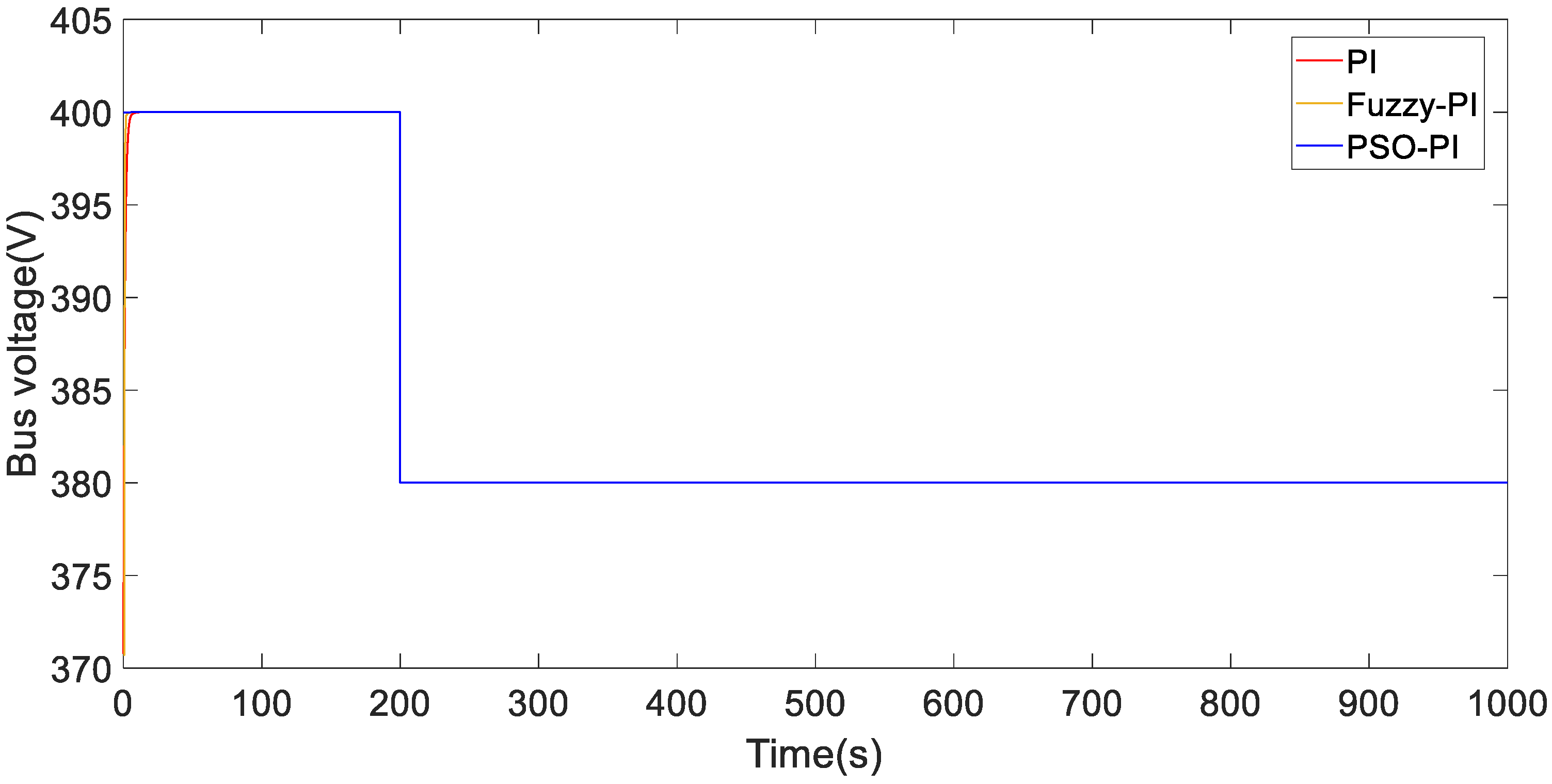

4.2.2. Power Generation Unit Failure

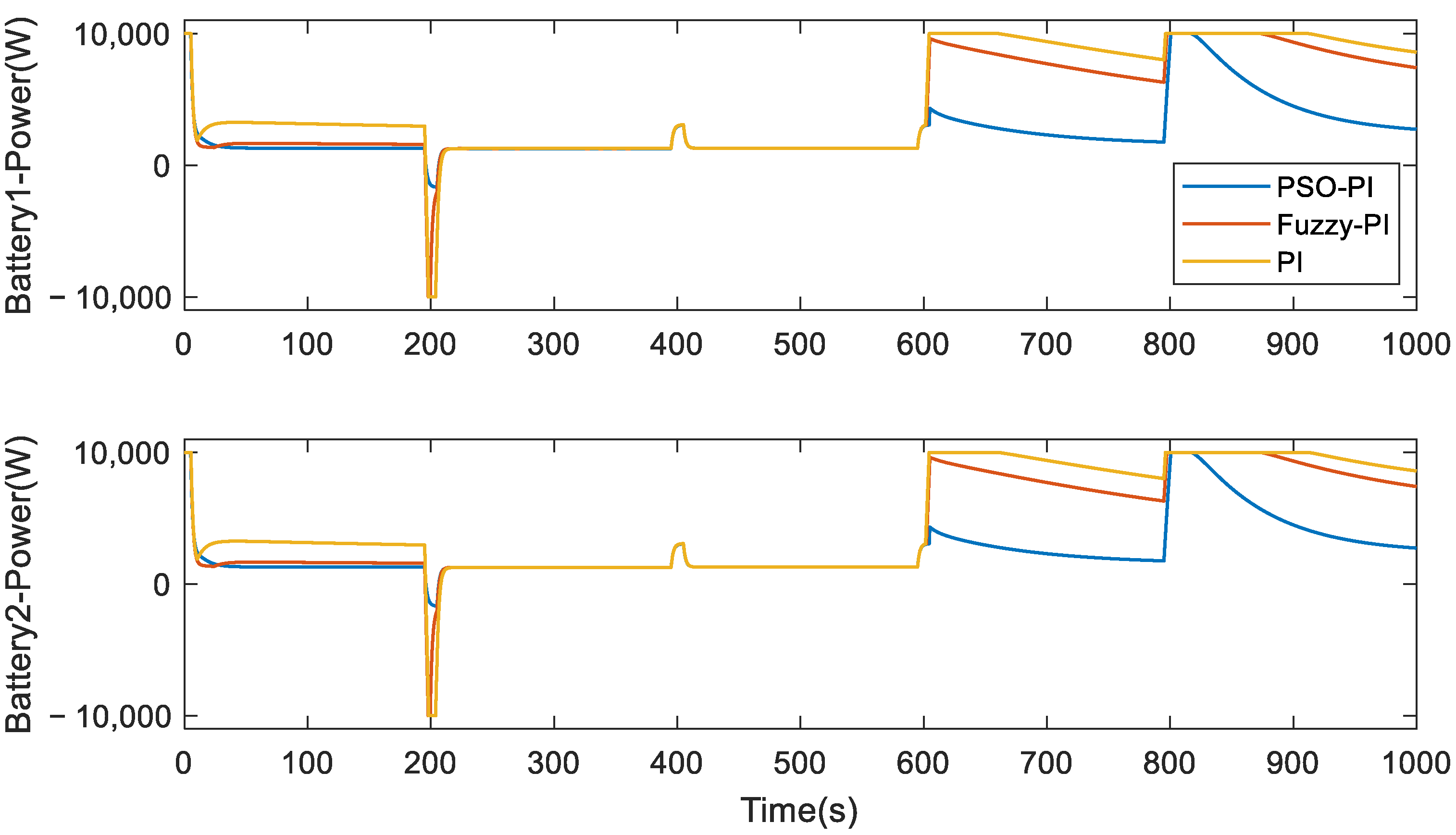

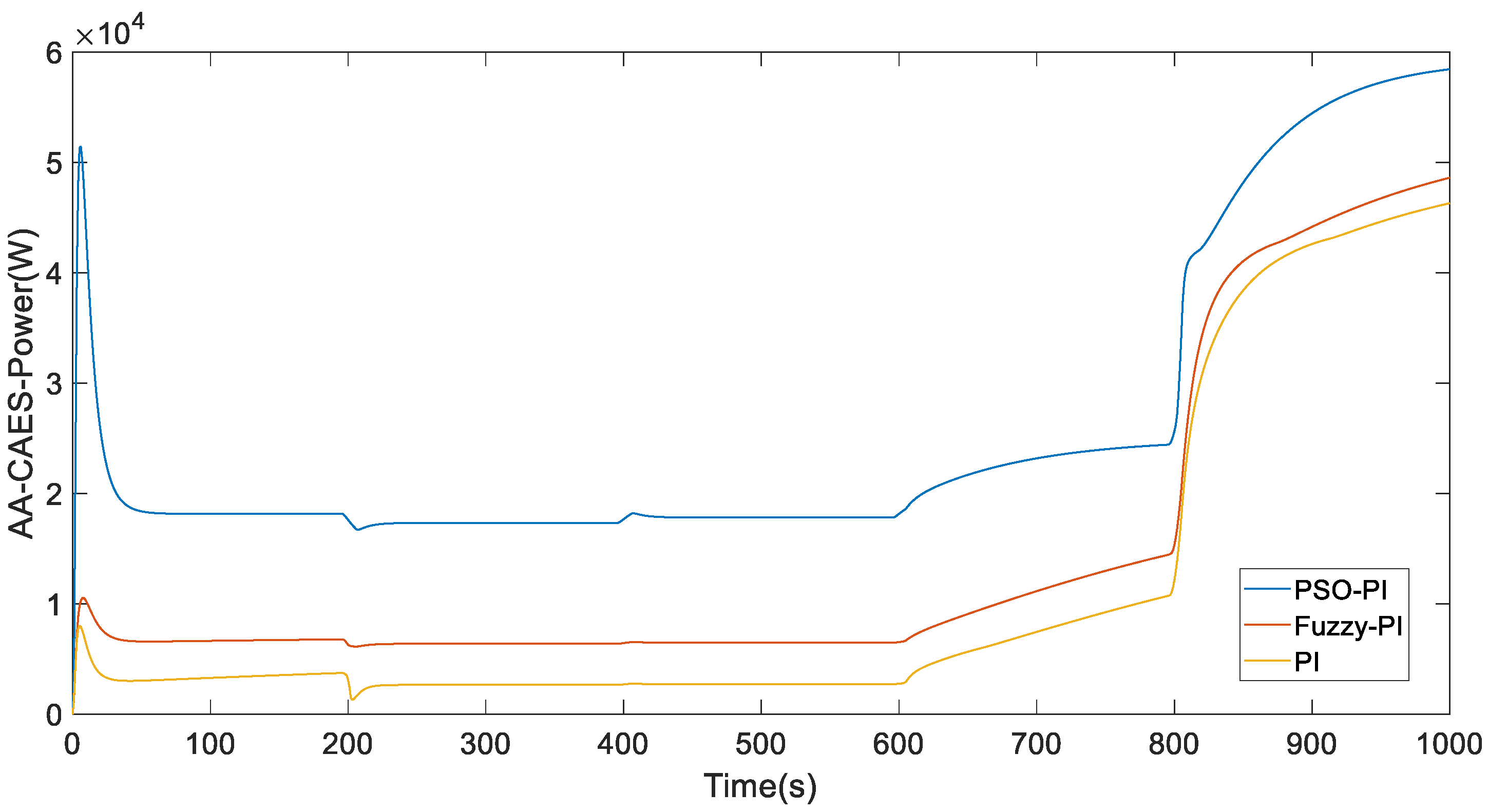

4.3. Composite Energy Storage Analysis

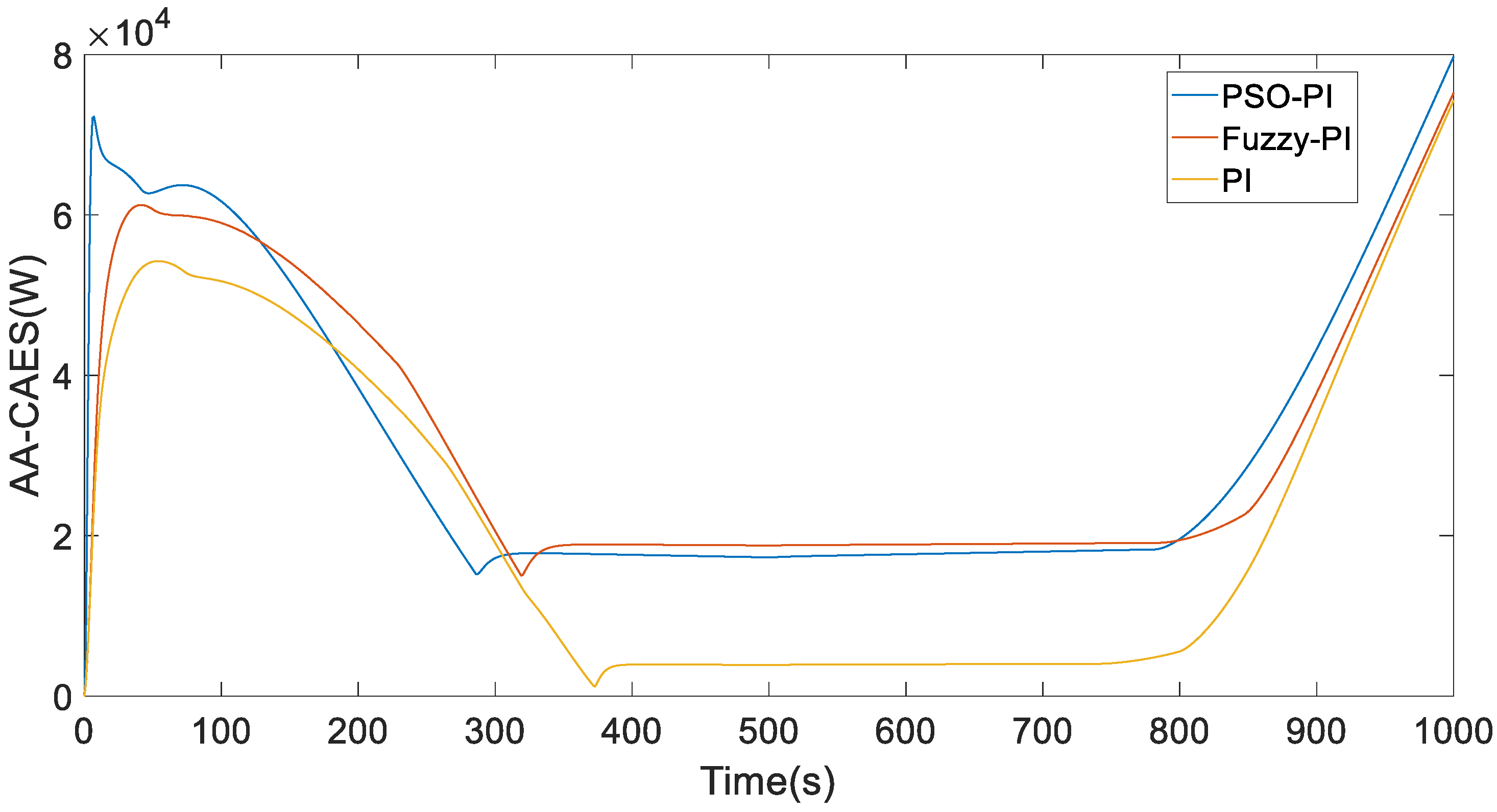

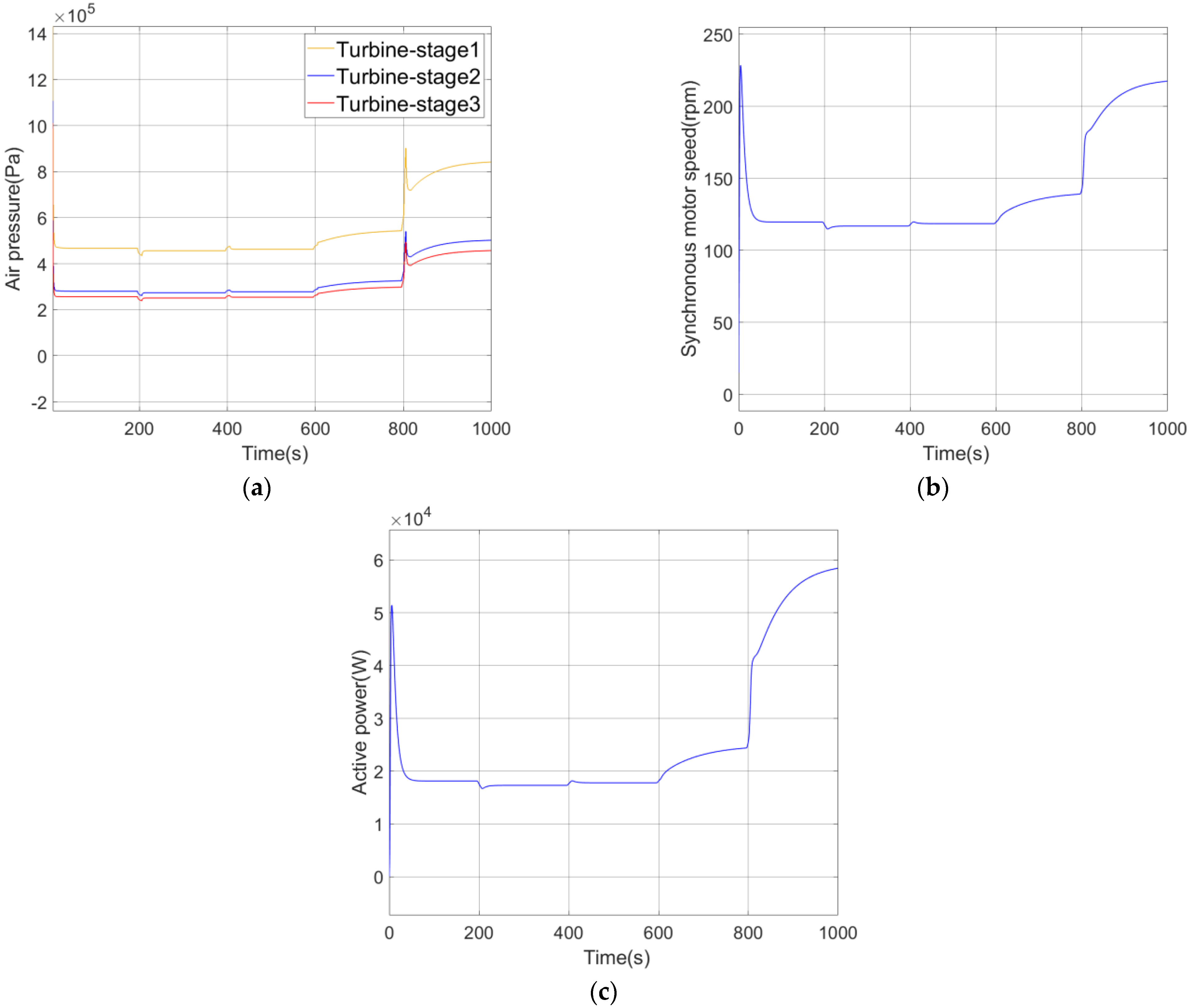

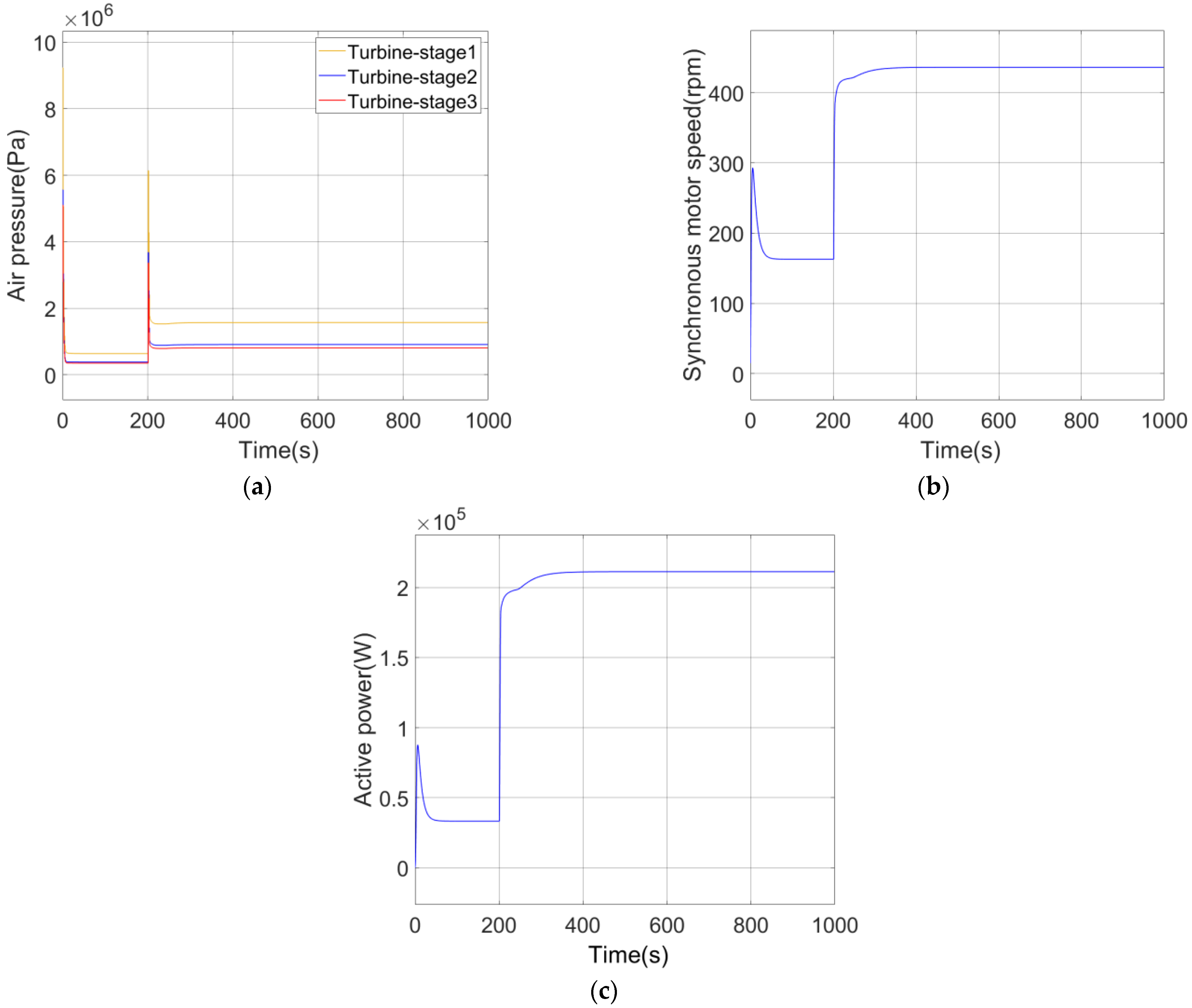

4.3.1. AA-CAES Analysis

- Light intensity fluctuation

- 2.

- Power generation unit failure

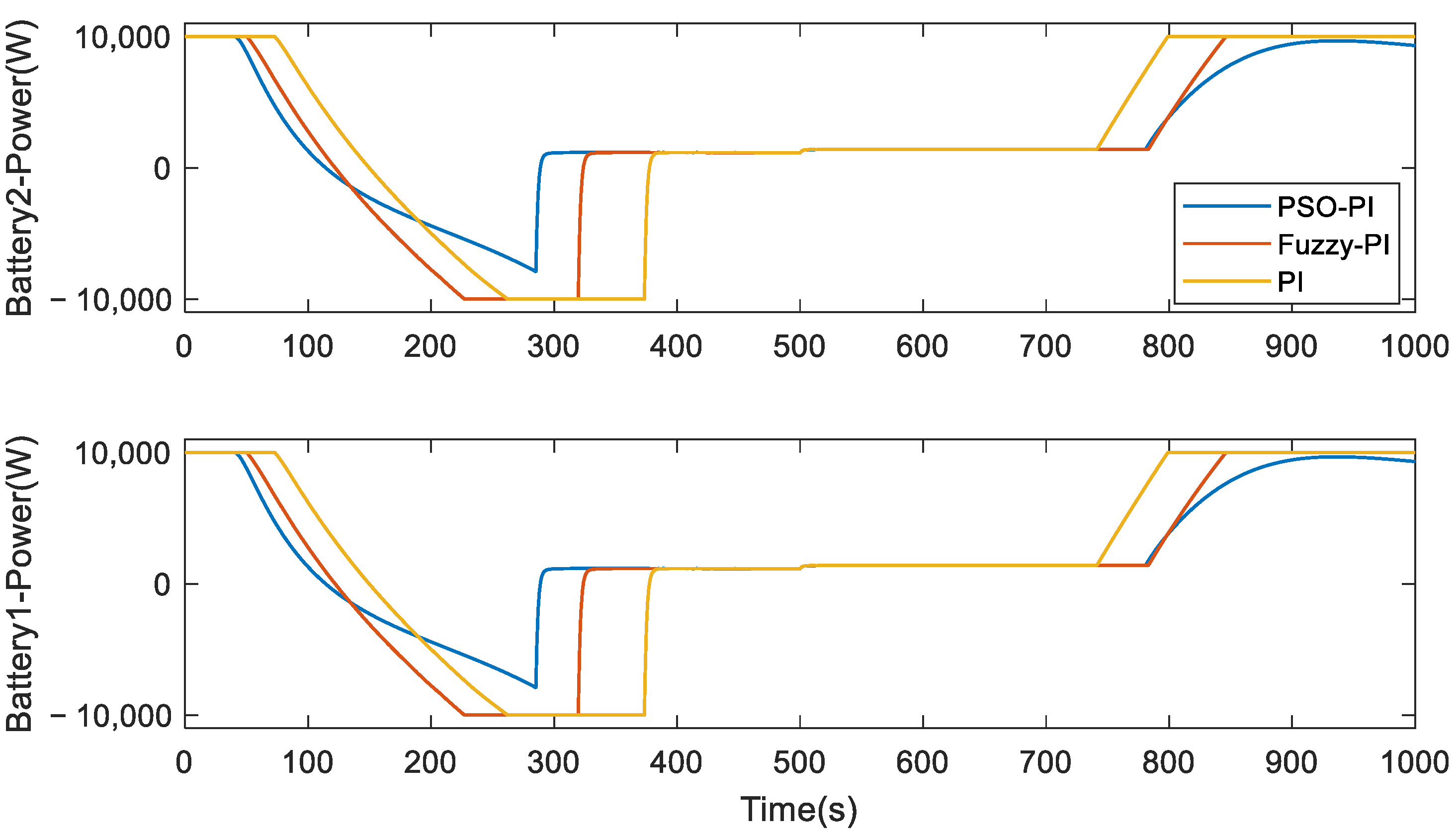

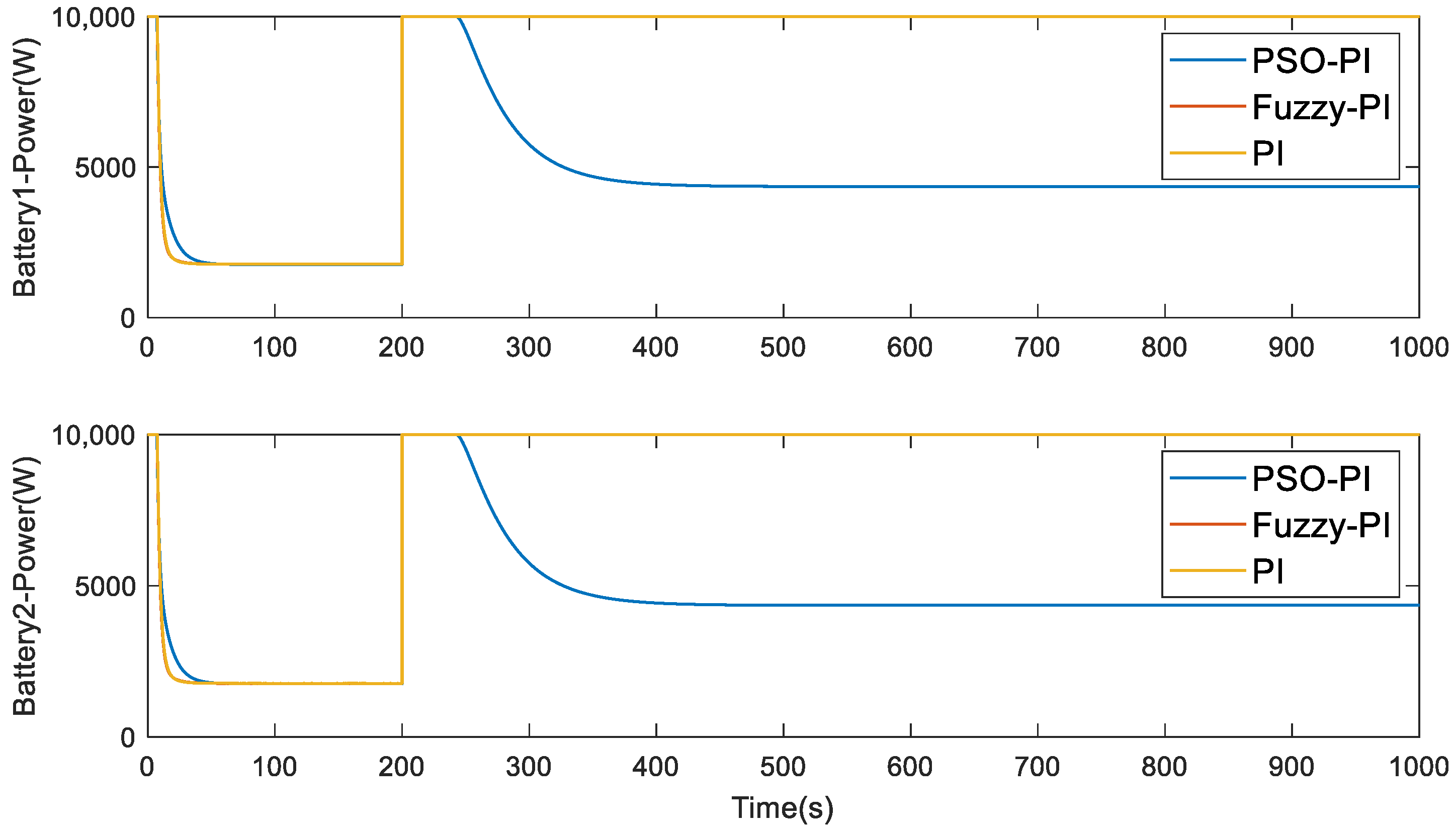

4.3.2. Battery Analysis

- Light intensity fluctuation

- 2.

- Power generation unit failure

5. Conclusions

- (1)

- The composite energy storage system and control strategy adopted can effectively suppress the volatility and intermittency of renewable energy and can deal with the sudden failure of the system and stabilize the DC bus voltage.

- (2)

- The PI parameter tuning methods adopted: fuzzy PI control and PSO PI control can realize the online tuning and optimization of PI parameters and achieve better voltage stabilization effects than traditional PI control.

- (3)

- The composite energy storage system adopted combines the advantages of AA-CAES and battery energy storage units, which can not only achieve rapid response to fluctuations, but also have sufficient capacity to support bus voltage.

- (4)

- The composite energy storage system adopted can prolong the single charging and discharging cycle of a battery and extend its service life when the cycle times of the battery are fixed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ito, Y.; Akagi, H. DC Microgrid Based Distribution Power Generation System. In Proceedings of the Power Electronics and Motion Control Conference, Xi’an, China, 14–16 August 2004. [Google Scholar]

- Dragiĉević, T.; Lu, X.; Vasquez, J.C.; Guerrero, J.M. DC Microgrids–Part I: A Review of Control Strategies and Stabilization Techniques. IEEE Trans. Power Electron. 2015, 31, 4876–4891. [Google Scholar]

- Zhi, N.; Zhang, H. Improved Hierarchical Control Strategy for DC Microgrid. High Volt. Eng. 2016, 42, 1316–1325. [Google Scholar]

- Zheng, L.; Wang, Z.; Lu, S.; Song, J.; Tian, M. Hierarchical Operation Control of Multi-energy Storage in DC Microgrid Based on State of Charge. Power Syst. Technol. 2021, 45, 1006–1015. [Google Scholar]

- Kan, J.; Xie, S.; Wu, Y.; Yao, Z.; Hu, G.; Chen, R. Parameter Design for LCL Filter Grid-connected Inverter Using Inverter-side Current Feedback Strategy. Autom. Electr. Power Syst. 2013, 37, 119–124. [Google Scholar]

- Guo, L.; Feng, Y.B.; Li, X.L.; Wang, C. Stability Analysis and Research of Active Damping Method for DC Microgrids. Proc. CSEE 2016, 36, 927–936. [Google Scholar]

- Nasirian, V.; Davoudi, A.; Lewis, F.L.; Guerrero, J.M. Distributed adaptive droop control for DC distribution systems. IEEE Trans. Energy Convers. 2014, 29, 944–956. [Google Scholar] [CrossRef]

- Li, B.; Liu, H.; Kong, X.; Gao, L.; Zhang, W.; Guan, T. Analysis and Prospect of Control Strategies for DC Distribution Systems. Electr. Power Constr. 2018, 39, 96–108. [Google Scholar]

- Liu, J.; Zhang, G.W.; Rizzoni, G. Robust stability analysis of DC microgrids with constant power loads. IEEE Trans. Power Syst. 2018, 33, 851–860. [Google Scholar] [CrossRef]

- Cao, S.; Ma, X.; Wang, G.; Lin, X.; Li, Z. System-friendly DC Microgrid Coordination Control Strategy Under AC Grid Fault. Proc. CSEE 2021, 41, 7950–7962. [Google Scholar]

- Azab, M.; Serrano, A. Optimal Tuning of Fractional Order Controllers for Dual Active Bridge-Based DC Microgrid Including Voltage Stability Assessment. Electronics 2021, 10, 1109. [Google Scholar] [CrossRef]

- Magaldi, G.L.; Serra, F.M.; Cristian, H.d.A.; Montoya, O.D.; Giral-Ramírez, D.A. Voltage Regulation of an Isolated DC Microgrid with a Constant Power Load: A Passivity-based Control Design. Electronics 2021, 10, 2085. [Google Scholar] [CrossRef]

- Zhong, C.; Zhou, Y.; Chen, J.; Liu, Z. DC-Side Synchronous Active Power Control of Two-Stage Photovoltaic Generation for Frequency Support in Islanded Microgrids. Soc. Sci. Electr. Publ. 2022, 8, 8361–8371. [Google Scholar]

- Zhang, Q.; Liu, Z.; Jiang, X.; Peng, Y.; Zhu, C.; Li, Z. Experimental investigation on performance improvement of cantilever piezoelectric energy harvesters via escapement mechanism from extremely Low-Frequency excitations. Sustain. Energy Technol. Assess. 2022, 53, 102591. [Google Scholar] [CrossRef]

- Sun, B.; Li, Y.; Zeng, Y.; Chen, J.; Shi, J. Optimization planning method of distributed generation based on steady-state security region of distribution network. Energy Rep. 2022, 8, 4209–4222. [Google Scholar] [CrossRef]

- Chen, W.; Shi, J.; Ren, L.; Tang, Y. Composite usage of multi-type energy storage technologies in micro-grid. Autom. Electr. Power Syst. 2010, 34, 112–115. [Google Scholar]

- Li, S.; Ye, C.; Ding, Y.; Song, Y. Reliability Assessment of Renewable Power Systems Considering Thermally-Induced Incidents of Large-Scale Battery Energy Storage. IEEE Trans. Power Syst. 2022. [Google Scholar] [CrossRef]

- Wang, X.; Wang, K.; He, J. Power distribution method of composite energy storage system based on state of charge. Mar. Electr. Electron. Eng. 2022, 42, 133–136. [Google Scholar]

- Li, X.; Liu, J. Real-time power distribution method adopting second-order filtering for hybrid energy storage system. Power Grid Technol. 2019, 43, 1650–1657. [Google Scholar]

- Li, H.; Zhang, Y.; Sun, W. Wind power fluctuation smoothing strategy with generalized energy storage under wavelet packet decomposition. Power Syst. Technol. 2020, 44, 4495–4504. [Google Scholar]

- Yang, X.; Cao, C.; Ren, J.; Gao, F. Control method of smoothing PV power output with battery energy storage system based on fuzzy ensemble empirical mode decomposition. High Volt. Technol. 2016, 42, 2127–2133. [Google Scholar]

- Chen, H.; Liu, J.; Guo, H.; Xu, Y.; Tan, C. Technical principle of compressed air energy storage system. Energy Storage Sci. Technol. 2013, 2, 146G151. [Google Scholar]

- Zhang, Y.; Yang, K.; Li, X.; Xu, J. The thermodynamic effect of air storage chamber model on advanced adiabatic compressed air energy storage system. Renew. Energy 2013, 57, 469–478. [Google Scholar] [CrossRef]

- Li, Y.; Miao, S.; Luo, X.; Yin, B.; Wang, J.; University, W. Day-ahead and Intra-day Time Scales Coordinative Dispatch Strategy of Power System With Compressed Air Energy Storage. Proc. CSEE 2018, 38, 2849–2860. [Google Scholar]

- Li, G.; Chen, L.; Zheng, T.; Mei, S.; Fan, Y.; Lu, Q. Preliminary Investigation on Operation Mode of Compressed Air Energy Storage System as Synchronous Condenser. J. Glob. Energy Interconnect. 2018, 1, 348–354. [Google Scholar]

- Daneshi, H.; Srivastava, A.K. Security-constrained unit commitment with wind generation and compressed air energy storage. Gener. Transm. Distrib. IET 2012, 6, 167–175. [Google Scholar] [CrossRef]

- Zhang, J.; Li, K.; Wang, M.; Lee, W.J.; Gao, H.; Zhang, C.; Li, K. A bi-level program for the planning of an islanded microgrid including CAES. IEEE Trans. Ind. Appl. 2016, 52, 2768–2777. [Google Scholar] [CrossRef]

- Wu, C.; Chen, Z.; Zhang, J.; Zhang, X.; He, Z. Cost/power supply reliability assessment of wind power generation system considering advanced adiabatic compressed air energy storage. Electr. Power Autom. Equip. 2020, 40, 62–71. [Google Scholar]

- Costa, T.; Arcanjo, A.; Vasconcelos, A.; Silva, W.; Azevedo, C.; Pereira, A.; Jatobá, E.; Filho, J.B.; Barreto, E.; Villalva, M.G.; et al. Development of a Method for Sizing a Hybrid Battery Energy Storage System for Application in AC Microgrid. Energies 2023, 16, 1175. [Google Scholar] [CrossRef]

- Ramos, F.; Pinheiro, A.; Nascimento, R.; Junior, W.d.A.S.; Mohamed, M.A.; Annuk, A.; Marinho, M.H.N. Development of Operation Strategy for Battery Energy Storage System into Hybrid AC Microgrids. Sustainability 2022, 14, 13765. [Google Scholar] [CrossRef]

- Nascimento, R.; Ramos, F.; Pinheiro, A.; Junior, W.d.A.S.; Arcanjo, A.M.C.; Filho, R.F.D.; Mohamed, M.A.; Marinho, M.H.N. Case Study of Backup Application with Energy Storage in Microgrids. Energies 2022, 15, 9514. [Google Scholar] [CrossRef]

- Pontes, L.; Costa, T.; Souza, A.; Dantas, N.; Vasconcelos, A.; Rissi, G.; Dias, R.; Mohamed, M.A.; Siano, P.; Marinho, M. Operational Data Analysis of a Battery Energy Storage System to Support Wind Energy Generation. Energies 2023, 16, 1468. [Google Scholar] [CrossRef]

- Teh, J.; Lai, C.M.; Cheng, Y.H. Impact of the real-time thermal loading on the bulk electric system reliability. IEEE Trans. Reliab. 2017, 66, 1110–1119. [Google Scholar] [CrossRef]

- Teh, J.; Lai, C.M. Reliability impacts of the dynamic thermal rating and battery energy storage systems on wind-integrated power networks. Sustain. Energy Grids Netw. 2019, 20, 2352–4677. [Google Scholar] [CrossRef]

- Lai, C.M.; Teh, J. Network topology optimisation based on dynamic thermal rating and battery storage systems for improved wind penetration and reliability. Appl. Energy 2022, 305, 117837. [Google Scholar] [CrossRef]

- Jiang, Z. Research on Power Balance of Islanded DC Microgrid Based on Nonlinear Adaptive Backstepping Control Strategy. Lanzhou Jiaotong Univ. 2021. [Google Scholar] [CrossRef]

- Mahmud, M.A.; Hossain, M.J.; Pota, H.R.; Amanullah, M.T.O. Robust Partial Feedback Linearizing Excitation Controller Design for Multimachine Power Systems. IEEE Trans. Power Syst. 2016, 32, 3–16. [Google Scholar] [CrossRef]

- Mccarthy, D.J. Vibration-Based Diagnostics of Reciprocating Machinery. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1994. [Google Scholar]

- Wang, J.; Pu, J.; Moore, P. A practical control strategy for servo-pneumatic actuator systems. Control Eng. Pract. 1999, 7, 1483–1488. [Google Scholar] [CrossRef]

- He, W.; Wang, J.; Ding, Y. New radial turbine dynamic modelling in a low-temperature adiabatic Compressed Air Energy Storage system discharging process. Energy Convers. Manag. 2017, 153, 144–156. [Google Scholar] [CrossRef]

- Li, Y. Research on Dynamic Simulation, Economic Estimation and Coordinated Scheduling Methods of Advanced Adiabatic Compressed Air Energy Storage System. Huazhong Univ. Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Cheng, T.; Lin, W.X.; Li, W.L. PID Control of Double-Loop Speed Control System Based on Bacteria-Particle Swarm Hybrid Optimization Algorithm. Appl. Mech. Mater. 2013, 241, 1850–1854. [Google Scholar] [CrossRef]

- Yu, H.; Wang, R. Intelligence Method in the PID Parameters Adjustment of Application. Autom. Panor. 2021, 38, 75–79. [Google Scholar]

- Yang, Z.; Chen, Y. Improved Particle Swarm Optimization and its Application in PID Tuning. Control Eng. China 2016, 23, 161–166. [Google Scholar]

- Wang, C.; Guo, G.; Zhao, J.; Han, Z.; Zhu, Y. Application of the Particle Swarm Optimization PID in VAV Air Conditioning System. Process Autom. Instrum. 2018, 39, 7–11. [Google Scholar]

| ΔKp | de/dt Membership | |||||||

|---|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZE | PS | PM | PB | ||

| e membership | NB | PB | PB | PM | PM | PS | ZE | ZE |

| NM | PB | PB | PM | PS | PS | ZE | NS | |

| NS | PM | PM | PM | PS | ZE | NS | NS | |

| ZE | PM | PM | PS | ZE | NS | NM | NM | |

| PS | PS | PS | ZE | NS | NS | NM | NM | |

| PM | PS | ZE | NS | NM | NM | NM | NB | |

| PB | ZE | ZE | NM | NM | NM | NB | NB | |

| ΔKi | de/dt Membership | |||||||

|---|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZE | PS | PM | PB | ||

| e membership | NB | NB | NB | NM | NM | NS | ZE | ZE |

| NM | NB | NB | NM | NS | NS | ZE | ZE | |

| NS | NB | NM | NS | NS | ZE | PS | PS | |

| ZE | NM | NM | NS | ZE | PS | PM | PM | |

| PS | NM | NS | ZE | PS | PS | PM | PB | |

| PM | ZE | ZE | PS | PS | PM | PB | PB | |

| PB | ZE | ZE | PS | PM | PM | PB | PB | |

| Inertia Weight | Acceleration Factor | Dimension | Population Size | Iterations | Minimum Fitness Value |

|---|---|---|---|---|---|

| ωmax = 0.9 | c1 = 0.8 | Dim = 12 | Size = 10 | Iter = 5 | Minfit = 0.001 |

| ωmin = 0.4 | c2 = 0.5 | Dim = 12 | Size = 10 | Iter = 5 | Minfit = 0.001 |

| Parameter Name | Numerical Value | Parameter Name | Numerical Value |

|---|---|---|---|

| Rated voltage of DC bus (V) | 400 | Maximum power of photovoltaic unit (VA) | 1 × 105 |

| Rated power of diesel generator (VA) | 1 × 106 | Rated power of diesel generator (VA) | 1.3 × 106 |

| Rated speed of diesel generator (rpm) | 1500 | AA-CAES rated power (VA) | 1 × 106 |

| Rated power of storage battery (VA) | 6000 | Battery energy storage limit power (VA) | 1 × 104 |

| Parameter Name | Numerical Value | Parameter Name | Numerical Value |

|---|---|---|---|

| Ambient air pressure (bar) | 1 | Number of heat exchange tubes (m) | 507 |

| Ambient temperature (K) | 298 | Inner diameter of pipe body (m) | 0.8 |

| Asynchronous motor | Piston compressor | ||

| Stator resistance (Ω) | 0.0138 | Initial air pressure in cylinder (bar) | 1.011 |

| Stator leakage resistance (H) | 0.0002 | Stroke of each cylinder (m) | 0.3690 |

| Rotor resistance (Ω) | 0.0077 | Crank radius of each cylinder (m) | 0.1845 |

| Rotor leakage inductance (H) | 0.0002 | Length of connecting rod of each cylinder (m) | 0.4716 |

| Excitation inductance (H) | 0.0077 | First stage: cylinder diameter (m) | 1.0868 |

| Moment of inertia (kg/m2) | 2.9 | First stage: clearance volume (m3) | 0.0012 |

| Centripetal turbine | Second stage: cylinder diameter (m) | 0.5895 | |

| Rotor inlet angle (degree) | 12.6 | Second stage: clearance volume (m3) | 0.0006 |

| Rotor outlet angle (degree) | 33.6 | Third stage: cylinder diameter (m) | 0.0289 |

| First stage: rotor inlet diameter (m) | 0.1728 | Third stage: clearance volume (m3) | 0.00035 |

| First stage: average diameter of rotor outlet (m) | 0.0773 | Gas cylinder | |

| First stage: rotor inlet width (m) | 0.0044 | Volume of air tank (m3) | 760 |

| First stage: rotor outlet width (m) | 0.0148 | Initial air pressure (bar) | 60 |

| Second stage: rotor inlet diameter (m) | 0.2300 | Initial air temperature (K) | 298 |

| Second stage: average diameter of rotor outlet (m) | 0.1050 | Natural heat transfer coefficient | 2.24 |

| Second stage: rotor inlet width (m) | 0.0074 | Forced heat transfer coefficient | 10.52 |

| Second stage: rotor outlet width (m) | 0.0253 | Synchronous motor | |

| Third stage: rotor inlet diameter (m) | 0.2600 | Rated power (VA) | 1 × 106 |

| Third stage: average diameter of rotor outlet (m) | 0.1144 | Rated line voltage (V) | 400 |

| Third stage: rotor inlet width (m) | 0.0192 | Stator resistance (pu) | 0.0095 |

| Third stage: rotor outlet width (m) | 0.0642 | Leakage inductance of stator winding (pu) | 0.05 |

| Shell and tube heat exchanger | d-axis excitation inductance (pu) | 2.06 | |

| Length of heat exchanger tube (m) | 4.2 | q-axis excitation inductance (pu) | 1.51 |

| Outer diameter of heat exchanger tube (m) | 0.0250 | Excitation winding resistance (pu) | 0.0020 |

| Inner diameter of heat exchanger tube (m) | 0.0225 | Excitation winding inductance (pu) | 0.0034 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Wang, C.; Han, J.; Yang, F.; Shen, Y.; Min, H.; Hu, W.; Song, H. Analysis of Voltage Control Strategies for DC Microgrid with Multiple Types of Energy Storage Systems. Electronics 2023, 12, 1661. https://doi.org/10.3390/electronics12071661

Yang Z, Wang C, Han J, Yang F, Shen Y, Min H, Hu W, Song H. Analysis of Voltage Control Strategies for DC Microgrid with Multiple Types of Energy Storage Systems. Electronics. 2023; 12(7):1661. https://doi.org/10.3390/electronics12071661

Chicago/Turabian StyleYang, Zhichun, Chenxia Wang, Ji Han, Fan Yang, Yu Shen, Huaidong Min, Wei Hu, and Huihui Song. 2023. "Analysis of Voltage Control Strategies for DC Microgrid with Multiple Types of Energy Storage Systems" Electronics 12, no. 7: 1661. https://doi.org/10.3390/electronics12071661

APA StyleYang, Z., Wang, C., Han, J., Yang, F., Shen, Y., Min, H., Hu, W., & Song, H. (2023). Analysis of Voltage Control Strategies for DC Microgrid with Multiple Types of Energy Storage Systems. Electronics, 12(7), 1661. https://doi.org/10.3390/electronics12071661