Intelligent Materials and Nanomaterials Improving Physical Properties and Control Oriented on Electronic Implementations

Abstract

:1. Introduction

- Section 2 discusses the methodology and the logic flow followed to define the research papers suitable for the combination of AI and electronics;

- Section 9 summarizes the main research perspectives, suggesting a new research scenario and framework for intelligent materials matching AI with electronic facilities;

- Section 10 summarizes the goals and the discussions developed in the work.

2. Review Methodology

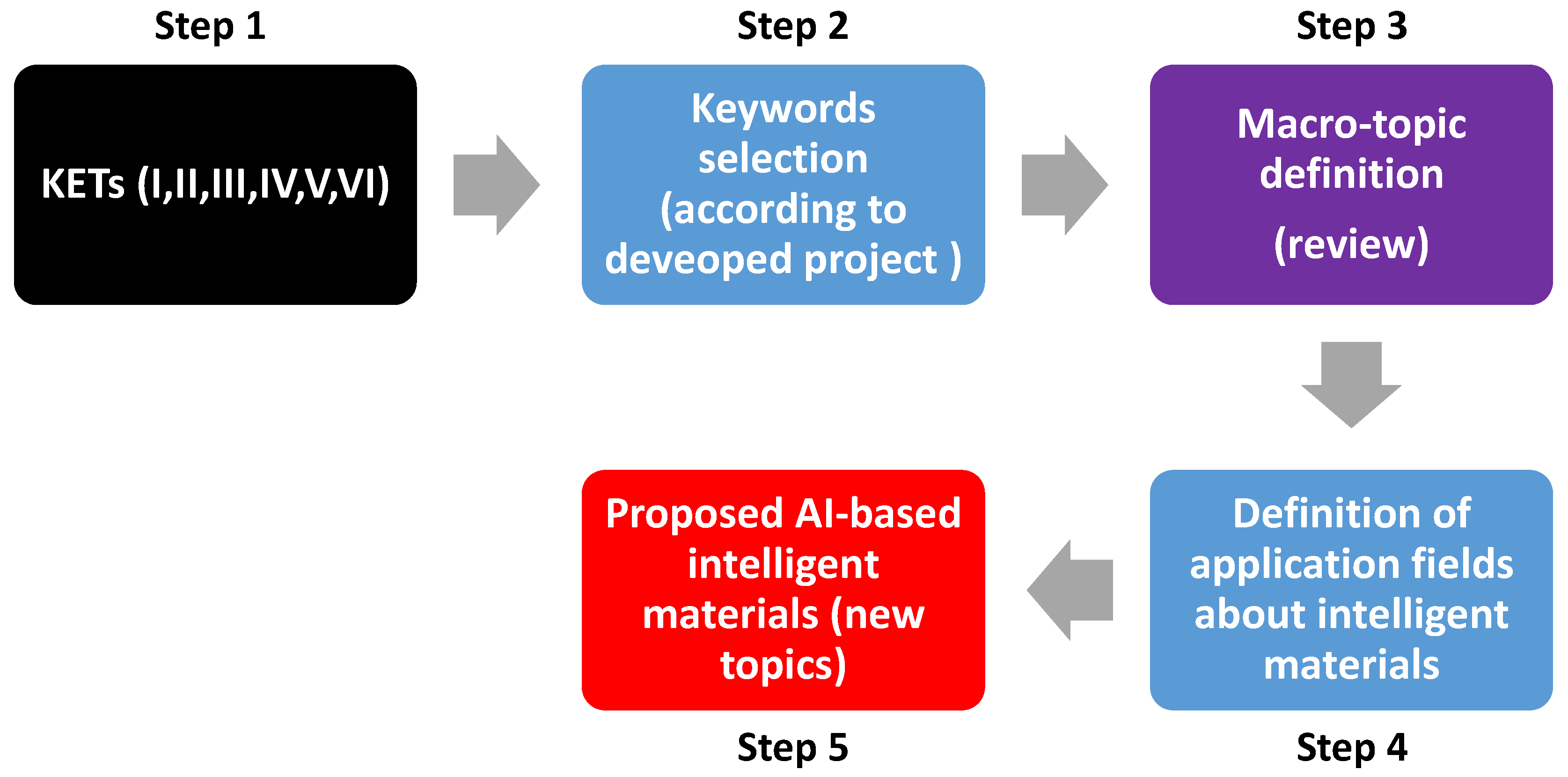

- Step 1. Finding of the main research fields (KETs) analyzing the research trajectories [5] matching with the review topic about sustainable manufacturing (smart factory) and human/environmental health (personal well-being and energy technologies);

- Step 2. Analysis of the research projects by extracting keywords to use for the state of the art analysis (European, Italian, and regional projects); different keywords (keywords used to search papers in literature) matching with project topics are extracted from projects, such as printing 3D/4D, biomaterials, nano/micro-fluidics, flexible electronics, nanocomposite materials, miniaturized electronic components, soft robotics, intelligent materials, intelligent food packaging, energy harvesting, miniaturized smart systems, nanomaterials, drugs and delivery, photonic-integrated circuits, self-healing materials, shape memory materials, environmental nanosensors, human body security, etc.

- Step 3. Definition of the macro-topics inferred from the examined scientific state of the art, such as 3D/4D printing techniques, materials in industrial manufacturing, laser manufacturing, pulsed spray techniques, electrospinning, plasma treatment, smart materials, intelligent self-adaptive materials, advanced energetic materials, AI design, AI and material sustainability, new polymer generation, food packaging, nanomaterials and medicine, environmental nanomaterials, flexible electronics, new materials in electronics, micro-/nanocircuits, electronic components, Internet of Things (IoT), smart materials, health security, and alarm and security systems; the literature is selected by taking into account one or both the following elements—the originality of the discussed topic and recent works;

- Step 4. Definition of possible new application fields according to the state of the art and to the possible implementation of AI (supervised and unsupervised machine learning (ML) algorithms), performing intelligence in various forms;

- Step 5. Definition of new focused research topics according to the application fields of Step 4.

3. (KET I) Advanced Manufacturing

- initial searching of techniques suitable for polymeric and nanomaterial manufacturing;

- matching of the fabrication techniques with the possible micro- and nanostructuration of the materials;

- possible and potential implementations of micro-/nanostructures in small and smart circuits.

| Macro-Topic (Defined in Step 3) | Application (Step 2) | Description of Application Field (Step 4) | Ref. | Possible Implementation as Intelligent Materials (New Research Topic: Step 5) |

|---|---|---|---|---|

| 3D Printing | Fused filament fabrication (FFF) | FFF applied to nanomaterials such as graphene nanosheets, improving mechanical, electrical, and thermal properties | [6] |

|

| FFF combined with artificial intelligence (AI) tools | AI data processing supporting exoskeleton parameters and material features for medical applications | [7] | AI-based fabrication of interchangeable materials externally controllable by dynamically adapting properties (maximum tensile force) | |

| 3D print matching with nanoparticles (NPs) for biomedicine | Printed 3D hybrid biomaterials including NPs | [8,9] | NPs in printed implanted systems, changing properties due to a controllable external source (AI data processing controlling drug and delivery using natural NPs, decreasing the hazard level) | |

| Flexible electronics | Nanomaterials and additive manufacturing techniques adopted to implement electrical conductive patterns | [10,11,12] |

| |

| Electronic components | Ink for extrusion-based 3D printing for microsupercapacitor realization | [13] | Real-time electrical layout modification by adding or subtracting conductive ink material according to the desirable input/output circuit signals (control of voltage source) | |

| Graphene printed | 3D printing of graphene oxide (GO)/geopolymer (GOGP) nanocomposite | [14] | Intelligent control of addition of GO in geopolymeric aqueous mixture (aluminosilicate and alkaline-source particles) to calibrate rheology properties of material | |

| Bioprinting technologies | 2D nanomaterials implemented by 3D printing technique extending the application of dynamic bio-inks | [15] | AI tailoring of material to control and to reduce toxicity (controlling the dynamism of 2D materials) | |

| 4D Printing (3D Printing + Time) | 4D printing in healthcare | 4D printing applied to smart implants, tissue engineering, drug delivery, and surgery tools | [16] | AI algorithms processing data to control material response by calibrating stimuli such as temperature or pH, able to modify shape or properties over time during surgery, or to adapt material growth to the specific healthcare environment |

| 4D printing hydrogel materials | Underwater shape transformation and control of water-responsive joints | [17] | AI controlling stimuli of water responsivity of the hydrogel intelligent material | |

| Load-bearing prosthetics | Orthopedic implants with superior performance implementing meta-biomaterials | [18,19] | AI controlling the load direction, simultaneously measuring the load over time | |

| AI-based empowered 4D printing technologies | Shape-morphing 4D-responsive materials | [20] | AI calibrating external stimuli for material reshaping, and material self-healing and self-assembly | |

| Materials in industrial manufacturing | Nanoparticle-infused plastic products | FFF extrusion of nanoparticles and recycled plastic-based filaments (optimization of FFF parameters by AI) | [21] | AI self-adaptive parametrization of nozzle temperature and print speed |

| Additive manufacturing (AM) of nanomaterials | Recent developments in nanomaterial applications in AM | [22,23] | AI classification of nanomaterials able to reconfigure the nanocomposite material after the application of stimuli | |

| Nanotechnologies and medical industry | Nanotechnology applications in field of dentistry | [24] | AI improving material self-adapting process in tooth repair | |

| Molecular nanomaterials in industry | Top-down and bottom-up processes to realize industrial nanocrystals | [25] | AI-based approach for the preparation of molecular nanomaterials | |

| Green nanomaterials suitable for biotoxicity profiles | AI supporting the analysis of bio-chemical interactions with the environment and living organisms (resistance of the material to exposure) | [26] | Optimization of the biotoxicity profile (AI controlling biotoxicity) | |

| Smart materials | Multifunctional parts performing sensing, control, and actuation functions | [27,28] | AI improving material self-diagnosis and self-restoration to apply self-repair | |

| Laser Manufacturing | Laser texturing optimizing surfaces | Laser texturing optimization of nanosecond laser parameters to enhance the quality characteristics of surface textures formed on nickel–aluminum–bronze (NAB) material | [29] | AI laser control of laser parameters |

| Laser texturing optimizing hydrophobicity | YAG laser forming textured surface on the surface of NAB for marine applications | [30] | AI laser control of laser parameters | |

| Laser texturing generating micro-nano-crystals | Laser texturing improving chitosan nanocomposite surface | [31,32] | AI automating laser parameters, controlling surface crystal dimensions and improving wettability properties | |

| Laser texturing realizing integrated antenna arrays | Laser texturing applied to masks for micro-antenna layout realization (surface layouts) | [33] | AI laser control (power, pulse signal delay, fluency, etc.), improving and regenerating electrical conductive surfaces | |

| Laser texturing realizing artificial skin | Laser texturing applied on PDMS to realize plasmonic patterns for optical pressure sensing | [33,34] | AI laser control (power, pulse signal delay, fluency, etc.), improving plasmonic resonance | |

| Two-photon polymerization | Microfabrication of 3D materials and polymeric photonic crystals | [35,36] | AI applied for reverse engineering of the material (reuse of the processed material) | |

| Laser ablation | Femtosecond laser ablation for high-resolution surfaces | [37] | AI locally controlling thermal effects of laser ablation, improving resolution of sample surfaces | |

| Pulsed Spray Technique | Self-assembled nanomaterial deposition | Realization of self-assembled pillar-like structures of nanodiamonds | [38] | AI controlling micro- and nano-pillar structuration |

| Realization of electrical conductive surface layers | Improvement of surface electrical current by nanodiamonds (local surface electrical current corresponding the nanodiamond depositions) | [39,40,41,42] | AI controlling the increase in the surface electrical current by adjusting nozzle parameters (number of pulses, spray power, etc.) | |

| Diamond-based layers generating photo-currents | Deposition of materials generating UV electrical currents | [43] | AI improving UV external source effect based on the material morphology | |

| Electrospinning | Electrospun nanofibers | Nanofibers controlled in size and adding nano-inclusions | [44,45,46] | AI to locally added oriented nanofibers, improving material properties |

| Plasma Treatment | Polymer treatment | Treatment of pure polymers, biocompatible polymers, polymer–metal, polymer–wood, polymer–nanocarbon composites, and others, improving wettability | [47,48] | AI analyzing local treatment gaining wettability or functionalization properties |

| Metallic surface treatment | Aluminum coating treatment enabling the interdiffusion of the elements between the coating and base material | [49] | AI procedure maintaining metallic surface characteristics (plasma treatment over time) | |

| Treatment of advanced materials | Cleaning of graphitic surfaces and precise ablation of individual graphene layers | [50] | AI procedure cleaning advanced material (plasma cleaning over time) |

4. (KET II) Advanced Materials

- first analysis of smart materials proposed in the literature focusing on NPs and on energy systems (important recent topic);

- definition of possible application fields, focusing the attention on physical and chemical “superproperties” (mechanical, electrical, electromagnetic, energy conversion);

- hypotheses of possible AI control concepts of the material properties, including self-adaptivity.

- finding elements enhancing the mass transfer coefficient in biogases;

- predicting the ionic material efficiency;

- tailoring the photovoltaic (PV) efficiency, nanofluid materials in solar energy, and electronic integration;

- optimizing the electronic integration in phase change materials (PCMs);

- and classifying efficient energy transport models (as for ultrasound nano-energetic systems).

| Macro-Topic (Defined in Step 3) | Application (Step 2) | Description of Application Field (Step 4) | Ref. | Possible Implementation as Intelligent Materials (New Research Topic: Step 5) |

|---|---|---|---|---|

| Smart materials | Graphene-based nanocomposite materials | Graphene nanoplatelet-based material as multi-functional and mechanically resilient advanced material | [51] | AI supporting the monitoring of crack growth and the localization of possible material damages by locally reconstructing the mechanical and electrical functions |

| Magnetic NPs | Magnetic particles behaving as micro-robots for biomedical applications | [52] | AI controlling movements of micro-robots by controlling the external magnetic field stimuli and avoiding micro- and nano-obstacles | |

| NPs with oxide shell | Enhancing light sintering technique for Cu NP ink in printed electronics (copper oxide shell) [53]; oxide layer on silicon NPs, providing chemical stability to the material [54] | [53,54] | AI controlling oxide thickness and thermal oxidation process | |

| Silica (SiO2) NPs | Silica NPs, improving protective and mechanical properties | [55] | AI controlling the increase in the rate of formation of the oxide layer (oxide layer generation or oxide layer crack repair) | |

| Coated metallic SiO2 NPs | Silica coating for colorimetric diagnostics and photothermal cancer therapy | [56] | Near-infrared light (NIR) stimuli calibrated by AI tuning the light-adsorbing capability according to the coating thickness (photothermal cancer therapy) | |

| Au-functionalized NPs | Au NPs functionalized with dodecanethiol by Nd:YAG pulsed laser (therapeutic applications) | [57] | AI controlling photodynamic and photothermal effects | |

| PDMS-based material | Nanocomposite PDMS material improving mechanical properties via specific filler | [58,59,60,61,62,63] | AI controlling parameters in PDMS nanocomposite fabrication, tailoring mechanical properties | |

| Advanced nanocomposite materials | Nanocomposite materials improving electrorheological, shape, and magnetic responses | [64,65,66] | AI controlling physical states of hybrid circuits (solid/liquid) for intelligent adaptive micro-robot implementations | |

| Intelligent self-adaptive materials | Self-healing materials | Self-healing of physical properties and corrosion-responsive materials | [67,68,69,70,71,72,73,74,75,76,77,78,79,80,81] | Algorithms adopted to regenerate micro- and nano-electronic circuits controlling external stimuli |

| Shape memory materials | Material having shape memory capability | [82,83,84,85,86,87,88] | AI controlling stimuli for shape auto-adaptive devices | |

| Advanced energetic materials | Sustainable biogas production | Maximization of biogas generation by NPs | [89] | Algorithms enabling the enhancement of mass transfer coefficient |

| Solar cells | Ionic liquid-based smart materials for solar cell implementation | [90] | Prediction and design parameters for ionic material efficiency | |

| Photovoltaic (PV) cells | Ultrathin 2D materials for solar energy to electricity conversion | [91] | AI-based model tailoring PV cells and electronic integration | |

| Nanomaterials for energy storage systems | Phase change materials (PCMs) for storage and conversion of solar thermal energy | [92] | AI-based model tailoring PCMs and electronic integration | |

| Nanofluids in solar energy | Nanofluid multifunctional systems in solar energy and ion-transport-based energy conversion systems (photovoltaic/thermal systems, geothermal, lighting/heating systems, desalination-related hybrid systems, and thermal energy storage (TES)-related hybrid systems) | [93,94,95] | AI-based model tailoring nanofluid materials in electronic circuits managing solar energy | |

| Energy-harvesting materials | Triboelectric energy-harvesting polymer-based materials | [96] | AI-based model tailoring energy-harvesting materials in electronic systems | |

| Nanocomposite materials for supercapacitor implementation | Electrochromism supercapacitor for energy storage systems | [97] | AI engine monitoring dynamically energy storage by color checking and circuit efficiency | |

| Energy transport | Ultrasound safe energy transport in smart materials | [98] | AI controlling and calibrating nanoenergy |

5. (KET III) Artificial Intelligence

- analysis of recent use of AI in material design and processing;

- search for new sustainable and polymeric materials improved by machine learning techniques;

- possible further AI improvements in processing data for material optimization.

| Macro-Topic (Defined in Step 3) | Application (Step 2) | Description of Application Field (Step 4) | Ref. | Possible Implementation as Intelligent Materials (New Research Topic: Step 5) |

|---|---|---|---|---|

| AI design | Tissue engineering (TE) | Tissue regeneration: AI data-driven 3D tissue engineering to enhance biomimicry; 3D convolutional neural networks (3D CNNs) predicting the mechanical properties of innovative scaffolds); AI predicting cell behavior | [99,100,101,102,103,104] | AI applied for reverse engineering of tissues in regenerative medicine matching with cell prediction behavior |

| Laboratory design | Creation of self-driving labs (SDLs) | [105] | Robotic AI parametrization of machines producing innovative materials | |

| Design of new computer architecture | Matching between AI and nanotechnologies | [106] | AI-based algorithms classifying innovative calculus cells in nanocomputing | |

| Design of metamaterials | Thermal metamaterial design | [107,108] | AI supporting device layout refinement, dynamically optimizing thermal concentration performance | |

| Nanomaterial design | AI-based design of plasmonic nanomaterials [109]; AI predicting cellular recognition of nanoparticles [110]; AI predicting antibacterial properties of NPs [111]; algorithms establishing dosimetry for inhalation toxicology [112,113,114] | [109,110,111,112,113,114] |

| |

| AI and material sustainability | Sustainable nanomaterials | Machine learning applied to environmental risk assessment (ERA) of nanomaterials [115]; triboelectric materials for sustainable implementations [116]; recycled carbon fibers [117]; sustainable bio-based polymers [118] | [115,116,117,118] |

|

| Nanomaterials in crop production | Materials having shape memory capability | [119,120,121] | Combination of AI controlling nanotechnology for production of sustainable foods and precision agriculture | |

| New polymer generation | Material prediction | ML applied to predict polymer properties and polymer life | [122,123,124,125,126,127] | Prediction of changes in physical properties over time by adopting material regeneration procedures |

| High-thermal-conductivity polymer | ML polymer generation protocol validated by combining predicted and experimental results | [128,129] | ML algorithms optimizing thermal properties by processing experimental data | |

| New polymer structures | Monomer synthesis by combining ML models with physical and chemical principles | [130] | AI orchestrating chemical composition of new polymers according to experimental results | |

| Bioelectronic polymers | Water-soluble conjugated polymers (WSCPs) | [131] | AI generating new classes of bioelectronic materials by reengineering biocompatibility | |

| High-performing electrically conductive materials | Hydrogels for wearable applications and other new electrically conductive materials | [132,133,134,135,136] | ML accelerating polymer discovery |

6. (KET IV) Life Science Technologies

- analysis of the state of the art, focusing the attention on important research topics correlated to health (food, medicine, pollution);

- identification of biocompatible polymers and nanomaterials that could be versatile for further health applications;

- identification of possible perspectives in AI data processing to optimize biocompatible materials and stimuli control in nanomedicine.

| Macro-Topic (Defined in Step 3) | Application (Step 2) | Description of Application Field (Step 4) | Ref. | Possible Implementation as Intelligent Materials (New Research Topic: Step 5) |

|---|---|---|---|---|

| Food packaging | Improvement of food packaging properties | Chitosan-based films extending food shelf life [137]; bio-based smart materials for food safety and sustainable solutions [138]; nanomaterials to increase the shelf life and reduce the spoilage of foods [139]; polymers avoiding food oxidation [140] | [137,138,139,140] |

|

| Biodegradable | New biodegradable active materials | [138,141,142,143,144] | AI tailoring antimicrobial/antioxidant activity of new materials | |

| Intelligent packaging | Real-time information about the quality and state of the food [145]; colorimetric detectors monitoring food quality [146,147]; data carriers, indicators, and sensors detecting food risk and food quality [148] | [145,146,147,148] | AI engines processing food environmental data with packaging material data and predicting food spoilage | |

| Nanomaterials and medicine | Disease diagnostics and treatment | Nanomaterials and pharmaceutical nanocarriers | [149,150,151,152,153,154,155] | ML applied for precision medicine implementations (nano-sensing and nano-treatment) |

| Antibacterial | Chitosan biopolymers [156,157,158] and NPs [159,160,161,162,163] having antibacterial properties | [156,157,158,159,160,161,162,163] | AI tailoring external stimuli to increase bacterial detection sensitivity | |

| Nanotoxicology | NP solutions in nanomedicine | [164,165,166] | AI predicting toxicological aspects to improve NP synthesis | |

| Drugs and delivery | Drug and delivery NPs | [167,168,169,170,171,172,173,174] | AI tailoring NPs’ drug release efficiency and defining the best external stimuli according to the implant systems | |

| Environmental nanomaterials | Environmental pollution | Nanomaterials (NPs and mesoporous NPs) controlling and removing air and water pollution | [175,176,177,178,179,180] | AI accelerating parameter process to remove micro- and nano-pollutants |

| Biological environment | Colorimetric and fluorescence sensing of reactive oxygen species (ROS) in biological environments signaling tissue homeostasis | [181] | AI combining nanomaterial properties with optical spectroscopic methods to detect ROS in various reactions and tuning interactions with cells |

7. (KET V) Micro–Nano Electronics and Photonics

- analysis of the state of the art, focusing the attention on recent application fields in electronics (flexible electronics, new integrated small circuital elements);

- identification of layouts and materials matching with high sensing and actuation properties;

- identification of possible perspectives on AI controlling input and output signals and improving sensing efficiency.

- using AI to achieve reconfigurable behavior (reshaping of the flexible substrate combining simultaneously different stimuli or after the application of a pressure force);

- improving the energy-harvesting properties (data processing to realize efficiently piezoelectric, thermoelectric, and triboelectric energy harvesters);

- tuning the circuit sensitivity (sensitivity of important circuit variables such as temperature and pressure according to the received external stimuli);

- accomplishing specific actuations in self-adaptive circuits (automated triggering of circuital elements based on the detected signals);

- controlling the storage computing process and designing electronic embedding solutions.

| Macro-Topic (Defined in Step 3) | Application (Step 2) | Description of Application Field (Step 4) | Ref. | Possible Implementation as Intelligent Materials (New Research Topic: Step 5) |

|---|---|---|---|---|

| Flexible electronics | Polymer composites for flexible artificial intelligence materials (AIMs) | Shape memory of biomedical pressure sensors | [182] | AI combining simultaneously different stimuli to achieve quick reconfigurable behavior |

| Human body flexible micro-sensors | Energy-harvesting and efficient flexible polymeric-based materials for wearable and implanted systems | [183,184,185,186,187] | AI-based algorithm to realize efficient piezoelectric, thermoelec- tric, and triboelectric energy harvester implanted systems | |

| Flexible 3D memristor | Flexible neuromorphic computing electronics | [188,189,190] | AI controlling neuromorphic storage computing process | |

| Flexible electronic skin | Multifunctional electronic skin (e-skin) integrating arrays of pressure and temperature sensors | [191,192,193,194,195,196,197] | AI tuning pressure temperature and pressure sensitivity (circuit sensitivity) according to the received stimuli | |

| Mechanical sensors | Machine learning data processing, enhancing mechanical sensing (pressure, strain, voice vibration, shear stress) in flexible electronics | [198] | Automation of the controlling and triggering circuits according to the detected signal (self-adaptive circuits) | |

| Flexible hybrid electronics in healthcare | Integration of conventional wafer-based electronics with flexible and stretchable solutions (embedded devices) | [199,200] | AI engineering new flexible electronic solutions starting with efficiency analysis of embedded devices | |

| New materials in electronics | Liquid smart materials | Liquid smart materials in soft robotics | [201,202,203,204] | AI enabling control of fluidity and of conductivity |

| Mechanical integrated electronic materials | Reconfigurable integrated circuits for gate switching in soft matter | [205] | AI implementing switching logics | |

| Smart materials in mechatronics/electronics | Innovative materials implementing piezoelectric micro-actuators, magnetorheological fluids and shape memory alloys, and energy-harvesting devices | [206,207,208,209,210,211] | AI-controlled systems influencing smart material detection (orientation, activation, NP movement, etc.) | |

| Carbon-based materials | Carbon nanotubes (CNT) and nanocomposite graphene-based smart materials for supercapacitors, electrodes, and electronic implementations | [212,213,214,215,216,217,218] | AI calibrating technological precision regarding sensitivity response | |

| Micro- and nanocircuits | Optical nanocircuits | Plasmonic Au NPs and lumped circuit modeling [219]; plasmonic superlenses transferring energy [220] | [219,220] | AI modeling and realizing nanocircuit layouts (scattering tailoring) |

| Optical circuits | Optical circuits [221,222,223,224] and optical quantum circuits [225,226,227] | [221,222,223,224,225,226,227] |

| |

| Electronic components | Materials for micro and smart electronic components | Micro-actuators, supercapacitors, nanocapacitors, nanoinductors, and transistors | [228,229,230,231,232] | AI controlling input and output signals of each electronic component [40] |

8. (KET VI) Security and Connectivity

- identification of possible matching between innovative nanomaterials and information technology;

- possible AI data processing approach, improving communication and security systems.

9. Discussion: A New Research Scenario and Framework for Intelligent Materials Matching AI with Electronic Facilities

- active intelligent materials (active behavior of materials able to reconfigure and repair themselves by acting on specific external stimuli, which makes available the directional movement or aggregation of molecules or atoms to repair damage);

- AI-based materials (AI designing materials able to react efficiently to external stimuli).

- Polymer design can be applied to existent polymers or to new ones. The polymers are classified as follows:

- natural polymers are generated directly from plants or animals present in nature (natural rubber, cellulose, pectin, chitosan, collagen, alginic acid, silk, etc.);

- synthetic polymers are synthesized and industrially produced (polypropylene, polyethylene, polyamide, poly(methyl methacrylate) (PMMA), polystyrene, polycarbonates (PC), silicon, poly(lactic-co-glycolic acid) (PLGA), nylon, polybutylene terephthalate (PBT), polyethylene terephthalate (PET), poly(vinylidene fluoride) (PVDF), polyvinyl chloride (PVC), PDMS, etc.);

- semi-synthetic polymers are derived from natural sources and chemical/physical treatment (cellulose derivates, cellulose nitrates, cellulose acetates, etc.).

10. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commission. Research and Innovation: Key Enabling Technologies Policy. Available online: https://research-and-innovation.ec.europa.eu/research-area/industrial-research-and-innovation/key-enabling-technologies_en (accessed on 18 July 2023).

- Massaro, A. Electronic in Advanced Research Industry: From Industry 4.0 to Industry 5.0 Advances; Wiley: Hoboken, NJ, USA; IEEE: New York, NY, USA, 2021; ISBN 9781119716877. [Google Scholar]

- Liu, K.; Tebyetekerwa, M.; Ji, D.; Ramakrishna, S. Intelligent Materials. Matter 2020, 3, 590–593. [Google Scholar] [CrossRef]

- Technology Readiness Levels (TRL). Available online: https://ec.europa.eu/research/participants/data/ref/h2020/other/wp/2018-2020/annexes/h2020-wp1820-annex-g-trl_en.pdf (accessed on 18 July 2023).

- La Puglia Delle Key Enabling Technologies. Available online: https://www.arti.puglia.it/wp-content/uploads/Report_La-Puglia-delle-KET.pdf (accessed on 20 July 2023).

- Yamamoto, B.E.; Trimble, A.Z.; Minei, B.; Ghasemi Nejhad, M.N. Development of Multifunctional Nanocomposites with 3-D Printing Additive Manufacturing and Low Graphene Loading. J. Thermoplast. Compos. Mater. 2019, 32, 383–408. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Dostatni, E.; Macko, M. AI-Optimized Technological Aspects of the Material Used in 3D Printing Processes for Selected Medical Applications. Materials 2020, 13, 5437. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Forgham, H.; Shen, A.; Wang, J.; Zhu, J.; Huang, X.; Tang, S.-Y.; Xu, C.; Davis, T.P.; Qiao, R. Nanomaterial Integrated 3D Printing for Biomedical Applications. J. Mater. Chem. B Mater. Biol. Med. 2022, 10, 7473–7490. [Google Scholar] [CrossRef] [PubMed]

- Mills, D.K. Future Medicine: The Impact of 3D Printing. J. Nanomater. Mol. Nanotechnol. 2015, 4, 1–3. [Google Scholar] [CrossRef]

- Słoma, M. 3D Printed Electronics with Nanomaterials. Nanoscale 2023, 15, 5623–5648. [Google Scholar] [CrossRef]

- Mubarak, S.; Divakaran, N.; Raghavan, A.; Ramachandran, S.K.; Wang, J. Advanced2DNanomaterials for Additive Manufacturing. In Nanotechnology-Based Additive Manufacturing; Wiley: Hoboken, NJ, USA, 2023; pp. 335–368. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.; Kim, J.-H.; Yeo, W.-H. Advanced Nanomaterials, Printing Processes, and Applications for Flexible Hybrid Electronics. Materials 2020, 13, 3587. [Google Scholar] [CrossRef]

- Shi, G.; Zhu, Y.; Batmunkh, M.; Ingram, M.; Huang, Y.; Chen, Z.; Wei, Y.; Zhong, L.; Peng, X.; Zhong, Y.L. Cytomembrane-Inspired MXene Ink with Amphiphilic Surfactant for 3D Printed Microsupercapacitors. ACS Nano 2022, 16, 14723–14736. [Google Scholar] [CrossRef]

- Zhong, J.; Zhou, G.-X.; He, P.-G.; Yang, Z.-H.; Jia, D.-C. 3D Printing Strong and Conductive Geo-Polymer Nanocomposite Structures Modified by Graphene Oxide. Carbon N. Y. 2017, 117, 421–426. [Google Scholar] [CrossRef]

- Gaihre, B.; Potes, M.A.; Serdiuk, V.; Tilton, M.; Liu, X.; Lu, L. Two-Dimensional Nanomaterials-Added Dynamism in 3D Printing and Bioprinting of Biomedical Platforms: Unique Opportunities and Challenges. Biomaterials 2022, 284, 121507. [Google Scholar] [CrossRef]

- Ibanga, I.J.; Bamidele, O.; Romero, C.B.; Mastul, A.-R.H.; Solomon, Y.; Jayme, C.B. Revolutionizing Healthcare with 3D/4D Printing and Smart Materials. Eng. Sci. Lett. 2023, 2, 13–21. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Milazzo, M.; Libonati, F. The Synergistic Role of Additive Manufacturing and Artificial Intelligence for the Design of New Advanced Intelligent Systems. Adv. Intell. Syst. 2022, 4, 2100278. [Google Scholar] [CrossRef]

- Bobbert, F.S.L.; Janbaz, S.; Zadpoor, A.A. Towards Deployable Meta-Implants. J. Mater. Chem. B Mater. Biol. Med. 2018, 6, 3449–3455. [Google Scholar] [CrossRef] [PubMed]

- Pugliese, R.; Regondi, S. Artificial Intelligence-Empowered 3D and 4D Printing Technologies toward Smarter Biomedical Materials and Approaches. Polymers 2022, 14, 2794. [Google Scholar] [CrossRef]

- Hossain, M.I.; Chowdhury, M.A.; Zahid, M.S.; Sakib-Uz-Zaman, C.; Rahaman, M.L.; Kowser, M.A. Development and Analysis of Nanoparticle Infused Plastic Products Manufactured by Machine Learning Guided 3D Printer. Polym. Test. 2022, 106, 107429. [Google Scholar] [CrossRef]

- Challagulla, N.V.; Rohatgi, V.; Sharma, D.; Kumar, R. Recent Developments of Nanomaterial Applications in Additive Manufacturing: A Brief Review. Curr. Opin. Chem. Eng. 2020, 28, 75–82. [Google Scholar] [CrossRef]

- Zheng, Y.; Wu, Z. (Eds.) Intelligent Nanotechnology: Merging Nanoscience and Artificial Intelligence; Elsevier—Health Sciences Division: Philadelphia, PA, USA, 2022. [Google Scholar]

- Malik, S.; Muhammad, K.; Waheed, Y. Nanotechnology: A Revolution in Modern Industry. Molecules 2023, 28, 661. [Google Scholar] [CrossRef]

- Subhan, M.A.; Choudhury, K.P.; Neogi, N. Advances with Molecular Nanomaterials in Industrial Manufacturing Applications. Nanomanufacturing 2021, 1, 75–97. [Google Scholar] [CrossRef]

- Konstantopoulos, G.; Koumoulos, E.P.; Charitidis, C.A. Digital Innovation Enabled Nanomaterial Manufacturing; Machine Learning Strategies and Green Perspectives. Nanomaterials 2022, 12, 2646. [Google Scholar] [CrossRef]

- Laws, J.; Parachuru, R. New and Emerging Smart Materials and Their Applications: A Review. J. Mater. Sci. Eng. 2021, 10, 1–6. [Google Scholar]

- Oliveira, J.; Correia, V.; Castro, H.; Martins, P.; Lanceros-Mendez, S. Polymer-Based Smart Materials by Printing Technologies: Improving Application and Integration. Addit. Manuf. 2018, 21, 269–283. [Google Scholar] [CrossRef]

- Bharatish, A.; Rajkumar, G.R.; Gurav, P.; Satheesh Babu, G.; Narasimha Murthy, H.N.; Roy, M. Optimization of Laser Texture Geometry and Resulting Functionality of Nickel Aluminium Bronze for Landing Gear Applications. Int. J. Lightweight Mater. Manuf. 2021, 4, 346–357. [Google Scholar] [CrossRef]

- Ezhilmaran, V.; Damodaram, R. Laser Surface Texturing on Nickel-Aluminium-Bronze Alloy for Improving the Hydrophobicity. Lasers Manuf. Mater. Process. 2021, 8, 15–27. [Google Scholar] [CrossRef]

- Spano, F.; Massaro, A.; Blasi, L.; Malerba, M.; Cingolani, R.; Athanassiou, A. In Situ Formation and Size Control of Gold Nanoparticles into Chitosan for Nanocomposite Surfaces with Tailored Wettability. Langmuir 2012, 28, 3911–3917. [Google Scholar] [CrossRef]

- Spano, F.; Castellano, A.; Massaro, A.; Fragouli, D.; Cingolani, R.; Athanassiou, A. Wettability Control by Laser Texturing Process Generating Localized Gold Nanoparticles on Polymeric Thin Films. J. Nanosci. Nanotechnol. 2012, 12, 4820–4824. [Google Scholar] [CrossRef]

- Massaro, A. Rapid Prototyping. In Electronics in Advanced Research Industries; Wiley: Hoboken, NJ, USA, 2021; pp. 381–444. [Google Scholar] [CrossRef]

- Massaro, A.; Spano, F.; Missori, M.; Malvindi, M.A.; Cazzato, P.; Cingolani, R.; Athanassiou, A. Flexible Nanocomposites with All-Optical Tactile Sensing Capability. RSC Adv. 2013, 4, 2820–2825. [Google Scholar] [CrossRef]

- Ovsianikov, A.; Viertl, J.; Chichkov, B.; Oubaha, M.; MacCraith, B.; Sakellari, I.; Giakoumaki, A.; Gray, D.; Vamvakaki, M.; Farsari, M.; et al. Ultra-Low Shrinkage Hybrid Photosensitive Material for Two-Photon Polymerization Microfabrication. ACS Nano 2008, 2, 2257–2262. [Google Scholar] [CrossRef]

- Harinarayana, V.; Shin, Y.C. Two-Photon Lithography for Three-Dimensional Fabrication in Micro/Nanoscale Regime: A Comprehensive Review. Opt. Laser Technol. 2021, 142, 107180. [Google Scholar] [CrossRef]

- Tulej, M.; Ligterink, N.F.W.; de Koning, C.; Grimaudo, V.; Lukmanov, R.; Keresztes Schmidt, P.; Riedo, A.; Wurz, P. Current Progress in Femtosecond Laser Ablation/Ionisation Time-of-Flight Mass Spectrometry. Appl. Sci. 2021, 11, 2562. [Google Scholar] [CrossRef]

- Cicala, G.; Massaro, A.; Velardi, L.; Senesi, G.S.; Valentini, A. Self-Assembled Pillar-like Structures in Nanodiamond Layers by Pulsed Spray Technique. ACS Appl. Mater. Interfaces 2014, 6, 21101–21109. [Google Scholar] [CrossRef] [PubMed]

- Cicala, G.; Massaro, A.; Velardi, L.; Senesi, G.S.; Perna, G.; Marzulli, D.; Melisi, D.; De Pascali, G.; Valentini, A.; Capozzi, V. Enhancement of Surface Electrical Current on Silicon via Nanodiamond Particles Deposited by Pulsed Spray Technique: Enhancement of Surface Electrical Current on Silicon. Phys. Status Solidi (A) 2015, 212, 2862–2868. [Google Scholar] [CrossRef]

- Massaro, A. Advanced Robotics. In Electronics in Advanced Research Industries; Wiley: Hoboken, NJ, USA, 2021; pp. 203–252. [Google Scholar] [CrossRef]

- Massaro, A.; Spano, F.; Athanassiou, A.; Cingolani, R. FEM Modeling of Conductivity and Electrical Coupling in Polymeric Nanocomposite Material. In 2011 Numerical Simulation of Optoelectronic Devices; IEEE: New York, NY, USA, 2011; pp. 85–86. [Google Scholar] [CrossRef]

- Cicala, G.; Massaro, A.; Velardi, L.; Senesi, G.S. Morphological and Electrical Characterization of Pillar-like Structures in Nanodiamond Layers. IEEE Trans. Nanotechnol. 2016, 15, 890–895. [Google Scholar] [CrossRef]

- Valentini, A.; Melisi, D.; De Pascali, G.; Cicala, G.; Velardi, L.; Massaro, A. High-Efficiency Nanodiamond-Based Ultraviolet Photocathodes. WO Patent 2017051318:A9, 8 June 2017. [Google Scholar]

- Stojanov, S.; Berlec, A. Electrospun Nanofibers as Carriers of Microorganisms, Stem Cells, Proteins, and Nucleic Acids in Therapeutic and Other Applications. Front. Bioeng. Biotechnol. 2020, 8, 130. [Google Scholar] [CrossRef]

- Ramakrishna, S.; Fujihara, K.; Teo, W.-E.; Yong, T.; Ma, Z.; Ramaseshan, R. Electrospun Nanofibers: Solving Global Issues. Mater. Today 2006, 9, 40–50. [Google Scholar] [CrossRef]

- Radacsi, N.; Campos, F.D.; Chisholm, C.R.I.; Giapis, K.P. Spontaneous Formation of Nanoparticles on Electrospun Nanofibres. Nat. Commun. 2018, 9, 4740. [Google Scholar] [CrossRef]

- Vesel, A. Deposition of Chitosan on Plasma-Treated Polymers—A Review. Polymers 2023, 15, 1109. [Google Scholar] [CrossRef]

- Levchenko, I.; Xu, S.; Baranov, O.; Bazaka, O.; Ivanova, E.P.; Bazaka, K. Plasma and Polymers: Recent Progress and Trends. Molecules 2021, 26, 4091. [Google Scholar] [CrossRef]

- Nikolaev, A.; Ramazanov, K.; Nazarov, A.; Mukhamadeev, V.; Zagibalova, E.; Astafurova, E. TEM Study of a Layered Composite Structure Produced by Ion-Plasma Treatment of Aluminum Coating on the Ti-6Al-4V Alloy. J. Compos. Sci. 2023, 7, 271. [Google Scholar] [CrossRef]

- Eichhorn, A.L.; Hoffer, M.; Bitsch, K.; Dietz, C. Adsorbate Formation/Removal and Plasma-induced Evolution of Defects in Graphitic Materials. Adv. Mater. Interfaces 2023, 10, 2300256. [Google Scholar] [CrossRef]

- Meng, Q.; Guo, G.; Qin, X.; Zhang, Y.; Wang, X.; Zhang, L. Smart Multifunctional Elastomeric Nanocomposite Materials Containing Graphene Nanoplatelets. Smart Mater. Manuf. 2023, 1, 100006. [Google Scholar] [CrossRef]

- Ramos-Sebastian, A.; Gwak, S.-J.; Kim, S.H. Multimodal Locomotion and Active Targeted Thermal Control of Magnetic Agents for Biomedical Applications. Adv. Sci. 2022, 9, e2103863. [Google Scholar] [CrossRef]

- Oh, G.-H.; Hwang, H.-J.; Kim, H.-S. Effect of Copper Oxide Shell Thickness on Flash Light Sintering of Copper Nanoparticle Ink. RSC Adv. 2017, 7, 17724–17731. [Google Scholar] [CrossRef]

- Xu, F.; Wagner, B.; Ghildiyal, P.; Mangolini, L.; Zachariah, M.R. Low Temperature Oxidation of Amorphous Silicon Nanoparticles. Phys. Rev. Mater. 2023, 7, 045403. [Google Scholar] [CrossRef]

- Krishtal, M.M.; Katsman, A.V.; Polunin, A.V. Effects of Silica Nanoparticles Addition on Formation of Oxide Layers on Al Si Alloy by Plasma Electrolytic Oxidation: The Origin of Stishovite under Ambient Conditions. Surf. Coat. Technol. 2022, 441, 128556. [Google Scholar] [CrossRef]

- Liu, S.; Han, M.-Y. Silica-Coated Metal Nanoparticles. Chem. Asian J. 2010, 5, 36–45. [Google Scholar] [CrossRef] [PubMed]

- Cruz-Rodríguez, J.C.; Camacho-López, M.Á.; Torres-Garcia, E.; Aranda-Lara, L.; Morales-Ávila, E.; Díaz-Sánchez, L.E.; Jiménez-Mancilla, N.; Isaac-Olivé, K. Characterization of the Absorption Properties of 5 Nm Spherical Gold Nanoparticles Functionalized with Dodecanothiol and without Functionalization with Potential Therapeutic Applications. Phys. Scr. 2023, 98, 055007. [Google Scholar] [CrossRef]

- Shi, Y.; Hu, M.; Xing, Y.; Li, Y. Temperature-Dependent Thermal and Mechanical Properties of Flexible Functional PDMS/Paraffin Composites. Mater. Des. 2020, 185, 108219. [Google Scholar] [CrossRef]

- Wang, X.; Shi, Z.; Meng, F.; Zhao, Y.; Wu, Z.; Lei, Y.; Xue, L. Interfacial Interaction-Induced Temperature-Dependent Mechanical Property of Graphene-PDMS Nanocomposite. J. Mater. Sci. 2020, 55, 1553–1561. [Google Scholar] [CrossRef]

- Massaro, A.; Troia, M.; Spano, F.; Carbone, G. Friction in Totally Optical Robotic Finger Oriented on Shear Force Measurement. IEEE Sens. J. 2013, 13, 548–555. [Google Scholar] [CrossRef]

- Konku-Asase, Y.; Yaya, A.; Kan-Dapaah, K. Curing Temperature Effects on the Tensile Properties and Hardness of Γ−Fe2O3 Reinforced PDMS Nanocomposites. Adv. Mater. Sci. Eng. 2020, 2020, 6562373. [Google Scholar] [CrossRef]

- Cataldi, U.; Caputo, R.; Kurylyak, Y.; Klein, G.; Chekini, M.; Umeton, C.; Bürgi, T. Growing Gold Nanoparticles on a Flexible Substrate to Enable Simple Mechanical Control of Their Plasmonic Coupling. J. Mater. Chem. C Mater. Opt. Electron. Devices 2014, 2, 7927–7933. [Google Scholar] [CrossRef]

- Massaro, A.; Spano, F.; Cazzato, P.; La Tegola, C.; Cingolani, R.; Athanassiou, A. Robot Tactile Sensing: Gold Nanocomposites as Highly Sensitive Real-Time Optical Pressure Sensors. IEEE Robot. Autom. Mag. 2013, 20, 82–90. [Google Scholar] [CrossRef]

- Li, C.; Chen, Y.; Wang, L.; Wang, Z.; Lin, Y.; Xiong, K.; Wang, B.; Hao, C. Electrorheological Response Behavior of PANI@MoS2 Core–Shell Nanocomposites. Adv. Eng. Mater. 2023, 25, 2300029. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, G.; Medina-Sánchez, M.; Guix, M.; Makarov, D.; Jin, D. Responsive Magnetic Nanocomposites for Intelligent Shape-Morphing Microrobots. ACS Nano 2023, 17, 8899–8917. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Chen, H.; Qin, H.; Cong, H.-P. Nanocomposite Hydrogel Actuators with Ordered Structures: From Nanoscale Control to Macroscale Deformations. Small Methods 2023, e2300414. [Google Scholar] [CrossRef] [PubMed]

- Du, P.; Wang, J.; Liu, G.; Zhao, H.; Wang, L. Facile Synthesis of Intelligent Nanocomposites as Encapsulation for Materials Protection. Mater. Chem. Front. 2019, 3, 321–330. [Google Scholar] [CrossRef]

- Pati, S.; Singh, B.P.; Dhakate, S.R. Self-Healing Polymer Composites Based on Graphene and Carbon Nanotubes. In Smart Polymer Nanocomposites; Springer International Publishing: Cham, Switzerland, 2017; pp. 119–152. [Google Scholar]

- Subramanian, V.; Varade, D. Self-Healed Materials from Thermoplastic Polymer Composites. In Smart Polymer Nanocomposites; Springer International Publishing: Cham, Switzerland, 2017; pp. 153–180. [Google Scholar]

- Joseph, J.P.; Singh, A.; Pal, A. Molecular Design Approaches to Self-Healing Materials from Polymer and Its Nanocomposites. In Smart Polymer Nanocomposites; Springer International Publishing: Cham, Switzerland, 2017; pp. 181–218. [Google Scholar]

- Tripathi, R.; Sharma, P.; Saini, A.; Verma, G. Self-Healed Materials from Elastomeric Composites: Concepts, Strategies and Developments. In Smart Polymer Nanocomposites; Springer International Publishing: Cham, Switzerland, 2017; pp. 219–242. [Google Scholar]

- Zhang, B.; Zhang, P.; Zhang, H.; Yan, C.; Zheng, Z.; Wu, B.; Yu, Y. A Transparent, Highly Stretchable, Autonomous Self-Healing Poly(Dimethyl Siloxane) Elastomer. Macromol. Rapid Commun. 2017, 38, 1700110. [Google Scholar] [CrossRef]

- Qi, M.; Yang, R.; Wang, Z.; Liu, Y.; Zhang, Q.; He, B.; Li, K.; Yang, Q.; Wei, L.; Pan, C.; et al. Bioinspired Self-healing Soft Electronics. Adv. Funct. Mater. 2023, 33, 2214479. [Google Scholar] [CrossRef]

- An, Z.-W.; Xue, R.; Ye, K.; Zhao, H.; Liu, Y.; Li, P.; Chen, Z.-M.; Huang, C.-X.; Hu, G.-H. Recent Advances in Self-Healing Polyurethane Based on Dynamic Covalent Bonds Combined with Other Self-Healing Methods. Nanoscale 2023, 15, 6505–6520. [Google Scholar] [CrossRef]

- Yimyai, T.; Crespy, D.; Rohwerder, M. Corrosion-Responsive Self-Healing Coatings. Adv. Mater. 2023, e2300101. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Ohm, Y.; Liao, J.; Luo, Y.; Cheng, H.-Y.; Won, P.; Roberts, P.; Carneiro, M.R.; Islam, M.F.; Ahn, J.H.; et al. A Self-Healing Electrically Conductive Organogel Composite. Nat. Electron. 2023, 6, 206–215. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Z.; Wang, H.; Jin, B.; Meng, C.; Chen, X.; Li, R.; Wang, H.; Xin, M.; Zhao, Z.; et al. Self-Healing, Reconfigurable, Thermal-Switching, Transformative Electronics for Health Monitoring. Adv. Mater. 2023, 35, e2207742. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Xu, Y.; Han, S.; Zhu, J.; Chen, A.; Zhang, J.; Chen, Y.; Yang, X.; Huang, J.; Guan, L. A Liquid-Free Conducting Ionoelastomer for 3D Printable Multifunctional Self-Healing Electronic Skin with Tactile Sensing Capabilities. Mater. Horiz. 2023. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, S.; Zhou, Y.; Dong, F.; Liu, H.; Xu, X. A Self-Healing and Antibacterial Electronic Skin Based on a Natural Small Molecule. J. Mater. Chem. C Mater. Opt. Electron. Devices 2023, 11, 1879–1890. [Google Scholar] [CrossRef]

- Zhu, S.; Liu, Z.; Li, W.; Zhang, H.; Dai, G.; Zhou, X. Research Progress of Self-healing Polymer Materials for Flexible Electronic Devices. J. Polym. Sci. 2023, 61, 1554–1571. [Google Scholar] [CrossRef]

- Yeasmin, R.; Han, S.-I.; Duy, L.T.; Ahn, B.; Seo, H. A Skin-like Self-Healing and Stretchable Substrate for Wearable Electronics. Chem. Eng. J. 2023, 455, 140543. [Google Scholar] [CrossRef]

- Khan, M.I.; Zagho, M.M.; Shakoor, R.A. A Brief Overview of Shape Memory Effect in Thermoplastic Polymers. In Smart Polymer Nanocomposites; Springer International Publishing: Cham, Switzerland, 2017; pp. 281–301. [Google Scholar]

- Ponnamma, D.; El-Gawady, Y.M.H.; Rajan, M.; Goutham, S.; Venkateswara Rao, K.; Al-Maadeed, M.A.-A. Shape Memory Behavior of Conducting Polymer Nanocomposites. In Smart Polymer Nanocomposites; Springer International Publishing: Cham, Switzerland, 2017; pp. 321–343. [Google Scholar]

- Rokaya, D.; Skallevold, H.E.; Srimaneepong, V.; Marya, A.; Shah, P.K.; Khurshid, Z.; Zafar, M.S.; Sapkota, J. Shape Memory Polymeric Materials for Biomedical Applications: An Update. J. Compos. Sci. 2023, 7, 24. [Google Scholar] [CrossRef]

- Kim, D.; Kim, M.; Reidt, S.; Han, H.; Baghizadeh, A.; Zeng, P.; Choi, H.; Puigmartí-Luis, J.; Trassin, M.; Nelson, B.J.; et al. Shape-Memory Effect in Twisted Ferroic Nanocomposites. Nat. Commun. 2023, 14, 750. [Google Scholar] [CrossRef]

- Idumah, C.I. Multifunctional Properties Optimization and Stimuli-responsivity of Shape Memory Polymeric Nanoarchitectures and Applications. Polym. Eng. Sci. 2023, 63, 1857–1873. [Google Scholar] [CrossRef]

- Alipour, S.; Pourjavadi, A.; Hosseini, S.H. Magnetite Embedded κ-Carrageenan-Based Double Network Nanocomposite Hydrogel with Two-Way Shape Memory Properties for Flexible Electronics and Magnetic Actuators. Carbohydr. Polym. 2023, 310, 120610. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; D’Ambrosio, N.; Liu, P.; Pasini, D.; Ma, L. Shape Memory Mechanical Metamaterials. Mater. Today 2023, 66, 36–49. [Google Scholar] [CrossRef]

- Govarthanan, M.; Manikandan, S.; Subbaiya, R.; Krishnan, R.Y.; Srinivasan, S.; Karmegam, N.; Kim, W. Emerging Trends and Nanotechnology Advances for Sustainable Biogas Production from Lignocellulosic Waste Biomass: A Critical Review. Fuel 2022, 312, 122928. [Google Scholar] [CrossRef]

- Pei, Y.; Zhang, Y.; Ma, J.; Fan, M.; Zhang, S.; Wang, J. Ionic Liquids for Advanced Materials. Mater. Today Nano 2022, 17, 100159. [Google Scholar] [CrossRef]

- Aftab, S.; Iqbal, M.Z.; Haider, Z.; Iqbal, M.W.; Nazir, G.; Shehzad, M.A. Bulk Photovoltaic Effect in 2D Materials for Solar-power Harvesting. Adv. Opt. Mater. 2022, 10, 2201288. [Google Scholar] [CrossRef]

- İnada, A.A.; Arman, S.; Safaei, B. A Novel Review on the Efficiency of Nanomaterials for Solar Energy Storage Systems. J. Energy Storage 2022, 55, 105661. [Google Scholar] [CrossRef]

- Sun, L.; Yang, L.; Zhao, N.; Song, J.; Li, X.; Wu, X. A Review of Multifunctional Applications of Nanofluids in Solar Energy. Powder Technol. 2022, 411, 117932. [Google Scholar] [CrossRef]

- Xiao, K.; Jiang, L.; Antonietti, M. Ion Transport in Nanofluidic Devices for Energy Harvesting. Joule 2019, 3, 2364–2380. [Google Scholar] [CrossRef]

- Soltani, M.; Moradi Kashkooli, F.; Alian Fini, M.; Gharapetian, D.; Nathwani, J.; Dusseault, M.B. A Review of Nanotechnology Fluid Applications in Geothermal Energy Systems. Renew. Sustain. Energy Rev. 2022, 167, 112729. [Google Scholar] [CrossRef]

- Rodrigues-Marinho, T.; Castro, N.; Correia, V.; Costa, P.; Lanceros-Méndez, S. Triboelectric Energy Harvesting Response of Different Polymer-Based Materials. Materials 2020, 13, 4980. [Google Scholar] [CrossRef]

- Mustafa, M.N.; Mohd Abdah, M.A.A.; Numan, A.; Sulaiman, Y.; Walvekar, R.; Khalid, M. Development of High-Performance MXene/Nickel Cobalt Phosphate Nanocomposite for Electrochromic Energy Storage System Using Response Surface Methodology. J. Energy Storage 2023, 68, 107880. [Google Scholar] [CrossRef]

- Athanassiadis, A.G.; Ma, Z.; Moreno-Gomez, N.; Melde, K.; Choi, E.; Goyal, R.; Fischer, P. Ultrasound-Responsive Systems as Components for Smart Materials. Chem. Rev. 2022, 122, 5165–5208. [Google Scholar] [CrossRef] [PubMed]

- Mackay, B.S.; Marshall, K.; Grant-Jacob, J.A.; Kanczler, J.; Eason, R.W.; Oreffo, R.O.C.; Mills, B. The Future of Bone Regeneration: Integrating AI into Tissue Engineering. Biomed. Phys. Eng. Express 2021, 7, 052002. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; McKee, J.A.; Fontenot, J.J.; Jung, J.P. Engineering Tissue Fabrication with Machine Intelligence: Generating a Blueprint for Regeneration. Front. Bioeng. Biotechnol. 2019, 7, 443. [Google Scholar] [CrossRef] [PubMed]

- Bermejillo Barrera, M.D.; Franco-Martínez, F.; Díaz Lantada, A. Artificial Intelligence Aided Design of Tissue Engineering Scaffolds Employing Virtual Tomography and 3D Convolutional Neural Networks. Materials 2021, 14, 5278. [Google Scholar] [CrossRef]

- Liu, S.; Yu, J.-M.; Gan, Y.-C.; Qiu, X.-Z.; Gao, Z.-C.; Wang, H.; Chen, S.-X.; Xiong, Y.; Liu, G.-H.; Lin, S.-E.; et al. Biomimetic Natural Biomaterials for Tissue Engineering and Regenerative Medicine: New Biosynthesis Methods, Recent Advances, and Emerging Applications. Mil. Med. Res. 2023, 10, 16. [Google Scholar] [CrossRef]

- Rafieyan, S.; Vasheghani-Farahani, E.; Baheiraei, N.; Keshavarz, H. MLATE: Machine Learning for Predicting Cell Behavior on Cardiac Tissue Engineering Scaffolds. Comput. Biol. Med. 2023, 158, 106804. [Google Scholar] [CrossRef]

- Guo, J.L.; Januszyk, M.; Longaker, M.T. Machine Learning in Tissue Engineering. Tissue Eng. Part A 2023, 29, 2–19. [Google Scholar] [CrossRef]

- Abolhasani, M.; Kumacheva, E. The Rise of Self-Driving Labs in Chemical and Materials Sciences. Nat. Synth. 2023, 2, 483–492. [Google Scholar] [CrossRef]

- Sacha, G.M.; Varona, P. Artificial Intelligence in Nanotechnology. Nanotechnology 2013, 24, 452002. [Google Scholar] [CrossRef]

- Wang, Y.; Sha, W.; Xiao, M.; Qiu, C.-W.; Gao, L. Deep-Learning-Enabled Intelligent Design of Thermal Metamaterials. Adv. Mater. 2023, 35, e2302387. [Google Scholar] [CrossRef] [PubMed]

- Ji, Q.; Chen, X.; Liang, J.; Fang, G.; Laude, V.; Arepolage, T.; Euphrasie, S.; Iglesias Martínez, J.A.; Guenneau, S.; Kadic, M. Deep Learning Based Design of Thermal Metadevices. Int. J. Heat Mass Transf. 2022, 196, 123149. [Google Scholar] [CrossRef]

- Xu, X.; Aggarwal, D.; Shankar, K. Instantaneous Property Prediction and Inverse Design of Plasmonic Nanostructures Using Machine Learning: Current Applications and Future Directions. Nanomaterials 2022, 12, 633. [Google Scholar] [CrossRef] [PubMed]

- Ban, Z.; Yuan, P.; Yu, F.; Peng, T.; Zhou, Q.; Hu, X. Machine Learning Predicts the Functional Composition of the Protein Corona and the Cellular Recognition of Nanoparticles. Proc. Natl. Acad. Sci. USA 2020, 117, 10492–10499. [Google Scholar] [CrossRef]

- Mirzaei, M.; Furxhi, I.; Murphy, F.; Mullins, M. A Machine Learning Tool to Predict the Antibacterial Capacity of Nanoparticles. Nanomaterials 2021, 11, 1774. [Google Scholar] [CrossRef]

- Singh, A.V.; Ansari, M.H.D.; Rosenkranz, D.; Maharjan, R.S.; Kriegel, F.L.; Gandhi, K.; Kanase, A.; Singh, R.; Laux, P.; Luch, A. Artificial Intelligence and Machine Learning in Computational Nanotoxicology: Unlocking and Empowering Nanomedicine. Adv. Healthc. Mater. 2020, 9, e1901862. [Google Scholar] [CrossRef]

- Singh, A.V.; Varma, M.; Laux, P.; Choudhary, S.; Datusalia, A.K.; Gupta, N.; Luch, A.; Gandhi, A.; Kulkarni, P.; Nath, B. Artificial Intelligence and Machine Learning Disciplines with the Potential to Improve the Nanotoxicology and Nanomedicine Fields: A Comprehensive Review. Arch. Toxicol. 2023, 97, 963–979. [Google Scholar] [CrossRef]

- Mu, L.; Yu, F.; Jia, Y.; Sun, S.; Li, X.; Zhang, X.; Hu, X. Machine Learning in Prediction of Nanotoxicology. In Machine Learning and Deep Learning in Computational Toxicology; Springer International Publishing: Cham, Switzerland, 2023; pp. 497–517. [Google Scholar]

- Scott-Fordsmand, J.J.; Amorim, M.J.B. Using Machine Learning to Make Nanomaterials Sustainable. Sci. Total Environ. 2023, 859 Pt 2, 160303. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, J.; Liu, Y.; Yuan, J.; Liu, T.; Du, G.; Zhu, S.; Nie, S. Sustainable Triboelectric Materials for Smart Active Sensing Systems. Adv. Funct. Mater. 2022, 32, 2208277. [Google Scholar] [CrossRef]

- Faure, A.; Mantaux, O.; Gillet, A.; Cazaurang, G. New Intelligent Semi-Products Based on Recycled Carbon Fibres. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1226, 012102. [Google Scholar] [CrossRef]

- Okolie, O.; Kumar, A.; Edwards, C.; Lawton, L.A.; Oke, A.; McDonald, S.; Thakur, V.K.; Njuguna, J. Bio-Based Sustainable Polymers and Materials: From Processing to Biodegradation. J. Compos. Sci. 2023, 7, 213. [Google Scholar] [CrossRef]

- Gigante, V.; Panariello, L.; Coltelli, M.-B.; Danti, S.; Obisesan, K.A.; Hadrich, A.; Staebler, A.; Chierici, S.; Canesi, I.; Lazzeri, A.; et al. Liquid and Solid Functional Bio-Based Coatings. Polymers 2021, 13, 3640. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.; Ma, S.; Lv, S.; Wang, Y.; Lü, S.; Liu, M. Nanomaterials for Targeted Delivery of Agrochemicals by an All-in-One Combination Strategy and Deep Learning. ACS Appl. Mater. Interfaces 2021, 13, 43374–43386. [Google Scholar] [CrossRef] [PubMed]

- Vasoya, N.H. Revolutionizing Nano Materials Processing through IoT-AI Integration: Opportunities and Challenges. J. Mater. Sci. Res. Rev. 2023, 6, 294–328. [Google Scholar]

- Chen, G.; Shen, Z.; Iyer, A.; Ghumman, U.F.; Tang, S.; Bi, J.; Chen, W.; Li, Y. Machine-Learning-Assisted De Novo Design of Organic Molecules and Polymers: Opportunities and Challenges. Polymers 2020, 12, 163. [Google Scholar] [CrossRef] [PubMed]

- Xie, S. Perspectives on Development of Biomedical Polymer Materials in Artificial Intelligence Age. J. Biomater. Appl. 2023, 37, 1355–1375. [Google Scholar] [CrossRef] [PubMed]

- Martin, T.B.; Audus, D.J. Emerging Trends in Machine Learning: A Polymer Perspective. ACS Polym. Au 2023, 3, 239–258. [Google Scholar] [CrossRef]

- Esteki, B.; Masoomi, M.; Moosazadeh, M.; Yoo, C. Data-Driven Prediction of Janus/Core-Shell Morphology in Polymer Particles: A Machine-Learning Approach. Langmuir 2023, 39, 4943–4958. [Google Scholar] [CrossRef]

- Park, N.; Manica, M.; Born, J.; Hedrick, J.; Erdmann, T.; Zubarev, D.; Mill, N.; Arrechea, P. An Extensible Platform for Enabling Artificial Intelligence Guided Design of Catalysts and Materials. ChemRxiv 2023. [Google Scholar] [CrossRef]

- Allen, A.E.A.; Tkatchenko, A. Machine Learning of Material Properties: Predictive and Interpretable Multilinear Models. Sci. Adv. 2022, 8, eabm7185. [Google Scholar] [CrossRef]

- Wu, S.; Kondo, Y.; Kakimoto, M.-A.; Yang, B.; Yamada, H.; Kuwajima, I.; Lambard, G.; Hongo, K.; Xu, Y.; Shiomi, J.; et al. Machine-Learning-Assisted Discovery of Polymers with High Thermal Conductivity Using a Molecular Design Algorithm. npj Comput. Mater. 2019, 5, 66. [Google Scholar] [CrossRef]

- Liu, B.; Vu-Bac, N.; Zhuang, X.; Fu, X.; Rabczuk, T. Stochastic Full-Range Multiscale Modeling of Thermal Conductivity of Polymeric Carbon Nanotubes Composites: A Machine Learning Approach. Compos. Struct. 2022, 289, 115393. [Google Scholar] [CrossRef]

- Yan, C.; Li, G. The Rise of Machine Learning in Polymer Discovery. Adv. Intell. Syst. 2023, 5, 2200243. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, H.; Zhang, M.; Yu, W.; Zhu, C.; Wang, P.; Huang, Y.; Lv, F.; Bai, H.; Wang, S. Water-Soluble Conjugated Polymers for Bioelectronic Systems. Mater. Horiz. 2023, 10, 1210–1233. [Google Scholar] [CrossRef]

- Omidian, H.; Chowdhury, S.D. High-Performing Conductive Hydrogels for Wearable Applications. Gels 2023, 9, 549. [Google Scholar] [CrossRef]

- Ziai, Y.; Zargarian, S.S.; Rinoldi, C.; Nakielski, P.; Sola, A.; Lanzi, M.; Truong, Y.B.; Pierini, F. Conducting Polymer-Based Nanostructured Materials for Brain-Machine Interfaces. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2023, e1895. [Google Scholar] [CrossRef]

- So, C.; Kim, Y.-S.; Park, J.H.; Kim, G.-Y.; Cha, D.; Ko, J.H.; Kang, B. Data-driven Design of Electrically Conductive Nanocomposite Materials: A Case Study of Acrylonitrile–Butadiene–Styrene/Carbon Nanotube Binary Composites. Adv. Intell. Syst. 2023, 5, 2200399. [Google Scholar] [CrossRef]

- Demirbay, B.; Bayram Kara, D.; Uğur, Ş. Multivariate Regression (MVR) and Different Artificial Neural Network (ANN) Models Developed for Optical Transparency of Conductive Polymer Nanocomposite Films. Expert Syst. Appl. 2022, 207, 117937. [Google Scholar] [CrossRef]

- Vivanco-Benavides, L.E.; Martínez-González, C.L.; Mercado-Zúñiga, C.; Torres-Torres, C. Machine Learning and Materials Informatics Approaches in the Analysis of Physical Properties of Carbon Nanotubes: A Review. Comput. Mater. Sci. 2022, 201, 110939. [Google Scholar] [CrossRef]

- Flórez, M.; Guerra-Rodríguez, E.; Cazón, P.; Vázquez, M. Chitosan for Food Packaging: Recent Advances in Active and Intelligent Films. Food Hydrocoll. 2022, 124, 107328. [Google Scholar] [CrossRef]

- Halonen, N.; Pálvölgyi, P.S.; Bassani, A.; Fiorentini, C.; Nair, R.; Spigno, G.; Kordas, K. Bio-Based Smart Materials for Food Packaging and Sensors—A Review. Front. Mater. 2020, 7, 82. [Google Scholar] [CrossRef]

- Dubey, A.; Irudhayaraj, S.; Jaiswal, A. Bio-Nanocomposites: A next Generation Food Packaging Materials. In Synthesis and Applications of Nanomaterials and Nanocomposites; Springer Nature: Singapore, 2023; pp. 197–231. [Google Scholar]

- Moeini, A.; Pedram, P.; Fattahi, E.; Cerruti, P.; Santagata, G. Edible Polymers and Secondary Bioactive Compounds for Food Packaging Applications: Antimicrobial, Mechanical, and Gas Barrier Properties. Polymers 2022, 14, 2395. [Google Scholar] [CrossRef]

- Sonatkar, J.; Kandasubramanian, B.; Ismail, S.O. 4D Printing: Pragmatic Progression in Biofabrication. Eur. Polym. J. 2022, 169, 111128. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Jafari, S.M.; Salehabadi, A.; Nafchi, A.M.; Uthaya Kumar, U.S.; Khalil, H.P.S.A. Biodegradable Green Packaging with Antimicrobial Functions Based on the Bioactive Compounds from Tropical Plants and Their By-Products. Trends Food Sci. Technol. 2020, 100, 262–277. [Google Scholar] [CrossRef]

- Amin, U.; Khan, M.K.I.; Maan, A.A.; Nazir, A.; Riaz, S.; Khan, M.U.; Sultan, M.; Munekata, P.E.S.; Lorenzo, J.M. Biodegradable Active, Intelligent, and Smart Packaging Materials for Food Applications. Food Packag. Shelf Life 2022, 33, 100903. [Google Scholar] [CrossRef]

- Sani, M.A.; Azizi-Lalabadi, M.; Tavassoli, M.; Mohammadi, K.; McClements, D.J. Recent Advances in the Development of Smart and Active Biodegradable Packaging Materials. Nanomaterials 2021, 11, 1331. [Google Scholar] [CrossRef]

- Babu, P.J. Nanotechnology Mediated Intelligent and Improved Food Packaging. Int. Nano Lett. 2022, 12, 1–14. [Google Scholar] [CrossRef]

- Dodero, A.; Escher, A.; Bertucci, S.; Castellano, M.; Lova, P. Intelligent Packaging for Real-Time Monitoring of Food-Quality: Current and Future Developments. Appl. Sci. 2021, 11, 3532. [Google Scholar] [CrossRef]

- Mohammadian, E.; Alizadeh-Sani, M.; Jafari, S.M. Smart Monitoring of Gas/Temperature Changes within Food Packaging Based on Natural Colorants. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2885–2931. [Google Scholar] [CrossRef]

- Müller, P.; Schmid, M. Intelligent Packaging in the Food Sector: A Brief Overview. Foods 2019, 8, 16. [Google Scholar] [CrossRef]

- Biswas, P.; Polash, S.A.; Dey, D.; Kaium, M.A.; Mahmud, A.R.; Yasmin, F.; Baral, S.K.; Islam, M.A.; Rahaman, T.I.; Abdullah, A.; et al. Advanced Implications of Nanotechnology in Disease Control and Environmental Perspectives. Biomed. Pharmacother. 2023, 158, 114172. [Google Scholar] [CrossRef] [PubMed]

- Miranda, B.; Rea, I.; Dardano, P.; De Stefano, L.; Forestiere, C. Recent Advances in the Fabrication and Functionalization of Flexible Optical Biosensors: Toward Smart Life-Sciences Applications. Biosensors 2021, 11, 107. [Google Scholar] [CrossRef]

- Nile, S.H.; Baskar, V.; Selvaraj, D.; Nile, A.; Xiao, J.; Kai, G. Nanotechnologies in Food Science: Applications, Recent Trends, and Future Perspectives. Nanomicro Lett. 2020, 12, 45. [Google Scholar] [CrossRef]

- Salieb-Beugelaar, G.B.; Wolf, M.; Lehner, R.; Liu, K.; Marsch, S.; Hunziker, P. Intelligent Nanomaterials for Medicine: Carrier Platforms and Targeting Strategies—State of the Art. In Nano-Enabled Medical Applications; Jenny Stanford Publishing: Singapore, 2020; pp. 1–60. [Google Scholar]

- Torchilin, V.P. Multifunctional Pharmaceutical Nanocarriers: Promises and Problems. In Nanotechnologies for the Life Sciences; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2012. [Google Scholar]

- Singh, R.; Sharma, A.; Saji, J.; Umapathi, A.; Kumar, S.; Daima, H.K. Smart Nanomaterials for Cancer Diagnosis and Treatment. Nano Converg. 2022, 9, 21. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Gao, X.; Wang, Y.; Xia, T.; Zhao, Y.; Meng, H. Precision Design of Engineered Nanomaterials to Guide Immune Systems for Disease Treatment. Matter 2022, 5, 1162–1191. [Google Scholar] [CrossRef]

- Biswal, A.; Swain, S.K. Chitosan: A Smart Biomaterial. In Chitosan Nanocomposites; Springer Nature: Singapore, 2023; pp. 1–25. [Google Scholar]

- Yang, X.; Lan, W.; Sun, X. Antibacterial and Antioxidant Properties of Phenolic Acid Grafted Chitosan and Its Application in Food Preservation: A Review. Food Chem. 2023, 428, 136788. [Google Scholar] [CrossRef] [PubMed]

- Mumtaz, S.; Ali, S.; Mumtaz, S.; Mughal, T.A.; Tahir, H.M.; Shakir, H.A. Chitosan Conjugated Silver Nanoparticles: The Versatile Antibacterial Agents. Polym. Bull. 2022, 80, 4719–4736. [Google Scholar] [CrossRef]

- Kavitha, A.; Doss, A.; Praveen Pole, R.P.; Pushpa Rani, T.P.K.; Prasad, R.; Satheesh, S. A Mini Review on Plant-Mediated Zinc Oxide Nanoparticles and Their Antibacterial Potency. Biocatal. Agric. Biotechnol. 2023, 48, 102654. [Google Scholar] [CrossRef]

- Menichetti, A.; Mavridi-Printezi, A.; Mordini, D.; Montalti, M. Effect of Size, Shape and Surface Functionalization on the Antibacterial Activity of Silver Nanoparticles. J. Funct. Biomater. 2023, 14, 244. [Google Scholar] [CrossRef]

- Qi, L.; Xu, Z.; Jiang, X.; Hu, C.; Zou, X. Preparation and Antibacterial Activity of Chitosan Nanoparticles. Carbohydr. Res. 2004, 339, 2693–2700. [Google Scholar] [CrossRef]

- Ameh, T.; Zarzosa, K.; Dickinson, J.; Braswell, W.E.; Sayes, C.M. Nanoparticle Surface Stabilizing Agents Influence Antibacterial Action. Front. Microbiol. 2023, 14, 1119550. [Google Scholar] [CrossRef] [PubMed]

- Bag, N.; Bardhan, S.; Roy, S.; Roy, J.; Mondal, D.; Guo, B.; Das, S. Nanoparticle-Mediated Stimulus-Responsive Antibacterial Therapy. Biomater. Sci. 2023, 11, 1994–2019. [Google Scholar] [CrossRef] [PubMed]

- Shinde, M.U.; Patwekar, M.; Patwekar, F.; Bajaber, M.A.; Medikeri, A.; Mohammad, F.S.; Mukim, M.; Soni, S.; Mallick, J.; Jawaid, T. Nanomaterials: A Potential Hope for Life Sciences from Bench to Bedside. J. Nanomater. 2022, 2022, 5968131. [Google Scholar] [CrossRef]

- Liao, V.H.-C. Nanoparticles in the Environment and Nanotoxicology. Nanomaterials 2023, 13, 1053. [Google Scholar] [CrossRef] [PubMed]

- Gupta, P.K. Nanotoxicology in Nanobiomedicine; Springer Nature: Cham, Switzerland, 2023. [Google Scholar]

- Otsuka, M. Intelligent Drug Delivery System for Artificial Bone Cement Based on Hydroxyapatite-Related Organic/Inorganic Composite Materials. In Innovative Bioceramics in Translational Medicine I; Springer: Singapore, 2022; pp. 231–253. [Google Scholar]

- Yusuf, A.; Almotairy, A.R.Z.; Henidi, H.; Alshehri, O.Y.; Aldughaim, M.S. Nanoparticles as Drug Delivery Systems: A Review of the Implication of Nanoparticles’ Physicochemical Properties on Responses in Biological Systems. Polymers 2023, 15, 1596. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Luo, C.; Pang, Z.; Zhang, J.; Ruan, S.; Wu, M.; Wang, L.; Sun, T.; Li, N.; Han, L.; et al. Advances of Nanoparticles as Drug Delivery Systems for Disease Diagnosis and Treatment. Chin. Chem. Lett. 2023, 34, 107518. [Google Scholar] [CrossRef]

- Jafernik, K.; Ładniak, A.; Blicharska, E.; Czarnek, K.; Ekiert, H.; Wiącek, A.E.; Szopa, A. Chitosan-Based Nanoparticles as Effective Drug Delivery Systems—A review. Molecules 2023, 28, 1963. [Google Scholar] [CrossRef]

- Dilliard, S.A.; Siegwart, D.J. Passive, Active and Endogenous Organ-Targeted Lipid and Polymer Nanoparticles for Delivery of Genetic Drugs. Nat. Rev. Mater. 2023, 8, 282–300. [Google Scholar] [CrossRef]

- Fabozzi, A.; Della Sala, F.; di Gennaro, M.; Barretta, M.; Longobardo, G.; Solimando, N.; Pagliuca, M.; Borzacchiello, A. Design of Functional Nanoparticles by Microfluidic Platforms as Advanced Drug Delivery Systems for Cancer Therapy. Lab Chip 2023, 23, 1389–1409. [Google Scholar] [CrossRef]

- Kolimi, P.; Narala, S.; Youssef, A.A.A.; Nyavanandi, D.; Dudhipala, N. A Systemic Review on Development of Mesoporous Nanoparticles as a Vehicle for Transdermal Drug Delivery. Nanotheranostics 2023, 7, 70–89. [Google Scholar] [CrossRef]

- Liu, H.; Su, Y.-Y.; Jiang, X.-C.; Gao, J.-Q. Cell Membrane-Coated Nanoparticles: A Novel Multifunctional Biomimetic Drug Delivery System. Drug Deliv. Transl. Res. 2023, 13, 716–737. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Li, Y.; Chen, Z.; Yang, H.; Cai, Y.; Wang, S.; Chen, J.; Hu, B.; Huang, Q.; Shen, C.; et al. Advanced Porous Nanomaterials as Superior Adsorbents for Environmental Pollutants Removal from Aqueous Solutions. Crit. Rev. Environ. Sci. Technol. 2023, 53, 1289–1309. [Google Scholar] [CrossRef]

- Chang, J.; Zhang, L.; Wang, P. Intelligent Environmental Nanomaterials. Environ. Sci. Nano 2018, 5, 811–836. [Google Scholar] [CrossRef]

- Malik, S.; Kumar, D. Perspectives of Nanomaterials in Microbial Remediation of Heavy Metals and Their Environmental Consequences: A Review. Biotechnol. Genet. Eng. Rev. 2023, 1–48. [Google Scholar] [CrossRef] [PubMed]

- Gallareta-Olivares, G.; Rivas-Sanchez, A.; Cruz-Cruz, A.; Hussain, S.M.; González-González, R.B.; Cárdenas-Alcaide, M.F.; Iqbal, H.M.N.; Parra-Saldívar, R. Metal-Doped Carbon Dots as Robust Nanomaterials for the Monitoring and Degradation of Water Pollutants. Chemosphere 2023, 312 Pt 1, 137190. [Google Scholar] [CrossRef] [PubMed]

- Amin, M.T.; Alazba, A.A.; Manzoor, U. A Review of Removal of Pollutants from Water/Wastewater Using Different Types of Nanomaterials. Adv. Mater. Sci. Eng. 2014, 2014, 825910. [Google Scholar] [CrossRef]

- Costa, J.A.S.; de Jesus, R.A.; Santos, D.O.; Neris, J.B.; Figueiredo, R.T.; Paranhos, C.M. Synthesis, Functionalization, and Environmental Application of Silica-Based Mesoporous Materials of the M41S and SBA-n Families: A Review. J. Environ. Chem. Eng. 2021, 9, 105259. [Google Scholar] [CrossRef]

- Kailasa, S.K.; Vajubhai, G.N.; Koduru, J.R.; Park, T.J. Recent Progress of Nanomaterials for Colorimetric and Fluorescence Sensing of Reactive Oxygen Species in Biological and Environmental Samples. Tren. Environ. Anal. Chem. 2023, 37, e00196. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Kayode, J.F.; Akinyoola, J.O.; Ikumapayi, O.M. Shape Memory Polymer Review for Flexible Artificial Intelligence Materials of Biomedical. Mater. Chem. Phys. 2023, 293, 126930. [Google Scholar] [CrossRef]

- Li, L.; Han, L.; Hu, H.; Zhang, R. A Review on Polymers and Their Composites for Flexible Electronics. Mater. Adv. 2023, 4, 726–746. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, Z.; Liu, Y.; Liu, Y.; Cao, X.; Yu, D.-G.; Wang, K. Piezoelectric Effect Polyvinylidene Fluoride (PVDF): From Energy Harvester to Smart Skin and Electronic Textiles. Adv. Mater. Technol. 2023, 8, 2300021. [Google Scholar] [CrossRef]

- So, M.Y.; Xu, B.; Li, Z.; Lai, C.L.; Jiang, C. Flexible Corrugated Triboelectric Nanogenerators for Efficient Biomechanical Energy Harvesting and Human Motion Monitoring. Nano Energy 2023, 106, 108033. [Google Scholar] [CrossRef]

- Lee, S.; Shi, Q.; Lee, C. From Flexible Electronics Technology in the Era of IoT and Artificial Intelligence toward Future Implanted Body Sensor Networks. APL Mater. 2019, 7, 031302. [Google Scholar] [CrossRef]

- Liu, Y.; He, K.; Chen, G.; Leow, W.R.; Chen, X. Nature-Inspired Structural Materials for Flexible Electronic Devices. Chem. Rev. 2017, 117, 12893–12941. [Google Scholar] [CrossRef]

- Wang, T.-Y.; Meng, J.-L.; Chen, L.; Zhu, H.; Sun, Q.-Q.; Ding, S.-J.; Bao, W.-Z.; Zhang, D.W. Flexible 3D Memristor Array for Binary Storage and Multi-states Neuromorphic Computing Applications. InfoMat 2021, 3, 212–221. [Google Scholar] [CrossRef]

- Ding, Q.; Jiao, W.; Wang, H.; Zhang, X.; Gao, S. Study of a Stretchable Polymer for Adjustable Flexible Organic Memristor. IEEE Trans. Electron. Devices 2023, 70, 3921–3927. [Google Scholar] [CrossRef]

- Panca, A.; Panidi, J.; Faber, H.; Stathopoulos, S.; Anthopoulos, T.D.; Prodromakis, T. Flexible Oxide Thin Film Transistors, Memristors, and Their Integration. Adv. Funct. Mater. 2023, 33, 2213762. [Google Scholar] [CrossRef]

- Kumaresan, Y.; Ozioko, O.; Dahiya, R. Multifunctional Electronic Skin with a Stack of Temperature and Pressure Sensor Arrays. IEEE Sens. J. 2021, 21, 26243–26251. [Google Scholar] [CrossRef]

- Fehr, D.; Sassenburg, R.; Blunschi, J.; Lay-Ekuakille, A.; Massaro, A.; Bonmarin, M.; Spano, F. A Capacitive Color-Changing Electronic Skin for Touch Sensing Applications. In Proceedings of the 2021 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Lausanne, Switzerland, 23–25 June 2021; IEEE: New York, NY, USA, 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Spano, F.; Dabrowska, A.; Quandt, B.M.; Boesel, L.; Rossi, R.M.; Massaro, A.; Lay-Ekuakille, A. Flexible Touch Sensors Based on Nanocomposites Embedding Polymeric Optical Fibers for Artificial Skin Applications. In Proceedings of the 2015 IEEE 15th International Conference on Nanotechnology (IEEE-NANO), Rome, Italy, 27–30 July 2015; IEEE: New York, NY, USA, 2015; pp. 1295–1298. [Google Scholar] [CrossRef]

- Chen, F.; Li, X.; Liu, G.; Zhao, J.; Zhao, L.; Shi, Y.; Shi, Y.; Xu, Z.; Guo, W.; Liu, Y. Flexible Electronic Skin Based on Silk/Polyurethane Composite Film Fabricated by Ink-jet Printing and Electrodeposition. Adv. Mater. Technol. 2023, 8, 2201980. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Y.; Liu, Y.; Wang, J.; Chen, J.; Chang, X.; Zhu, Y. Flexible and Transparent Electronic Skin Sensor with Sensing Capabilities for Pressure, Temperature, and Humidity. ACS Appl. Mater. Interfaces 2023, 15, 24923–24932. [Google Scholar] [CrossRef]

- Ekun, R.O.; Jonathan, E.M.; Emmanuel, O.I.; Atoe, B.; Ifijen, I.H. An Overview of Graphene-Based Nanomaterials in Electronic Skin Biosensing. In The Minerals, Metals & Materials Series; Springer Nature: Cham, Switzerland, 2023; pp. 3–13. [Google Scholar]

- Lin, S.; Hu, S.; Song, W.; Gu, M.; Liu, J.; Song, J.; Liu, Z.; Li, Z.; Huang, K.; Wu, Y.; et al. An Ultralight, Flexible, and Biocompatible All-Fiber Motion Sensor for Artificial Intelligence Wearable Electronics. Npj Flex. Electron. 2022, 6, 1–8. [Google Scholar] [CrossRef]

- Wang, Y.; Adam, M.L.; Zhao, Y.; Zheng, W.; Gao, L.; Yin, Z.; Zhao, H. Machine Learning-Enhanced Flexible Mechanical Sensing. Nanomicro Lett. 2023, 15, 55. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Zhang, Y.; Cai, S.; Han, Z.; Liu, X.; Wang, F.; Cao, Y.; Wang, Z.; Li, H.; Chen, Y.; et al. Flexible Hybrid Electronics for Digital Healthcare. Adv. Mater. 2020, 32, e1902062. [Google Scholar] [CrossRef]

- Li, T.; Wang, Q.; Su, Y.; Qiao, F.; Pei, Q.; Li, X.; Tan, Y.; Zhou, Z. AI-Assisted Disease Monitoring Using Stretchable Polymer-Based Sensors. ACS Appl. Mater. Interfaces 2023, 15, 30924–30934. [Google Scholar] [CrossRef]

- Chen, S.; Wang, H.-Z.; Liu, T.-Y.; Liu, J. Liquid Metal Smart Materials toward Soft Robotics. Adv. Intell. Syst. 2023, 5, 2200375. [Google Scholar] [CrossRef]

- Jiang, M.; Chen, S.; Zhang, P.; Sun, Y.; Ye, J.; Deng, Y.; Li, L.; Liu, J. Liquid Metal Enabled Plant Injectable Electronics. Mater. Today 2023, 66, 50–61. [Google Scholar] [CrossRef]

- Cao, J.; Li, X.; Liu, Y.; Zhu, G.; Li, R.-W. Liquid Metal-Based Electronics for On-Skin Healthcare. Biosensors 2023, 13, 84. [Google Scholar] [CrossRef]

- Li, G.; Zhang, M.; Liu, S.; Yuan, M.; Wu, J.; Yu, M.; Teng, L.; Xu, Z.; Guo, J.; Li, G.; et al. Three-Dimensional Flexible Electronics Using Solidified Liquid Metal with Regulated Plasticity. Nat. Electron. 2023, 6, 154–163. [Google Scholar] [CrossRef]

- El Helou, C.; Grossmann, B.; Tabor, C.E.; Buskohl, P.R.; Harne, R.L. Mechanical Integrated Circuit Materials. Nature 2022, 608, 699–703. [Google Scholar] [CrossRef]

- Spaggiari, A.; Castagnetti, D.; Golinelli, N.; Dragoni, E.; Scirè Mammano, G. Smart Materials: Properties, Design and Mechatronic Applications. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 2019, 233, 734–762. [Google Scholar] [CrossRef]

- He, Q.; Li, X.; Zhang, H.; Briscoe, J. Nano-engineered Carbon Fibre-based Piezoelectric Smart Composites for Energy Harvesting and Self-powered Sensing. Adv. Funct. Mater. 2023, 33, 2213918. [Google Scholar] [CrossRef]

- Chanda, A.G.; Punera, D. Electro-Elasto-Statics of Porosity-Gradient Smart Functionally Graded Plates with Piezoelectric Fibre-Reinforced Composite. Eur. J. Mech. A Solids 2023, 100, 104997. [Google Scholar] [CrossRef]

- Saha, P.; Mandal, K. Magnetic Field Stimulated Dielectric, Electronic and Thermal Properties of Magnetite Nano-Hollow Spheres Based Magnetorheological Fluids. J. Magn. Magn. Mater. 2023, 565, 170237. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Jiang, J.; Zhang, Q.; Ke, Y.; Qiu, S. Actuation Response of Typical Biased Shape Memory Alloy Wire under Variable Electric Heating Rates: Experimental Investigation and Modeling. J. Intell. Mater. Syst. Struct. 2023, 1045389X2311573. [Google Scholar] [CrossRef]

- Masa’id, A.; Lenggana, B.W.; Ubaidillah, U.; Susilo, D.D.; Choi, S.-B. A Review on Vibration Control Strategies Using Magnetorheological Materials Actuators: Application Perspective. Actuators 2023, 12, 113. [Google Scholar] [CrossRef]

- Liu, R.; Kim, J.G.; Dhakal, P.; Li, W.; Ma, J.; Hou, A.; Merkel, C.; Qiu, J.; Zoran, M.; Wang, S. Neuromorphic Properties of Flexible Carbon Nanotube/Polydimethylsiloxane Nanocomposites. Adv. Compos. Hybrid Mater. 2023, 6, 14. [Google Scholar] [CrossRef]

- Rahman, M.J.; Hossain, M.F.; Islam, M.J.; Mieno, T.; Chowdhury, M.N. Carbon Nanotube Reinforced Natural Rubber Nanocomposite as a Stretchable Electronic Material. J. Mater. Eng. Perform. 2023, 32, 5338–5345. [Google Scholar] [CrossRef]

- Miao, J.; Fan, T. Flexible and Stretchable Transparent Conductive Graphene-Based Electrodes for Emerging Wearable Electronics. Carbon N. Y. 2023, 202, 495–527. [Google Scholar] [CrossRef]

- Smaisim, G.F.; Abed, A.M.; Al-Madhhachi, H.; Hadrawi, S.K.; Al-Khateeb, H.M.M.; Kianfar, E. Graphene-Based Important Carbon Structures and Nanomaterials for Energy Storage Applications as Chemical Capacitors and Supercapacitor Electrodes: A Review. Bionanoscience 2023, 13, 219–248. [Google Scholar] [CrossRef]

- Memisoglu, G.; Murugesan, R.C.; Zubia, J.; Rozhin, A.G. Graphene Nanocomposite Membranes: Fabrication and Water Treatment Applications. Membranes 2023, 13, 145. [Google Scholar] [CrossRef]

- Bahadır, E.B.; Sezgintürk, M.K. Applications of Graphene in Electrochemical Sensing and Biosensing. Trends Analyt. Chem. 2016, 76, 1–14. [Google Scholar] [CrossRef]

- Kartika, A.E.; Setiyanto, H.; Manurung, R.V.; Jenie, S.N.A.; Saraswaty, V. Silver Nanoparticles Coupled with Graphene Nanoplatelets Modified Screen-Printed Carbon Electrodes for Rhodamine B Detection in Food Products. ACS Omega 2021, 6, 31477–31484. [Google Scholar] [CrossRef] [PubMed]

- Farooq, S.; Shafique, S.; Ahsan, Z.; Cardozo, O.; Wali, F. Tailoring the Scattering Response of Optical Nanocircuits Using Modular Assembly. Nanomaterials 2022, 12, 2962. [Google Scholar] [CrossRef] [PubMed]

- Boriskina, S.V.; Reinhard, B.M. Spectrally and Spatially Configurable Superlenses for Optoplasmonic Nanocircuits. Proc. Natl. Acad. Sci. USA 2011, 108, 3147–3151. [Google Scholar] [CrossRef]

- Al-Baiaty, Z.; Cumming, B.P.; Gan, X.; Gu, M. Optomagnetic Plasmonic Nanocircuits. Nanoscale Adv. 2019, 1, 3131–3138. [Google Scholar] [CrossRef]

- Liu, N.; Wen, F.; Zhao, Y.; Wang, Y.; Nordlander, P.; Halas, N.J.; Alù, A. Individual Nanoantennas Loaded with Three-Dimensional Optical Nanocircuits. Nano Lett. 2013, 13, 142–147. [Google Scholar] [CrossRef]