Dynamic Capability Theory Based Study on Performance of Intelligent Manufacturing Enterprise under RFID Influence

Abstract

1. Introduction

2. Theoretical Basis and Research Hypotheses

2.1. Dynamic Capability Theory

2.2. RFID Investment from the Perspective of DCT

2.3. Enterprise’s Intelligent Manufacturing Capability from the Perspective of DCT

2.4. Relationships among RFID Investment Level, Intelligent Manufacturing Capability and Enterprise Performance

2.4.1. Relationships between RFID Investment Level and Enterprise Performance

2.4.2. Relationship between RFID Investment Level and Intelligent Manufacturing Capability of an Enterprise

2.4.3. Relationship between Intelligent Manufacturing Capability and Enterprise Performance

2.5. Moderating Role of Entrepreneurship

3. Materials and Methods

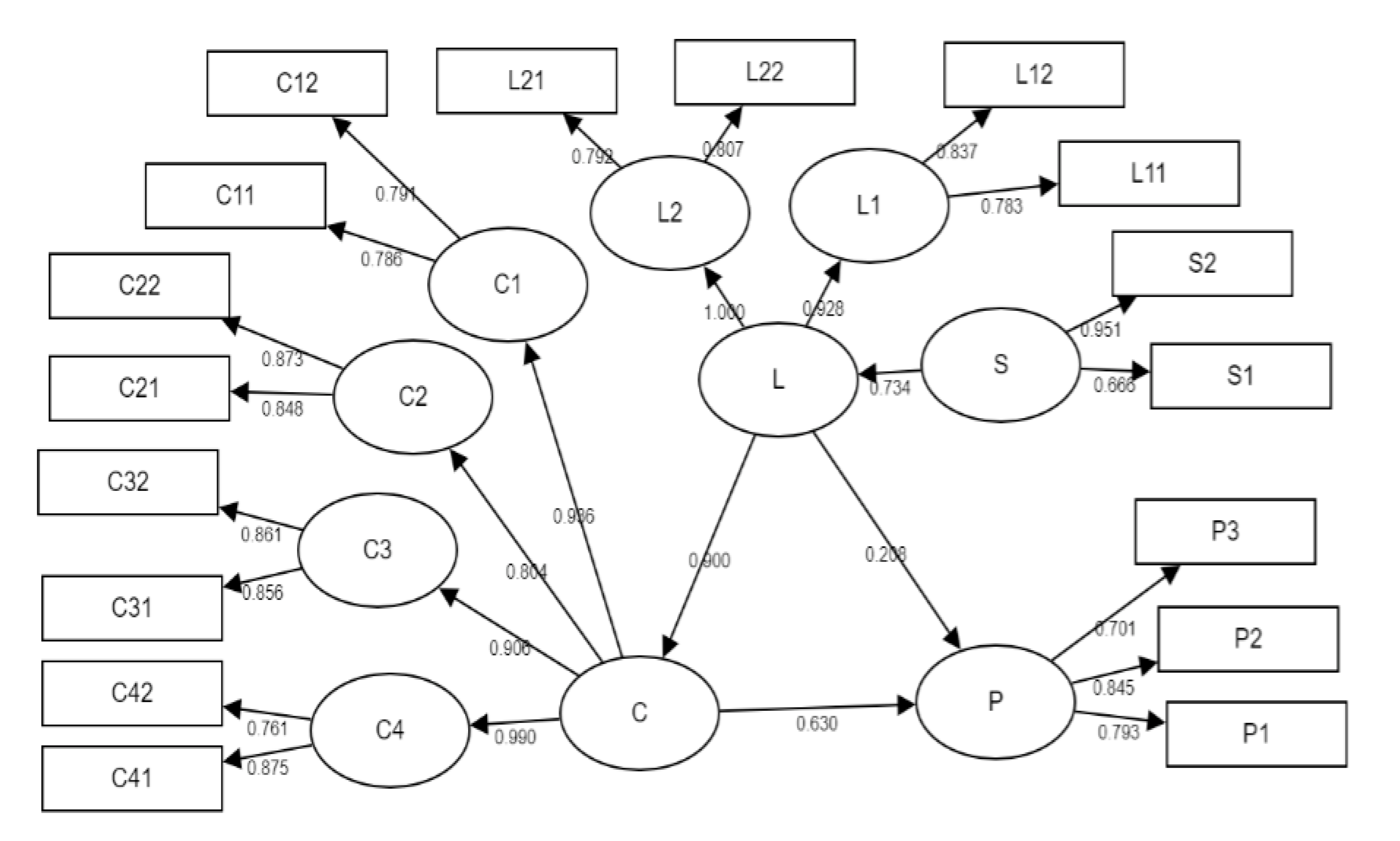

3.1. Conceptual Model

3.2. Index Design

3.3. Sample Survey

3.4. Analysis of Reliability and Validity

3.5. Data Discrimination Analysis

4. Structural Equation Modeling

4.1. Fitting of the Structural Equation Model

4.1.1. Fitting Test

4.1.2. Structural Equation Modeling

4.2. Moderated Mediating Effect

4.2.1. Mediating Effect of Intelligent Manufacturing Capability

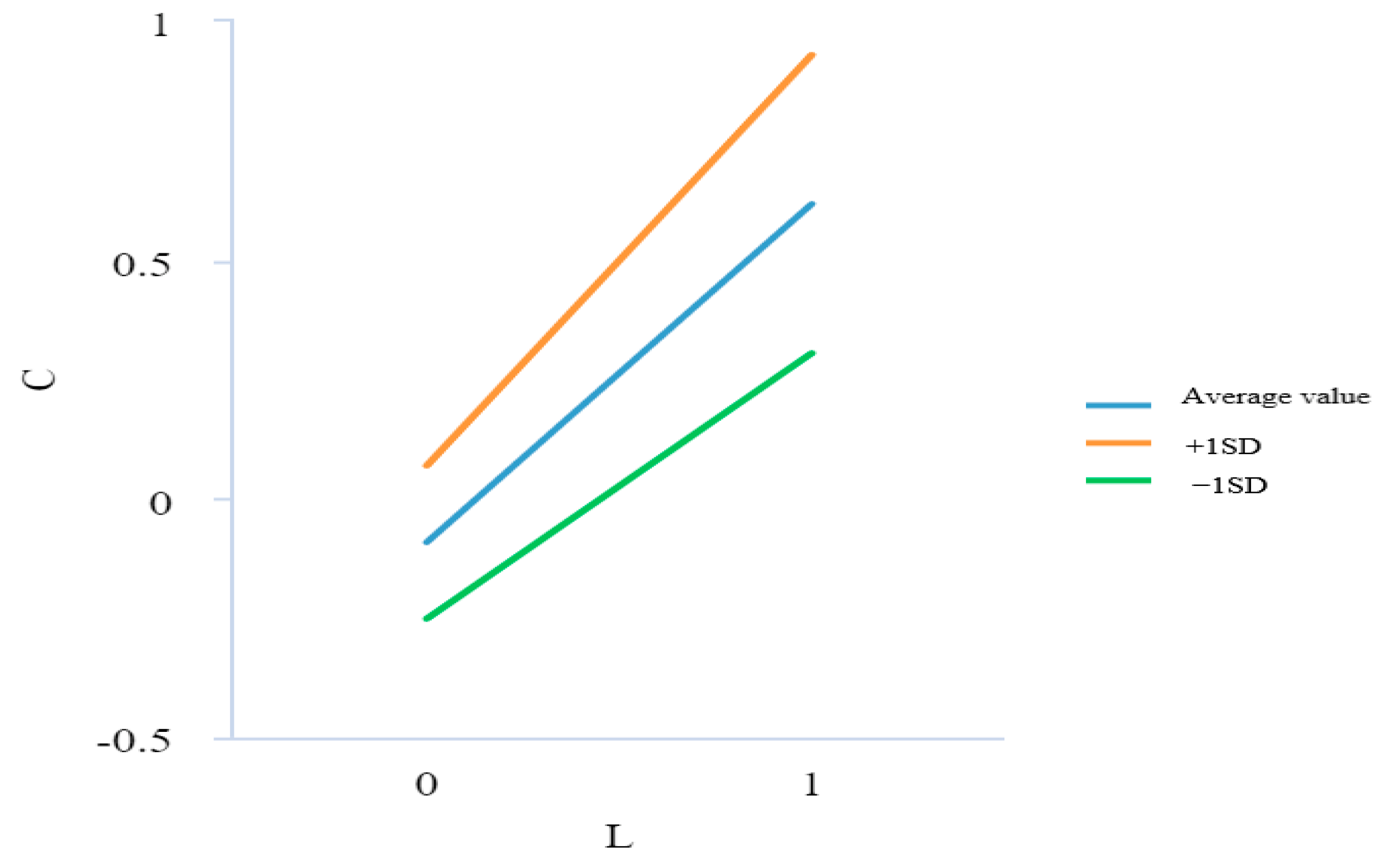

4.2.2. Direct Moderating Effect of Entrepreneurship

4.2.3. Moderated Mediation Effect

5. Hypothesis Testing and Findings

5.1. Hypothesis Testing

5.2. Findings

- Finding 1: H1, H2, H3 and H4 indicate that the higher the level of investment in RFID technology is, the greater the intelligent manufacturing capacity of a manufacturing enterprise will be, and correspondingly, the higher the enterprise performance will be. In response to the “intelligent manufacturing” transformation of China’s manufacturing industry, an enterprise should make full use of advanced information technology to assist it in building its “intelligent manufacturing” capability. Only RFID technology being integrated into the relevant aspects of manufacturing and internalized into the enterprise’s ability, can it drive the enterprise’s performance to grow. This also enlightens that China’s manufacturing enterprises shall not only invest heavily in technical infrastructure, but also pay more attention to the integration and application of new technologies to achieve the value creation of technology investment.

- Finding 2: The test of the H1a hypothesis shows that the RFID investment level is not the investment in technology infrastructure that companies usually think. In fact, the effectiveness of limited technical investment made according to the company’s manufacturing strategy is the key element to reflect the level of technological investment.

- Finding 3: It is feasible to use the four secondary latent variables of C to evaluate an enterprise’s intelligent manufacturing energy. Among them, the promotion of RFID technology to enterprise management and decision-making ability can best reflect the enterprise’s “intelligent manufacturing” capability. What is novel is that the enterprise’s vertical and horizontal business collaboration capability (C3), as a key factor in the enterprise’s “intelligent manufacturing” capability, does not have to mediate utility but can be moderated by S. In contrast, the willingness to cooperate (C2) has the least influence on the enterprise’s “intelligent manufacturing” capability, but it has a mediation effect but is not moderated by S. The reason may be that an enterprise’s business collaboration capability, as the core factor of the enterprise’s intelligent manufacturing capability, is more a reaction to the synergistic structural effect of the enterprise supply chain, and is not directly driven by RFID technology, so the mediation effect of C3 is not significant. However, driven by strong entrepreneurship, the RFID technology characteristics in business collaboration will be highlighted, and then C3 will tend to produce mediating utility under the mediation of S. The willingness of an enterprise to cooperate (C2) is the basis for it to carry out collaborative manufacturing, and should become a mediating variable, but willingness as a reflection of choice, will not change arbitrarily with the strength of entrepreneurship, otherwise, any development strategy of enterprises is difficult to implement.

- Finding 4: H5 shows that the greater the innovation and risk-taking spirit of entrepreneurs are, the easier it will be for enterprises to increase investment in RFID, so under different entrepreneurships, enterprises have different awareness of RFID investment levels and investment strengths.

- Finding 5: H51 indicates that the influence of RFID investment on an enterprise’s “intelligent manufacturing” capability is also affected by entrepreneurship. Under different entrepreneurial characteristics, the same RFID technology investment will produce different “intelligent manufacturing” capabilities. This is because companies with a high degree of pioneering and adventurous spirit are more courageous to absorb the energy of advanced technology and enhance their dynamic capability.

- Finding 6: Even if entrepreneurship is high, there is no direct moderated relationship between L and P (H52). This further proves that RFID technology cannot have an influence on the enterprise “intelligent manufacturing” before it is transformed into a certain enterprise “intelligent manufacturing” capability. No matter how advanced the technology and how much investment, lack of effective application, it does not work as well as it should.

- Finding 7: According to the test of H6 and H61, the stronger the entrepreneurship is, the stronger the influence of the enterprise’s intelligent manufacturing capability on the relationship between RFID investment level and enterprise performance will be. This modulated mediation effect also implies that a manufacturing enterprise should cultivate and give full play to entrepreneurship when using advanced information technology to carry out “intelligent manufacturing” transformation, to avoid being tied up in the process of change and inefficient or even failed “intelligent manufacturing” transformation.

- Finding 8: For the evaluation of enterprise performance, many scholars give different indicators. Different from the conventional enterprise performance evaluation goals, the enterprise “intelligent manufacturing” performance indicators proposed in this paper based on the goal of “intelligent manufacturing” of manufacturing enterprises in China, are tested to be appropriate. Moreover, it is clear that an enterprise should pay the most attention to product innovation and product market share (H3a) in the “intelligent manufacturing” environment, and pay attention to whether the company’s intelligent manufacturing behavior improves or enhances customer service satisfaction. In addition, traditionally, people have used to emphasize the operating costs in the enterprise performance. However, they ignore the variability of enterprise performance indicators in different operating environments. The research in this paper shows that operating costs are still important, but less so than P2 and P3. The reason for this may be that enterprises that implement intelligent manufacturing pay more attention to the ultimate goal of “intelligent manufacturing”, so the cost of “intelligent manufacturing” within the affordable range is acceptable.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tian, Z.P. Research on Intelligent Upgrading of Manufacturing Industry in Shandong Province under “Internet plus”. Master’s Thesis, Liaocheng University, Liaocheng, China, 2018. [Google Scholar]

- Kang, Y.S.; Kim, H.; Lee, Y.H. Implementation of an RFID-Based Sequencing-Error-Proofing System for Automotive Manufacturing Logistics. Appl. Sci. 2018, 8, 109. [Google Scholar] [CrossRef]

- Jin, J.J.; Guo, M.; Chen, X.; Zhou, W.H. RFID adoption and its long-term impact on firm value: An empirical research based on global public companies. J. Ind. Eng. Eng. Manag. 2018, 32, 212–219. [Google Scholar]

- Moon, S.; Xu, S.; Hou, L.; Wu, C.; Wang, X.; Tam, V.W.Y. Rfid-aided tracking system to improve work efficiency of scaffold supplier: Stock management in Australasian supply chain. J. Constr. Eng. Manag. 2018, 144, 04017115. [Google Scholar] [CrossRef]

- Cao, W.; Jiang, P.Y.; Jiang, K.Y.; Lu, P. Radio frequency identification-based real-time data collecting and visual monitoring for discrete manufacturing workshop. Comput. Integr. Manuf. Syst. 2017, 23, 273–284. [Google Scholar]

- Liukkonen, M. RFID technology in manufacturing and supply chain. Int. J. Comput. Integr. Manuf. 2018, 28, 861–880. [Google Scholar] [CrossRef]

- Jiang, C.; Xie, F.J.; Liu, H.M. Dynamic Firm Competence Analysis in Punctuated Equilibrim. Ind. Eng. Manag. 2007, 12, 30–34. [Google Scholar]

- Barreto, I. Dynamic Capabilities: A Review of Past Research and an Agenda for the Future. J. Manag. 2009, 36, 256–280. [Google Scholar] [CrossRef]

- Dutta, K. Exploring dynamic capabilities: A systems thinking approach. Syst. Res. Behav. Sci. 2021, 38, 125–136. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Zhou, M.; Luo, J.Q.; Kuang, S.B. The Structure and Measurements of Virtualization Enterprise Dynamic Abilities. Soft Sci. 2014, 28, 124–129. [Google Scholar]

- Qian, J.J.; He, Y. Dynamic Capability Evolution and Digital Transformation of Traditional Enterprise. China Soft Sci. 2021, 6, 135–143. [Google Scholar]

- Jian, Z.Q.; Wang, C.; Chen, J.H. Strategic Orientation, Dynamic Capability and Technological Innovation: Moderating Role of Environmental Uncertainty. R D Manag. 2015, 27, 65–76. [Google Scholar]

- Yang, X.; Liu, C.; He, Y.C. Research on the Mechanism of Business Model Innovation to Enterprise Performance from the Perspective of Dynamic Capabilities—With Listed Manufacturing Companies as an Example. Ind. Technol. Econ. 2019, 38, 120–128. [Google Scholar]

- Leng, W.; Jiang, P.Y. Dynamic scheduling in RFID-driven discrete manufacturing system by using multi-layer network metrics as heuristic information. J. Intell. Manuf. 2019, 30, 979–994. [Google Scholar] [CrossRef]

- Ali, S.; Green, P.; Robb, A. Information technology investment governance: What is it and does it matter? Int. J. Account. Inf. Syst. 2015, 18, 1–25. [Google Scholar] [CrossRef]

- Ali, S.; Green, P.; Robb, A.; Masli, A. Governing information technology (IT) investment: A contingency perspective on organization’s IT investment goals. Aust. J. Manag. 2021, 47, 3–23. [Google Scholar] [CrossRef]

- Zelbst, P.J.; Green, K.W.; Sower, V.E.; Reyes, P.M. Impact of RFID on manufacturing effectiveness and efficiency. Int. J. Oper. Prod. Manag. 2012, 32, 329–350. [Google Scholar] [CrossRef]

- Han, X.Y.; Dong, J.J.; Xu, Z.L. The Effects of Dynamic Capability on Service Intelligence Performance in Manufacturing Enterprises. Ind. Technol. Econ. 2020, 39, 119–124. [Google Scholar]

- Huang, J.; Guo, G.X.; Liu, M.; Qin, Y. Research on the Intelligent Transformation and Upgrade Path of China’s Automobile Manufacturing Enterprises from the Perspective of Dynamic Capabilities—Case Study based on 3 Domestic Manufacturing Companies. Sci. Technol. Prog. Policy 2018, 35, 121–129. [Google Scholar]

- Shi, L.; Ding, X.; Li, M.; Yuan, L. Research on the capability maturity evaluation of intelligent manufacturing based on firefly algorithm, sparrow search algorithm, and BP neural network. Complexity 2021, 2021, 5554215. [Google Scholar] [CrossRef]

- Aral, S.; Weill, P. IT Assets, organizational capabilities, and firm performance: How resource allocations and organizational differences explain performance variation. Organ. Sci. 2007, 18, 763–780. [Google Scholar] [CrossRef]

- Yang, H.; Kim, S.W. Managerial capabilities of information technology and firm performance: Role of e procurement system type. Int. J. Prod. Res. 2014, 52, 4488–4506. [Google Scholar]

- Beccalli, E. Does IT investment improve bank performance? evidence from Europe. J. Bank. Financ. 2007, 31, 2205–2230. [Google Scholar] [CrossRef]

- Meng, Q. “Productivity Paradox” and the Comparison of Impact of IT Investments in U.S. and China. Ind. Eng. Manag. 2005, 10, 68–73. [Google Scholar]

- Xue, L.; Ray, G.; Sambamurthy, V. Efficiency or Innovation: How Do Industry Environments Moderate the Effects of Firms’ IT Asset Portfolios? MIS Q. 2012, 36, 509–528. [Google Scholar] [CrossRef]

- Meng, S.; Yong, H.S.; Chul, W.L. Influential Factors for the IT Investment Decision Making Quality: An Empirical Study Focus on IT Governance. Inf. Syst. Rev. 2018, 20, 87–110. [Google Scholar]

- Schmidt, M.; Thoroe, L.; Schumann, M. RFID and barcode in manufacturing logistics: Interface concept for concurrent operation. Inf. Syst. Manag. 2013, 30, 100–115. [Google Scholar] [CrossRef]

- Liu, S.S. The Long-Term Impact of RFID Technology Adoption on Enterprise Performance: An Empirical Study Based on a Global Perspective. Master’s Thesis, Zhejiang University, Hangzhou, China, 2015. [Google Scholar]

- Wang, D.Q.; Luo, X.X. Research on the performance contribution of IT investment based on the enterprise competence theory. Sci. Res. Manag. 2010, 31, 137–146. [Google Scholar]

- Wu, W.Y.; Liu, J.Y. Mechanism and Optimization Path of Intelligent Manufacturing to Promote Industrial Transformation and Upgrading in China. J. Univ. Financ. Econ. 2020, 33, 19–26. [Google Scholar]

- Lu, N.; Zhou, W.; Dou, Z.W. Can intelligent manufacturing empower manufacturing?—An empirical study considering ambidextrous capabilities. Ind. Manag. Data Syst. 2022, 123, 188–203. [Google Scholar] [CrossRef]

- Liu, T.; Yang, X.; Guo, Y. Study on Promoting Intelligent Manufacturing Path Choice of Manufacturing Enterprises Based on Coevolution Strategy. Discret. Dyn. Nat. Soc. 2021, 2021, 3552911. [Google Scholar] [CrossRef]

- Ruan, X.X. Comprehensive Analysis of Chinese Intelligent Manufacturing Capability and its Influence on Manufacturing Competitiveness. J. Zhengzhou Inst. Aeronaut. Ind. Manag. 2017, 35, 39–49. [Google Scholar]

- Xu, X.; Zhang, H.; Zhou, S.S. Research on the Relationship between Structure Embeddedness, Dynamic Capabilities and Organizational Performance:A Mixed Model. Sci. Technol. Prog. Policy 2019, 36, 99–107. [Google Scholar]

- Williams, C.C.; Martinez–Perez, A.; Kedir, M.A. Informal entrepreneurship in developing economies: The impacts of starting up unregistered on firm performance. Entrep. Theory Pract. 2017, 41, 773–799. [Google Scholar] [CrossRef]

- Johansson, D.; Karlsson, J. Information technology and high-impact entrepreneurship. Int. J. Entrep. Ventur. 2022, 14, 449–471. [Google Scholar] [CrossRef]

- Sun, X.B.; Zhao, D.H.; Zhang, D.P.; Tian, F. Entrepreneurship and sustainable innovation capabilities in platform enterprises: The mediating role of knowledge integration. Chin. Manag. Stud. 2021, 16, 627–652. [Google Scholar] [CrossRef]

- Zhao, D.; Tian, F.; Sun, X.; Zhang, D. The effects of entrepreneurship on the enterprises’ sustainable innovation capability in the digital era: The role of organizational commitment, person–organization value fit, and perceived organizational support. Sustainability 2021, 13, 6156. [Google Scholar] [CrossRef]

- Kim, S.J.; Kim, N.S. The Mediating Effect of Social Contribution Activities on the Relationship between Social Entrepreneurship and Organizational Performance. J. Korea Contents Assoc. 2021, 21, 771–782. [Google Scholar]

- Xu, H.E.; Zhao, B.X. A Study on the Relationship between IT Input and Output of Networked Platform for Small and Medium-sized Enterprises—Based on the Data Analysis of Small and Medium-sized Enterprises in Jiangsu Province. East China Econ. Manag. 2015, 29, 27–34. [Google Scholar]

- Melville, N.; Gurbaxani, K.V. Review: Information technology and organizational performance: An integrative model of it business value. Mis Q. 2004, 28, 283–322. [Google Scholar] [CrossRef]

- Ji, M.; Zhang, S.F. IT Foundation, IT Innovation Synergy Capability and Innovation Performance —The Empirical Research Based on the Micro-Data of China Enterprises. J. Jiangsu Univ. Technol. 2019, 25, 55–65. [Google Scholar]

- Jing, Y.; Li, W.C. Research on Behavioral Mechanism of Enterprises RFID Adoptionunder Intelligent Manufacturing Environment. Ind. Technol. Econ. 2017, 36, 86–91. [Google Scholar]

- Covin, J.G.; Garrett, R.P.; Kuratko, D.F.; Shepherd, D.A. Value proposition evolution and the performance of internal corporate ventures. J. Bus. Ventur. 2015, 30, 749–774. [Google Scholar] [CrossRef]

- Robinson, K.L.; Dassie, W.; Christy, R.D. Entrepreneurship and Small Business Development as a Rural Development Strategy. South. Rural. Sociol. SRS 2004, 20, 1–23. [Google Scholar]

- Seo, J. The effects of entrepreneurship and corporate social responsibility on firm performance. J. Korea Contents Assoc. 2016, 16, 426–433. [Google Scholar] [CrossRef]

- The Evaluation Method for Intelligent Manufacturing (2016 Edition of Zhejiang Province); Hangzhou Science and Technology: Hangzhou, China, 2016; pp. 29–34.

- Wang, Y.M.; Zhang, X.W. Research on Intelligent Manufacturing Capability Maturity Index System of China’s Manufacturing Industry under Intelligent Economy. Sci. Decis. Mak. 2021, 292, 118–132. [Google Scholar]

- Wu, J.Y.; Li, Q. Spatial Effect of Digital Transformation Driving the Integration of Manufacturing and Service Industries. J. Stat. 2022, 3, 42–56. [Google Scholar]

- Wan, X.Y.; Zhao, H.; Zhang, Y. Construction and Measurement of Intelligent Development Evaluation Index System in China. Chongqing Soc. Sci. 2020, 306, 84–97. [Google Scholar]

- Zhou, L.P.; Jiang, Z.B.; Geng, N.; Niu, Y.; Cui, F.; Liu, K.; Qi, N. Production and operations management for intelligent manufacturing: A systematic literature review. Int. J. Prod. Res. 2022, 60, 808–846. [Google Scholar] [CrossRef]

- Deng, K.W. Research on Evaluation of Intelligent Manufacturing Capability and Layout Superiority of Supply Chains by Big Data Analysis. J. Glob. Inf. Manag. 2022, 30, 20. [Google Scholar] [CrossRef]

- Wang, R.M.; Wei, M. China’s Intelligent Manufacturing Capability and Influencing Factors: An Empirical Study Based on 18 Provinces and Municipalities. J. Ningbo Univ. Lib. Arts Ed. 2019, 32, 50–55. [Google Scholar]

- Ding, X.H.; Shi, L.; Li, M.; Chen, C. Research on Intelligent Manufacturing Capability Maturity Evaluation Based on BP Neural Network. J. Qingdao Univ. Nat. Sci. Ed. 2019, 32, 20–25. [Google Scholar]

- Bellavitis, C.; Filatotchev, I.; Souitaris, V. The Impact of Investment Networks on Venture Capital Firm Performance: A Contingency Framework. Br. J. Manag. 2017, 28, 102–119. [Google Scholar] [CrossRef]

- Henseler, J.; Hubona, G.; Ray, P.A. Using PLS path modeling in new technology research: Updated guidelines. Ind. Manag. Data Syst. 2016, 116, 2–20. [Google Scholar] [CrossRef]

- Grewal, R.; Cote, J.A.; Baumgartner, H. Multicollinearity and Measurement Error in Structural Equation Models: Implications for Theory Testing. Mark. Sci. 2004, 23, 519–529. [Google Scholar] [CrossRef]

- Amini, A.; Alimohammadlou, M. Toward equation structural modeling: An integration of interpretive structural modeling and structural equation modeling. J. Manag. Anal. 2021, 8, 693–714. [Google Scholar] [CrossRef]

| Constructs | Measurement Items | Variable Explanation | Literature Sources | |

|---|---|---|---|---|

| Investment level in RFID (L) | RFID’ basic investment (L1) | Investment in infrastructure (L11) | Application scale of RFID technology | [40,41,42,43] |

| Technicians (L12) | Cultivate matching technicians | |||

| Consistent input with corporate strategy (L2) | Input on adjusting enterprise strategy (L21) | Investment in the internal consistency of RFID and enterprise management | ||

| Technical level of RFID (L22) | RFID’s support for intelligent manufacturing | |||

| Entrepreneurship (S) | Pioneering spirit (S1) | Innovation of products and services | [44,45,46] | |

| Adventurous spirit (S2) | The courage to innovate against existing conditions | |||

| Intelligent manufacturing capability of an enterprise (C) | Information capability (C1) | Information gathering capability (C11) | Manufacturing data acquisition capability, that is, it can fully collect production site information such as manufacturing progress, on-site operation, quality inspection, equipment status, etc. | [47,48] |

| Information visualization (C12) | Ability to data visualization, information sharing and intelligent management in production based on industrial Internet | |||

| Strategic cooperation willingness (C2) | Trust (C21) | Trust promotion between parties in the new technological environment | [49,50,51] | |

| Initiative of cooperation (C22) | Under the dynamic cooperation environment, the cooperation frequency and resource utilization rate between enterprises are increased by more than 10% | |||

| Business collaboration capability (C3) | Vertical collaboration (C31) | Product life-cycle collaboration throughout design, manufacturing, quality, logistics and other links | ||

| Horizontal collaboration (C32) | Collaboration between manufacturing supply chain and productive service supply chain | |||

| Management decision-making ability (C4) | Problem sensitivity (C41) | Problem prediction and reasoning ability based on real-time data | [47,52,53] | |

| Business intelligence processing capability (C42) | Business automation capability, such as automatic replenishment of inventory | |||

| Intelligent manufacturing performance of an enterprise (P) | Operating cost (P1) | In contrast, operating costs were reduced by more than 20 percent | [47,54,18] | |

| Product market share and product innovation rate (P2) | The production cycle of the product is shortened by more than 30% and it occupies more than a third of the market | |||

| Service satisfaction (P3) | The rate of defective products and customer complaints will be reduced by more than 20% | |||

| Constructs | Items | Factor Loadings | Common Factor | Std. Devi | Cronbach’s α | CR | AVE | |

|---|---|---|---|---|---|---|---|---|

| Factor1 | Factor2 | |||||||

| S | S1 | 0.015 | 0.817 | 0.667 | 0.896 | 0.945 | 0.642 | 0.779 |

| S3 | 0.263 | 0.795 | 0.701 | 0.856 | ||||

| L1 | L11 | 0.6 | 0.411 | 0.529 | 1.143 | 0.62 | 0.765 | |

| L12 | 0.488 | 0.61 | 0.611 | 0.833 | ||||

| L2 | L21 | 0.5 | 0.594 | 0.602 | 1.004 | 0.62 | 0.764 | |

| L22 | 0.466 | 0.661 | 0.655 | 1.08 | ||||

| C2 | C21 | 0.59 | 0.468 | 0.567 | 0.753 | 0.745 | 0.853 | |

| C22 | 0.647 | 0.394 | 0.574 | 0.884 | ||||

| C3 | C31 | 0.816 | 0.116 | 0.679 | 0.963 | 0.736 | 0.847 | |

| C32 | 0.817 | 0.149 | 0.69 | 1.016 | ||||

| C4 | C41 | 0.735 | 0.327 | 0.647 | 0.877 | 0.672 | 0.804 | |

| C42 | 0.812 | 0.222 | 0.709 | 1.03 | ||||

| C5 | C52 | 0.705 | 0.48 | 0.727 | 0.943 | 0.649 | 0.844 | |

| C53 | 0.627 | 0.417 | 0.567 | 0.95 | ||||

| P | P12 | 0.52 | 0.452 | 0.475 | 1.113 | 0.661 | 0.793 | |

| P21 | 0.574 | 0.447 | 0.53 | 1.112 | ||||

| P22 | 0.505 | 0.496 | 0.501 | 0.944 | ||||

| Cumulative variance interpretation rate (after rotation) | 36.358% | 61.368% | − | − | − | − | − | |

| KMO value | 0.909 | − | − | − | − | − | ||

| Bartlett’s spherical value | 2789.682 | − | − | − | − | − | ||

| df | 136 | − | − | − | − | − | ||

| p | 0 | − | − | − | − | − | ||

| L1 | L2 | C1 | C2 | C3 | C4 | P | S | |

| L1 | 0.801 | − | − | − | − | − | − | − |

| L2 | 0.733 | 0.788 | − | − | − | − | − | − |

| C1 | 0.626 | 0.644 | 0.787 | − | − | − | − | − |

| C2 | 0.574 | 0.56 | 0.598 | 0.863 | − | − | − | − |

| C3 | 0.616 | 0.601 | 0.673 | 0.716 | 0.858 | − | − | − |

| C4 | 0.663 | 0.772 | 0.722 | 0.603 | 0.754 | 0.82 | − | − |

| P | 0.595 | 0.631 | 0.653 | 0.602 | 0.585 | 0.667 | 0.806 | − |

| S | 0.496 | 0.611 | 0.496 | 0.382 | 0.473 | 0.481 | 0.516 | 0.813 |

| Common Indicators | χ2/df | GFI | RMSEA | RMR | CFI | NFI | NNFI | IFI |

|---|---|---|---|---|---|---|---|---|

| Criteria | <3 | >0.9 | <0.10 | <0.05 | >0.9 | >0.9 | >0.9 | >0.9 |

| Value | 2.957 | 0.907 | 0.094 | 0.047 | 0.902 | 0.896 | 0.91 | 0.923 |

| Item | Total Effect | Mediating Effect | 95% BootCI | Mediating |

|---|---|---|---|---|

| L1 ≥ C1 ≥ P | 0.294 ** | 0.087 | 0.037~0.148 | Full |

| L1 ≥ C2 ≥ P | 0.294 ** | 0.076 | 0.010~0.184 | Full |

| L1 ≥ C3 ≥ P | 0.294 ** | −0.016 | −0.088~0.036 | No |

| L1 ≥ C4 ≥ P | 0.294 ** | 0.05 | 0.011~0.107 | Full |

| L2 ≥ C1 ≥ P | 0.414 ** | 0.092 | 0.034~0.162 | Full |

| L2 ≥ C2 ≥ P | 0.414 ** | 0.07 | 0.012~0.144 | Full |

| L2 ≥ C3 ≥ P | 0.414 ** | −0.015 | −0.079~0.036 | No |

| L2 ≥ C4 ≥ P | 0.414 ** | 0.137 | 0.036~0.250 | Full |

| P | C1 | C2 | C3 | C4 | |

| Constant | 0.000 (0.000) | −0.123 * (−2.222) | −0.011 (−0.170) | −0.093 (−1.572) | −0.094 (−1.917) |

| L | 0.209 ** (2.805) | 0.585 ** (10.082) | 0.587 ** (8.859) | 0.556 ** (9.016) | 0.746 ** (14.488) |

| S | − | 0.227 ** (3.689) | 0.037 (0.531) | 0.202 ** (3.077) | 0.094 (1.712) |

| L*S | − | 0.206 ** (4.003) | 0.018 (0.305) | 0.155 ** (2.833) | 0.158 ** (3.454) |

| C1 | 0.243 ** (3.481) | − | − | − | − |

| C2 | 0.225 ** (3.393) | − | − | − | − |

| C3 | −0.047 (−0.594) | − | − | − | − |

| C4 | 0.231 ** (2.716) | − | − | − | − |

| Sample size | 230 | 230 | 230 | 230 | 230 |

| R2 | 0.56 | 0.516 | 0.368 | 0.453 | 0.619 |

| Adjusted R2 | 0.548 | 0.507 | 0.357 | 0.443 | 0.612 |

| F | F(5224) = 57.085, p = 0.000 | F(3226) = 80.279, p = 0.000 | F(3226) = 43.931, p = 0.000 | F(3226) = 62.407, p = 0.000 | F(3226) = 122.376, p = 0.000 |

| Mediating Variable | Level | Effect | BootSE | BootLLCI | BootULCI |

|---|---|---|---|---|---|

| C1 | +1SD | 0.092 | 0.039 | 0.035 | 0.187 |

| Mean | 0.142 | 0.041 | 0.065 | 0.226 | |

| −1SD | 0.192 | 0.054 | 0.086 | 0.296 | |

| C2 | −1SD | 0.128 | 0.052 | 0.03 | 0.237 |

| Mean | 0.132 | 0.05 | 0.032 | 0.232 | |

| +1SD | 0.136 | 0.051 | 0.034 | 0.239 | |

| C3 | −1SD | −0.019 | 0.037 | −0.103 | 0.041 |

| Mean | −0.026 | 0.048 | −0.13 | 0.057 | |

| +1SD | −0.033 | 0.06 | −0.157 | 0.076 | |

| C4 | −1SD | 0.136 | 0.048 | 0.044 | 0.237 |

| Mean | 0.172 | 0.059 | 0.055 | 0.29 | |

| +1SD | 0.209 | 0.074 | 0.065 | 0.359 |

| Hypotheses | Supported? | |

|---|---|---|

| H1 | L ≥ P | No |

| H2 | L ≥ C | Yes |

| H3 | C ≥ P | Yes |

| H4 | L ≥ C ≥ P | Yes |

| H5 | S ≥ L | Yes |

| H51 | The moderating effect of S on “L ≥ C” | No |

| H52 | The moderating effect of S on “L ≥ P” | Yes |

| H6 | Moderated mediating effect of C by S | Yes |

| H1a | L2 is more important than L1 | Yes |

| H2a | C4 is the most critical factor in C (i.e., most affected by RFID) | Yes |

| H2b | C2 is the least important in C (i.e., the least affected by RFID) | Yes |

| H3a | P2 is the most critical factor in P and is most affected by C | Yes |

| H61 | The higher S, the greater the performance of “L ≥ C ≥ P” | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Liu, C. Dynamic Capability Theory Based Study on Performance of Intelligent Manufacturing Enterprise under RFID Influence. Electronics 2023, 12, 1374. https://doi.org/10.3390/electronics12061374

Wang W, Liu C. Dynamic Capability Theory Based Study on Performance of Intelligent Manufacturing Enterprise under RFID Influence. Electronics. 2023; 12(6):1374. https://doi.org/10.3390/electronics12061374

Chicago/Turabian StyleWang, Weibin, and Caihong Liu. 2023. "Dynamic Capability Theory Based Study on Performance of Intelligent Manufacturing Enterprise under RFID Influence" Electronics 12, no. 6: 1374. https://doi.org/10.3390/electronics12061374

APA StyleWang, W., & Liu, C. (2023). Dynamic Capability Theory Based Study on Performance of Intelligent Manufacturing Enterprise under RFID Influence. Electronics, 12(6), 1374. https://doi.org/10.3390/electronics12061374