Binary Neighborhood Coordinate Descriptor for Circuit Board Defect Detection

Abstract

1. Introduction

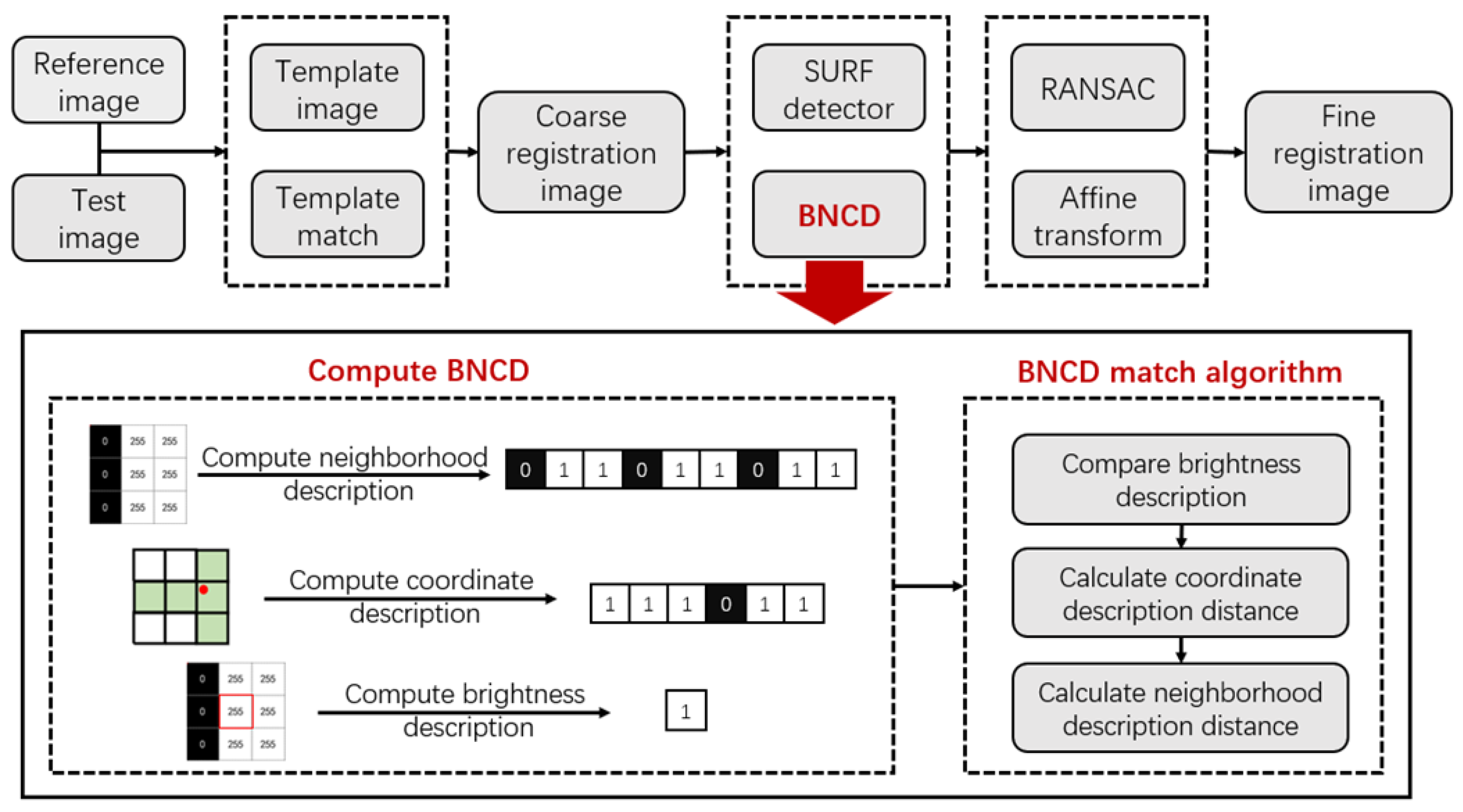

2. Proposed Algorithm

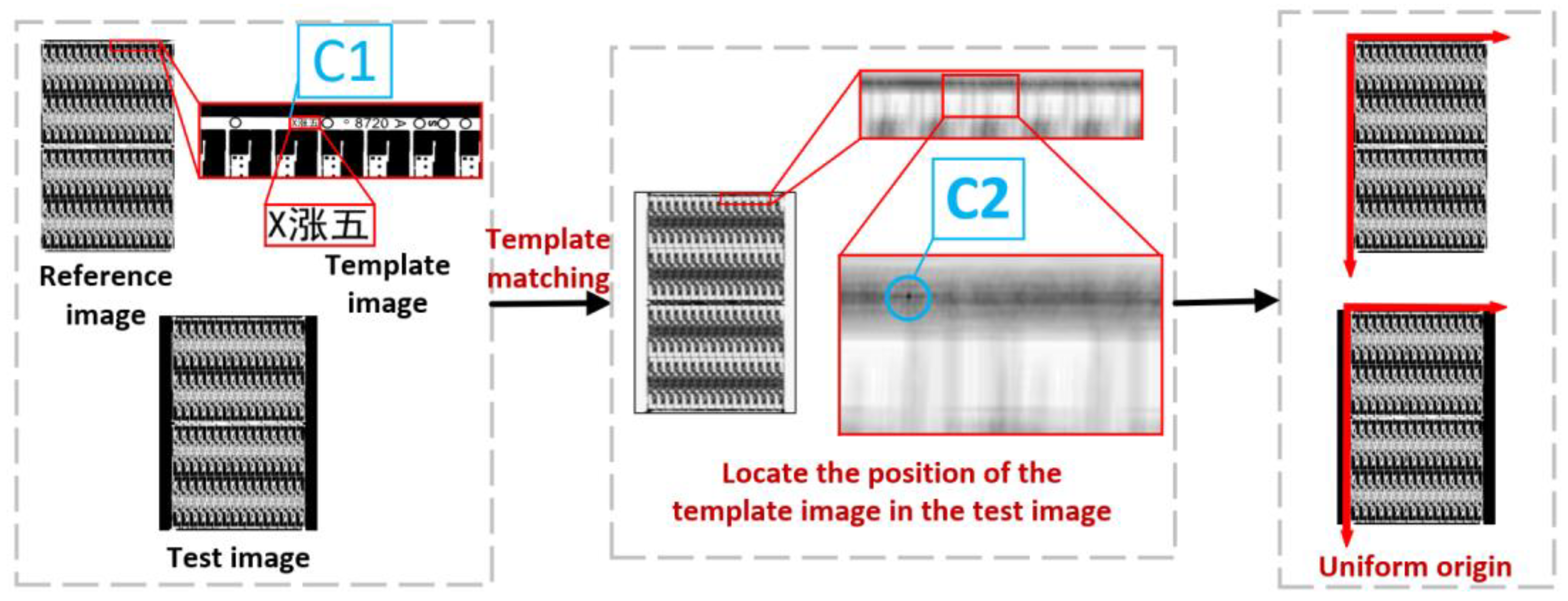

2.1. Coarse Registration Based on Template Matching

| Algorithm 1: Coarse Registration Algorithm Based on Template Matching |

| Input: test image Itest, reference image Ireference Output: test image after coarse registration Itest’ |

|

2.2. Speeded-Up Roubust Feature

- Create box filters () of different sizes, and then convolve the target image I to obtain the second-order differential responses at each scale.

- Calculate the Hessian determinant image according to (2), and construct an image pyramid.where is an approximate box filter in x-direction, and and are similar. Formula (2) calculates the approximate value of the determinant of Hessian matrix. multiplied by ω is to balance the error caused by the approximation of box filters. ω is generally taken as 0.9.

- Use non-maximum suppression in the 3 × 3 × 3 neighborhood to preliminarily determine the keypoints, and then perform interpolation operations to determine the precise location and scale of the keypoints.

2.3. Binary Neighborhood Coordinate Descriptor

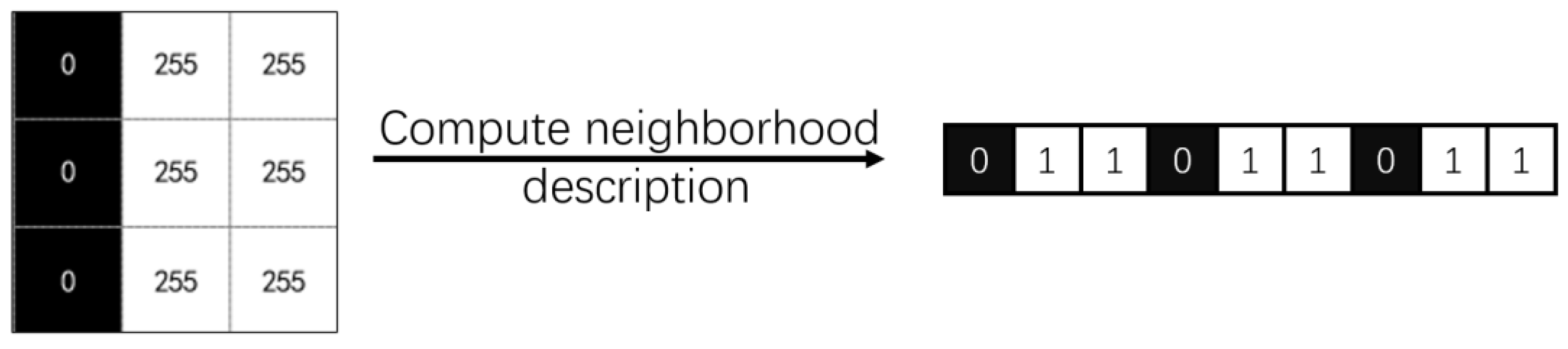

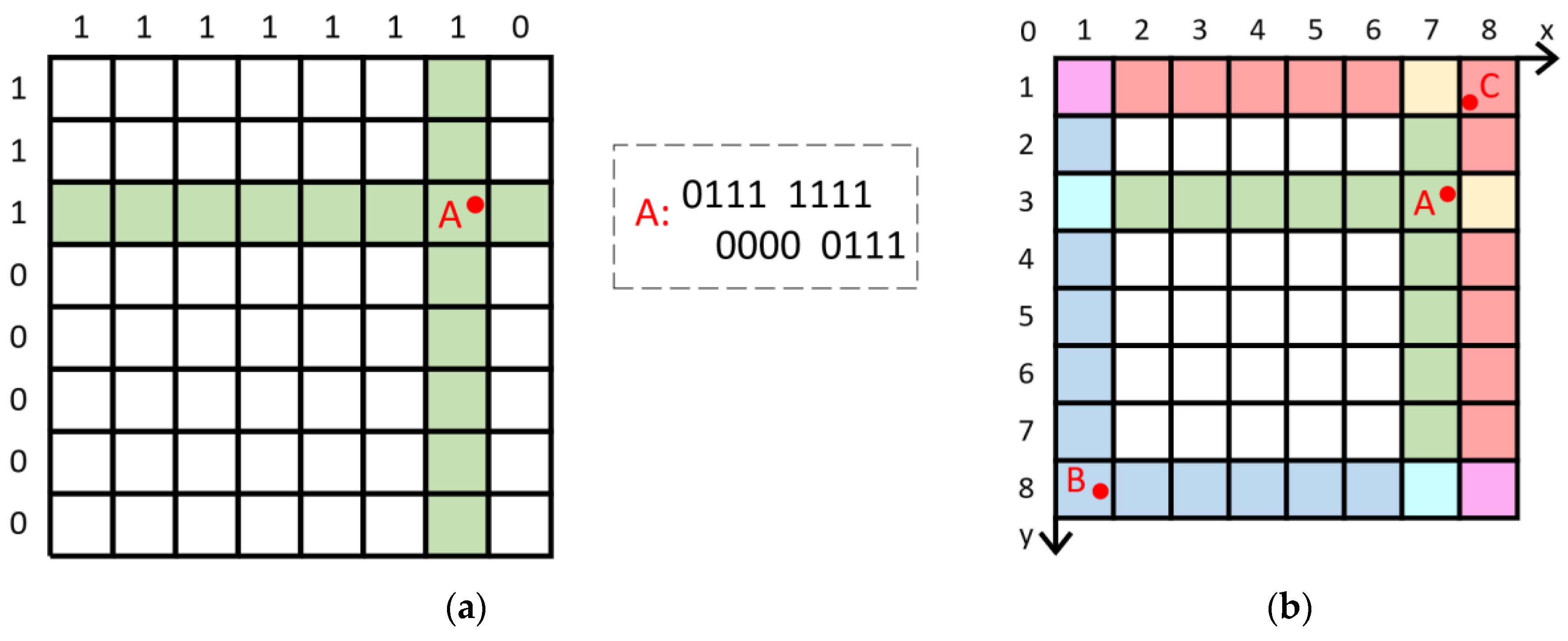

2.3.1. Neighborhood Description

2.3.2. Coordinate Description

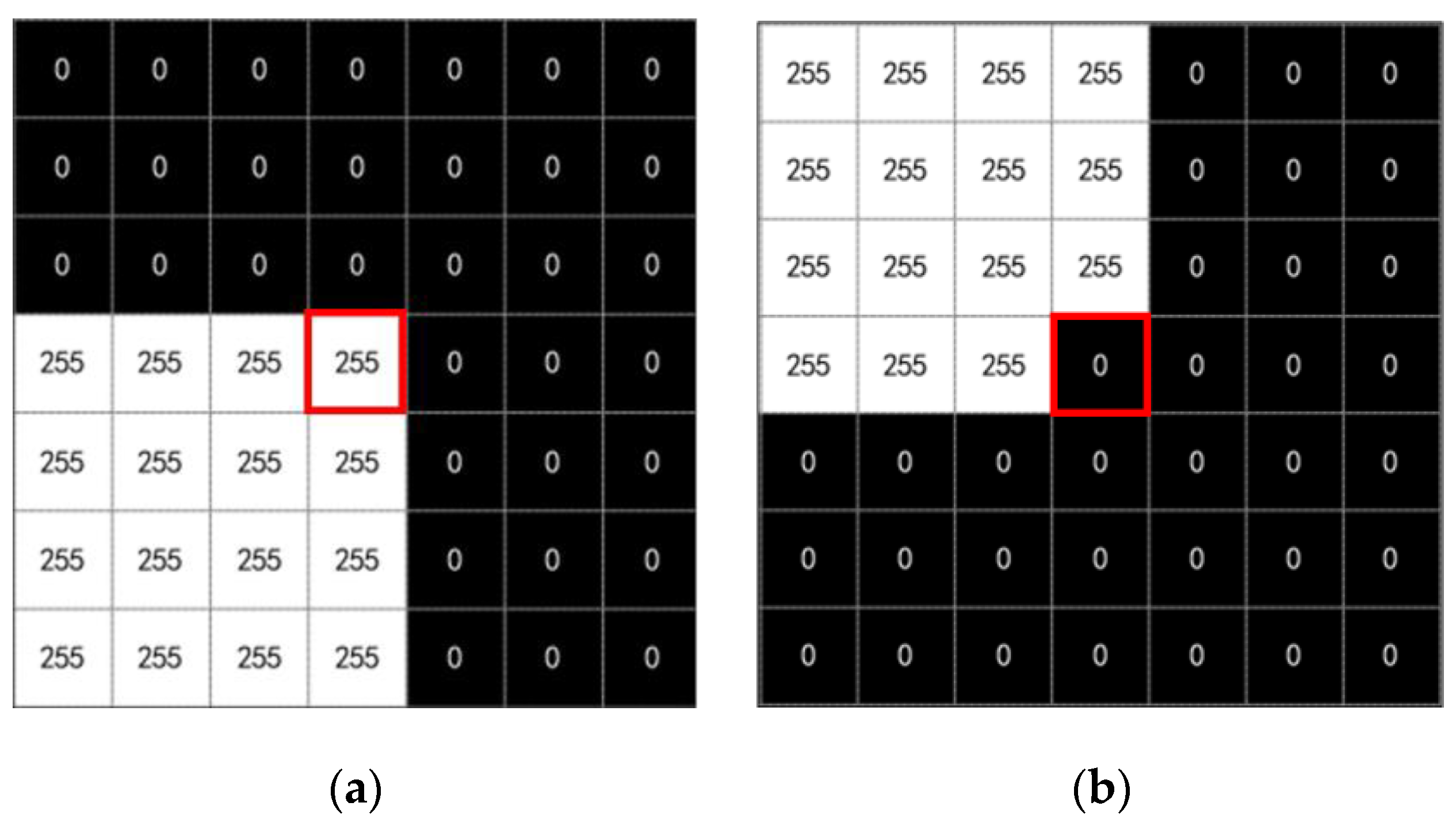

2.3.3. Brightness Description

2.3.4. Matching Algorithm for BNCD

| Algorithm 2: BNCD Matching Algorithm |

|

|

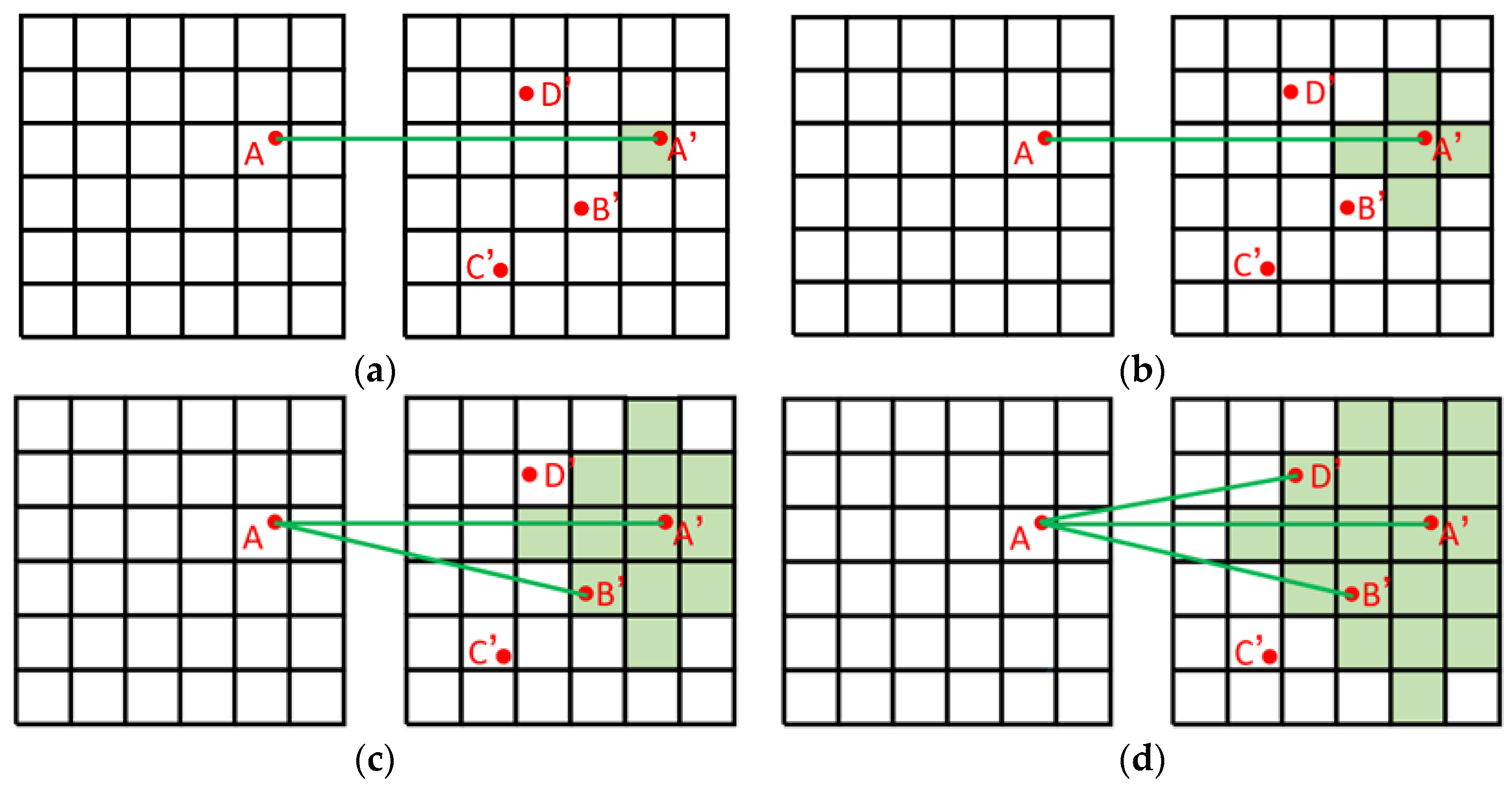

2.3.5. BNCD Failure Situation

2.4. RANSAC

| Algorithm 3: Random Sample Consensus Algorithm |

| Input: number of iterations kmax, confidence interval η0, matching result M Output: optimal transformation matrix Hbest |

|

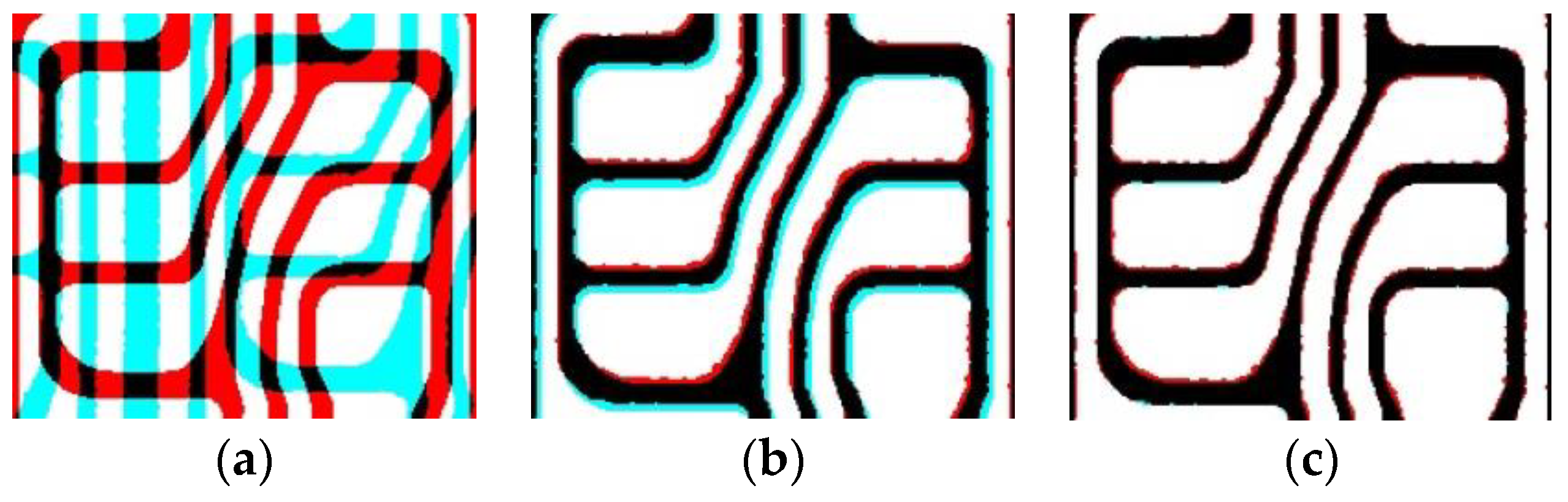

3. Results and Discussion

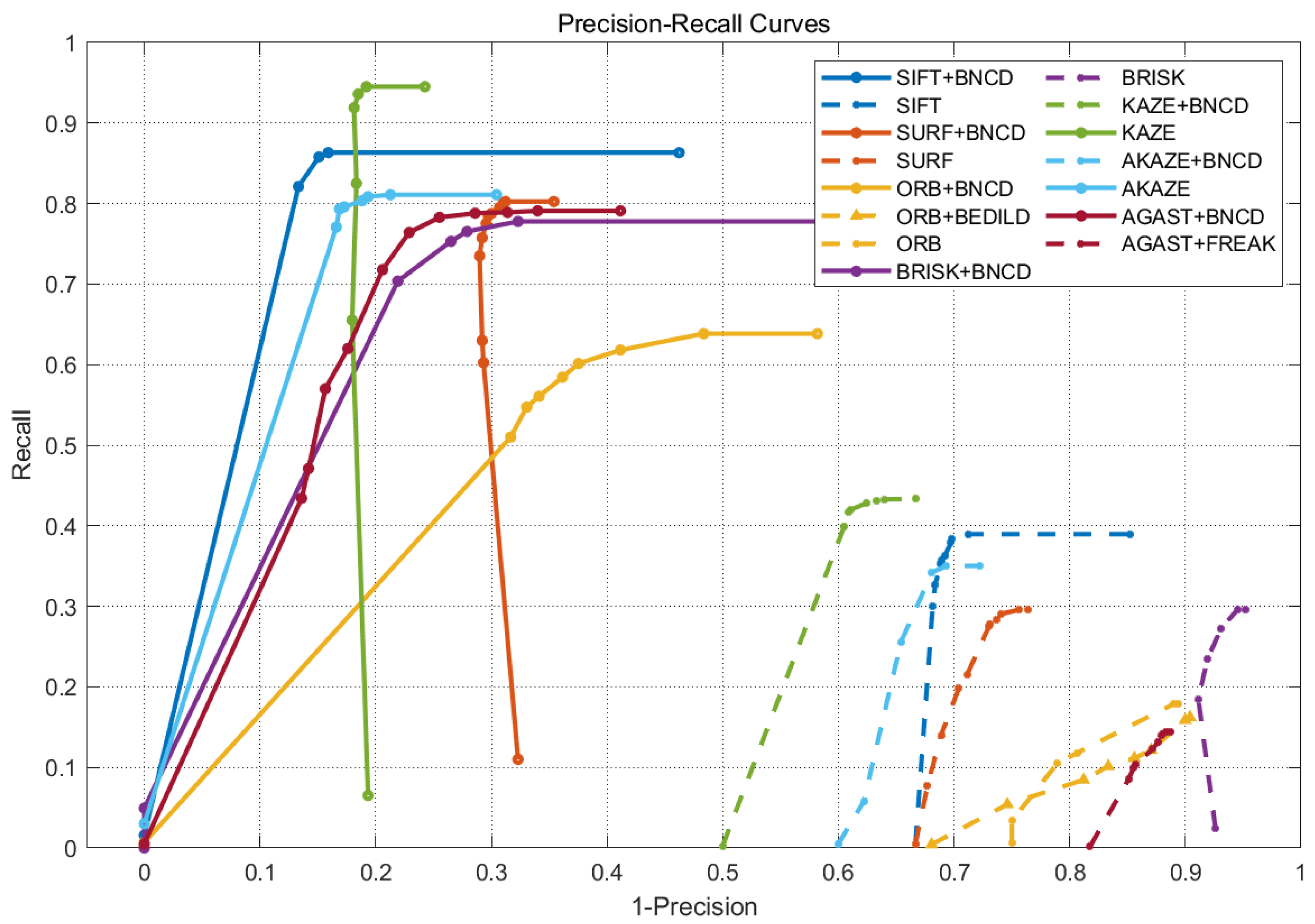

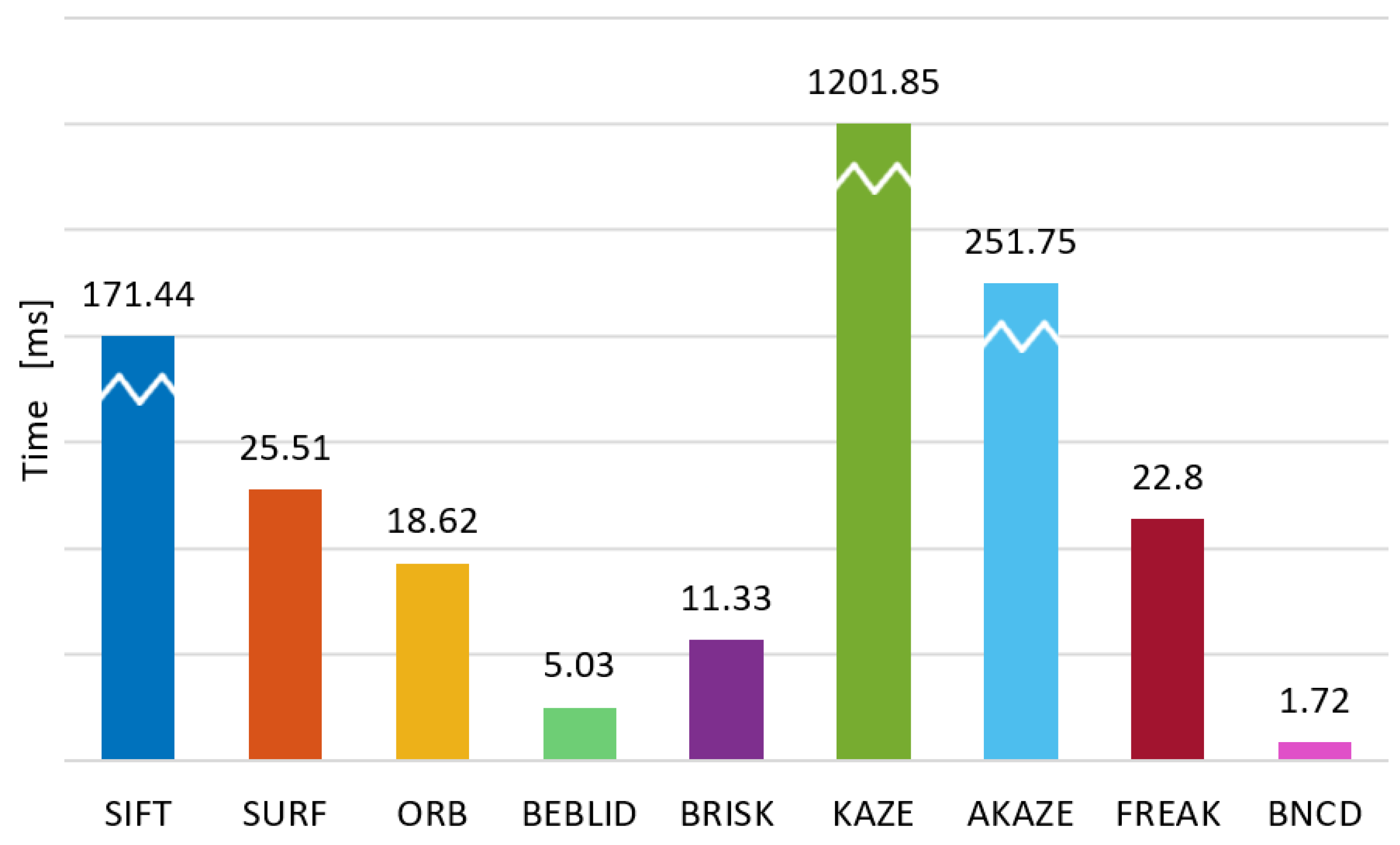

3.1. Comparison with State-of-the-Art Descriptors

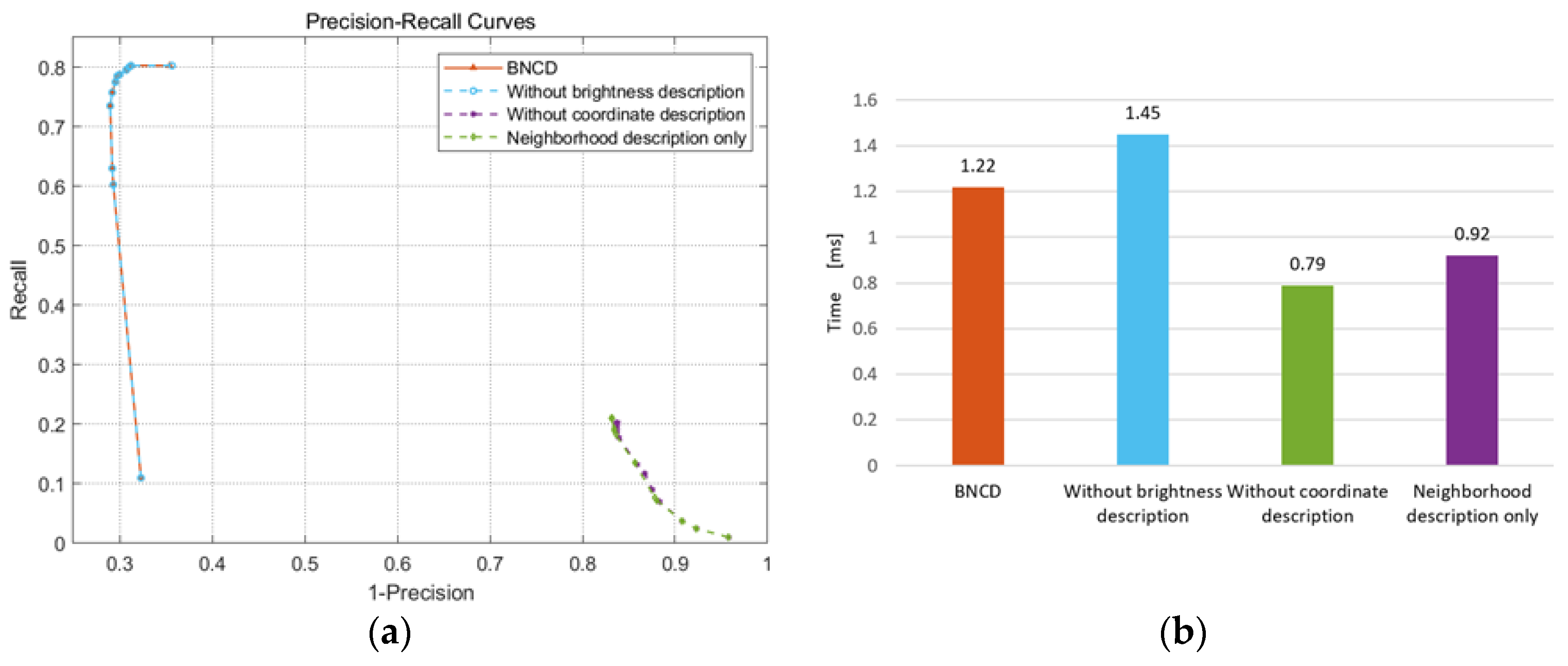

3.2. The Influence of Coordinate Description and Brightness Description on BNCD

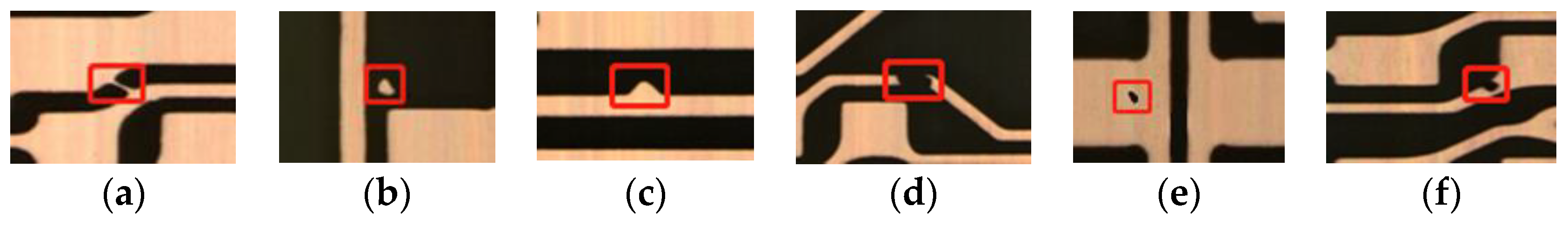

3.3. Circuit Board Inspection Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, H.; Zhang, Y.; Lv, W.; Yin, J.; Qasim, T.; Wang, D. A Deep Convolutional Generative Adversarial Networks-Based Method for Defect Detection in Small Sample Industrial Parts Images. Appl. Sci. 2022, 12, 6569. [Google Scholar] [CrossRef]

- Deng, H.; Cheng, Y.; Feng, Y.; Xiang, J. Industrial Laser Welding Defect Detection and Image Defect Recognition Based on Deep Learning Model Developed. Symmetry 2021, 13, 1731. [Google Scholar] [CrossRef]

- Avola, D.; Cascio, M.; Cinque, L.; Fagioli, A.; Foresti, G.L.; Marini, M.R.; Rossi, F. Real-time deep learning method for automated detection and localization of structural defects in manufactured products. Comput. Ind. Eng. 2022, 172, 108512. [Google Scholar] [CrossRef]

- Baygin, M.; Karakose, M.; Sarimaden, A.; Akin, E. Machine vision based defect detection approach using image processing. In Proceedings of the 2017 International Artificial Intelligence and Data Processing Symposium (IDAP), Malatya, Turkey, 16–17 September 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Hua, G.; Huang, W.; Liu, H. Accurate image registration method for PCB defects detection. J. Eng. 2018, 2018, 1662–1667. [Google Scholar] [CrossRef]

- Hassanin, A.-A.I.M. A real-time approach for automatic defect detection from PCBs based on SURF features and morphological operations. Multimed. Tools Appl. 2019, 78, 34437–34457. [Google Scholar] [CrossRef]

- Melnyk, R.; Havrylko, Y.; Hatsosh, D. Printed Circuit Boards Short and Open Defects Detection by Thinning and Flood-fill Algorithms. In Proceedings of the 2021 IEEE 16th International Conference on the Experience of Designing and Application of CAD Systems (CADSM), Lviv, Ukraine, 22–26 February 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Qi, M.; Yin, T.; Cheng, G.; Xu, Y.; Meng, H.; Wang, Y.; Cui, S. Research on Printing Defects Inspection of Solder Paste Images. Wirel. Commun. Mob. Comput. 2022, 2022, 8651956. [Google Scholar] [CrossRef]

- Guo, Z.; Xu, L.; Ran, G.; Chen, J. PCB Defect Detection Based on ORB Algorithm and Image Difference. Digit. Technol. Appl. 2022, 40, 38–41+142. (In Chinese) [Google Scholar] [CrossRef]

- Gao, L.; Zheng, F.; Bian, J.Y. Using computer theory to detect PCB defects in an IoT environment. J. Supercomput. 2022, 78, 18887–18914. [Google Scholar] [CrossRef]

- Bay, H.; Ess, A.; Tuytelaars, T.; Gool, L.V. Speeded-Up Robust Features (SURF). Comput. Vis. Image Underst. 2008, 110, 346–359. [Google Scholar] [CrossRef]

- Liu, H.; Deng, M.; Xiao, C.; Xu, X. Image fusion algorithm based on adaptive weighted coefficients. In Proceedings of the IEEE 10th International Conference on Signal Processing Proceedings, Beijing, China, 24–28 October 2010; pp. 748–751. [Google Scholar] [CrossRef]

- Fischler, M.A.; Bolles, R.C. Random sample consensus: A paradigm for model fitting with applications to image analysis and automated cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Mikolajczyk, K.; Schmid, C. A performance evaluation of local descriptors. IEEE Trans. Pattern Anal. Mach. Intell. 2005, 27, 1615–1630. [Google Scholar] [CrossRef] [PubMed]

- Farhat, M.; Chaabouni-Chouayakh, H.; Ben-Hamadou, A. Self-supervised endoscopic image key-points matching. Expert Syst. Appl. 2023, 213, 118696. [Google Scholar] [CrossRef]

| Defect Type | Total Defects | TP | TP Rate (%) | FP | FP Rate (%) | FN |

|---|---|---|---|---|---|---|

| Short | 91 | 88 | 96.7 | 6 | 6.38 | 3 |

| Spurious copper | 78 | 78 | 100 | 0 | 0 | 0 |

| Spur | 81 | 80 | 98.77 | 2 | 2.44 | 1 |

| Open | 71 | 69 | 97.18 | 0 | 0 | 2 |

| Pinhole | 66 | 66 | 100 | 0 | 0 | 0 |

| Mouse bite | 112 | 112 | 100 | 2 | 1.75 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Hu, X.; Zhang, T.; Liu, S.; Hu, K.; He, T.; Yang, X.; Ye, J.; Wang, H.; Tan, Y.; et al. Binary Neighborhood Coordinate Descriptor for Circuit Board Defect Detection. Electronics 2023, 12, 1435. https://doi.org/10.3390/electronics12061435

Zhang J, Hu X, Zhang T, Liu S, Hu K, He T, Yang X, Ye J, Wang H, Tan Y, et al. Binary Neighborhood Coordinate Descriptor for Circuit Board Defect Detection. Electronics. 2023; 12(6):1435. https://doi.org/10.3390/electronics12061435

Chicago/Turabian StyleZhang, Jiaming, Xuejuan Hu, Tan Zhang, Shiqian Liu, Kai Hu, Ting He, Xiaokun Yang, Jianze Ye, Hengliang Wang, Yadan Tan, and et al. 2023. "Binary Neighborhood Coordinate Descriptor for Circuit Board Defect Detection" Electronics 12, no. 6: 1435. https://doi.org/10.3390/electronics12061435

APA StyleZhang, J., Hu, X., Zhang, T., Liu, S., Hu, K., He, T., Yang, X., Ye, J., Wang, H., Tan, Y., & Liang, Y. (2023). Binary Neighborhood Coordinate Descriptor for Circuit Board Defect Detection. Electronics, 12(6), 1435. https://doi.org/10.3390/electronics12061435