Review of Nanoscale Vacuum Devices

Abstract

1. Introduction

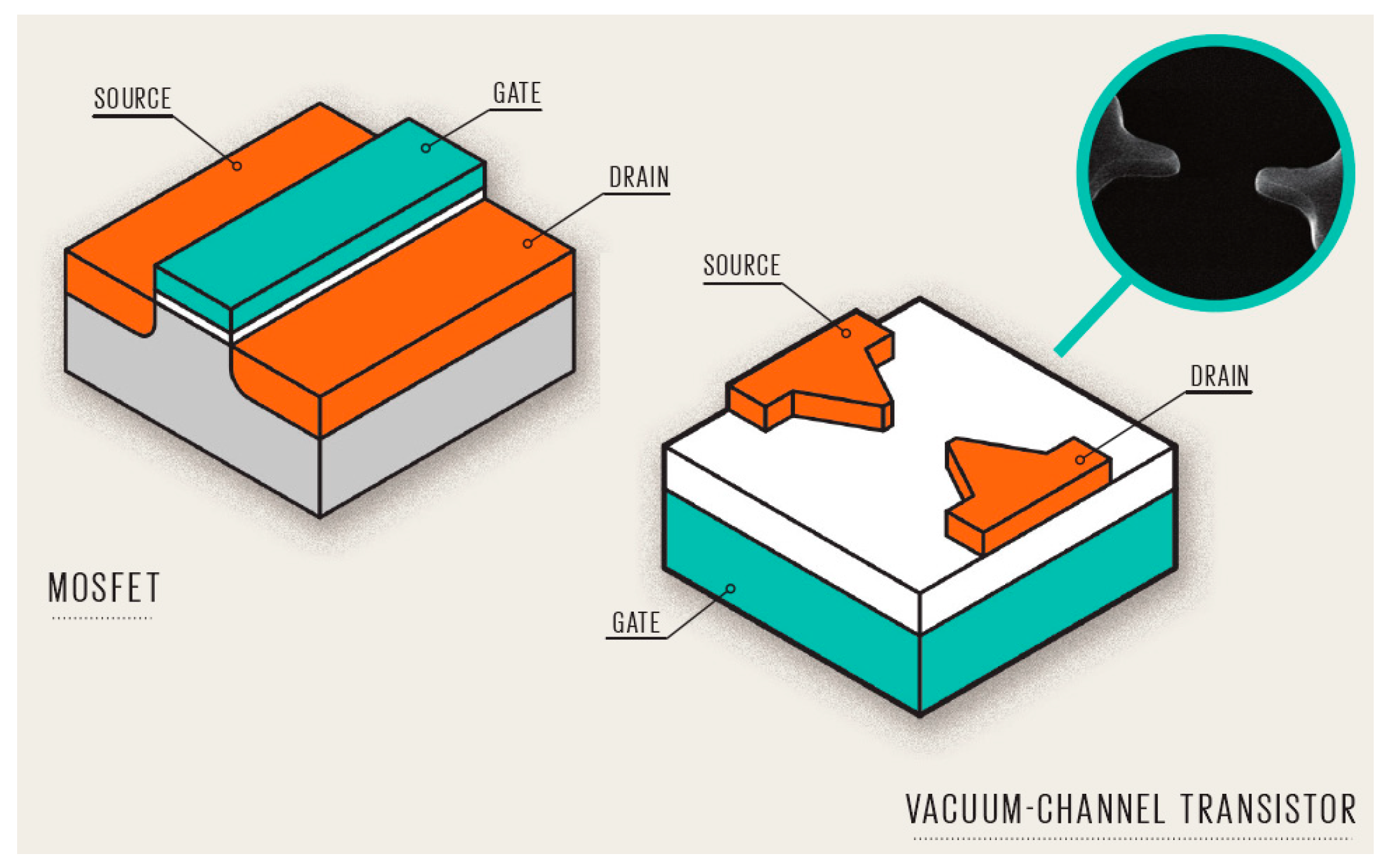

2. Structures

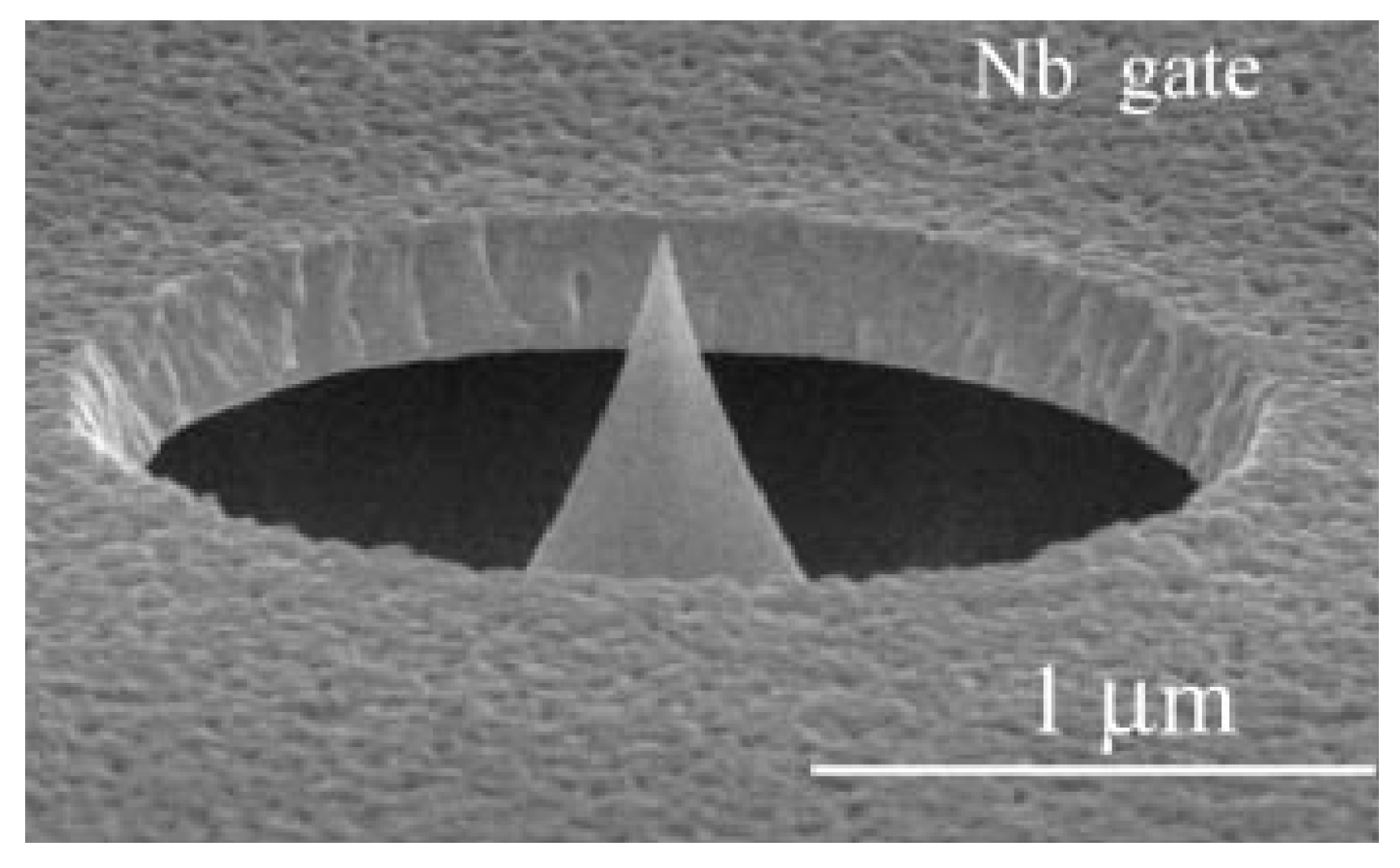

2.1. Lateral Structures

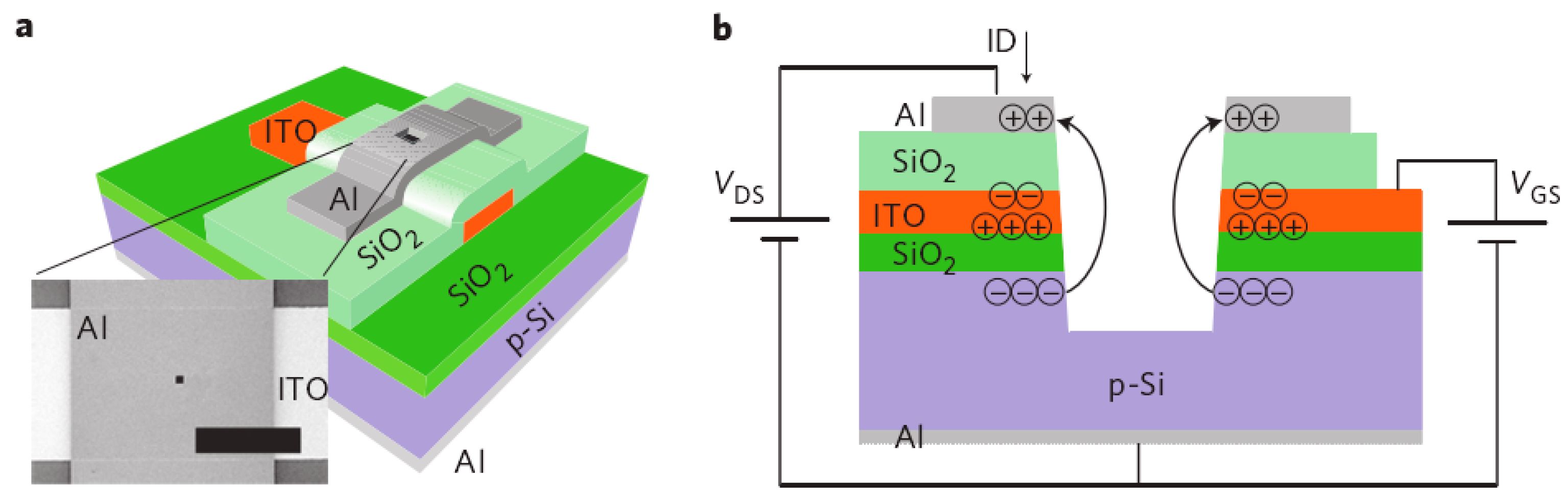

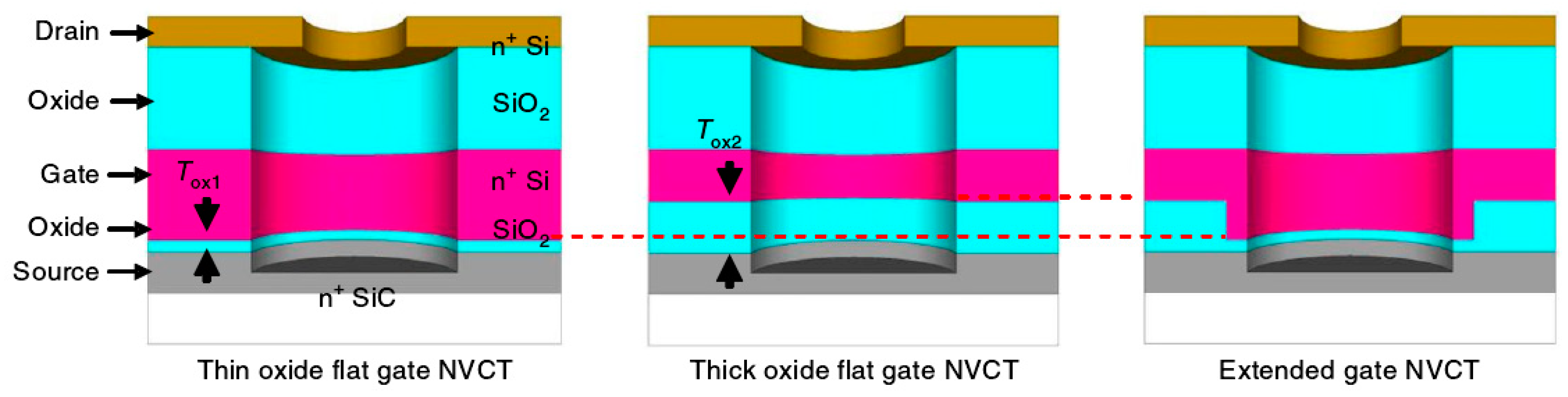

2.2. Vertical Structures

2.3. Gate-All-around Structures

2.4. Other Structures

3. Materials

3.1. Metals

3.2. Graphene

3.3. Silicon Carbide

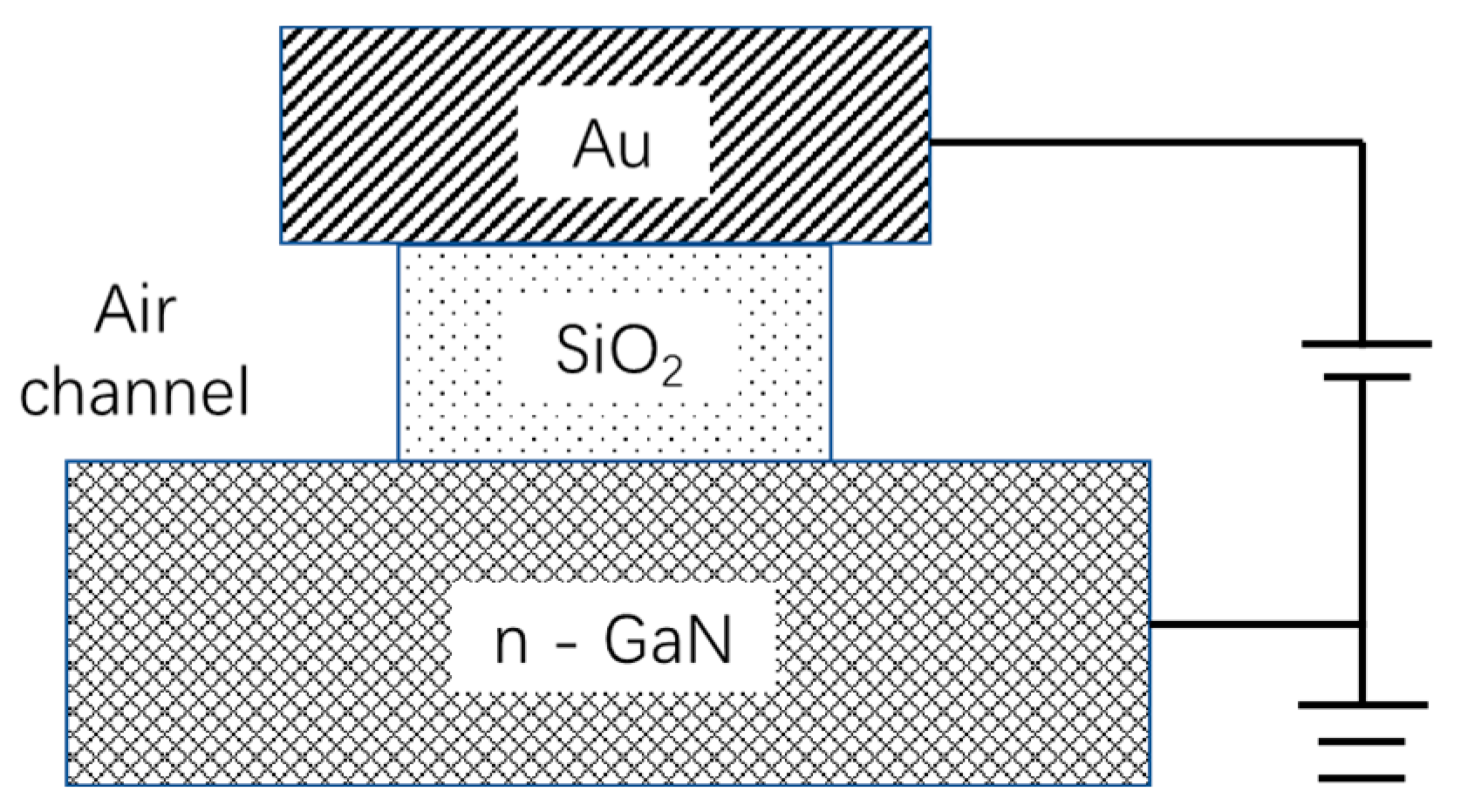

3.4. Gallium Nitride

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Brinkman, W.F.; Haggan, D.E.; Troutman, W.W. A history of the invention of the transistor and where it will lead us. IEEE J. Solid-State Circuits 1997, 32, 1858–1865. [Google Scholar] [CrossRef]

- Barbour, E. The cool sound of tubes. IEEE Spectrum 1998, 35, 24–35. [Google Scholar] [CrossRef]

- Symons, R.S. Tubes: Still Vital After All These Years. IEEE Spectrum 1998, 35, 52–63. [Google Scholar] [CrossRef]

- Gilmour, A.S.; Ebrary, I. Klystrons, Traveling Wave Tubes, Magnetrons, Crossed-Field Amplifiers, and Gyrotrons; Artech House: Norwood, MA, USA, 2011. [Google Scholar]

- Armstrong, C.M.; Kowalczyk, R.; Zubyk, A.; Berg, K.; Meadows, C.; Chan, D.; Schoemehl, T.; Duggal, R.; Hinch, N.; True, R.B.; et al. A compact extremely high frequency MPM power amplifier. IEEE Trans. Electron Devices 2018, 65, 2183–2188. [Google Scholar] [CrossRef]

- Pan, P.; Tang, Y.; Bian, X.; Zhang, L.; Lu, Q.; Li, Y.; Feng, Y.; Feng, J. A G-Band Traveling Wave Tube With 20 W Continuous Wave Output Power. IEEE Electron Device Lett. 2020, 41, 1833–1836. [Google Scholar] [CrossRef]

- Kim, H.K. Vacuum transistors for space travel. Nat. Electron. 2019, 2, 374–375. [Google Scholar] [CrossRef]

- Shoulders, K.R. Microelectronics Using Electron-Beam-Activated Machining Techniques. Adv. Comput. 1961, 2, 135–138. [Google Scholar] [CrossRef]

- Spindt, C.A. A Thin-Film Field-Emission Cathode. J. Appl. Phys. 1968, 39, 3504–3505. [Google Scholar] [CrossRef]

- Spindt, C.A.; Brodie, I.; Hunphrey, L. Physical Properties of Thin Film Field Emission Cathode with Molybdenum Cones. J. Appl. Phys. 1976, 47, 5248–5263. [Google Scholar] [CrossRef]

- Gray, H.F.; Campisi, G.J.; Greene, R.F. A Vacuum Field Effect Transistor Using Silicon Field Emitter Arrays. In Proceedings of the 1986 International Electron Devices Meeting (IEDM), Washington, DC, USA, 7–10 December 1986; pp. 776–777. [Google Scholar]

- Park, S.S.; Park, D.I.; Hahm, S.H.; Lee, J.H.; Choi, H.C.; Lee, J.H. Fabrication of a Lateral Field Emission Triode with a High Current Density and High Transconductance Using the Local Oxidation of the Polysilicon Layer. IEEE Trans. Electron Devices 1999, 46, 1283–1289. [Google Scholar] [CrossRef]

- Driskill-Smith, A.A.G.; Hasko, D.G.; Ahmed, H. Nanoscale field emission structures for ultra-low voltage operation at atmospheric pressure. Appl. Phys. Lett. 1997, 71, 3159–3161. [Google Scholar] [CrossRef]

- Han, J.W.; Oh, J.S.; Meyyappan, M. Vacuum nanoelectronics: Back to the future?—Gate insulated nanoscale vacuum channel transistor. Appl. Phys. Lett. 2012, 100, 213505. [Google Scholar] [CrossRef]

- Srisonphan, S.; Jung, Y.; Kim, H. Metal–oxide–semiconductor field-effect transistor with a vacuum channel. Nat. Nanotech 2012, 7, 504–508. [Google Scholar] [CrossRef] [PubMed]

- Stoner, B.R.; Glass, J.T. Nothing is like a vacuum. Nat. Nanotechnol. 2012, 7, 485–487. [Google Scholar] [CrossRef] [PubMed]

- America Institute of Physics. Return of the Vacuum Tube. Science Daily. 18 May 2012. Available online: https://news.sciencemag.org/physics/2012/05/return-vacuum-tube (accessed on 10 February 2020).

- Feng, J.; Li, X.; Hu, J.; Cai, J. General Vacuum Electronics. J. Electromagn. Eng. Sci. 2020, 20, 1–8. [Google Scholar] [CrossRef]

- Chang, W.T.; Hsu, H.J.; Pao, P.H. Vertical Field Emission Air-Channel Diodes and Transistors. Micromachines 2019, 10, 858. [Google Scholar] [CrossRef]

- Higuchi, T.; Maisenbacher, L.; Liehl, A.; Dombi, P.; Hommelhoff, P. A nanoscale vacuum-tube diode triggered by few-cycle laser pulses. Appl. Phys. Lett. 2015, 106, 051109. [Google Scholar] [CrossRef]

- Jones, W.M.; Lukin, D.; Scherer, A. Ultra-low turn-on field emission devices characterized at atmospheric pressures and high temperatures. In Proceedings of the 2016 International Vacuum Nanoelectronics Conference (IVNC), Vancouver, BC, Canada, 11–15 July 2016. [Google Scholar] [CrossRef]

- Chang, W.T.; Chuang, T.Y.; Su, C.W. Metal-based asymmetric field emission diodes operated in the air. Microelectron. Eng. 2020, 232, 111418. [Google Scholar] [CrossRef]

- Chang, W.T.; Cheng, M.C.; Chuang, T.Y.; Tsai, M.Y. Field Emission Air-Channel Devices as a Voltage Adder. Nanomaterials 2020, 10, 2378. [Google Scholar] [CrossRef]

- Liu, M.; Fu, W.; Yang, Y.; Li, T.; Wang, Y. Excellent field emission properties of VO2(A) nanogap emitters in air. Appl. Phys. Lett. 2018, 112, 093104. [Google Scholar] [CrossRef]

- Sapkota, K.R.; Leonard, F.; Talin, A.A.; Gunning, B.P.; Kazanowska, B.A.; Jones, K.S.; Wang, G.T. Ultralow Voltage GaN Vacuum Nanodiodes in Air. Nano Lett. 2021, 21, 1928–1934. [Google Scholar] [CrossRef]

- Subramanian, K.; Kang, W.P.; Davidson, J.L. Nanocrystalline diamond lateral vacuum microtriode. Appl. Phys. Lett. 2008, 93, 203511. [Google Scholar] [CrossRef]

- Subramanian, K.; Kang, W.P.; Davidson, J.L.; Ghosh, N.; Galloway, K.F. A review of recent results on diamond vacuum lateral field emission device operation in radiation environments. Microelectron. Eng. 2011, 88, 2924–2929. [Google Scholar] [CrossRef]

- Pescini, L.L.; Tilke, A.; Blick, R.H.; Lorenz, H.; Kotthaus, J.P.; Eberhardt, W.; Kern, D. Nanoscale lateral field-emission triode operating at atmospheric pressure. Adv. Mater. 2001, 13, 1780–1783. [Google Scholar] [CrossRef]

- Chang, W.T.; Pao, P.H. Field Electrons Intercepted by Coplanar Gates in Nanoscale Air Channel. IEEE Trans. Electron Devices 2019, 66, 3961–3966. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Oh, H.; Meyyappan, M.; Han, J.W.; Lee, J.S. Design guidelines for nanoscale vacuum field emission transistors. J. Vac. Sci. Technol. B 2016, 34, 042201. [Google Scholar] [CrossRef]

- Han, J.W.; Meyyappan, M. The device made of nothing. IEEE Spectrum 2014, 51, 30–35. [Google Scholar] [CrossRef]

- Han, J.W.; Oh, J.S.; Meyyappan, M. Cofabrication of vacuum field emission transistor (VFET) and MOSFET. IEEE Trans. Nanotechnol. 2014, 13, 464–468. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Q.; Tao, Z.; Zhai, Y.; Chen, G.; Qi, Z.; Zhang, X. High-Quality and Stable Electron Emission Device with Sub-30-nm Aligned Nanogap Arrays. IEEE Trans. Electron Devices 2017, 64, 2364–2368. [Google Scholar] [CrossRef]

- Nirantar, S.; Ahmed, T.; Ren, G.; Gutruf, P.; Xu, C.; Bhaskaran, M.; Walia, S.; Sriram, S. Metal–Air Transistors: Semiconductor-free field-emission air-channel nanoelectronics. Nano Lett. 2018, 18, 7478–7484. [Google Scholar] [CrossRef]

- Spindt, C.A.; Holland, C.E.; Rosengreen, A.; Brodie, I. Field-emitter arrays for vacuum microelectronics. IEEE Trans. Electron Devices 1991, 38, 2355–2363. [Google Scholar] [CrossRef]

- Hirano, T.; Kanemaru, S.; Tanoue, H.; Itoh, J. Fabrication of a New Si Field Emitter Tip with Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET) Structure. Jpn. J. Appl. Phys. 1996, 35, 6637–6640. [Google Scholar] [CrossRef]

- Bozler, C.O.; Harris, C.T.; Rabe, S.; Rathman, D.D.; Smith, H.I. Arrays of gated field-emitter cones having 0.32 μm tip-to-tip spacing. J. Vac. Sci. Technol. B 1994, 12, 629–632. [Google Scholar] [CrossRef]

- Park, I.J.; Jeon, S.G.; Shin, C. A New Slit-Type Vacuum-Channel Transistor. IEEE Trans. Electron Devices 2014, 61, 4186–4191. [Google Scholar] [CrossRef]

- Shen, Z.; Wang, X.; Wu, S.L.; Tian, J. A new kind of vertically aligned field emission transistor with a cylindrical vacuum channel. Vacuum 2017, 137, 163–168. [Google Scholar] [CrossRef]

- Han, J.W.; Seol, M.L.; Moon, D.I.; Hunter, G.; Meyyappan, M. Nanoscale vacuum channel transistors fabricated on silicon carbide wafers. Nat. Electron. 2019, 2, 405–411. [Google Scholar] [CrossRef]

- Leobandung, E.; Gu, J.; Guo, L.; Chou, S.Y. Wire-channel and wrap-around-gate metal-oxide-semiconductor field-effect transistors with a significant reduction of short channel effects. J. Vac. Sci. Technol. B 1997, 15, 2791–2794. [Google Scholar] [CrossRef]

- Colinge, J.P.; Gao, M.H.; Romano, A.; Maes, H.; Claeys, C. Silicon-on-insulator “gate-all-around” MOS device. In Proceedings of the 1990 IEEE SOS/SOI Technology Conference, Key West, FL, USA, 2–4 October 1990; pp. 137–138. [Google Scholar] [CrossRef]

- Singh, N.; Agarwal, A.; Bera, L.K.; Liow, T.Y.; Yang, R.; Rustagi, S.C.; Tung, C.H.; Kumar, R.; Lo, G.Q.; Balasubramanian, N.; et al. High-performance fully depleted silicon nanowire (diameter ≤ 5 nm) gate-all-around CMOS devices. IEEE Electron Device Lett. 2006, 27, 383–385. [Google Scholar] [CrossRef]

- Han, J.W.; Ahn, J.H.; Choi, Y.K. Damage immune field effect transistors with vacuum gate dielectric. J. Vac. Sci. Technol. B 2011, 29, 011014. [Google Scholar] [CrossRef]

- Han, J.W.; Moon, D.I.; Oh, J.S.; Choi, Y.K.; Meyyappan, M. Vacuum gate dielectric gate-all-around nanowire for hot carrier injection and bias temperature instability free transistor. Appl. Phys. Lett. 2014, 104, 253506. [Google Scholar] [CrossRef]

- Han, J.W.; Moon, D.I.; Meyyappan, M. Nanoscale Vacuum Channel Transistor. Nano Lett. 2017, 17, 2146–2151. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Liang, S.; Shi, D.; Yang, S.; Lei, Y.; Li, T.; Wang, Y. An emission stable vertical air channel diode by a low-cost and IC compatible BOE etching process. Nanoscale 2021, 13, 5693–5699. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Zhao, H.; Zhao, J.; Huang, R.; Wang, J.; Chen, F.; Zhang, J.; Li, M. GaN Nanoscale Air Channel Devices with mA-level Output by IC compatible processes. In Proceedings of the 2022 International Vacuum Nanoelectronics Conference (IVNC), Seoul, Republic of Korea, 5–8 July 2022; pp. 17–18. [Google Scholar]

- Han, J.W.; Seol, M.L.; Meyyappan, M. A nanoscale vacuum field emission gated diode with an umbrella cathode. Nanoscale Adv. 2021, 3, 1725–1729. [Google Scholar] [CrossRef] [PubMed]

- Lenk, C.; Lenk, S.; Holz, M.; Guliyev, E.; Hofmann, M.; Ivanov, T.; Rangelow, I.W.; Behzadirad, M.; Rishinaramangalam, A.K.; Feezell, D.; et al. Experimental study of field emission from ultrasharp silicon, diamond, GaN, and tungsten tips in close proximity to the counter electrode. J. Vac. Sci. Technol. B 2018, 36, 06JL03. [Google Scholar] [CrossRef]

- Bhattacharya, R.; Turchetti, M.; Keathley, P.D.; Berggren, K.K.; Browning, A. Long term field emission current stability characterization of planar field emitter devices. J. Vac. Sci. Technol. B 2021, 39, 053201. [Google Scholar] [CrossRef]

- Li, X.; Han, P.; Xie, Y.; Du, T.; Cai, J.; Feng, J. Environments Adaptability and Failure Analysis of Nanoscale Vacuum Channel Transistors. In Proceedings of the 2020 IEEE International Conference on Vacuum Electronics (IVEC), Monterey, CA, USA, 20–23 April 2020; pp. 381–382. [Google Scholar]

- Rose, L.B.D.; Scherer, A.; Jones, W.M. Suspended Nanoscale Field Emitter Devices for High-Temperature Operation. IEEE Trans. Electron Devices 2020, 67, 5125–5131. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Castro Neto, A.H.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef]

- Marconcini, P.; Macucci, M. The k.p method and its application to graphene, carbon nanotubes and graphene nanoribbons: The Dirac equation. Riv. Nuovo Cim. 2011, 34, 489–584. [Google Scholar] [CrossRef]

- Giannazzo, F.; Greco, G.; Roccaforte, F.; Sonde, S.S. Vertical Transistors Based on 2D Materials: Status and Prospects. Crystals 2018, 8, 70. [Google Scholar] [CrossRef]

- Chavarin, C.A.; Strobel, C.; Kitzmann, J.; Bartolomeo, A.D.; Lukosius, M.; Albert, M.; Bartha, J.W.; Wenger, C. Current Modulation of a Heterojunction Structure by an Ultra-Thin Graphene Base Electrode. Materials 2018, 11, 345. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Wei, X.; Zhang, Z.; Chen, Q.; Peng, L. A Graphene-Based Vacuum Transistor with a High ON/OFF Current Ratio. Adv. Funct. Mater. 2015, 25, 5972–5978. [Google Scholar] [CrossRef]

- Xu, J.; Gu, Z.; Yang, W.; Wang, Q.; Zhang, X. Graphene-Based Nanoscale Vacuum Channel Transistor. Nanoscale Res. Lett. 2018, 13, 311. [Google Scholar] [CrossRef] [PubMed]

- Neudeck, P.; Krasowski, M.; Prokop, N. Assessment of durable SiC JFET technology for +600 °C to −125 °C integrated circuit operation. ECS Trans. 2011, 8, 163–176. [Google Scholar] [CrossRef]

- Wang, L.; Wei, G.; Gao, F.; Li, C.; Yang, W. High-temperature stable field emission of b-doped SiC nanoneedle arrays. Nanoscale 2015, 7, 7585–7592. [Google Scholar] [CrossRef]

- Liu, M.; Li, T.; Wang, Y. SiC emitters for nanoscale vacuum electronics: A systematic study of cathode–anode gap by focused ion beam etching. J. Vac. Sci. Technol. B 2017, 35, 031801. [Google Scholar] [CrossRef]

- Kozawa, T.; Suzuki, M.; Taga, Y.; Gotoh, Y.; Ishikawa, J. Fabrication of GaN field emitter arrays by elective area growth technique. J. Vac. Sci. Technol. B 1998, 16, 833–835. [Google Scholar] [CrossRef]

- Ławrowski, R.; Langer, C.; Prommesberger, C.; Schreiner, R. Microrods and microlines by three-dimensional epitaxially grown GaN for field emission cathodes. In Proceedings of the 2017 International Vacuum Nanoelectronics Conference (IVNC), Regensburg, Germany, 10–14 July 2017; pp. 130–131. [Google Scholar]

- Pearton, S.J.; Ren, F.; Patrick, E.; Law, M.E.; Alexander, Y. Polyakov. Review-Ionizing Radiation Damage Effects on GaN Devices. ECS J. Solid State Sci. Technol. 2016, 5, Q35–Q60. [Google Scholar] [CrossRef]

- Zhao, D.S.; Liu, R.; Fu, K.; Yu, G.; Cai, Y.; Huang, H.; Wang, Y.; Sun, R.; Zhang, B. An Al0.25Ga0.75N/GaN Lateral Field Emission Device with a Nano Void Channel. Chin. Phys. Lett. 2018, 35, 114–117. [Google Scholar] [CrossRef]

- Wang, G.T.; Sapkota, K.R.; Talin, A.A.; Leonard, F.; Gunning, B.P.; Vizkelethy, G. Ultra-low Voltage GaN Vacuum Nanoelectronics. In Proceedings of the 2022 Compound Semiconductor Week (CSW), Ann Arbor, MI, USA, 1–3 June 2022; pp. 1–2. [Google Scholar]

- Sze, S.M.; Ng, K.K. Physics and Properties of Semiconductors-A Review in Physics of Semiconductor Devices; Wiley: Hoboken, NJ, USA, 2006; pp. 5–75. [Google Scholar]

- Neudeck, P.G.; Okojie, R.S.; Chen, L.Y. High-temperature electronics—A role for wide bandgap semiconductors? Proc. IEEE 2002, 90, 1065–1076. [Google Scholar] [CrossRef]

- Guo, X.; Xun, Q.; Li, Z.; Du, S. Silicon carbide converters and MEMS devices for high-temperature power electronics: A critical review. Micromachines 2019, 10, 406. [Google Scholar] [CrossRef] [PubMed]

| Device Structure | Strength | Weakness |

|---|---|---|

| Lateral structure | Good compatibility with ICs | Poor critical dimension Uniformity |

| Vertical structure | Precise air-channel control | High parasitic capacitance and current leakage |

| GAA structure | Effective control of emission | Complex structure and difficult fabrication |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Feng, J. Review of Nanoscale Vacuum Devices. Electronics 2023, 12, 802. https://doi.org/10.3390/electronics12040802

Li X, Feng J. Review of Nanoscale Vacuum Devices. Electronics. 2023; 12(4):802. https://doi.org/10.3390/electronics12040802

Chicago/Turabian StyleLi, Xinghui, and Jinjun Feng. 2023. "Review of Nanoscale Vacuum Devices" Electronics 12, no. 4: 802. https://doi.org/10.3390/electronics12040802

APA StyleLi, X., & Feng, J. (2023). Review of Nanoscale Vacuum Devices. Electronics, 12(4), 802. https://doi.org/10.3390/electronics12040802