Estimation of Lithium-Ion Battery State of Charge Based on Genetic Algorithm Support Vector Regression under Multiple Temperatures

Abstract

:1. Introduction

1.1. Background

1.2. Related Work and Research Gap

1.3. Contributions

- By adopting a data-driven approach, this paper introduces a combined estimation model that integrates GA for biological features and SVR.

- Addressing the complex nonlinear characteristics of SOC, this research tackles the SOC prediction problem within the realm of Hilbert space. This approach underscores the capacity of advanced mathematical techniques in resolving intricate problems.

- The model’s sensitivity to temperature variations is comprehensively analyzed and emphasized. The GASVR model exhibits superior accuracy and robustness when compared to traditional models that rely on Euclidean space.

1.4. Structure of This Paper

2. Antecedent Theory

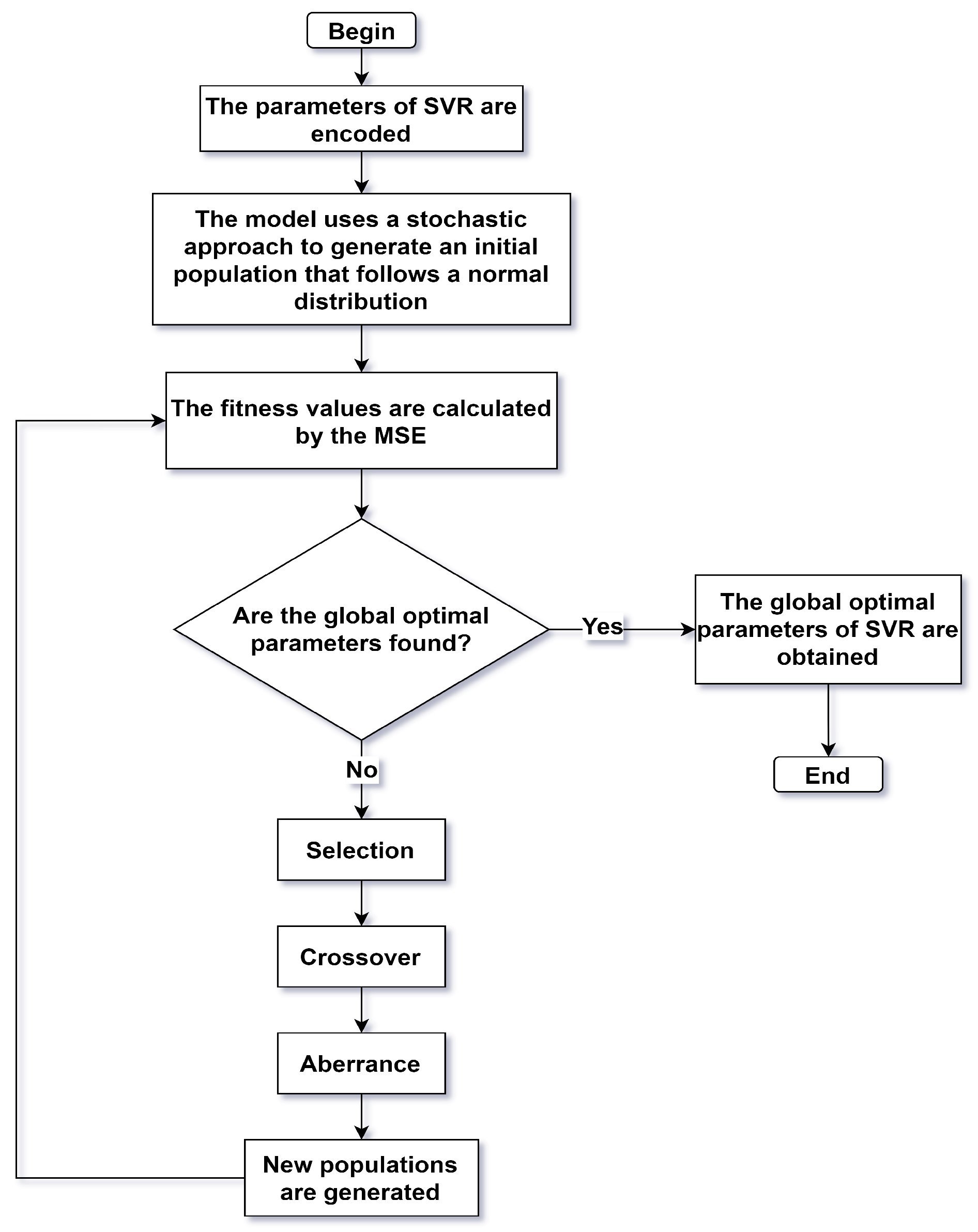

2.1. Genetic Algorithm

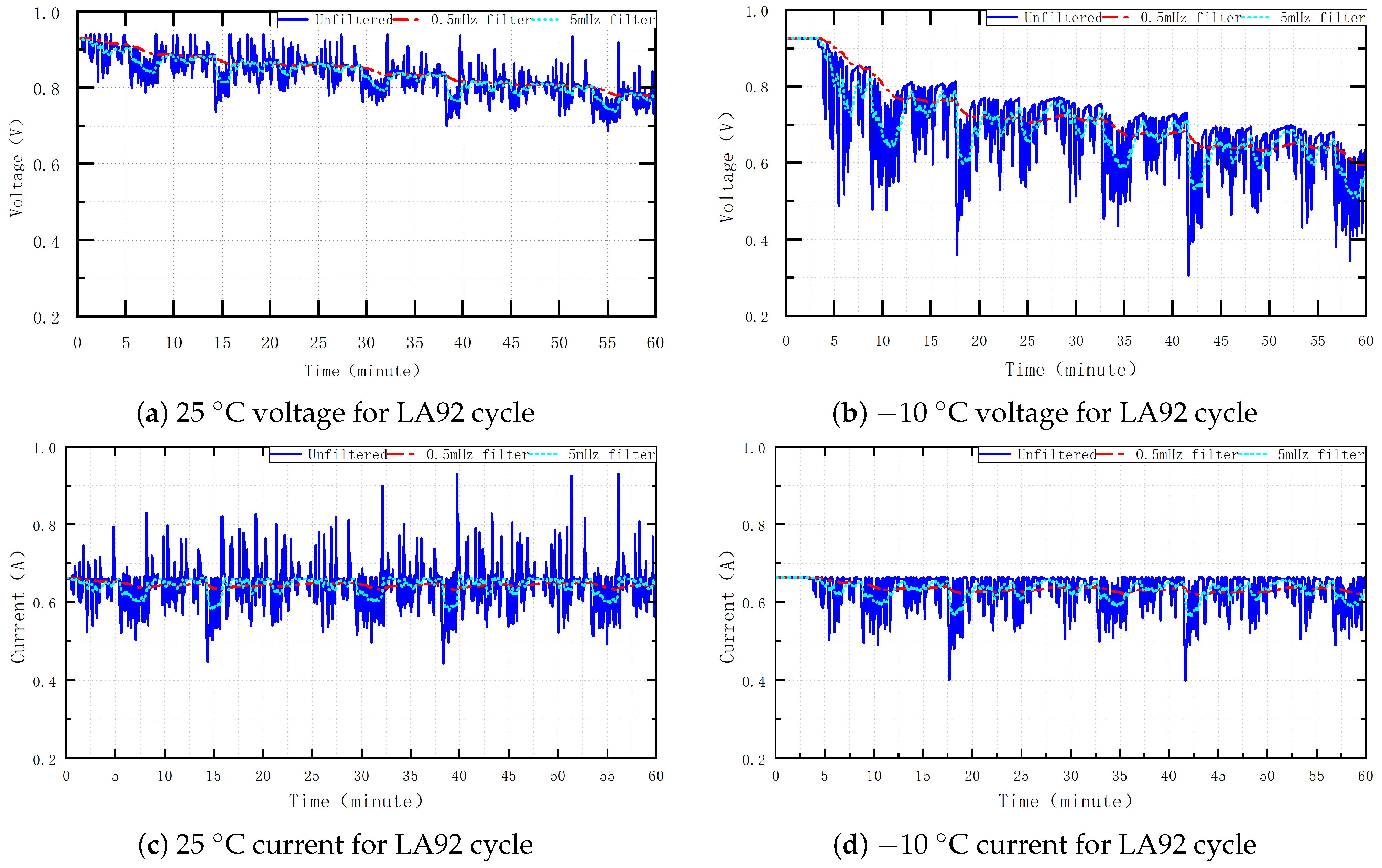

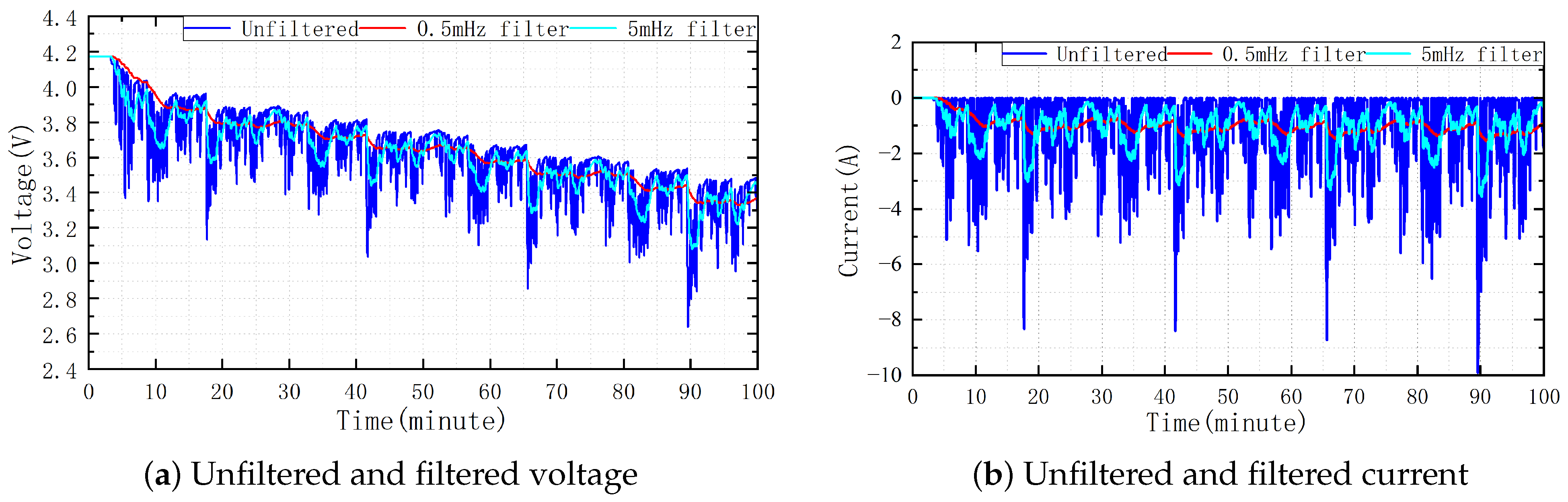

2.2. Data Processing

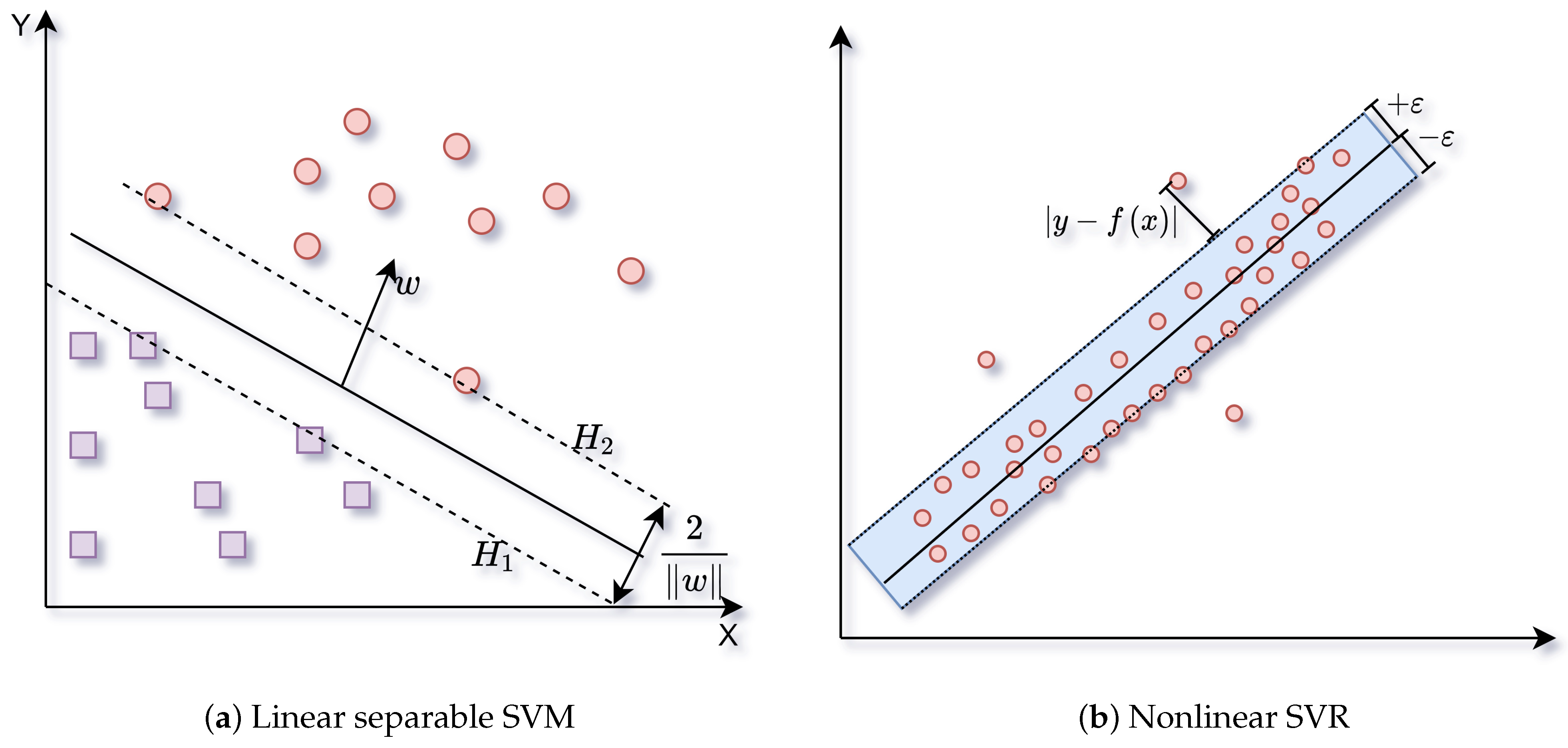

2.3. Support Vector Regression

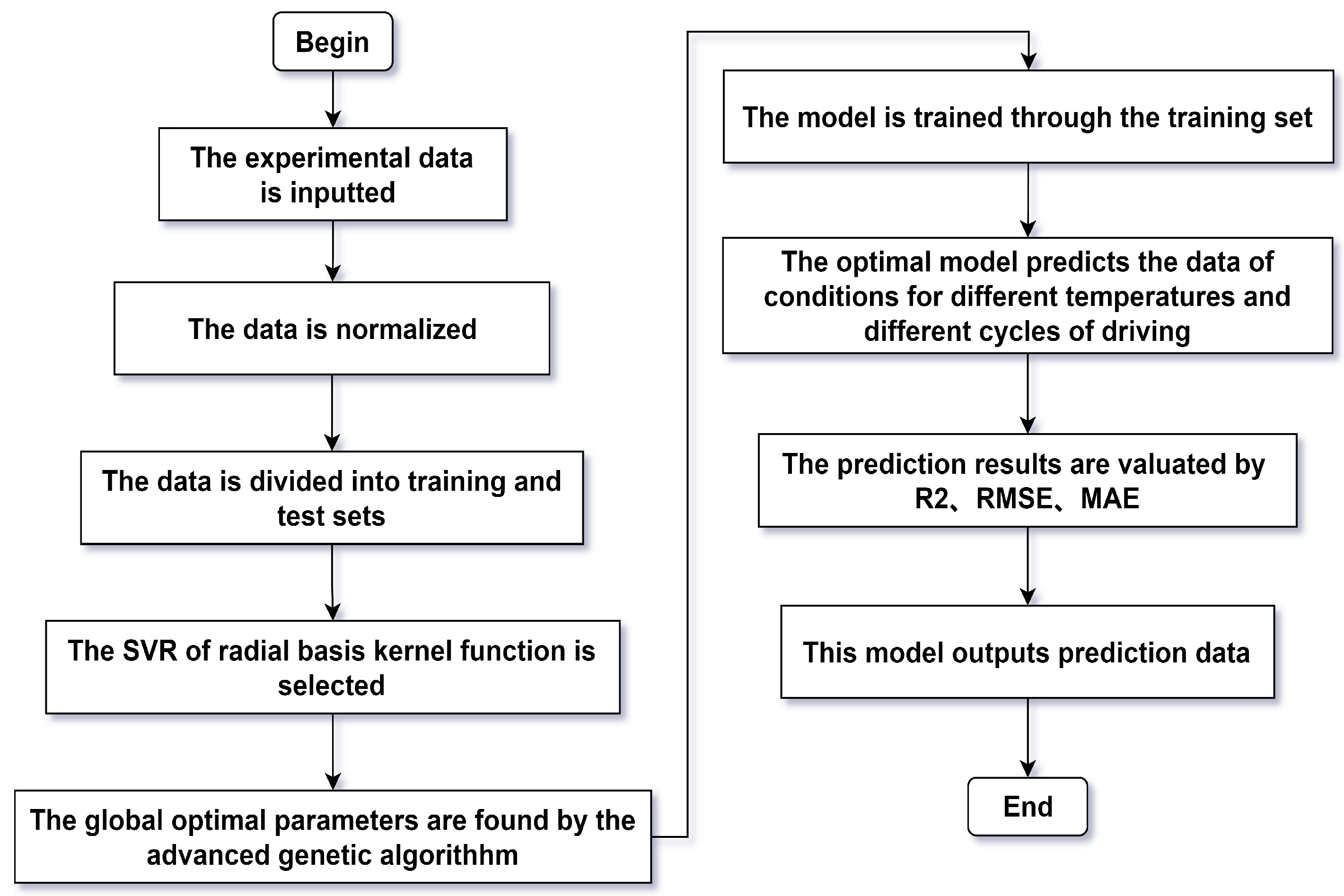

3. GASVR Model and Result

3.1. GASVR (Using the GA to Optimize SVR)

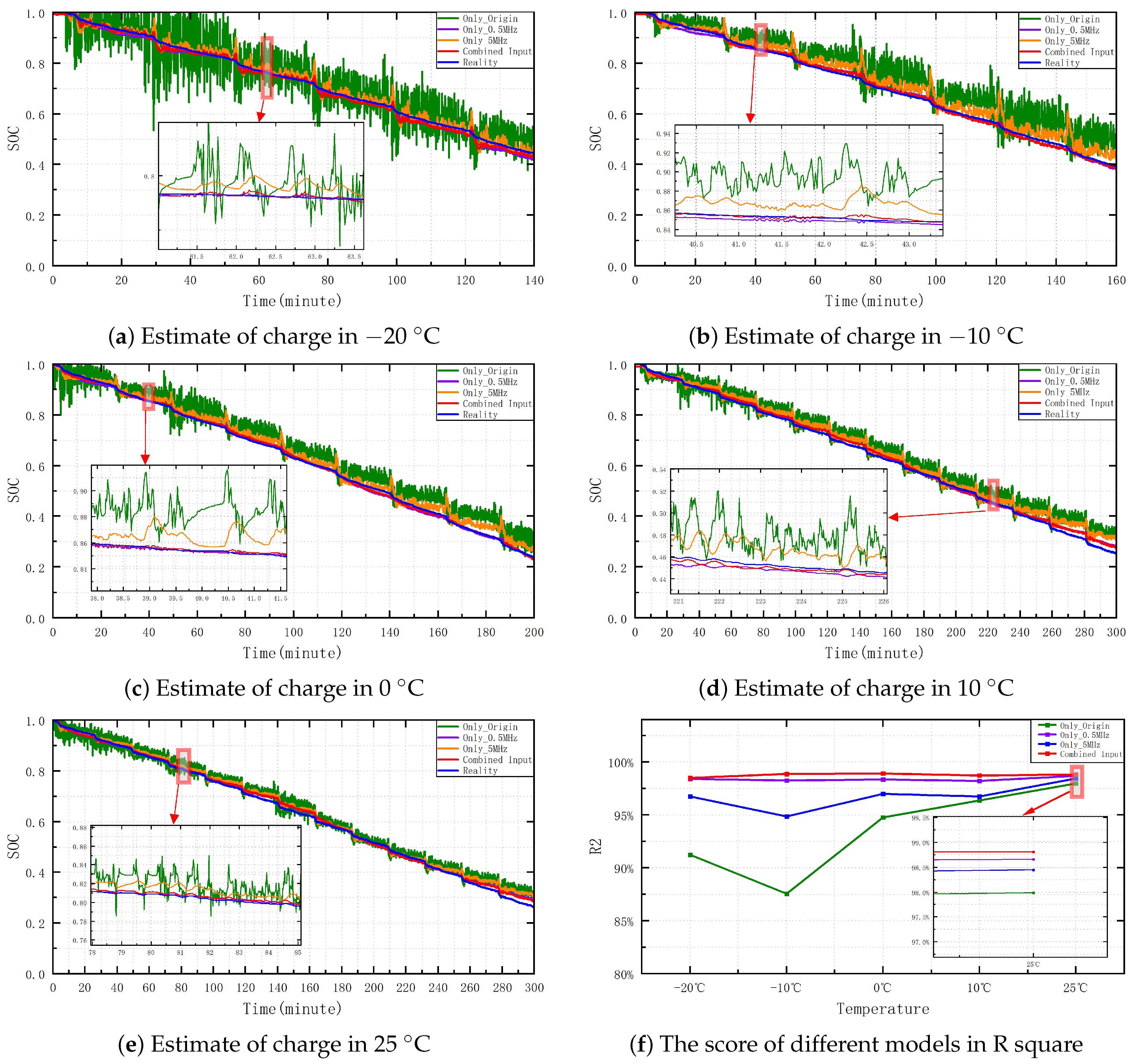

3.2. Impact of Input Data on the Model

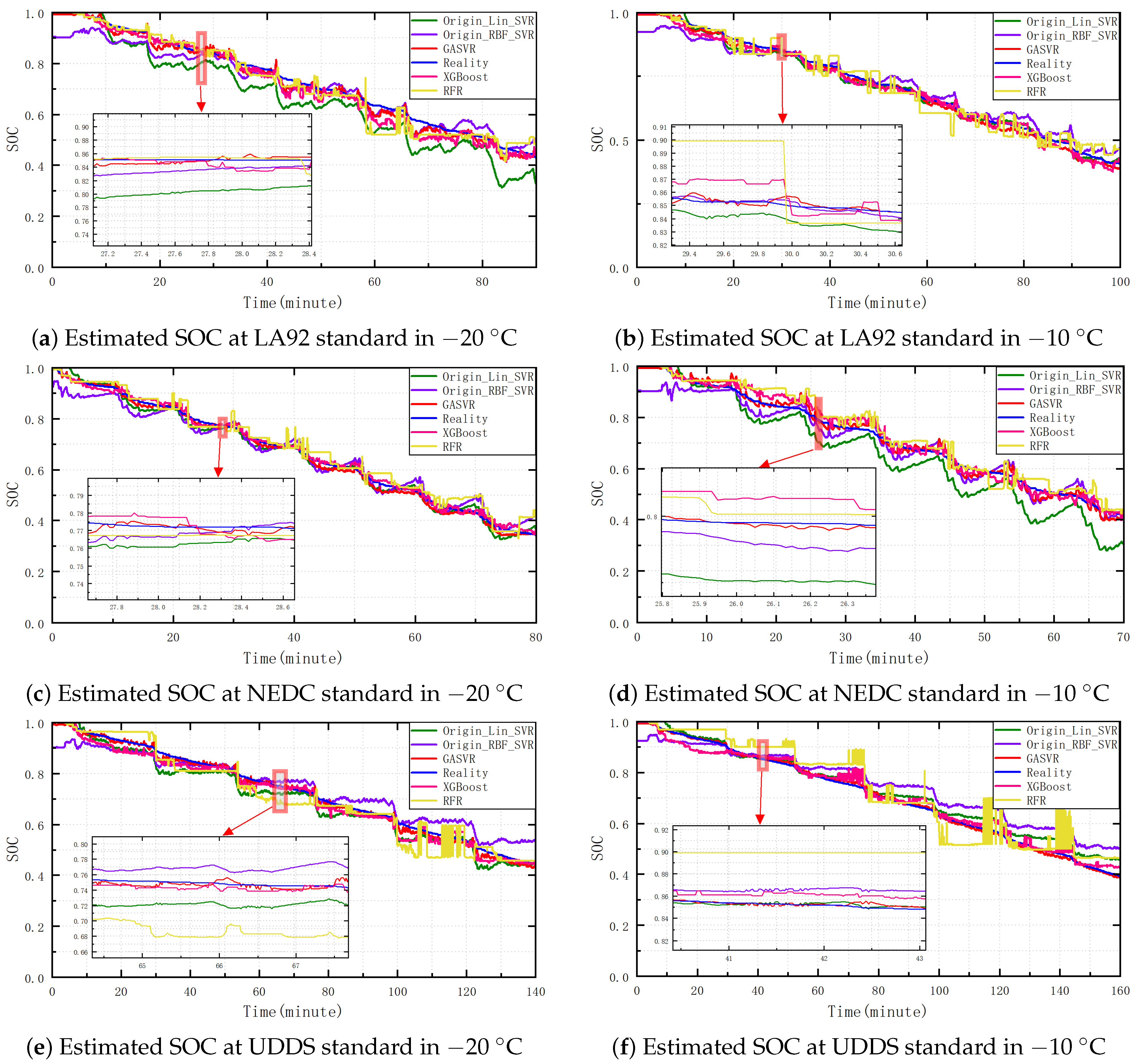

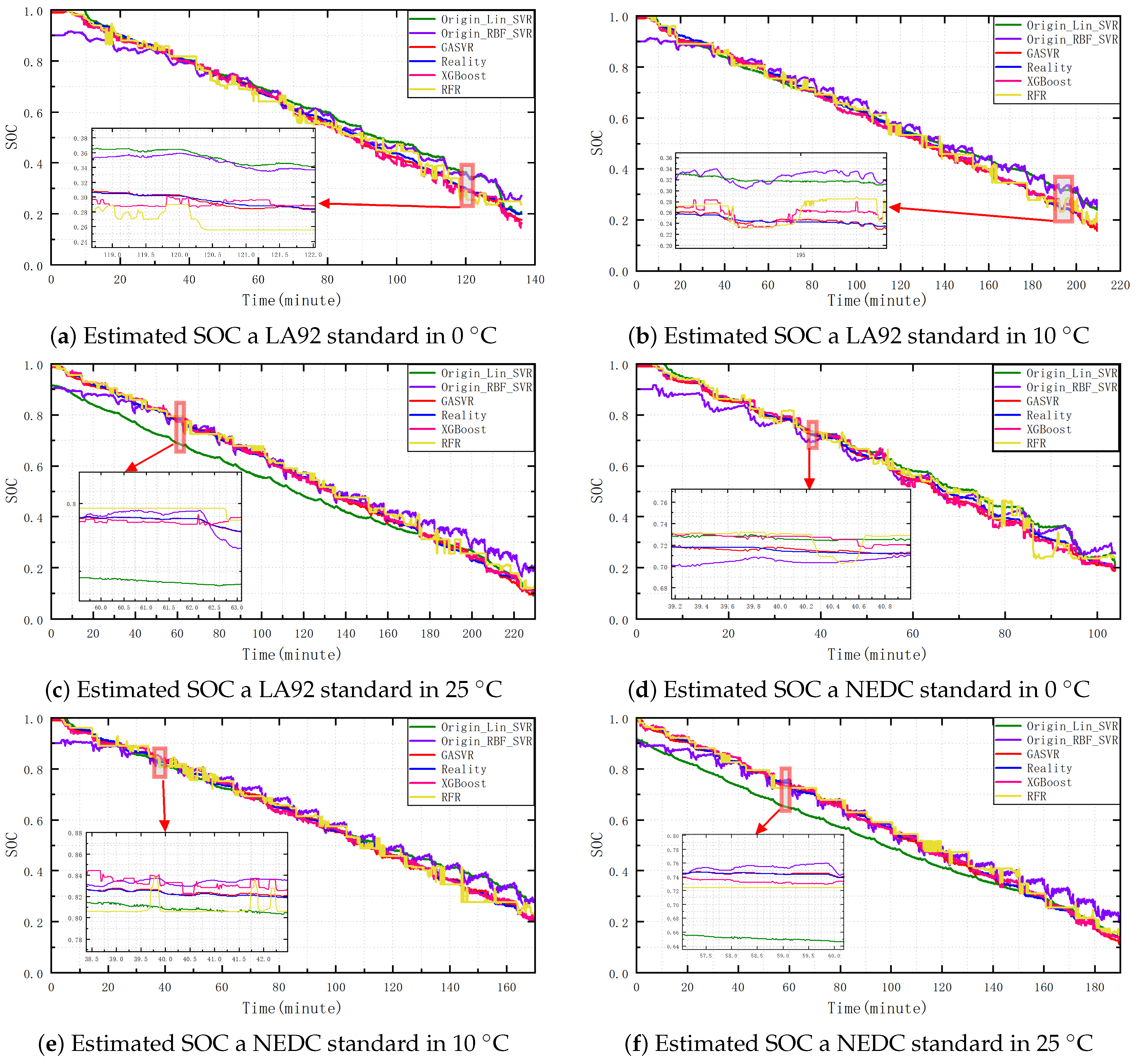

3.3. Impact of Temperature

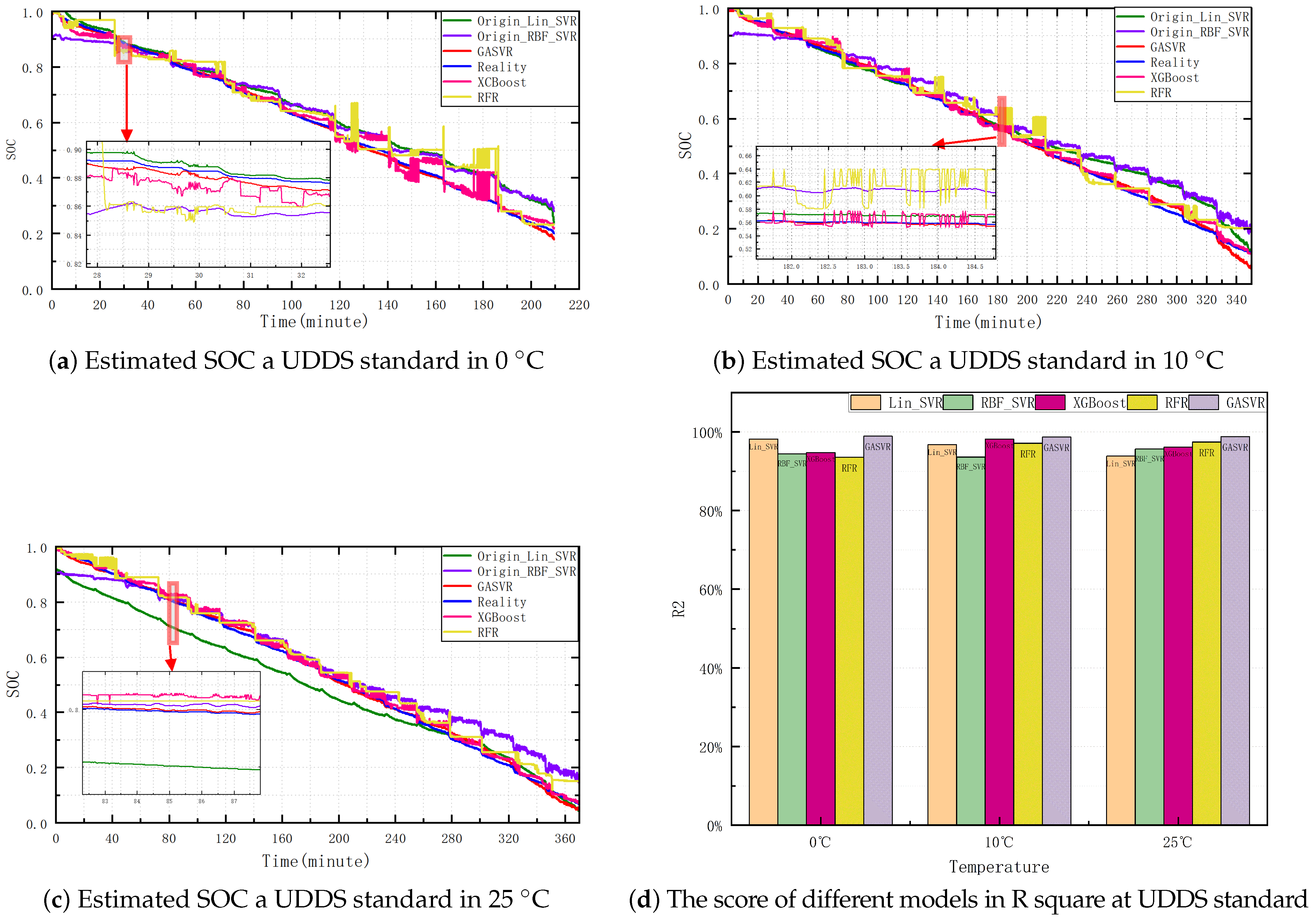

3.4. Results

3.5. Model Evaluation Methods

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SOC | state of charge |

| SVR | support vector regression |

| SVM | support vector machine |

| GA | genetic algorithm |

| XGBoost | extreme gradient boosting |

| RFR | random forest regression |

References

- Um, B.-H.; Kim, Y.-S. Review: A chance for korea to advance algal-biodiesel technology. J. Ind. Eng. Chem. 2009, 15, 1–7. [Google Scholar] [CrossRef]

- Jian, S. Environmental protection policy, technological innovation and dynamic effects of carbon emission intensity: Simulation analysis based on three-sector dsge model. J. Chongqing Univ. Soc. Sci. Ed. 2020, 26, 31–45. [Google Scholar] [CrossRef]

- Cai, T.; Liu, H.; Bao, X. Analysis and research on carbon dioxide utilization technology in coal chemical industry. Chain Coal 2017, 44, 98–105. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Tian, Y. Comparative studies on carbon dioxide emissions of typical modern coal chemical processes. Chem. Ind. Eng. Prog. 2016, 35, 4060–4064. [Google Scholar] [CrossRef]

- Dong, R. International Energy Agency: Analysis of Global CO2 Emissions in 2022. China Power Enterp. Manag. 2023, 7, 94–95. Available online: https://kns.cnki.net/kcms2/article/abstract?v=A67obWUfw0k2M7nn3Vatj_HwL8pmrWFlEHIUwsuEs4Lc04b-6UX5jIP0PzvmdaIJFn6ox_Gc72q7ADS_xUJ3psFiXpzDbHuRTYSaUOpHigDN5kCYhQZa6yrREUimoNWydzcfczHH-PqyWsWmE495uw==&uniplatform=NZKPT&language=CHS (accessed on 19 October 2023).

- Zhang, Y.; Hao, Y. Esg performance, financing constraints and high-quality innovation of coal companies under carbon peaking and carbon neutrality goals. Min. Res. Dev. 2023, 194–201. [Google Scholar] [CrossRef]

- Corti, F.; Gulino, M.-S.; Laschi, M.; Lozito, G.M.; Pugi, L.; Reatti, A.; Vangi, D. Time-domain circuit modelling for hybrid supercapacitors. Energies 2021, 14, 6837. [Google Scholar] [CrossRef]

- Yang, H. Estimation of supercapacitor charge capacity bounds considering charge redistribution. IEEE Trans. Power Electron. 2018, 33, 6980–6993. [Google Scholar] [CrossRef]

- Zheng, Y.; Ouyang, M.; Han, X.; Lu, L.; Li, J. Investigating the error sources of the online state of charge estimation methods for lithium-ion batteries in electric vehicles. J. Power Sources 2018, 377, 161–188. [Google Scholar] [CrossRef]

- Cao, C. Research on Modeling and SOC Estimation of LiFePO4 Battery Considering Temperature Effect. Master’s Thesis, Hefei University of Technology, Hefei, China, 2017. [Google Scholar]

- He, H.; Zhang, X.; Xiong, R.; Xu, Y.; Guo, H. Online model-based estimation of state-of-charge and open-circuit voltage of lithium-ion batteries in electric vehicles. Energy 2012, 39, 310–318. [Google Scholar] [CrossRef]

- Sepasi, S.; Ghorbani, R.; Liaw, B.Y. Improved extended kalman filter for state of charge estimation of battery pack. J. Power Sources 2014, 255, 368–376. [Google Scholar] [CrossRef]

- Ma, X.; Tao, Q.; Yin, W.-B.; Qiu, D.-F.; Zhang, J.-D.; Zhao, B. On-line estimation of power battery soc based on fpga. DEStech Trans. Comput. Sci. Eng. 2018. Available online: https://1library.net/document/q5wvvvrq-line-estimation-power-battery-soc-based-fpga.html#fulltext-content (accessed on 19 October 2023).

- Li, J.; Barillas, J.K.; Guenther, C.; Danzer, M.A. A comparative study of state of charge estimation algorithms for lifepo4 batteries used in electric vehicles. J. Power Sources 2013, 230, 244–250. [Google Scholar] [CrossRef]

- Mao, X.; Song, S.; Ding, F.J. Optimal BP neural network algorithm for state of charge estimation of lithium-ion battery using PSO with Levy flight. J. Energy Storage 2022, 49, 104139.1–104139.5. [Google Scholar] [CrossRef]

- Xia, X.; Bhatt, N.P.; Khajepour, A.; Hashemi, E. Integrated inertial-lidar-based map matching localization for varying environments. IEEE Trans. Intell. Veh. 2023, 1–12. [Google Scholar] [CrossRef]

- Xia, X.; Xu, R.; Ma, J. Secure cooperative localization for connected automated vehicles based on consensus. IEEE Sens. J. 2023, 23, 25061–25074. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, K.; Zhu, C.; Zhang, X.; Zhang, D. Co-estimation of state-of-charge and state-of-health for lithium-ion batteries using an enhanced electrochemical model. IEEE Trans. Ind. Electron. 2022, 69, 2684–2696. [Google Scholar] [CrossRef]

- Poloni, T.; Figueroa-Santos, M.A.; Siegel, J.B.; Stefanopoulou, A.G. Integration of non-monotonic cell swelling characteristic for state-of-charge estimation. In Proceedings of the 2018 Annual American Control Conference (ACC), Milwaukee, WI, USA, 27–29 June 2018; pp. 2306–2311. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, X.; Deng, Z.; Yang, L. Application of electrochemical impedance spectroscopy in battery management system: State of charge estimation for aging batteries. J. Energy Storage 2023, 57, 106275. [Google Scholar] [CrossRef]

- Wadi, A.; Abdel-Hafez, M.; Hashim, H.A.; Hussein, A.A. An invariant method for electric vehicle battery state-of-charge estimation under dynamic drive cycles. IEEE Access 2023, 11, 8663–8673. [Google Scholar] [CrossRef]

- Wang, M.; Wang, G.; Xiao, Z.; Sun, Y.; Zheng, Y. State of charge estimation of lifepo4 in various temperature scenarios. Batteries 2023, 9, 43. [Google Scholar] [CrossRef]

- Du, C.-Q.; Shao, J.-B.; Wu, D.-M.; Ren, Z.; Wu, Z.-Y.; Ren, W.-Q. Research on co-estimation algorithm of soc and soh for lithium-ion batteries in electric vehicles. Electronics 2022, 11, 181. [Google Scholar] [CrossRef]

- Lin, Q.; Li, X.; Tu, B.; Cao, J.; Zhang, M.; Xiang, J. Stable and accurate estimation of soc using exogenous kalman filter for lithium-ion batteries. Sensors 2023, 23, 467. [Google Scholar] [CrossRef]

- Wang, L.; Lu, D.; Liu, Q.; Liu, L.; Zhao, X. State of charge estimation for lifepo4 battery via dual extended kalman filter and charging voltage curve. Electrochim. Acta 2019, 296, 467. [Google Scholar] [CrossRef]

- Luan, Z.; Qin, Y.; Hu, B.; Zhao, W.; Wang, C. Estimation of state of charge for hybrid unmanned aerial vehicle li-ion power battery for considering rapid temperature change. J. Energy Storage 2023, 59, 106479. [Google Scholar] [CrossRef]

- Qiu, Y.; Li, X.; Chen, W.; Duan, Z.M.; Yu, L. State of charge estimation of vanadium redox battery based on improved extended kalman filter. ISA Trans. 2019, 94, 326–337. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Hannan, M.A.; Hussain, A.; Ayob, A.; Saad, M.H.M.; Karim, T.F.; How, D.N.T. Data-driven state of charge estimation of lithium-ion batteries: Algorithms, implementation factors, limitations and future trends. J. Clean. Prod. 2020, 277 Pt 2, 124110.1–124110.29. [Google Scholar] [CrossRef]

- Qian, C.; Xu, B.; Xia, Q.; Ren, Y.; Yang, D.; Wang, Z. A dual-input neural network for online state-of-charge estimation of the lithium-ion battery throughout its lifetime. Materials 2022, 15, 5933. [Google Scholar] [CrossRef]

- Ali, O.; Ishak, M.K.; Ahmed, A.B.; Salleh, M.F.M.; Ooi, C.A.; Khan, M.F.A.J.; Khan, I. On-line wsn soc estimation using gaussian process regression: An adaptive machine learning approach. Alex. Eng. J. 2022, 61, 9831–9848. [Google Scholar] [CrossRef]

- Zhang, G.; Xia, B.; Wang, J.J. Intelligent state of charge estimation of lithium-ion batteries based on l-m optimized back-propagation neural network. J. Energy Storage 2021, 44 Pt B, 103442.1–103442.16. [Google Scholar] [CrossRef]

- Anton, J.C.Á.; Nieto, P.J.G.; de Cos Juez, F.J.; Sanchez Lasheras, F.; Gonzalez Vega, M.; Roqueni Gutierrez, M.N. Battery state-of-charge estimator using the svm technique. Appl. Math. Model. 2013, 37, 6244–6253. [Google Scholar] [CrossRef]

- Zhang, L.; Li, K.; Du, D.; Zhu, C.; Zheng, M. A sparse least squares support vector machine used for soc estimation of li-ion batteries. IFAC-PapersOnLine 2019, 52, 256–261. [Google Scholar] [CrossRef]

- Hu, C.; Ma, L.; Guo, S.; Guo, G.; Han, Z. Deep learning enabled state-of-charge estimation of lifepo4 batteries: A systematic validation on state-of-the-art charging protocols. Energy 2022, 246, 123404. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Hannan, M.A.; Hussain, A.; Ayob, A.; Saad, M.H.M.; Muttaqi, K.M. State of charge estimation in lithium-ion batteries: A neural network optimization approach. Electronics 2020, 9, 1546. [Google Scholar] [CrossRef]

- Duan, W.; Song, C.; Peng, S.; Xiao, F.; Shao, Y.; Song, S. An improved gated recurrent unit network model for state-of-charge estimation of lithium-ion battery. Energies 2020, 13, 6366. [Google Scholar] [CrossRef]

- Javid, G.; Abdeslam, D.O.; Basset, M. Adaptive online state of charge estimation of evs lithium-ion batteries with deep recurrent neural networks. Energies 2021, 14, 758. [Google Scholar] [CrossRef]

- Yan, C.; Li, M.; Zhou, X. Application of improved genetic algorithm in function optimization. Appl. Res. Comput. 2019, 36, 2982–2985. [Google Scholar] [CrossRef]

- Chen, Q.; Hu, X. Design of intelligent control system for agricultural greenhouses based on adaptive improved genetic algorithm for multi-energy supply system. Energy Rep. 2022, 8, 12126–12138. [Google Scholar] [CrossRef]

- Ozcalici, M.; Bumin, M. Optimizing filter rule parameters with genetic algorithm and stock selection with artificial neural networks for an improved trading: The case of borsa istanbul. Expert Syst. Appl. 2022, 208, 118120. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, G.; Li, Y.; Duo, Z.; Sun, C. Optimization of hydrogen liquefaction process based on parallel genetic algorithm. Int. J. Hydrogen Energy 2022, 47, 27038–27048. [Google Scholar] [CrossRef]

- Mota, B.; Faria, P.; Vale, Z. Residential load shifting in demand response events for bill reduction using a genetic algorithm. Energy 2022, 260, 124978. [Google Scholar] [CrossRef]

- Kollmeyer, P. Panasonic 18650PF Li-ion Battery Data; Mendeley Data, V1; University of Wisconsin Madison, McMaster University: Madison, WI, USA, 2018. [Google Scholar] [CrossRef]

- Kollmeyer, P.; Skells, M. Turnigy Graphene 5000 mAh 65C Li-ion Battery Data; Mendeley Data, V1; University of Wisconsin Madison, McMaster University: Madison, WI, USA, 2020. [Google Scholar] [CrossRef]

- Vidal, C.; Malysz, P.; Naguib, M.; Emadi, A.; Kollmeyer, P.J.J. Estimating battery state of charge using recurrent and non-recurrent neural networks. J. Energy Storage 2022, 47, 103660.1–103660.12. [Google Scholar] [CrossRef]

- Onyekwena, C.C.; Xue, Q.; Li, Q.; Wan, Y.; Feng, S.; Umeobi, H.I.; Liu, H.; Chen, B. Support vector machine regression to predict gas diffusion coefficient of biochar-amended soil. Appl. Soft Comput. 2022, 127, 109345. [Google Scholar] [CrossRef]

- Jana, D.K.; Bhunia, P.; Adhikary, S.D.; Bej, B. Optimization of effluents using artificial neural network and support vector regression in detergent industrial wastewater treatment. Clean. Chem. Eng. 2022, 3, 100039. [Google Scholar] [CrossRef]

- Sharin, S.N.; Radzali, M.K.; Sani, M.S.A. A network analysis and support vector regression approaches for visualising and predicting the COVID-19 outbreak in malaysia. Healthc. Anal. 2022, 2, 100080. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Xu, K.; Xue, G.; Liu, J.; Xu, Z. Prediction of coal spontaneous combustion temperature based on improved grey wolf optimizer algorithm and support vector regression. Fuel 2022, 324, 124670. [Google Scholar] [CrossRef]

- Liu, W.; Xia, X.; Xiong, L.; Lu, Y.; Gao, L.; Yu, Z. Automated vehicle sideslip angle estimation considering signal measurement characteristic. IEEE Sens. J. 2021, 21, 21675–21687. [Google Scholar] [CrossRef]

| Characteristics | Value |

|---|---|

| The objective function ※ | |

| Initial population size | 100 |

| Chromosome length | 3 |

| Mutation probability | 0.0175 |

| Crossover probability | 0.7 |

| Calculation the fitness | MSE |

| Battery Datasets | Panasonic | Turnigy |

|---|---|---|

| Cycler Manufacturer | Digatron Firing Circults | Digatron Firing Circults |

| Test Channel | 25 A, 0–18 V channel | 75 A, 0–5 V channel |

| Data Acquisition | 10 Hz | 10 Hz |

| Accuracy | ±0.1% full scale | ±0.1% full scale |

| Thermal chamber | Cincinatti Subzero ZP8 | Envirotronics |

| Internal volume | 8 cu. Ft | 8 cu. Ft |

| Accuracy | ±0.5 C | ±0.5 C |

| Input Types | −20 C | −10 C | 0 C | 10 C | 25 C |

|---|---|---|---|---|---|

| Original Input | 91.24% | 87.52% | 94.78% | 96.38% | 97.98% |

| Low-Pass Filtered Input (0.5 mHZ) | 98.38% | 98.25% | 98.34% | 98.18% | 98.65% |

| Low-Pass Filtered Input (5 mHZ) | 96.75% | 94.83% | 94.95% | 96.74% | 98.44% |

| Combined Input | 98.47% | 99.85% | 98.91% | 98.70% | 98.81% |

| Standard | Temperature | Origin_Lin_SVR | Origin_RBF_SVR | XGBoost | RFR | GASVR |

|---|---|---|---|---|---|---|

| UDDS | −20 C | 88.89% | 88.66% | 90.08% | 93.31% | 98.47% |

| UDDS | −10 C | 95.21% | 92.35% | 97.89% | 90.50% | 98.85% |

| LA92 | −20 C | 70.44% | 94.89% | 93.51% | 94.93% | 98.79% |

| LA92 | −10 C | 95.83% | 96.51% | 98.10% | 96.41% | 99.94% |

| NEDC | −20 C | 75.04% | 96.88% | 87.55% | 94.17% | 98.60% |

| NEDC | −10 C | 98.01% | 95.29% | 98.13% | 96.65% | 99.50% |

| Standard | Evaluation Method | Temperature | Origin_Lin | Origin_SVR | XGBoost | RFR | GASVR |

|---|---|---|---|---|---|---|---|

| LA92 | −20 C | 70.44% | 95.88% | 93.51% | 98.93% | 98.79% | |

| LA92 | −10 C | 95.82% | 95.50% | 99.10% | 98.41% | 98.94% | |

| LA92 | 0 C | 96.43% | 95.89% | 98.35% | 98.21% | 98.83% | |

| LA92 | 10 C | 96.73% | 95.37% | 98.57% | 98.56% | 98.89% | |

| LA92 | 25 C | 92.85% | 95.96% | 97.61% | 98.44% | 98.91% | |

| NEDC | −20 C | 75.03% | 95.28% | 87.55% | 94.17% | 98.60% | |

| NEDC | −10 C | 97.01% | 96.80% | 98.13% | 96.65% | 98.50% | |

| NEDC | 0 C | 96.19% | 96.10% | 98.26% | 97.85% | 98.77% | |

| NEDC | 10 C | 96.92% | 95.88% | 98.43% | 98.28% | 98.92% | |

| NEDC | 25 C | 94.36% | 96.15% | 98.16% | 98.28% | 98.92% | |

| LA92 | RMSE | −20 C | 9.65% | 4.01% | 4.36% | 3.86% | 1.95% |

| LA92 | RMSE | −10 C | 4.10% | 3.80% | 1.87% | 2.13% | 1.50% |

| LA92 | RMSE | 0 C | 3.79% | 3.17% | 1.69% | 1.89% | 0.97% |

| LA92 | RMSE | 10 C | 3.57% | 3.52% | 1.43% | 1.57% | 1.02% |

| LA92 | RMSE | 25 C | 5.33% | 3.45% | 2.12% | 1.76% | 0.98% |

| NEDC | RMSE | −20 C | 9.02% | 3.92% | 5.43% | 3.54% | 2.06% |

| NEDC | RMSE | −10 C | 2.70% | 3.40% | 1.89% | 2.31% | 1.39% |

| NEDC | RMSE | 0 C | 4.18% | 3.02% | 1.67% | 1.78% | 1.12% |

| NEDC | RMSE | 10 C | 4.35% | 3.10% | 1.16% | 1.12% | 0.84% |

| NEDC | RMSE | 25 C | 5.37% | 3.17% | 1.97% | 1.49% | 0.95% |

| LA92 | MAE | −20 C | 8.48% | 3.26% | 4.38% | 3.23% | 1.57% |

| LA92 | MAE | −10 C | 2.45% | 3.18% | 1.67% | 2.28% | 1.30% |

| LA92 | MAE | 0 C | 3.95% | 2.33% | 1.36% | 1.54% | 0.97% |

| LA92 | MAE | 10 C | 3.69% | 2.73% | 1.14% | 1.13% | 0.84% |

| LA92 | MAE | 25 C | 4.59% | 3.14% | 2.63% | 1.32% | 0.84% |

| NEDC | MAE | −20 C | 7.27% | 3.16% | 5.40% | 3.12% | 1.63% |

| NEDC | MAE | −10 C | 1.96% | 2.90% | 1.40% | 2.78% | 1.15% |

| NEDC | MAE | 0 C | 2.44% | 2.58% | 1.22% | 1.54% | 0.93% |

| NEDC | MAE | 10 C | 2.33% | 3.32% | 1.28% | 1.47% | 0.73% |

| NEDC | MAE | 25 C | 4.61% | 3.18% | 1.86% | 1.18% | 0.77% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Li, Z.; Wei, J. Estimation of Lithium-Ion Battery State of Charge Based on Genetic Algorithm Support Vector Regression under Multiple Temperatures. Electronics 2023, 12, 4433. https://doi.org/10.3390/electronics12214433

Chen C, Li Z, Wei J. Estimation of Lithium-Ion Battery State of Charge Based on Genetic Algorithm Support Vector Regression under Multiple Temperatures. Electronics. 2023; 12(21):4433. https://doi.org/10.3390/electronics12214433

Chicago/Turabian StyleChen, Chao, Zhenhua Li, and Jie Wei. 2023. "Estimation of Lithium-Ion Battery State of Charge Based on Genetic Algorithm Support Vector Regression under Multiple Temperatures" Electronics 12, no. 21: 4433. https://doi.org/10.3390/electronics12214433

APA StyleChen, C., Li, Z., & Wei, J. (2023). Estimation of Lithium-Ion Battery State of Charge Based on Genetic Algorithm Support Vector Regression under Multiple Temperatures. Electronics, 12(21), 4433. https://doi.org/10.3390/electronics12214433