Research on Posture Sensing and Error Elimination for Soft Manipulator Using FBG Sensors

Abstract

1. Introduction

- The arrangement of optical fibers in the soft robot cannot accurately follow the geometric assumptions. This is caused by the manufacturing error of soft robots and FBG sensors, as well as other aleatoric factors.

- Errors may be introduced in the reconstruction algorithm of FBG sensing as models can never be completely accurate, especially for soft structures. This may be caused by the unexpected impacts of models on sensors and robots, such as body twisting and temperature changes.

- Due to the discrete distribution of sensing points on the fiber, the bending information between the two points cannot be detected. Although the interpolation method is constantly optimized, the error caused by the lack of original information cannot be eliminated.

2. Materials and Methods

2.1. Materials

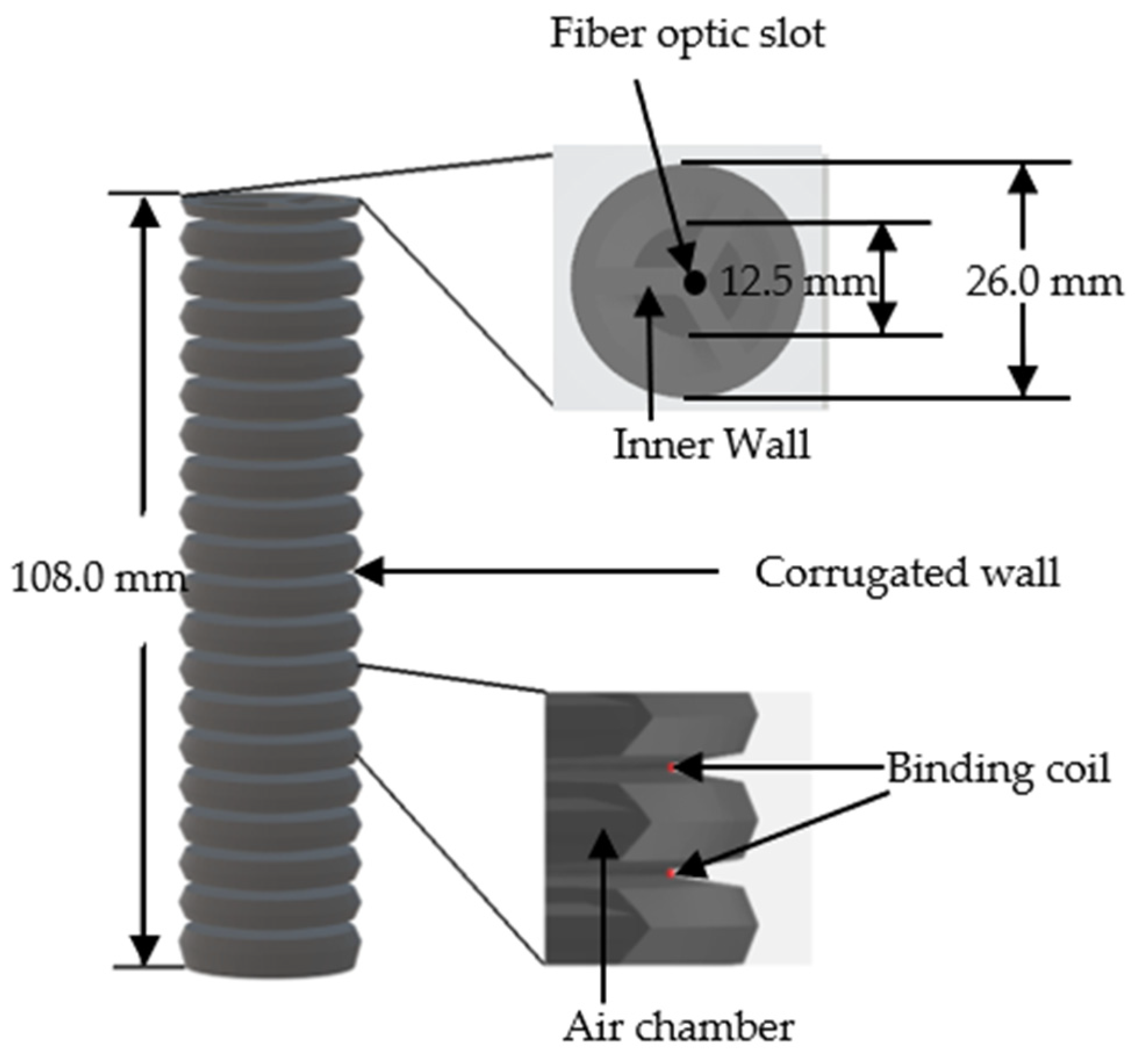

2.2. Structure of the Soft Manipulator

2.3. FBG Sensing Principle

2.4. Design of the LSTM Neural Network

- As it is a data-driven method, training errors can be introduced no matter what optimizer, hyperparameter, and network structure can be chosen.

- Because of the “black-box” character of the neural network, the information processing is incomprehensible for people, which makes the sensing results unreliable to a certain degree. The network just gives numbers, and people have to decide whether to believe it blindly.

3. Experiments and Results

3.1. Simulation

3.2. Experiment Platform and Devices

3.3. Dataset Building and Model Training

3.3.1. Dataset Building from the Experiment

3.3.2. Model Training

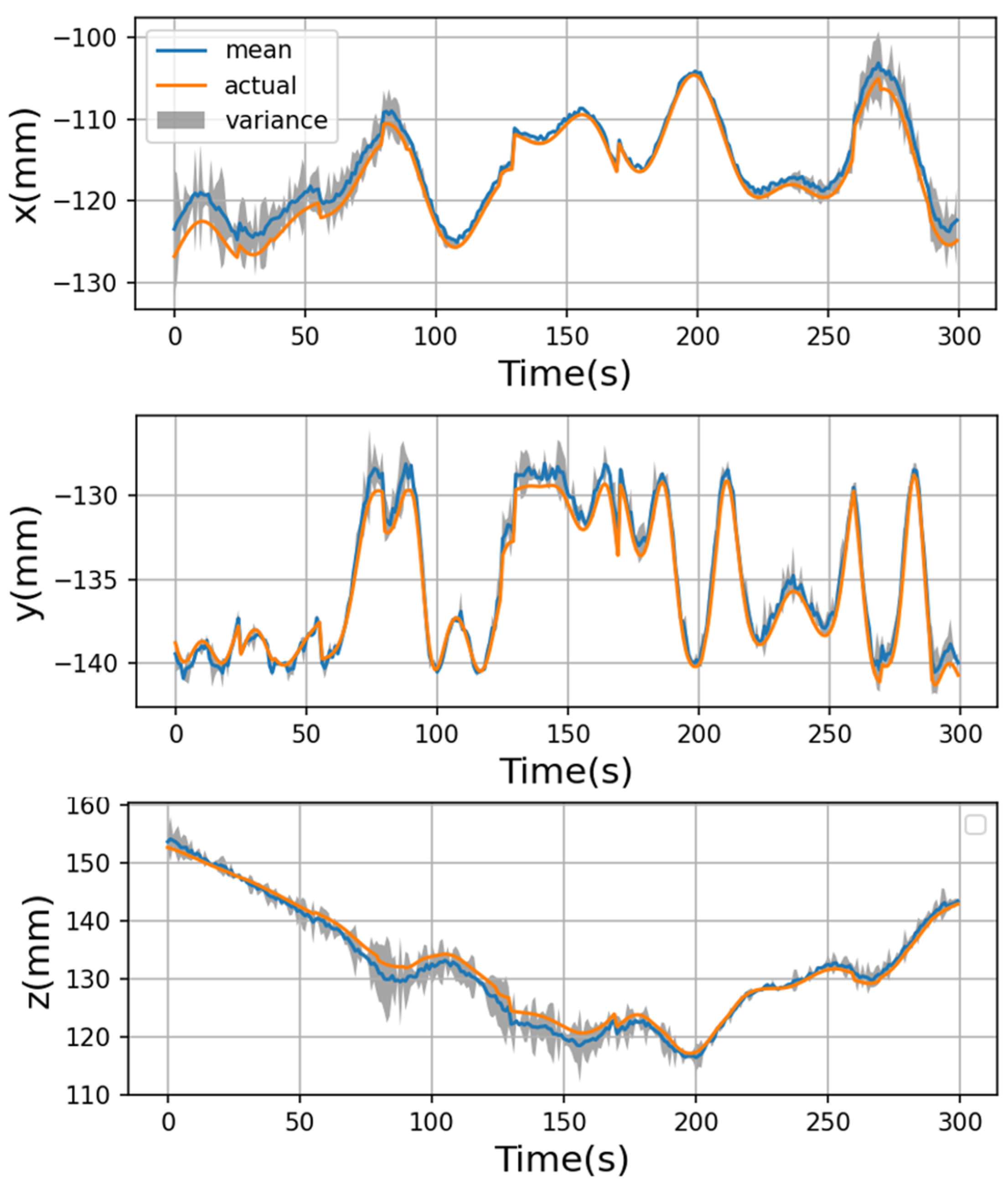

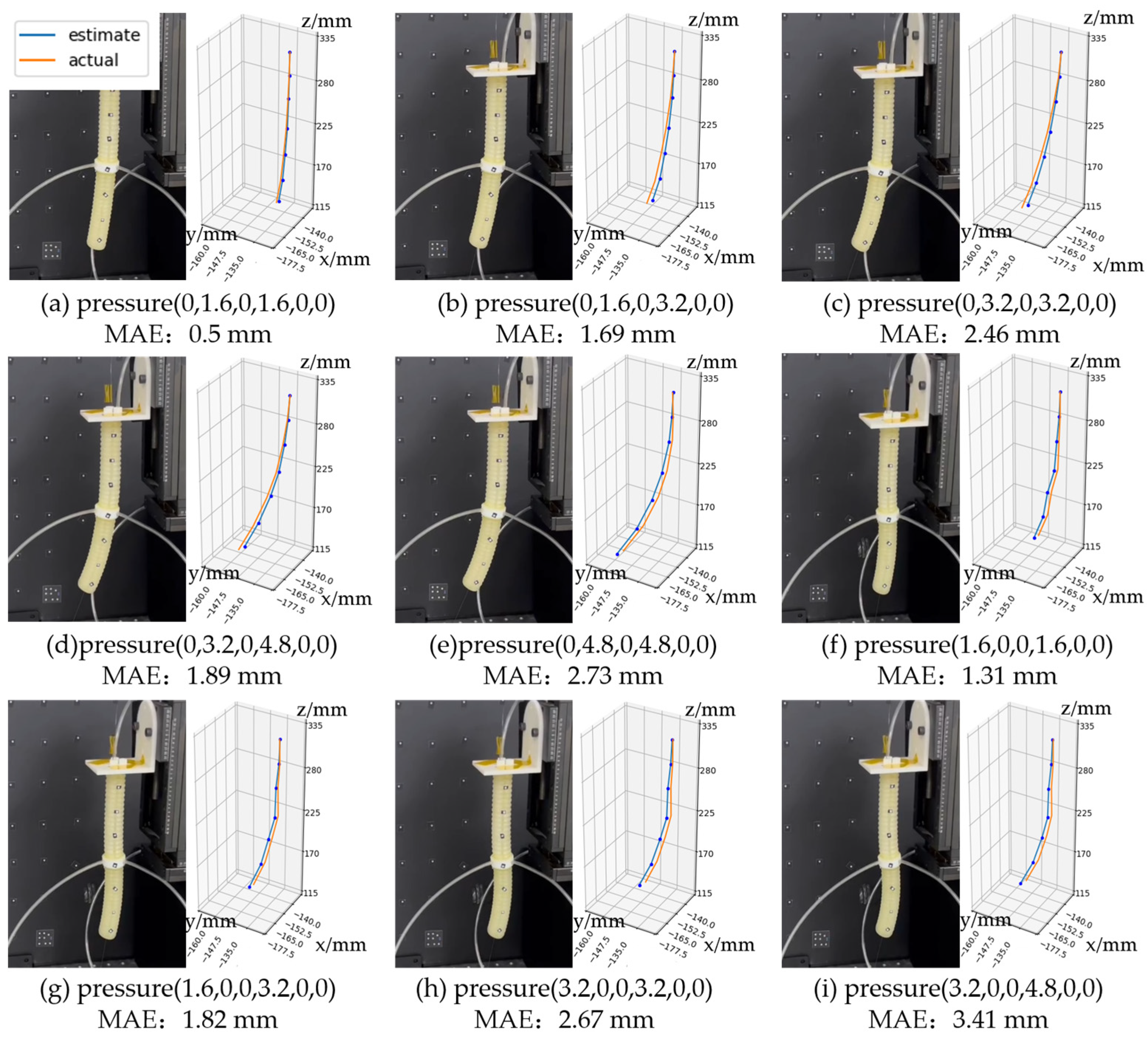

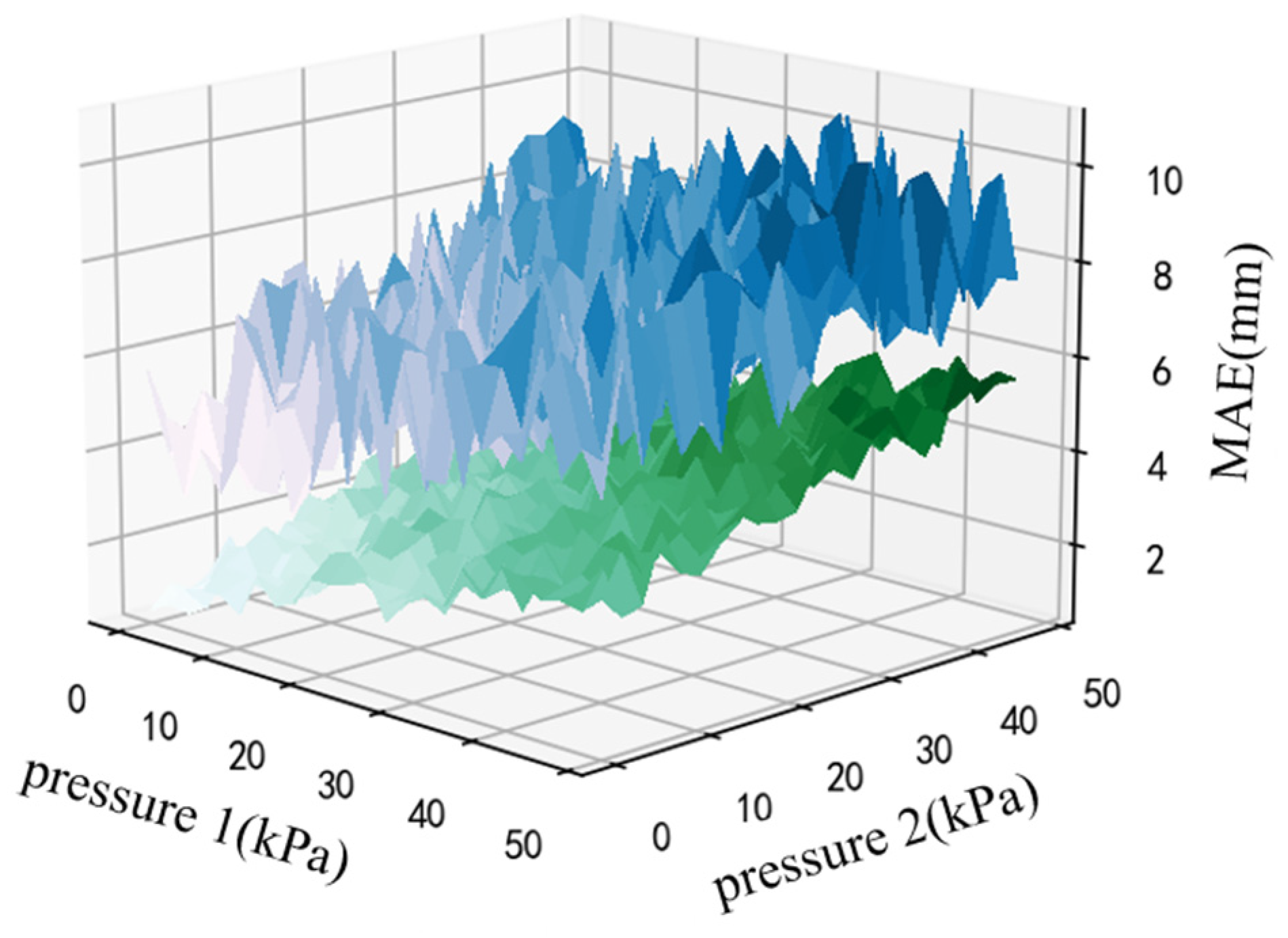

3.4. Results and Discussions

4. Conclusions and Future Development

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| A | b | c | d | e | f | g | h | I | |

| 1-1 | 1533.11 | 1533.08 | 1533.1 | 1533.1 | 1533.03 | 1532.87 | 1532.86 | 1532.85 | 1532.85 |

| 1-2 | 1536.43 | 1536.42 | 1536.46 | 1536.47 | 1536.47 | 1536.34 | 1536.34 | 1536.35 | 1536.36 |

| 1-3 | 1540.69 | 1540.69 | 1540.7 | 1540.7 | 1540.73 | 1540.61 | 1540.61 | 1540.6 | 1540.61 |

| 1-4 | 1543.99 | 1543.94 | 1543.95 | 1543.9 | 1543.9 | 1543.97 | 1543.97 | 1543.97 | 1543.97 |

| 1-5 | 1548.35 | 1548.3 | 1548.29 | 1548.24 | 1548.25 | 1548.38 | 1548.33 | 1548.34 | 1548.27 |

| 2-1 | 1531.59 | 1531.59 | 1531.57 | 1531.57 | 1531.59 | 1531.9 | 1531.89 | 1531.86 | 1531.86 |

| 2-2 | 1536.24 | 1536.23 | 1536.23 | 1536.23 | 1536.22 | 1536.34 | 1536.33 | 1536.31 | 1536.34 |

| 2-3 | 1540.35 | 1540.34 | 1540.33 | 1540.32 | 1540.28 | 1540.36 | 1540.35 | 1540.33 | 1540.34 |

| 2-4 | 1543.56 | 1543.57 | 1543.54 | 1543.53 | 1543.54 | 1543.52 | 1543.52 | 1543.51 | 1543.51 |

| 2-5 | 1548.44 | 1548.46 | 1548.46 | 1548.47 | 1548.47 | 1548.41 | 1548.43 | 1548.42 | 1548.44 |

| 3-1 | 1532.83 | 1532.85 | 1532.88 | 1532.88 | 1532.91 | 1532.73 | 1532.74 | 1532.78 | 1532.78 |

| 3-2 | 1536.43 | 1536.43 | 1536.42 | 1536.42 | 1536.39 | 1536.41 | 1536.41 | 1536.41 | 1536.43 |

| 3-3 | 1540.86 | 1540.88 | 1540.89 | 1540.87 | 1540.88 | 1540.9 | 1540.89 | 1540.93 | 1540.94 |

| 3-4 | 1544.21 | 1544.25 | 1544.28 | 1544.31 | 1544.37 | 1544.19 | 1544.19 | 1544.21 | 1544.2 |

| 3-5 | 1548.45 | 1548.48 | 1548.48 | 1548.52 | 1548.51 | 1548.41 | 1548.45 | 1548.45 | 1548.5 |

References

- Wen, L.; Wang, H.S. Prospect of soft robot research: Structure, actuation and control. Robot 2018, 40, 577. [Google Scholar]

- Lin, K.-Y.; Gamboa-Gonzalez, A.; Wehner, M. Soft Robotic Sensing, Proprioception via Cable and Microfluidic Transmission. Electronics 2021, 10, 3166. [Google Scholar] [CrossRef]

- Hu, W.Q.; Lum, G.Z.; Mastrangeli, M. Small-scale soft bodied robot with multimodal locomotion. Nature 2018, 554, 81–85. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, H.; Aaron, O.Y.W.; Yeow, B.S. Fabrication and Initial Cadaveric Trials of Bi-directional Soft Hydrogel Robotic Benders Aiming for Biocompatible Robot-Tissue Interactions. In Proceedings of the 2018 3rd International Conference on Advanced Robotics and Mechatronics, Singapore, 18 July 2018. [Google Scholar] [CrossRef]

- Guan, Q.H.; Sun, J.; Liu, Y.J. Development status and trend of pneumatic soft robot. Sci. Sin. (Technol.) 2020, 50, 897–934. [Google Scholar]

- Condino, S.; Ferrari, V.; Freschi, C.; Alberti, A.; Berchiolli, R.; Mosca, F.; Ferrari, M. Electromagnetic navigation platform for endovascular surgery: How to develop sensorized catheters and guidewires. Int. J. Med. Robot. Comput. Assist. Surg. 2012, 8, 300–310. [Google Scholar] [CrossRef]

- Zou, Q.; Zheng, J.; Su, Q. A wave-inspired ultrastretchable strain sensor with predictable cracks. Sens. Actuators A Phys. 2019, 300, 111658. [Google Scholar] [CrossRef]

- Zou, Q.; Wang, Y.; Yang, F. An intrinsically embedded pressure-temperature dual-mode soft sensor towards soft robotics. Sens. Actuators A Phys. 2021, 332, 113084. [Google Scholar] [CrossRef]

- Cianchetti, M.; Renda, F.; Licofonte, A. Sensorization of continuum soft robots for reconstructing their spatial configuration. In Proceedings of the 2012 4th IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24 June 2012. [Google Scholar] [CrossRef]

- Felt, W.; Remy, C.D. Smart braid: Air muscles that measure force and displacement. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14 September 2014. [Google Scholar] [CrossRef]

- Tao, Y.D.; Gu, G.Y. Design of a soft pneumatic actuator finger with self-strain sensing. In Proceedings of the Intelligent Robotics and Applications: 10th International Conference, Wuhan, China, 16 August 2017. [Google Scholar]

- Tapia, J.; Knoop, E.; Mutn, M. Make sense: Automated sensor design for proprioceptive soft robots. Soft Robot. 2020, 7, 332–345. [Google Scholar] [CrossRef]

- Truby, R.L.; Wehner, M.; Grosskopf, A.K. Soft somatosensitive actuators via embedded 3D printing. Adv. Mater. 2018, 30, 1706383. [Google Scholar] [CrossRef]

- Yin, H.B.; Zhang, Y.; Wang, J.Y. Position prediction of soft finger driven by SMA based on fiber Bragg grating sensor. IEEE Sens. J. 2020, 21, 2951–2962. [Google Scholar] [CrossRef]

- Ya, M.; Liu, Q.; Hamza, S.N. Movement detection in soft robotic gripper using sinusoidally embedded fiber optic sensor. Sensors 2020, 20, 1312. [Google Scholar]

- Zhuang, W.; Sun, G.K.; Li, H. FBG based shape sensing of a silicone octopus tentacle model for soft robotics. Optik 2018, 165, 7–15. [Google Scholar] [CrossRef]

- Tejedor, J.; Macias-Guarasa, J.; Martins, H.F.; Martin-Lopez, S.; Gonzalez-Herraez, M.A. Multi-Position Approach in a Smart Fiber-Optic Surveillance System for Pipeline Integrity Threat Detection. Electronics 2021, 10, 712. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A.; Kaźmierczak, A.; Piramidowicz, R. State-of-the-Art Optical Devices for Biomedical Sensing Applications—A Review. Electronics 2021, 10, 973. [Google Scholar] [CrossRef]

- Li, K. Review of the Strain Modulation Methods Used in Fiber Bragg Grating Sensors. J. Sens. 2016, 2016, 1284520. [Google Scholar] [CrossRef]

- Song, C.S.; Zhang, J.X.; Yang, M.; Zhang, J.G.; Yuan, W. Strain transfer error experiments and analysis on CFRP laminates using FBG sensors. In Proceedings of the 2nd Annual International Conference on Advanced Materials, Mechanical and Structural Engineering, Jeju, Republic of Korea, 18 September 2015; p. 6. [Google Scholar]

- Fei, Y.; Wang, J.; Pang, W. A Novel Fabric-Based Versatile and Stiffness-Tunable Soft Gripper Integrating Soft Pneumatic Fingers and Wrist. Soft Rob. 2019, 6, 1–20. [Google Scholar] [CrossRef]

- Kefal, A.; Yildiz, M. Modeling of sensor placement strategy for shape sensing and structural health monitoring of a wing-shaped sandwich panel using inverse finite element method. Sensors 2017, 17, 2775. [Google Scholar] [CrossRef]

- Tessler, A.; Roy, R.; Esposito, M.; Surace, C.; Gherlone, M. Shape sensing of plate and shell structures undergoing large displacements using the inverse finite element method. Shock Vib. 2018, 2018, 8076085. [Google Scholar] [CrossRef]

- Floris, I.; Madrigal, J.; Sales, S.; Calderon, P.A.; Adam, J.M. Twisting compensation of optical multicore fiber shape sensors for flexible medical instruments. In Proceedings of the Conference on Optical Fibers and Sensors for Medical Diagnostics and Treatment Applications XX, San Francisco, CA, USA, 1 February 2020. [Google Scholar]

- He, Y.L.; Gao, L.K.; Bai, Y.C.; Zhu, H.W.; Sun, G.K.; Zhu, L.Q.; Xu, H.D. Stretchable optical fibre sensor for soft surgical robot shape reconstruction. Opt. Appl. 2021, 51, 589–604. [Google Scholar]

- Chen, X.T.; Stegagno, P.; Zeng, W.; Yuan, C.Z. Localized motion dynamics modeling of a soft robot: A data-driven adaptive learning approach. In Proceedings of the American Control Conference, Atlanta, GA, USA, 8 June 2022. [Google Scholar]

- Truby, R.L.; Della Santina, C.; Rus, D. Distributed proprioception of 3D configuration in soft, sensorized robots via deep learning. IEEE Robot. Autom. Lett. 2020, 5, 3299–3306. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Shih, B.; Laschi, C.; Tolley, M.T. Soft robot perception using embedded soft sensors and recurrent neural networks. Sci. Robot. 2019, 4, 26. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, K.; Minami, Y.; Tokudome, Y.; Tokudome, Y.; Inoue, K.; Kuniyoshi, Y.; Nakajima, K. Continuum-Body-Pose Estimation From Partial Sensor Information Using Recurrent Neural Networks. IEEE Robot. Autom. Lett. 2022, 7, 11244–11251. [Google Scholar] [CrossRef]

- Gal, Y.; Ghahramani, Z. Dropout as a bayesian approximation: Representing model uncertainty in deep learning. In Proceedings of the 33rd International Conference on Machine Learning, New York, NY, USA, 20 June 2016. [Google Scholar]

- Kendall, A.; Gal, Y. What Uncertainties Do We Need in Bayesian Deep Learning for Computer Vision? In Proceedings of the 31st Annual Conference on Neural Information Processing Systems, Long Beach, CA, USA, 4 December 2017. [Google Scholar]

- Jia, G.; Aneek, E.; Li, X.; Yue, C.; Ka-Wai, K.; Mable, P.F. Bidirectional Soft Silicone Curvature Sensor Based on Off-Centered Embedded Fiber Bragg Grating. IEEE Photonics Technol. Lett. 2016, 28, 2237–2240. [Google Scholar]

| Dataset | LSTM Network Model | MAE | RMSE |

|---|---|---|---|

| simulation | Unoptimized | 2.1 | 3.6 |

| Optimized | 2.0 | 3.1 | |

| experiment | unoptimized | 7.9 | 10.2 |

| Optimized | 2.9 | 4.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; He, Y.; Geng, P.; Yang, Y. Research on Posture Sensing and Error Elimination for Soft Manipulator Using FBG Sensors. Electronics 2023, 12, 1476. https://doi.org/10.3390/electronics12061476

Li W, He Y, Geng P, Yang Y. Research on Posture Sensing and Error Elimination for Soft Manipulator Using FBG Sensors. Electronics. 2023; 12(6):1476. https://doi.org/10.3390/electronics12061476

Chicago/Turabian StyleLi, Wenyu, Yanlin He, Peng Geng, and Yi Yang. 2023. "Research on Posture Sensing and Error Elimination for Soft Manipulator Using FBG Sensors" Electronics 12, no. 6: 1476. https://doi.org/10.3390/electronics12061476

APA StyleLi, W., He, Y., Geng, P., & Yang, Y. (2023). Research on Posture Sensing and Error Elimination for Soft Manipulator Using FBG Sensors. Electronics, 12(6), 1476. https://doi.org/10.3390/electronics12061476