Design and Implementation of Automatic Cooling Case Based on High-Power and High-Density Power Supply Array

Abstract

:1. Introduction

2. Related Works

3. Design of an Automatic Cooling Case

3.1. Conduction Heat Dissipation Design

3.1.1. Selection of Conductive Heat Dissipation Materials

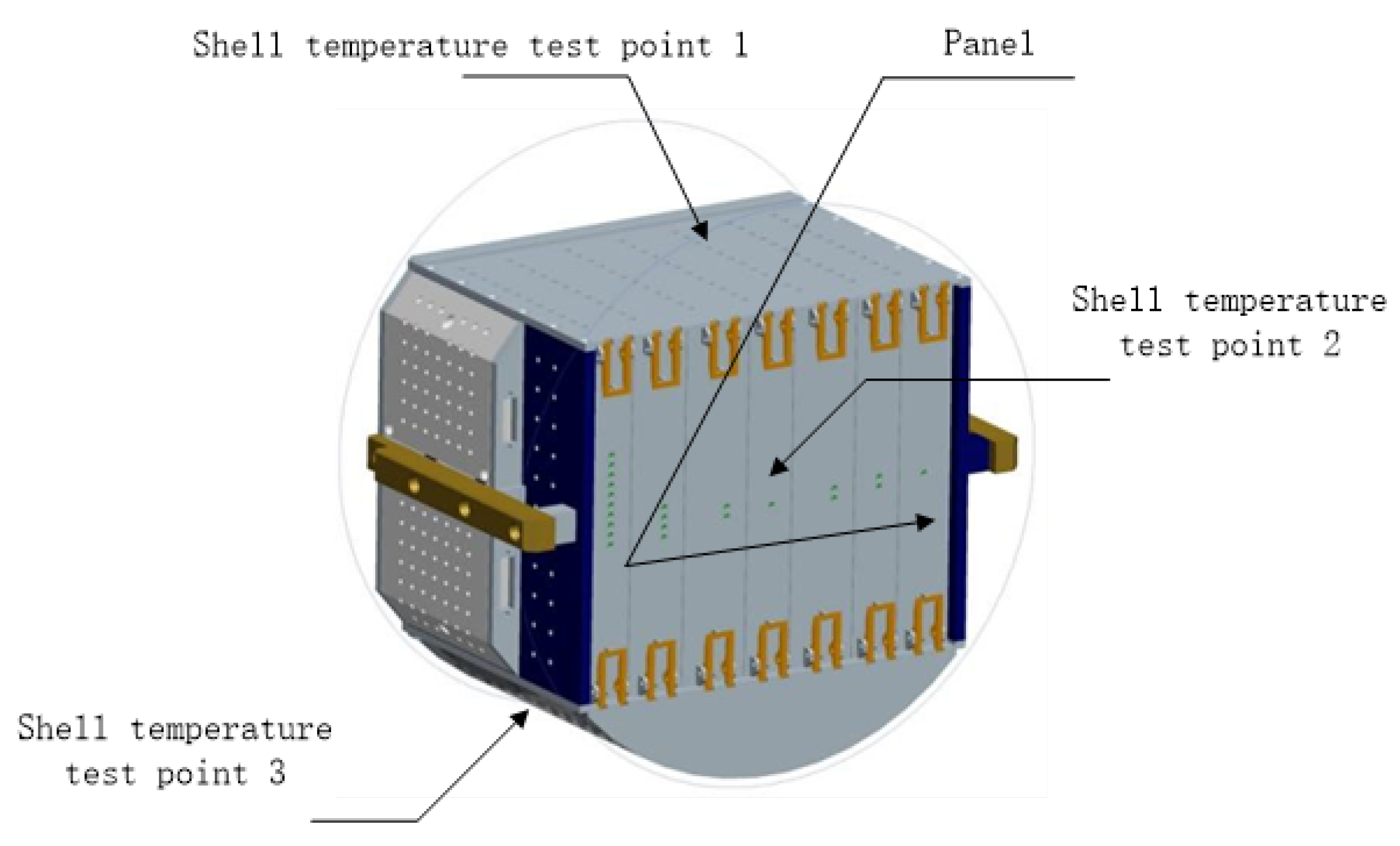

3.1.2. Structure Design of Conduction Heat Dissipation

3.2. The Design of Forced Air Cooling

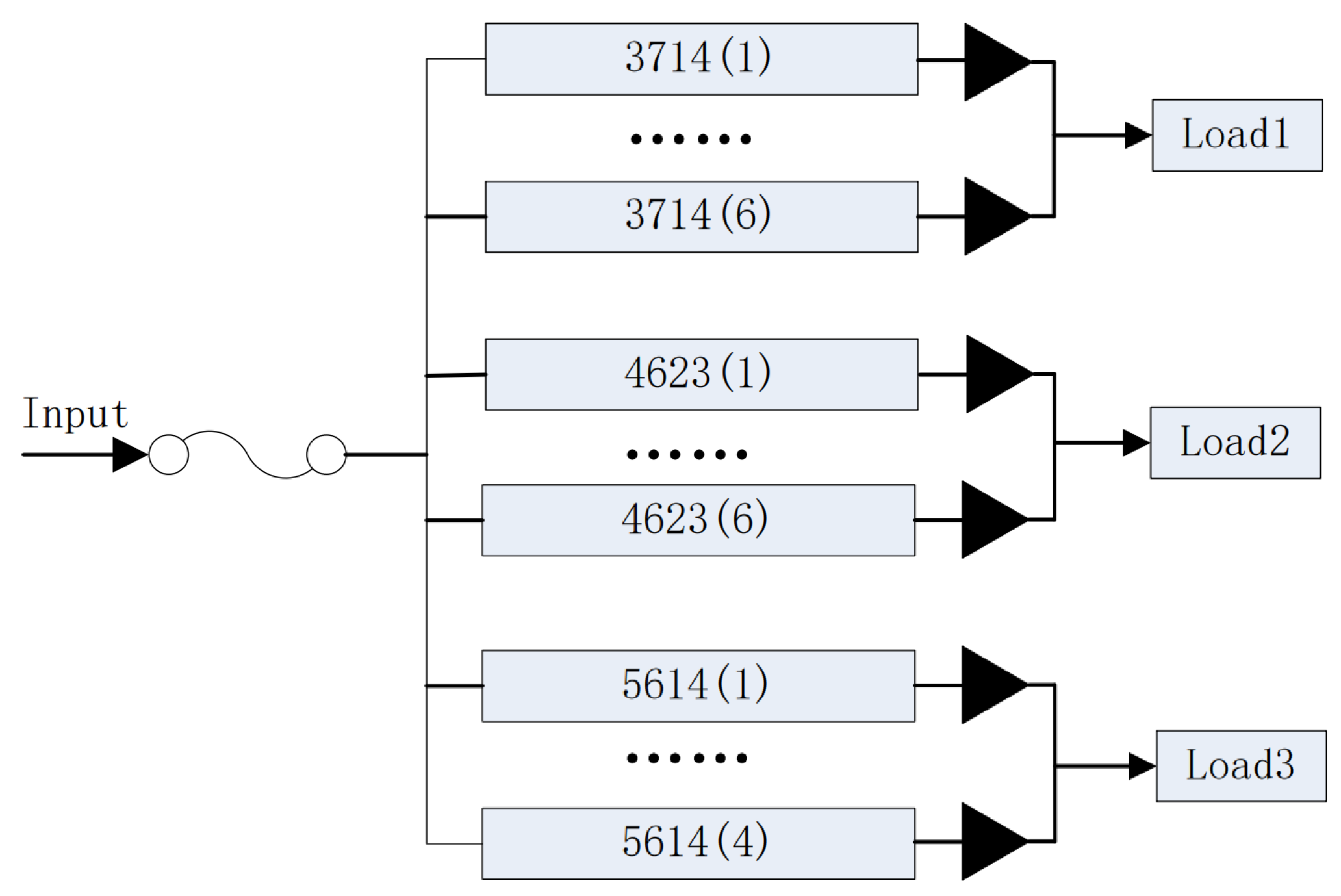

3.3. The Design of High-Power Density Power Array

3.4. Design of Automatic Control Components

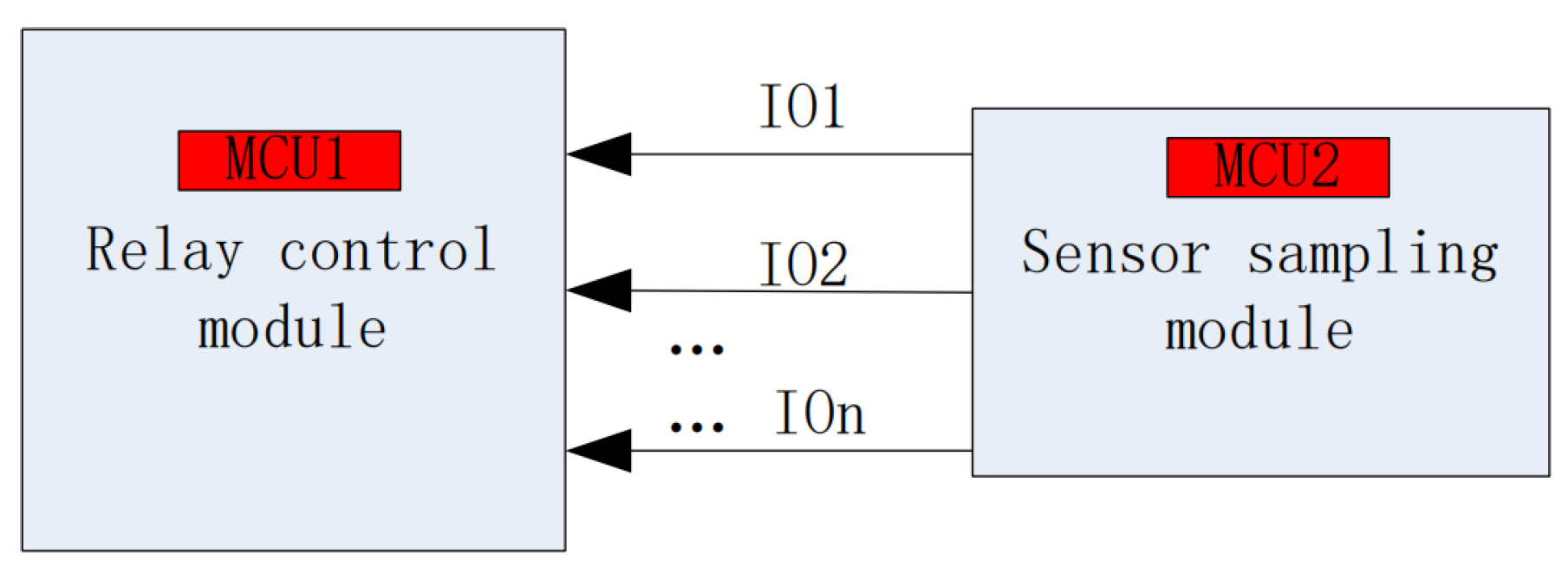

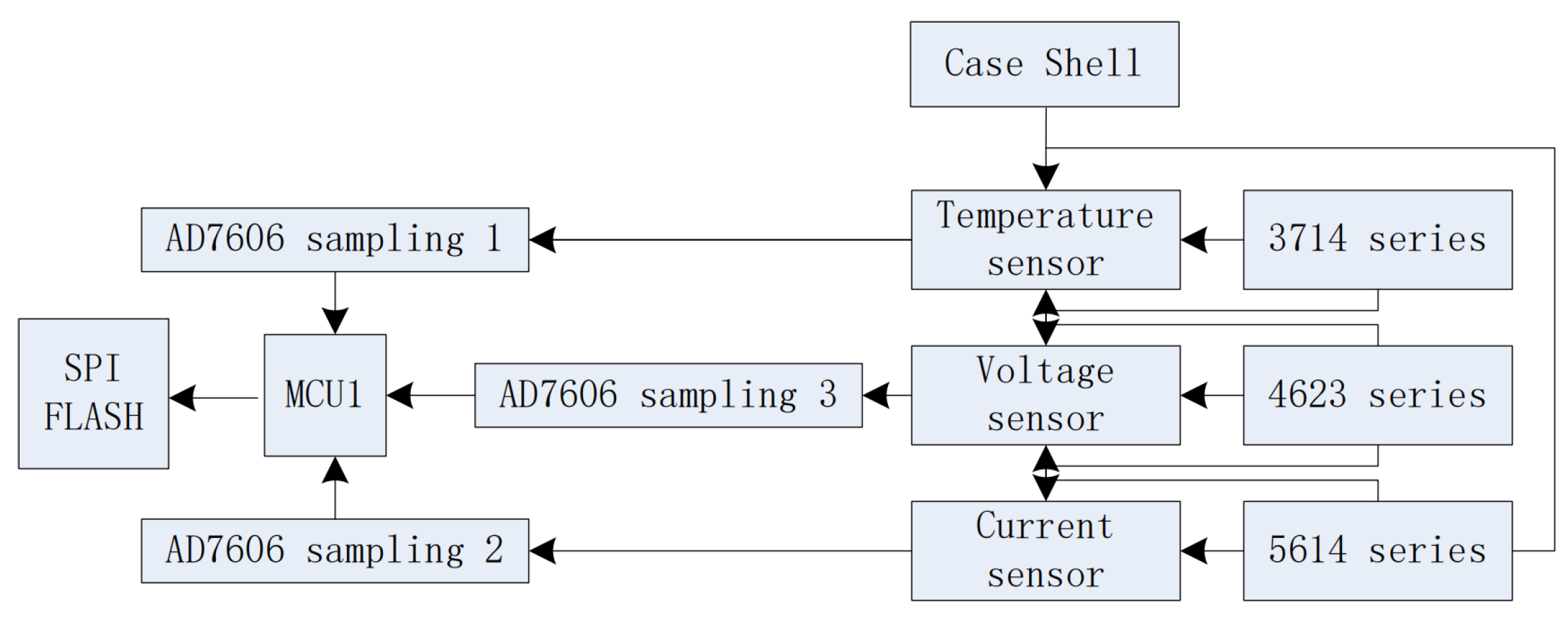

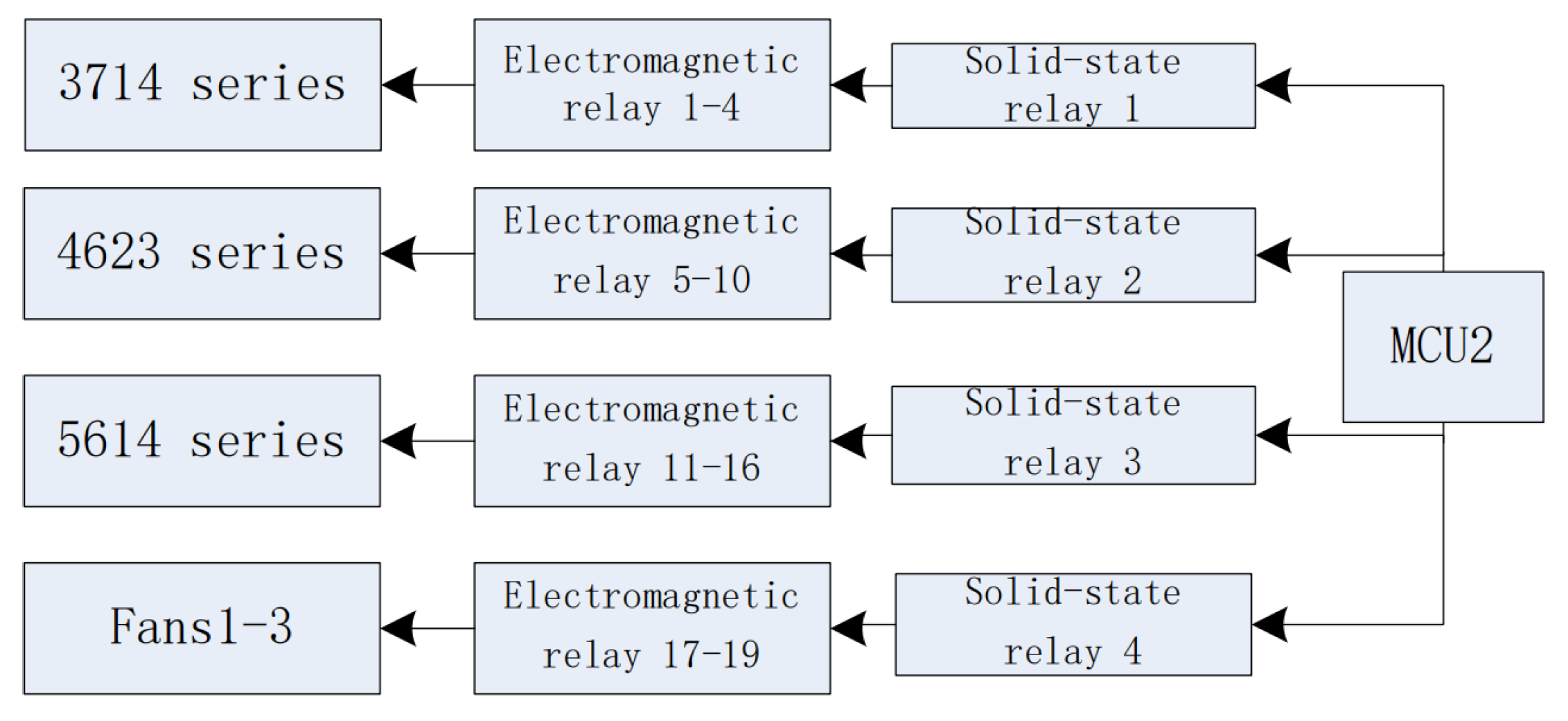

3.4.1. Design of the Automatic Control Module

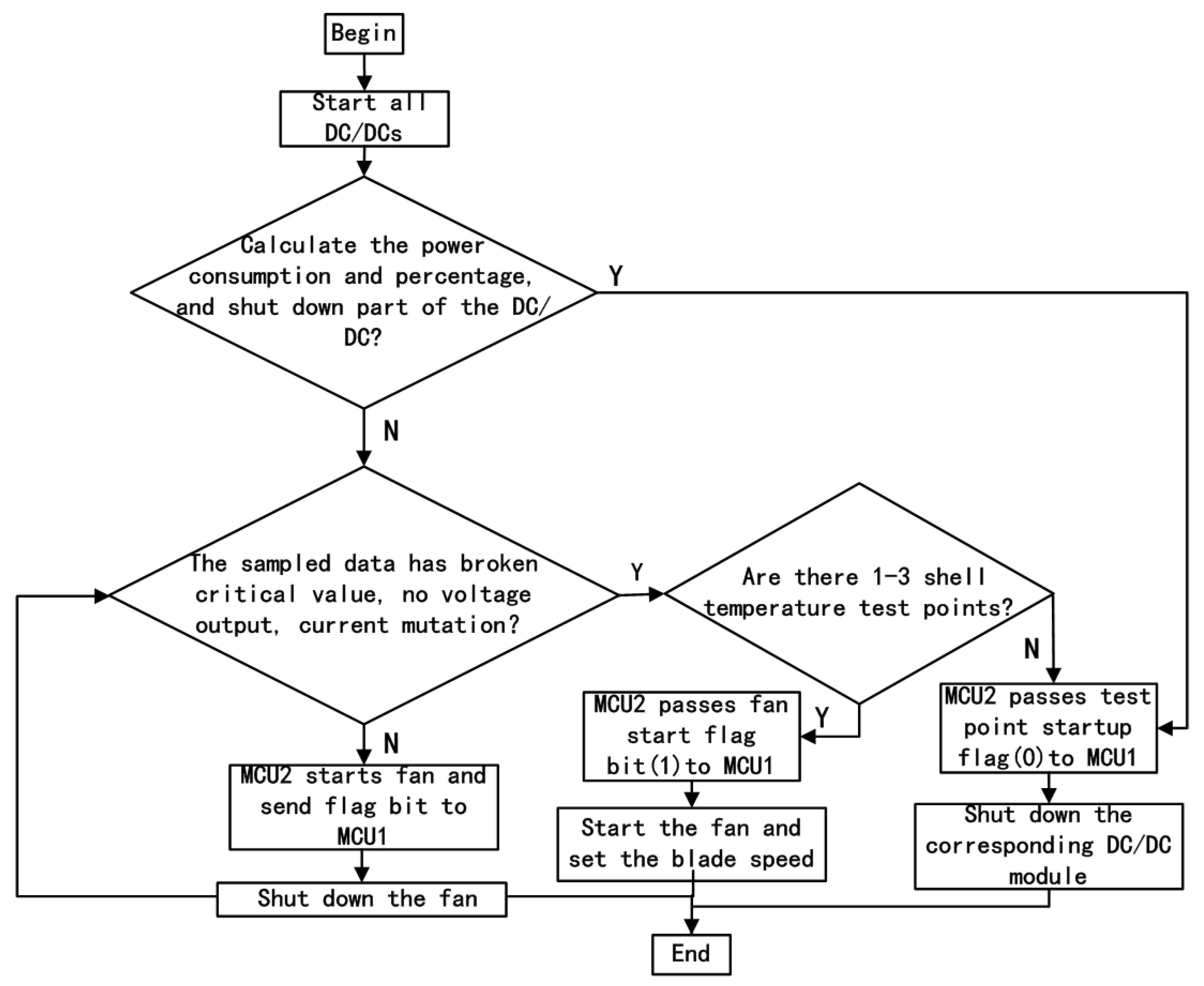

3.4.2. Design of Automatic Control Software

4. Analysis of Test Results and Comparison of Related Performance Parameters

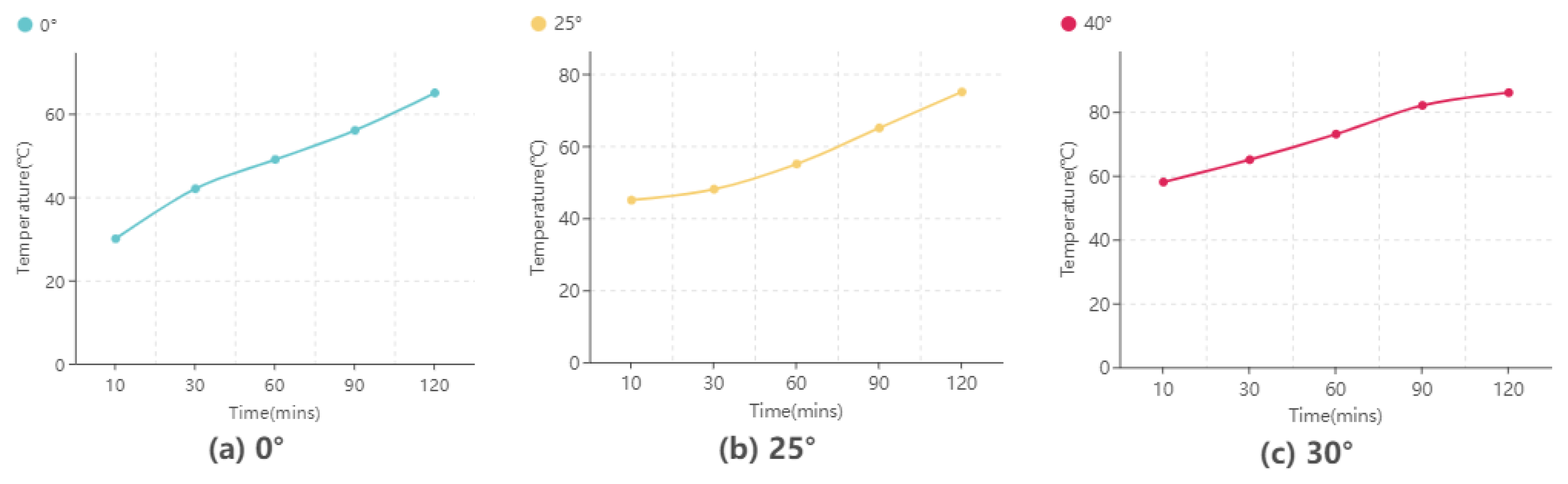

4.1. Analysis of Test Results

4.2. Comparison of Related Performance Parameters

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lv, Y. Research and Design of a Two-Channel High-Side Intelligent Power Switching Circuit. Master’s Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2022. [Google Scholar]

- Ben, A.; Xie, P.; Huang, F.; Yu, H. Analysis and Design of Modular DC Power Cabinet Heat Dissipation in Substation. Mach. Des. Manuf. Eng. 2020, 49, 57–61. [Google Scholar]

- Li, Y.; Li, Z.; Gao, L. Structural Thermal Design of a High Power Density Closed Power Supply. Electro-Mech. Eng. 2012, 28, 15–36. [Google Scholar]

- Tan, H. Optimization Design and Simulation Analysis of Heat Dissipation of an Airborne Equipment Power Cabinet. South China Agric. Mach. 2015, 52, 138–140. [Google Scholar]

- Yang, T. Structure and Heat Dissipation Analysis of Shipborne Water-cooled Cabinet. Ship Electron. Countermeas. 2022, 45, 106–110. [Google Scholar]

- Yu, Q.; Ge, X. Heat dissipation Optimization of High Power Supply Module. Electron. World 2021, 8, 170–171. [Google Scholar]

- Fu, P.; Wen, W.; Li, Y. Research on Ventilation and Heat Dissipation Structure and Method of a New Energy Storage Power Supply. Technol. Mark. 2020, 27, 33–34. [Google Scholar]

- Zhang, G.; Gao, Z.; Yang, L.; Zhang, C. Design and Simulation Analysis of Heat Dissipation in Dense Arrangement of Multi-Switch Power Supply. Road Mach. Constr. Mech. 2020, 37, 85–89. [Google Scholar]

- Huang, X.; Li, D.; Wei, H.; Hou, S. Optimization design of Heat Dissipation for High Power Microwave Power Supply. Autom. Inf. Eng. 2023, 44, 39–45. [Google Scholar]

- Niu, Y.; Gan, F.; Gao, M.; Shi, J. Thermal resistance Model Establishment and Heat dissipation Design of DC/DC Power Module. Power Electron. Technol. 2021, 55, 137–140. [Google Scholar]

- Zhou, Z.; Tang, H.; Yang, C.; Liu, L. Research on Improving the Working Life of Power Module. Shanghai Electr. Technol. 2014, 7, 14–17. [Google Scholar]

- Li, X.; Cao, W.; Pei, Q. Thermal properties of AZ91D. J. Henan Polytech. Univ. 2010, 29, 685–688. [Google Scholar]

- Xing, Y.; Xu, K.; Liu, Y.; Zhang, L.; Qi, C. Research progress of graphene’s high thermal conductivity Mechanism and Heat Transfer Enhancement. Chem. Eng. 2015, 29, 54–60. [Google Scholar]

- Yan, L.; Huang, H.; Li, S.; Qu, G. Research on the Standard and Application of Aviation Miniaturized Chassis. Meas. Control Technol. Mag. 2021, 1, 484–487. [Google Scholar]

- Li, Z. Calculation Method and Optimization of Thermal Conductivity of Heat dissipation Hole in Printed Circuit Board. Mod. Electron. Tech. 2014, 37, 143–147. [Google Scholar]

- Yu, G.; Li, F.; Tian, H. Design of ultra-thin Switching Power Supply with High Power Density. Appl. Electron. Tech. 2021, 1, 484–487. [Google Scholar]

- Shuai, W. Design of Output Parallel Current Sharing Circuit. Electron. Prod. World 2023, 30, 95–97. [Google Scholar]

- Yang, Y. Design of a temperature monitoring system based on single chip microcomputer and DS18B20. J. Nonferrous Met. Des. 2022, 49, 66–69. [Google Scholar]

- Jiang, S.; Wang, B.; Yu, L.; Yu, T. Design and implementation of Multi-channel Data Sampling System Based on FPGA+AD7606. Electron. Des. Eng. 2022, 30, 103–107. [Google Scholar]

- Yang, L. Analysis of Application Strategy of Relay in Automation Engineering. Ind. Innov. Res. 2023, 2, 154–156. [Google Scholar]

- Xu, Y. An Intelligent Cooling System for Hydraulic Fan Motor. Hydraul. Pneum. Seals 2023, 43, 63–65. [Google Scholar]

- Yang, A.; Yang, J.; Sun, B.; Yao, C. Modeling Design of Heat Dissipation Hole in Special Case Based on Icepak Analysis. J. Mach. Des. 2022, 39, 143–147. [Google Scholar]

- Peng, H.; Hu, J.; Tao, G. Design of Heat Dissipation in Portable Miniaturized Signal Processing Case. Electro-Mech. Eng. 2020, 36, 18–21. [Google Scholar]

| Classification | Solutions | Reference |

|---|---|---|

| Physical structure heat dissipation | natural air cooling | [3] |

| conduction cooling | [3] | |

| forced air cooling | [4] | |

| circulating water cooling | [5] | |

| Modeling optimization heat dissipation | Thermodynamic analysis software | [5] |

| DC/DC Efficiency at Full Load Output | Thermal Consumption Coefficient |

|---|---|

| 86% | 0.16 |

| 89% | 0.12 |

| 90% | 0.11 |

| 92% | 0.09 |

| 95% | 0.05 |

| N | DC/DC | Maximum Power | Efficiency | Power Density | Number | Input | Output | Heat Density |

|---|---|---|---|---|---|---|---|---|

| 1 | DCM3714 | 600 W | 94.0% | 18.9 W/cm | 6 | 200–420 V | 12–28 V | 116 W/cm |

| 2 | DCM4623 | 500 W | 92.8% | 63.5 W/cm | 6 | 160–420 V | 12–28 V | 47 W/cm |

| 3 | DCM5614 | 1300 W | 96.0% | 27.5 W/cm | 4 | 180–400 V | 22–36 V | 166 W/cm |

| Equipment | Function |

|---|---|

| Power array | Test source |

| Several 300 V high-voltage power supplies | Supply array power |

| Electronic loads | Test the performance of the power arrays |

| Temperature, voltage, current sensors | Monitor running data of the power array |

| Several multimeters | Monitor DC/DC abnormal data |

| Automatic control module and control DC/DC startup and shutdown |

| Environmental Temperature | Before Cooling | After Cooling | Percentage of Cooling |

|---|---|---|---|

| 0° | 72° | 65° | 9.2% |

| 25° | 81° | 75° | 8.0% |

| 40° | 90° | 86° | 4.6% |

| Case | Volume | Reliability | Intelligent Control | Test Power on Load | Overall Design Power | Case Power Density | Test Time |

|---|---|---|---|---|---|---|---|

| The Case | (28 × 23 × 15) cm | High | Yes | 10,000 W | 10,000 W | 10 W/cm | 2 h |

| G1 | (42 × 26 × 29) cm | High | No | 100 W | 600 W | 0.003 W/cm | 2 h |

| G2 | (22 × 16 × 50) cm | High | No | 0 W | 150 W | 0 W/cm | 2 h |

| G3 | (11 × 56 × 12) cm | High | No | 600 W | 600 W | 7.2 W/cm | 2 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Feng, H.; Zhang, G.; Yang, C. Design and Implementation of Automatic Cooling Case Based on High-Power and High-Density Power Supply Array. Electronics 2023, 12, 4353. https://doi.org/10.3390/electronics12204353

Chen Z, Feng H, Zhang G, Yang C. Design and Implementation of Automatic Cooling Case Based on High-Power and High-Density Power Supply Array. Electronics. 2023; 12(20):4353. https://doi.org/10.3390/electronics12204353

Chicago/Turabian StyleChen, Zerui, Hangwei Feng, Guoguang Zhang, and Chong Yang. 2023. "Design and Implementation of Automatic Cooling Case Based on High-Power and High-Density Power Supply Array" Electronics 12, no. 20: 4353. https://doi.org/10.3390/electronics12204353

APA StyleChen, Z., Feng, H., Zhang, G., & Yang, C. (2023). Design and Implementation of Automatic Cooling Case Based on High-Power and High-Density Power Supply Array. Electronics, 12(20), 4353. https://doi.org/10.3390/electronics12204353